-

Posts

1,597 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by John Ruy

-

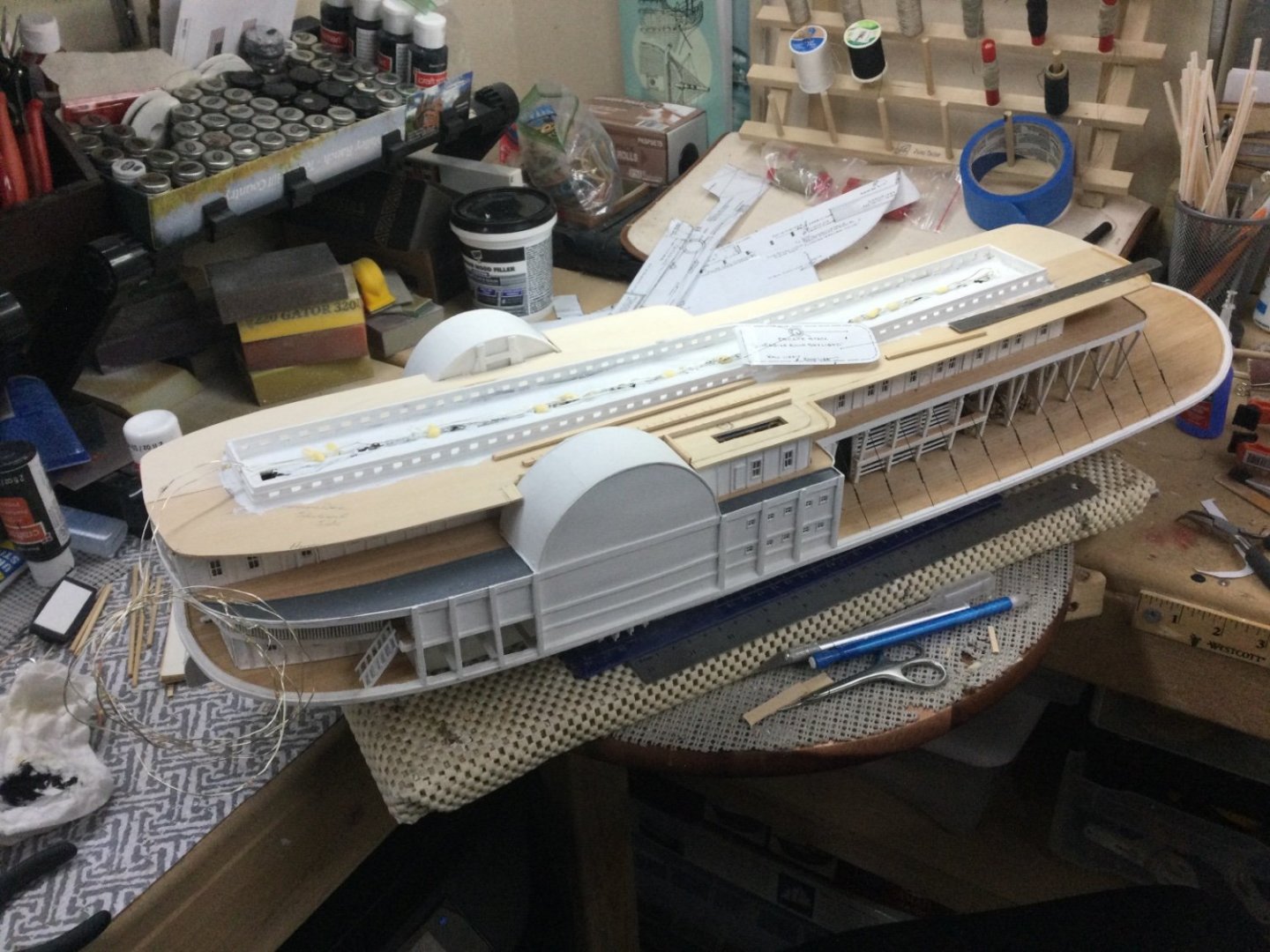

