marsalv

NRG Member-

Posts

607 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by marsalv

-

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

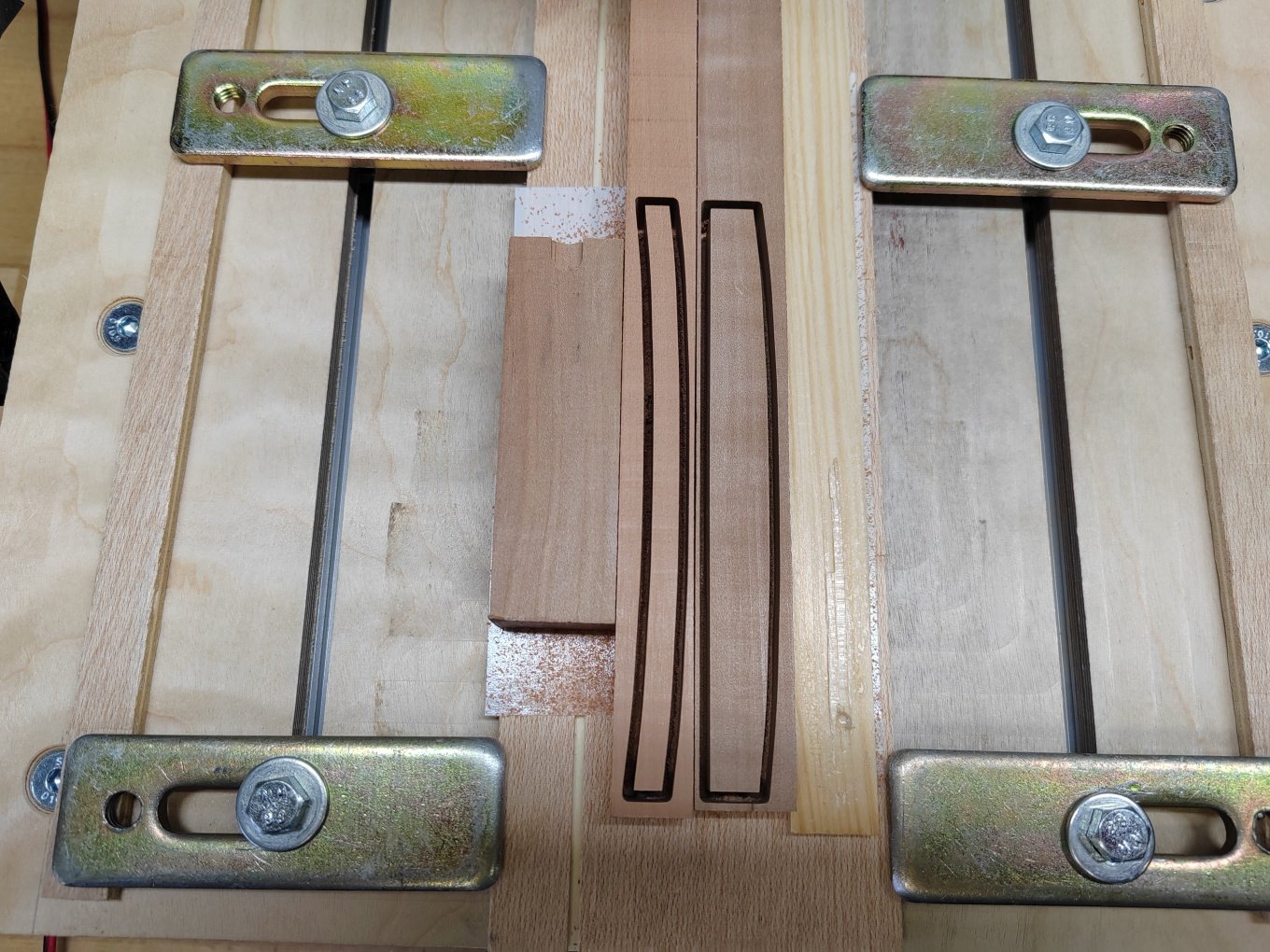

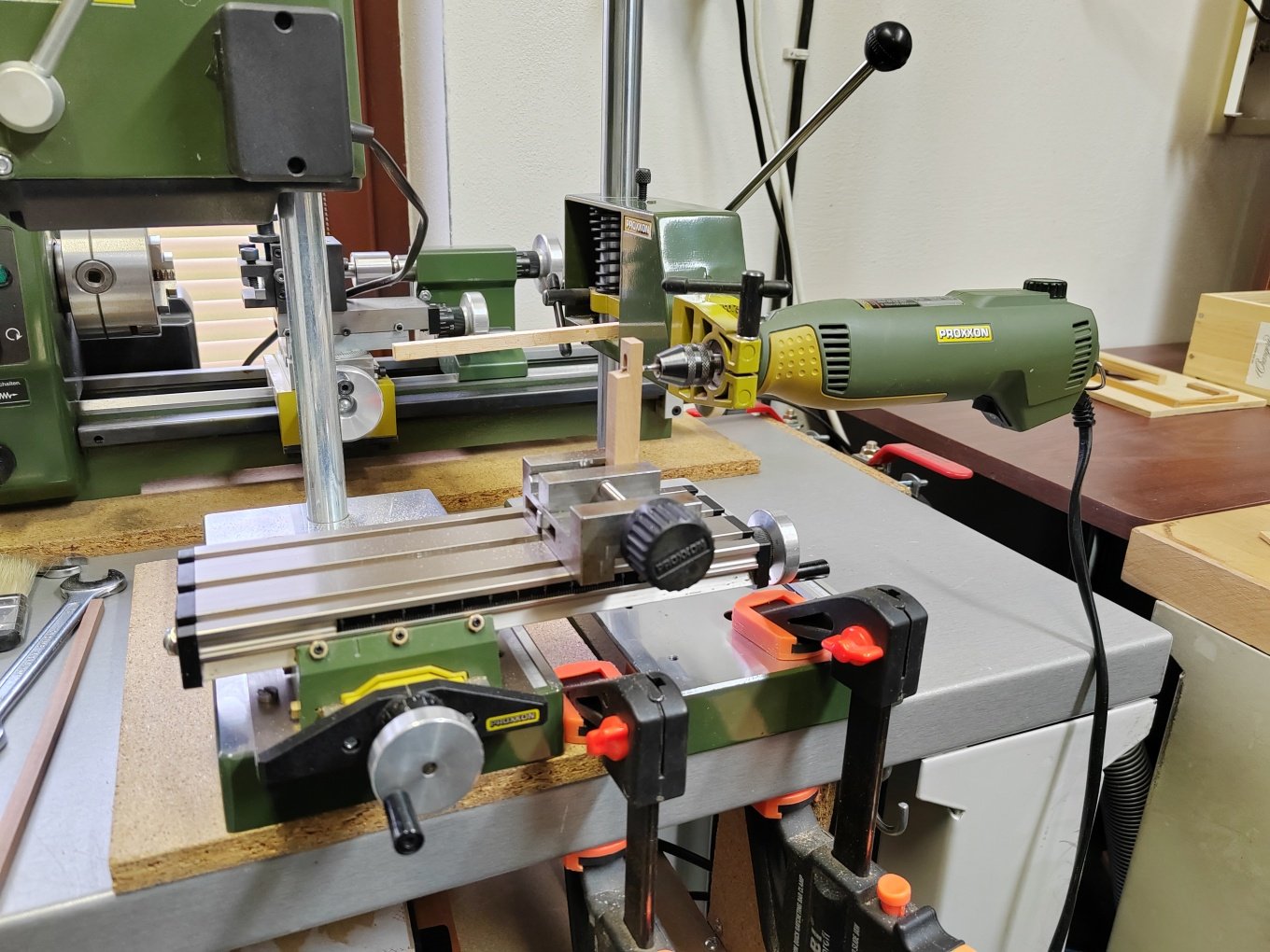

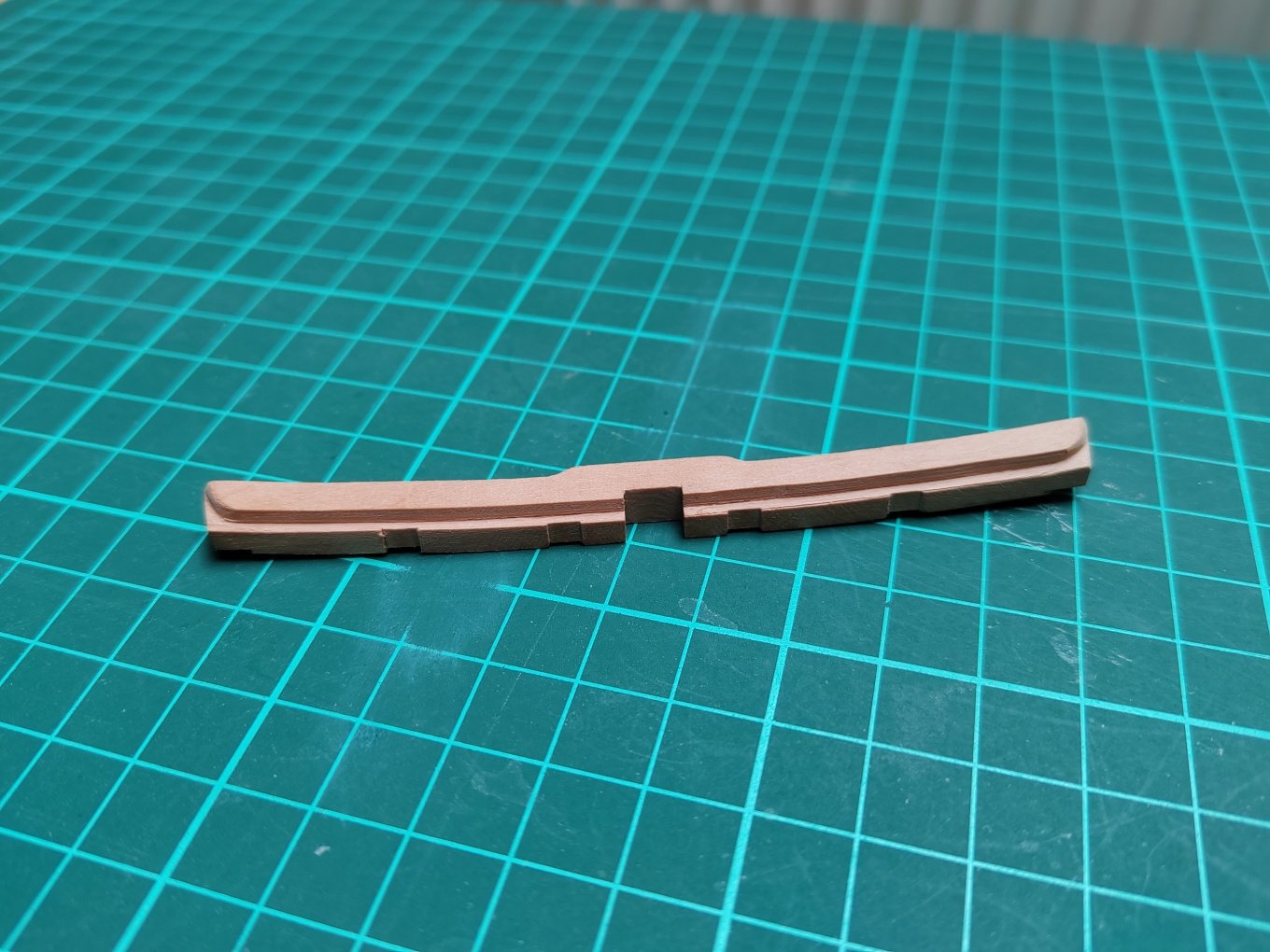

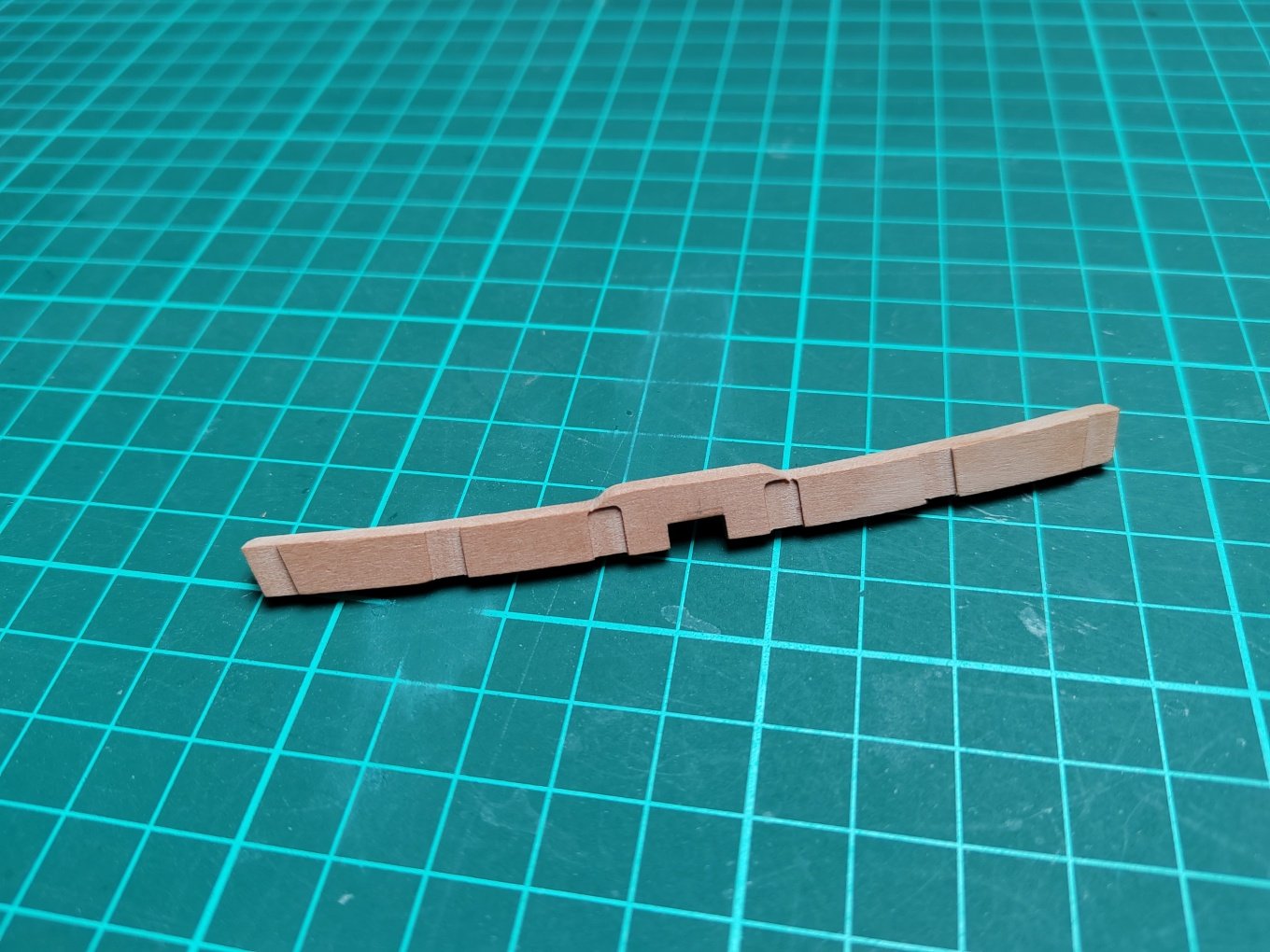

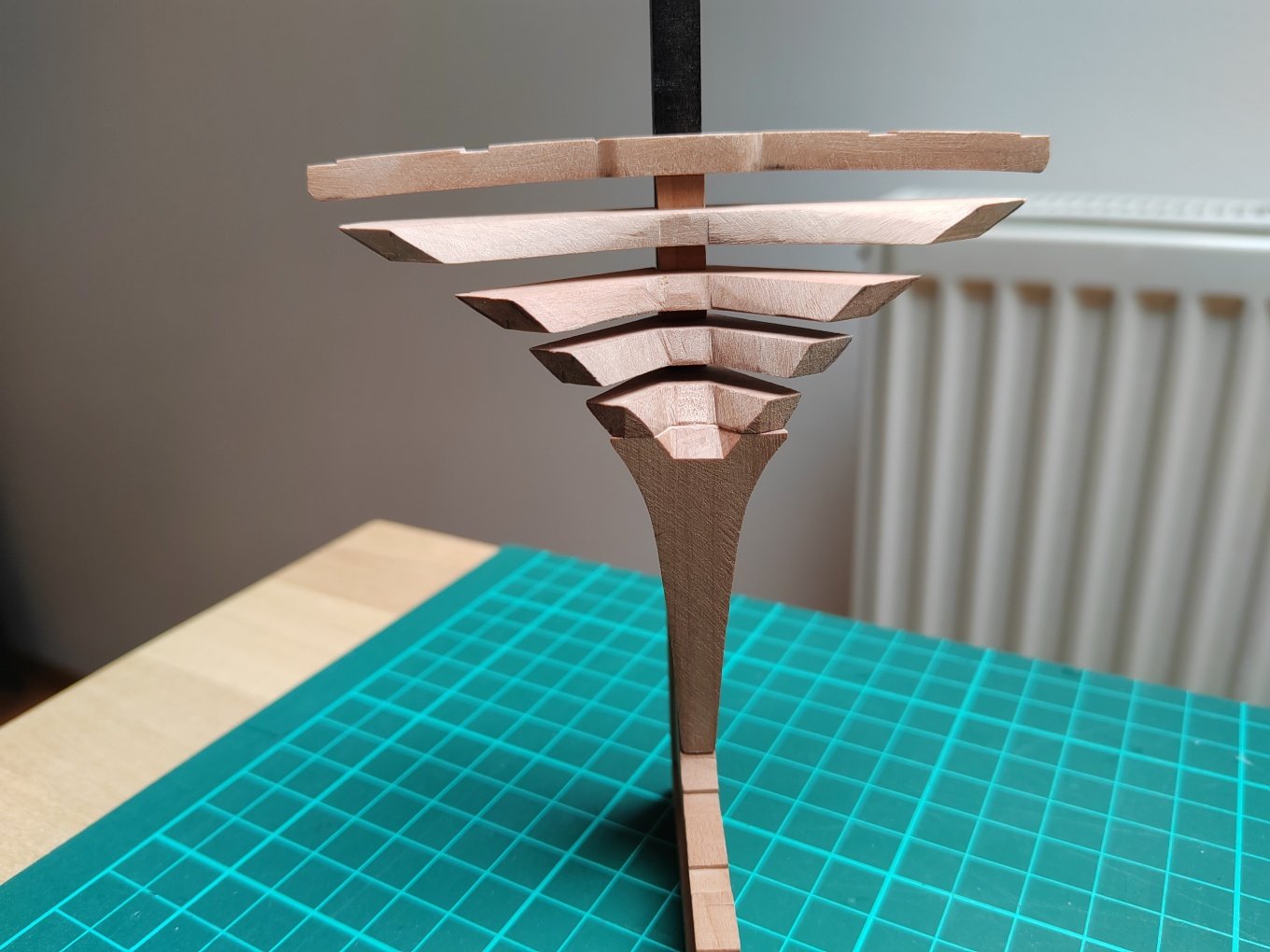

