-

Posts

314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KrisWood

-

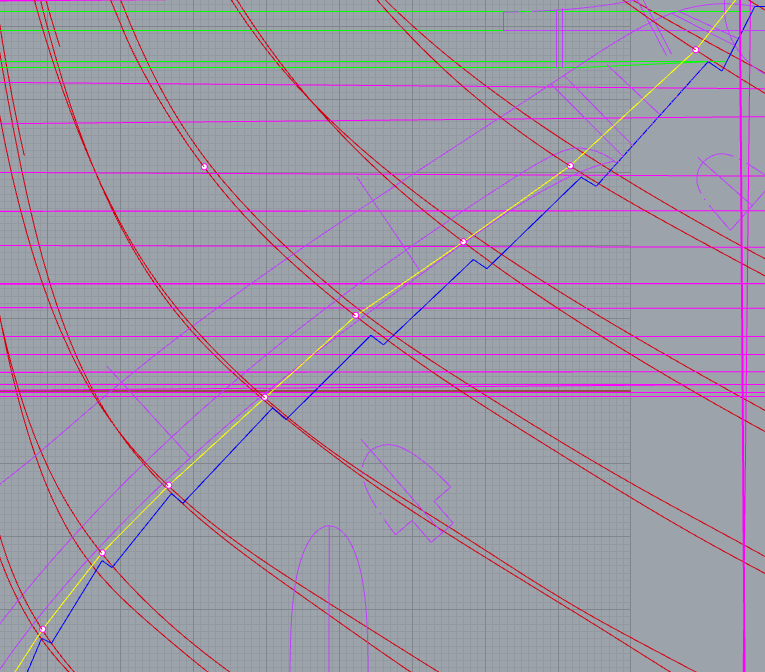

I've got a problem. My hand drawn lines for the ship are out of alignment. I'm not sure when it happened or how, but for some reason the plans themselves don't seem to agree with each other even within two views of the same plan... So frustrating... In short, I successfully plotted my projection surfaces by the numbers and projected my frames onto them at the correct angles! Then I realized, the surfaces were too small. I did some troubleshooting and found that my hand drawn top view is too narrow by a few centimeters, despite the fact that all my reference image views are the same scale! I have no idea where I went wrong here. In the attached image the yellow line is plotted with math calculating the angle at which the inclined frame intersects the top inner edge of each plank of the hull. The blue line is hand drawn and represents where the front view says those points should be. Can anyone PLEASE give me some tips on correctly setting up references images in Rhino so that they're all the correct scale? These are all based on raster reference images that include multiple points with scales written. Thanks, Kris Edit: Well, I figured out my problem. I've been drawing all my curves as projections from two curves, mostly top view and side view. The ship exists in three dimensional space so Rhino projects the two views as if they were distributed evenly across the entire length of the space. In reality there is a third front/rear view which would inform where on the other two curves each point should fall, but I don't see a way to create curves from three views...

-

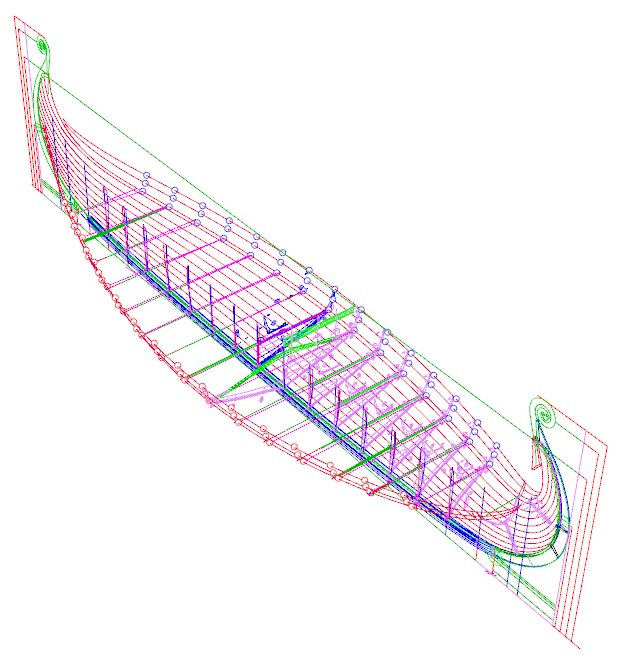

Gradually adding more and more things from the new report to the model, by number rather than by eyeball.

