marsalv

NRG Member-

Posts

607 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by marsalv

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

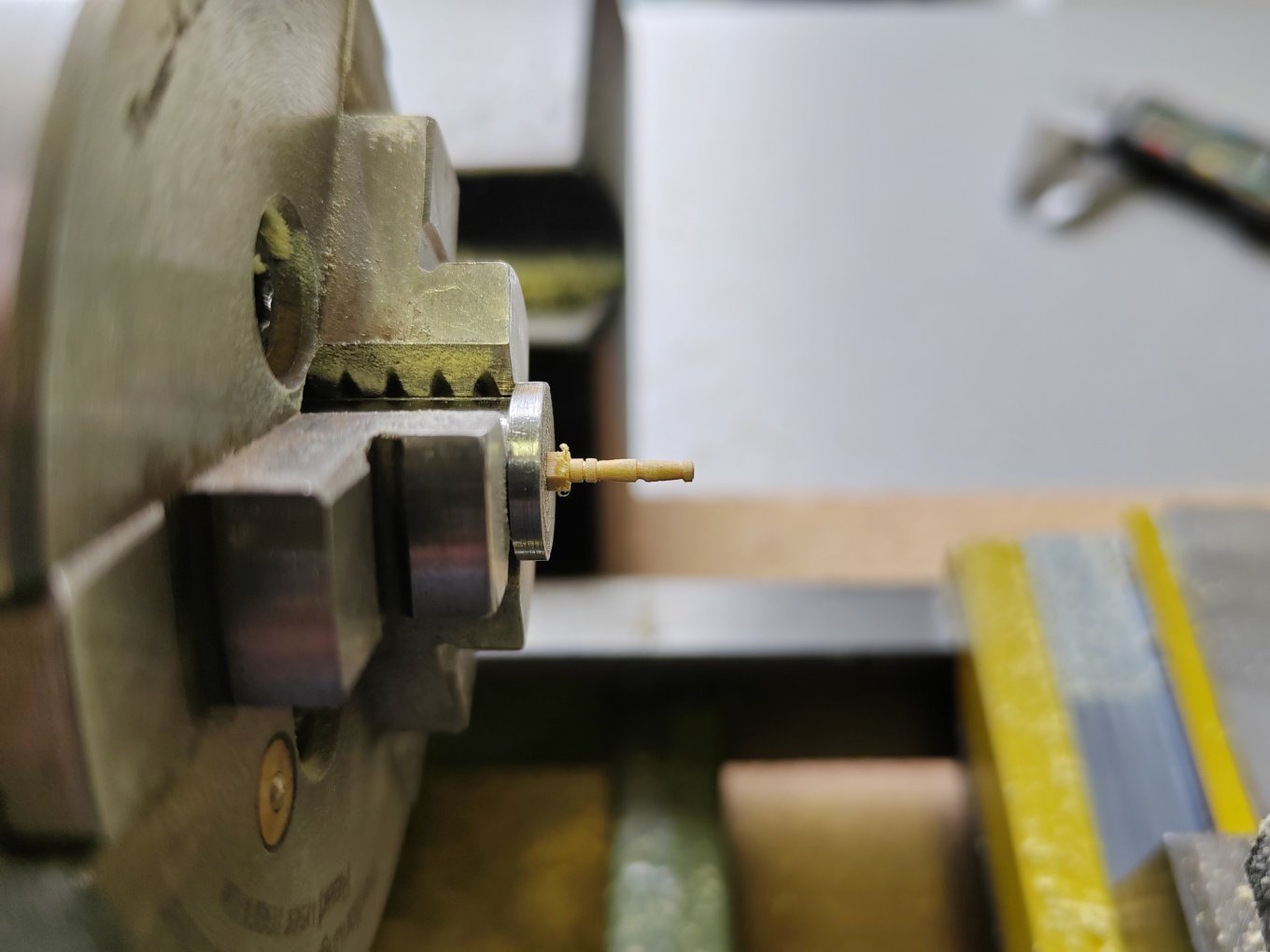

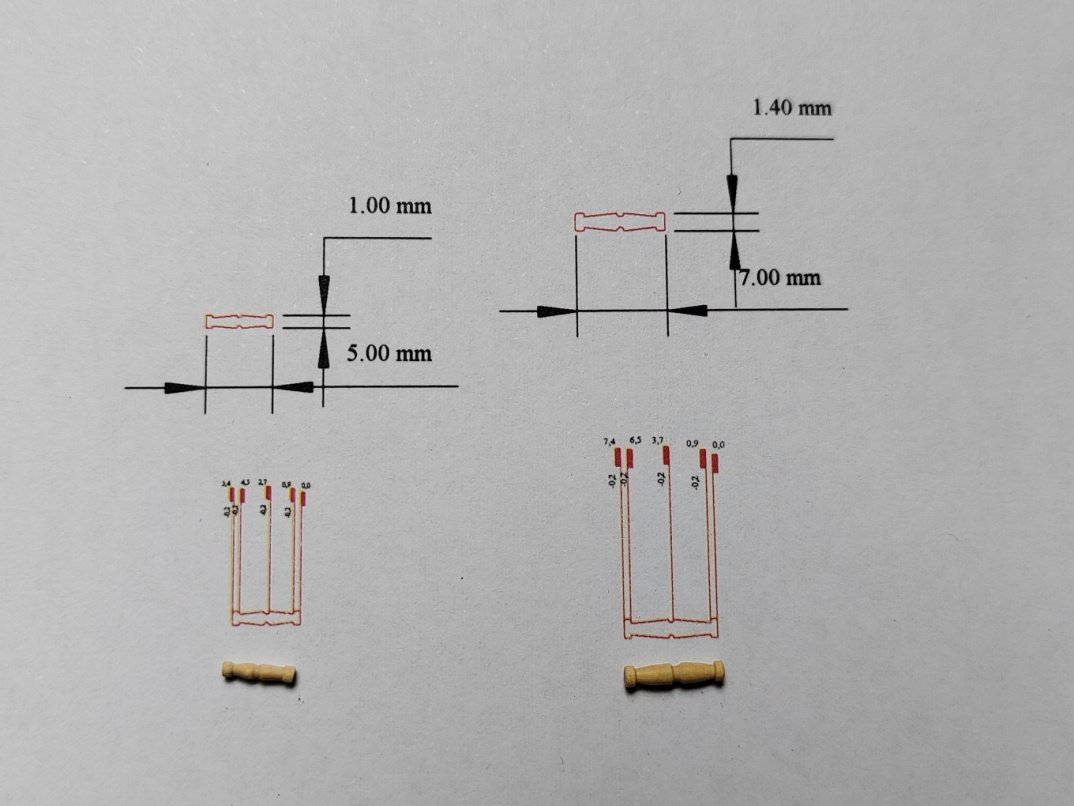

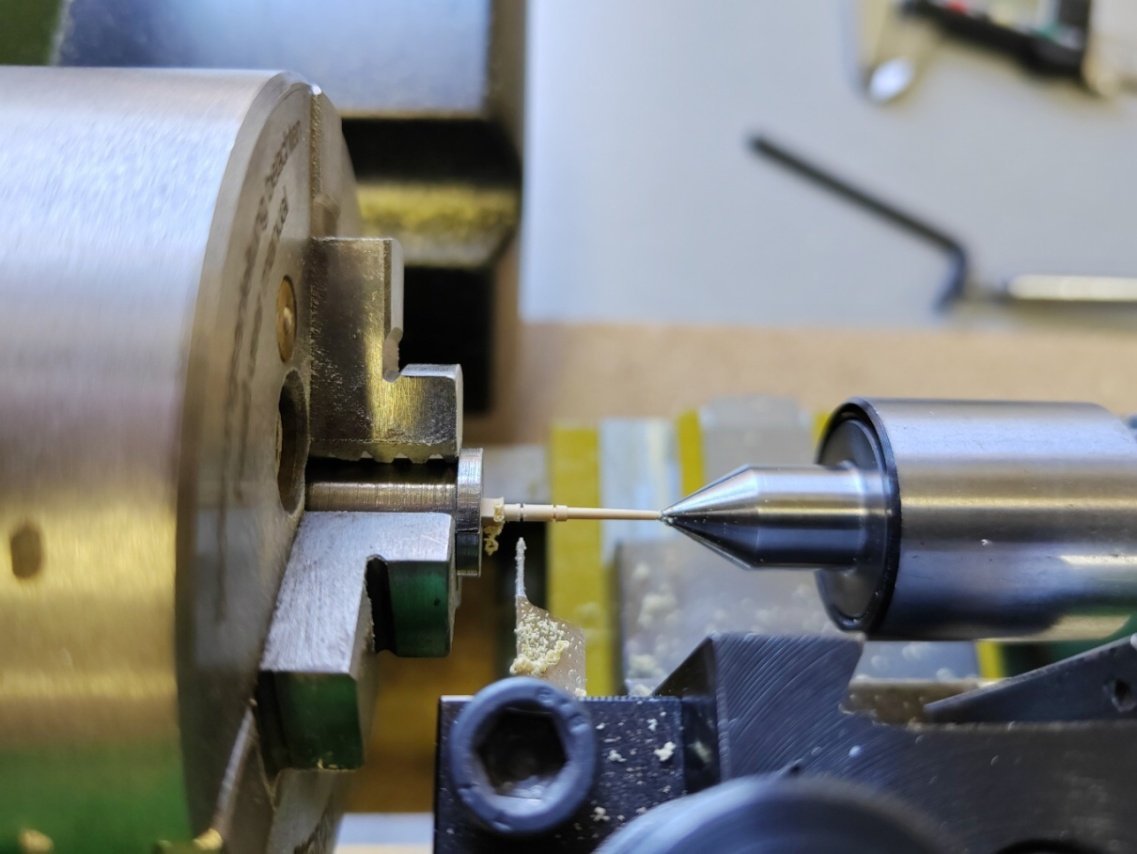

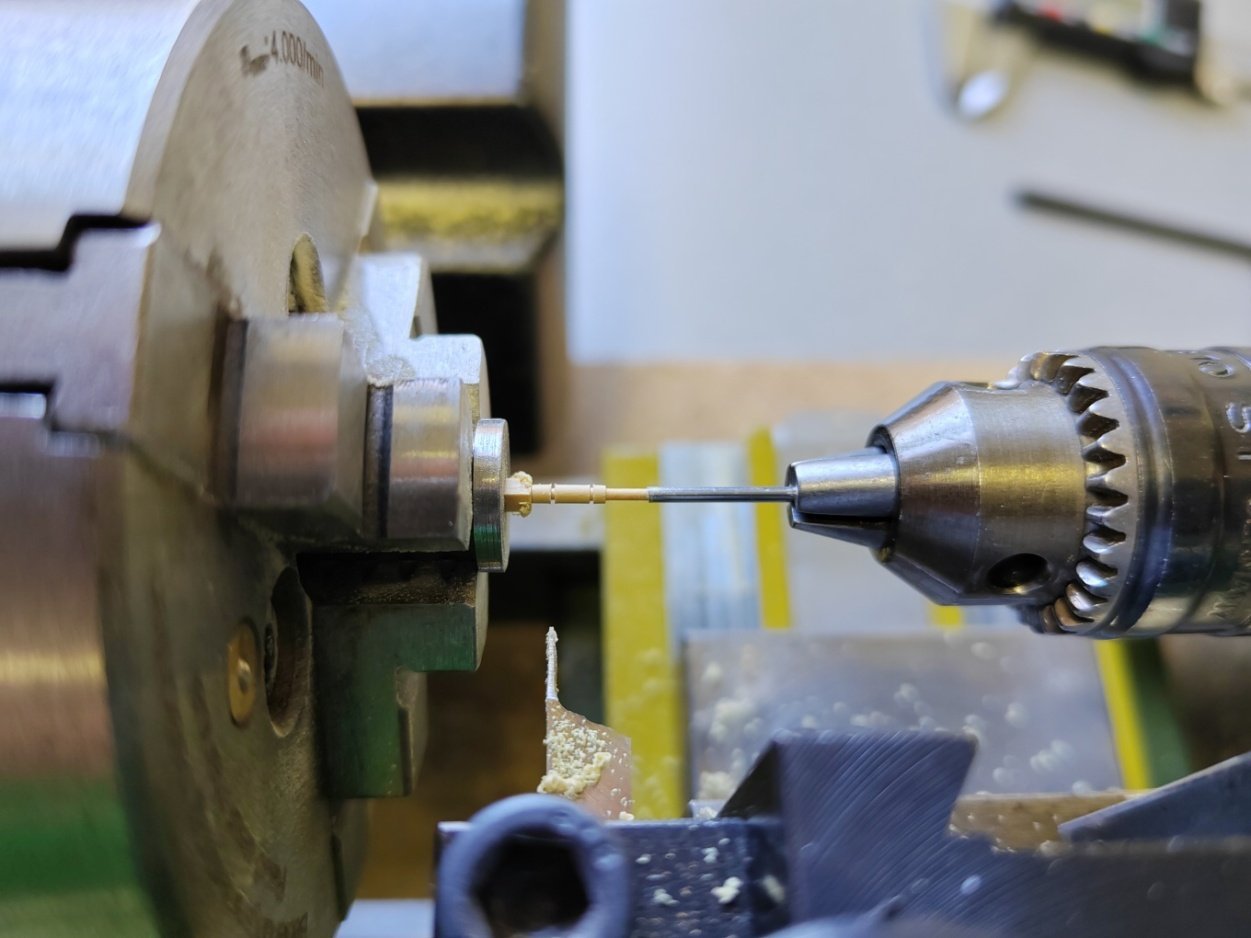

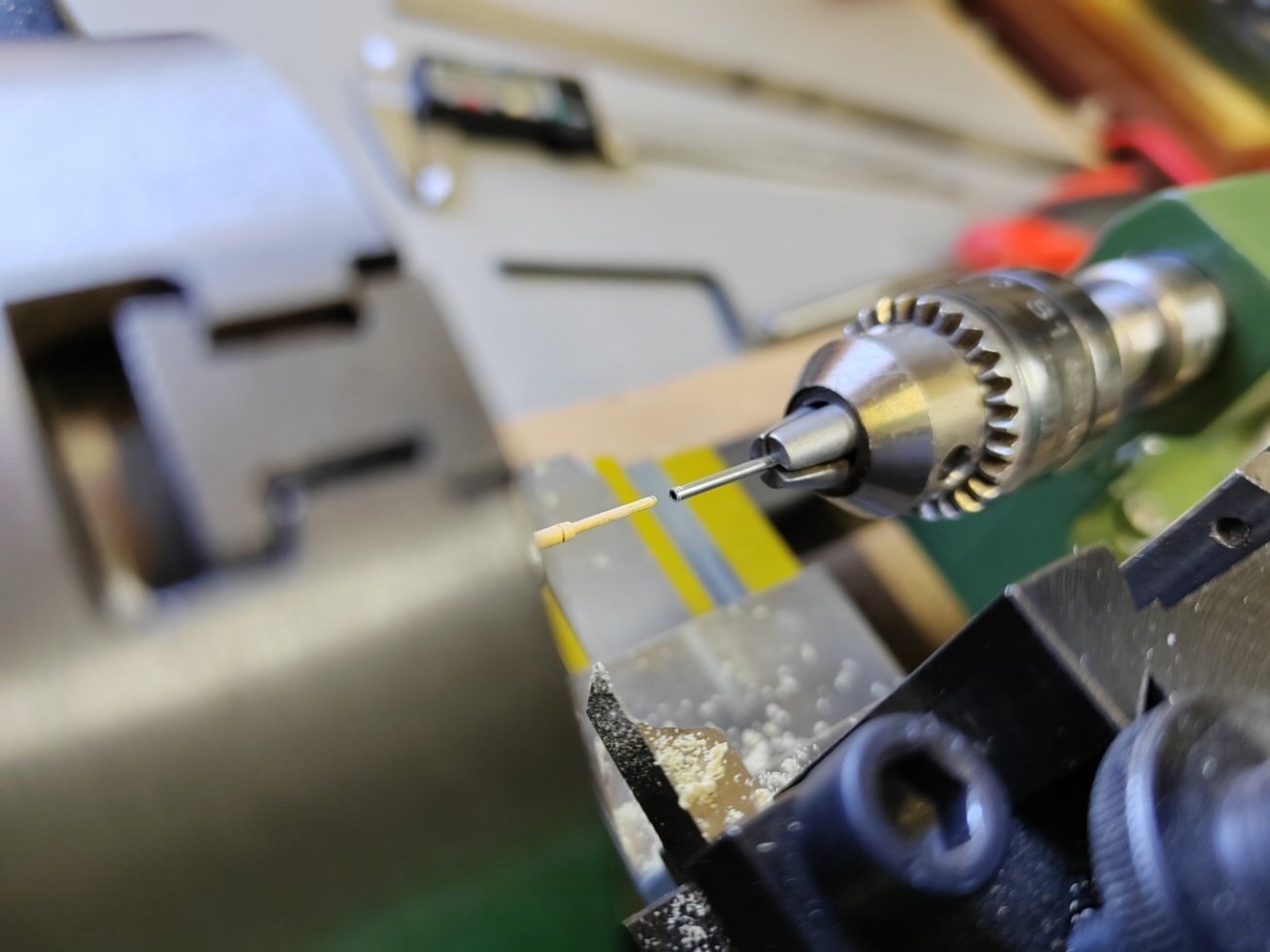

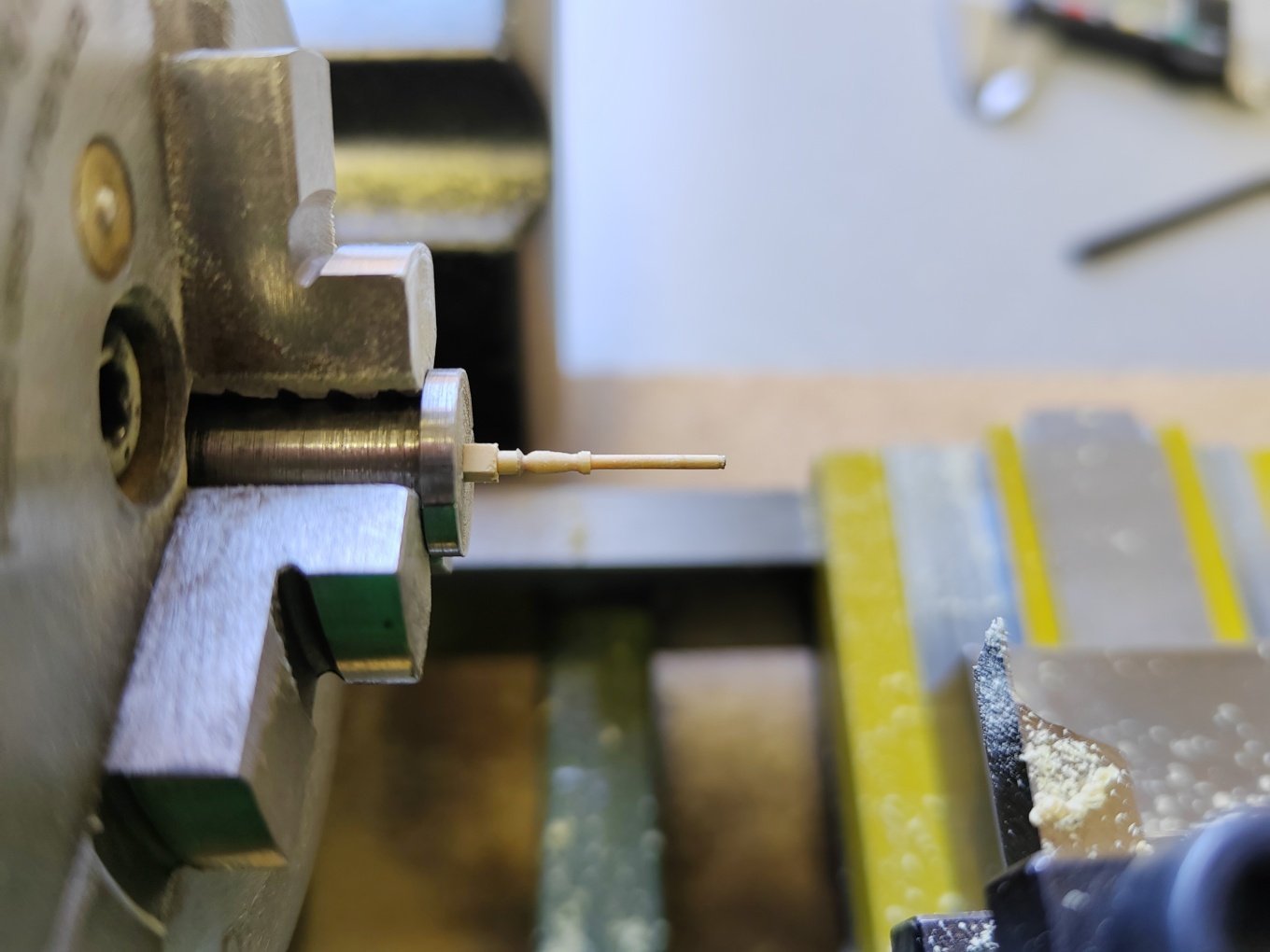

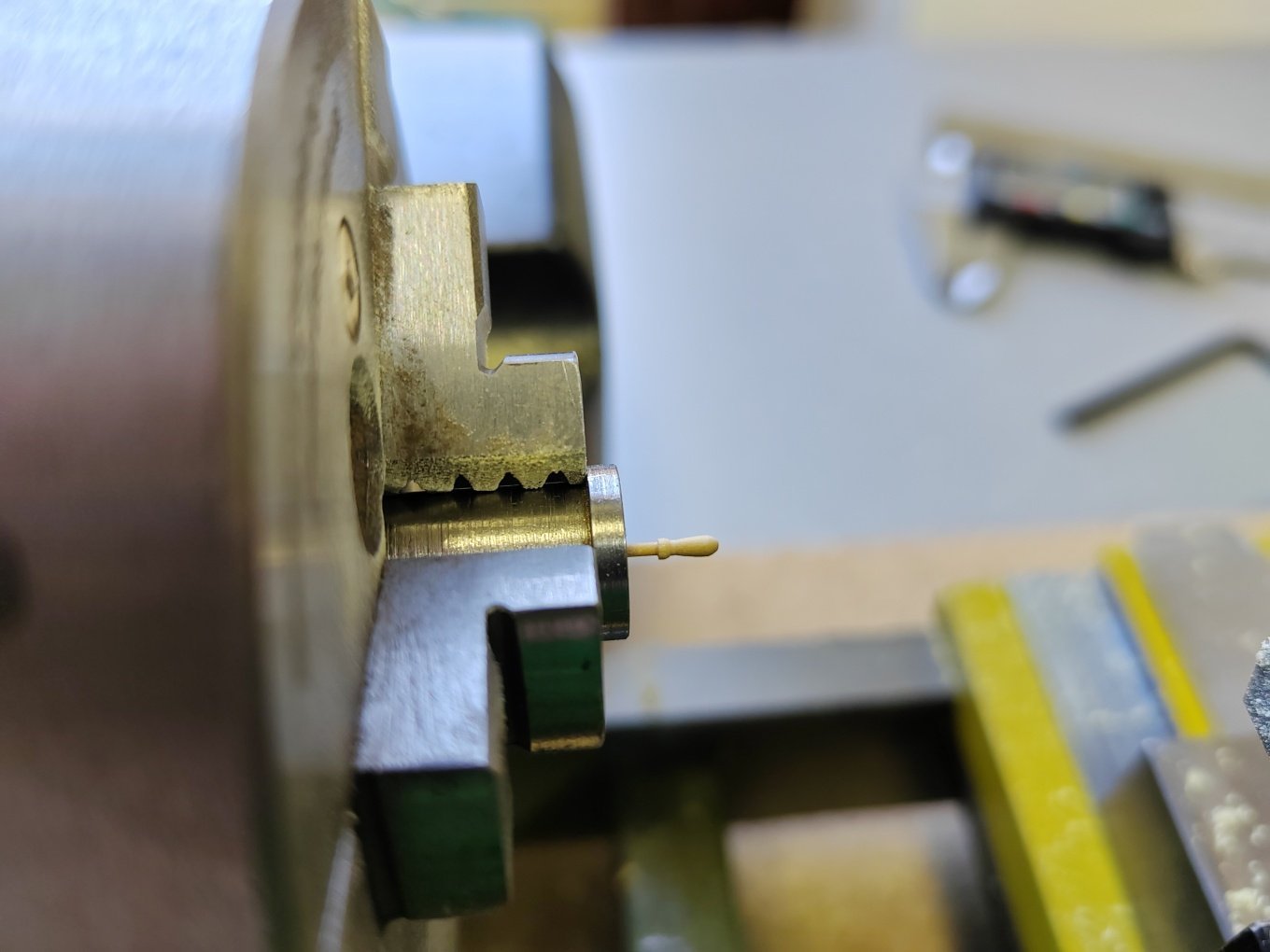

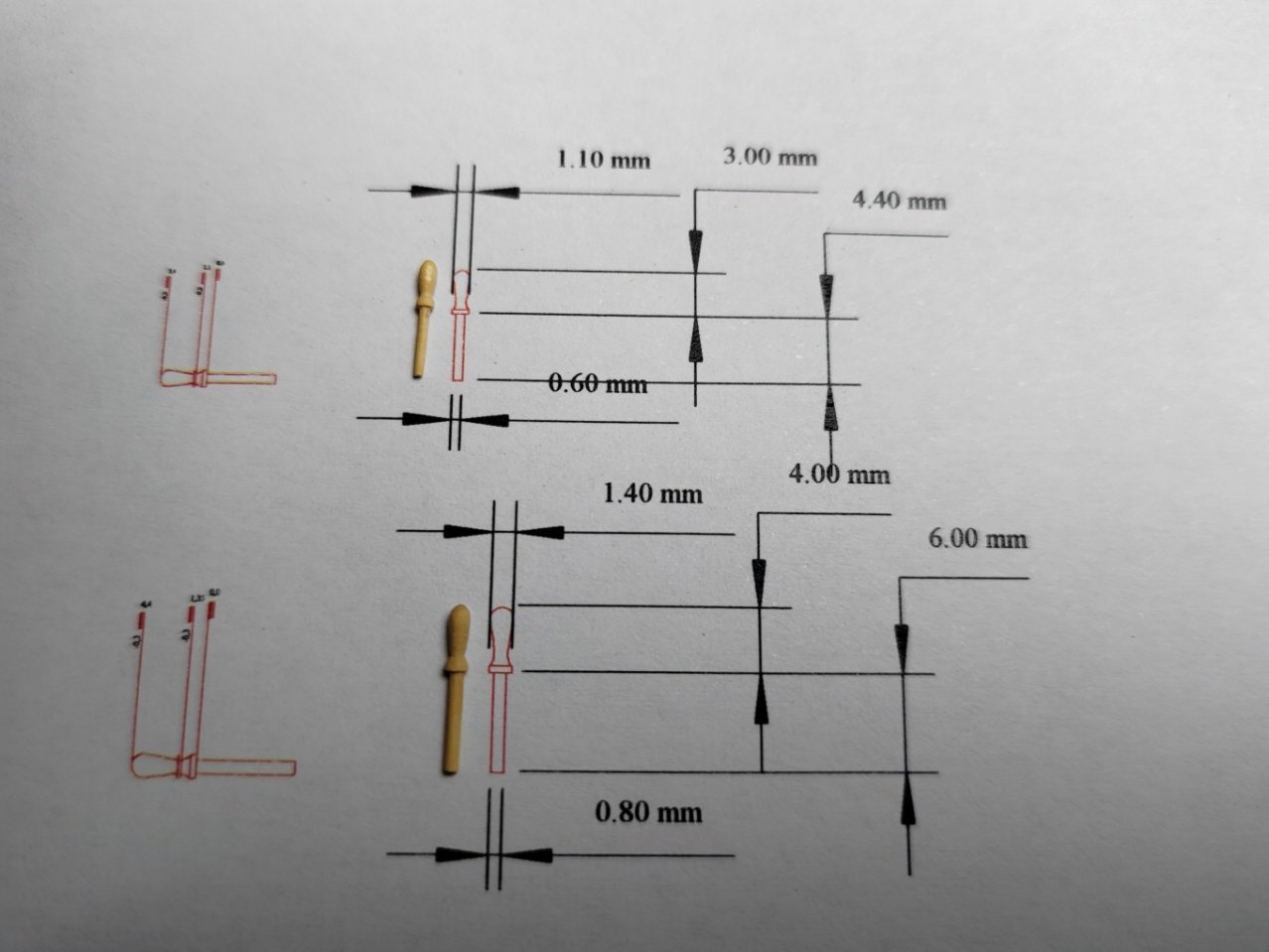

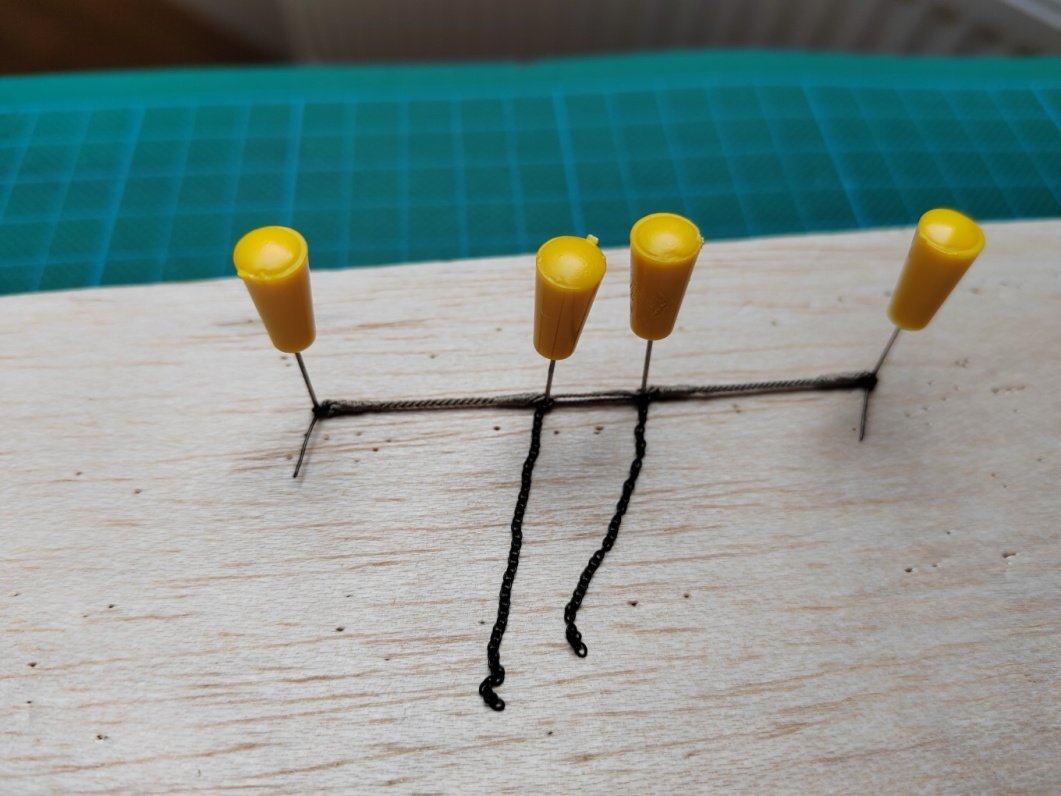

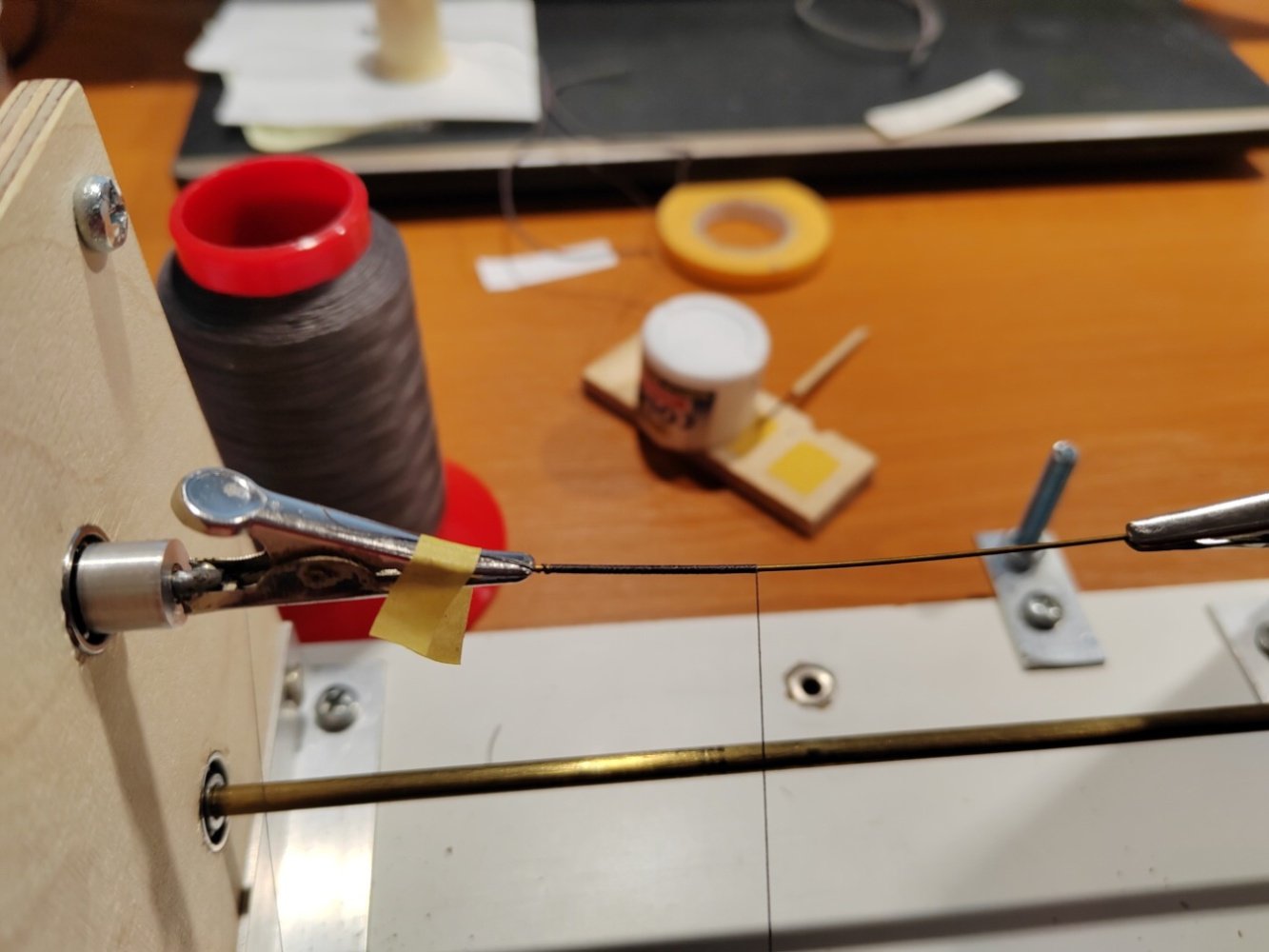

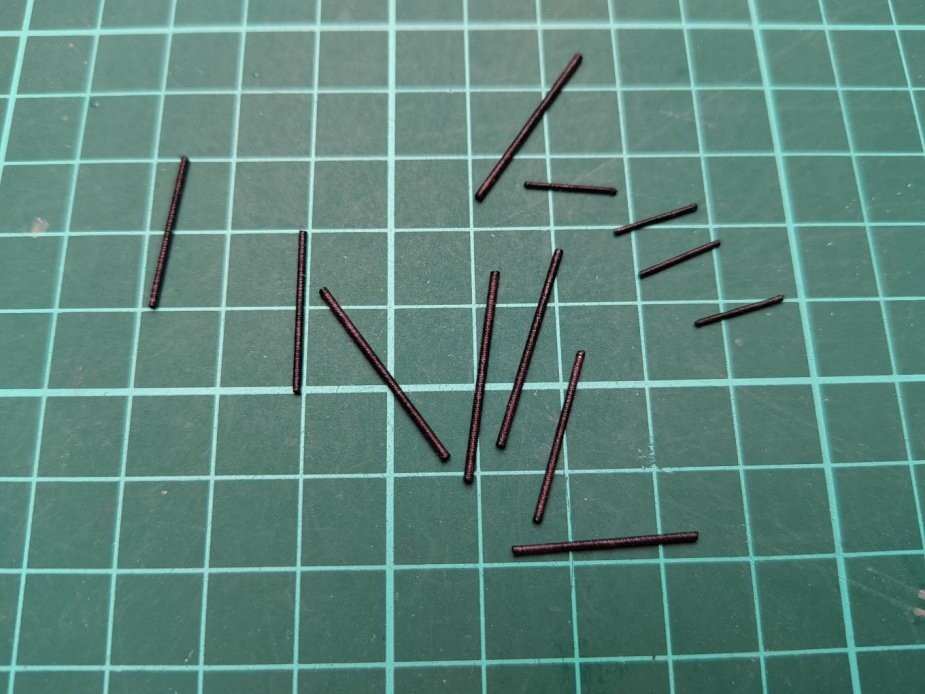