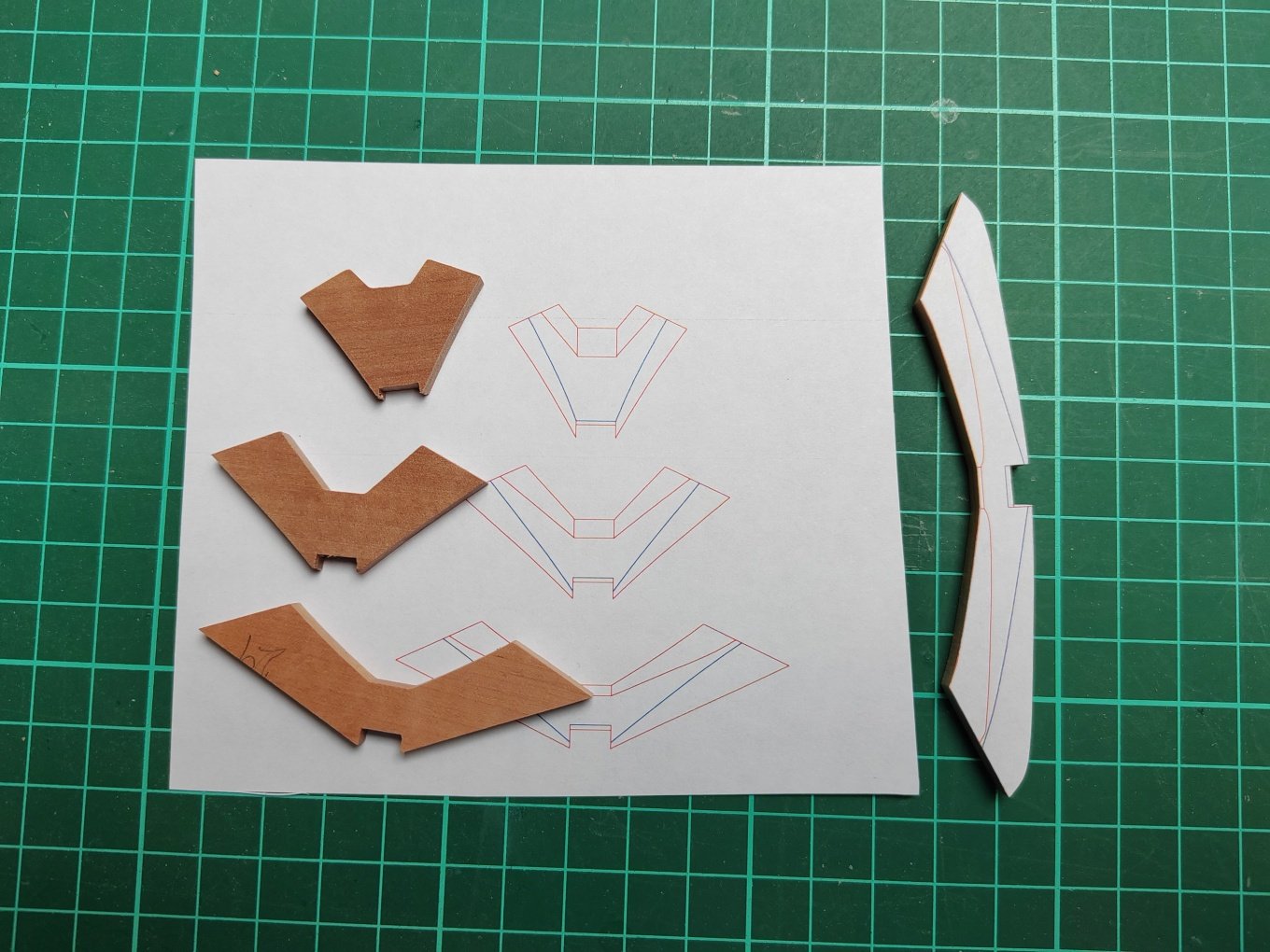

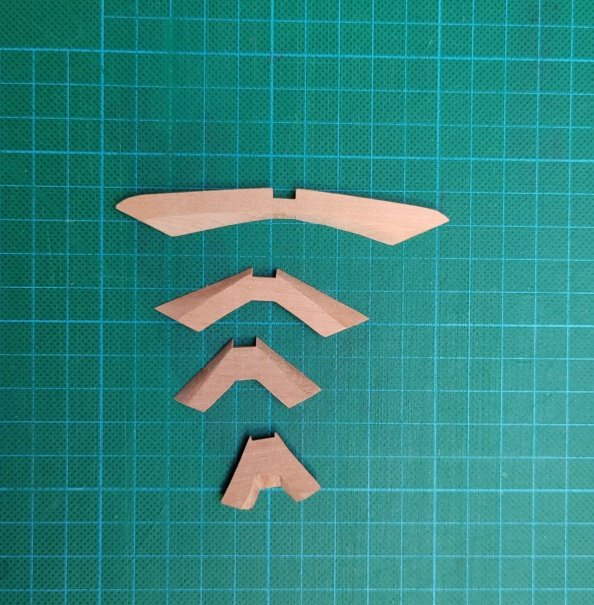

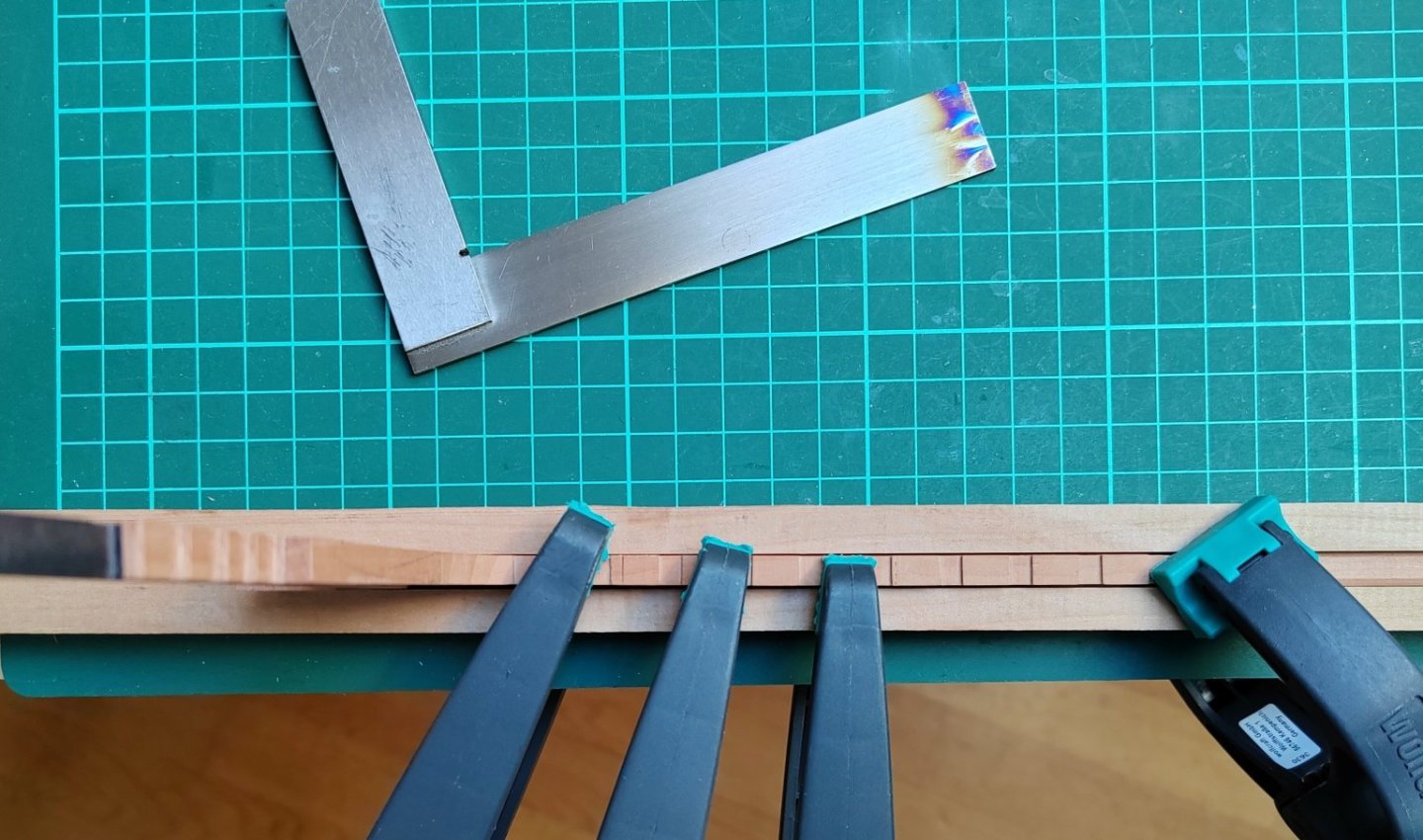

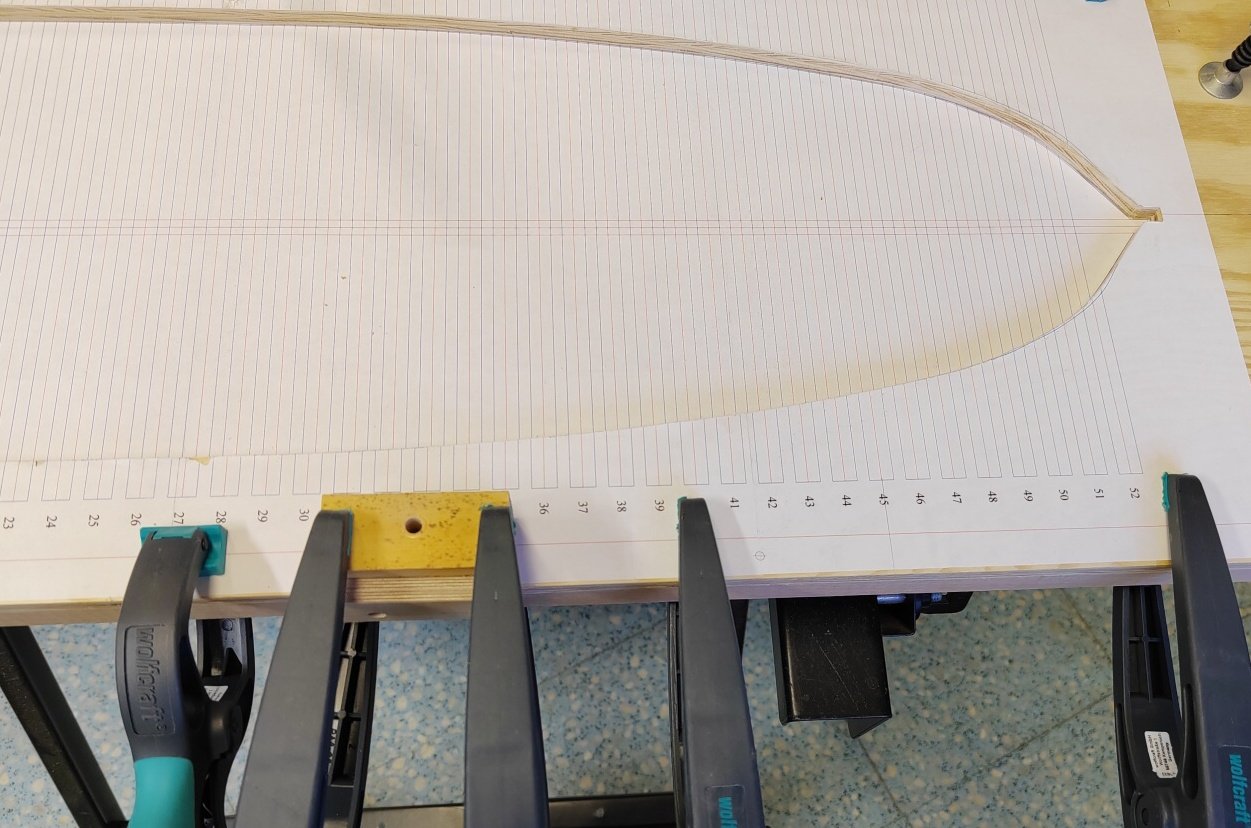

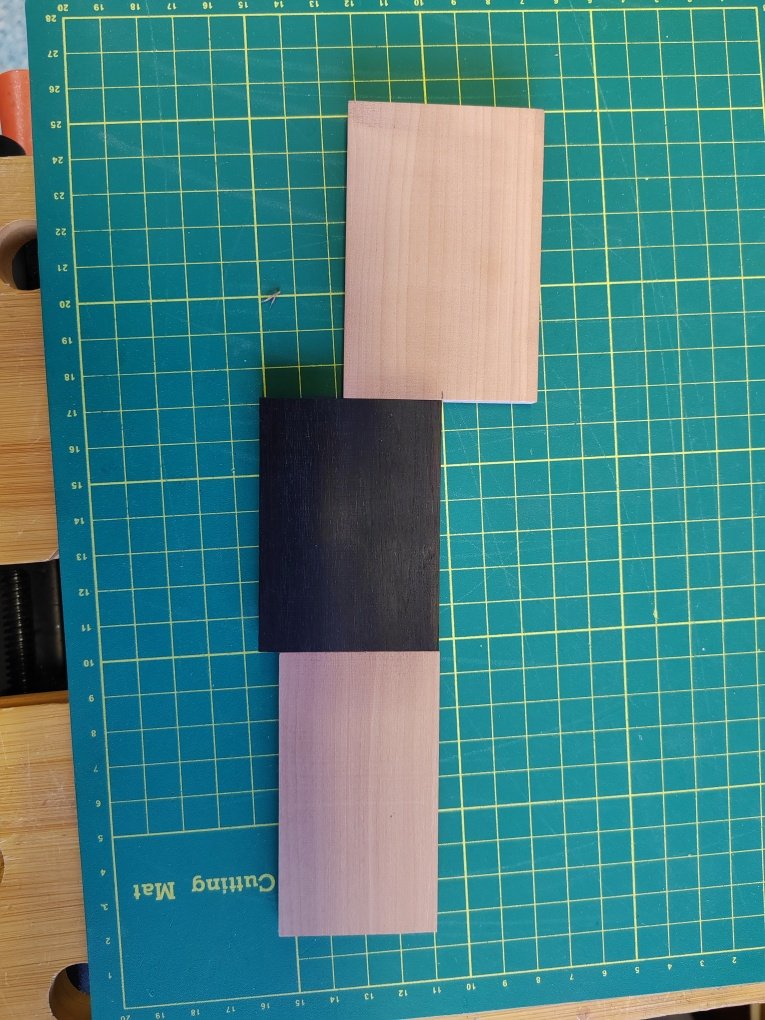

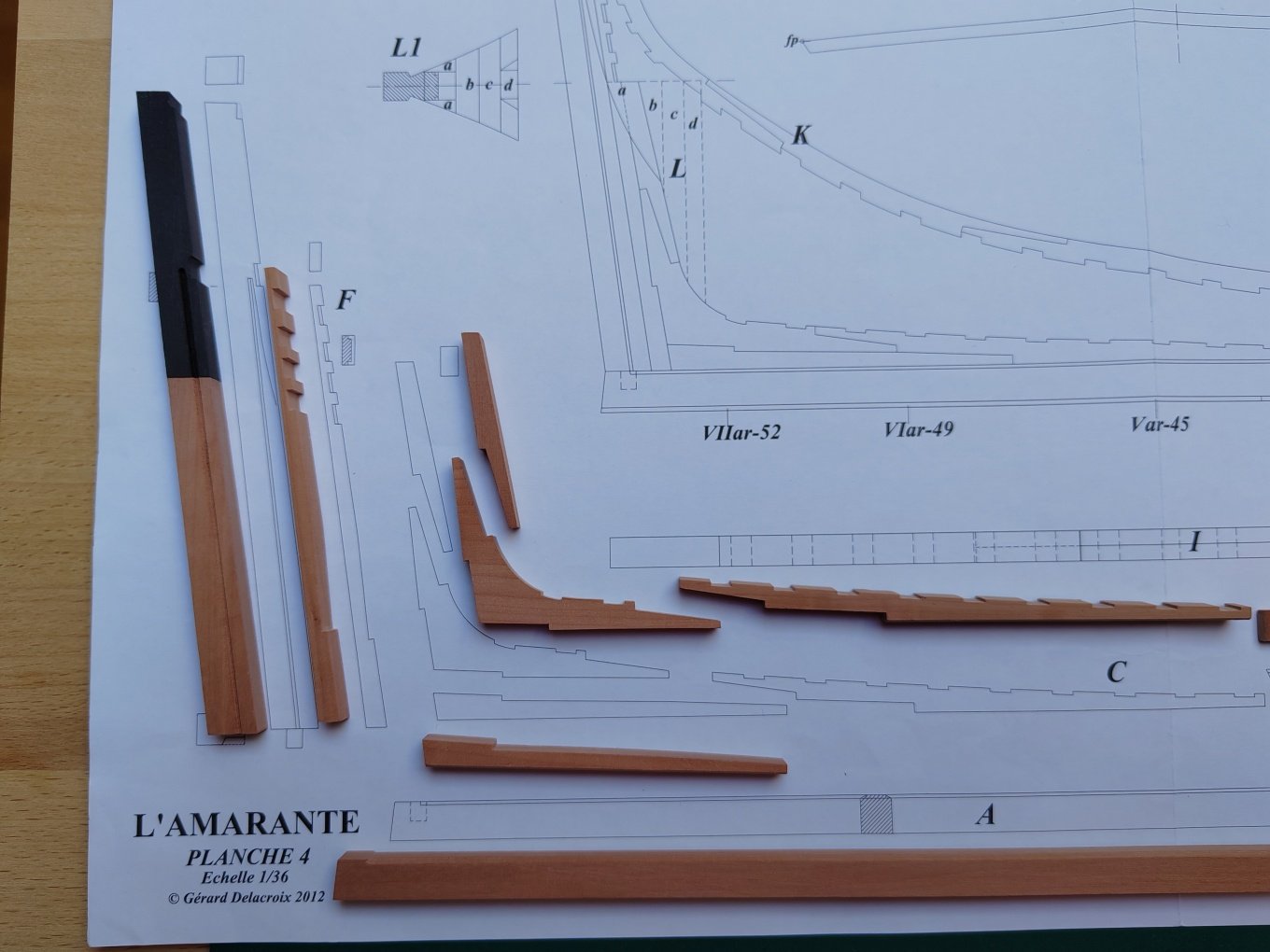

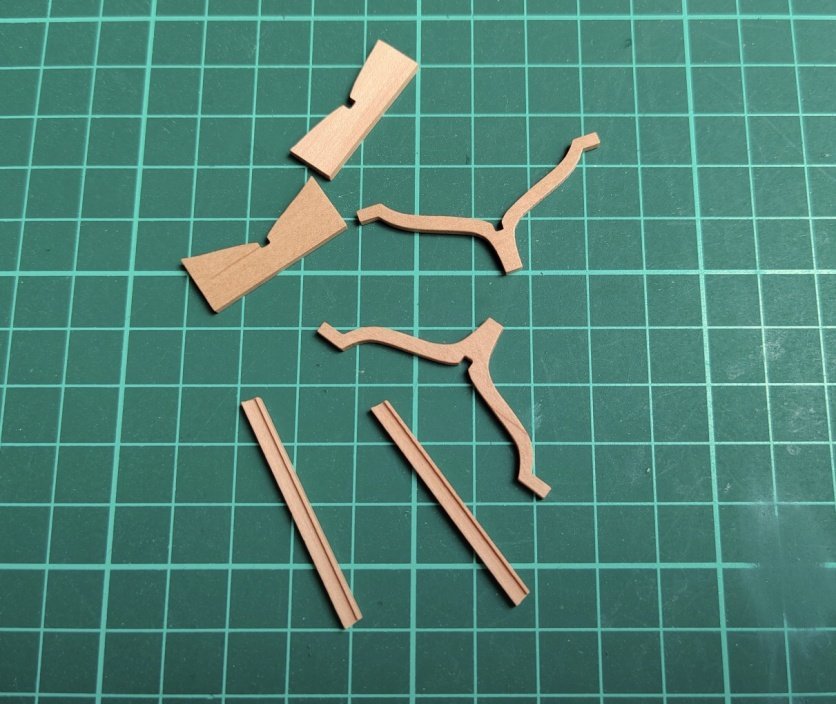

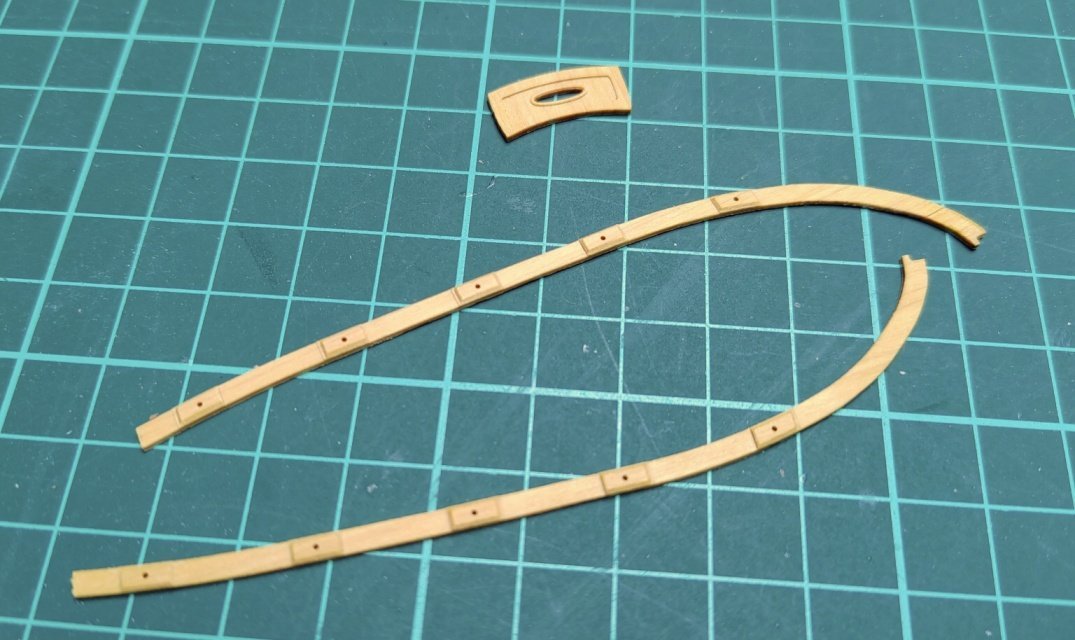