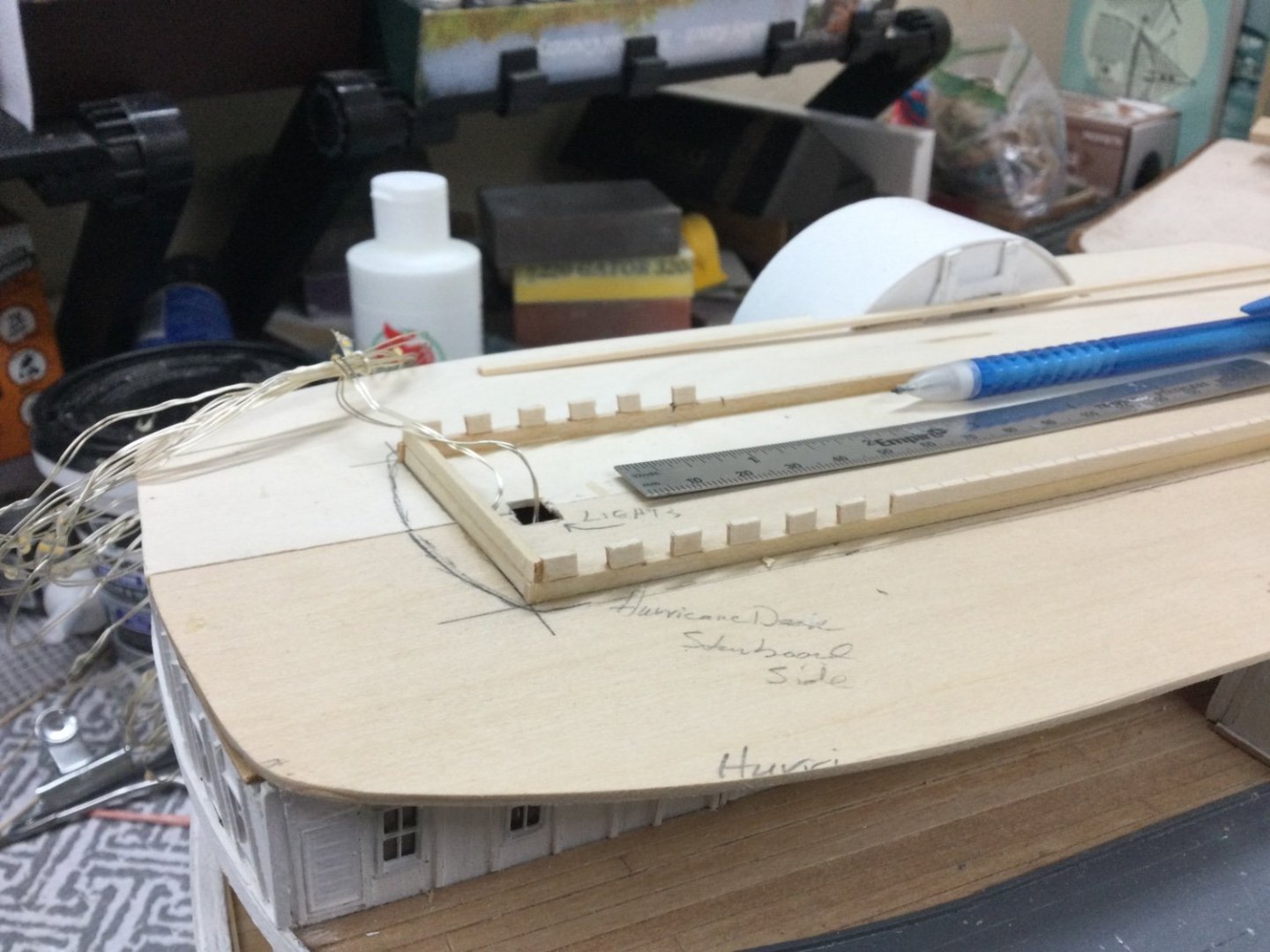

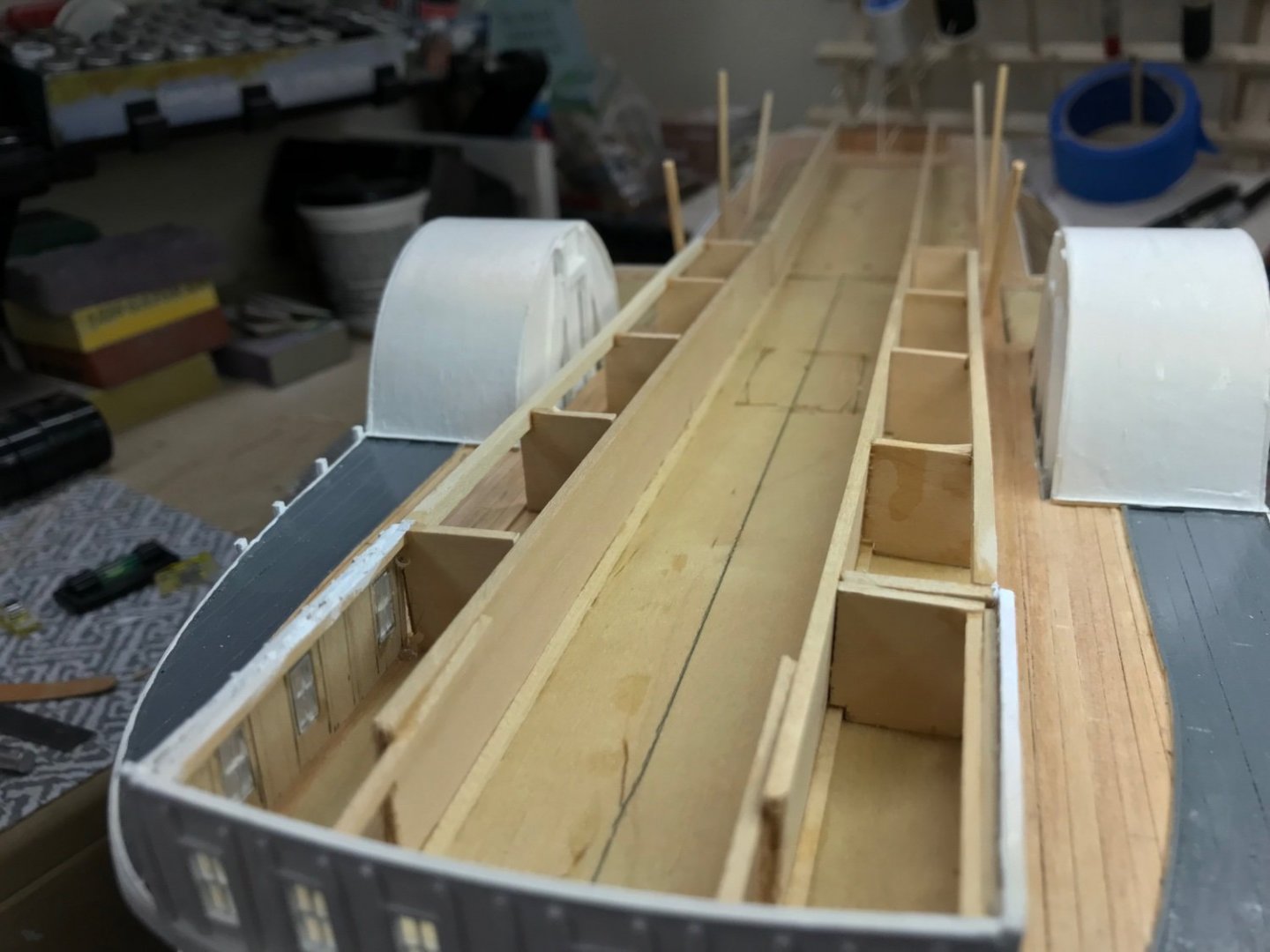

Skylight/Transoms sub decked… Also installed the Hog Frames. Time to start planking the Hurricane Deck. Cheers 🍻

