-

Posts

7,406 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Thanks for the answer Bob, an excellent technique for color separation, thats for sure.... Nils

-

Awesome work Mike, a lovely cutter, the plank fitting to the bowpost looks fantastic and professional made Nils

- 452 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Many thanks Denis, glad you like it Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Very fine and accurate work Bob, I like your color giving. How did you get the blue color so sharply in the middle-line of the head rails (wow !!) Nils

-

thanks for your words of sympathy Garry, maybe the experience (laminating wooden bends), if not already known, may also be of help to fellow builders Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Many thanks Bob and Bill, there are probably quite a lot of valuable "know hows" in relation with model aircraft building, especially those made in the good old way with all the framework and shrink-span tissue coating..... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Keith, Thanks for your words, I should have thought of the "laminating way" of those bends earlier..... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Carl and Michael, and all the "likes"... Carl, the etched stair sides and the steps are only folded and you`re right, afterwards (after priming and painting) glue into place with a drop of CA Michael, right, I agree, although I have highest respect for the skills of those professional builders work in much earlier days Nils Here is a little update ....... on the making of the aft handrail portion in place where the railing performs the rounded bend. I tried several times two flat bend the mahagony handrail by wetting and soaking, with and without heat, etc, very frustrating and without success. Then came the idea not to flat-bend over the 1,5 mm wide side, but to flat-bend and laminate 3 single 0,5 mm thick strips with CA and with help of a little jig, Sigh of relief, it worked out well. Only have to mount and carefully sand down to the required flatness

