Theodosius

Members-

Posts

322 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Dave_E reacted to a post in a topic:

PHOENIX 1787 by ccoyle - Master Korabel - 1/72 - Russian brigantine of the Black Sea Fleet

Dave_E reacted to a post in a topic:

PHOENIX 1787 by ccoyle - Master Korabel - 1/72 - Russian brigantine of the Black Sea Fleet

-

thibaultron reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

thibaultron reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Canute reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Canute reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

mtaylor reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

mtaylor reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

chris watton reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

chris watton reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Theodosius reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Theodosius reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Theodosius reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Theodosius reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Theodosius reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Theodosius reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Scuttle Butt reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

Scuttle Butt reacted to a post in a topic:

HMS Sphinx 1775 by mugje - Vanguard Models - 1:64

-

chris watton reacted to a post in a topic:

HM Gun Brig Adder 1797 by DB789 - Vanguard Models - 1:64

chris watton reacted to a post in a topic:

HM Gun Brig Adder 1797 by DB789 - Vanguard Models - 1:64

-

cdrusn89 reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

cdrusn89 reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

-

DB789 reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

DB789 reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

-

DB789 reacted to a post in a topic:

HM Gun Brig Adder 1797 by DB789 - Vanguard Models - 1:64

DB789 reacted to a post in a topic:

HM Gun Brig Adder 1797 by DB789 - Vanguard Models - 1:64

-

Theodosius reacted to a post in a topic:

HM Gun Brig Adder 1797 by DB789 - Vanguard Models - 1:64

Theodosius reacted to a post in a topic:

HM Gun Brig Adder 1797 by DB789 - Vanguard Models - 1:64

-

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

-

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

-

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

-

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

-

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

-

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

Theodosius reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

-

I am amazed about your rigging! Incredibble for this size!

- 479 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

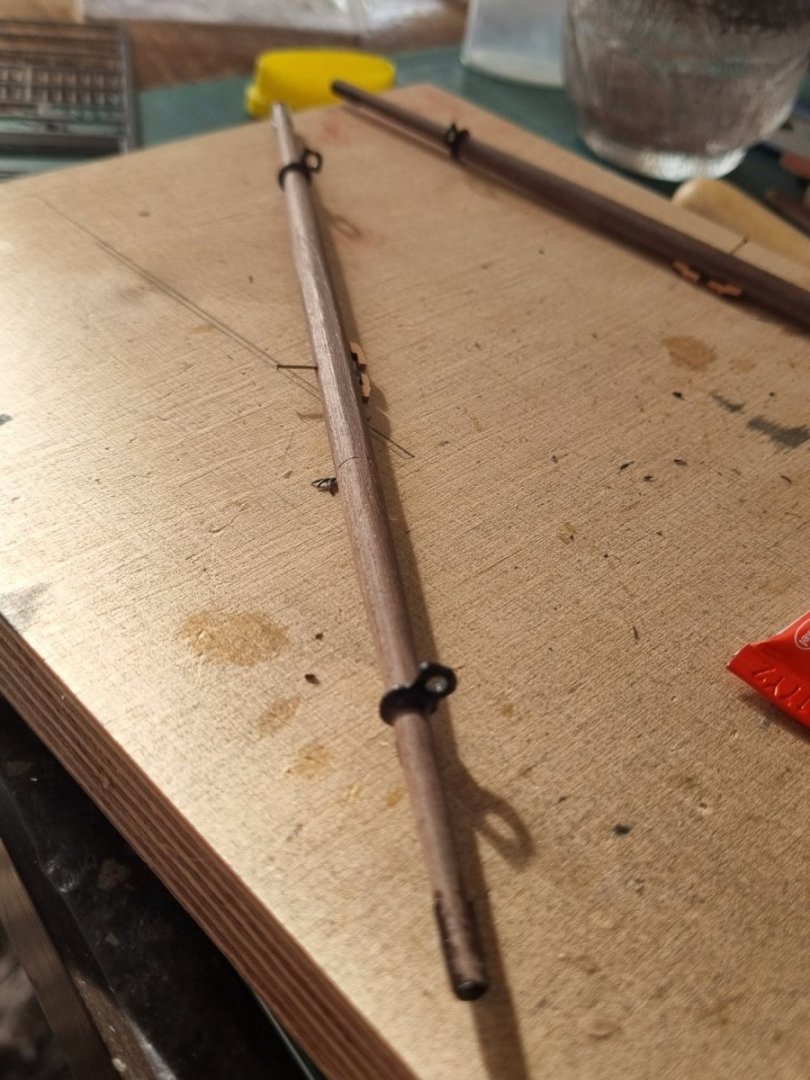

Milestone reached: all the spars are ready from a wood working point of view. That means, the 'building' is finished, but the complete rigging is to do next. Some inbetweens: Some spars taperd and the 8-sided, äh, 'things' are worked out: Two points about the next pictures. First, I ran out of PE-cleats(?). A short email dialog with Chris brought clarity to my fault: he very politly pointed out, that the use of pe-parts at this point was overhoult, and I should use the plenty of wooden parts. Damn! The wooden parts looks much better than the pe parts, and I could not figure this out by myself. Only excuse I have is, that in the plan sheets I only found references to the pe and not the wooden parts. Well, to much use of blinkers on my side :-). Second point: I lost one of the holsters for the additional smal spars on top of the main spars. Sorry for my lack of propper nautical terms. I made a new one out of the black paper and stiffen it with ca-glue. It is more bulky than the orginial pe-part, but if you don't know, only on the second view, so I hope I'm ok there. All spars ready for rigging in front of the boat: To give me an idea of how it might look in the end, I put all together, but only with the pins and no glue, so all is still wonky:

-

Your rigging as good as your painting! Lovely model!

- 479 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.