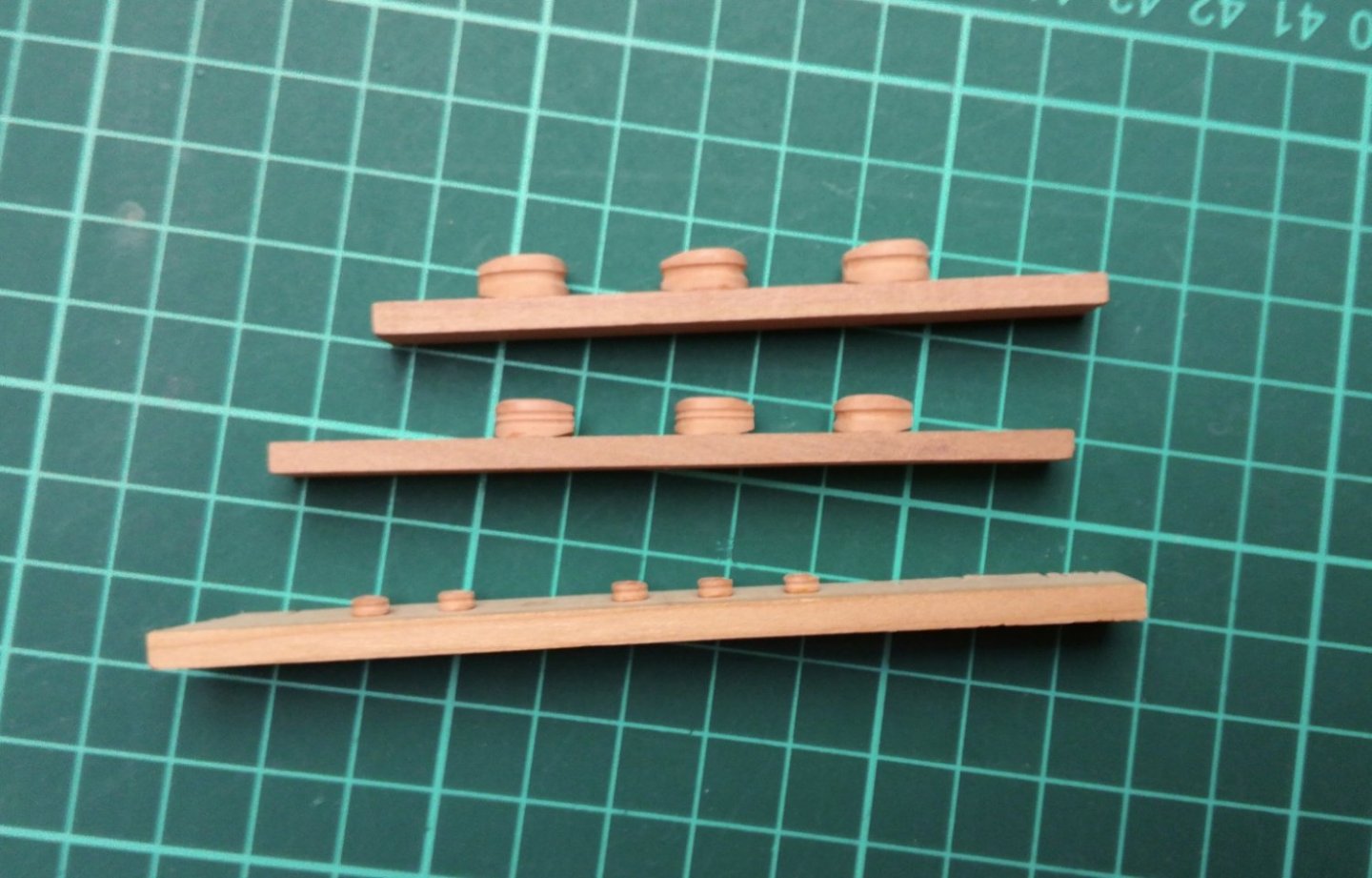

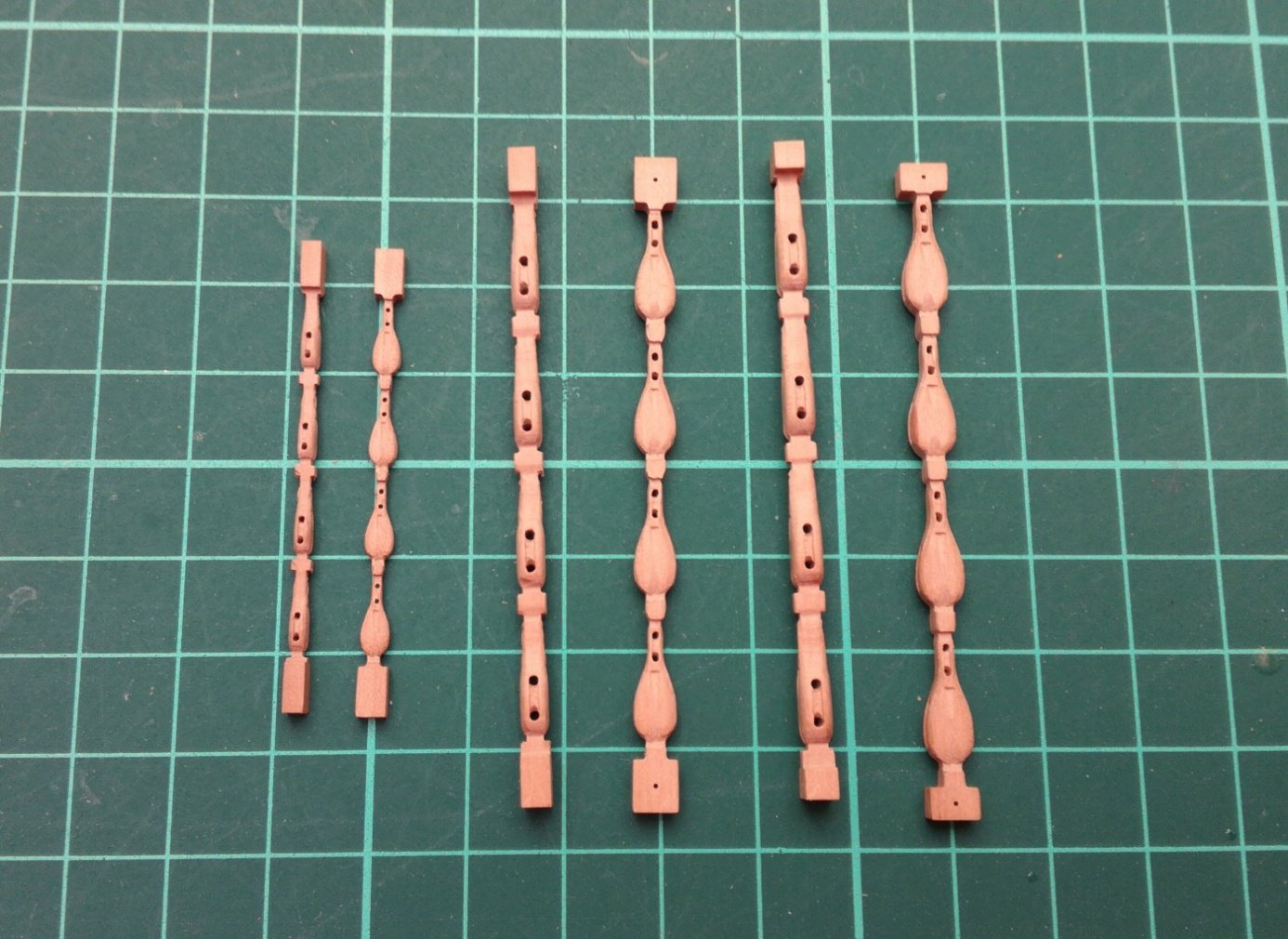

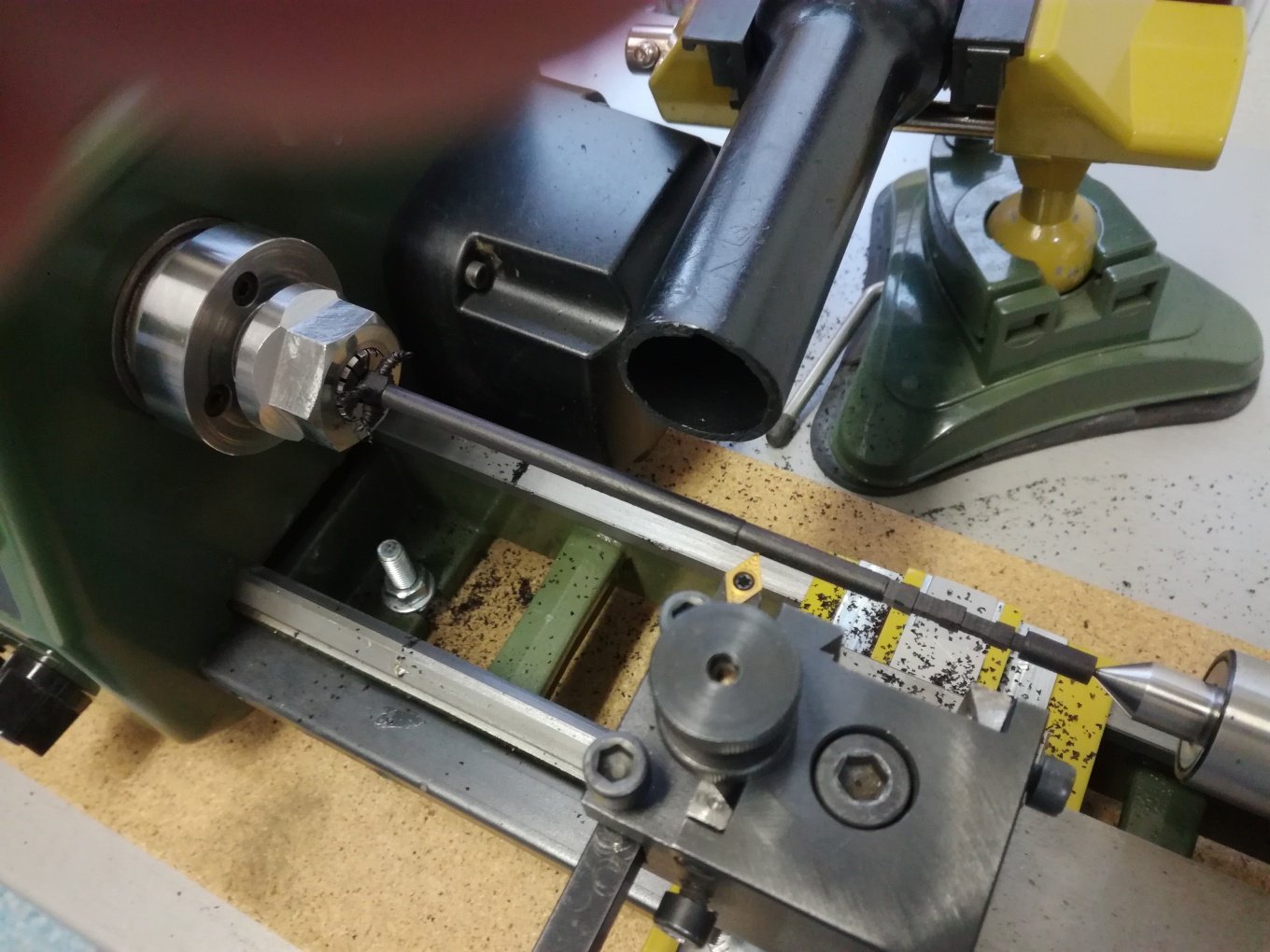

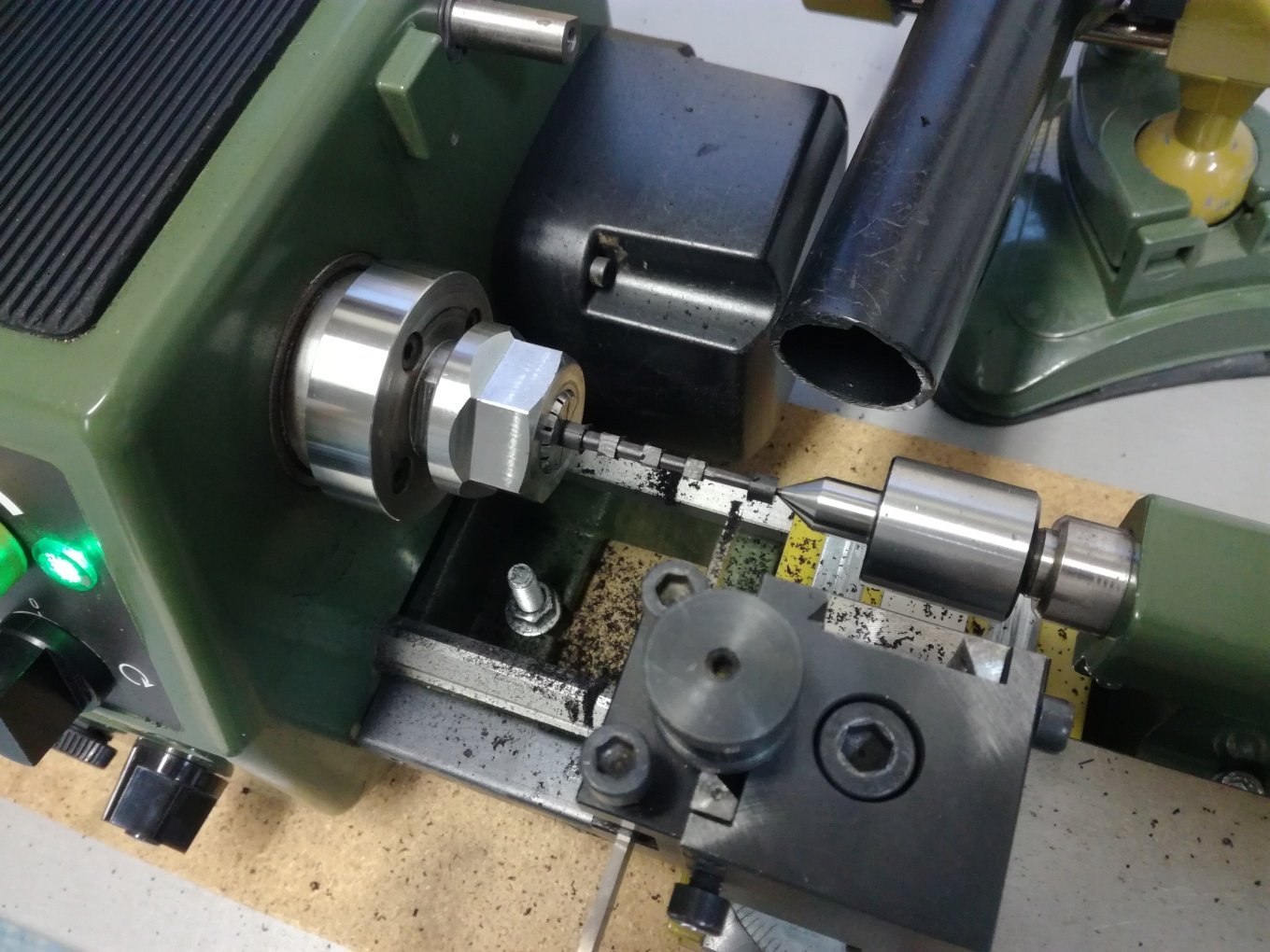

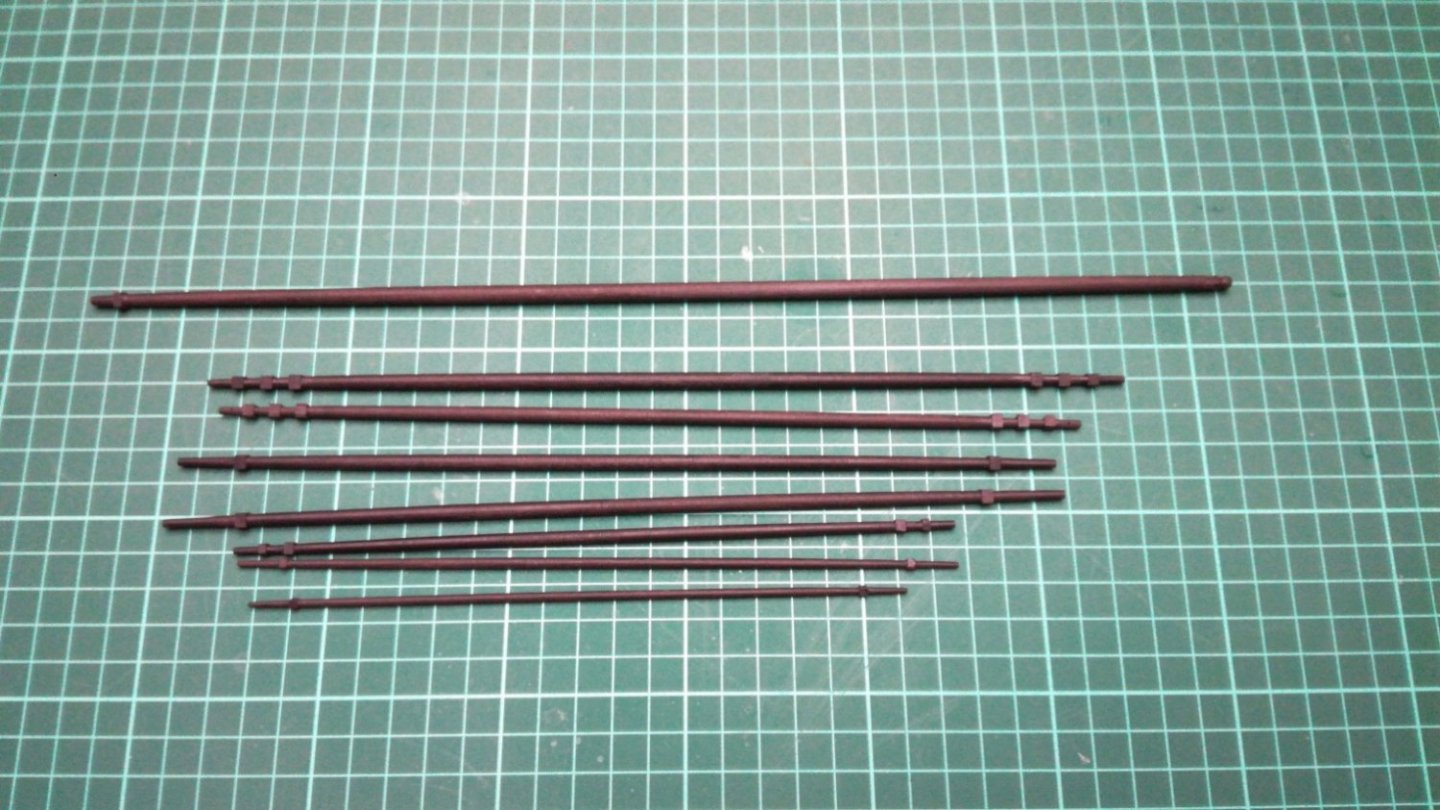

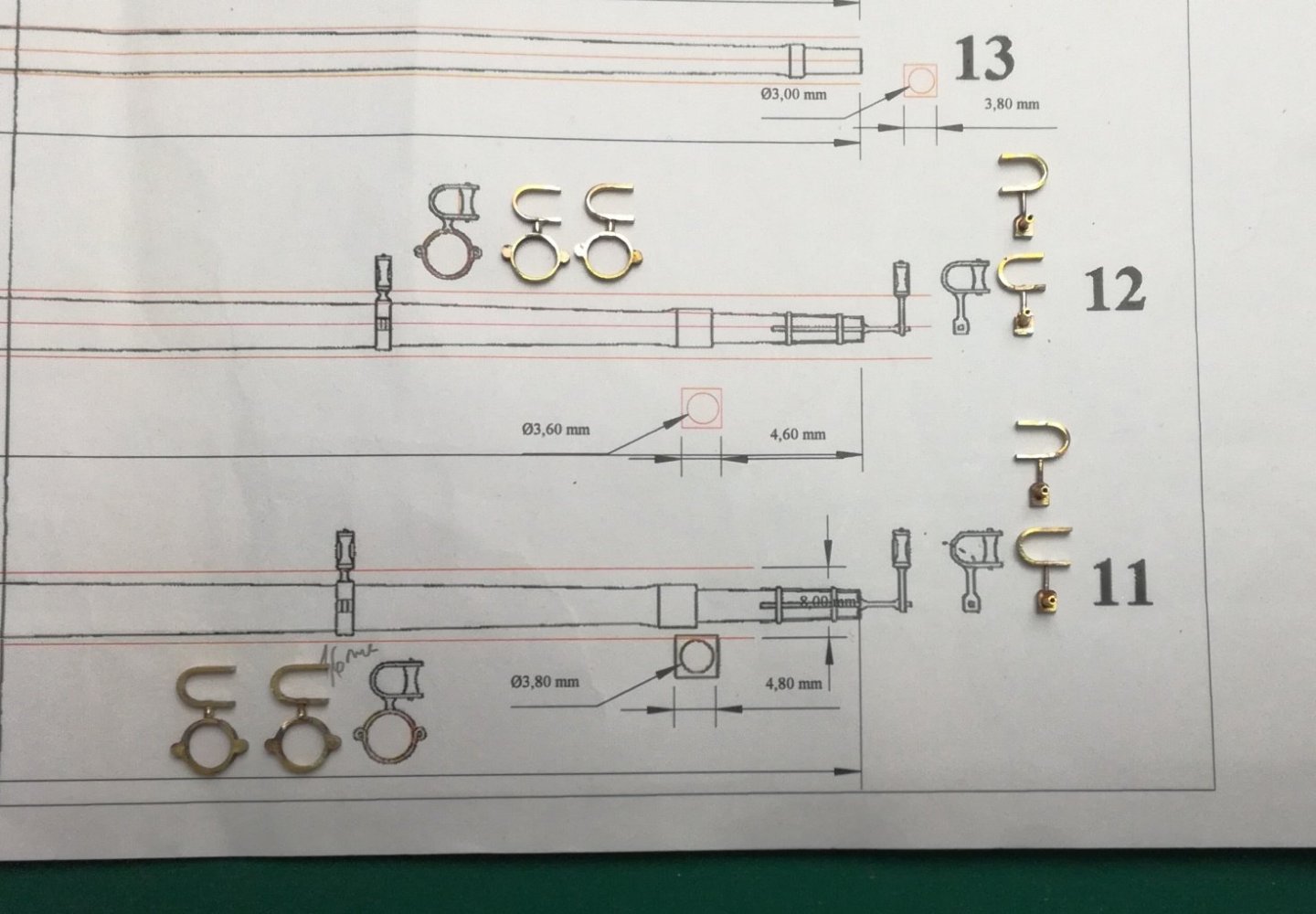

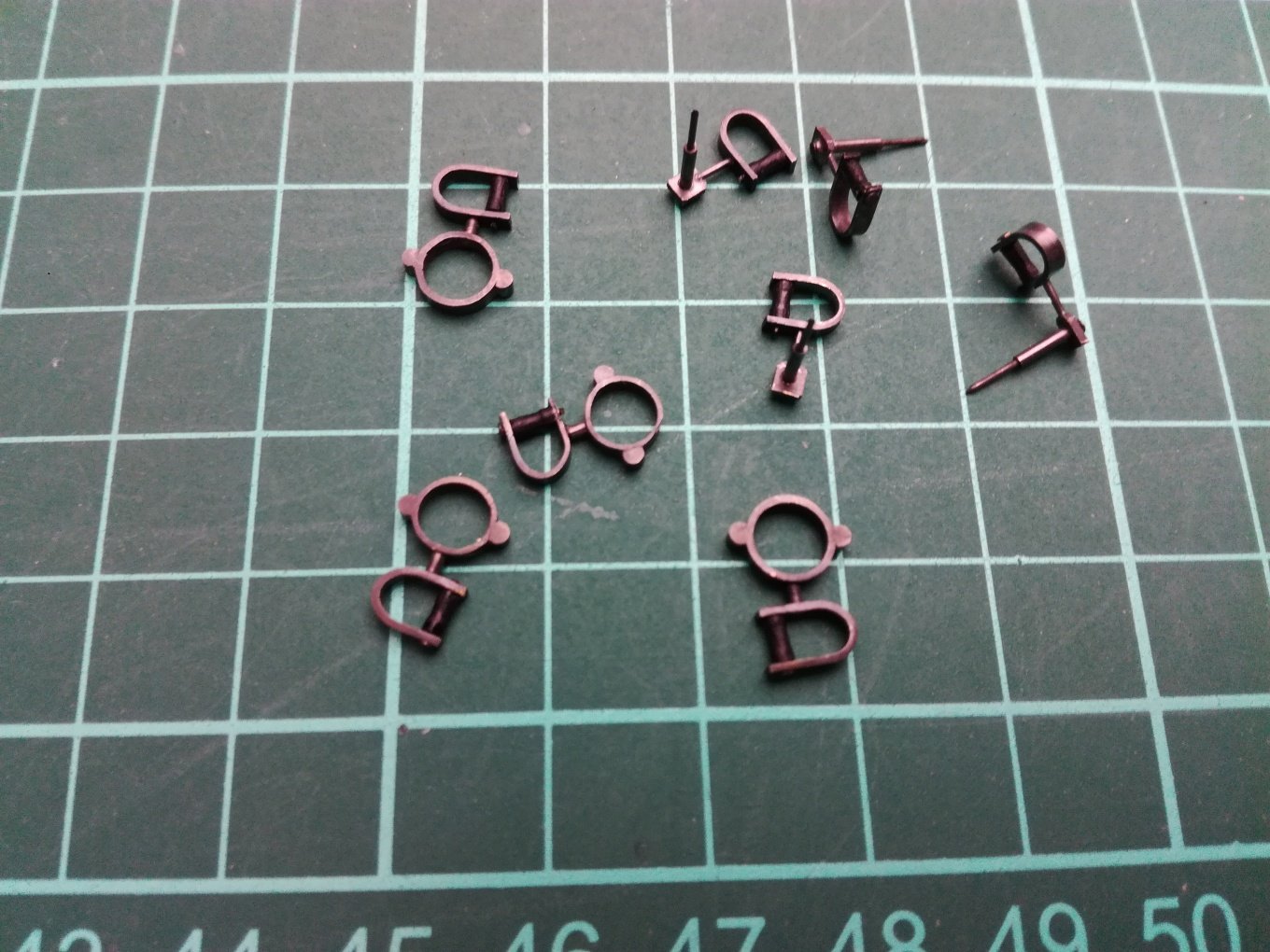

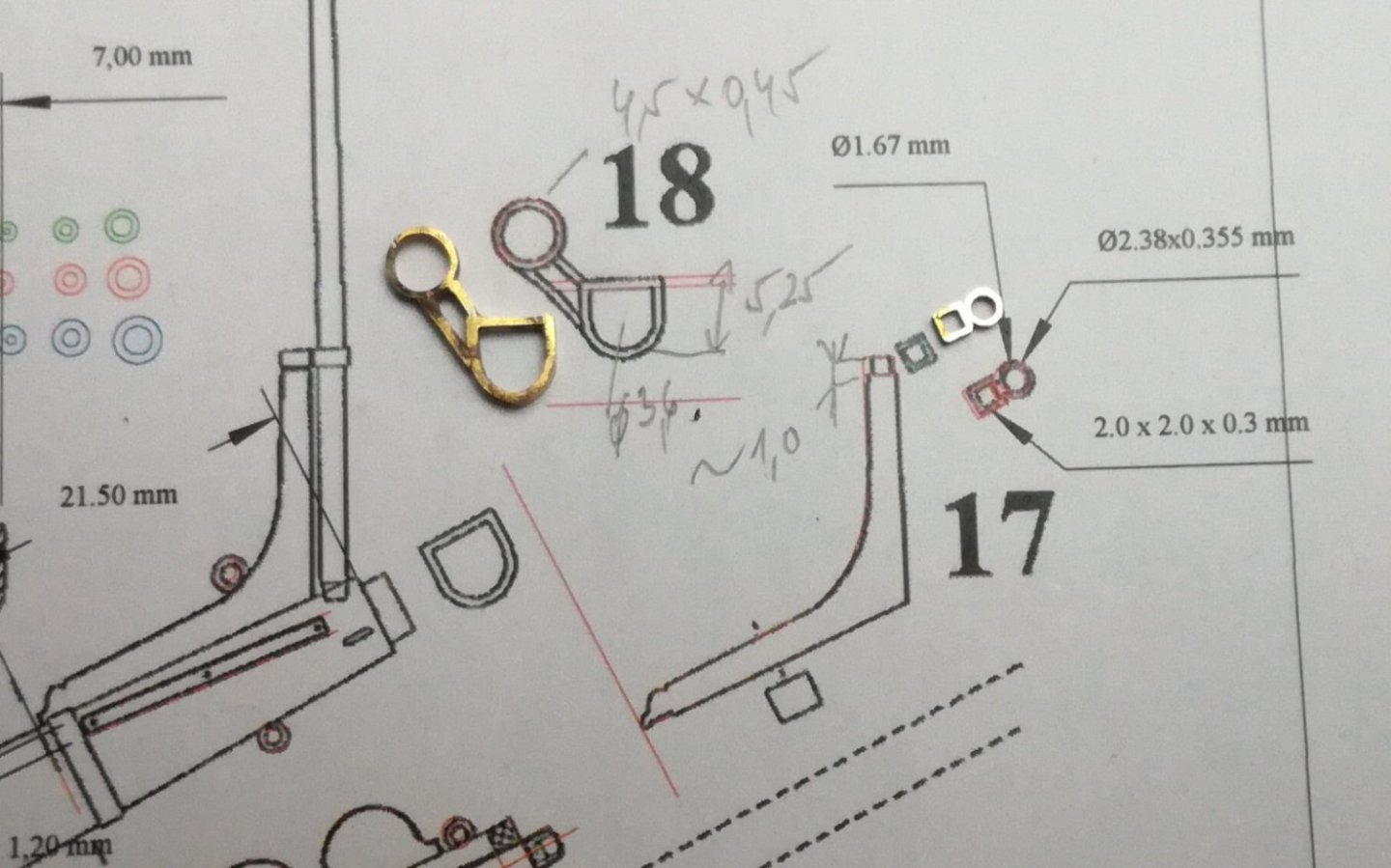

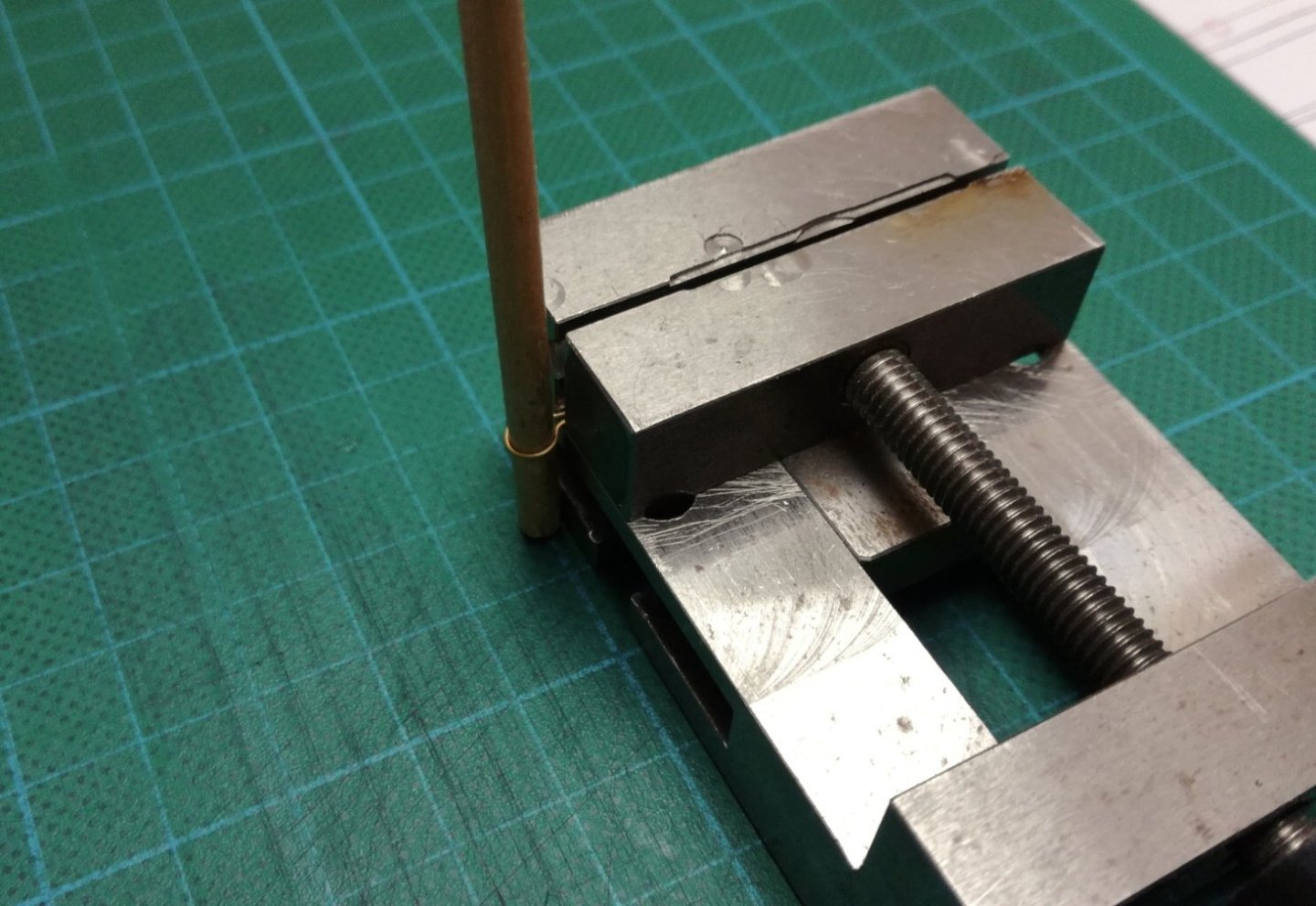

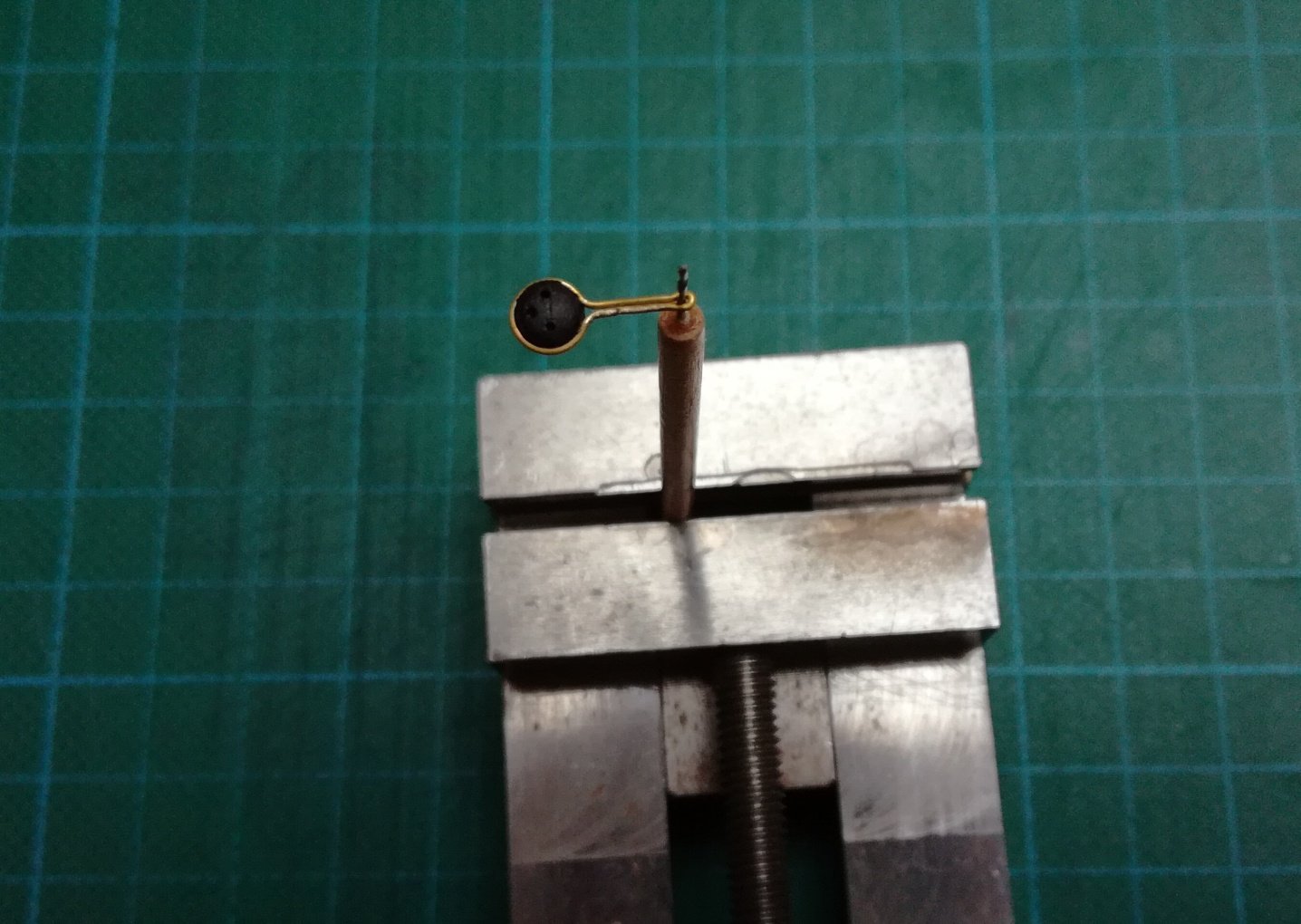

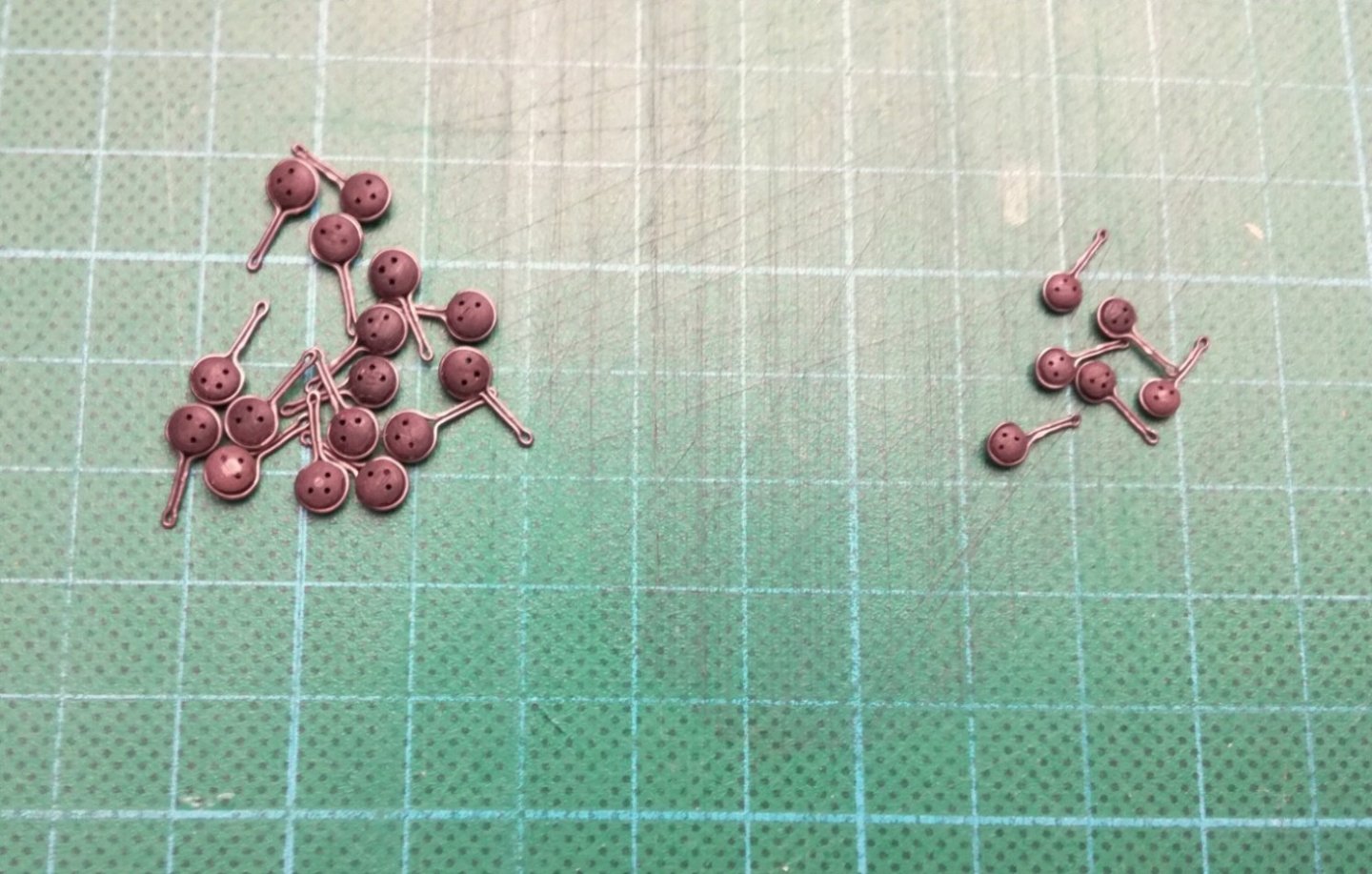

Thank you guys. Before installing the yards on the mast, it was necessary to make the belaying pins.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