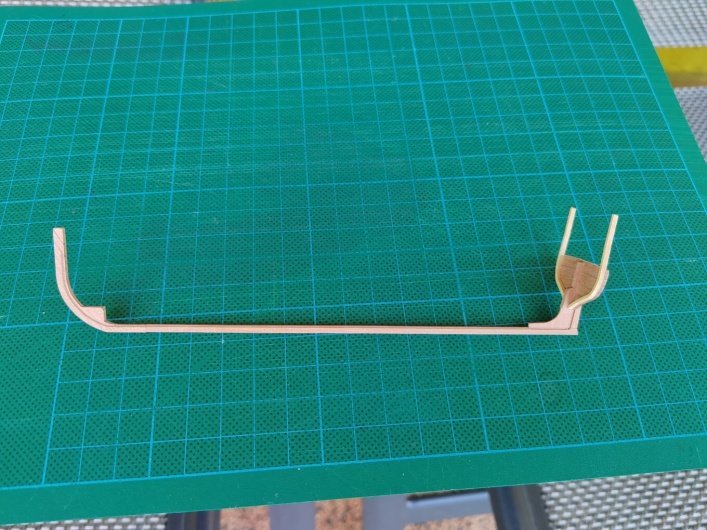

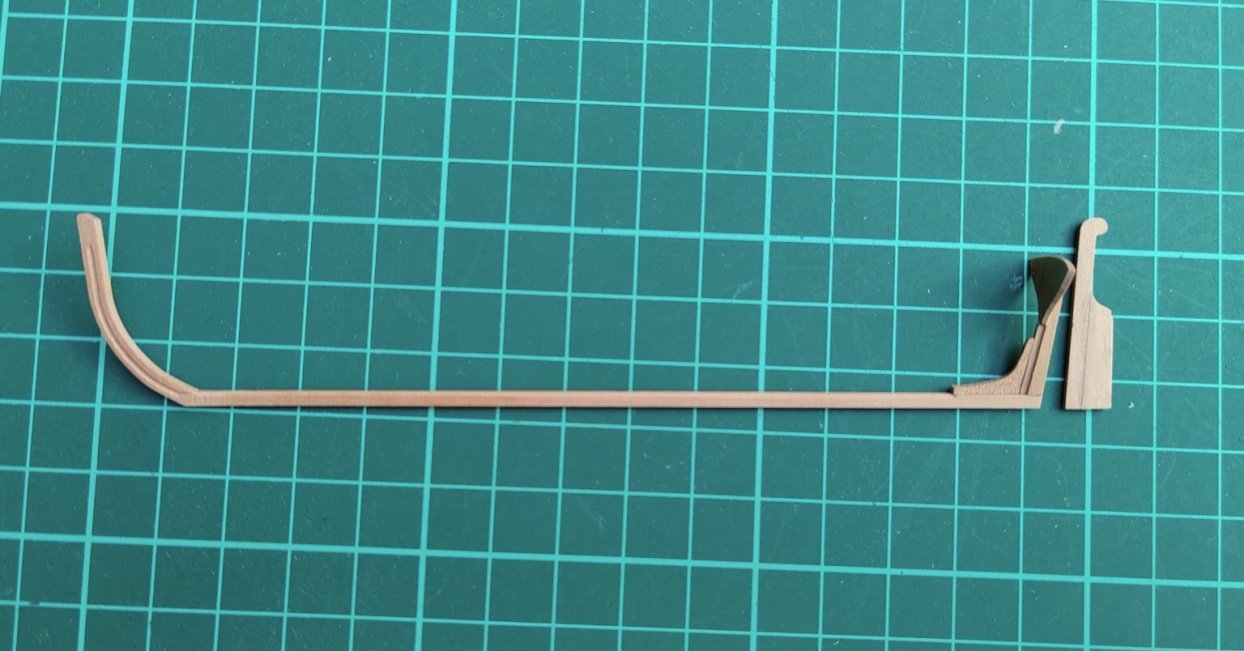

To allanyed: Material used for this part is boxwood. The part is made using a cnc milling machine, which enables precise milling from both sides. The procedure can be seen in the photos in post 8. I continue with the construction of the wing transom. -