-

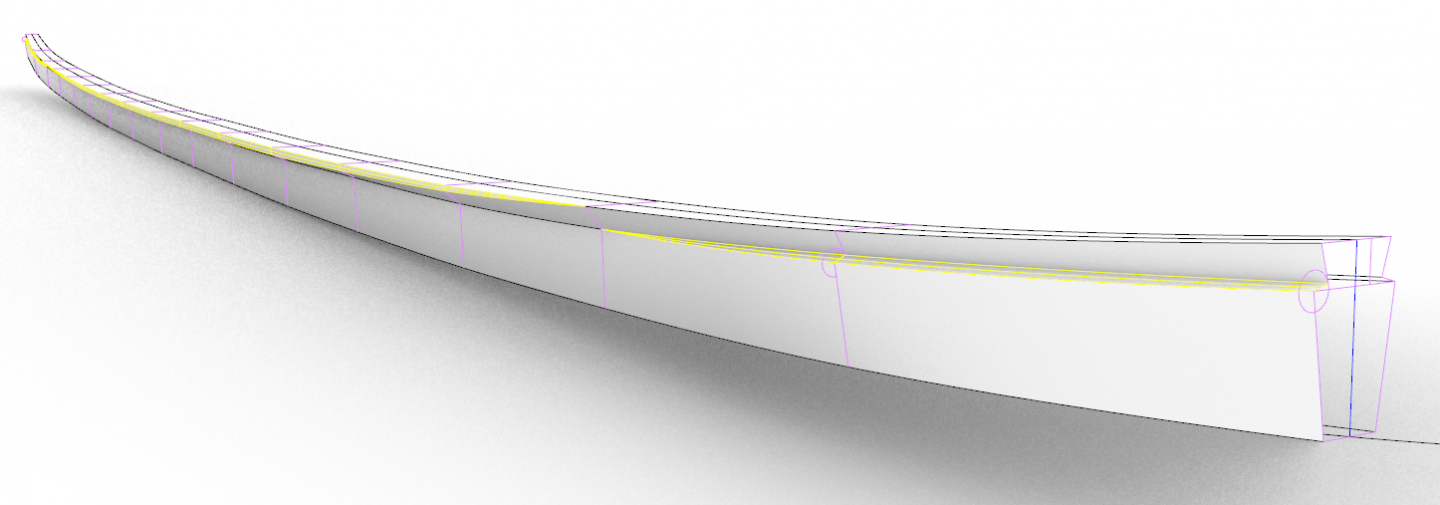

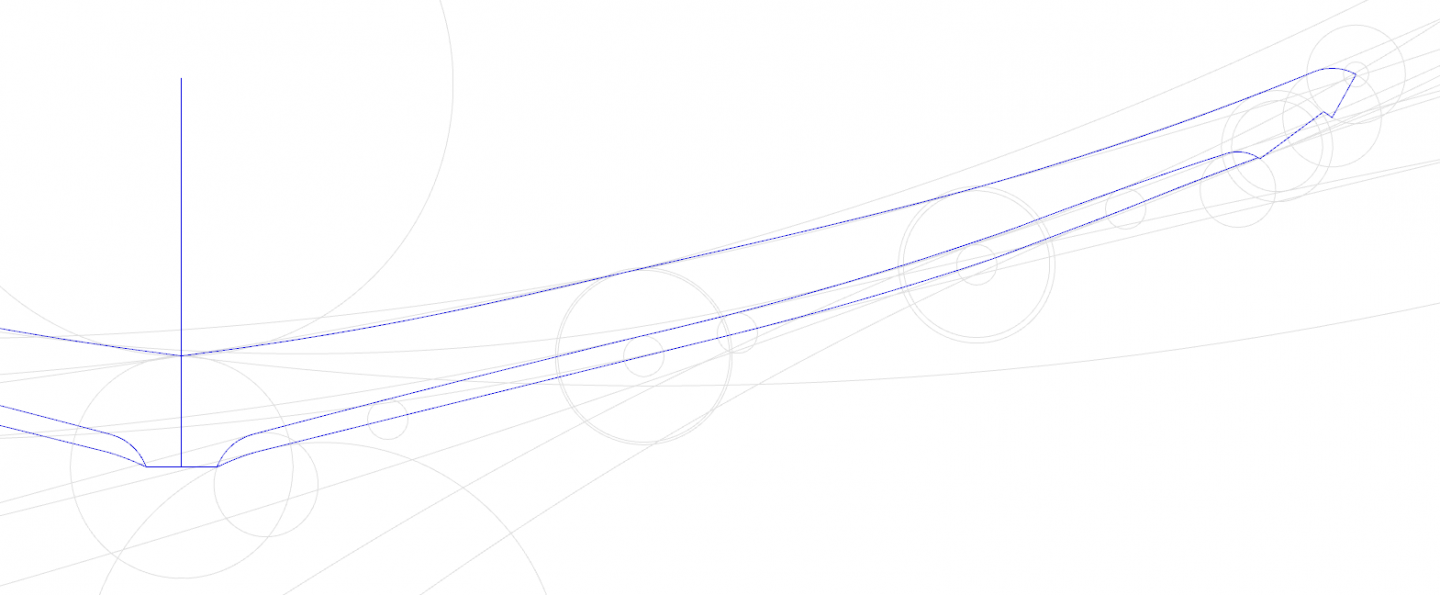

While reading the work more thoroughly, I found the reason for the few discrepancies in Bind II. In "Rekonstruktion af Osebergskibet Bind I" Chapter 6.2 page 98, Bischoff explains that some of the plans were hand drawn but processed digitally in Photoshop, and others were entirely digital and drawn in Rhinoceros. Because Photoshop uses a raster interface rather than a vector one, it cannot do exact measurements. It can only do measurements to the nearest pixel at the working scale. This thread is getting ridiculously long and I'm not even building with wood again yet, so I'll combine my next post with my last one. I don't know if any of you remember how many months I spent agonizing over the keel alone. Even after I bought the Saga Oseberg book by Thomas Finderup I couldn't figure out exactly how it was shaped. Now I've got exact numbers for every single curve of it. Here is one mathematically perfect keel.

-

Quick note to anyone trying to build from the plans in Rekonstruktion af Osebergskibet Bind I & II. The drawings do not always line up with the numbers. Always err on the side of the numbers, except when the numbers disagree with each other (they conflict sometimes but it's usually pretty obvious which is the correct one). In the event that a drawing in Bind II is significantly different from the numbers and / or other drawings, Ms Bischoff has done a VERY thorough job of explaining the correct measurements and their reasons in Bind I. Quick note to self, always check the documentation!!! Now to redraw some things that I made faulty assumptions on...

