marsalv

NRG Member-

Posts

614 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by marsalv

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

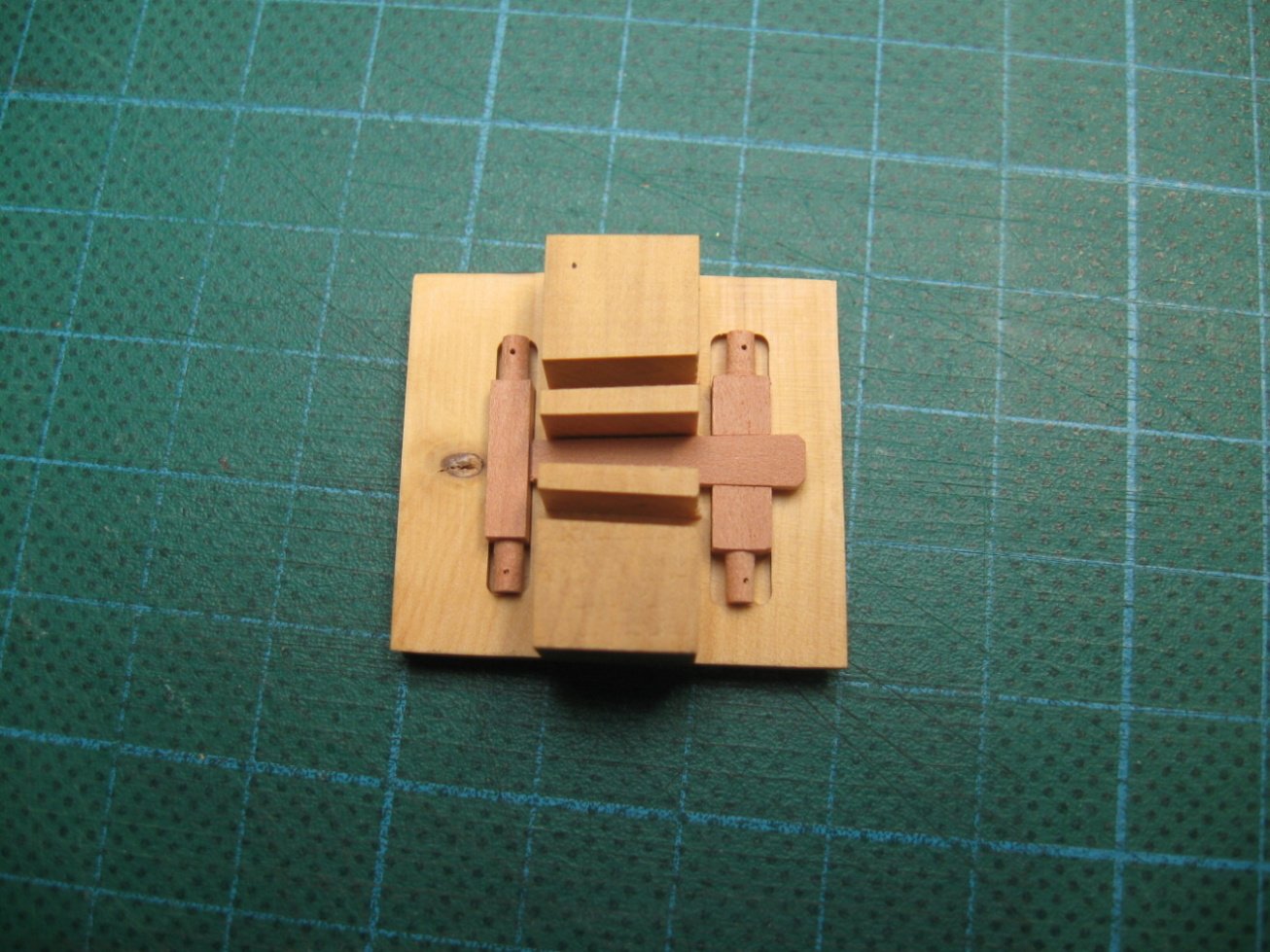