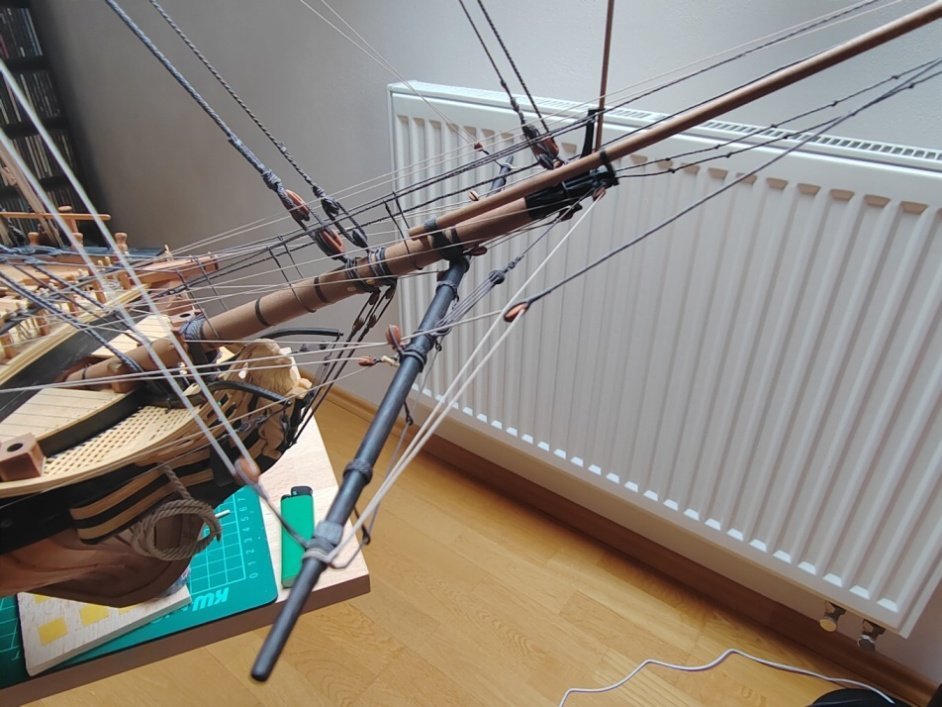

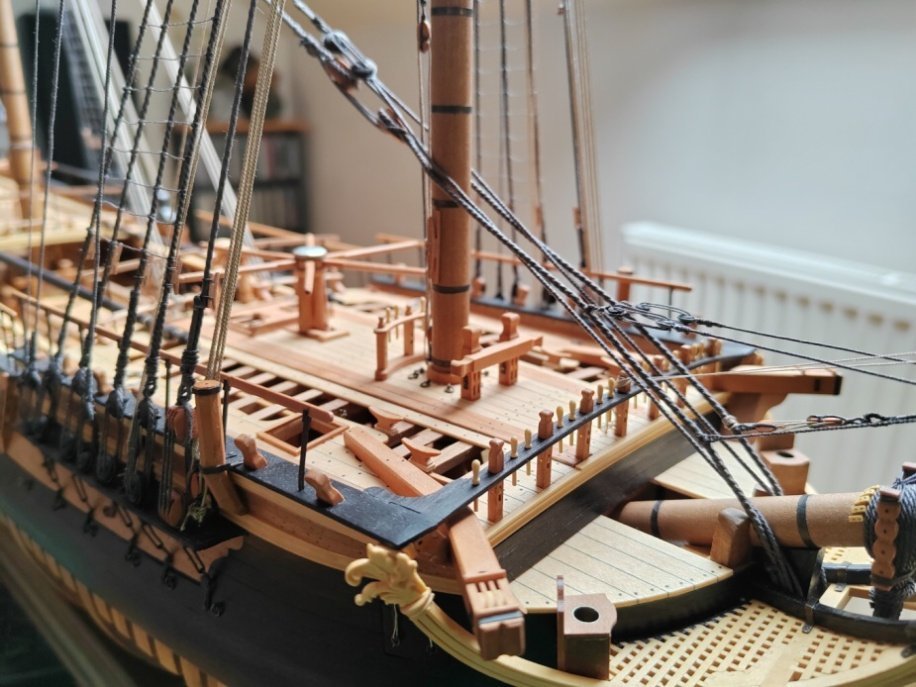

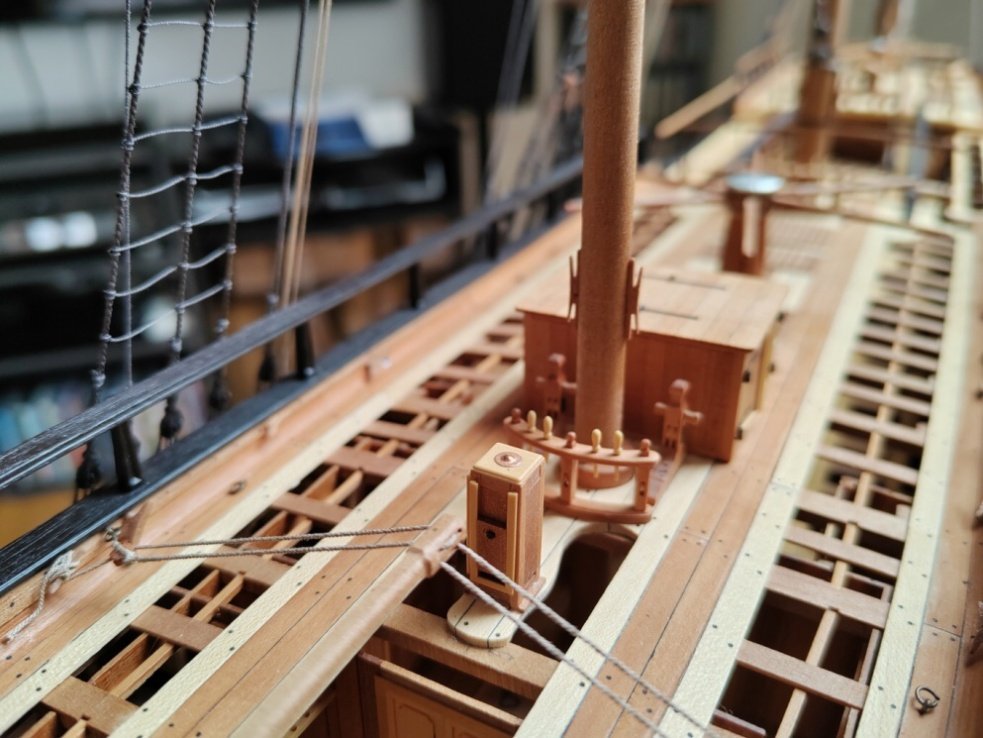

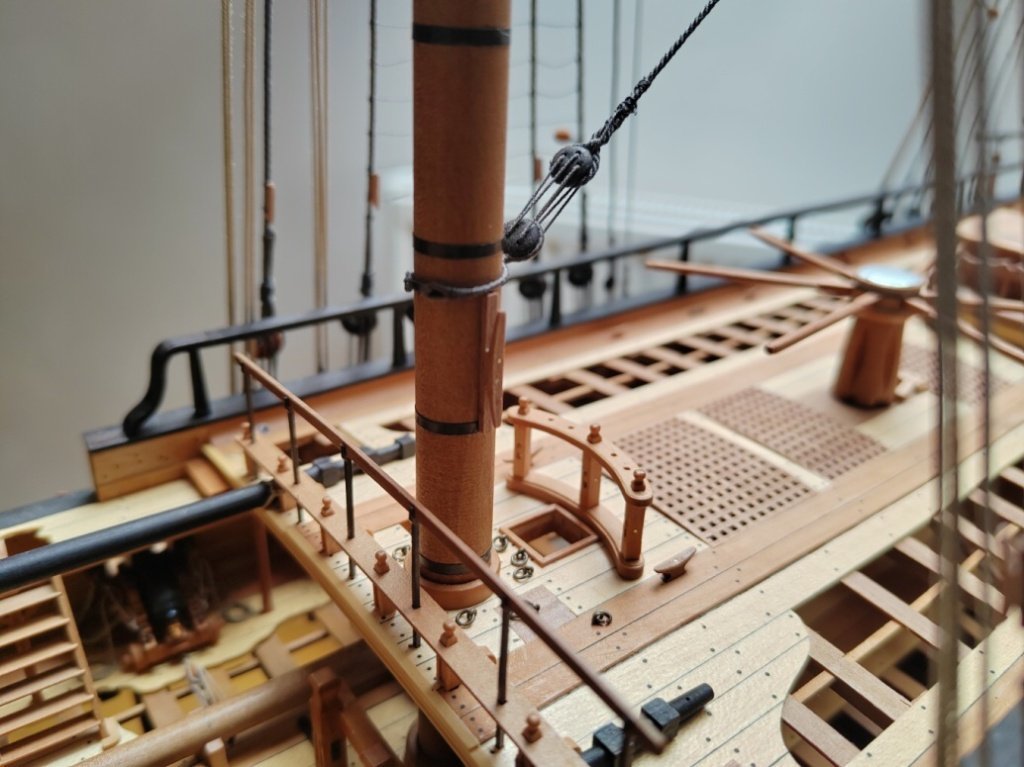

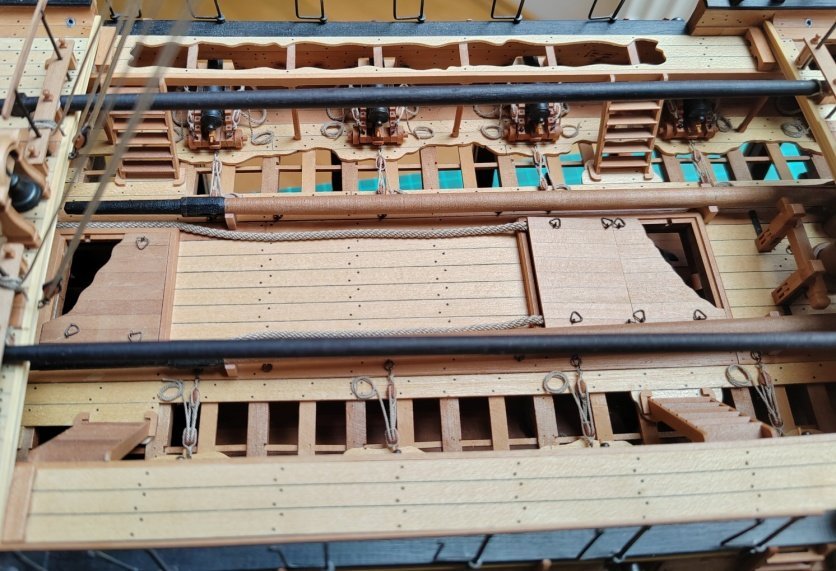

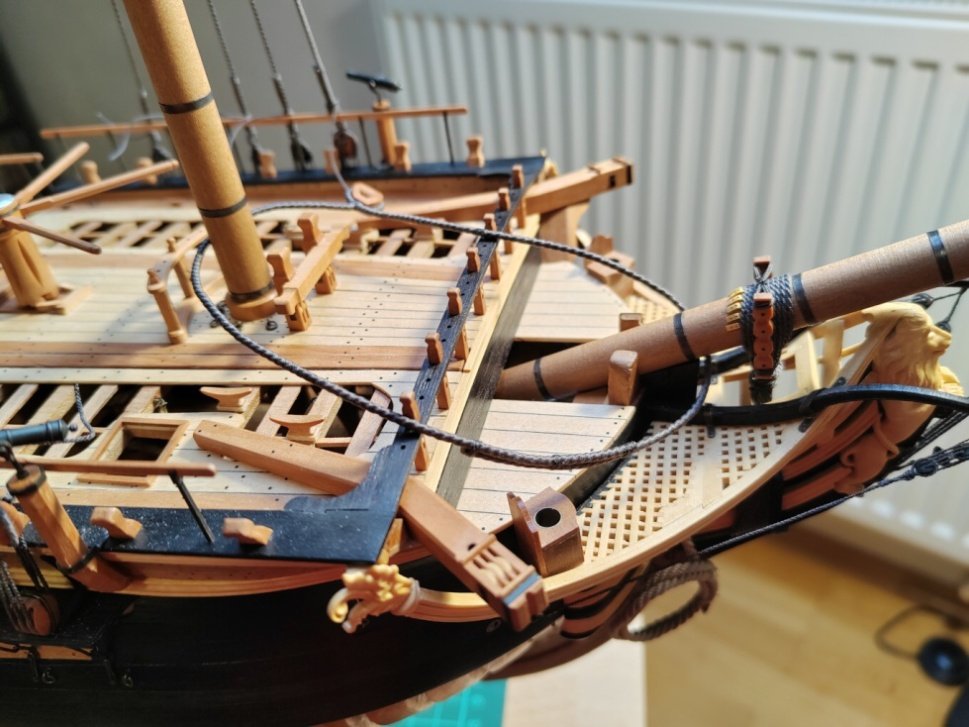

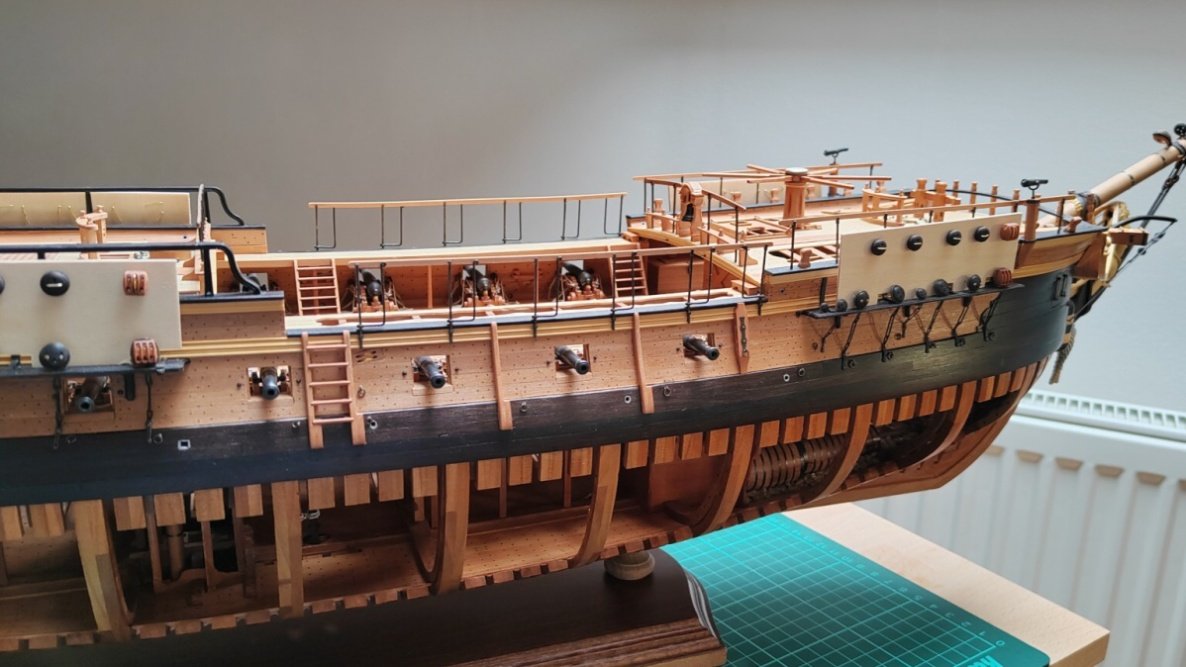

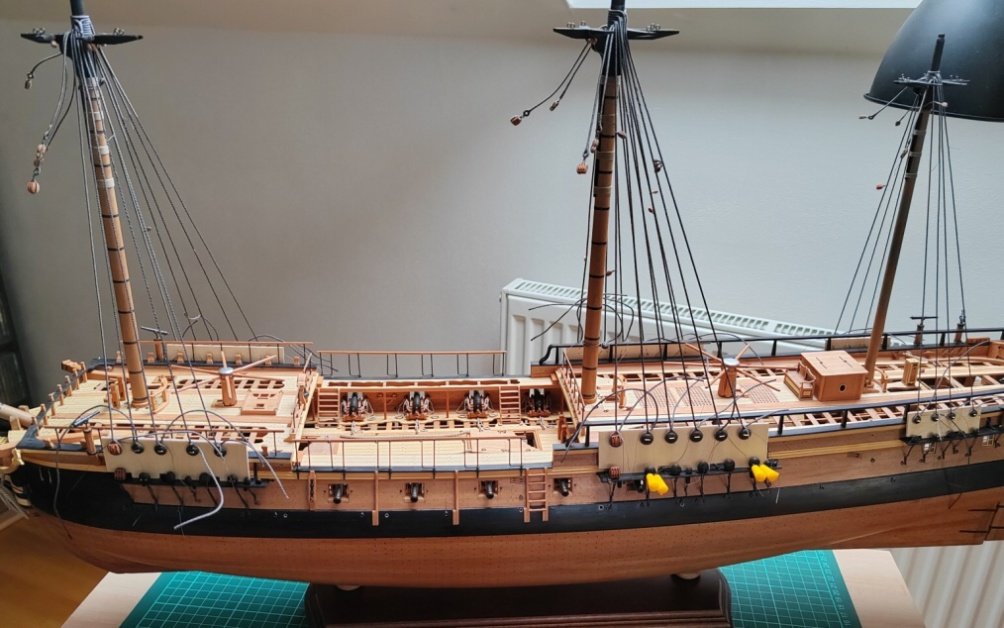

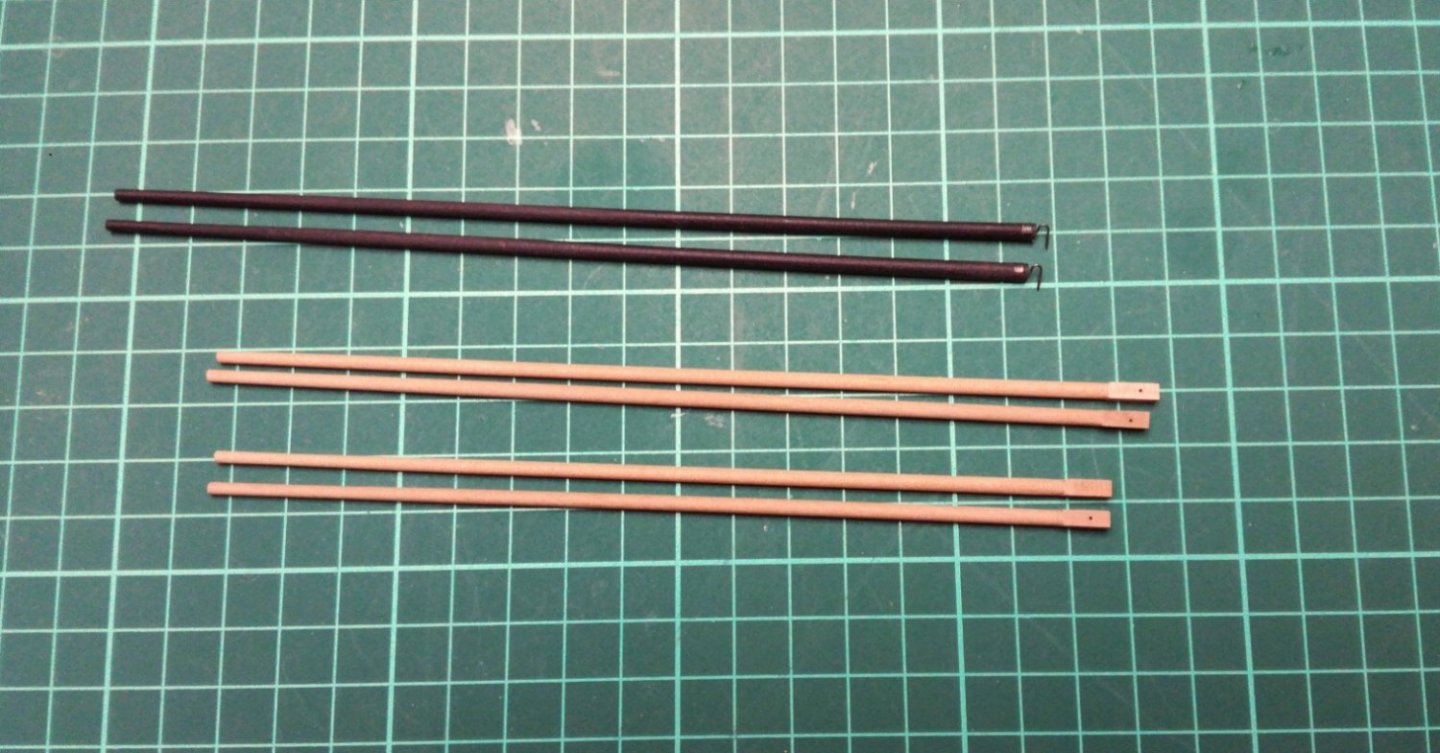

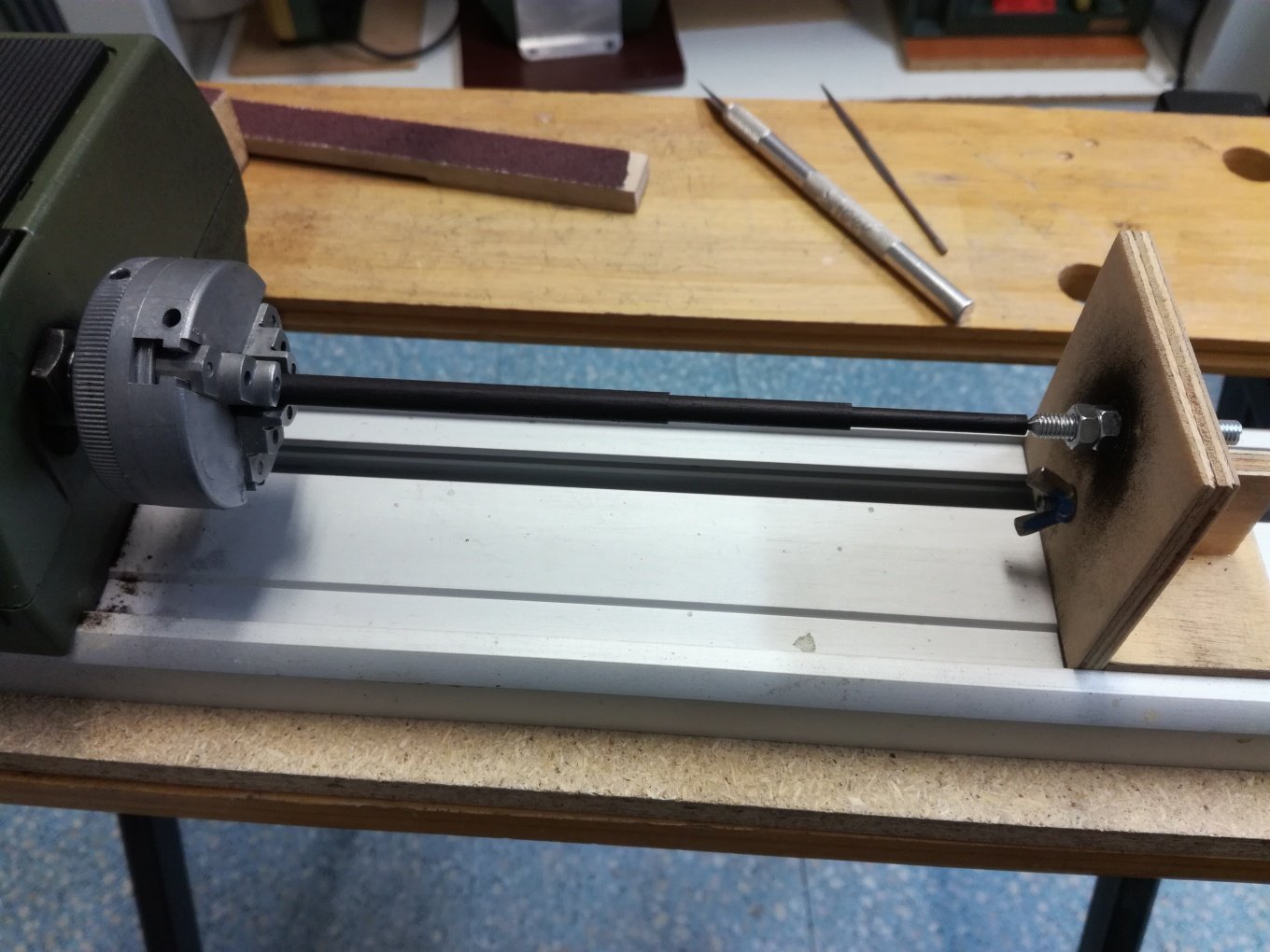

Before installing the yards on the mast, I added a few more details - mast and shroud cleats, spare masts and yards, rigging of the rudder.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