-

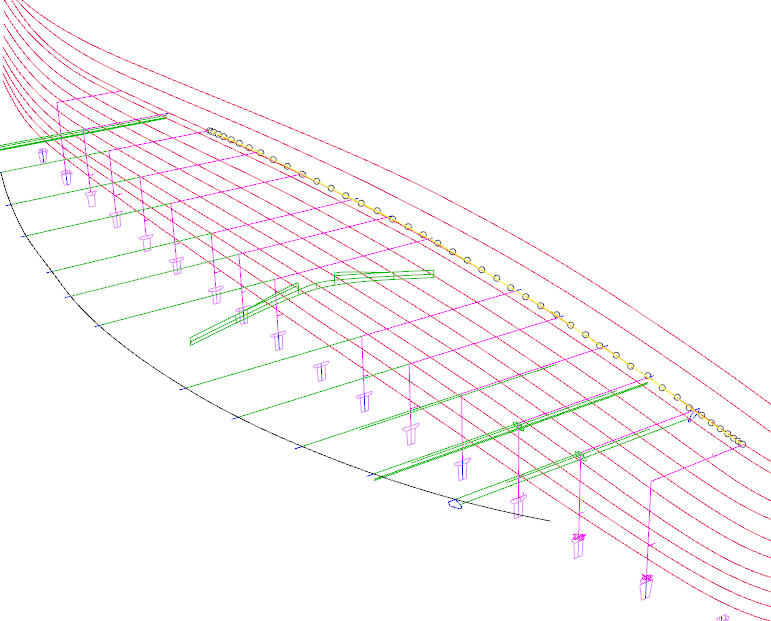

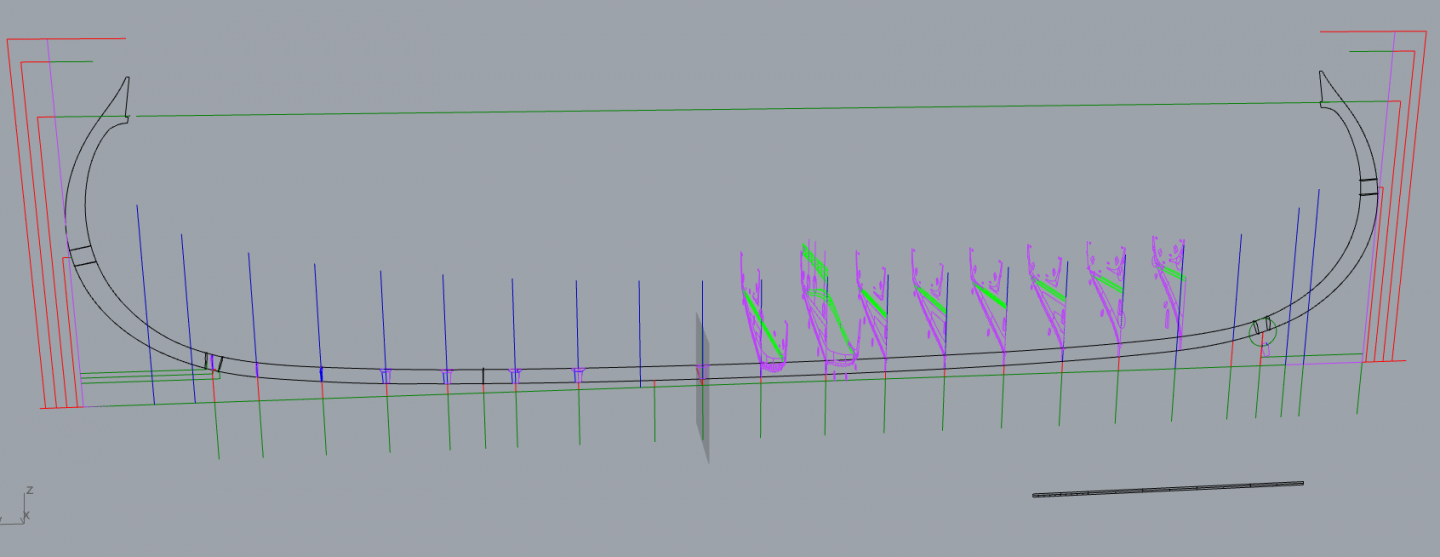

After wrestling with the old plans trying to get them lined up with my frames from the new plans I gave up and decided to plot only the points for which the new plans give numeric values. It got me within one pixel from the reference images for the old plans, so I'm going to call it "good enough" The black line is the new intersection of the deck beams with the hull, the selected (yellow with dots) line is the mirror of the black line and represents the starboard version of the same thing. The red curves are my old lines.