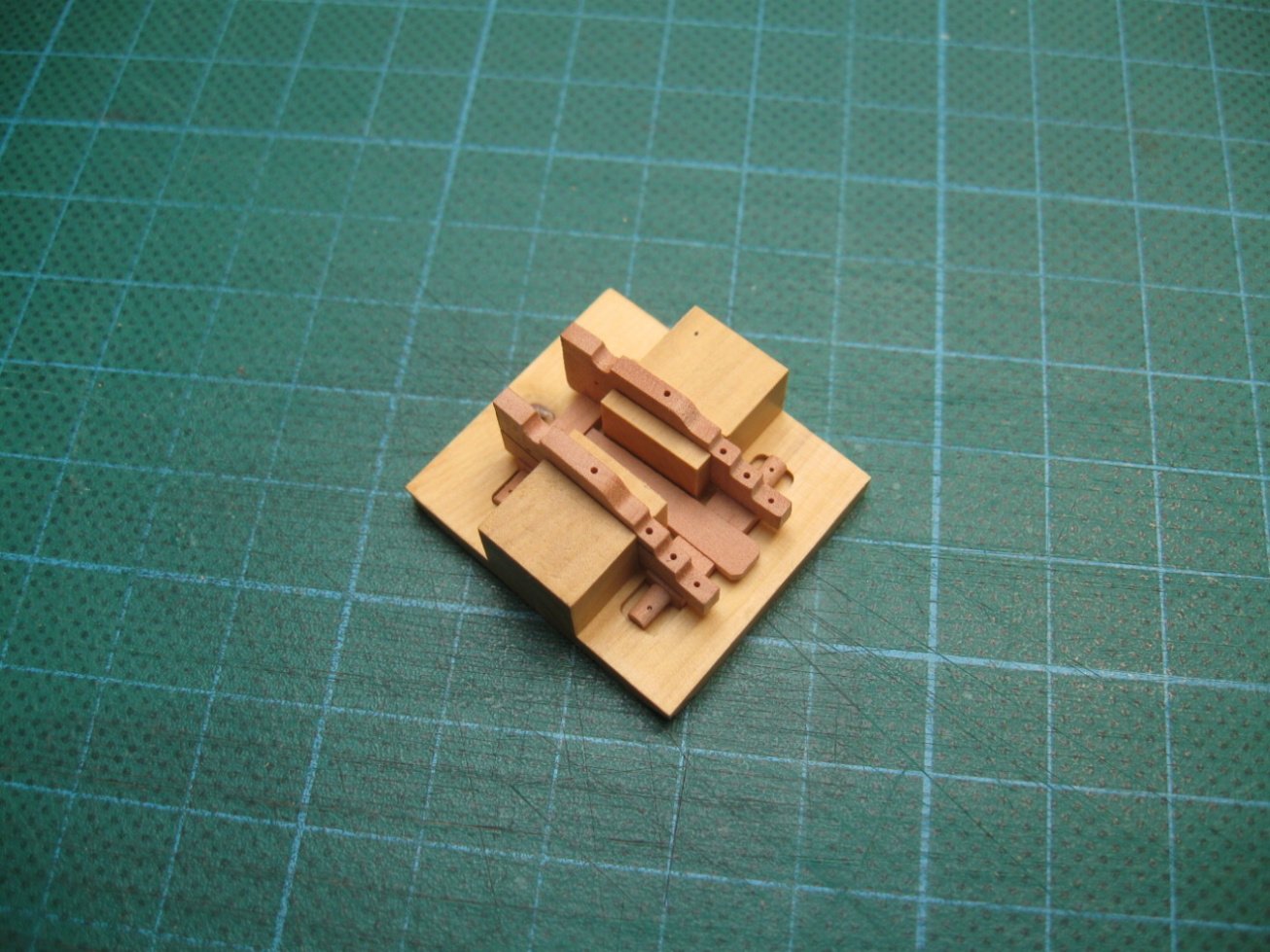

