-

Posts

7,407 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

good progress Tim, and beautiful details.... Nils

- 227 replies

-

- BlueJacket Shipcrafters

- Stephen Hopkins

-

(and 2 more)

Tagged with:

-

Pretty good rigging Bob, she surely is coming along realistic looking, a beautiful model..... Nils

-

Thank you very much John, there are so many points to continue with the ships fitting out in the moment, I realy have to try and get them done one by one, although there are so many ideas (thinking ahead in my mind), that I would like to proceed in many different positions at the same time, just to see if the thoughts would work out.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

all along the way good ideas and good progress Rob, love that figurehead and the winches.... Nils

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

Hi Marcus, good to hear from you, thanks for looking in...., I`m glad you like build... Am meantime jumping on to the next section and sequence... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Welcome on board John, and thanks for your kind compliment, much appreciated...... I`m often looking at old pics and photographs of the ship, life on its decks, etc. , to find out some of the details... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Many thanks Carl, Juzek and Piet, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Denis, Michael and Bob Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Denis, and B.E. for you kind comments... the nearly midship bridge platform goes over the whole ship width and allows a good sight alongsides for the crew (and passengers). There still needs to be the upper railing attached and the platform fitted out. The dark grey horizontal tank with the two vents on top, is the one for daily warm water and is heated by exhaust gasexchanger of the second funnel On the platform where the tank is standing on, there are brought in 4 interlocked eyelets with counter flat heads from below to take up some of the appropriate funnel stays safely Also many thanks to all the "Likes" Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

very nice work Ferit, the small fracture with the upper mainmast, will be relatively easy to mend, after doing so you will be happy with your beautiful ship again .... Nils

-

Thank you very much Bob, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Johann, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you Patrick, it was indeed a little mass production (37 ea.) of tiny square brass plates and square windowframes, and soldering these together, but I think the effort was worth it.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Albert, NIls

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

ancre Chebece 1750 by Jeronimo - FINISHED

Mirabell61 replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

Hi Karl, can full understand why you have chosen to build this model. The introducing pics are so fantastic and inspiring, wonderful lines of the ship and a "must" to get started with it..... Nils -

Thank you so much Greg, John and Patrick, for your nice words and compliments, Very much appreciated.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

A very nice build ! Congrats Tadeuz, that ship looks excellent NIls

- 15 replies

-

- gjoa

- polar exploration

-

(and 1 more)

Tagged with:

-

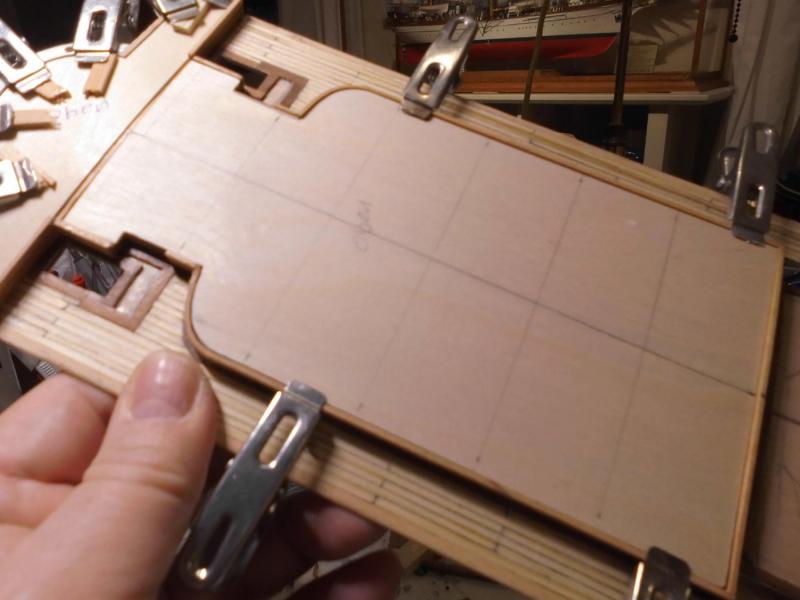

small update.... this little structure sits up on the boats deck between 2 nd. and 3 rd. funnel. This is the position where the large 1 st class dining lounge is situated over several decks across the whole width of the ship, because here no stackshafts interfere with the dining area. The half round stucture will be modeled to the light dome of the dining lounge comprising about 30 single little "glassed" frames Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

A nice word Greg, thanks very much... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Many thanks Bill, Denis and Jeff, Bill, you`re so right, the Auger is the one for rough timber, thanks for your advise to clear and withdraw the bit. (avoid to get stuck ) I`ll save it up if I ever need to build a log-cabin in the woods Denis, yes, I`m very pleased with that tool.... Jeff, so now there has been found a good solutíon... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Update.... outcome of the 25 mm hole drilling trials... today I had a pleasant surprise with the fresh received new drilling crown. I had to try it out straight away, and am very pleased with the results.... Nils good quality tool the center drill with the (threaded9 adapter can take up diam 14 to 30 mm, drill crowns cut at 10° angle, no problem with the center drill function smooth hole sides, no breaking out at surfaces

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Update... stuctures on the boats deck, and always considering the deck curvature over the width Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Bob, Thanks for your nice input here..... you seem to be reading my mind, that was also my (up the sleeve solution) if the other do`nt work like intended.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thanks for your kind reccomendation Jeff, I have`nt done any fuirther trials on that behalf yet, but shall give feedback on outcome later on... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.