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

-

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

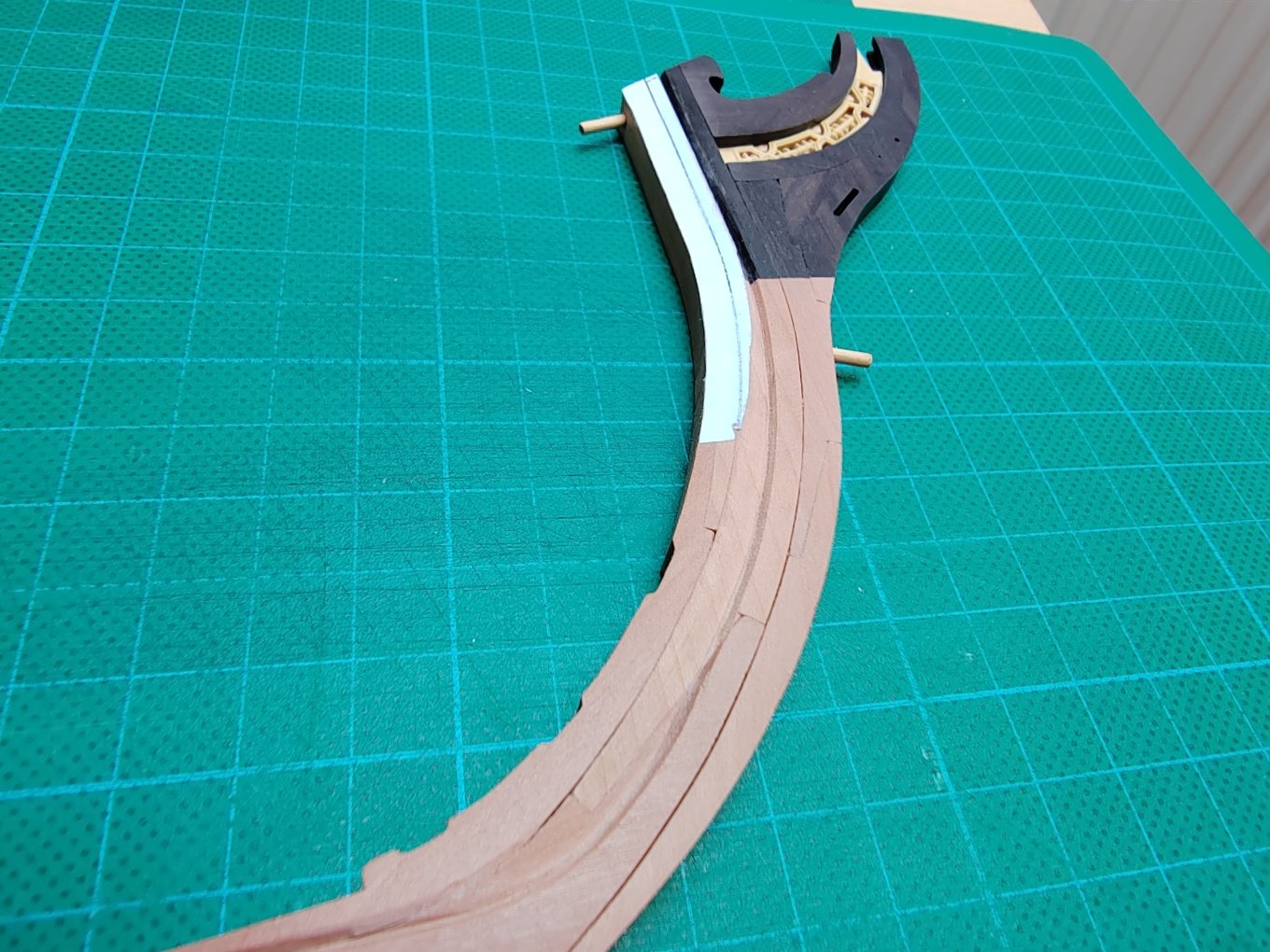

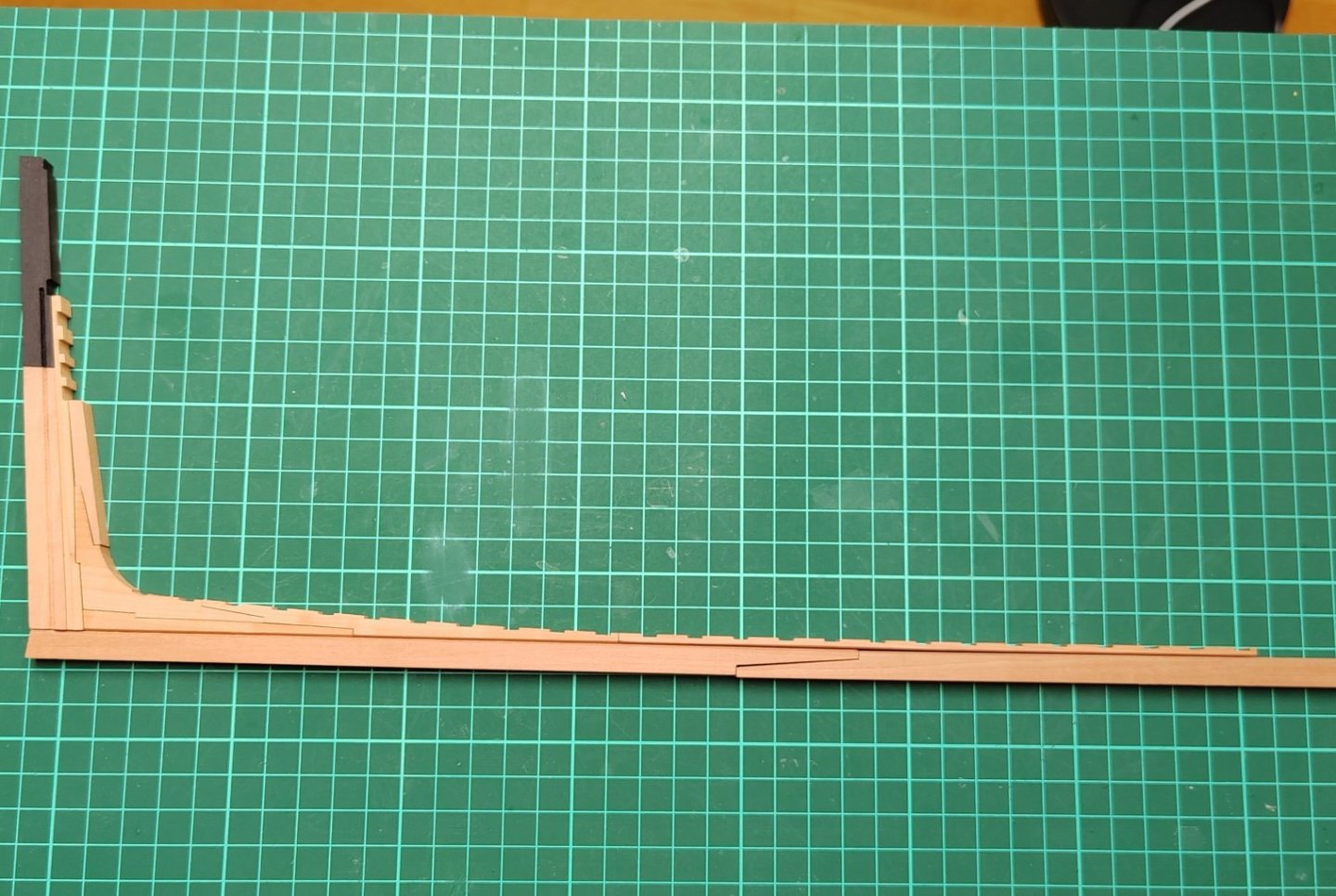

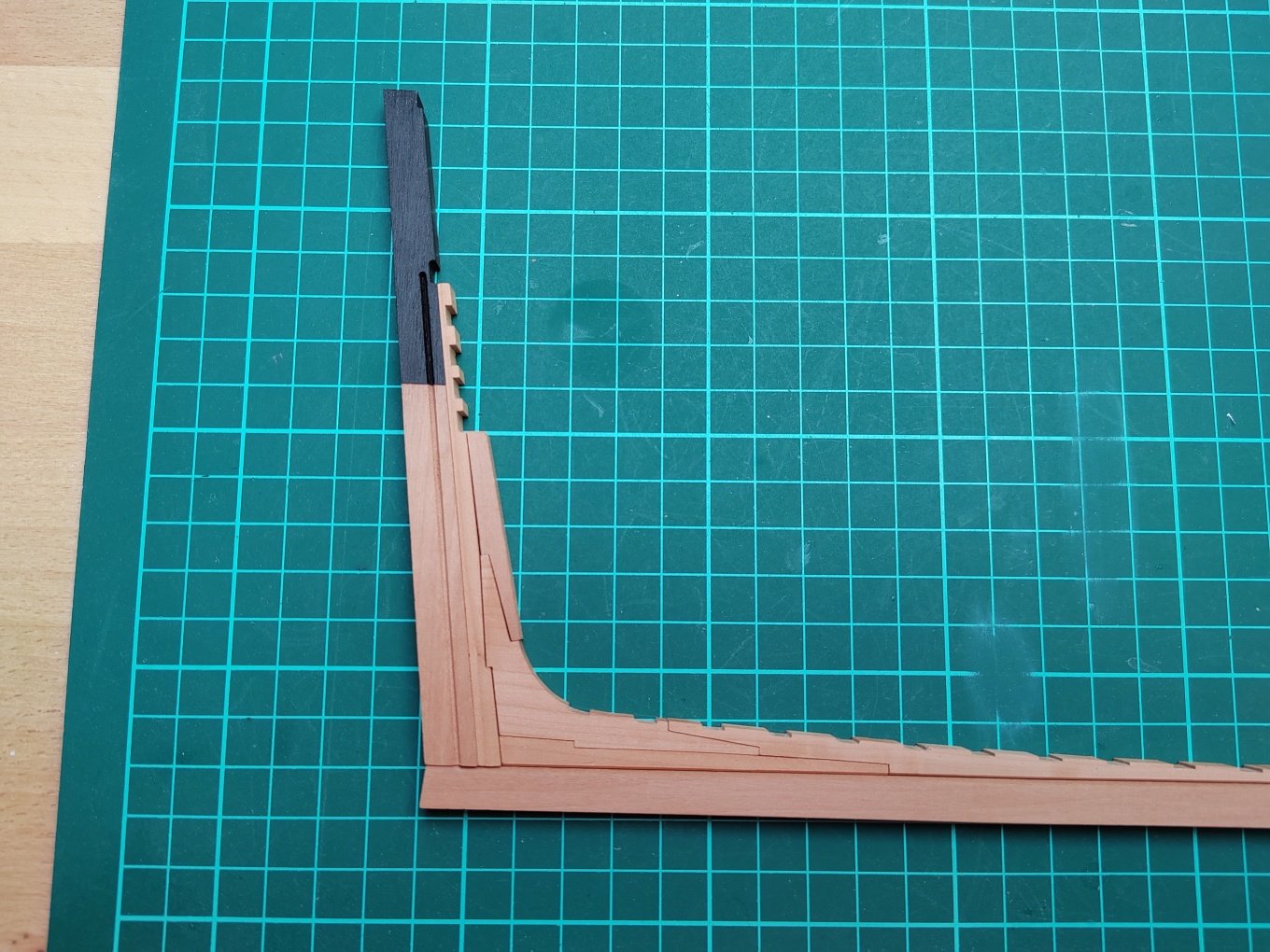

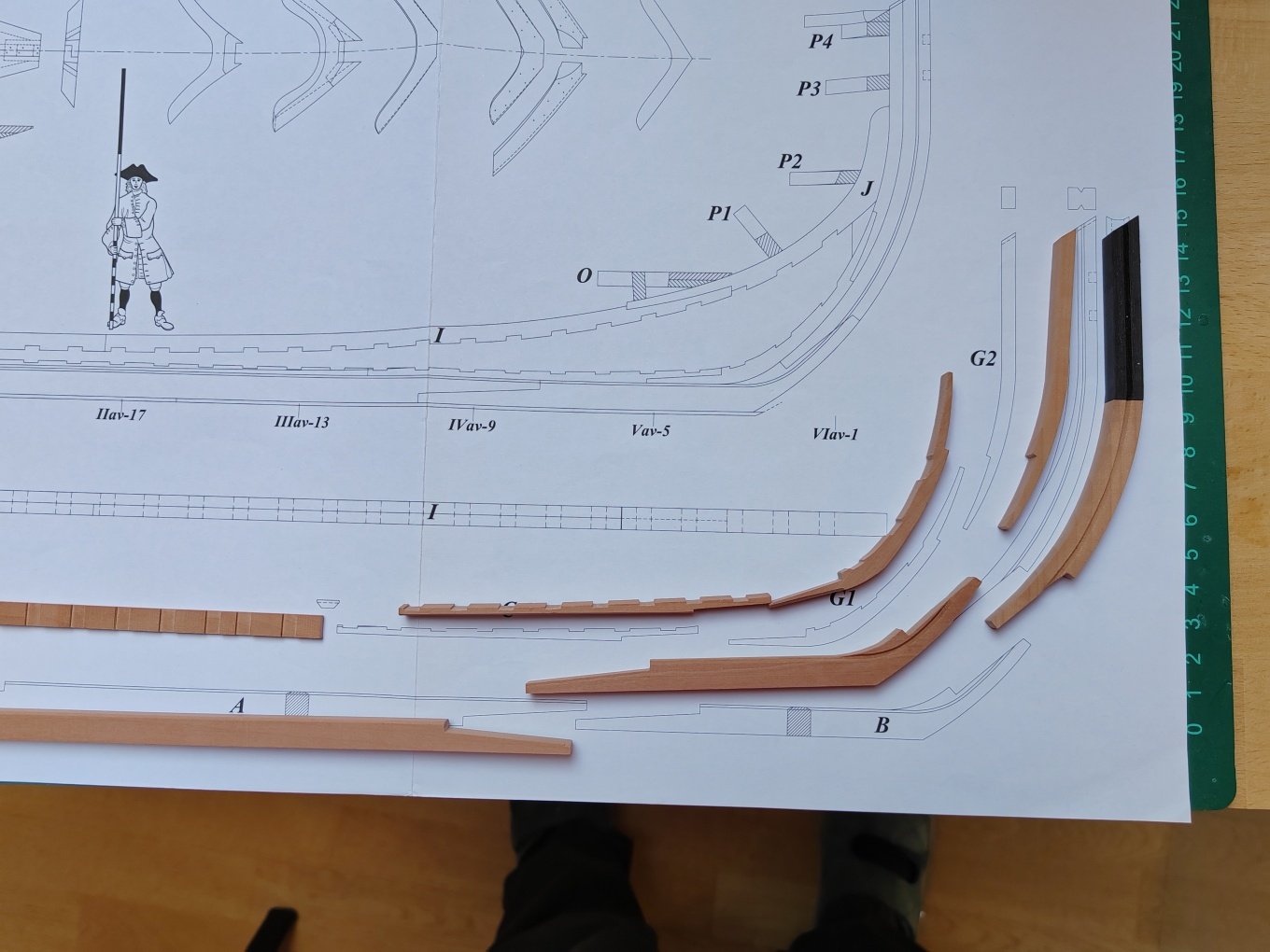

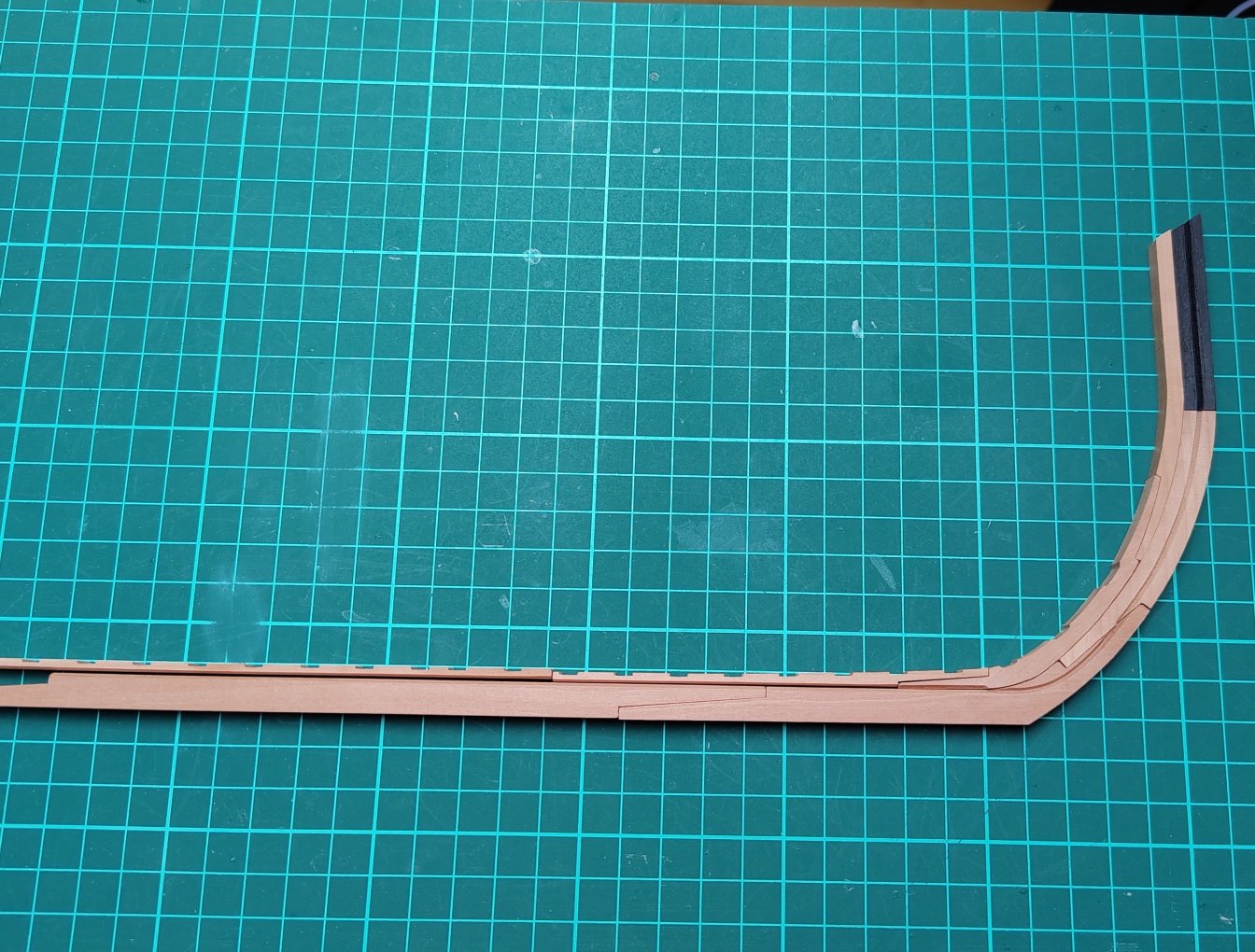

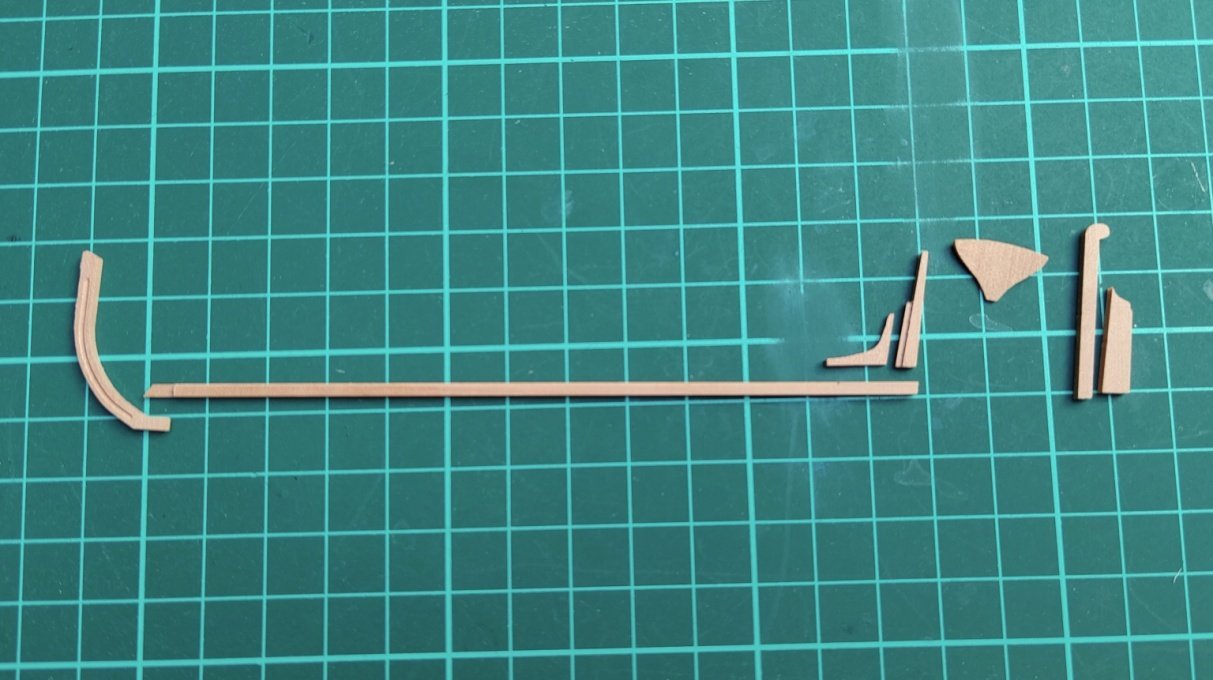

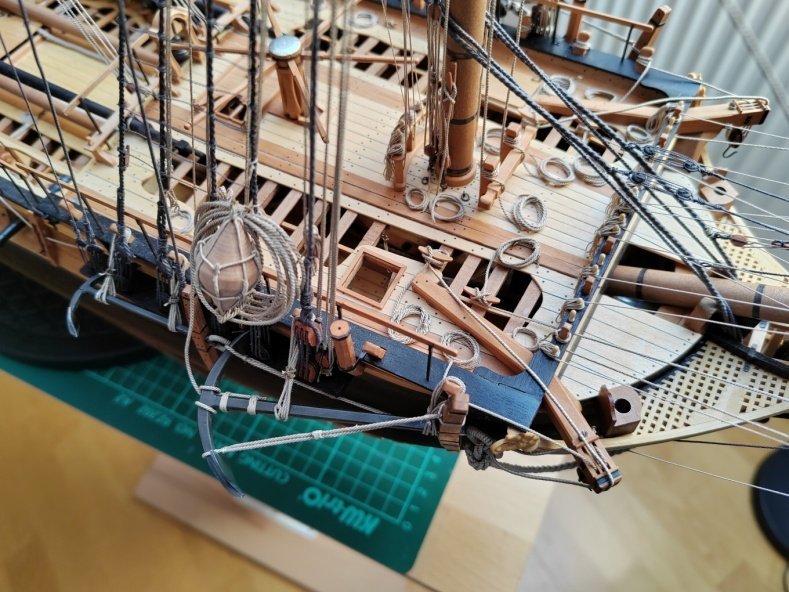

Thanks to all. Knee of the head. With Le Gros Ventre, I installed the knee of the head only on the already completely finished hull, which caused me a bit of a problem (the gap between the stem and the knee of the head). That's why I decided to make and attach the knee of the head already at this stage of the construction. In this case, the installation went without any problems. -

L'Amarante by marsalv - 1:36 - POF

marsalv replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

To tartane: - L´Amarante is sloop of war which was designed by J.L. Ollivier. There were three versions that differed only in decoration - La Palme, L´Anemone and L´Amarante. Some information about the ship's history is from the GD monograph - see photo. -