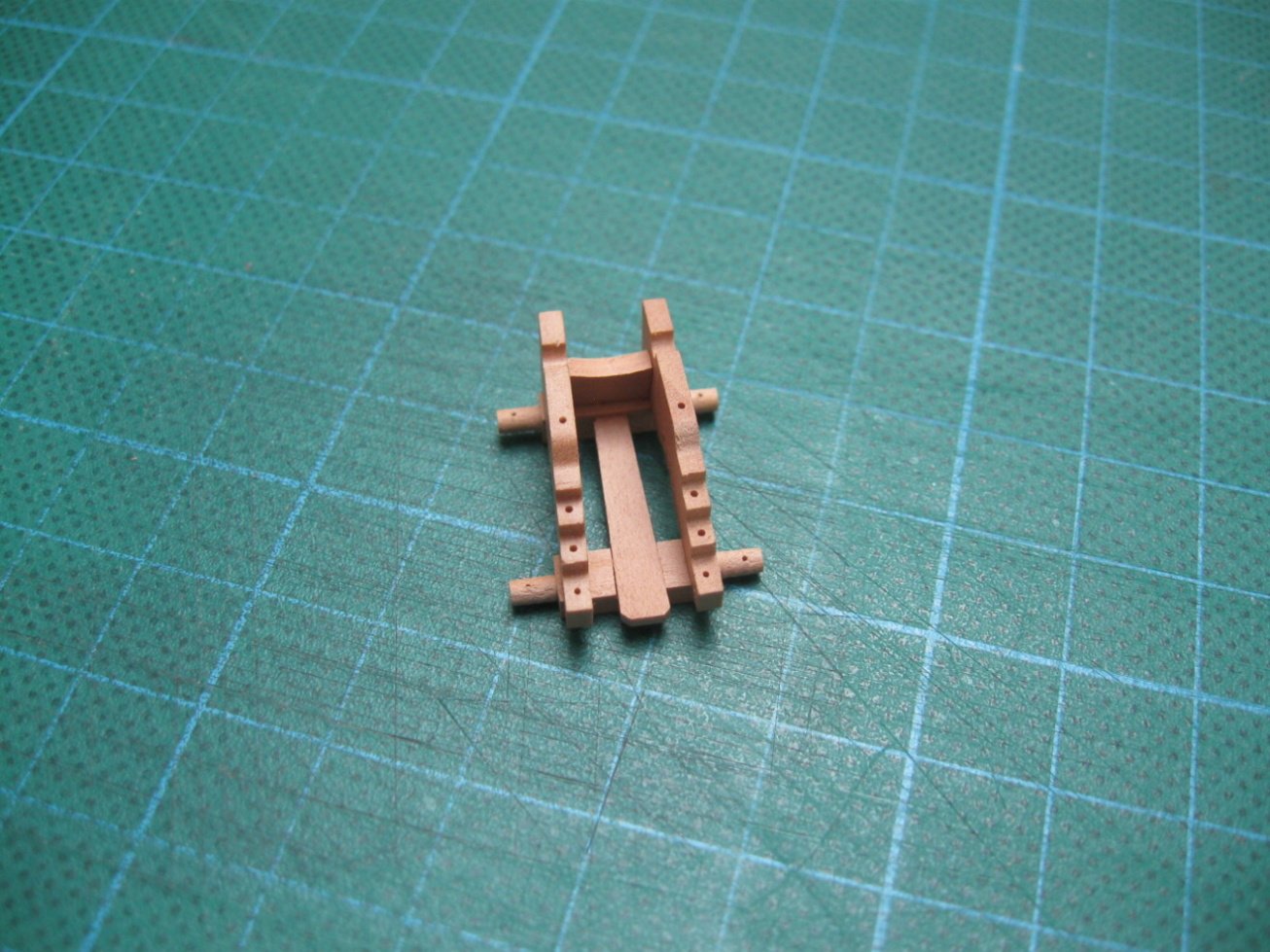

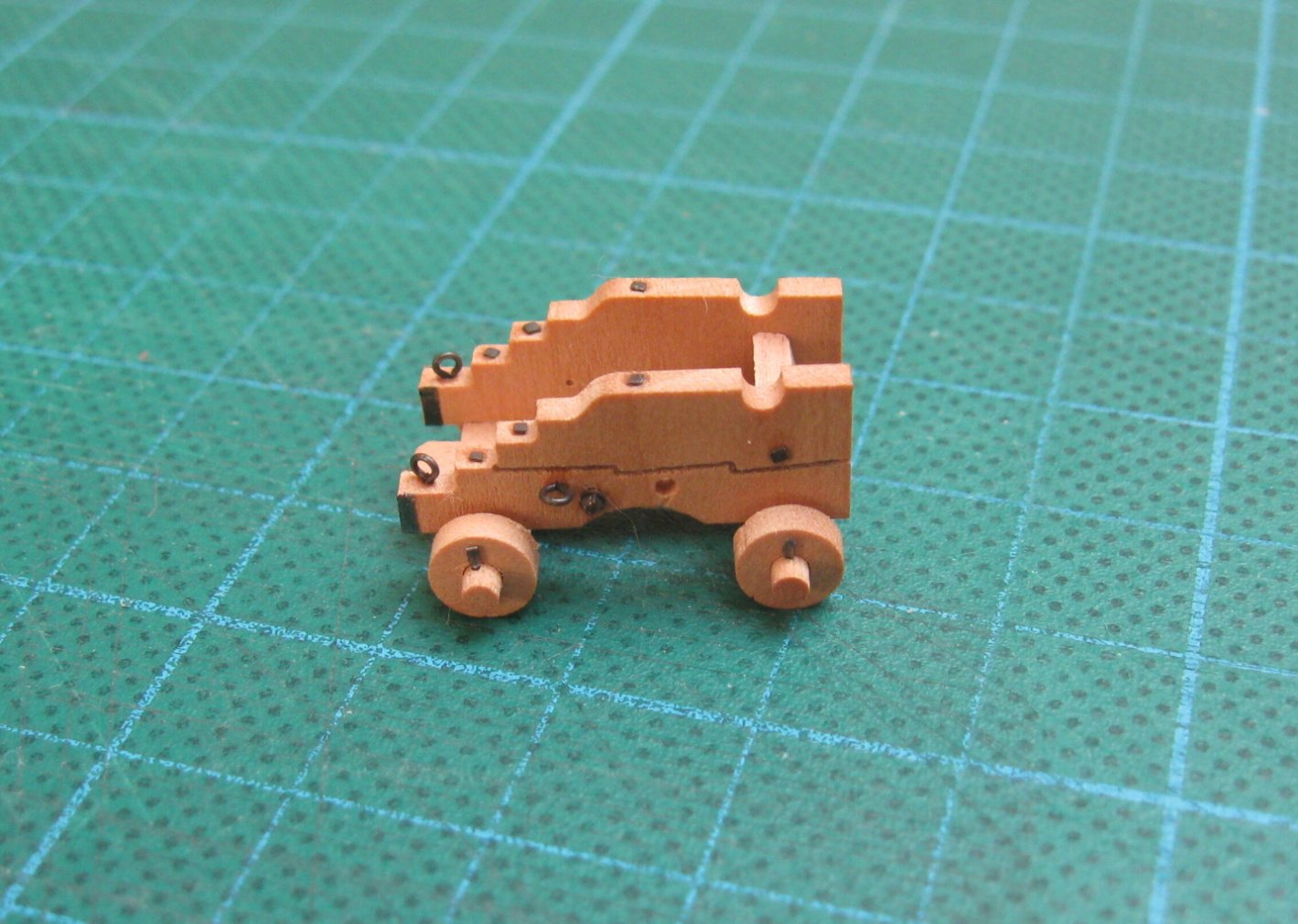