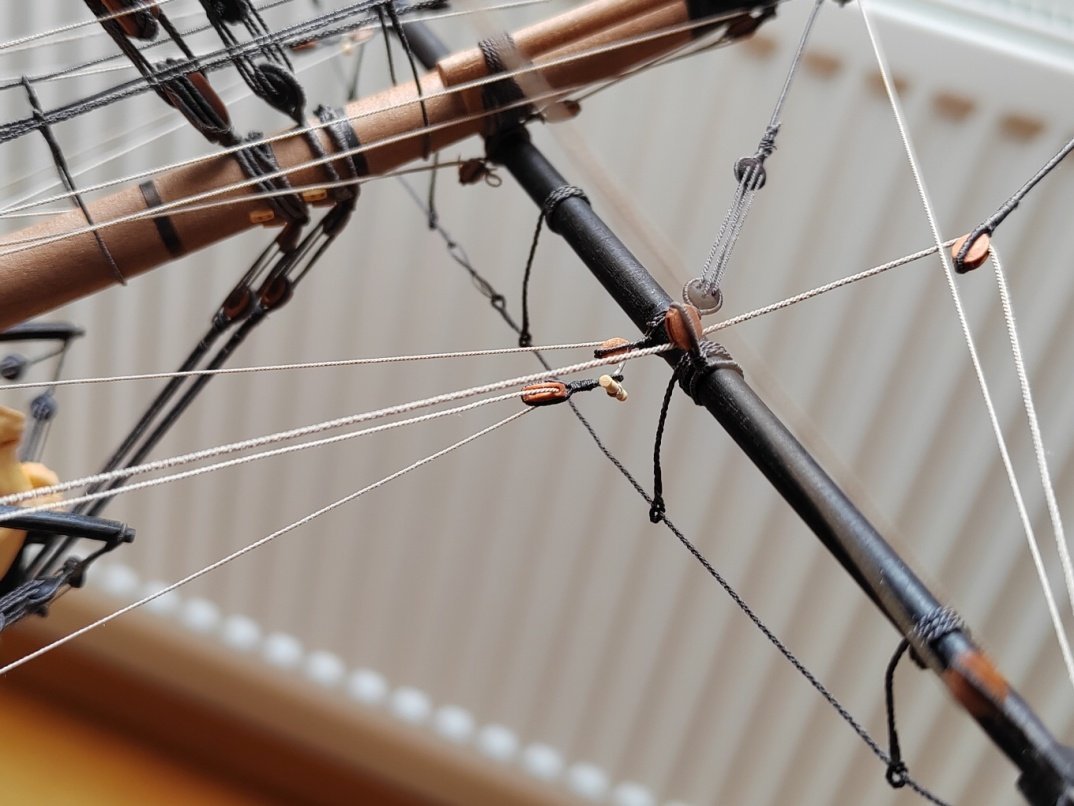

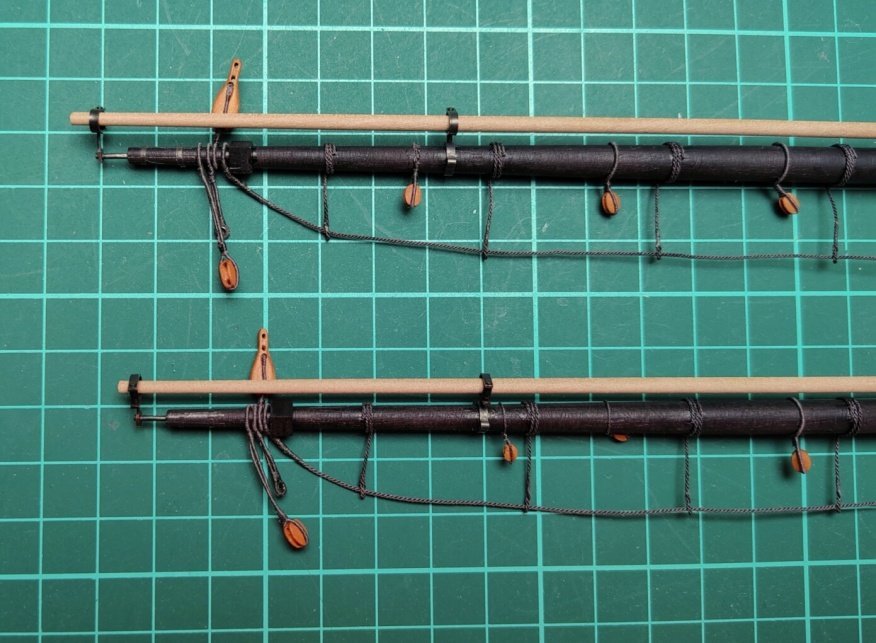

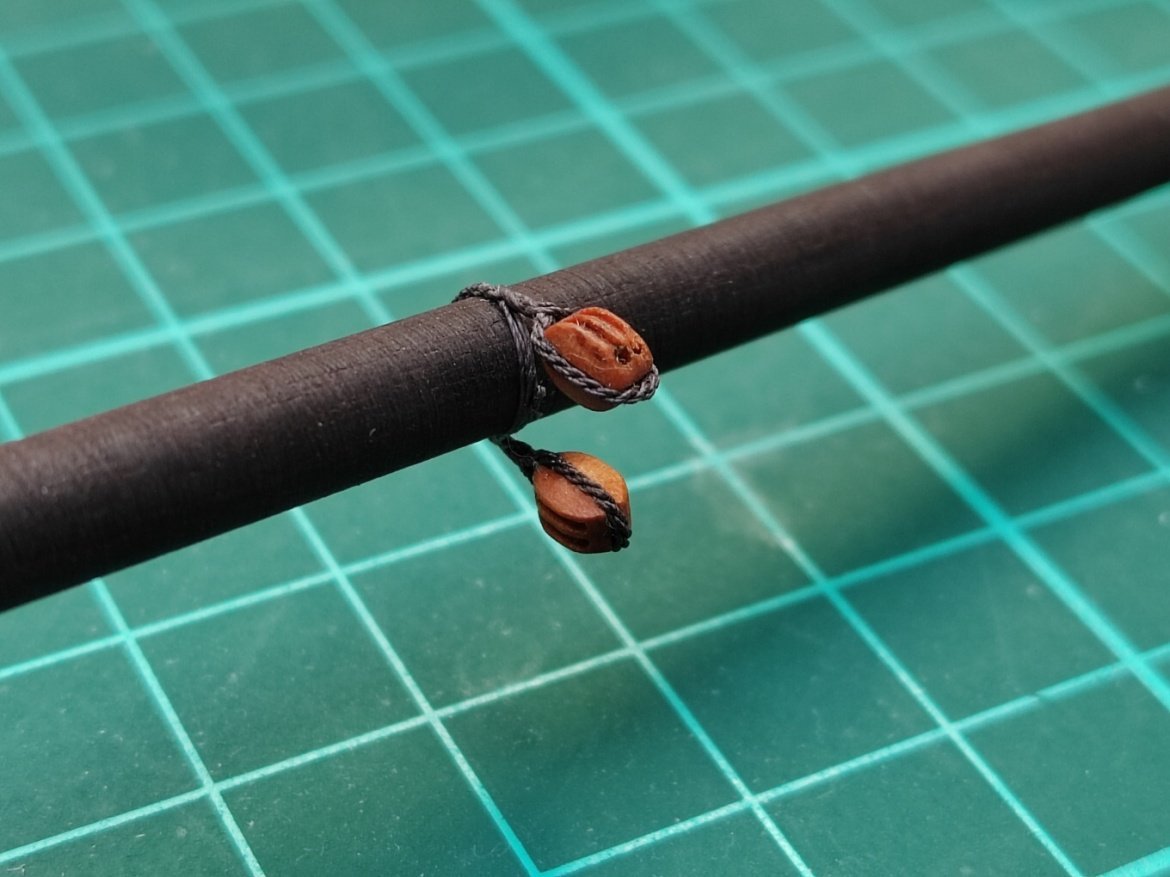

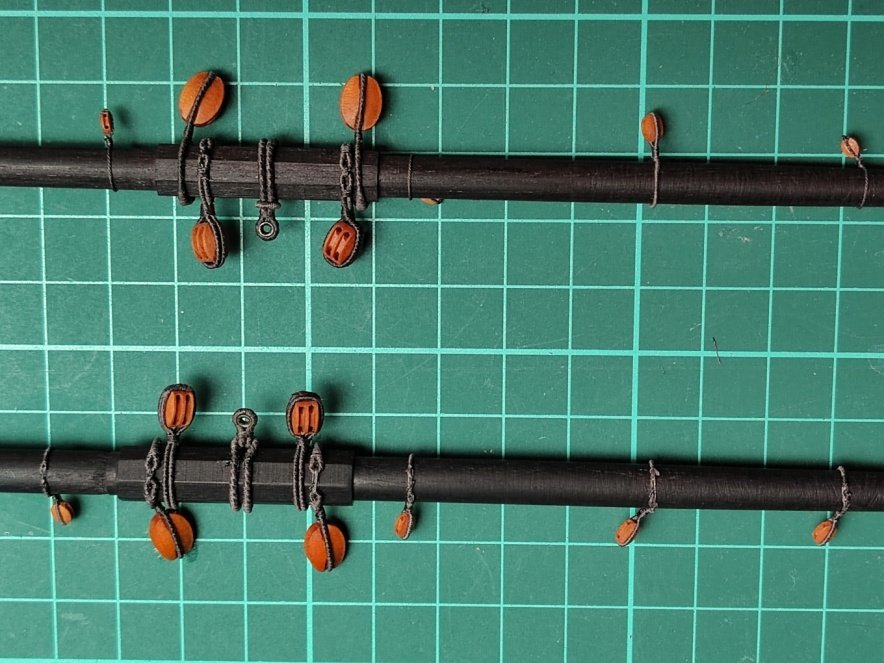

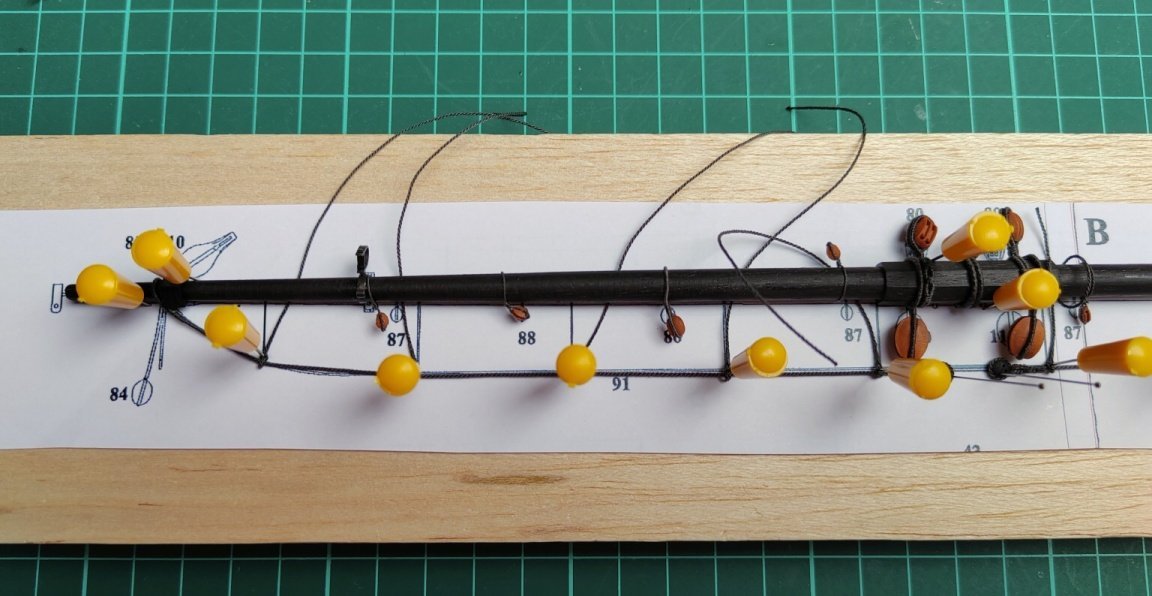

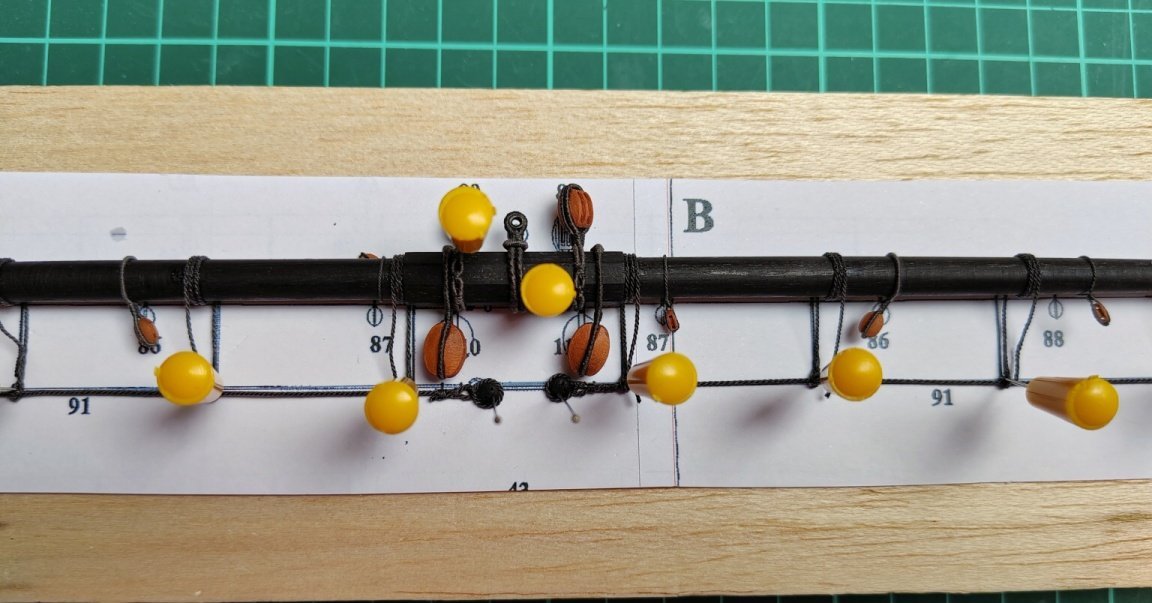

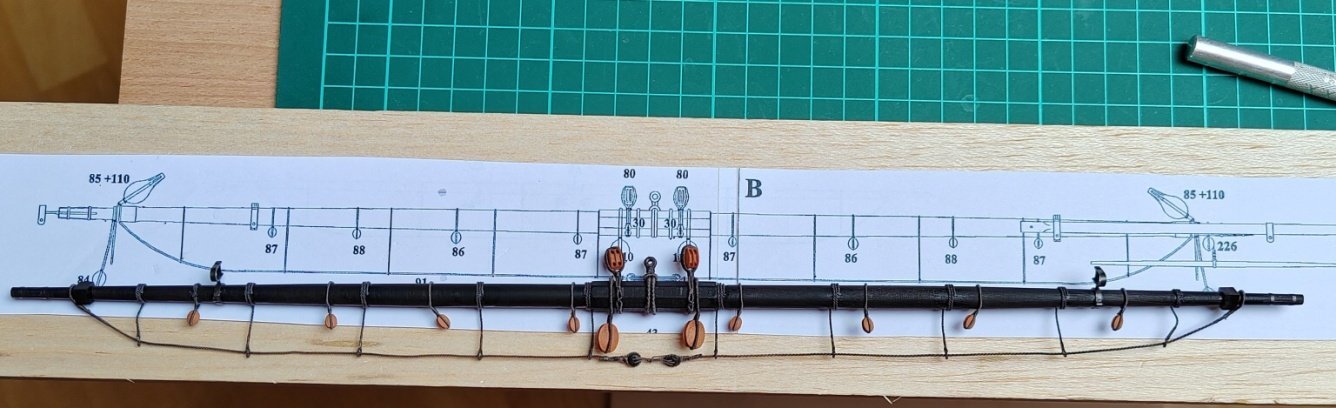

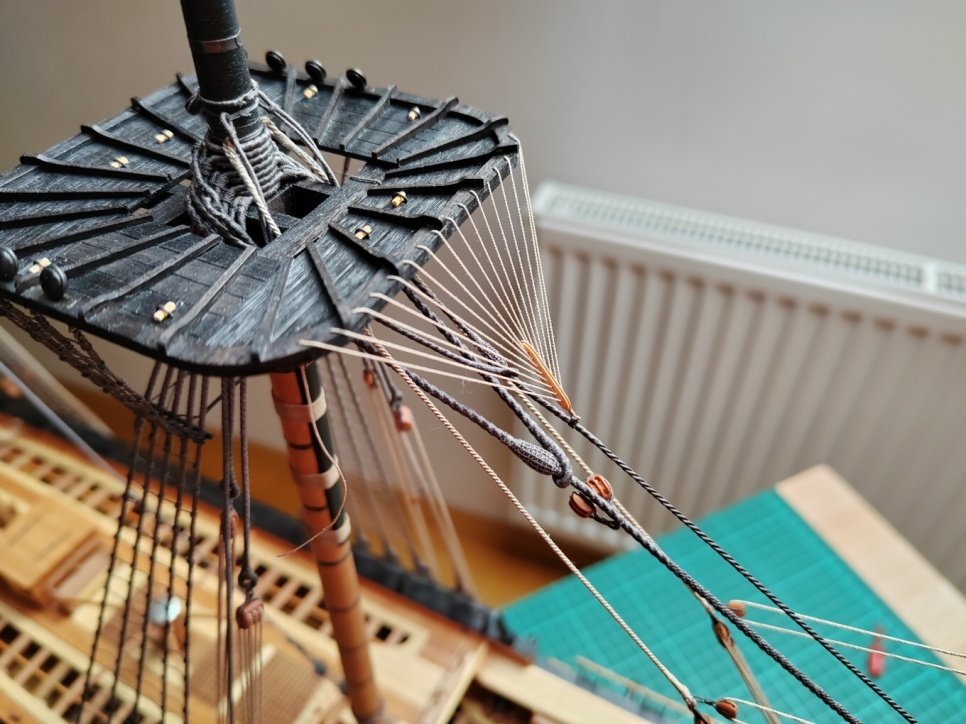

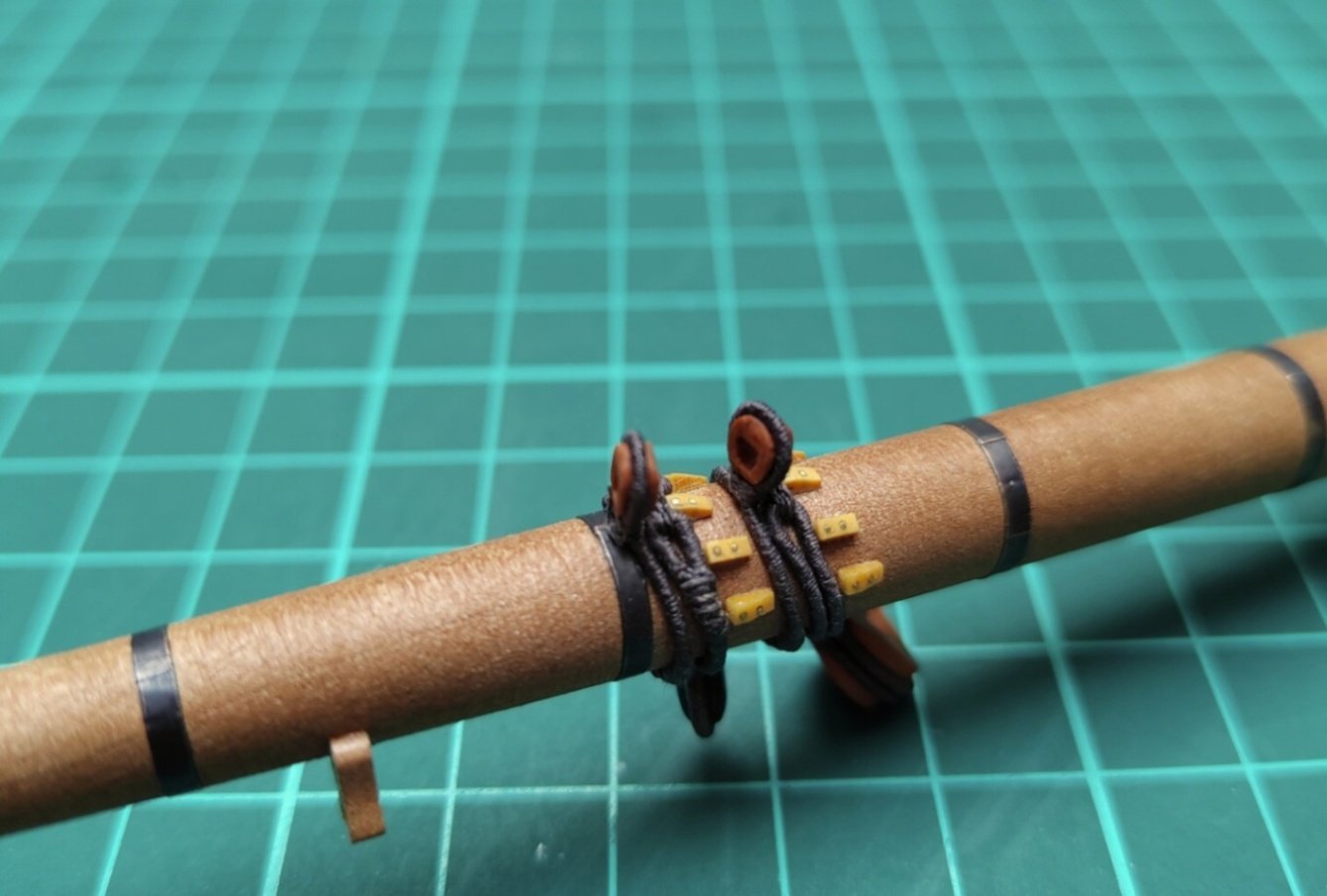

Thank you guys for all likes and comments. Today only answer to the question from dvm27. The footropes are fixed in position with CA glue. Unsightly excess glue is removed with a debonder if necessary.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