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

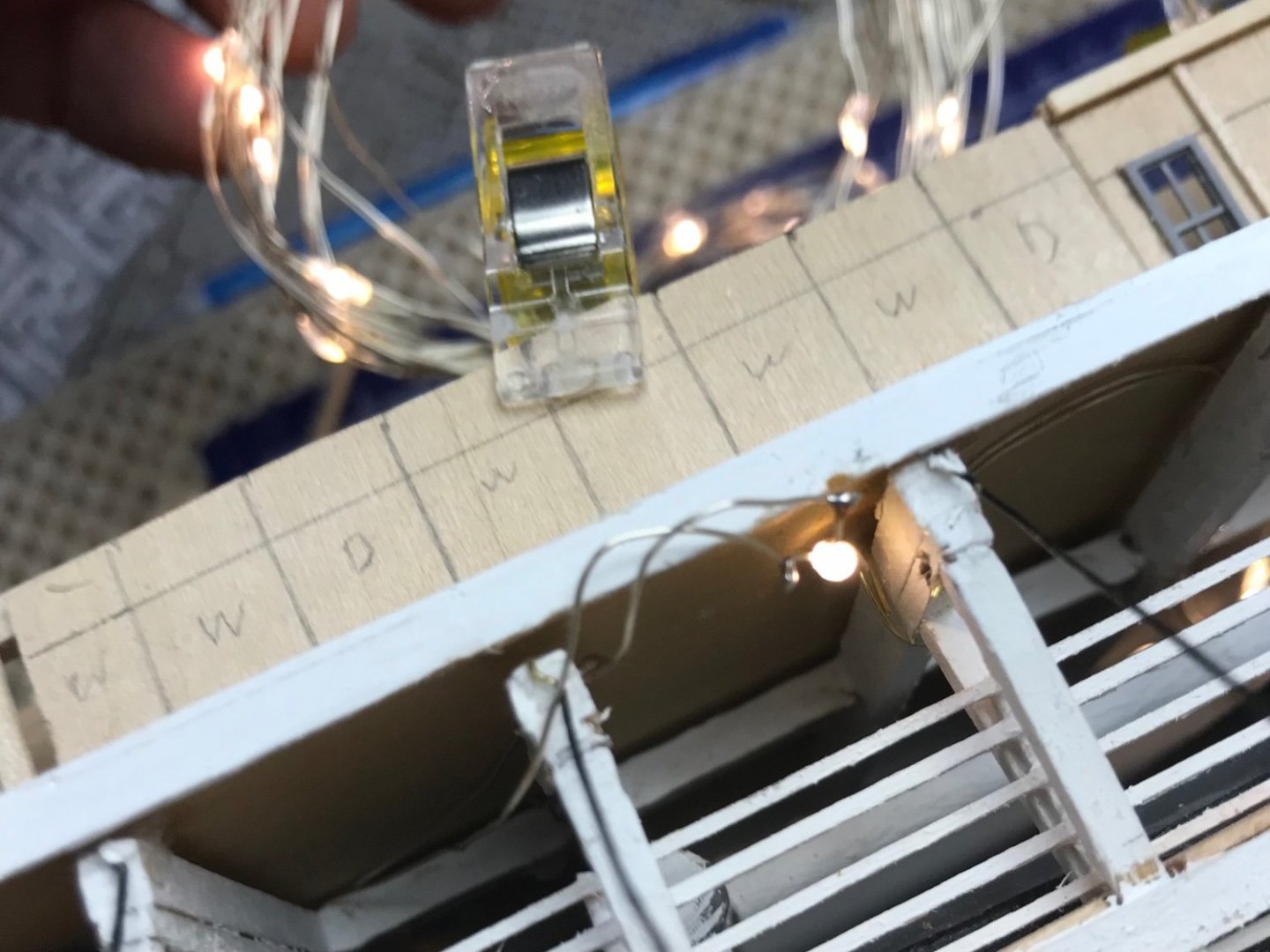

Saloon Skylights… The skylights on the hurricane deck were above the Grand Dinning Hall. Skylight/Transom Windows framed out. 1/32” strips for molding… Chandeliers hung inside the dinning hall. 😎 Almost ready for the Texas sub-Deck… Cheers 🍻

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

Kevin, Nice work, you got me interested. I’m pulling up a chair to see where this goes. Thanks John