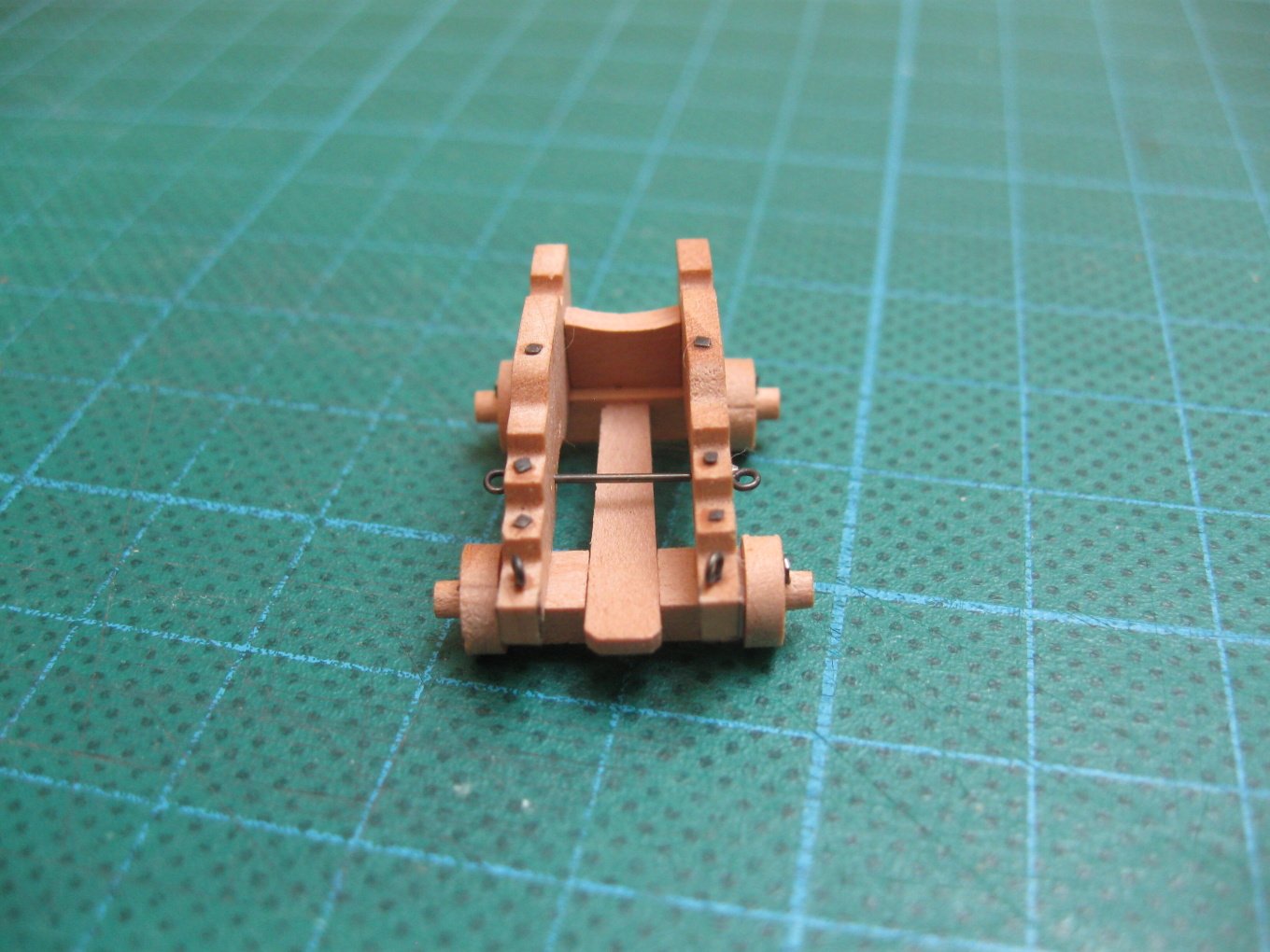