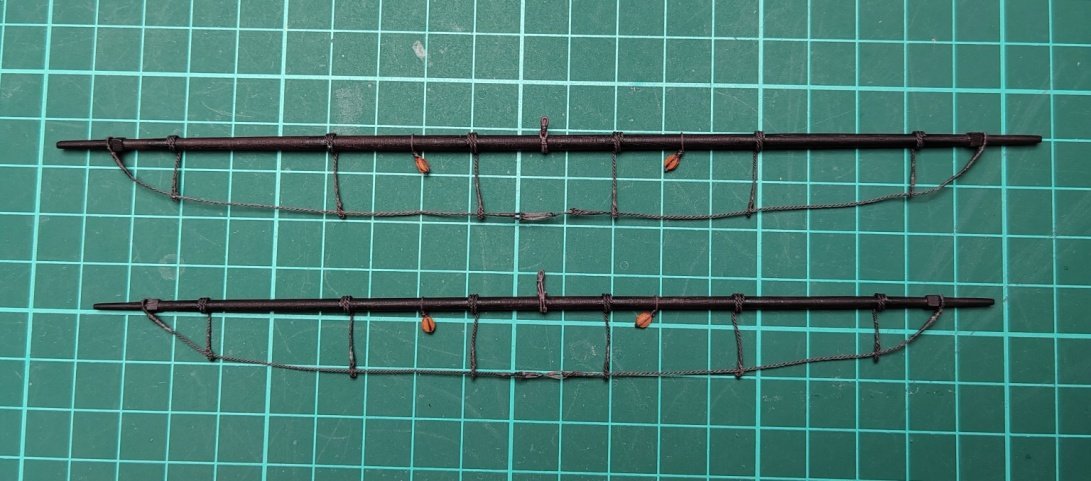

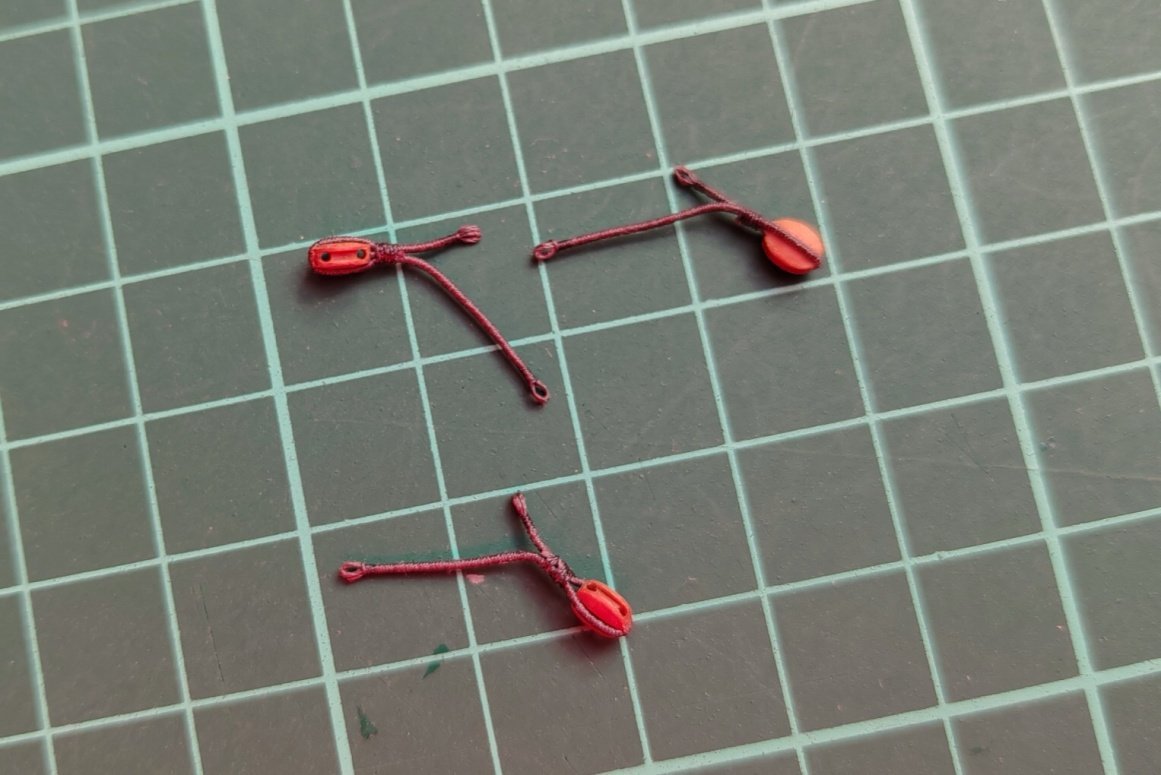

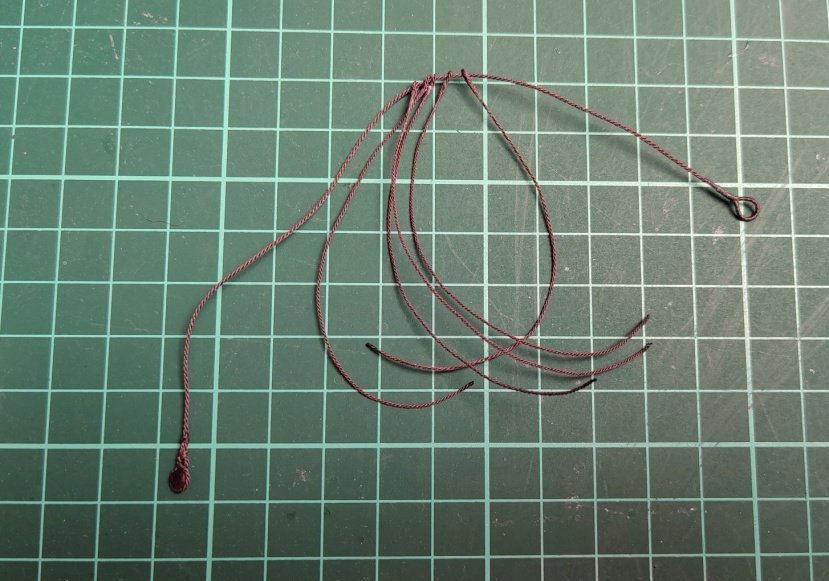

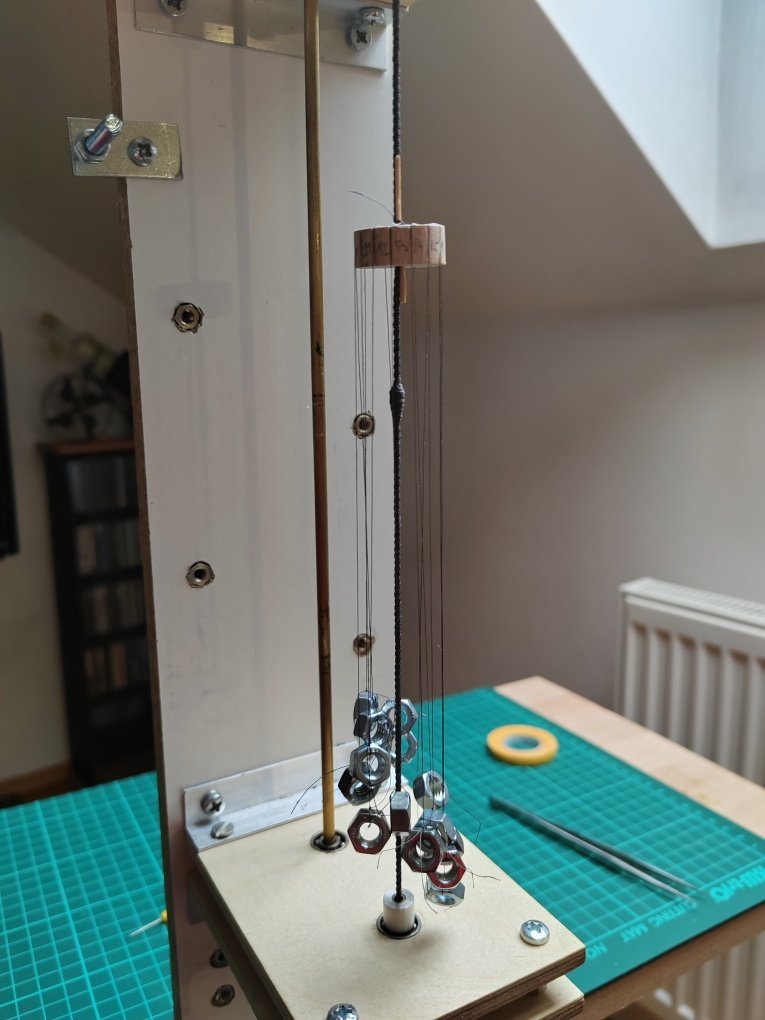

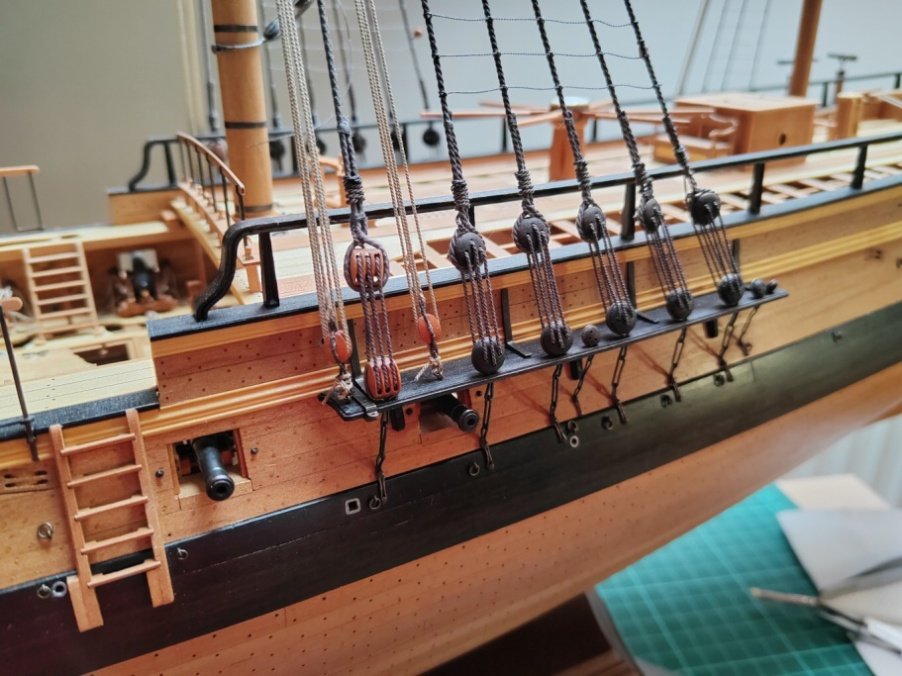

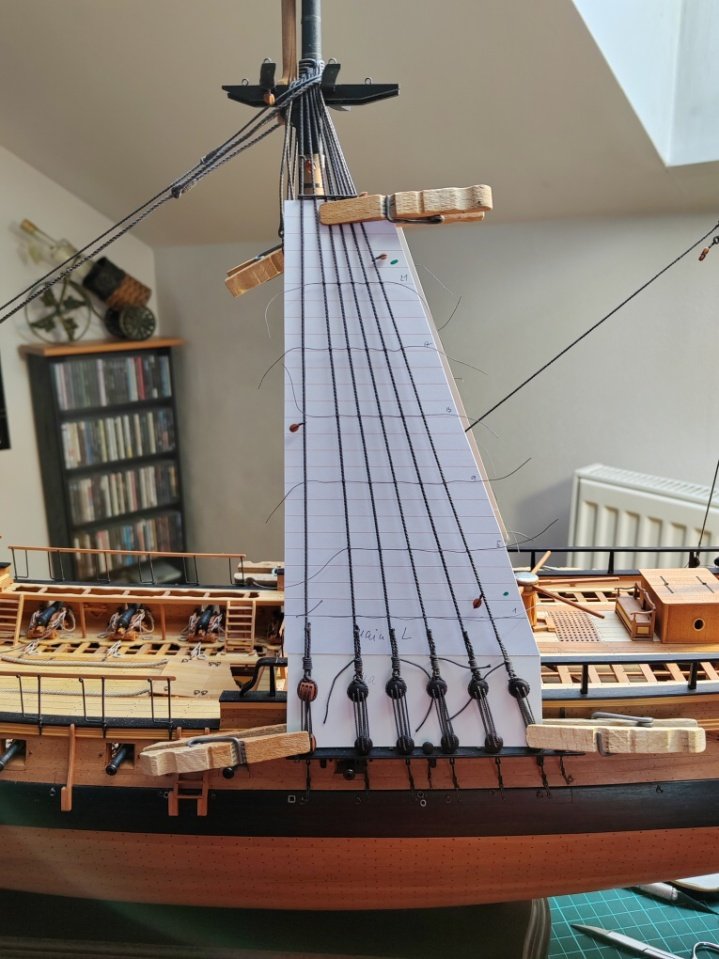

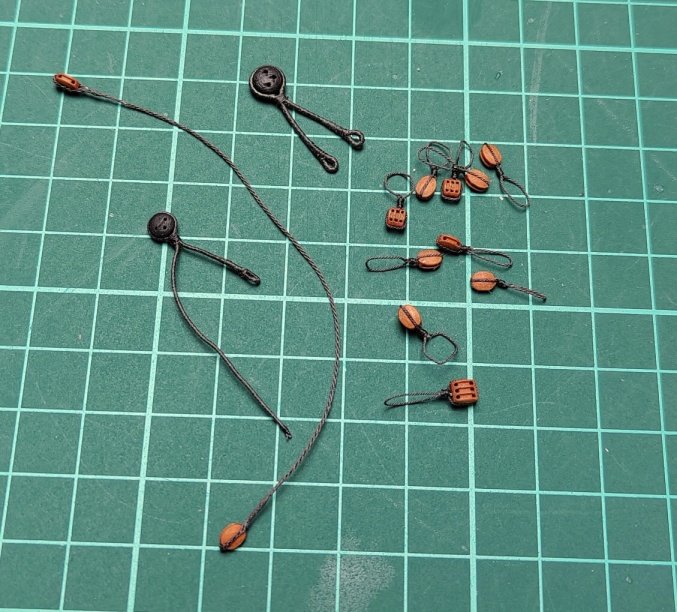

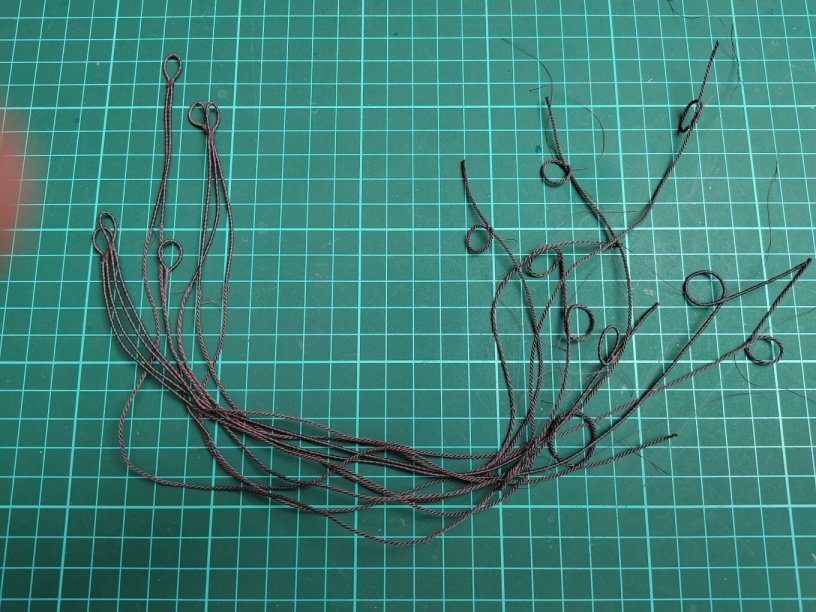

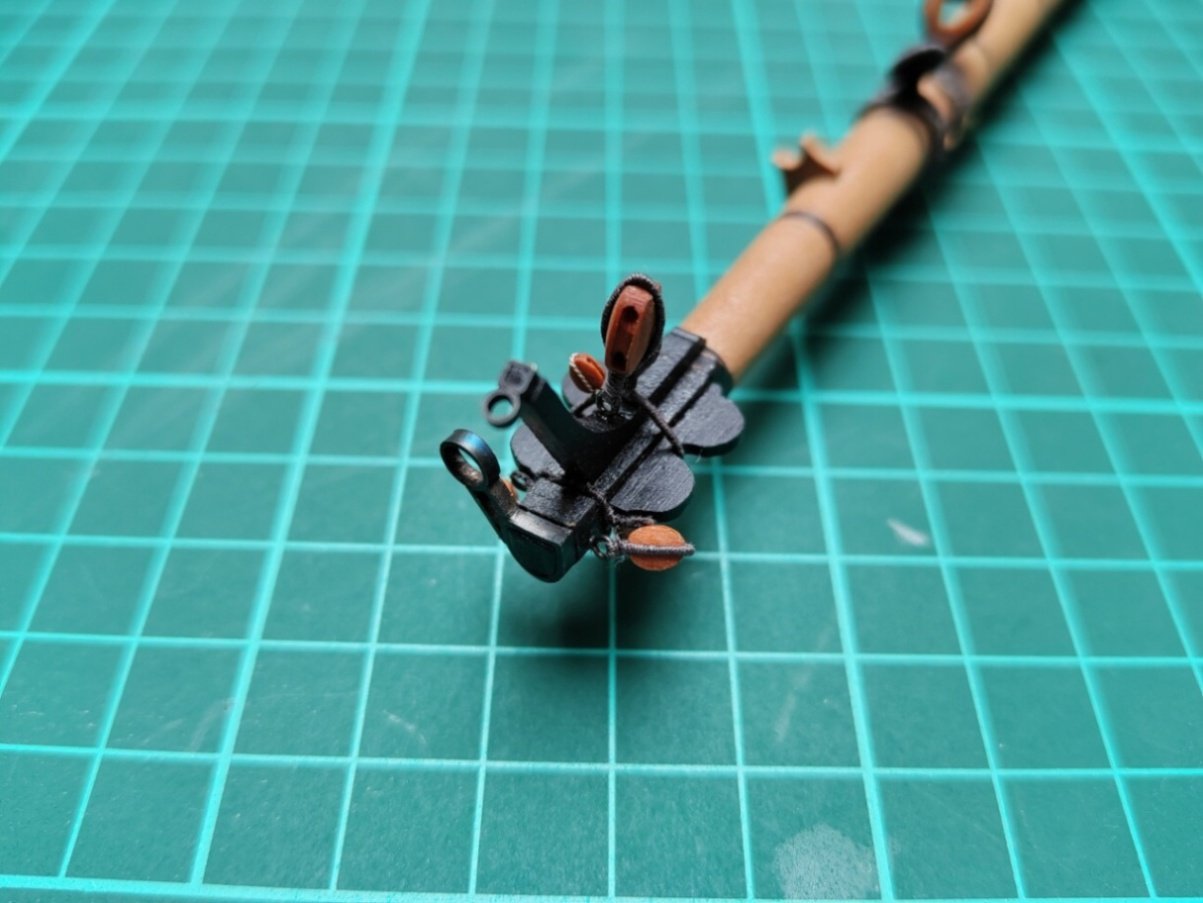

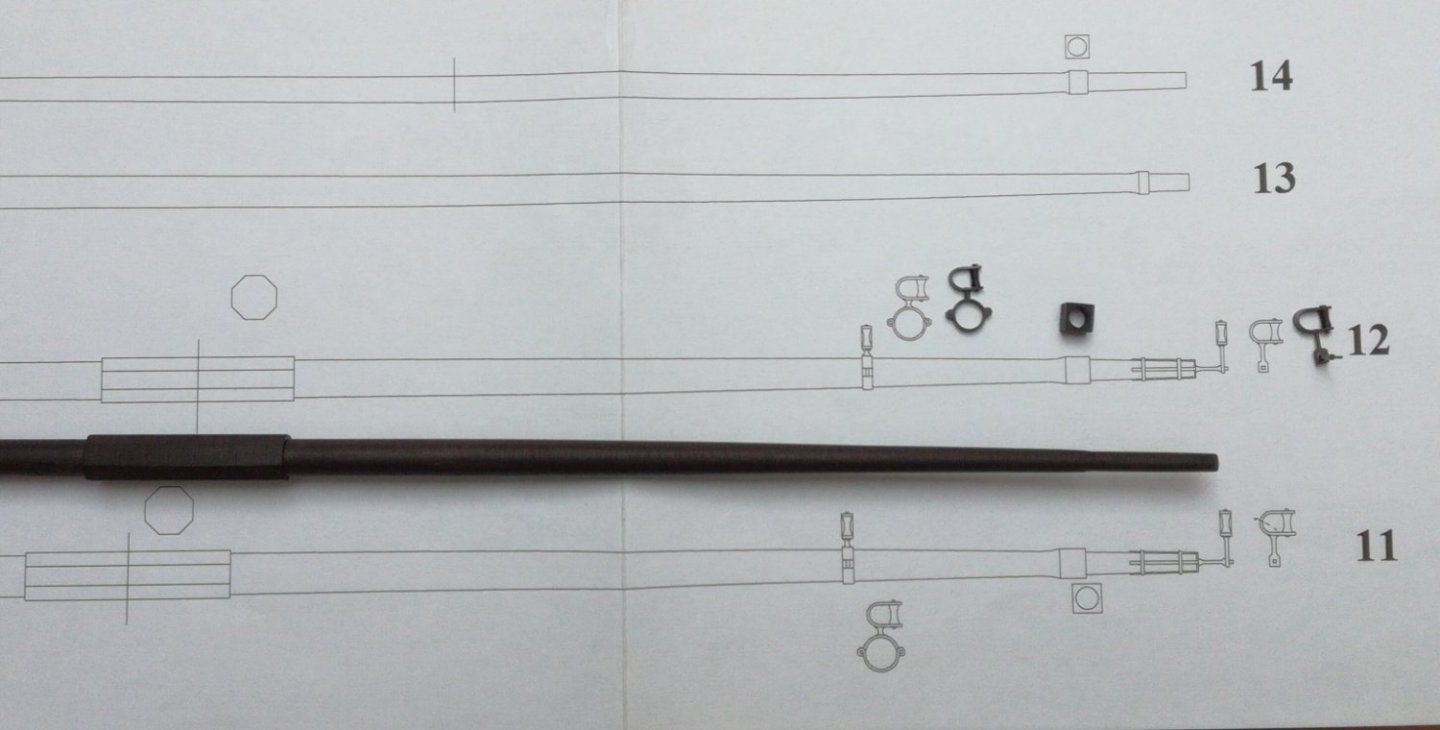

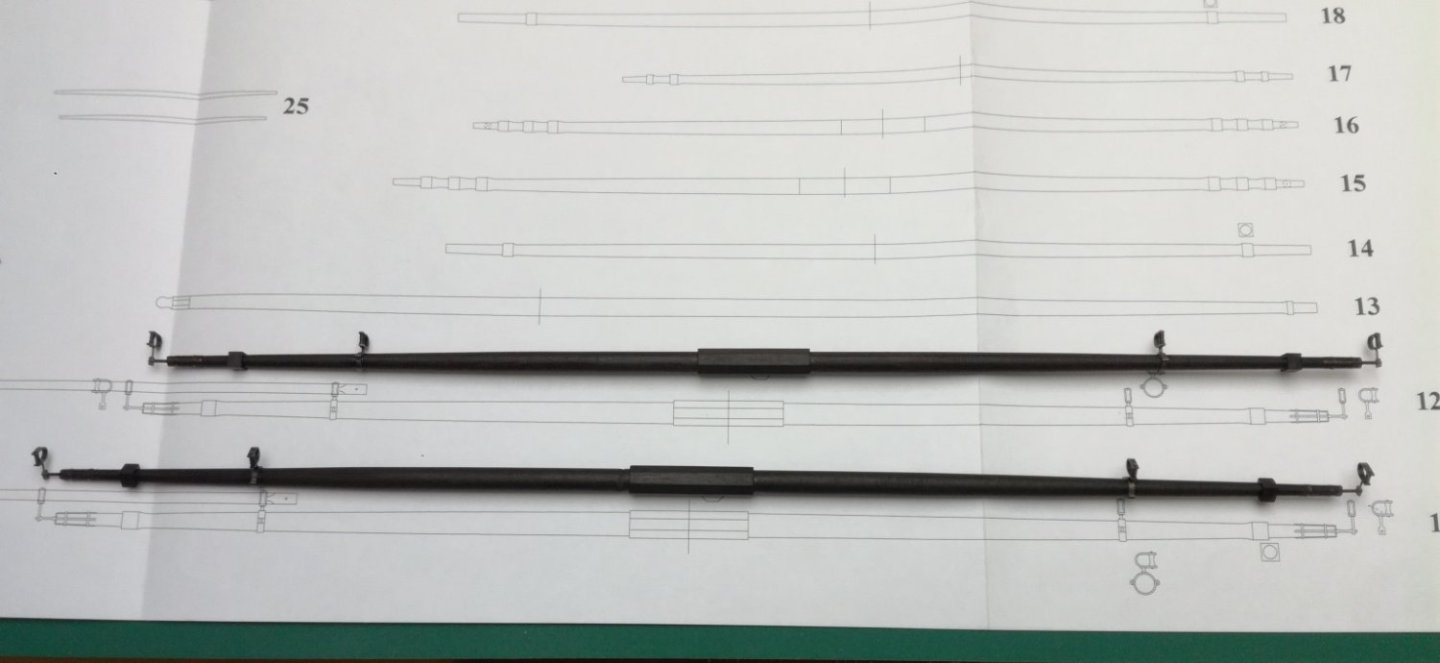

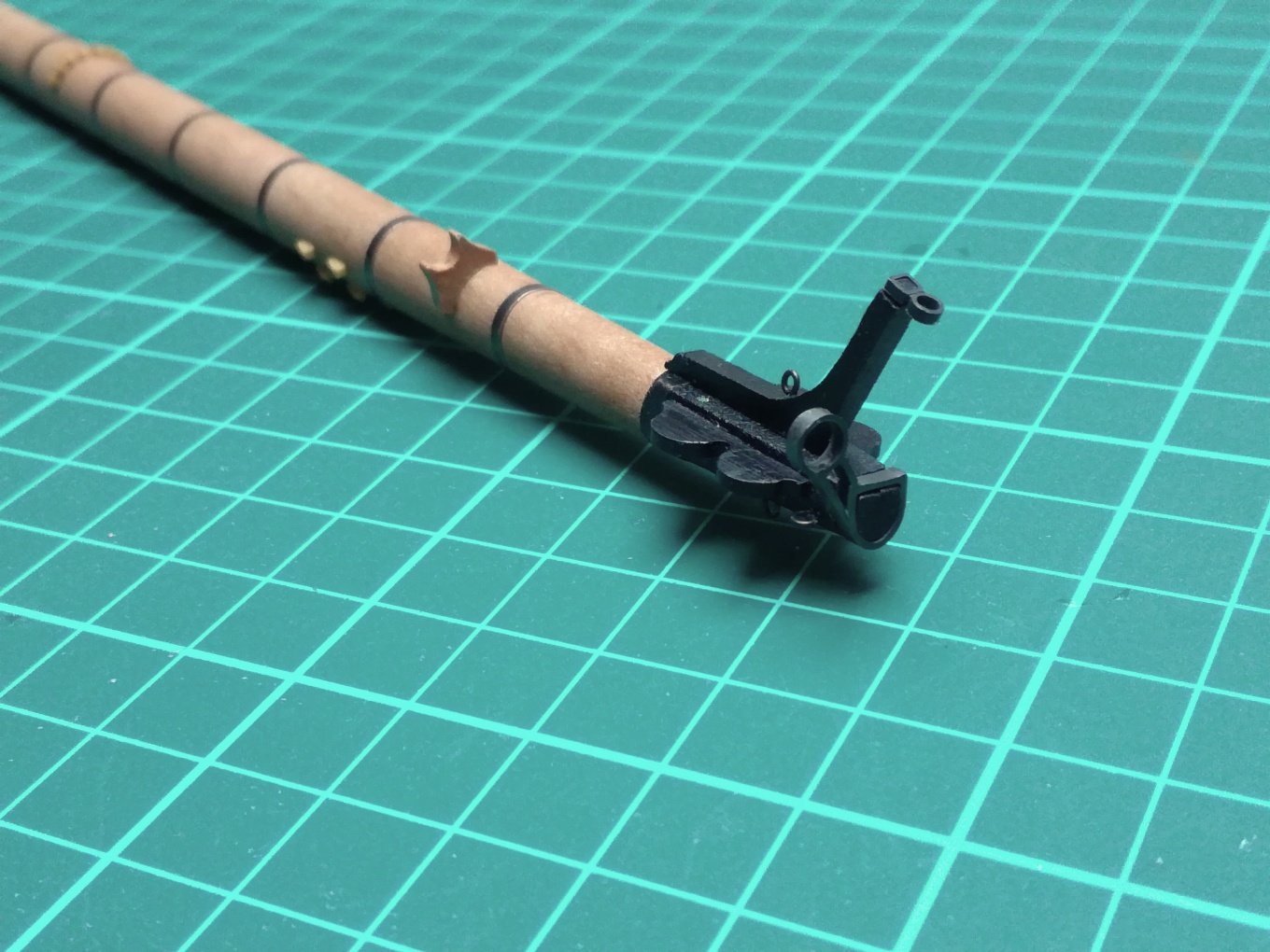

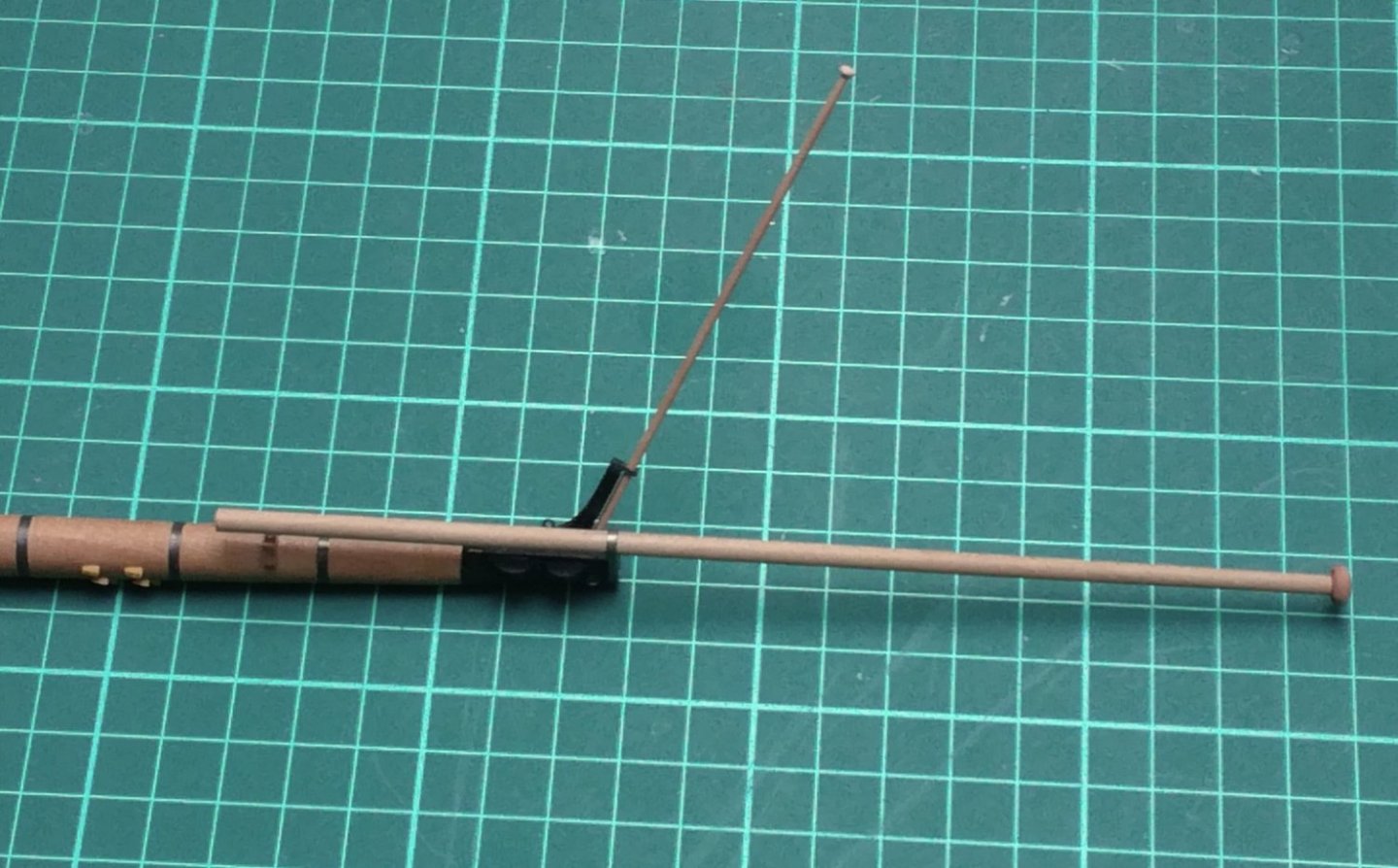

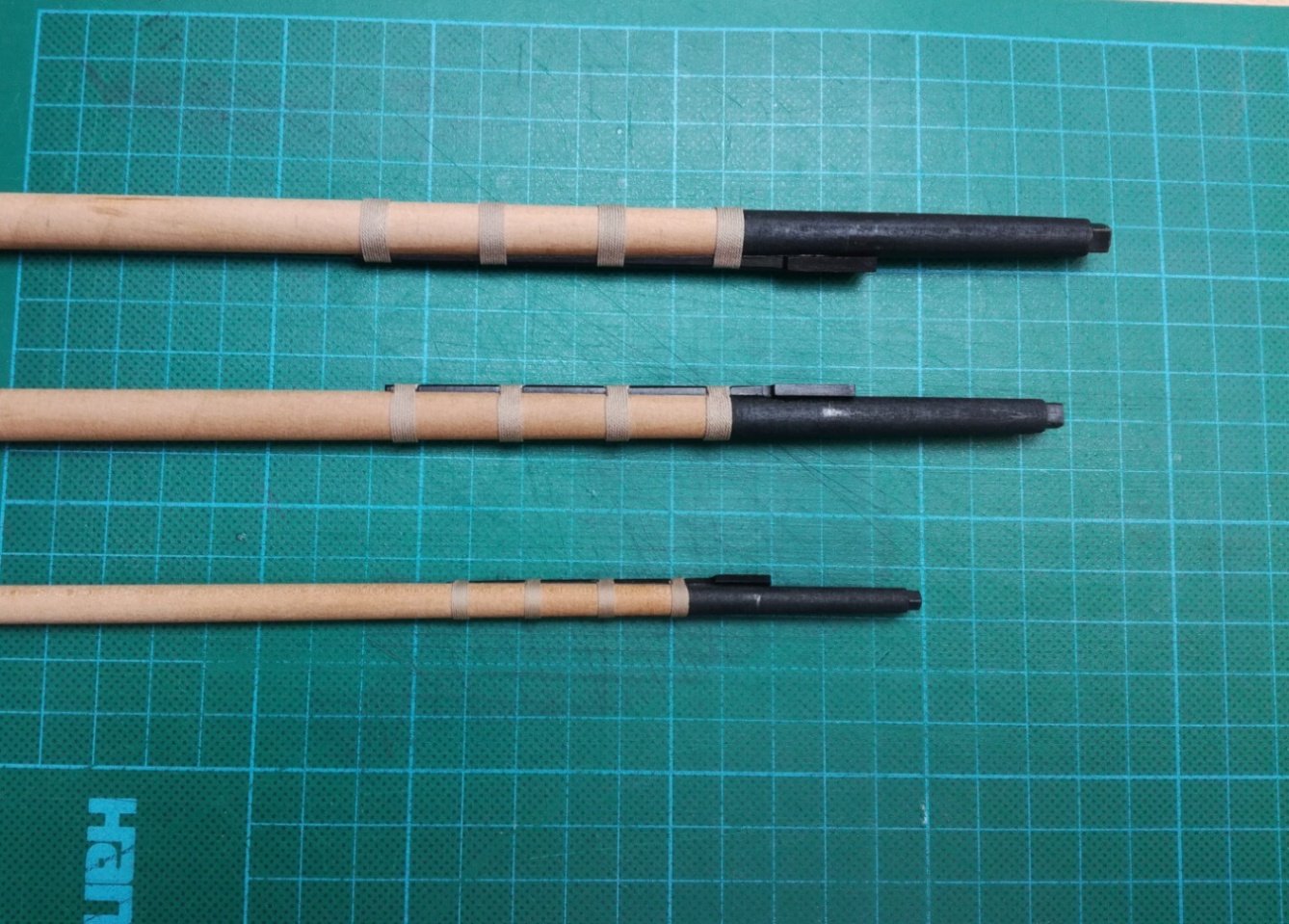

Thank you guys for all comments and likes. The running rigging I started by installing the blocks and footropes on the yards. I chose the fore and main lower yards first, which are the most difficult.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