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

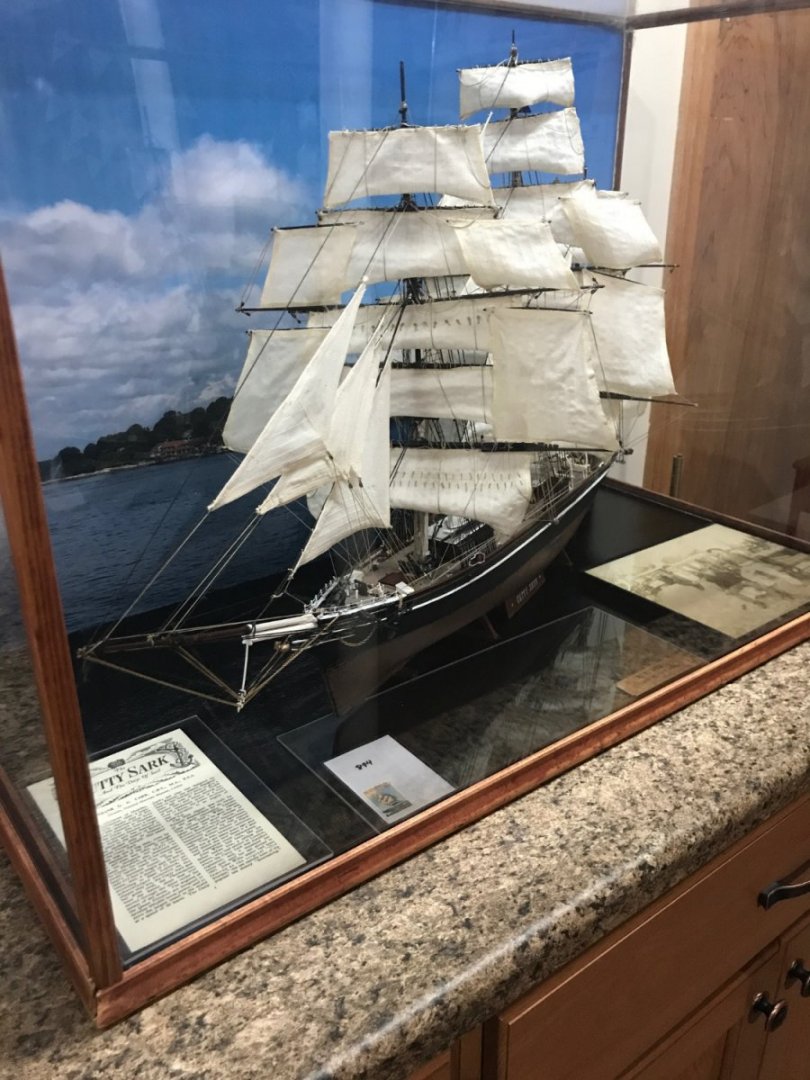

Kevin, Very interesting, The Cutty Sark was my first model in retirement that I attempted to enhance with cloth sails. I then moved on to the USS Constitution by Revell. That’s where I went down the rabbit hole. I found a source for enhancement parts in the Czech Republic. They have everything from Wood decking to wood blocks and cloth sails for your Cutty. You can go nuts. 😆 You might want to give them a look see. https://www.hismodel.com/articles-category-14 Also the Cutty is in a museum in England where you might find some good info. Cheers and welcome aboard. 🍻

-

I pick this photo off the internet when I built my Cutty Sark 5 or 6 years ago. It was a Revell Plastic kit 1/96, but I didn’t go into the detail you are. That was back then. I’ve improved since then. 😎 Note the block on the far left of the photo and the hook 🪝 and rope tied off to the winch. Nice rope coil on the right hand side, as well. Photography didn’t allow for action shots in those days. Ok, everyone smile and don’t move. poof 💥 Good luck with your build. John