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

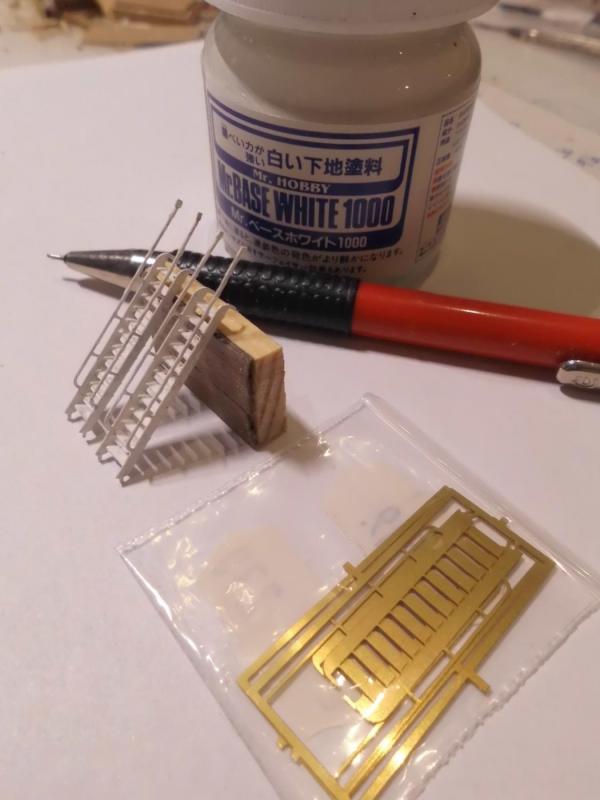

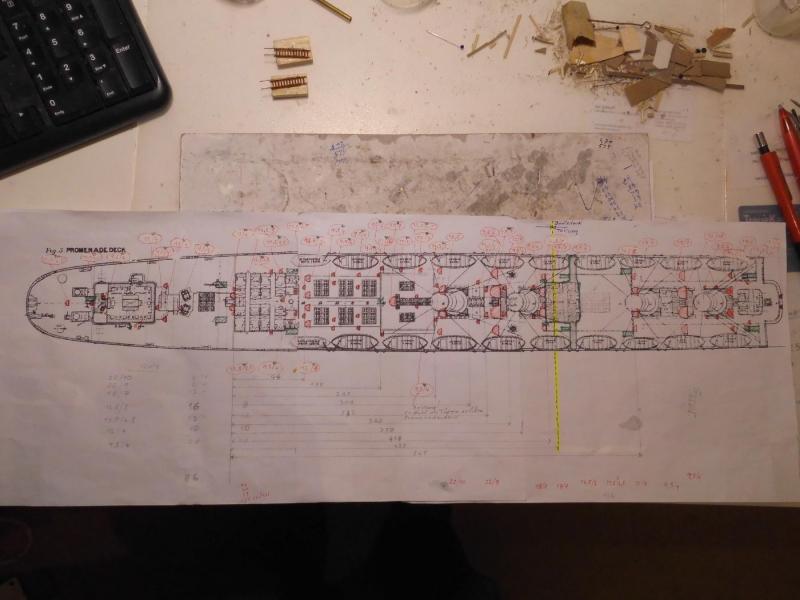

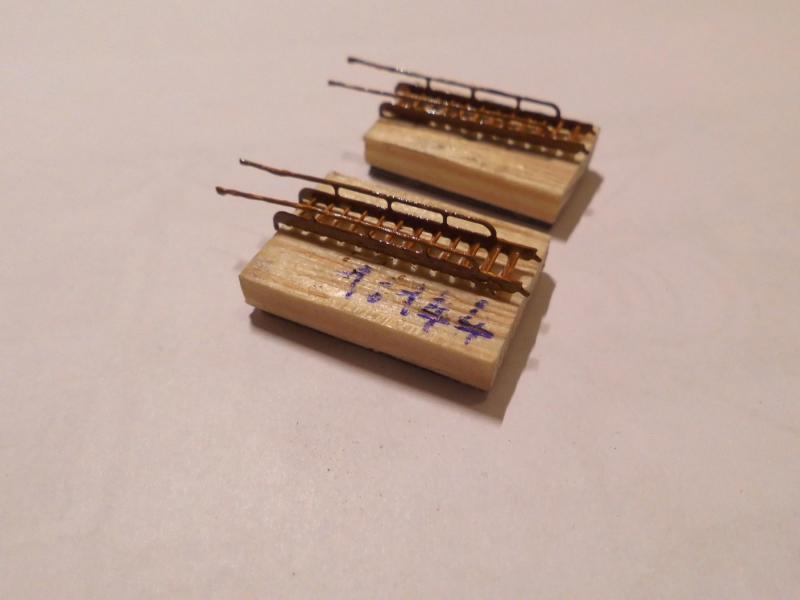

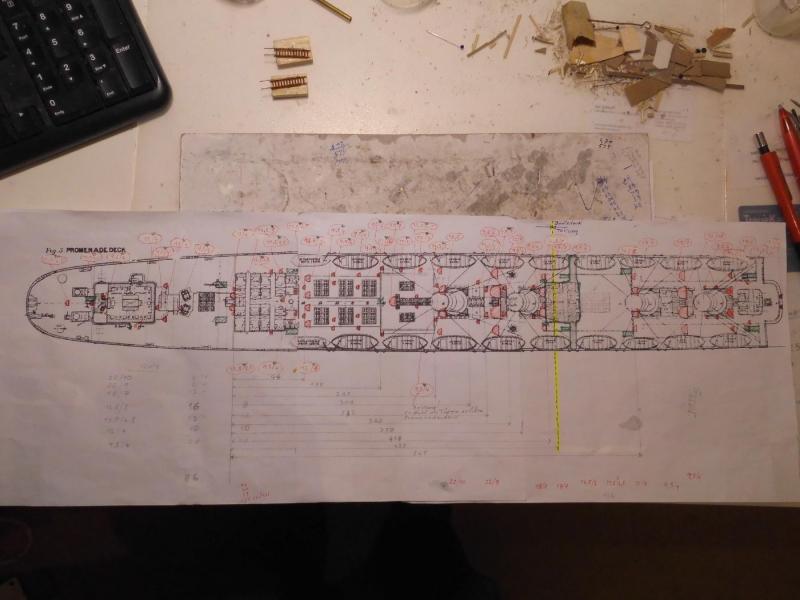

Little update... the stairways are quite easy made due to the pricise brass etch patterns. One of my most importent work documents is the orientation plan for vents, red indicated (size and tube diameter), and the stairs, green indicated Nils folding and primercoating the stairs

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Alex, great work with the metal stamp and it`s heattreatment process, looks like it will have a long stand time. What thickness are your brass plates, and do you have to aneal those for stamping ? Nils

-

Ed, thank you very much, its slowly coming together and its fun with the fitting out of the decks.... as far as the work is concerned, I can only return a bunch of compliments to you for your wonderful "Exreme Clipper " build, which I love so much, a great model shipwright performence Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Gerhard, I`m only adding tiny bits and pieces, but when holding the hull in hands I can feel the constantly increasing weight, although the hull was such a lightweight, when taking it off the build-slipway some months ago. Probably its the brass parts and the metal plating coat that owe to the weight.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Steve, your "caulking" of the hull plank edges prior to mounting pays off... , I like the effect very much Nils

- 165 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Patrick, you`re surely becoming to be a specialist for interlocking removeable sections on a model. A professional modelmaker company for extrusion dye formed resin section part kits could not have done it better, Great model and super work, Bravo !! Nils

-

Thank you very much Patrick and John (Neptune), and thanks to all the "likes" Patrick. a very kind compliment, much appreciated, glad you like it... John, thanks so much for your nice words, and for your catch up.... I`ve put on the aft portion of the boats deck now on permanently and it worked out fine. Of course something came to eye after mounting it and clamping it down, I noticed that two of the benches below on the promenade deck were just mounted in the way/ space where the upward stairs should be placed, and four of the holes for the downward vent tubes had been planked-over on the boats deck and forgotten to be cut free again, but both little misfits can easily be put right again. Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Those sweet lockers look very nice Karl.... Nils

- 164 replies

-

- Model Shipways

- Finished

-

(and 1 more)

Tagged with:

-

Karl, thank you very much for your compliment and your nice words, much appreciated... Viele grüsse aus Glinde Nils

- 164 replies

-

- Model Shipways

- Finished

-

(and 1 more)

Tagged with:

-

Pandora by marsalv - FINISHED - 1:52

Mirabell61 replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

beautiful work Marsalv, those chainplates look very well done.... Nils -

Thank you very much John, I also love those benches, they were the nicest I found after some related search with help of the web.... (photo etch kits), they are for the "Titanic" in scale 1:144 Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much for your kind comments and compliments, Albert, Bob (raf), Jeff, David, Denis Bob (cap`n), I`m so pleased that you liked the progress Also thanks to all the "Likes" for looking in... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Great to see you back at the table again Patrick, I`ve been missing your update posts the last days.... Nils

-

Chuck, your rigging so far looks lovely, as well as cutter and masting wunderbare Arbeit !! Nils

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.