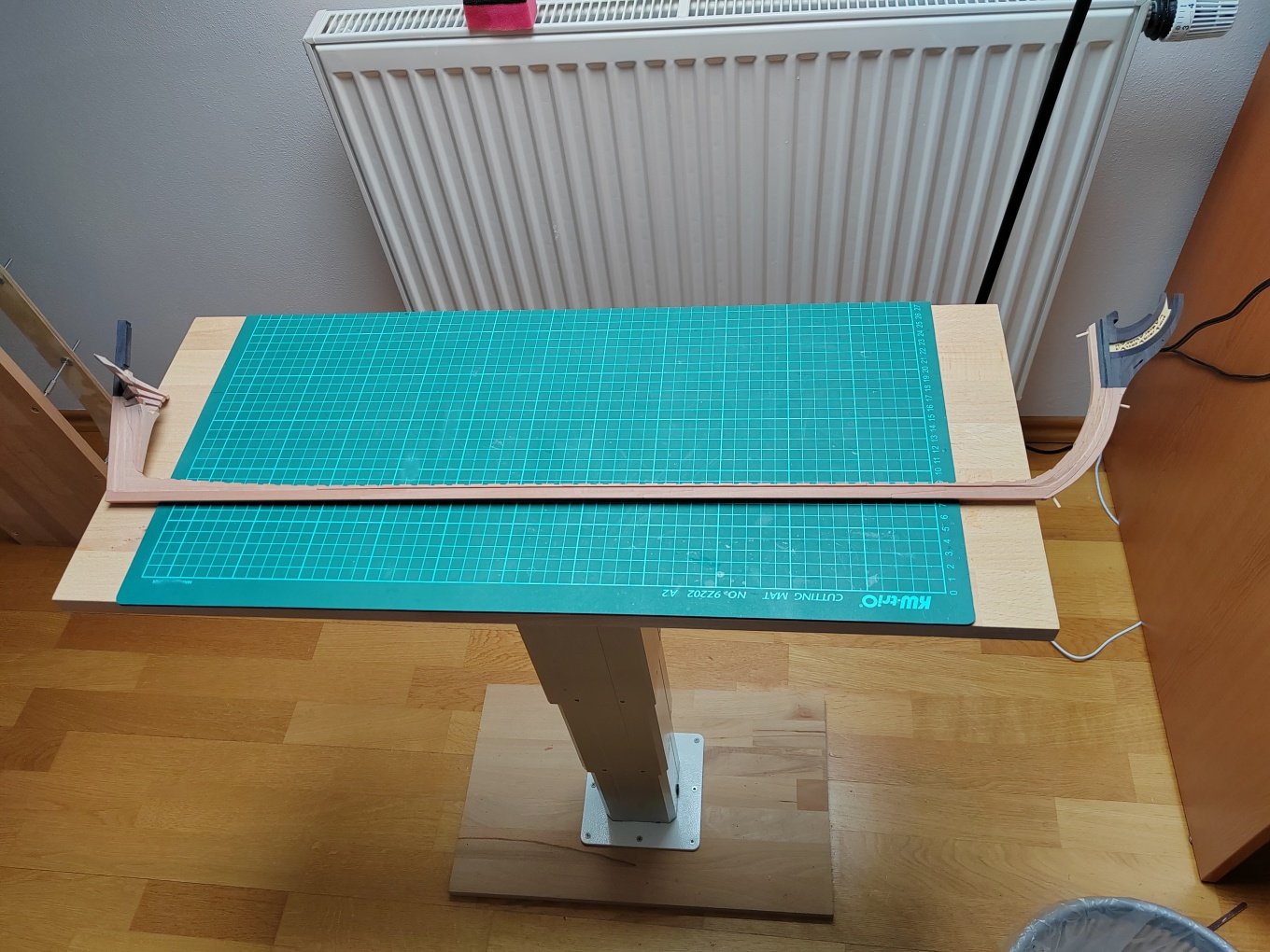

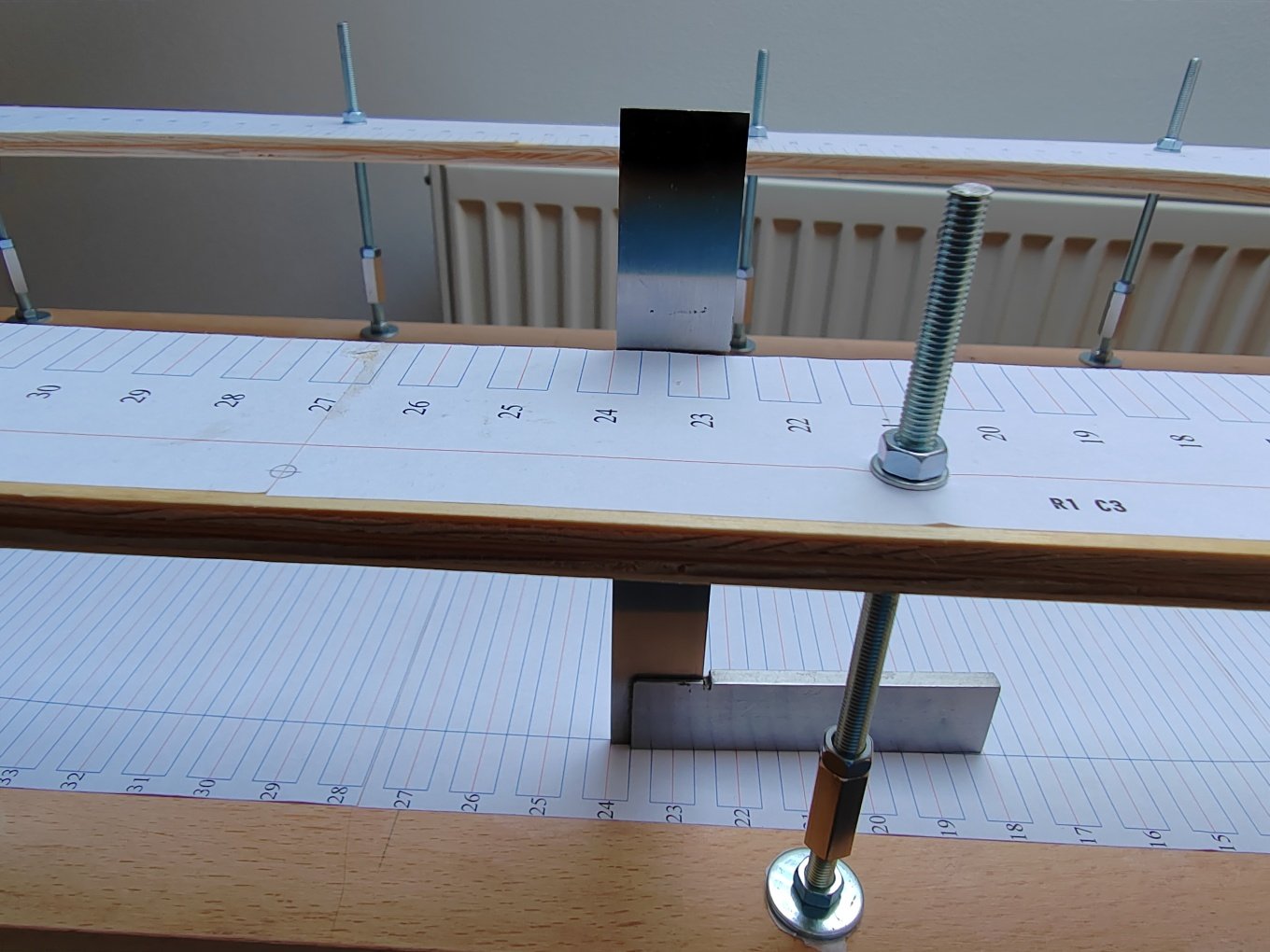

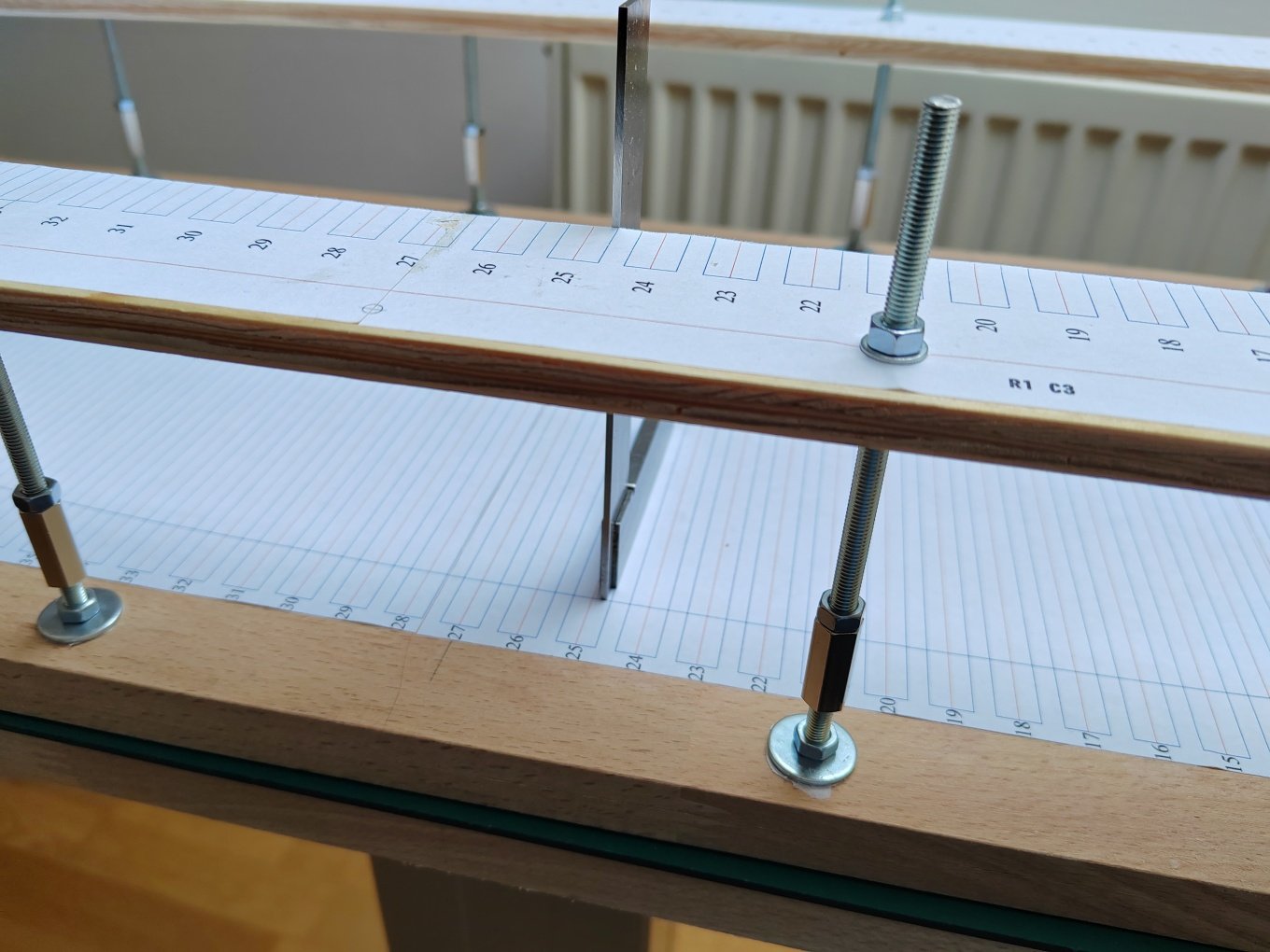

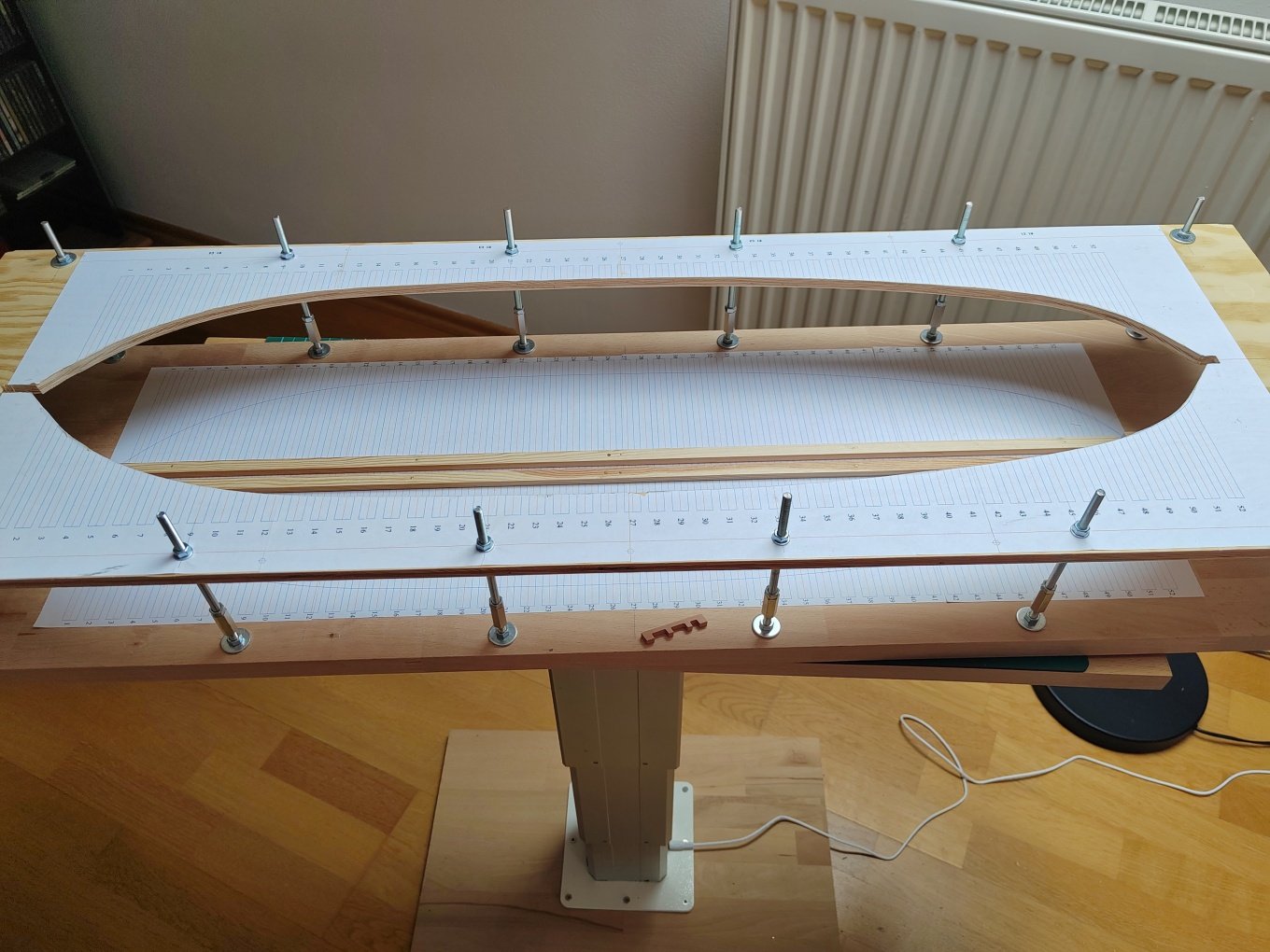

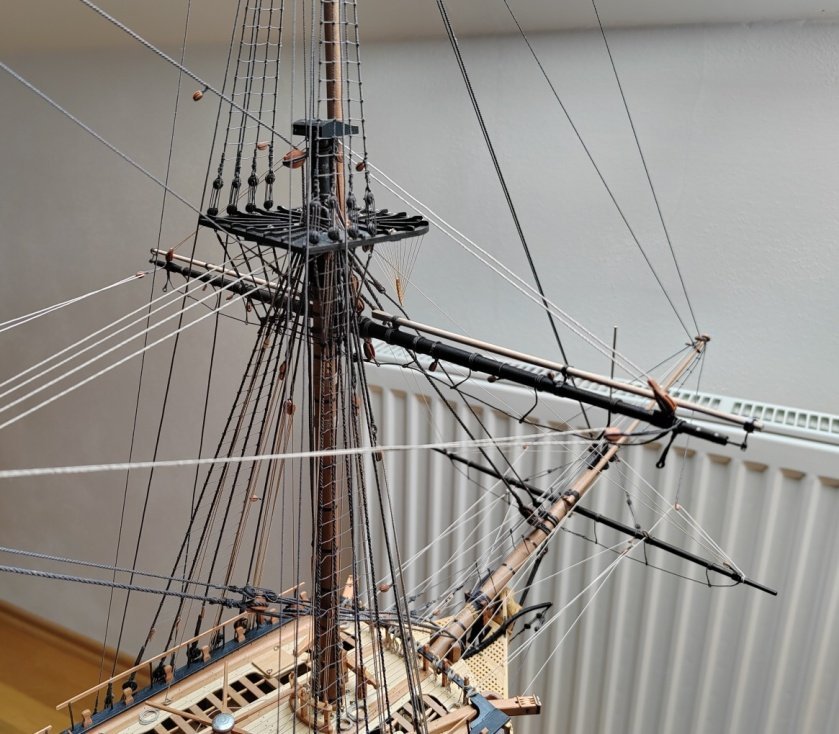

Hello everyone. Last year I successfully completed the construction of the Le Gros Ventre model according to Gerard Delacroix's monograph and I chose L'Amarante as the next model (also according to GD's monograph). I started the construction of the POF at the end of last year and will gradually publish photos from the construction process here. First, I made a jig for installing the individual frames on the keel and started assembling the keel.

-

Thank you guys for nice comments. To dvm27: some pictures from exhibitions you can find here: https://wchs-c-2023.eu/cz/zpravy/id:11385/mozaika-z-vystavy https://shipsofscale.com/sosforums/threads/naviga-c-from-czech-republic.12620/

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

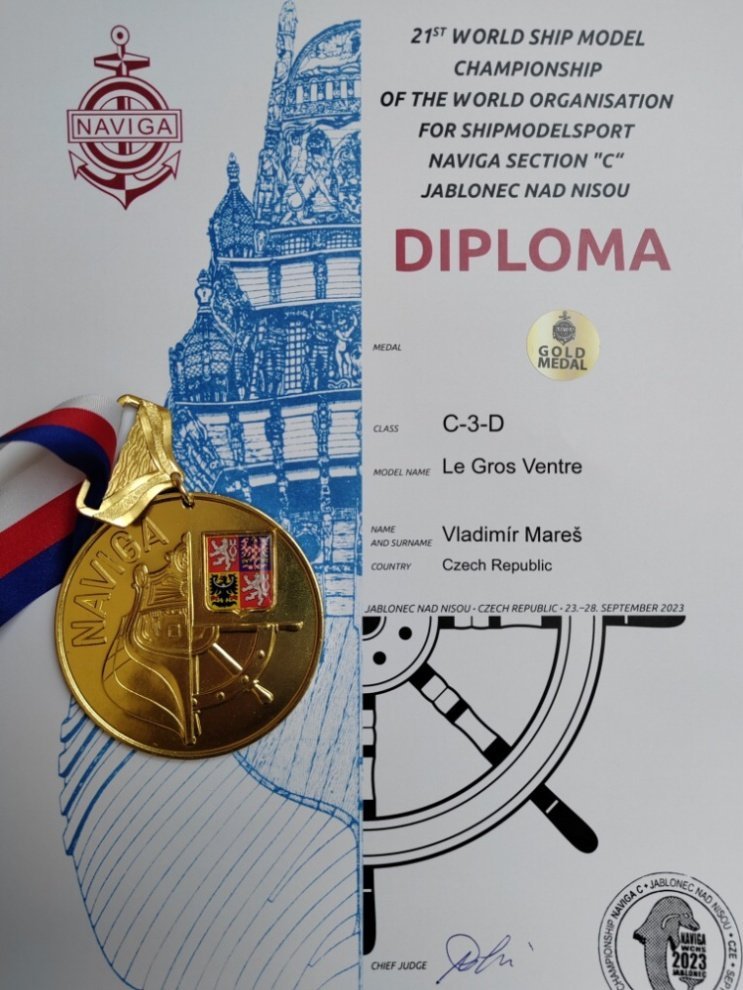