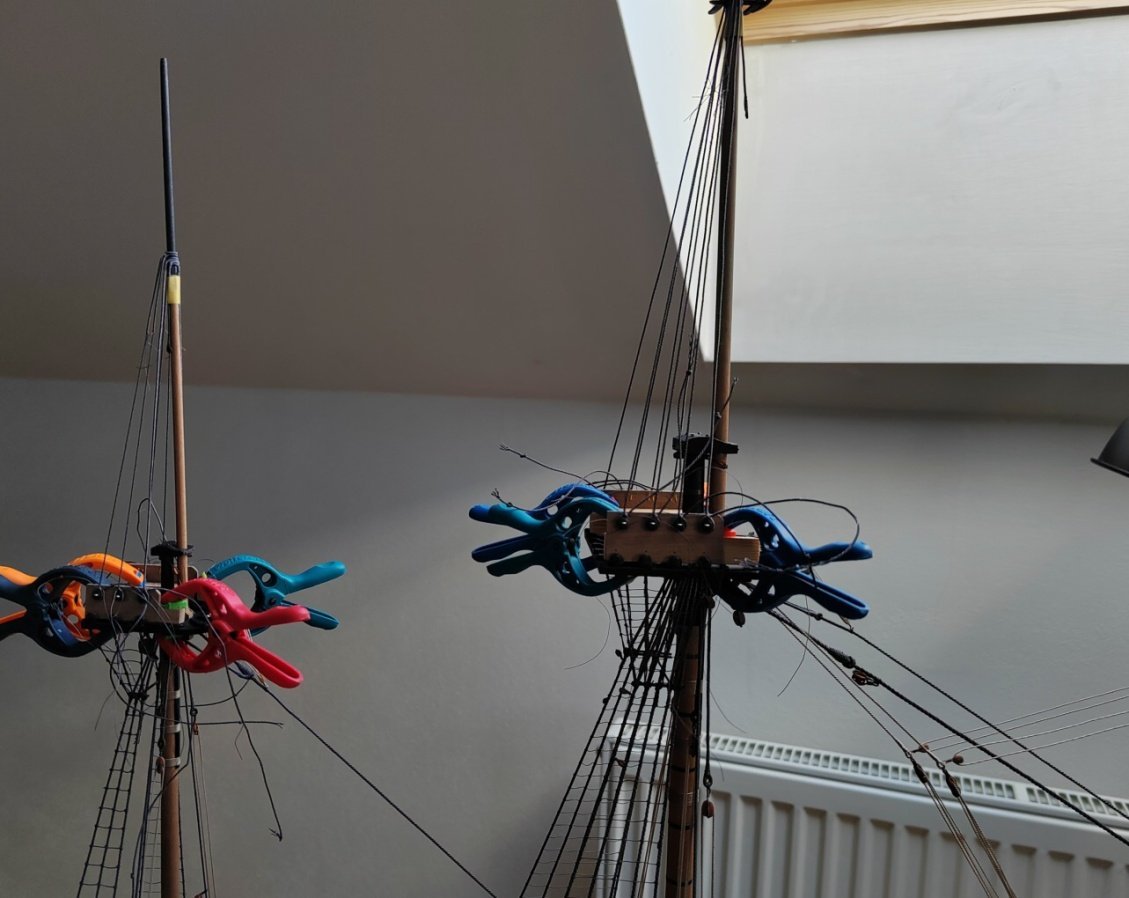

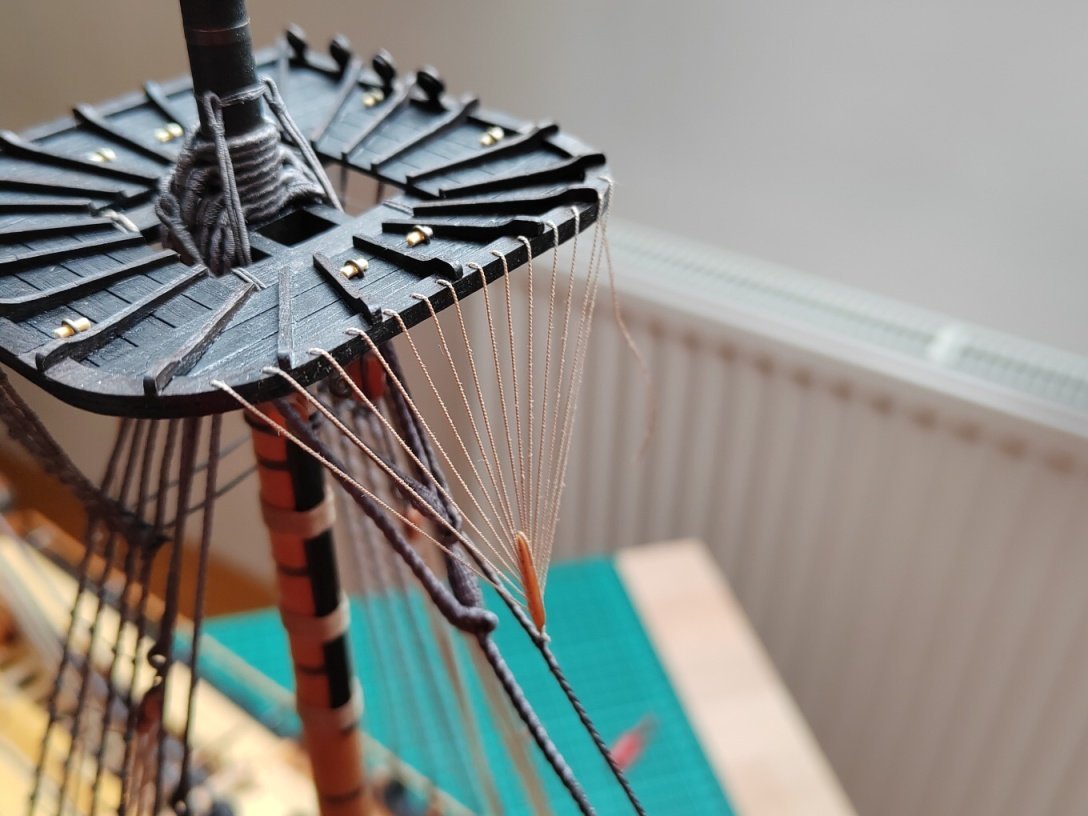

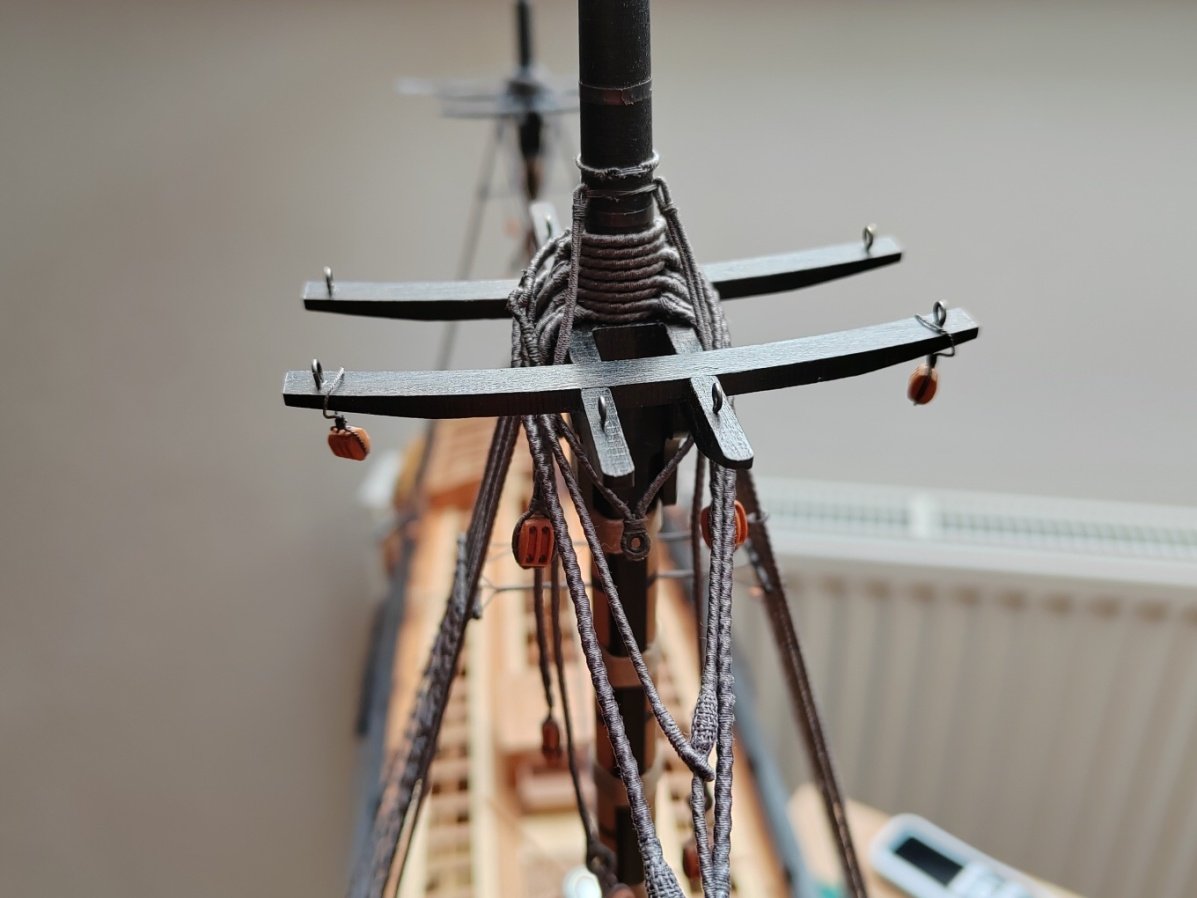

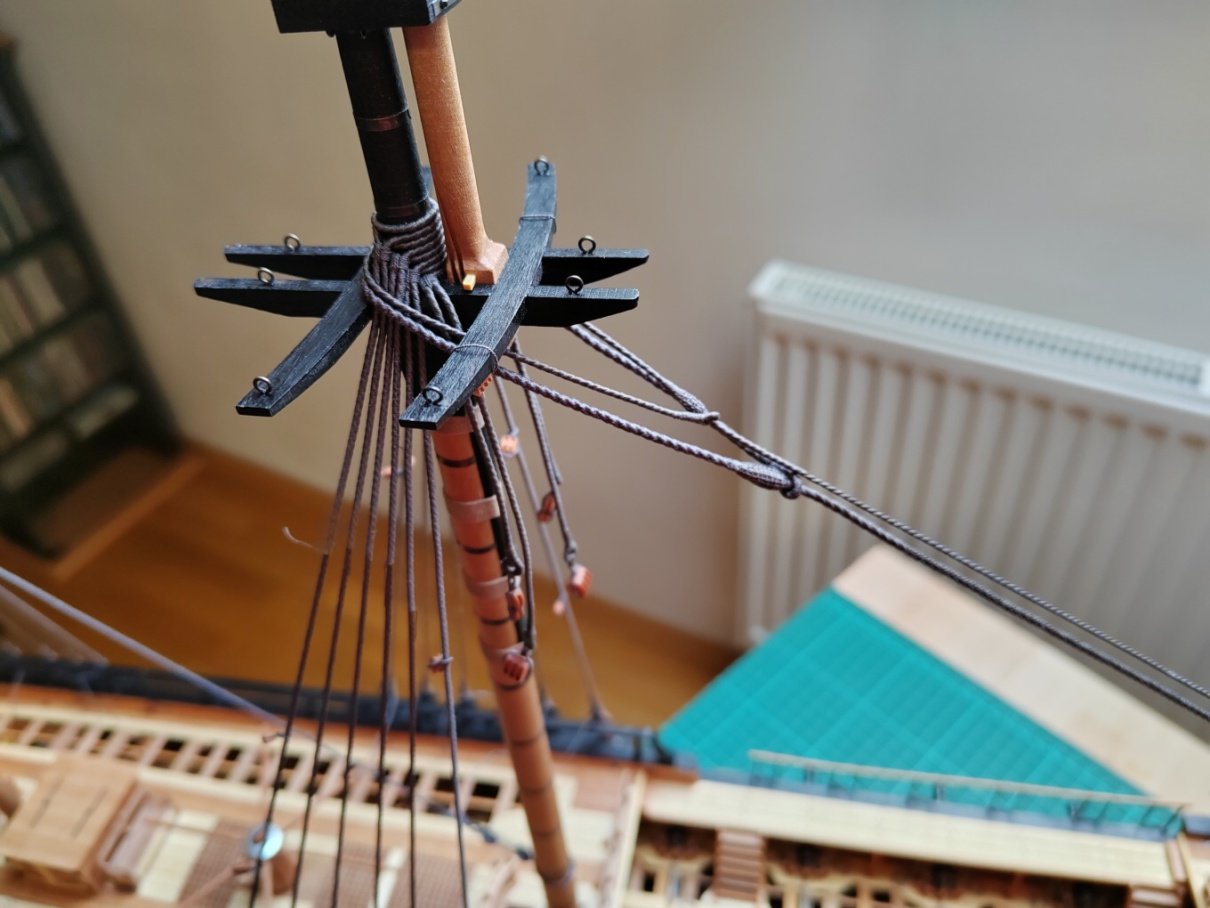

Futtock shrouds and crowfeets. This completes the lower masts standing rigging. I will continue with top masts standing rigging.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

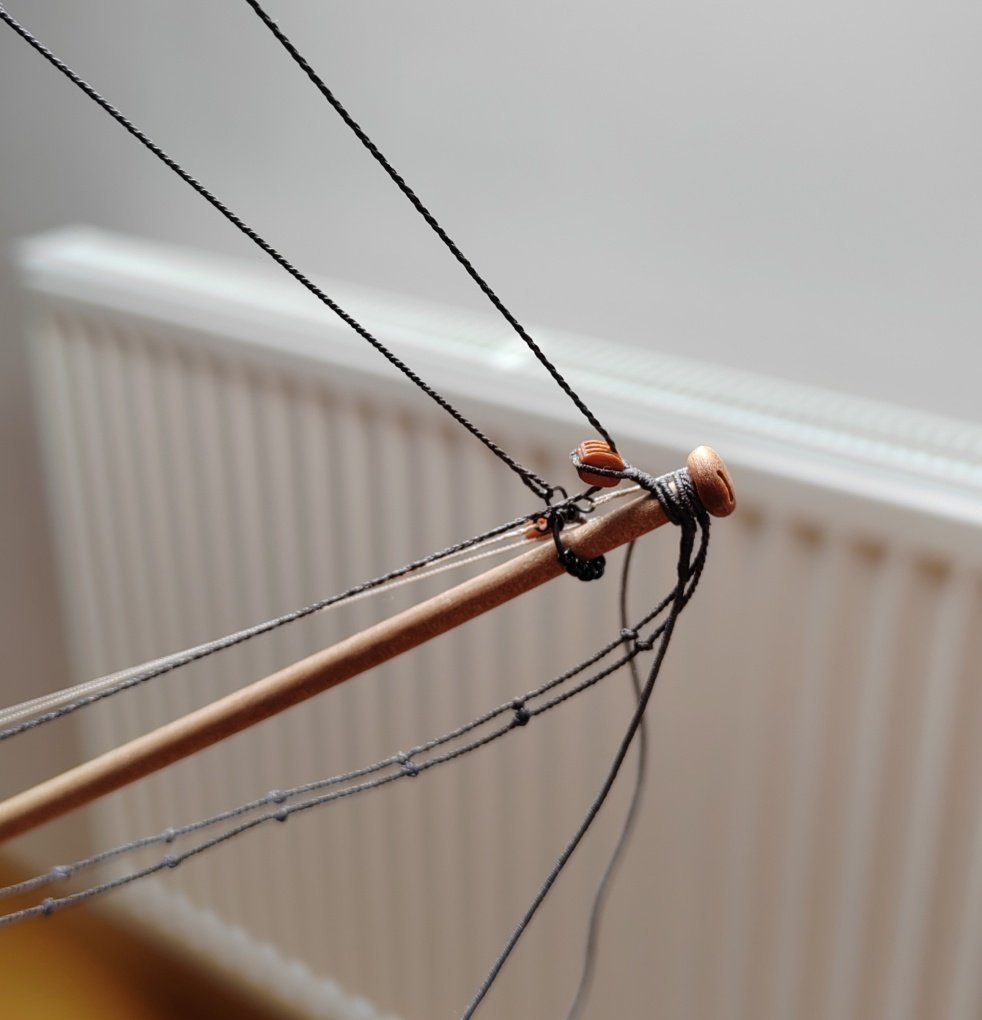

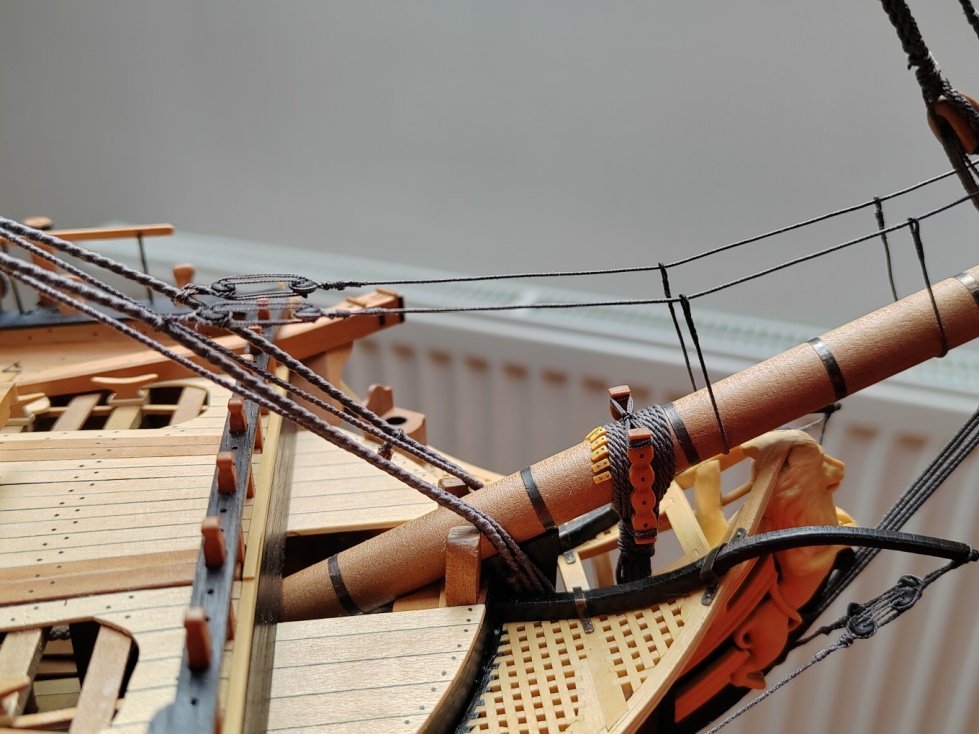

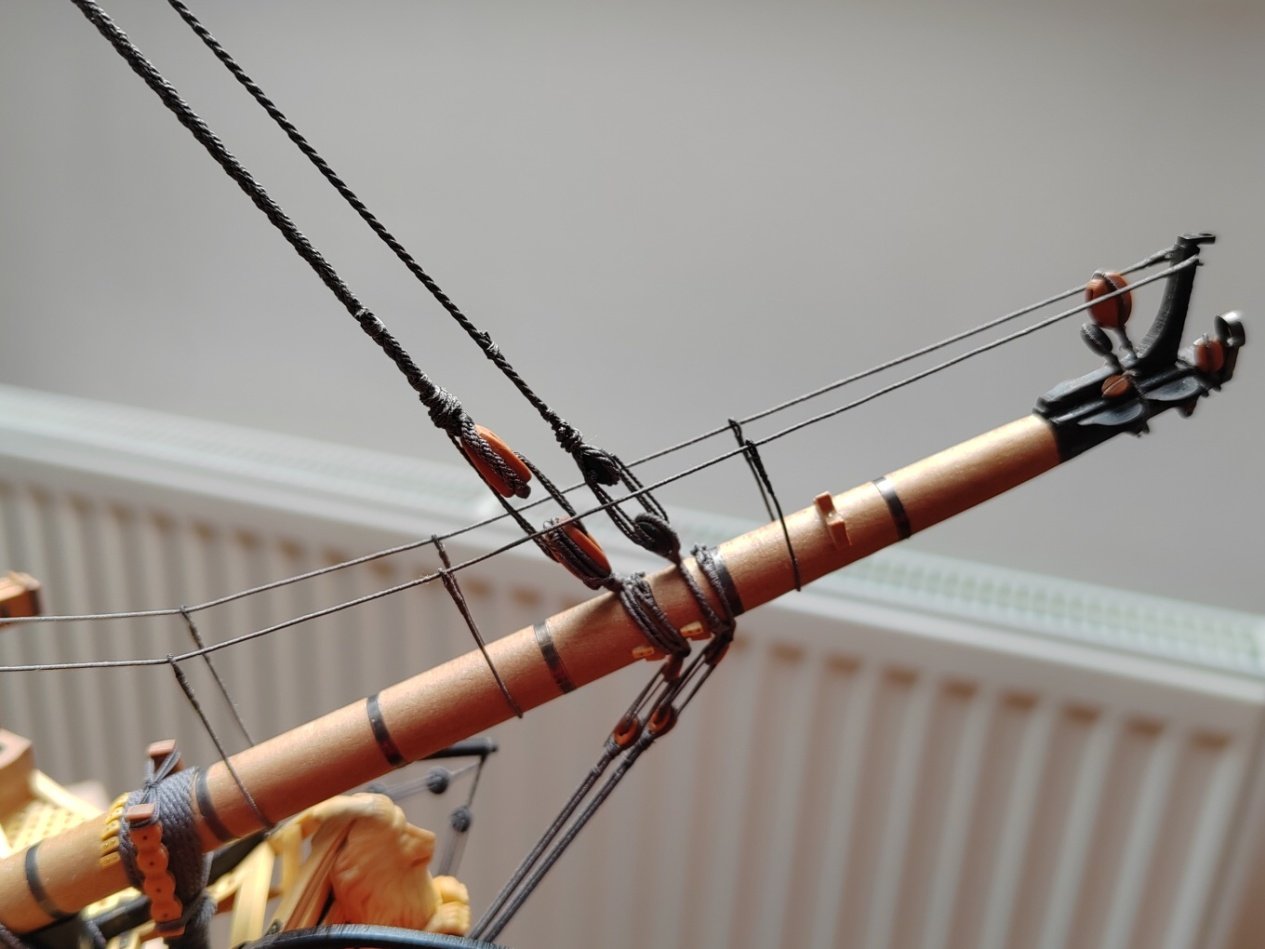

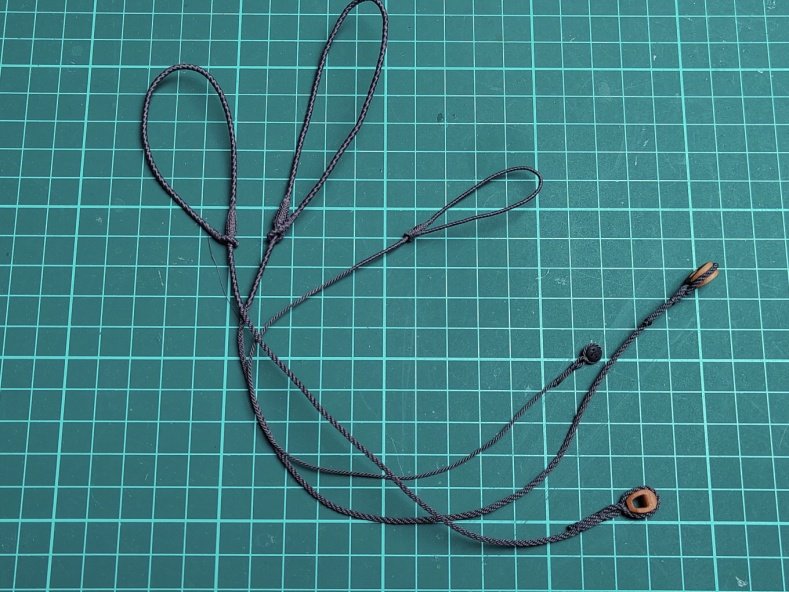

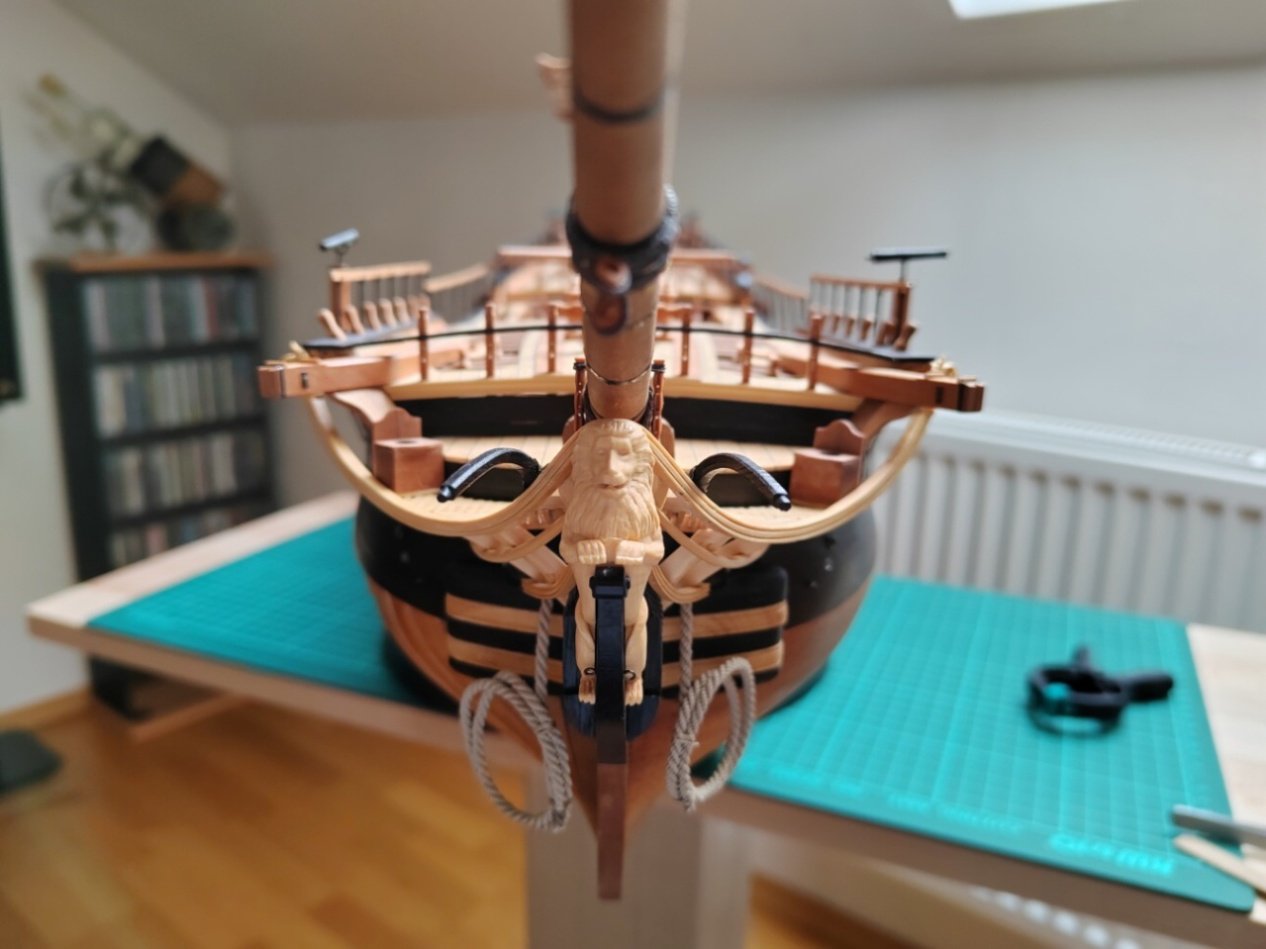

Thank you giampieroricci, I try to match your model at least a little . I continue with catharpins and bowsprit horses.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

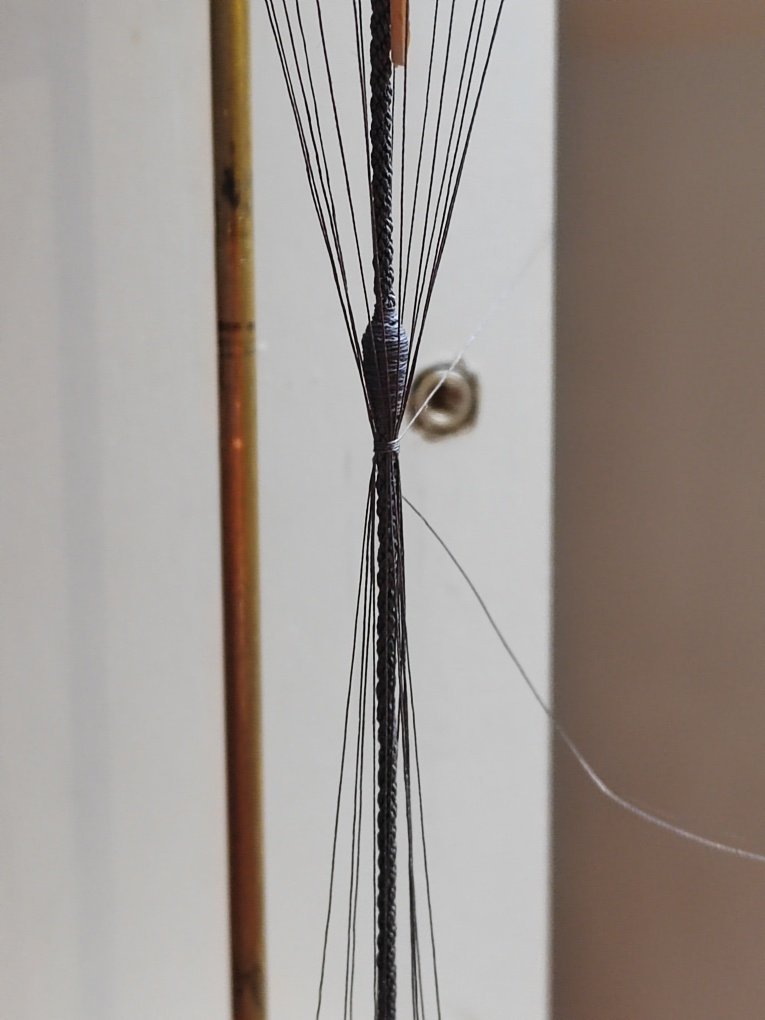

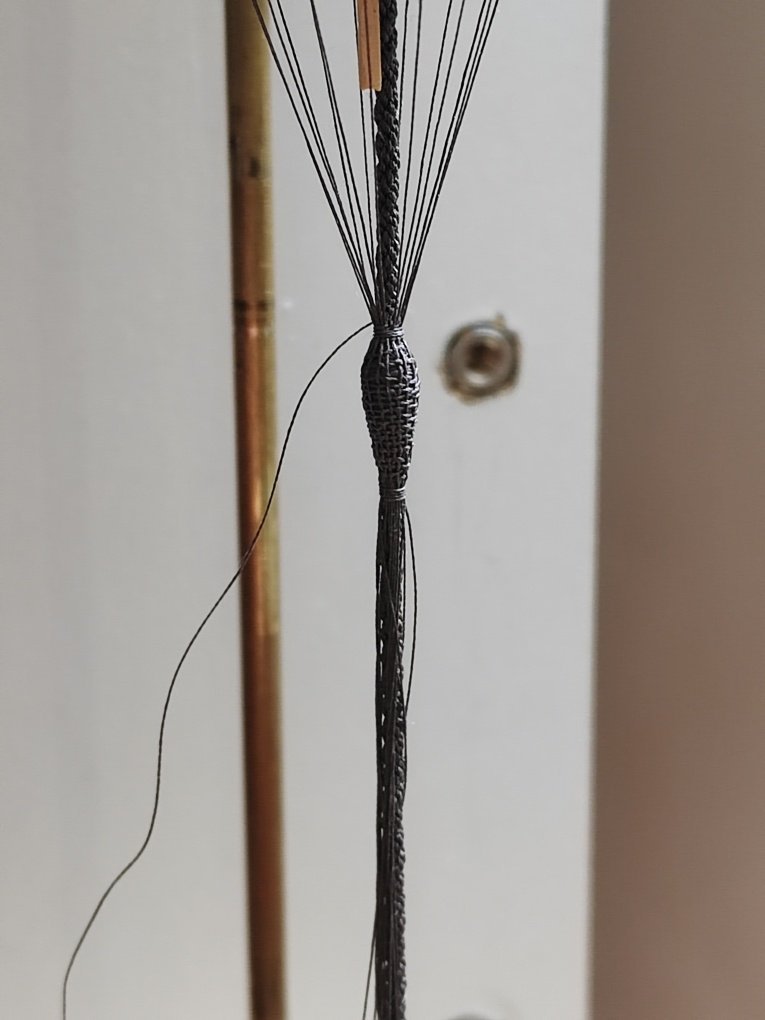

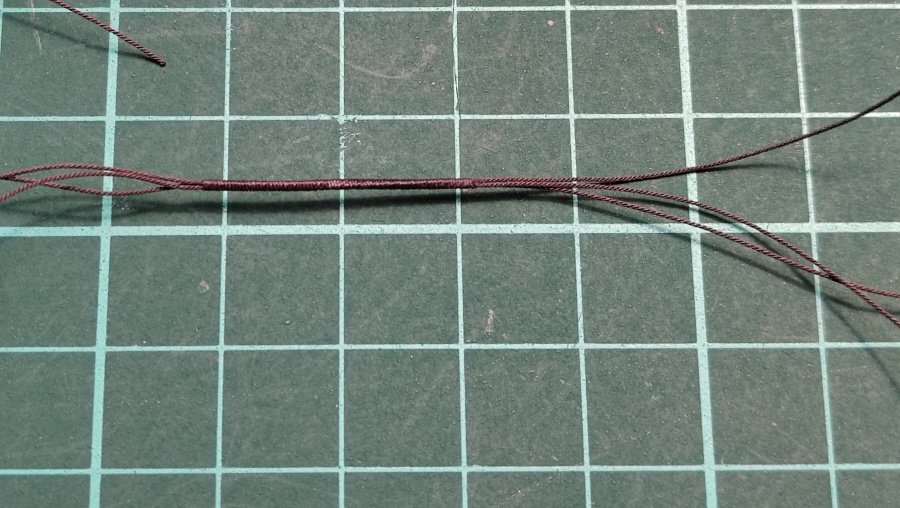

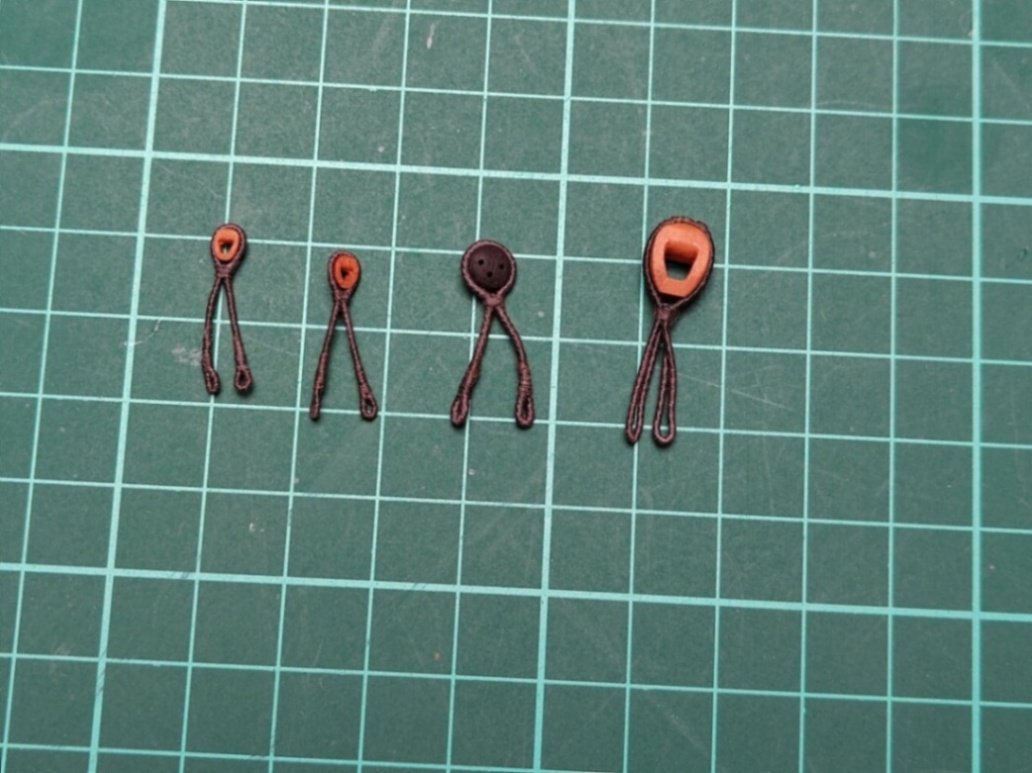

Thank you all for the very positive responses, they are embarrassing me a bit. To dvm27: It is not an exact copy of real splice. The ends of the rope are cut to a length of approx. 2 - 5 mm (depending on the size of the ceiling), the number of threads is then reduced by half on each side. Subsequently, the ends of the ropes are connected to each other and with the help of PVA and fingers, a connection is made. Finally, wrapping is done on the joint thus formed. So even if it's fake, the result doesn't look bad.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

I am very pleased with the positive reactions to the use of a CNC milling machine in the construction of the model, but to be honest, I myself would need a lot of lessons from more experienced people (at least as far as 3D computer modeling is concerned). To Vladimir_Wairoa: I use French Sajou threads, which are waxed (at least that's what the manufacturer says), so I don't have so many problems with "hair" on the ropes. I continue making pendants and lower mast shrouds.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

