-

Posts

774 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tmj

-

Quite true Mr. Aug! We can't truly see the deck on both sides. What I'm looking at is the location of the pilot house between the 'stacks'. The PH could very well be centered and what I'm seeing in my mind's eye is a simple illusion, however. To 'me' it looks like the PH is closer to the stack in the background than it is to the one in the foreground. Every time I study this photo I see something different. "Where's Columbo when you really need him?" 🤔

-

It's very interesting how different eyes and different minds can see totally different things while viewing the same subject! 🙂 Sensible or not, this is what 'I' see. My railings abruptly end in space because the view of the rest of those railings is not visible. Only 'Billy' knows what's going on 'behind the scenes'. I also see the pilot house being off-centered. Doesn't mean it was. That's just how it appears to 'me' in the photo.

-

Something 'else' just caught my eye on this curious boat. What could 'this' be? The angle of its projection suggests that it's not just a 'wooden' feature nor a photographic anomaly, but rather something like a bent 'pipe' running forward out of the pilot house. Could this have anything to do with the indoor 'bar'? LOL

-

I'm going out on a limb again. Could Billy have possibly had 'two' doors for the pilot house, one forward and one aft? I see what must be a handrail, and also some curious carpentry in the aft end of the pilot house. Could that irregular open panel on the port side be a door? Maybe there was a stair coming up from 'inside', not on the outside. One entered the pilot house from the rear end and came out on the upper deck from the forward door.

-

Holy smokes, looks 'GREAT'! "Very nice job, indeed!"

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

I have a question concerning scale and actual dimensions of ol' Billy. Was lumber for boats like this not typically milled to certain standards of the times, much like lumber is milled today? I'm asking this because of the different dimensions of lumber planks being used as 'siding' on the exterior of the 'above-deck' buildings. Could the width of those exterior planks/boards hold a clue as to the actual scale dimensions of the boat... or were things like lumber made with non-standard milling practices back when/where Billy was built? In guessing, I'd say the wide horizontal planks were around six inches wide and the vertical planks were about three inches wide. I came up with this by looking at the height of the windows where the wide horizontal planks are located. I might be way off base, dunno. I'm just looking for any known dimensions to accurately scale the photo by. I'm thinking that the dimensional lumber might hold a clue if known dimensions of that lumber can be revealed. 😕

-

Very clever idea Glen! I'm late but will be keeping up with future progress for sure.

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

After my planks are properly 'spiled' to shape, I like to wrap them with paper towels then gently moisten the paper towels with tap water. Don't flood it until it's dripping water, just get the paper towels plenty moist and wrap everything in cooking foil for about 24 hours. If you are using a soft wood, you can then simply clamp those planks to your bulkheads or frames and let them dry until the next day. Soft wood will easily take all of the twists and curves while drying. Harder woods will need a bit of help via heat. I use the same process only I use heat on the tighter bends prior to clamping the moist planks onto the frames/bulkheads. This works pretty well most of the time, however. You'll probably need to work the harder wood planks with a bit more heat while clamped in place, and maybe even after drying overnight to conquer the tighter bends and twists. Don't get into a hurry and don't try to bend too far/tight in one heat. Sneak up on those tight bends a little bit at a time. You'll eventually get there! 😉 Once dry your planks will be ready for glue. This is my hot bender of choice. It works extremely well for 'me'. Here's a launch I'm working on. The three center floorboards are glued in place. The outer most floorboards are currently being 'wet-formed' to shape around the glued center boards, until tomorrow when they will be dry and ready to be glued down. This is soft wood with no tight bends so no heat will be required.