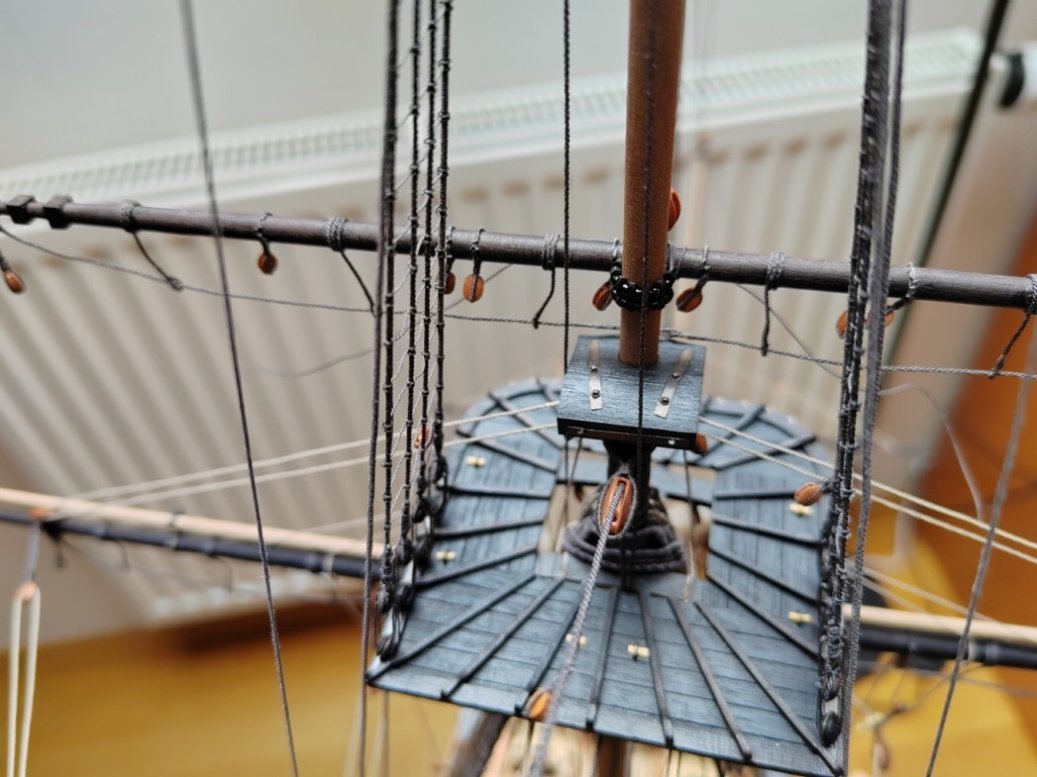

Once again, thanks to everyone for the positive responses. The last two photos remain to be posted. This week I participated in the Class C World Championship (NAVIGA organization) where I received a gold medal for the Le Gros Venter model. I would like to take this opportunity to thank Mr. Gerard Delacrox for his technical support during the construction. My next model will again be according to Mr. Delacroix's plans - L'Amarante. marsalv

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

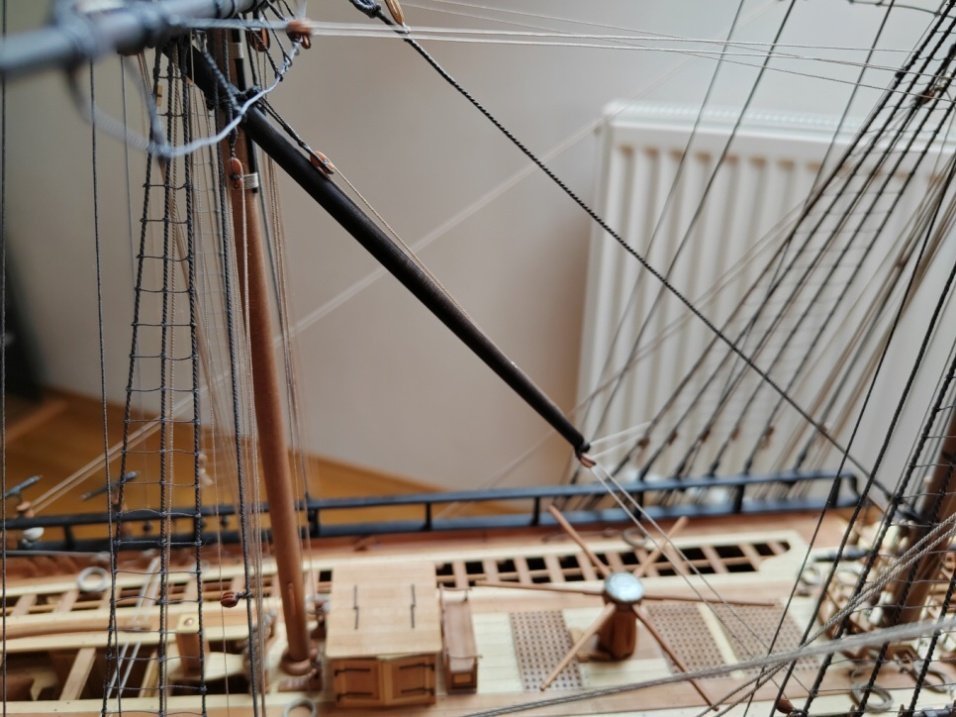

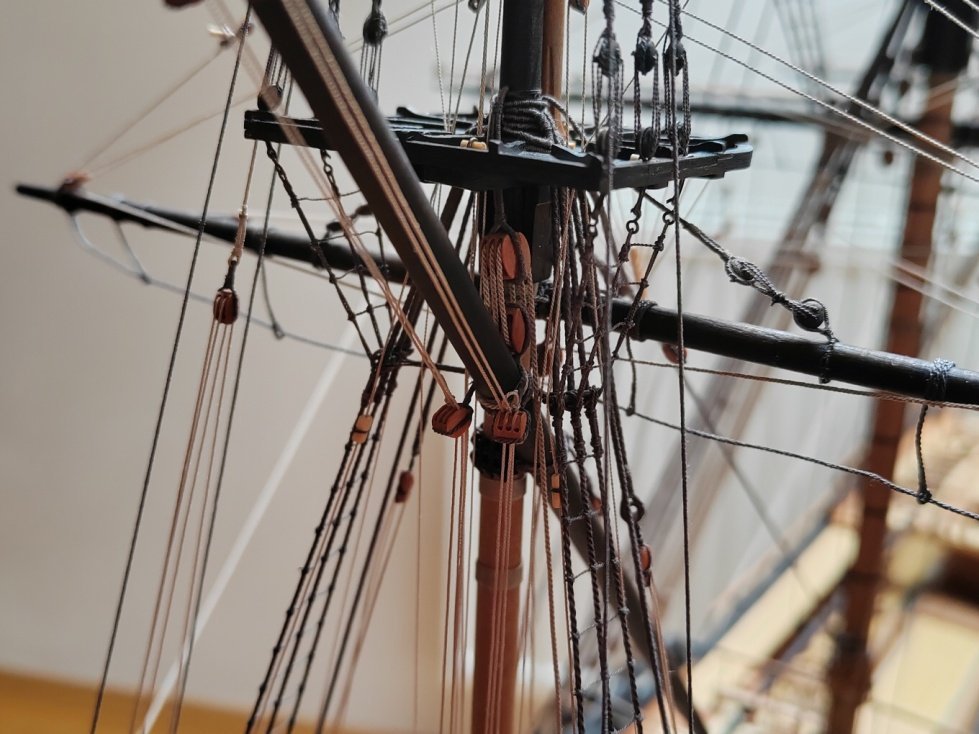

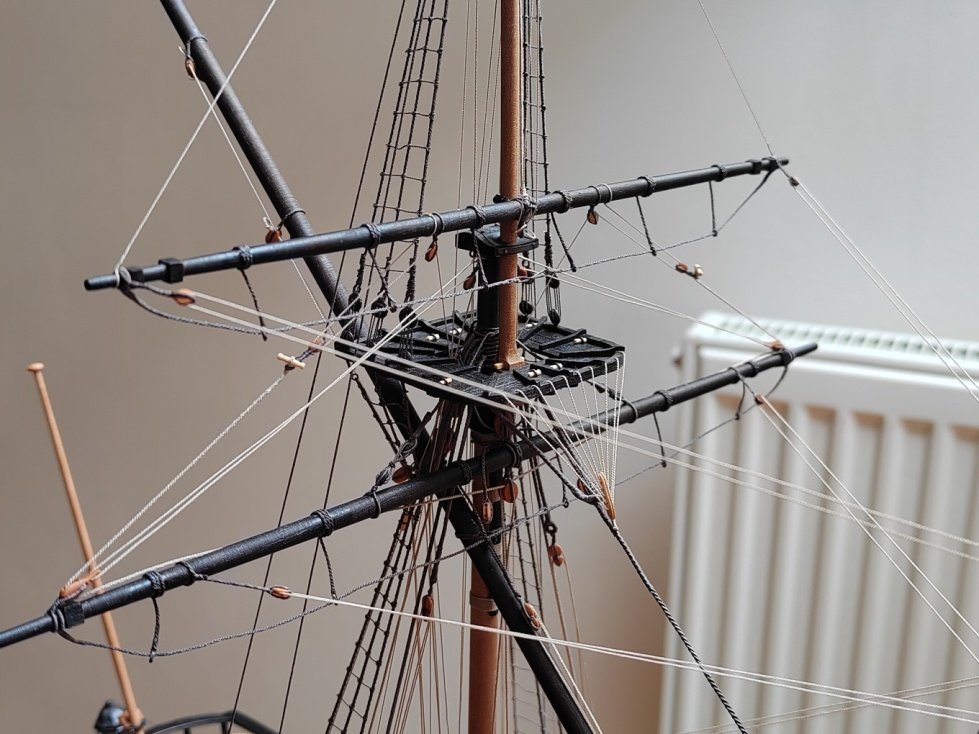

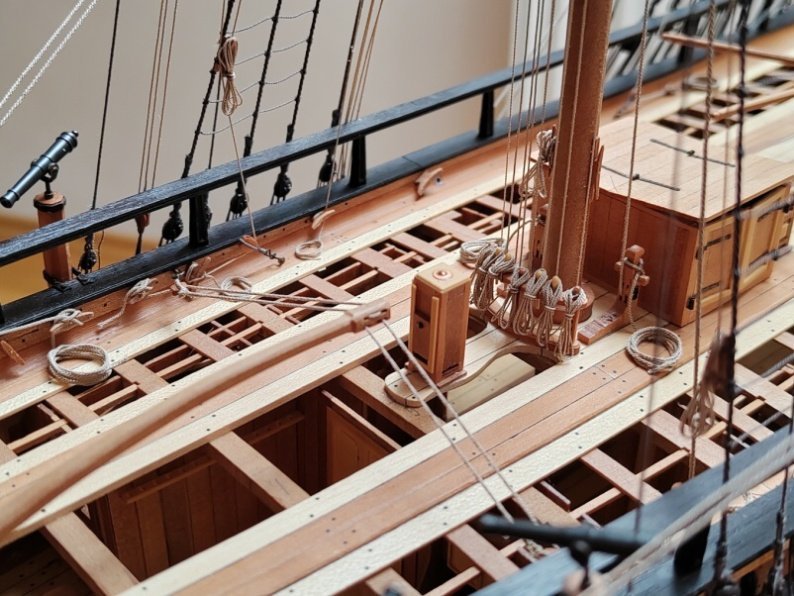

The construction came to an end after approx. 4600 hours. All that remains is to post a few last photos and thank all the followers for watching and commenting on the progress of the model construction. Thank you.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