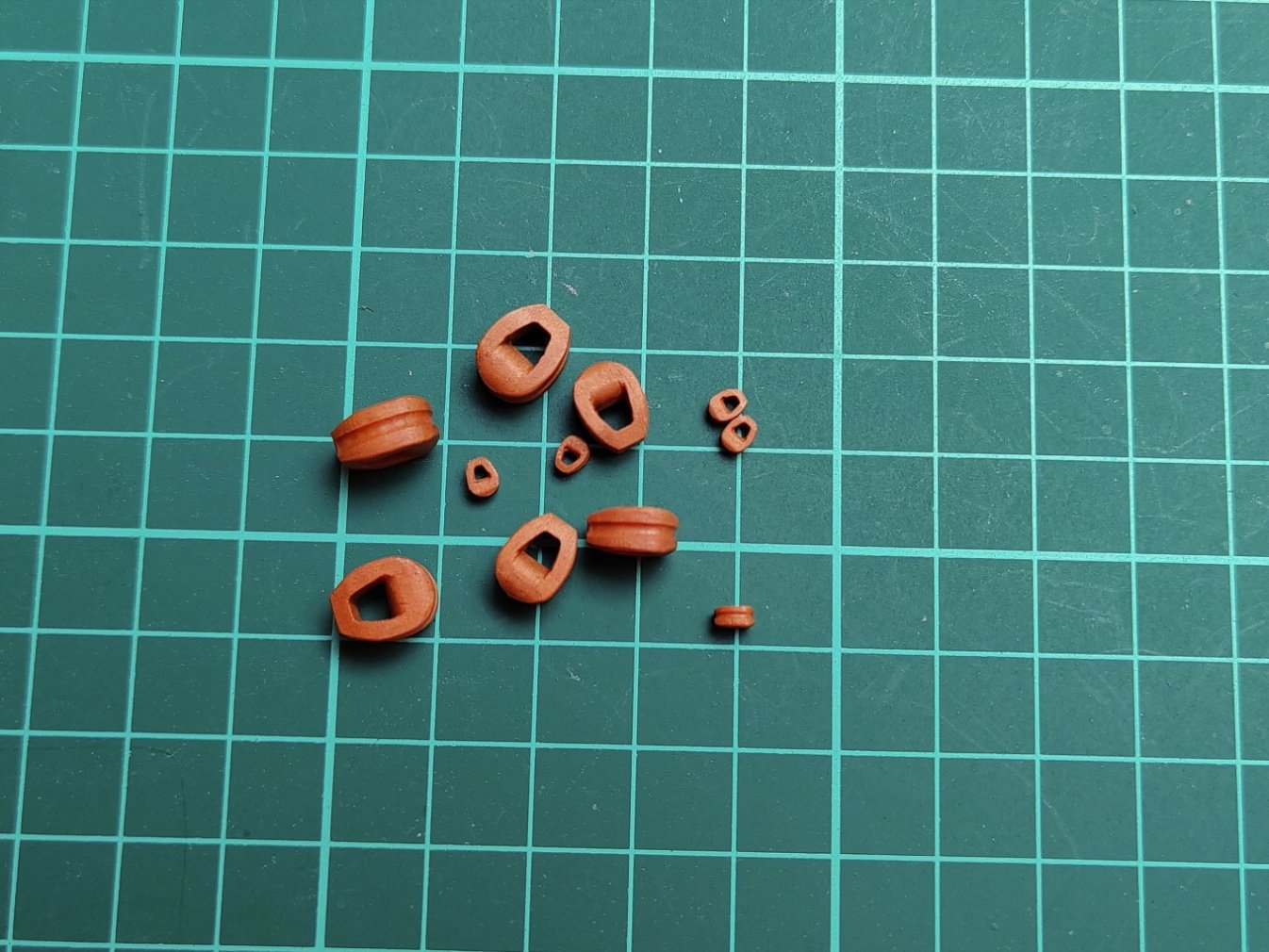

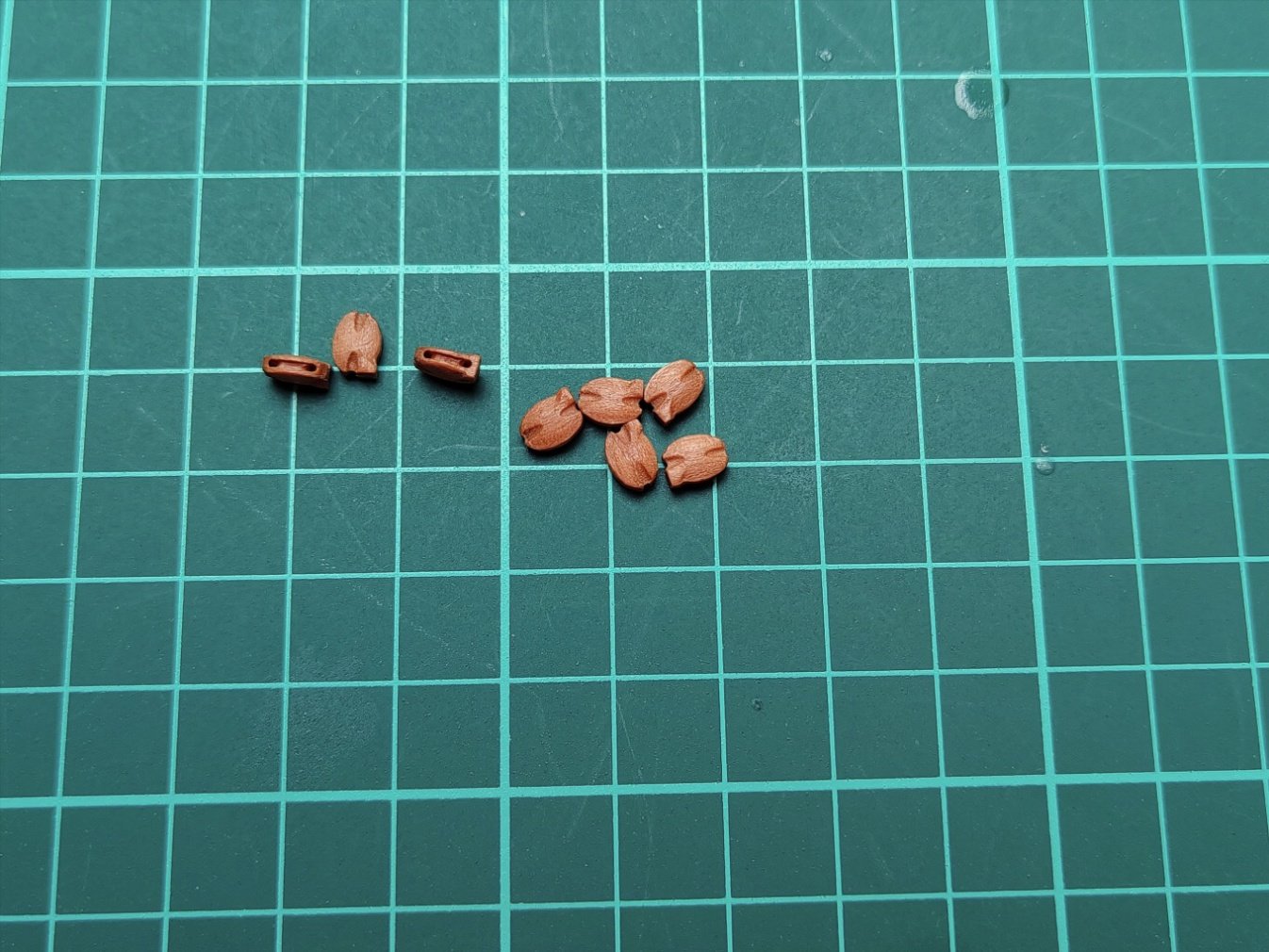

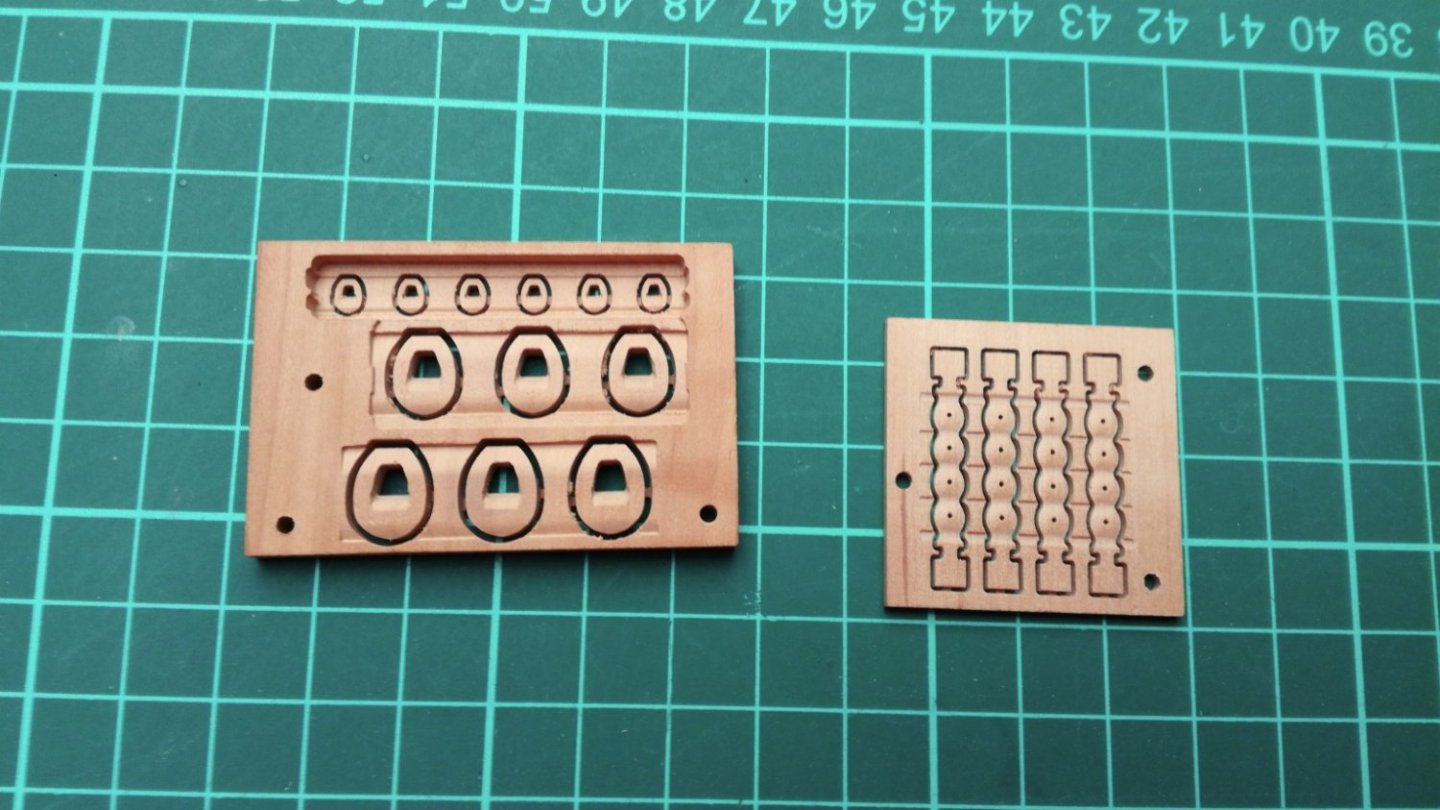

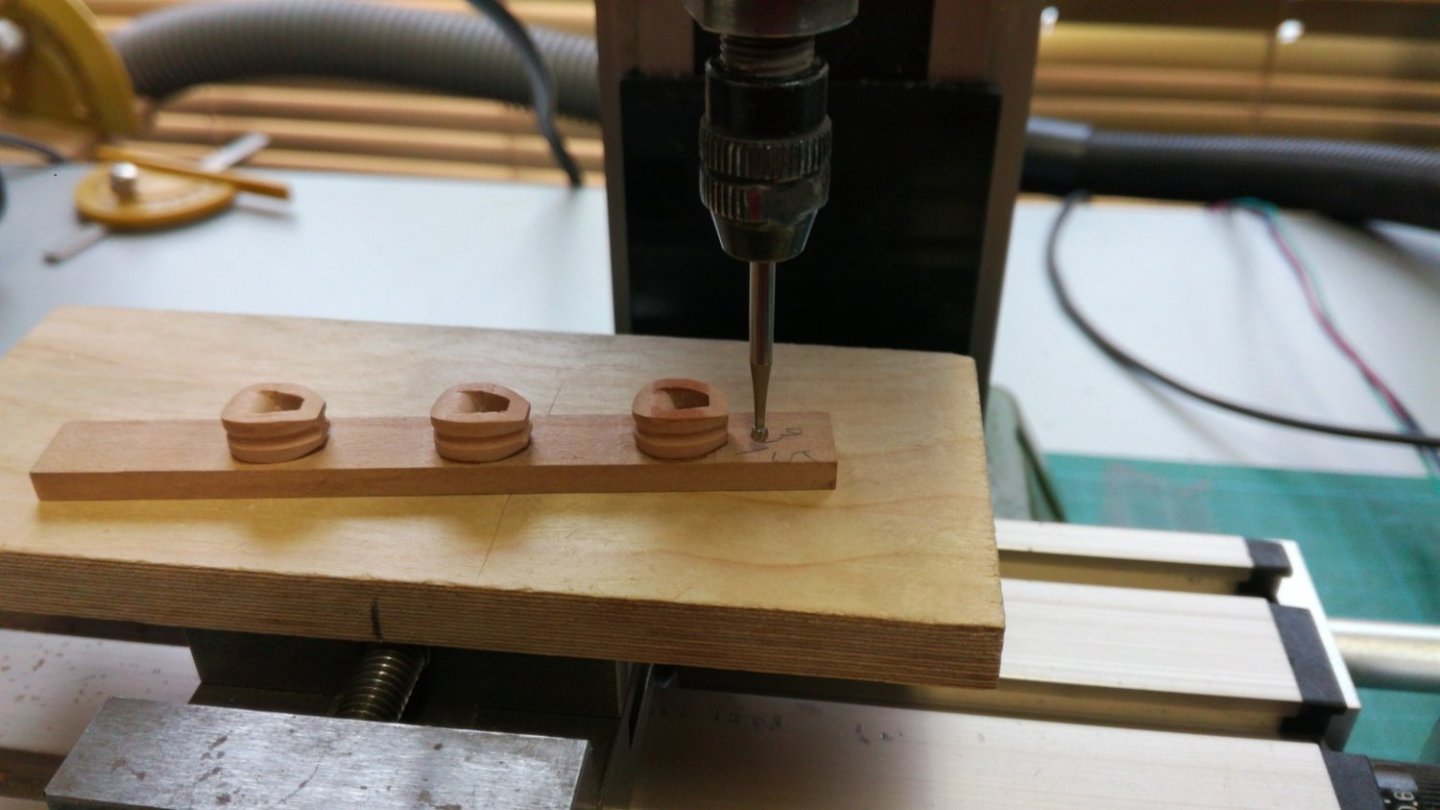

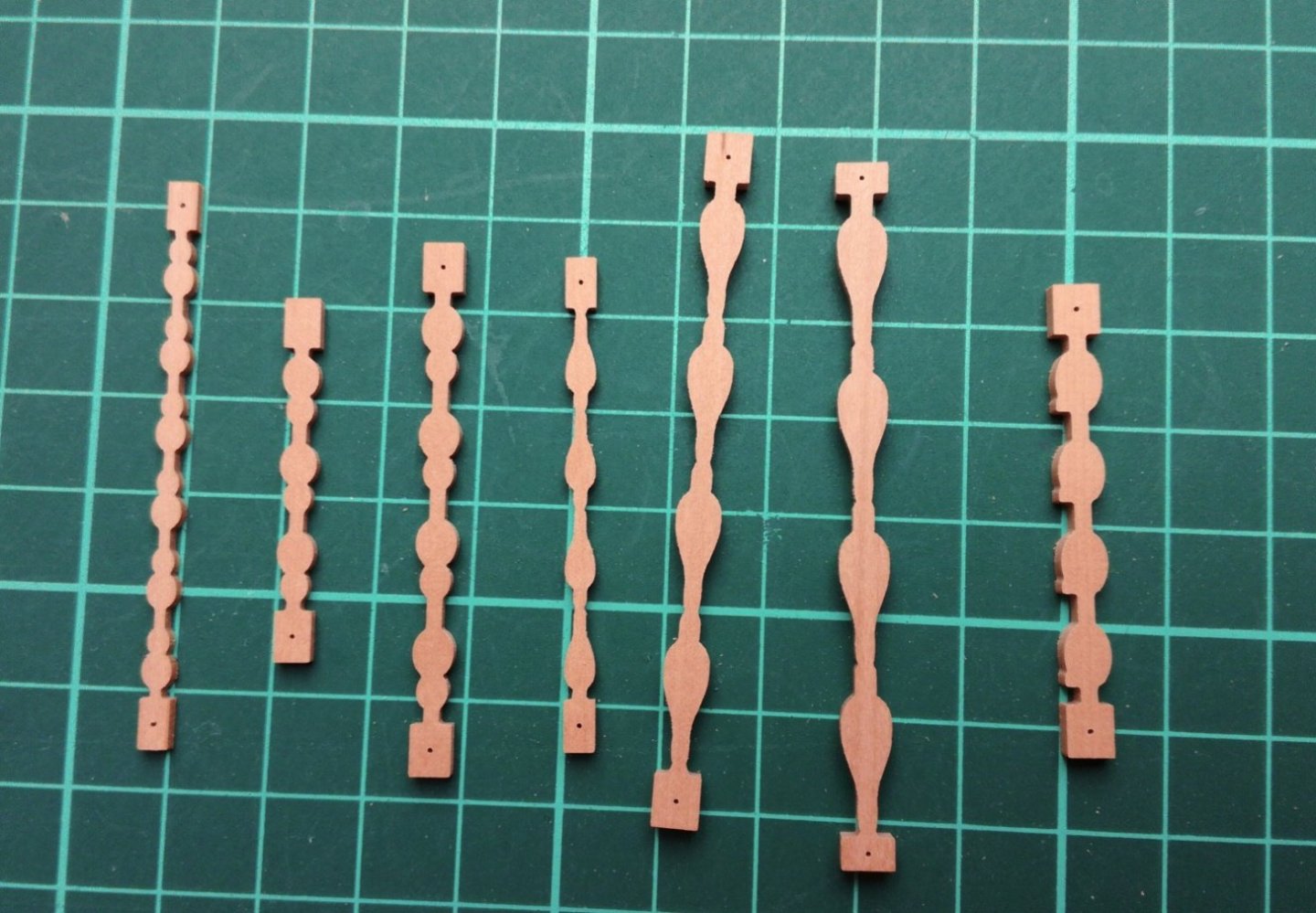

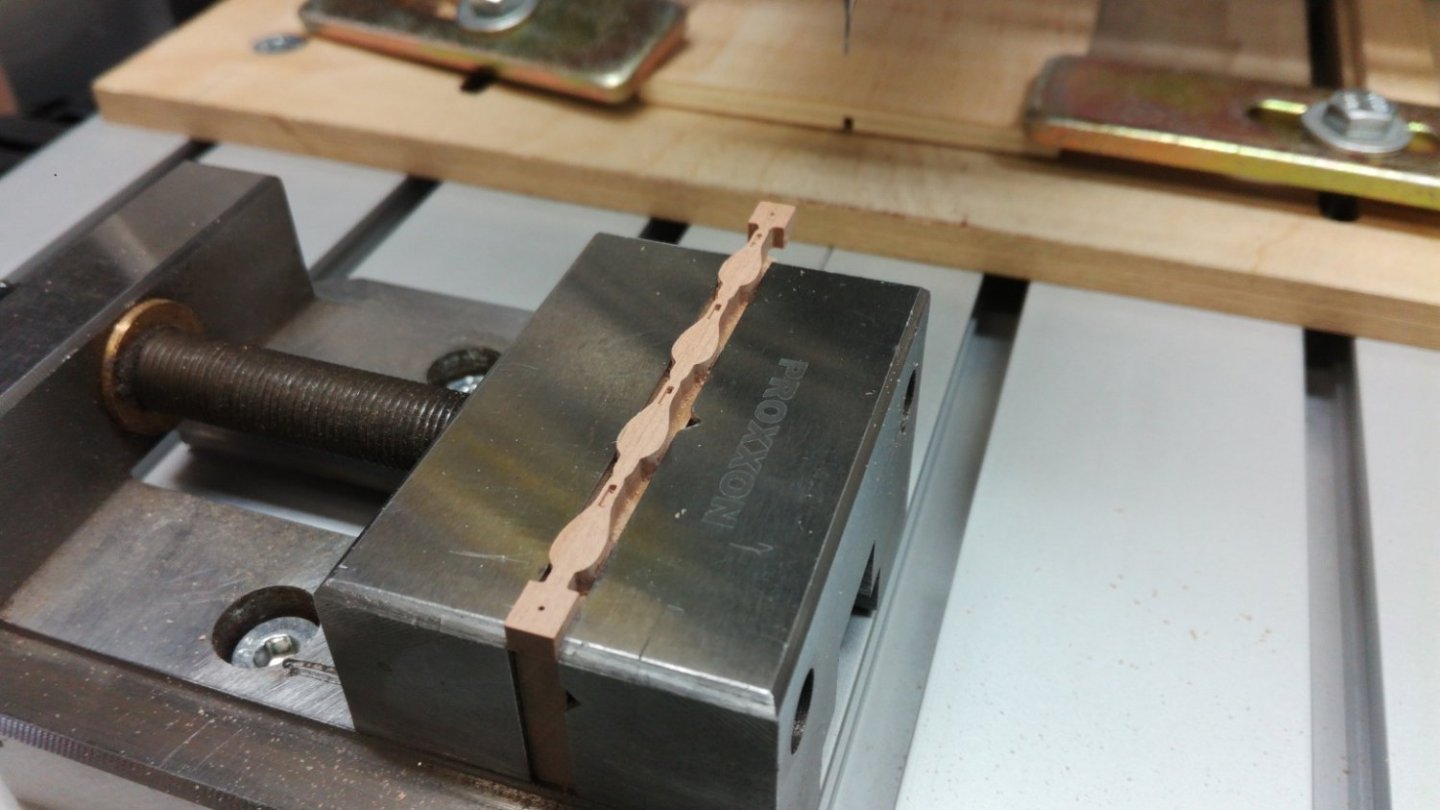

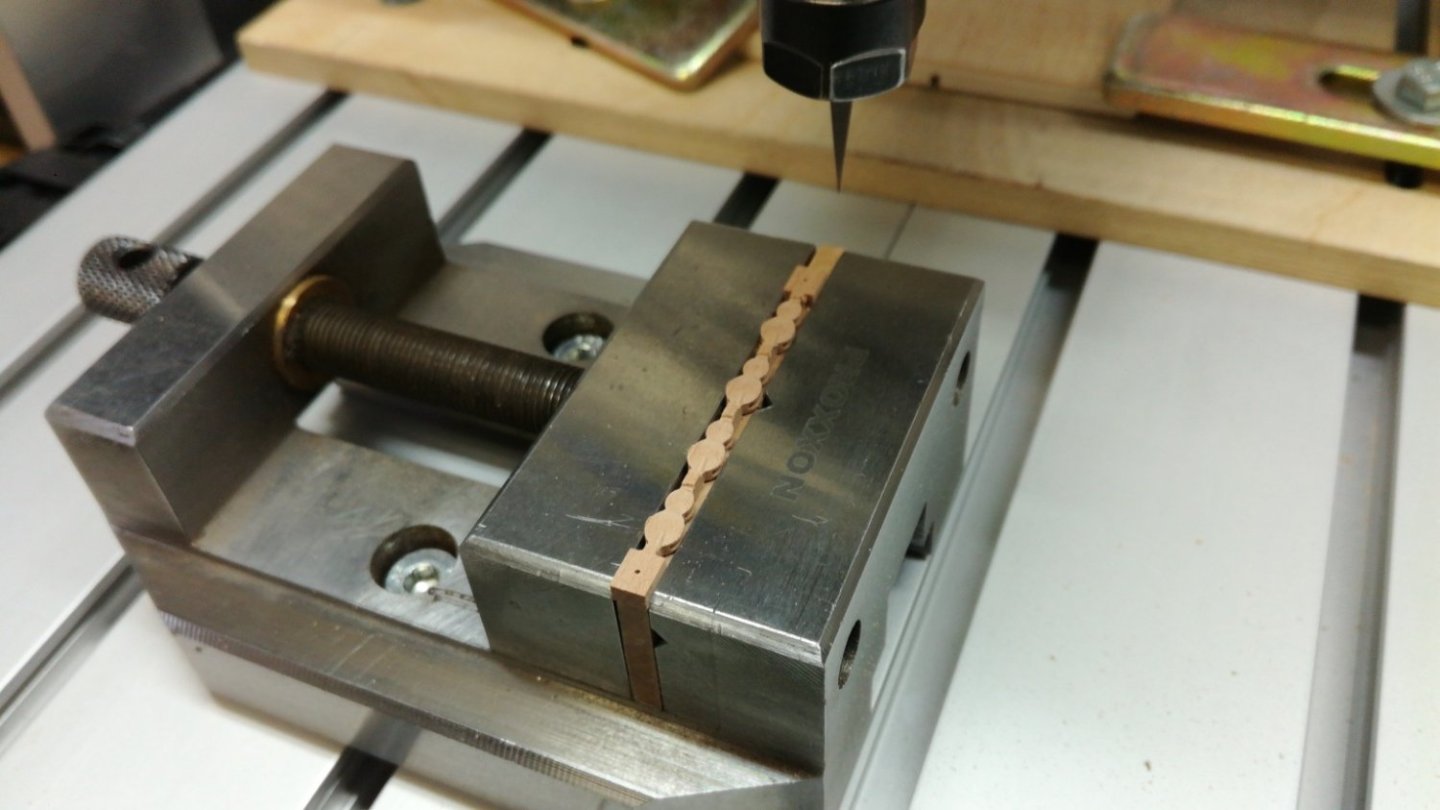

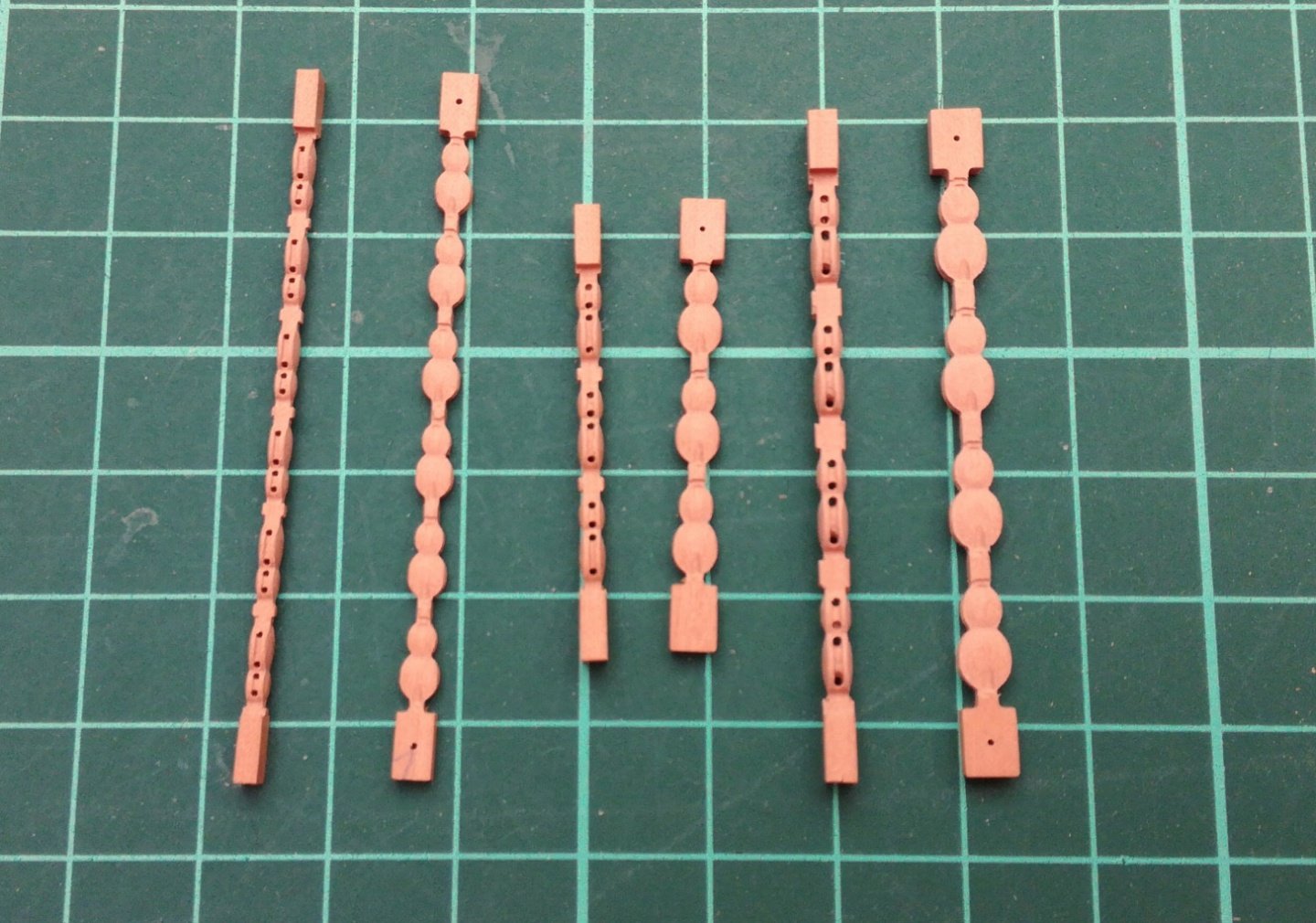

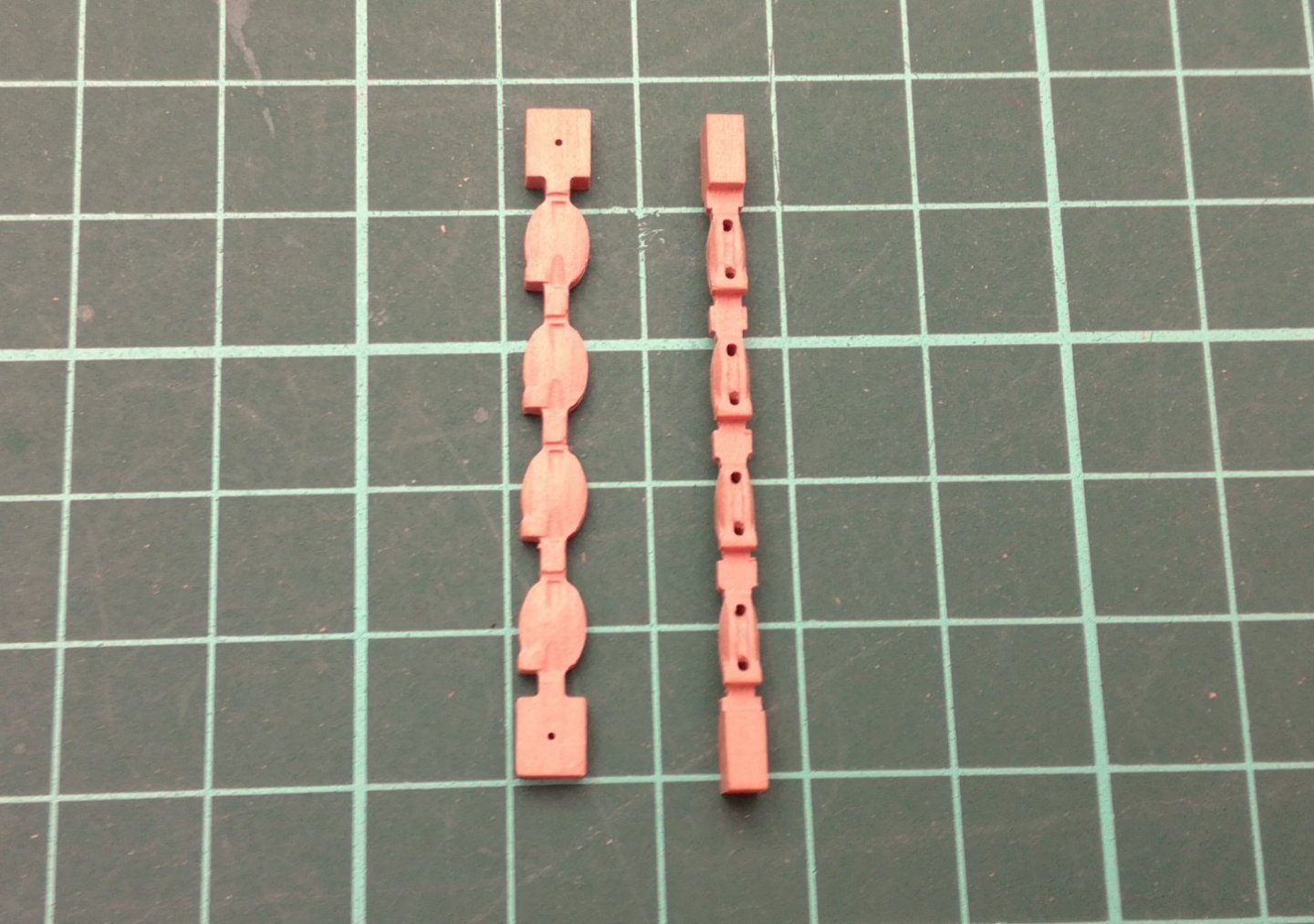

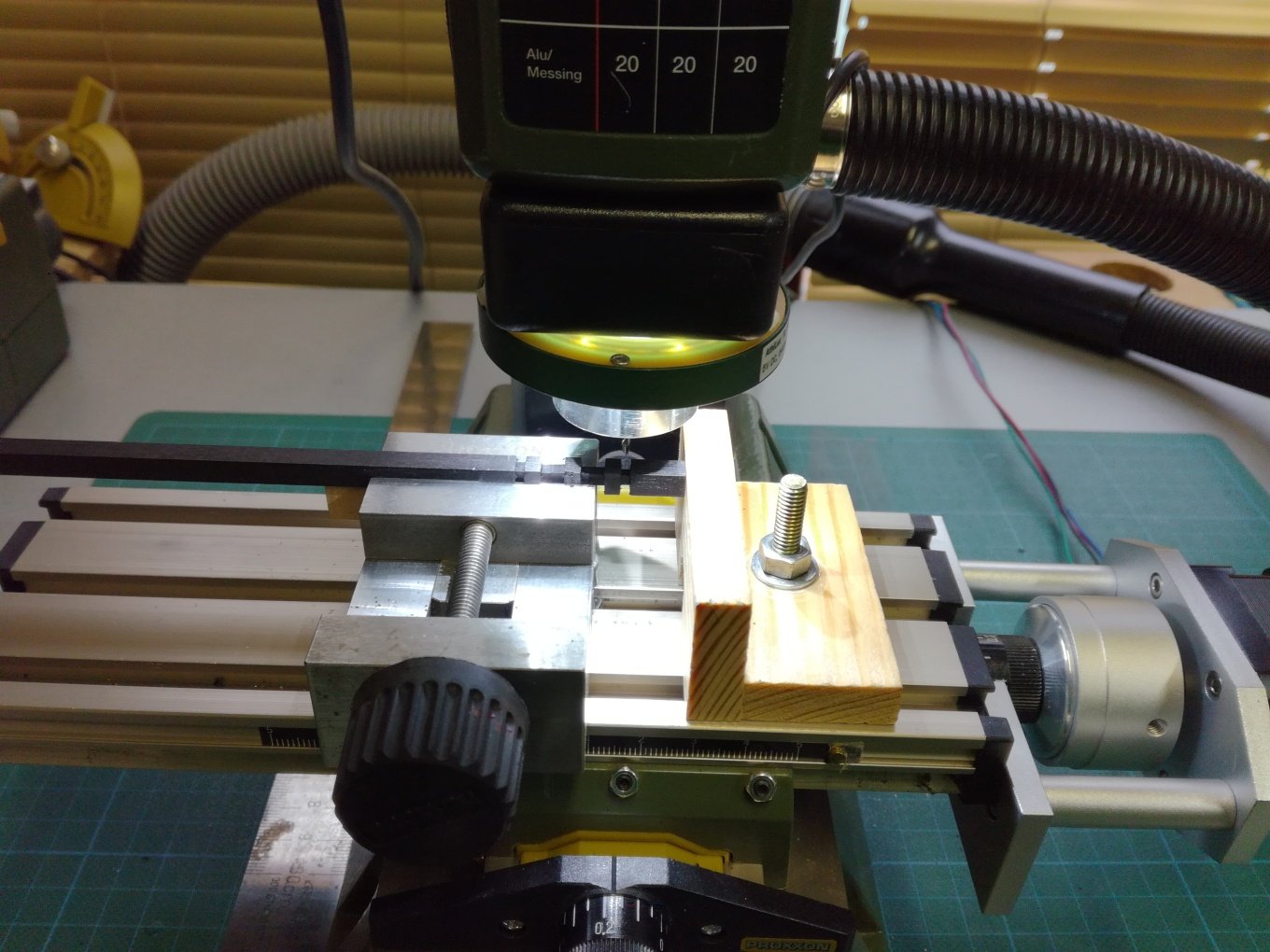

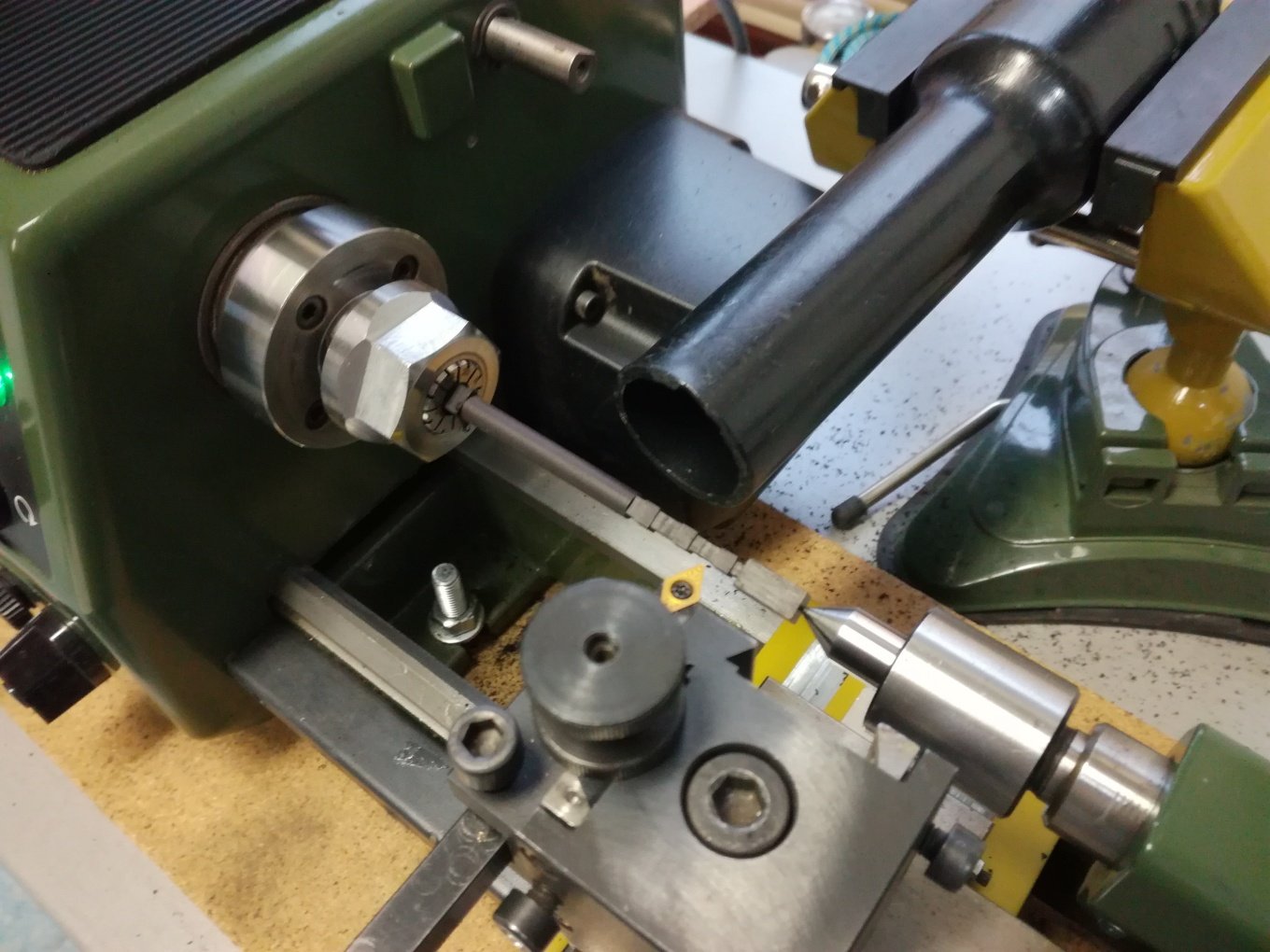

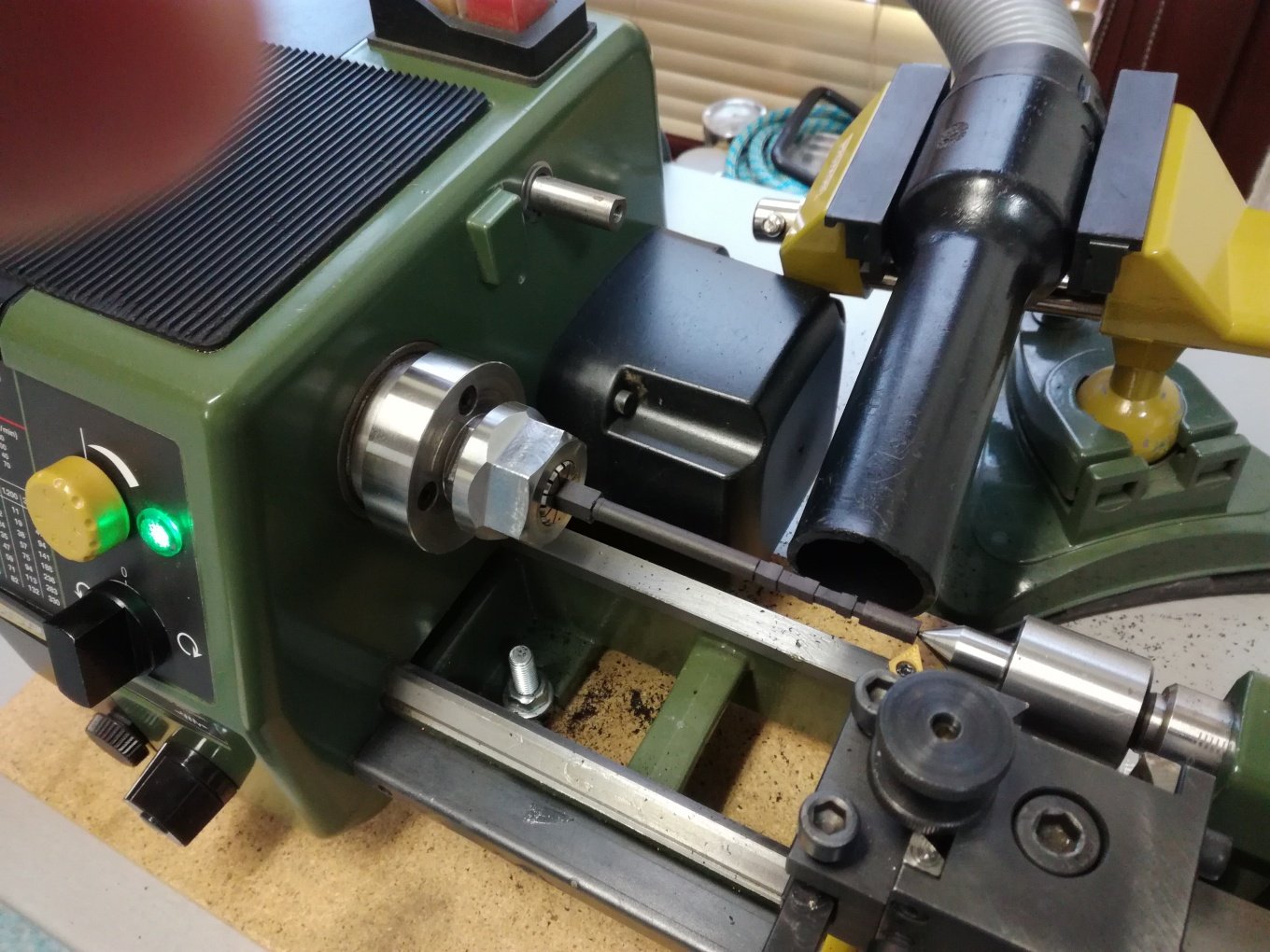

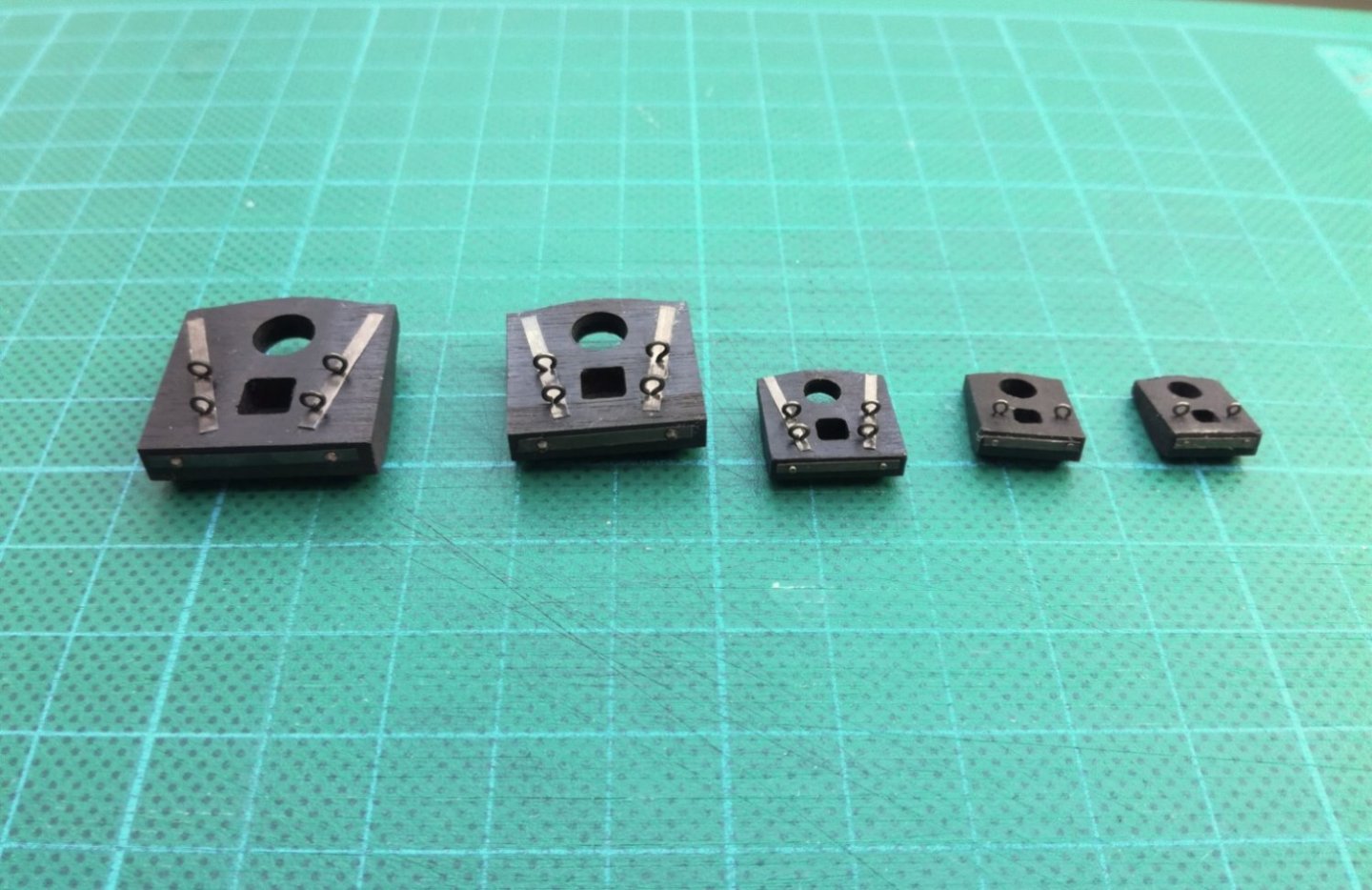

Thank you guys for very nice comments. Preparing to make these blocks was quite a challenge for me. But the result exceeded all my expectations. Uncritically, I have to admit that I myself am very satisfied with the result.. To Hsae - The blocks are made with a CNC milling machine, not from Proxxon, but a commonly available Chinese milling machine. The material for the blocks is pear. The construction of the model moved to the next stage - rigging. I start by attaching the bowsprit.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

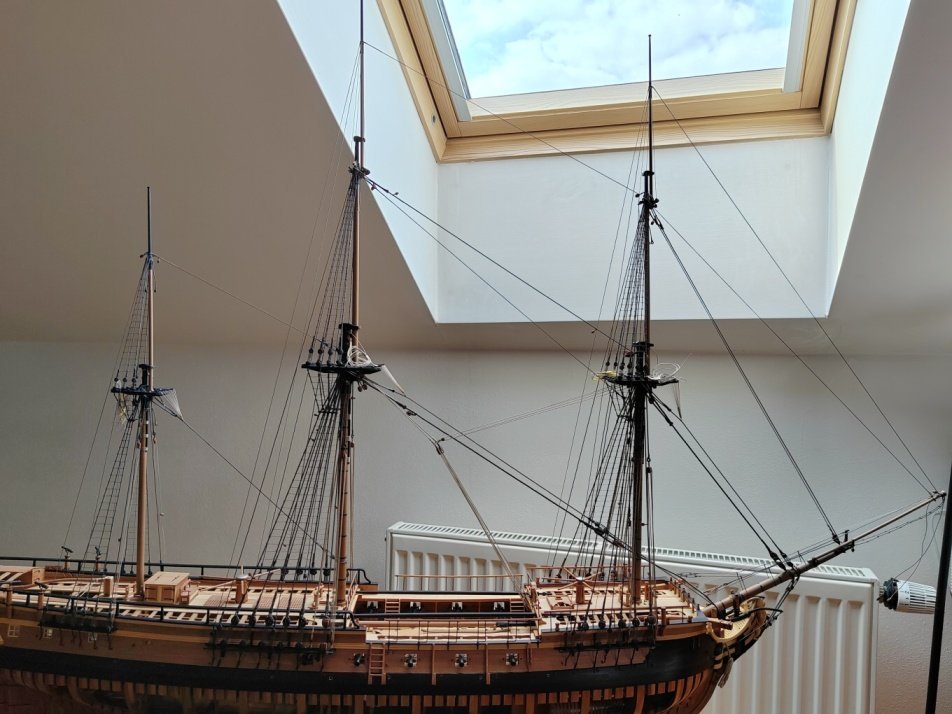

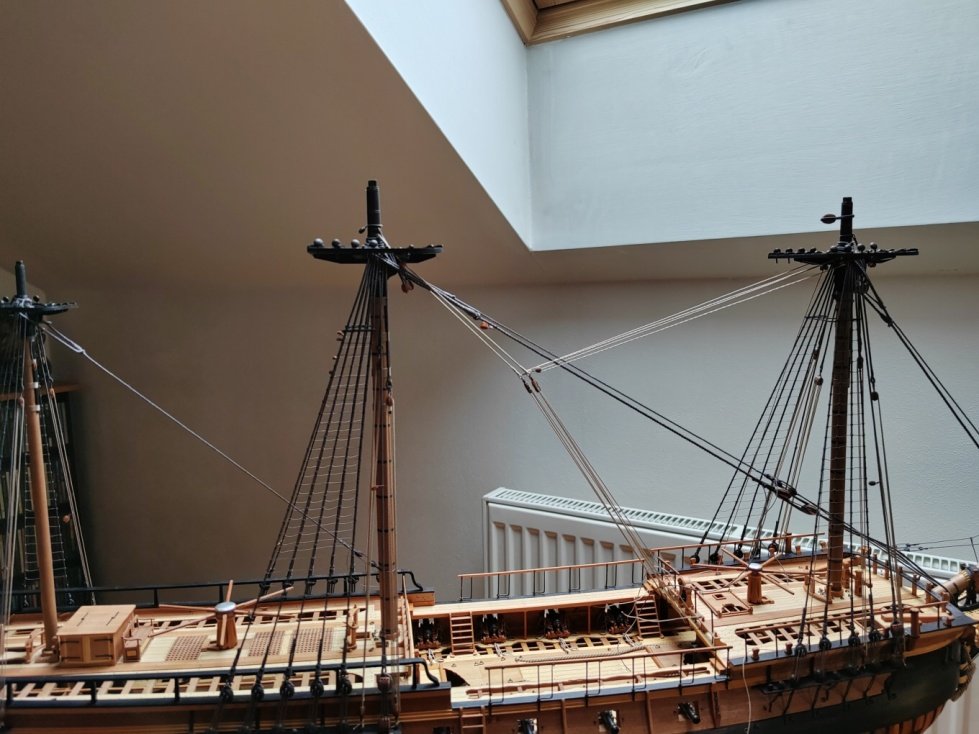

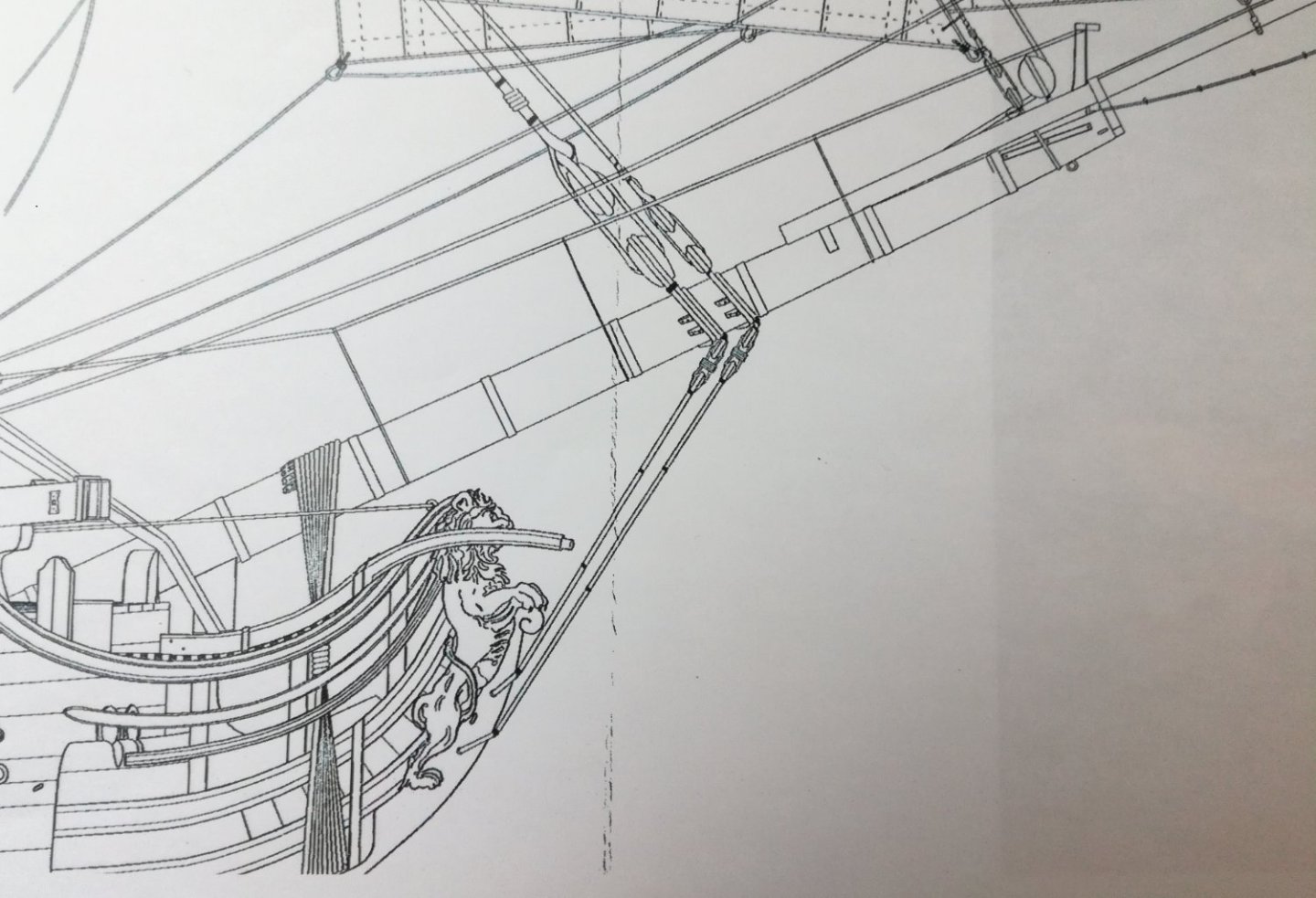