-

I was once considering the 'Canal Boat Life', after retirement, in the UK where it's big, however. I own too many toys that I'm not interested in parting with. It wouldn't work. Most folks 'downsize' when they retire but I'm thinking that I'll need to 'Upsize'! I'd need a large canal boat plus a barge or two! I'd look like a floating Italian string of sausage links trying to get through the locks 'one link at a time'! 🫤 LOL

-

Keep the OOD on watch and closely guard those lines 'till construction resumes... less any land-dwelling critters find said lines amusing and quickly take it upon themselves to create adventure from any loose ends! 😲

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

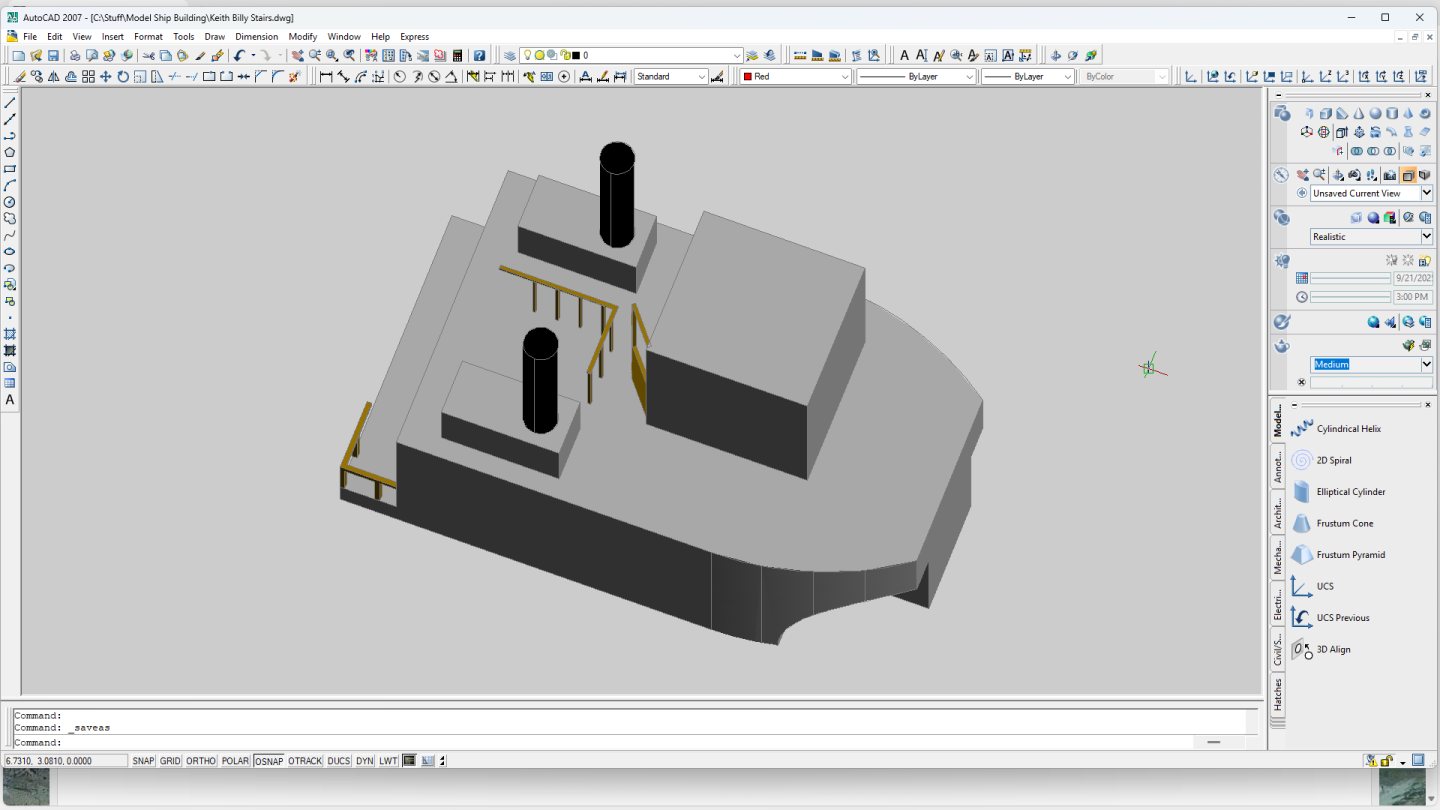

"Sternwheeler - Houston, Copy." "Be advised... we're working on it............"

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Hold on. I need to find my jeweler's loop so I can see this better!

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.