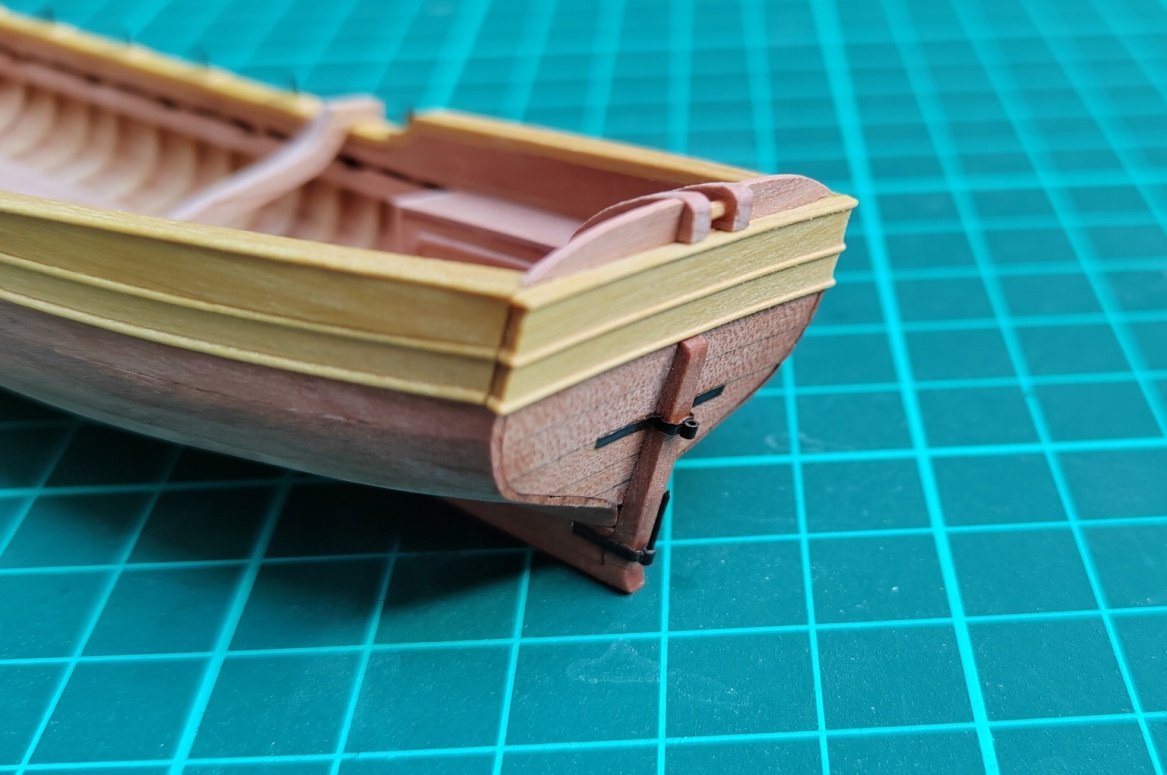

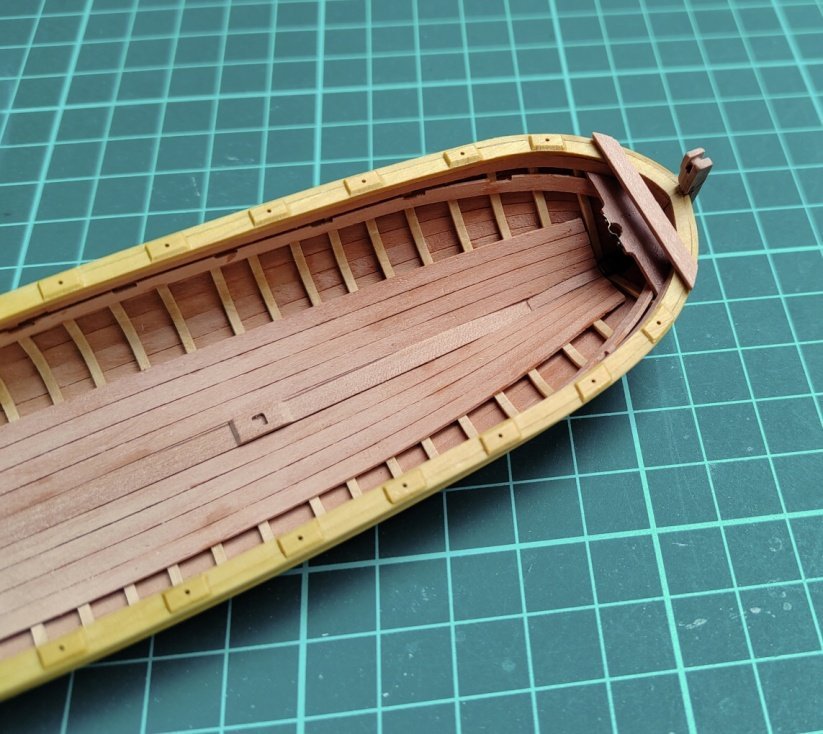

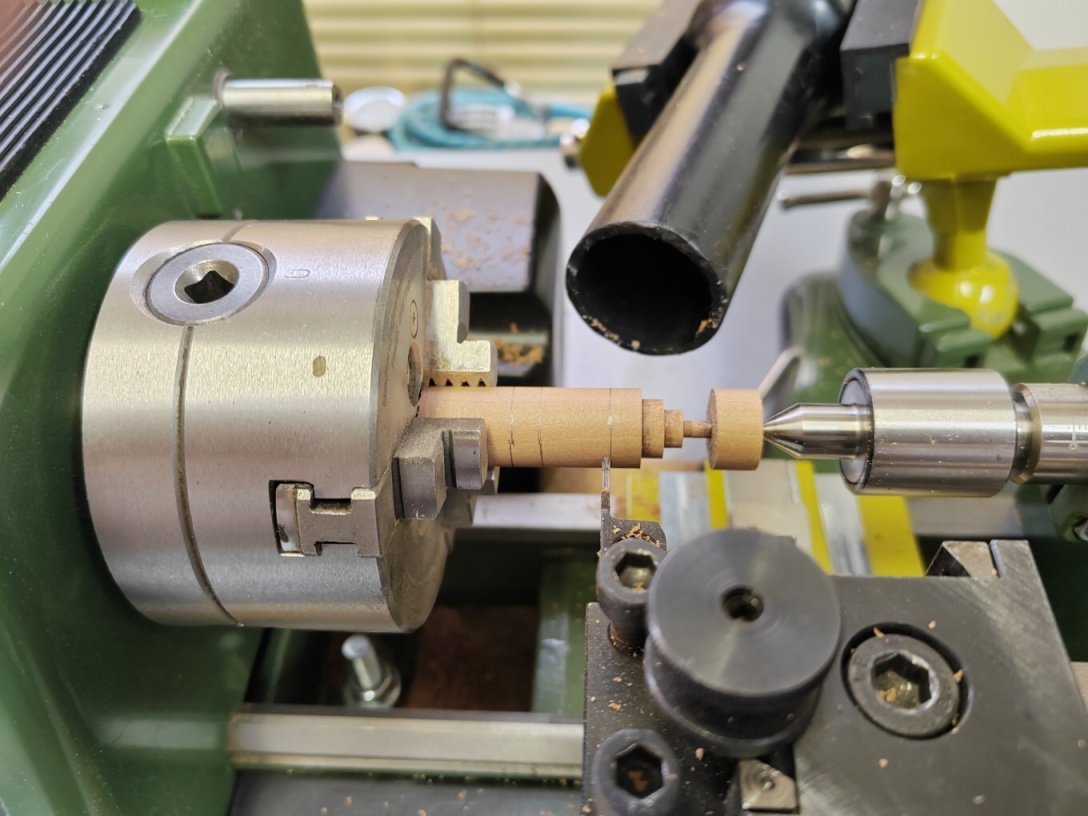

To botra288: the adjustable tabel is "homemade", but you can buy something similar here: https://www.renishaw.com/shop/Product.aspx?Product=R-PCA-135075-12-6 Finishing work continues on the larger boat.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