-

I found a better way to draw the frames themselves based on the measurements in the reconstruction report. The lines in the plans don't always agree with the provided measurements. Rather than trying to trace every line exactly as drawn and hoping I have pixel in the reference image at the right scale, draw circles at each point with a radius equal to the measurement, then draw more circles along the tangents of the measurement circles. The result is one beautiful and mathematically correct frame. Now is it just me or do these circles have more than a passing similarity with something carved into a different Viking ship....

-

Just a minor status update: All the front views for the forward frames are drawn, at least for the starboard side. I've done both the port and starboard sides of the two frames at the midship. Next step will be aft frames and mirroring everything over to port.

-

Hi Steven, That does make sense, and I suspect is the way the plans were designed to be used in the first place, given that the port and starboard placements are drawn separately, and that all front views only show the starboard half of each frame. Thanks! Kris

-

Hello Christian, That should work, thank you! All plans for Saga Oseberg are drawn to the inside of the plank, which makes things a little easier, though it's also further complicated by the fact that the frames do not actually reach the faces of the planks, but sit on clamps which are hewn from the same wood as the planks themselves and are not shown in the plans. Fortunately the published documentation of building the reconstruction describes the clamps thoroughly so I can figure that part out when I get to that point.

-

Thank you, Steven! I understand the concept you illustrated, and I've used it in other projects for cant frames, but the frames on Viking ships are a little different. They are angled on two axes rather than one. I'd rather not link images directly from the paper linked above because I don't own the images, so I'll reference the specific pages instead. Here's the link again: https://www.academia.edu/49550641/Rekonstruktion_af_Osebergskibet_Bind_II Plans 12 through 27 depict the frames from the front view. Plans 28a (profile view, starboard on top, port on bottom) and 28b (top view) depict the frames in-situ within the hull. You can see that the frames are not projected straight onto these axes, either. The frame timbers themselves are more angled. The knees are more vertical. In many places the frames are perpendicular to the curves of the strakes rather than to the longitudinal axis. Does that make more sense? In any event my question was more, "how does one accomplish this in Rhino" than "how does one accomplish this on paper".

-

Hi Roger, I'll post some images when I get to that point. I'm still drawing all the frames because I didn't have good plans to work from for them until now. After that I'll redraw the strakes and re-fair them, and then I'll be ready to work on placing the frames correctly within the hull.

-

Well, it's back to the drawing board for me. I went to combine the new plans with my existing ones and found that the lines I'd drawn previously. When I tried to add my newly drawn frames with exact measurements I couldn't get them to fit! Apparently when I'd faired the strakes I lost several centimeters of the hull's breadth. The other difficulty I ran into is that the new plans show the frames viewed from the front, but they also include the exact position and angle in top and profile views for each frame. I can draw the frames easily enough in the front view, but how can I project them onto the angled position they end up in?

-

I rely entirely upon Google Translate and what little I remember of taking German in highschool (a good portion of the Danish words that Google mistranslates are similar enough to German that I can read them). 😆 Fortunately, this latest report has a glossary of Nordic shipbuilding terms in it that is a bit easier for Google to translate. 🙂

-

Before my last post the other day, I'd been quiet for a long time. Several months ago my laptop died and so I was no longer able to work on my project. Around the same time I had to get a second job to keep up with the bills, so I didn't have time for projects anyway. On the bright side, the second job meant I finally had enough money to buy a new laptop. Reading the two volume reconstruction report by Ms Bischoff has inspired me to get back into my project. Having read the report and reviewed the plans, I see now that I got several things wrong and I'm going to need to start over, this time doing it entirely by the numbers instead of by eye. I've already started on the keel using the new dimensions. It's much easier to plot out the T shape now that I have the numbers for sections I'd been missing before and guessing at by eye, and I can already tell it's not going to be as fragile as it was before. Meanwhile I still have very little time (due to the two jobs and all). Does anyone want to collaborate on plugging in the numbers from the report above into Rhino?