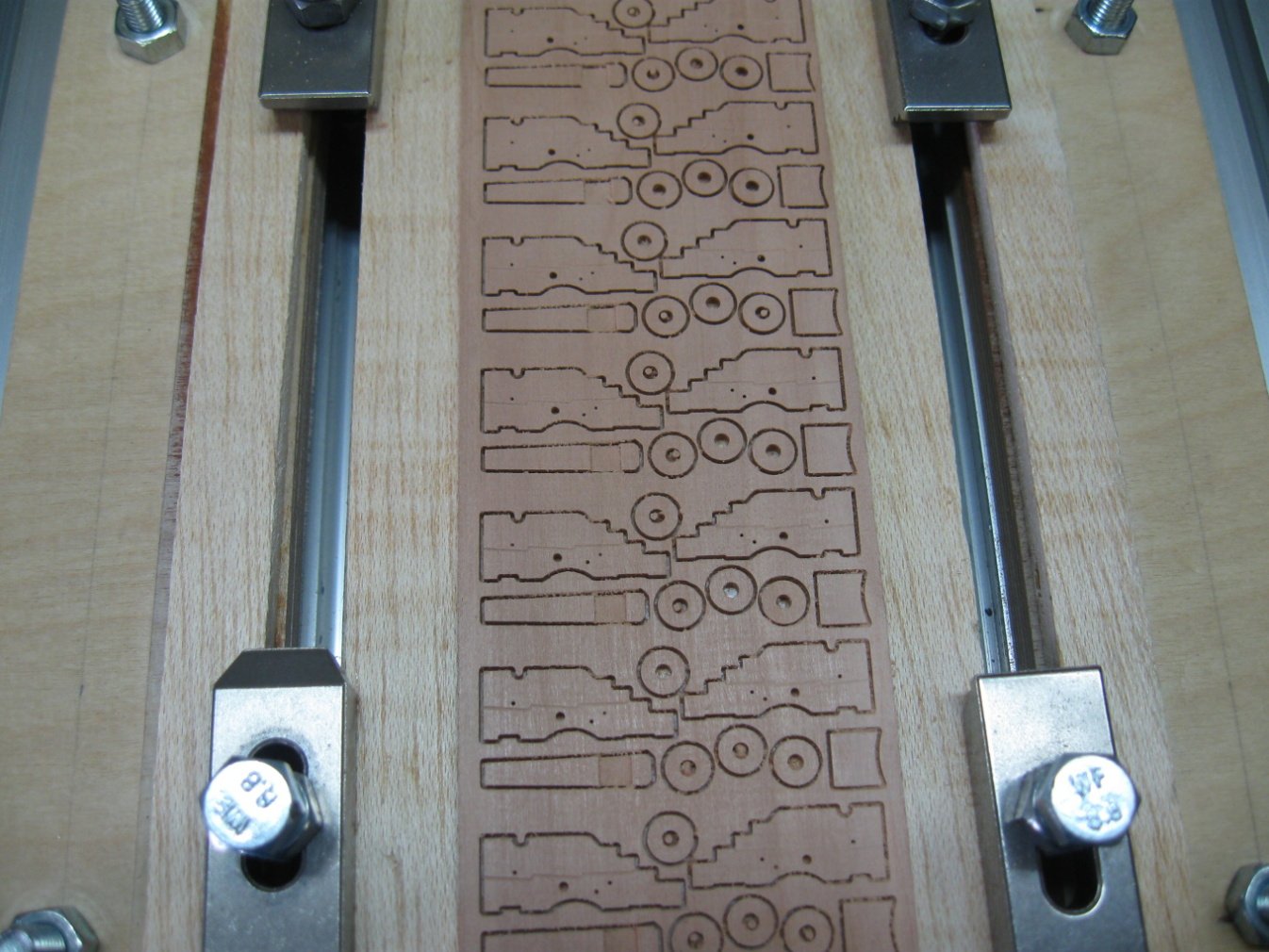

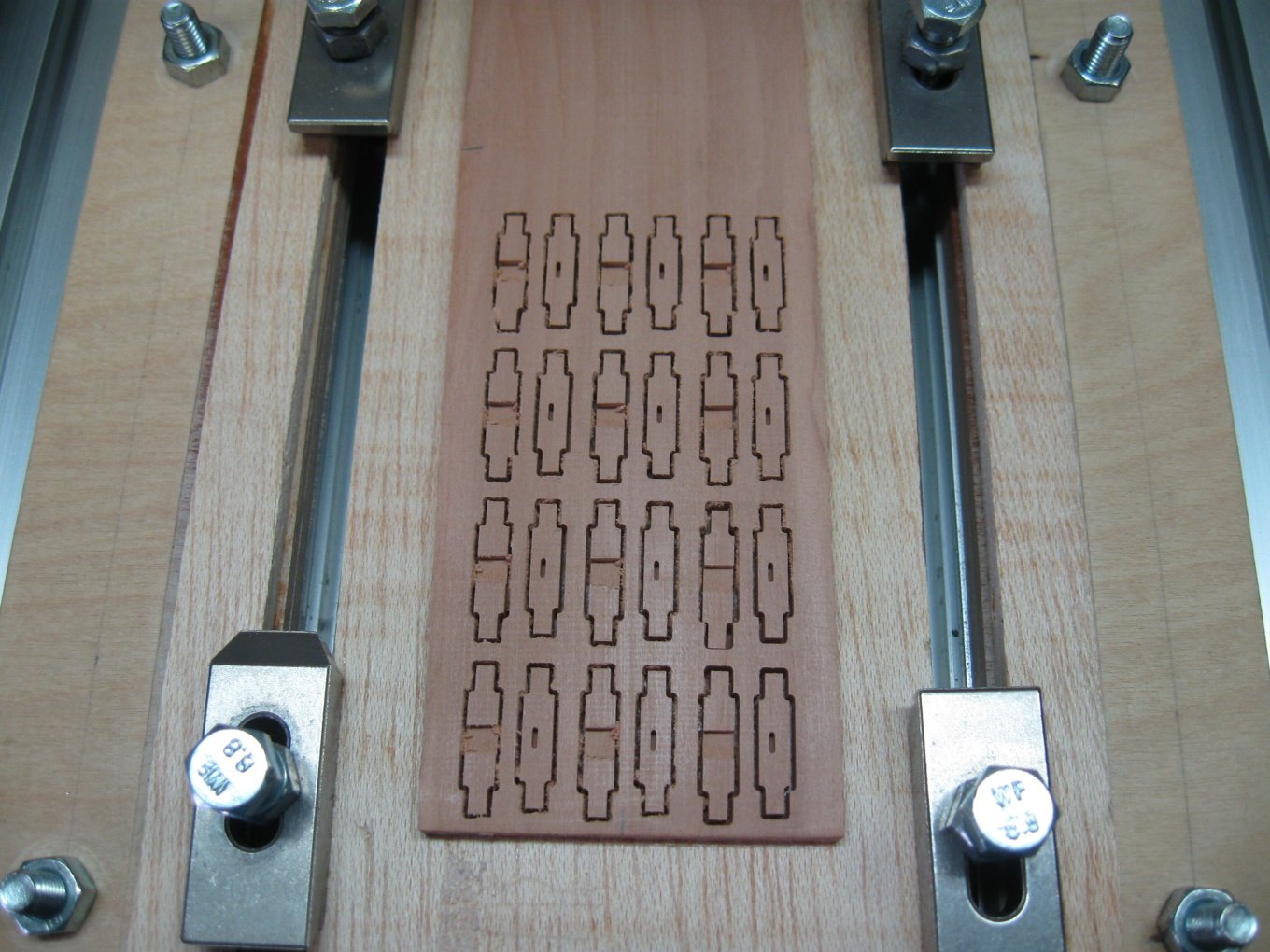