-

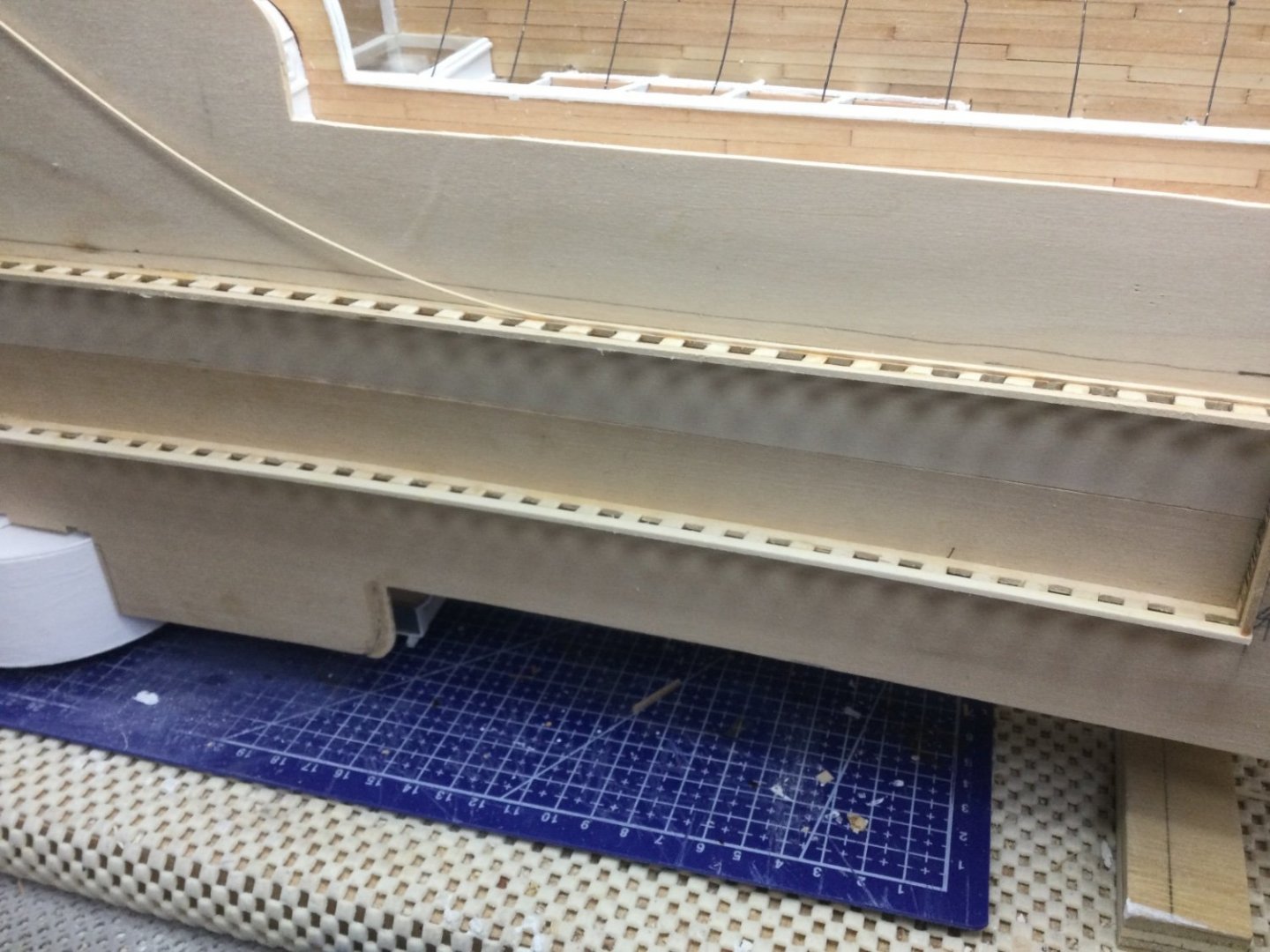

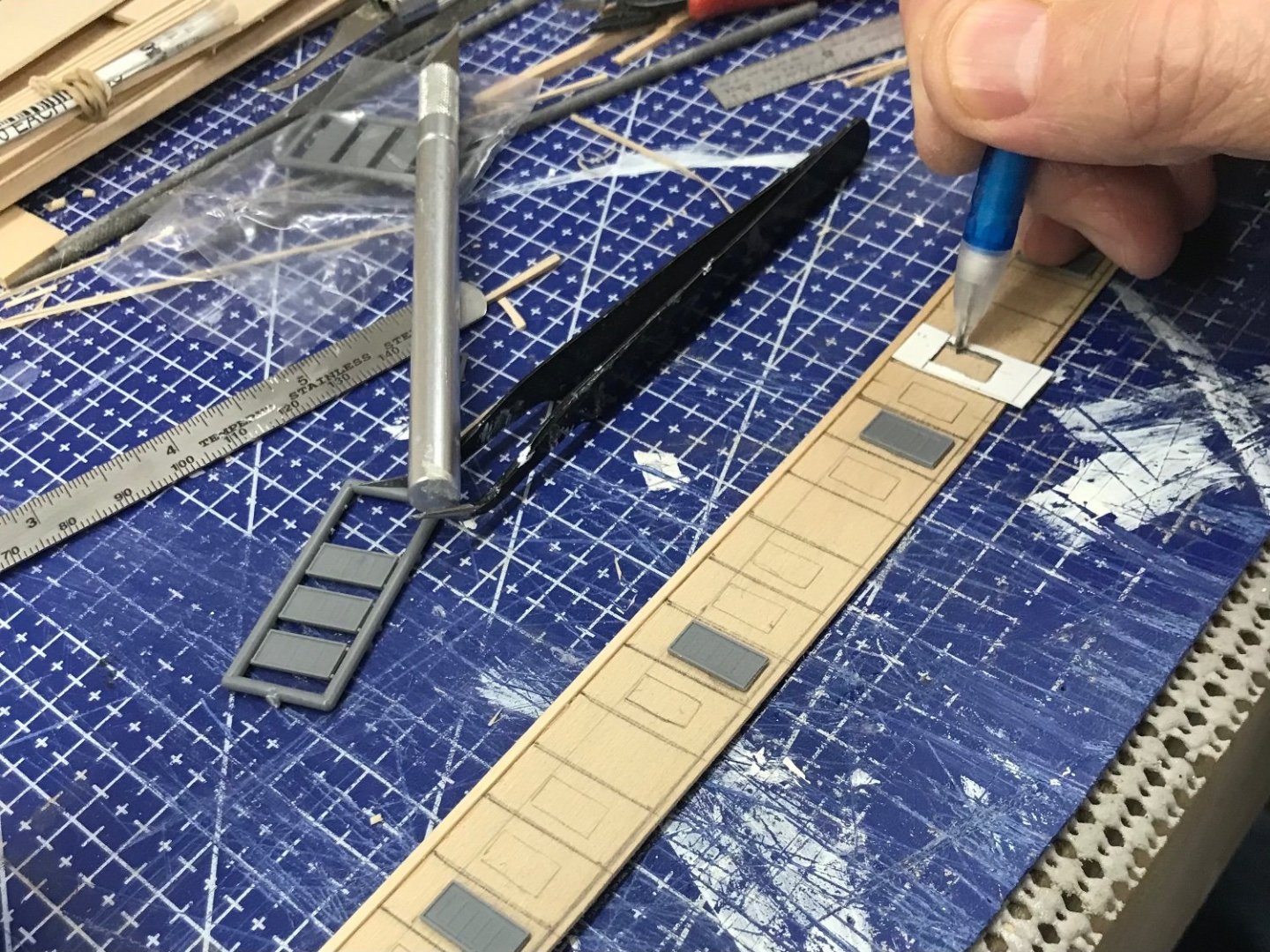

Hurricane sub deck… Copied blue prints to create templates. Trimmed up sub deck to exact fitting for Railing Post. Sub decking fitted ready for installation. Cheers 🍻

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

Windows and Doors on the Boiler Deck completed… Ran lighting through the State Rooms. Ready for the Hurricane Deck and Railings. 😎

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

Here is a photo of my CWM with standing rigging completed. The rigging is from Marine Model Companies 1939 Rigging Blueprints. Hope this helps…

-

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

Side Cabins completed… A bit of Micro Electrical work needed to repair where the Carpenters drilled a hole for the Hog Frame. Seems the wiring was cut on the underside of the boiler deck. Fortunately, the electrician was able to affect repairs and construction may resume. 😆 There’s always something… Check out the special effects in the side cabin windows. Back to cutting in Widows… Cheers 🍻