-

Note to self, just found these.... https://www.academia.edu/49550751/Rekonstruktion_af_Osebergskibet_Bind_I https://www.academia.edu/49550641/Rekonstruktion_af_Osebergskibet_Bind_II Complete reconstruction plans for every single part of the ship. 😲

-

Note to self so I can find it later, a museum scan of the deck plan as reconstructed/displayed.

-

So... I accidentally guessed that I'm getting a CNC machine for my birthday in May, (I told my fiancee I want to buy one and she admitted that she's already buying me one so that I wouldn't buy it before then). I'm now rethinking my plans for this project. If I update my plans so that they're "printable" on a CNC machine, I can shape and cut out my parts on there instead of by hand! The question is, has anyone here built a ship model using parts shaped or cut by CNC before? What considerations should I take into account while designing my parts so that they CAN be cut/shaped on 3 axes? Can anyone share with me a CAD file of parts designed for this purpose so I can see what the final product should look like and imitate it?

-

Sorry I'm late to this one! I did some quick research and came up with the following: https://www.etymonline.com/search?q=hulc I looked up the dutch "hulke" and found the following: https://www.naval-encyclopedia.com/medieval-ships/ This gives a number of analogues to compare to. It's closest related to the Hanseatic Cogues. The French and Dutch terms are "Hourque" and "Hulke", respectively. It's not a "nef" nor a "carraque", nor a "galleon". Does that help at all?

- 186 replies

-

- keelless

- reverse clinker

- (and 4 more)

-

Die Kogge Von Bremen by kentyler

KrisWood replied to kentyler's topic in - Subjects built Up to and including 1500 AD

I'm looking forward to seeing how this one goes! 😀 -

@AnobiumPunctatum, yes, I'm trying to find the article that goes with the photos of the Oseberg model on the site, in hopes that there may be more photos or written descriptions of the processes used in building the model.

-

I've decided to go with the two part T method and have drawn up the parts to be printed. I'll make sawdust tomorrow after work. Meanwhile my German is too rusty to make sense of this site. Can anyone help me find how to order a copy of this magazine? https://www.arbeitskreis-historischer-schiffbau.de/logbuch/logbuch-archiv/2000-2009/lg-2004-1/

-

I picked up my blueprints today! They're perfect! Exactly at scale, and each page has a different set of parts perfectly printed. I got some tracing paper and some carbon paper so I can transfer the parts easily to wood. Meanwhile, I think I may have a best of both worlds compromise solution to my keel problem. I've got several lengths of 1/4" poplar that are wide enough for even the curviest parts of the keel and stems. The widest cross section of the keel is just a hair under 1/4" at 1:25 scale. My print layers are modeled at 1/32" thickness, which make for layers so thin they snap just assembling the parts. If I replace the inner 8/32" layers with a single 1/4" layer I'll end up with a stronger keel. I'll just have to figure out how to cut a scarf. As for the T, I can use the remaining outer layers to build up the "wings" of the T. Does that sound like it should work?

-

@bolin, how do you get the two parts of the keel aligned and flush so there are no gaps? My model is going to be floating some day so I'm also concerned that the two parts might come apart in water or may not be water tight. Do you think this method would be a problem for a floating model?

-

Gokstad by @Liberto Liberto used a mill with a more modern style keel that only curves in two dimensions with a rabbet instead of a T. This is what gave me the idea of starting out with just a rabbet and then sanding or planing down the portion below the rabbet to make the vertical part the correct width. This only works because Liberto's keel is a consistent width. The Oseberg keel tapers narrower as it moves away from the midship frame, then widens briefly before reaching the stems, then narrows again as it moves up the stems.

-

The next few posts will be links to MSW build logs with similar keels. First up, @bolin's medieval longship: This one uses the same method @bigpetr described, but the keel is straight along the entire length.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.