To No Idea: As garyshipwrighter partially answered you, the small blocks are intended as a stop for gammoning and collars (fore stay, fore preventer stay, inner and outer bobstay) - see enclosed picture. I finished all the masts and tried installing them on the model.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

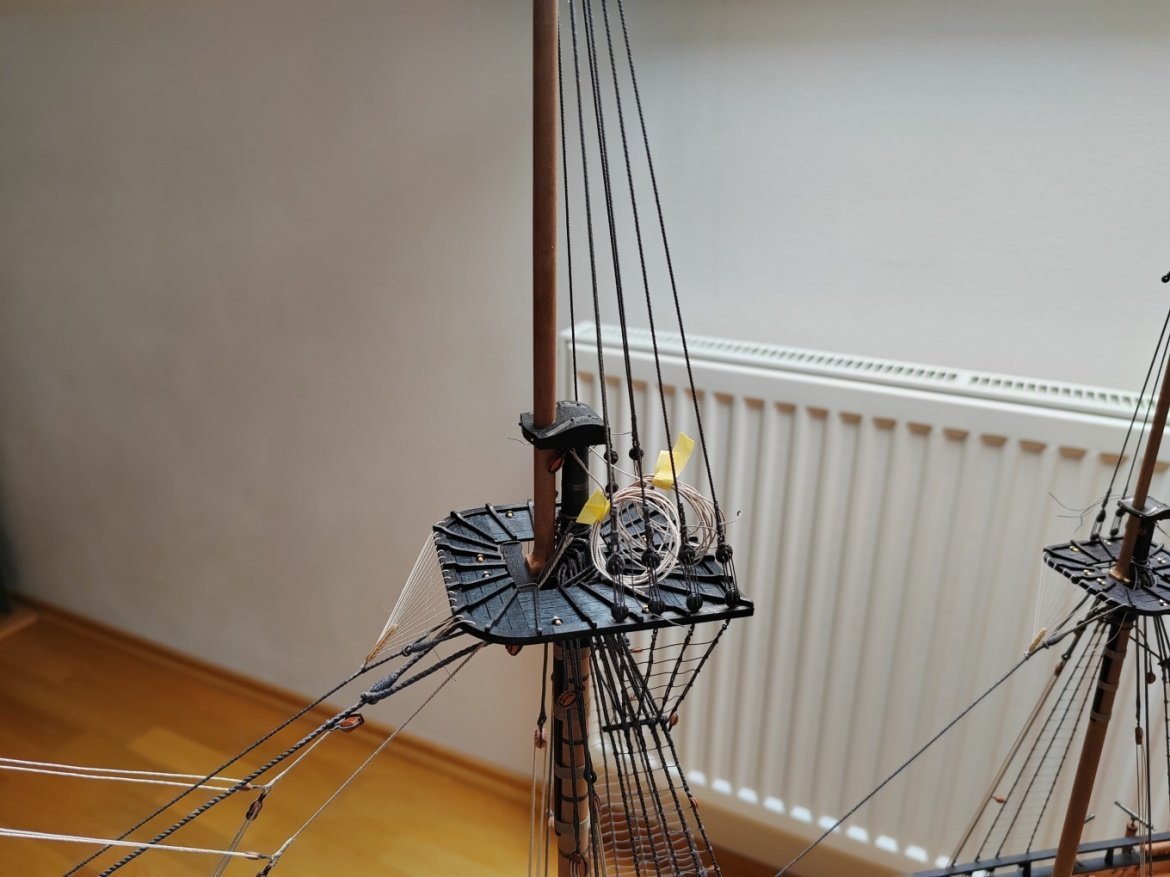

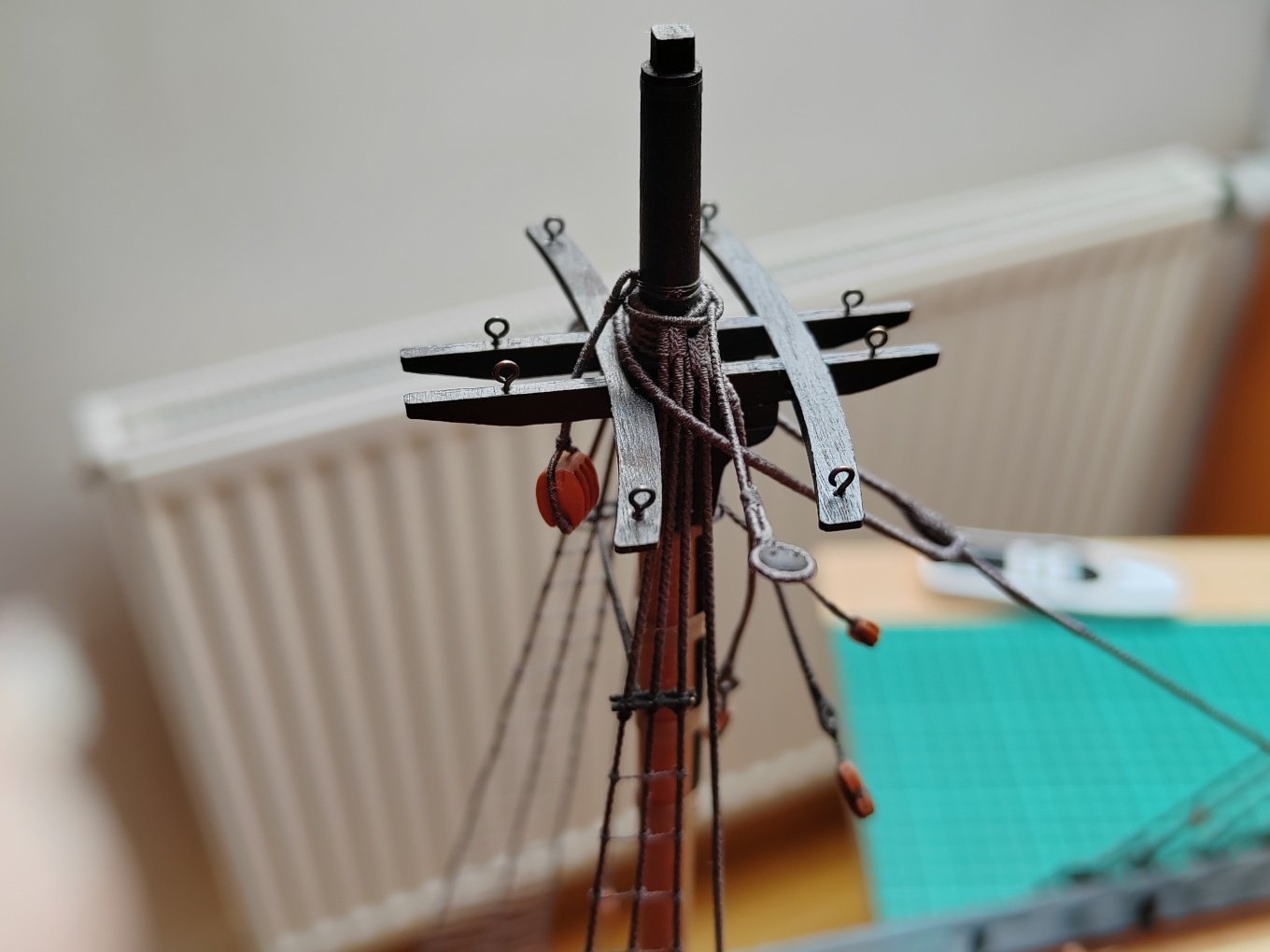

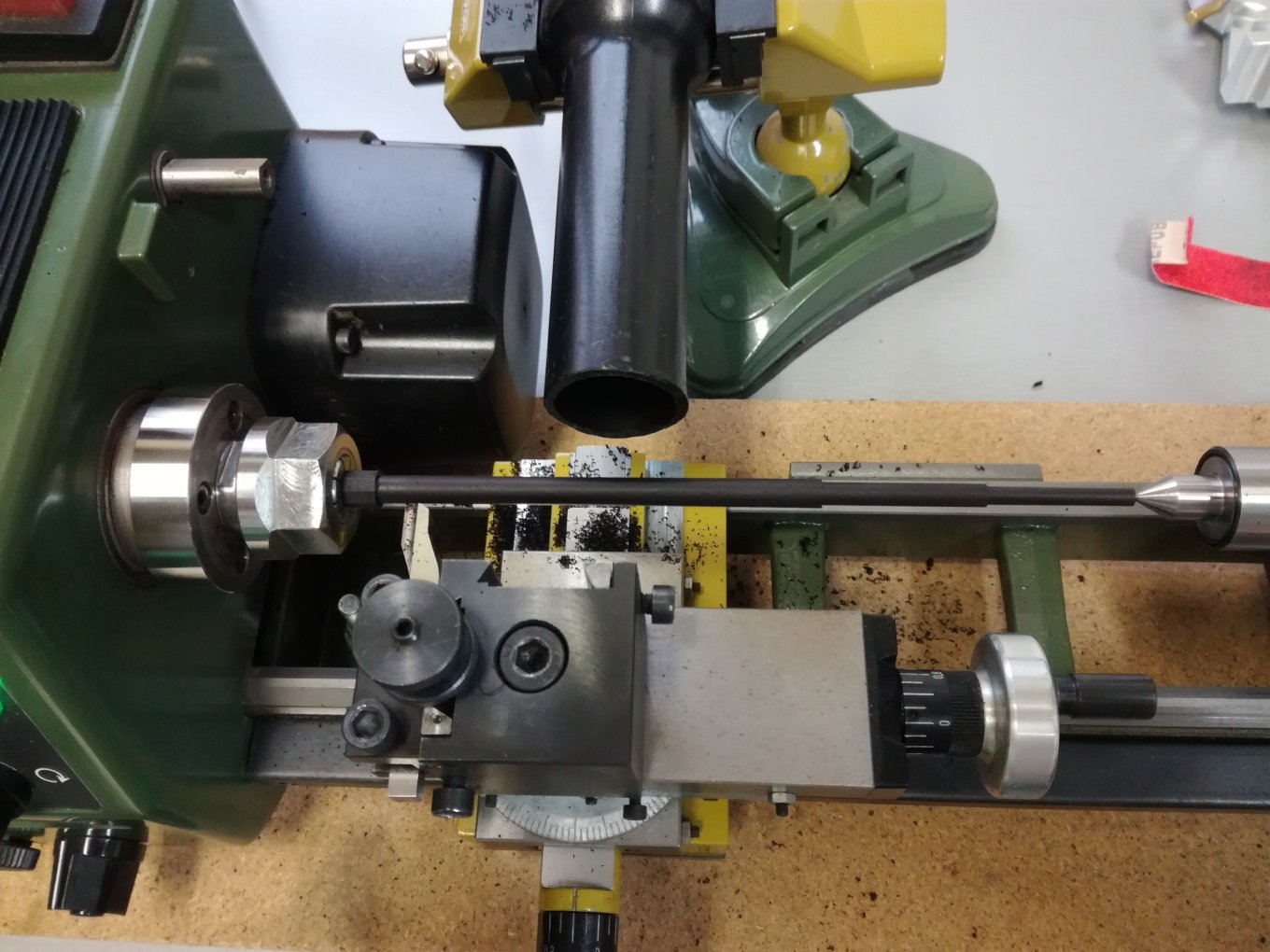

To Hubac´s Historian: Chain segments are soldered with silver solder paste. Using solder paste instead of solid solder has the advantage that it is possible to dispense a really minimal amount of solder onto the soldered joint. In places where a really minimal amount is needed, it helps to first heat the soldering parts with a flame and only then dose the solder paste. The solder spreads when it touches a heated area, which makes dosing easier. To Richard Dunn: I am going to rig my model, but only rigging without sails. To Daniel.b: I only have one stepper motor (x-axis) attached to the MF70, so it doesn't work like a real CNC machine. I only use it for x-axis scrolling (on/off switch). For these purposes, I have made a simple driver to control the stepper motor (i.e. without connecting to a PC). Topmast deadeyes and futtock-plates. Tops are completed.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.