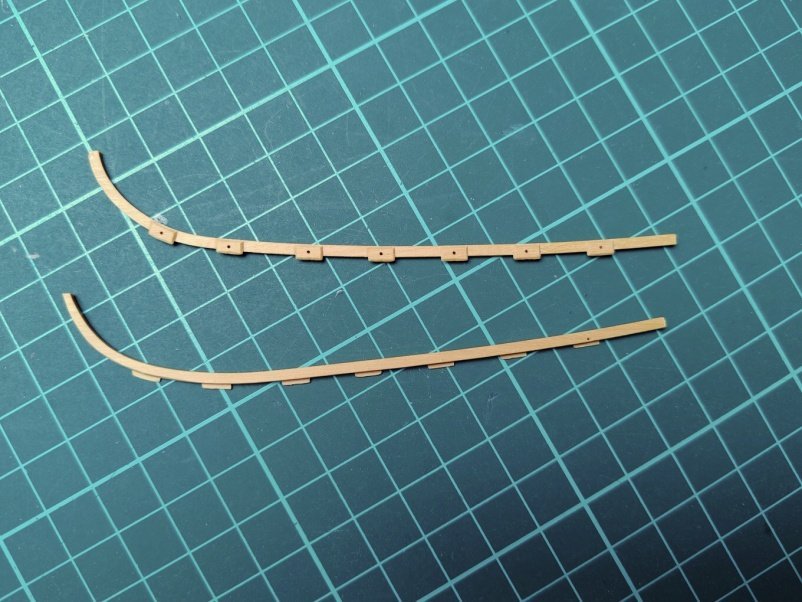

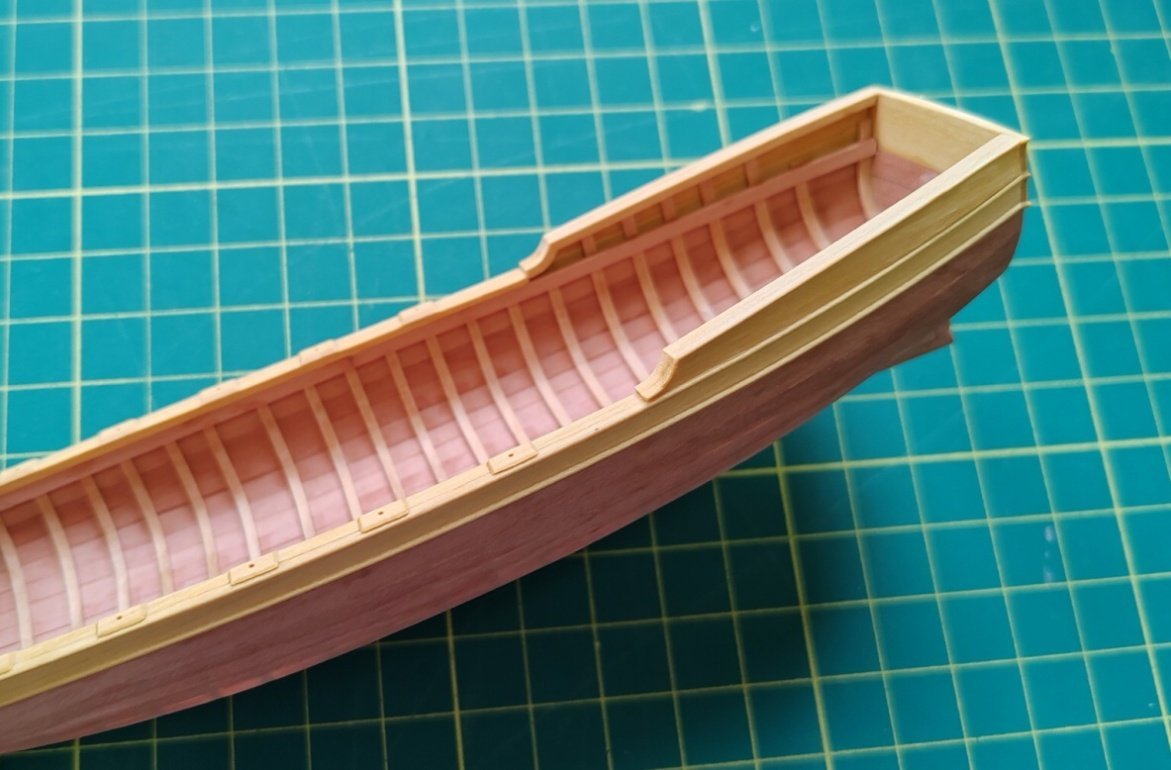

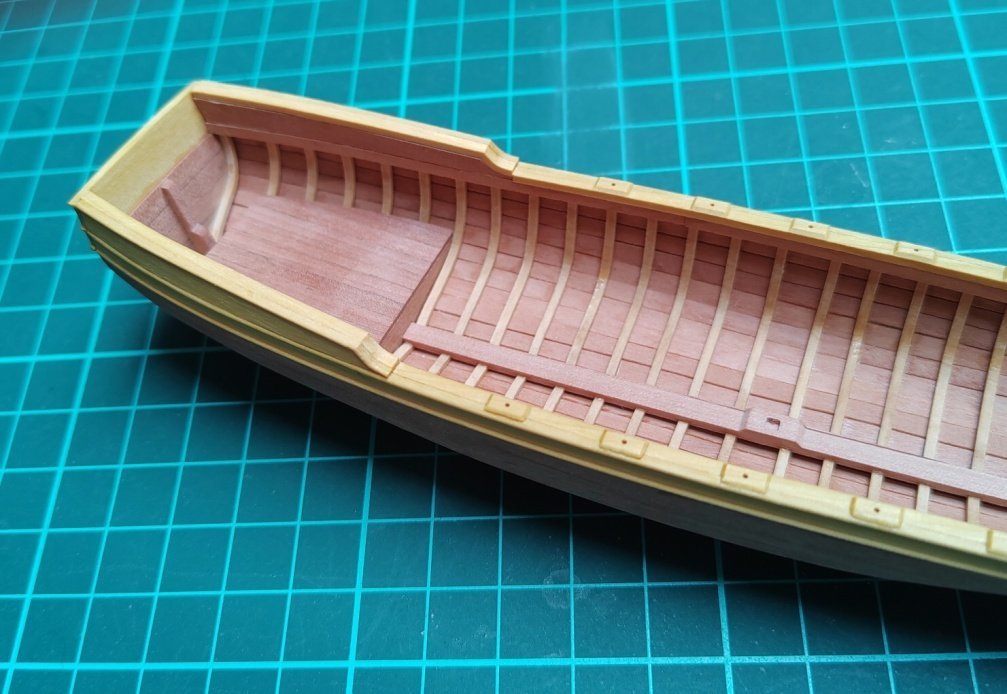

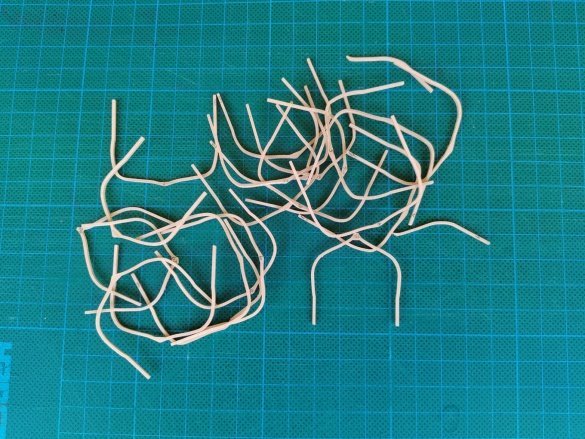

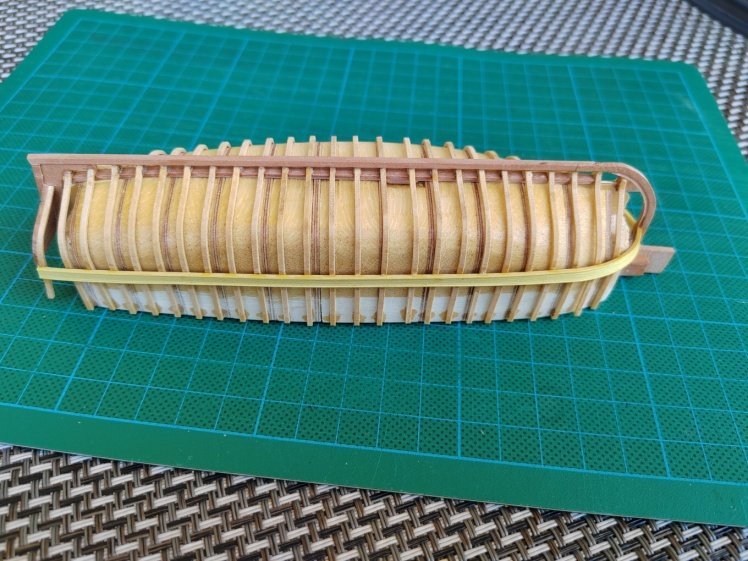

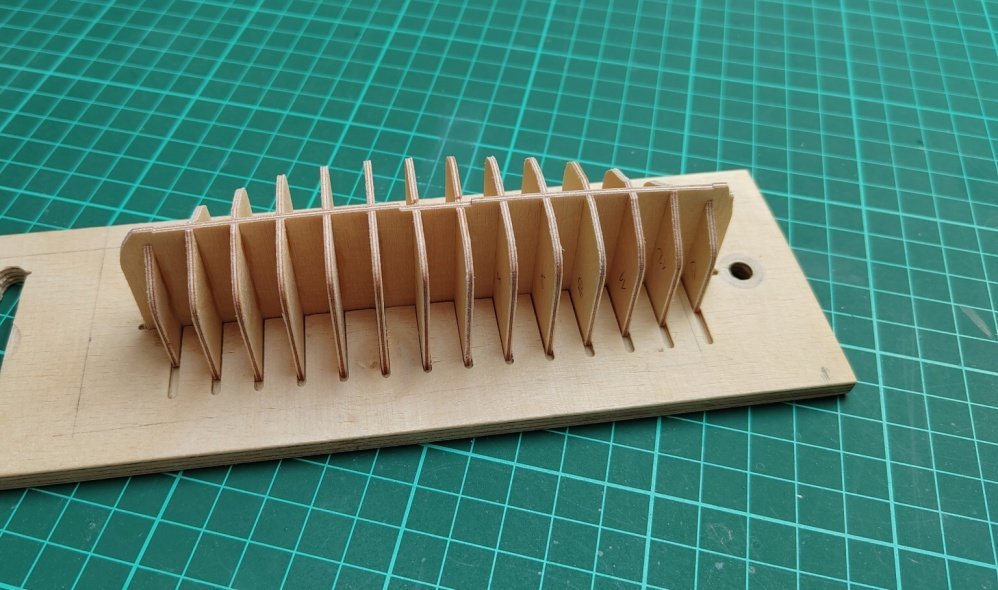

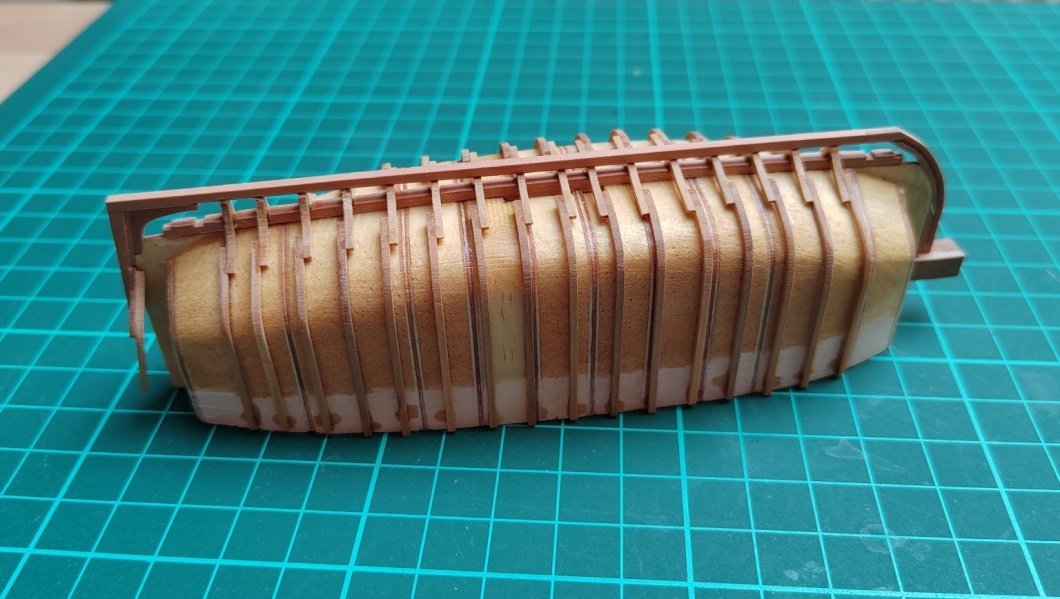

Thank you guys for compliments. To mtbediz - This is a normal slotting cutter, with only a reduced diameter of the shank to be used in the Proxxon milling machine. (https://www.uni-max.cz/produkty/drevoobrabeni/stopkove-nastroje/drazkovaci-frezy/dvoubrite-kratke/drazkovaci-freza-2br-6-19-8-mm) I continue with the second - bigger boat. Here I decided to make the frames from one piece only, because in the end the connection of the individual parts of the frames will be hidden under the floor and will not be visible.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

HMS SUSSEX by KarenM - FINISHED - 1:48

marsalv replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

Unbelievably beautiful work. Bravo. -

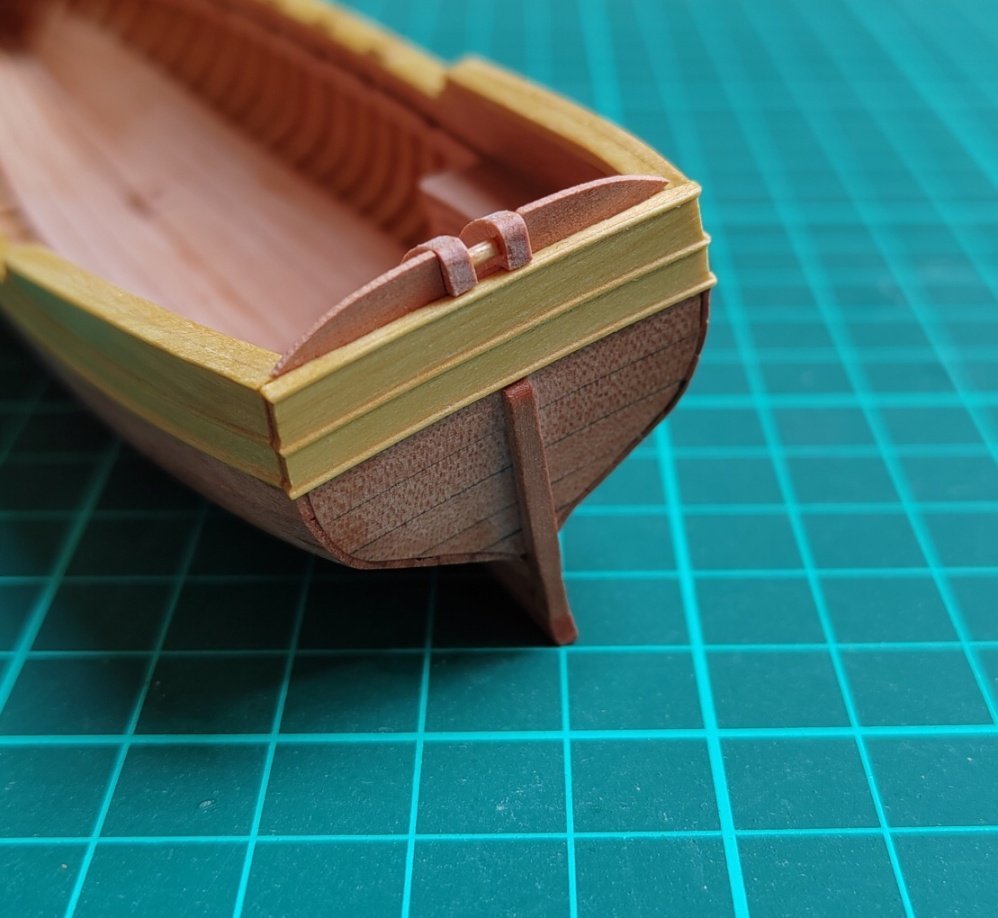

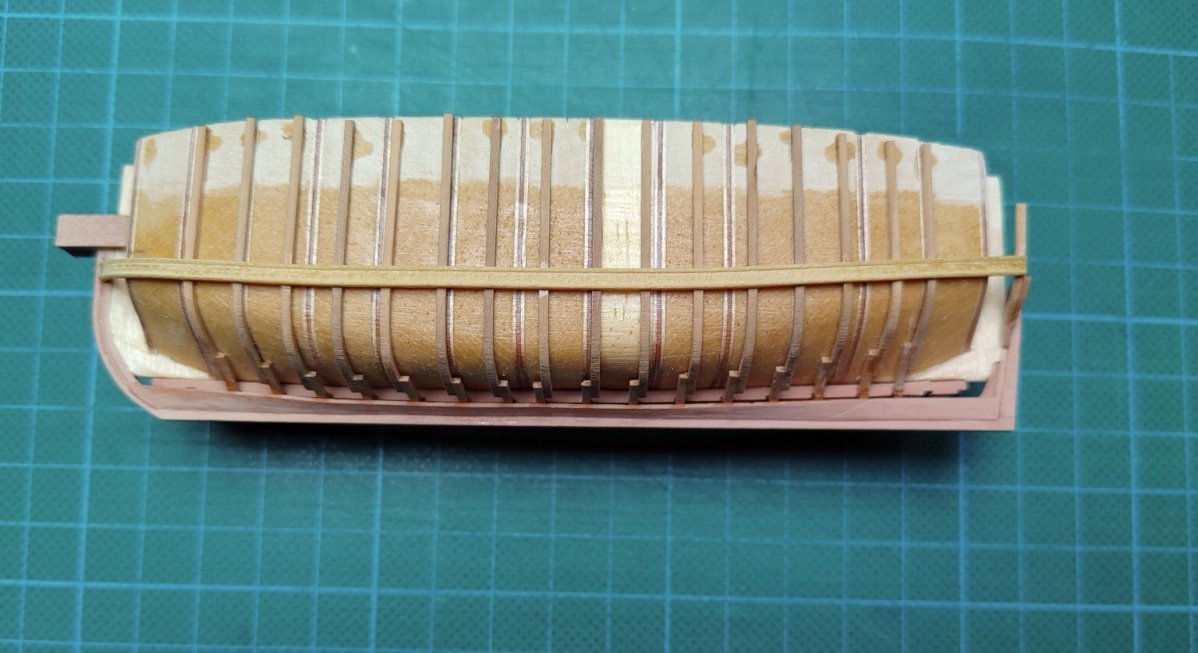

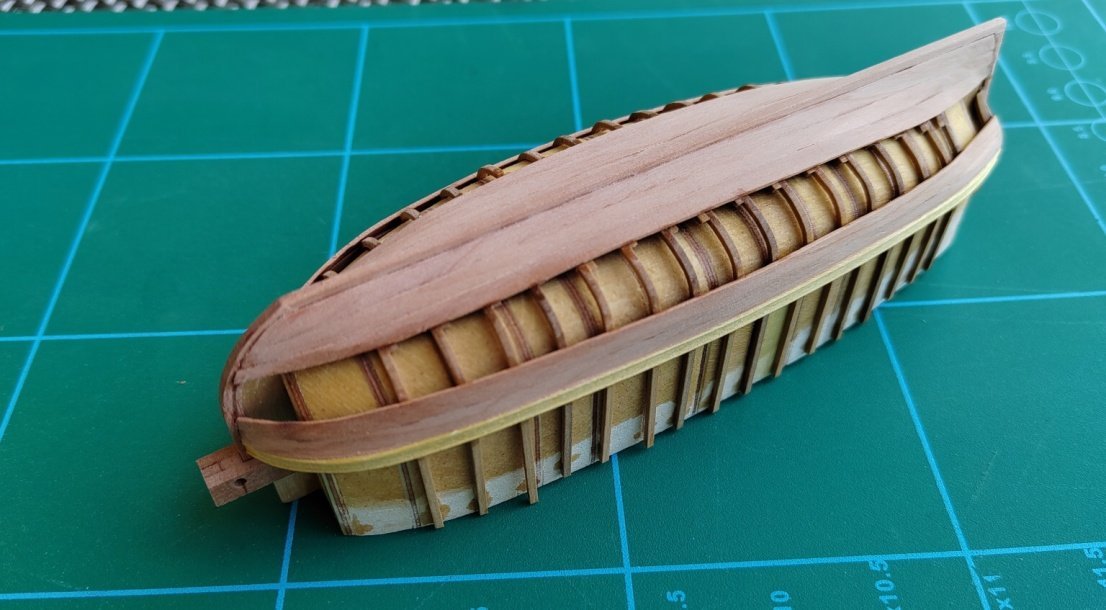

You're right, druxey. But after gluing a few planks on the ribs, the whole structure is strengthened and there are no problems with it. I finished the outer planking of the small boat. Now I will start on the frame of the larger boat.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

To Kevin-the-lubber - The materials in the monograph are well prepared and provide all the important information for building the model. However, if any information is missing or there is any ambiguity, Gerard Delacroix (the author of the monograph) will be very willing and quick to answer the relevant questions. So the anchors are placed in their places, so to complete the model, all that remains is to make two boats.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

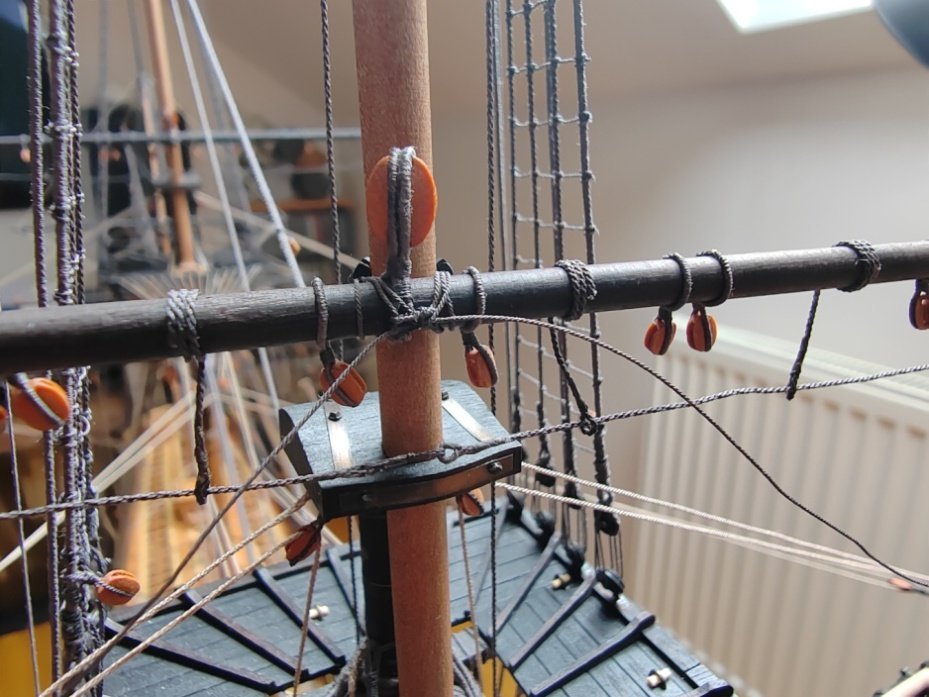

Thank you guys for nice comments and all likes. To Strelok - my next project will be L´Amarante according to plan G. Delacroix. To dvm27 - The only advantage of my age (really the only one) is that I am now retired and therefore have plenty of time to build the model. But this does not mean that it is a full-time job - it is usually 3-4 hours a day. Preparation of anchors for hanging - buoy, fish strops.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.