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

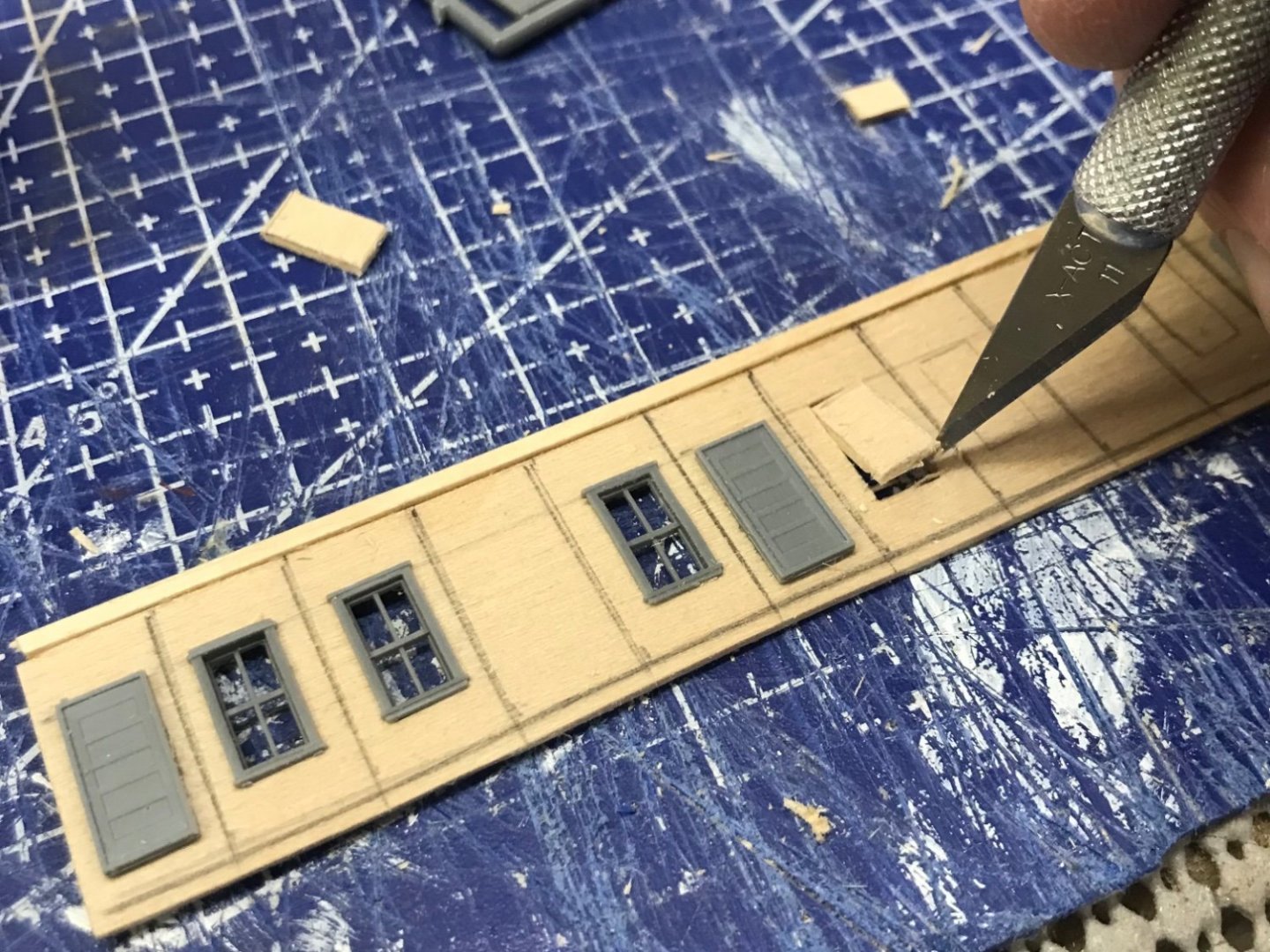

More walls ready for more windows… Saloon Doors and my first “curved” walls. Onwards to cutting in more windows… Cheers 🍻

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

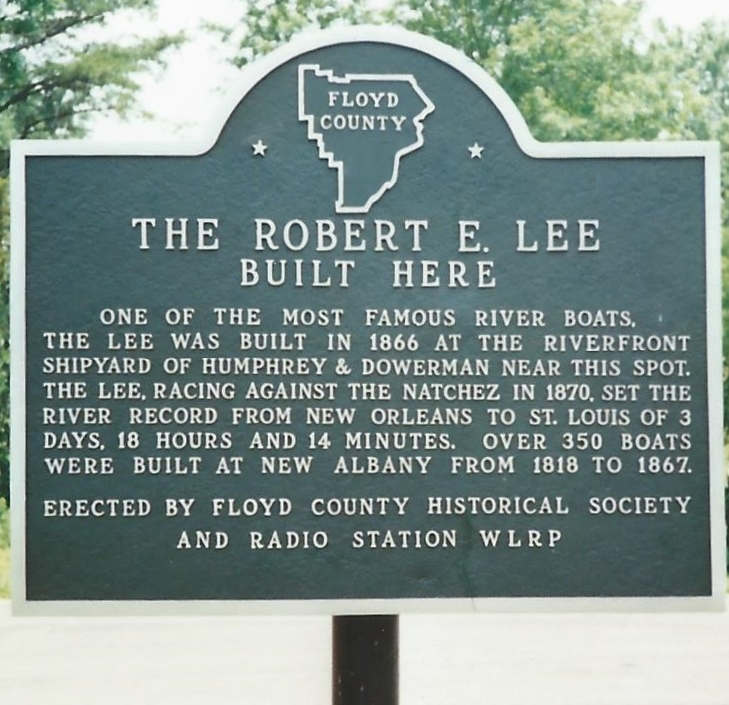

Some Interesting history of the shipyard that built the Robert E Lee. https://fchsin.org/markers/RobertELee/RobertELee.html Enjoy 😉

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

More Windows… … and more framing for more windows. 🤪 Repetition does make for improved carpentry skills. Vintage photo (courtesy Floyd County Library) of the Hey Day of Shipbuilding in New Albany, IN. On the Ohio River bank with 1000s of carpenters and many tons of lumber. Cheers 🍻

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

-

State Room walls… Framing progress… I have a plan now 😆 Boiler Deck Stern State Rooms completed. Cheers 🍻

- 238 replies

-

- Robert E Lee

- steamboat

- (and 3 more)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.