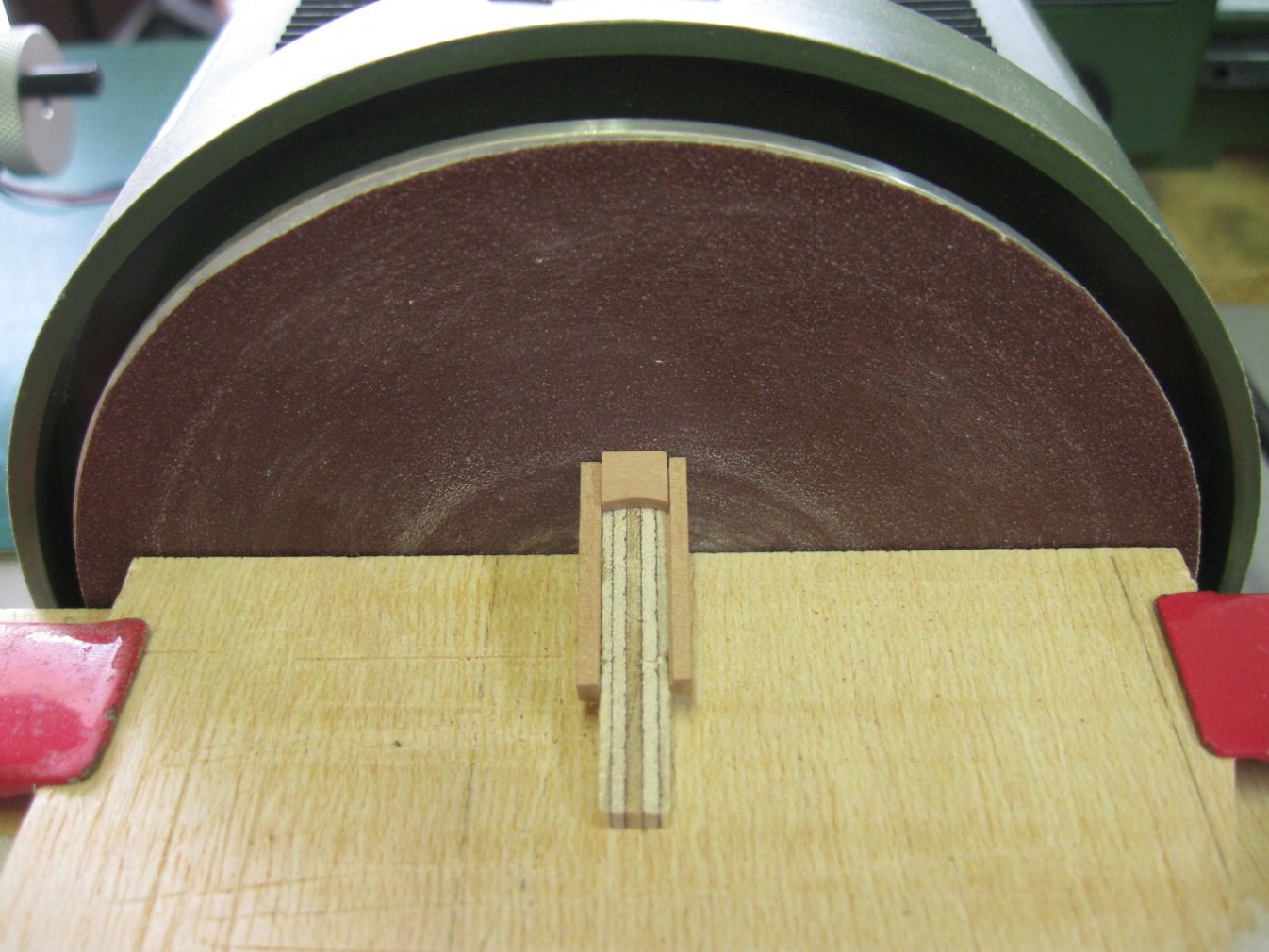

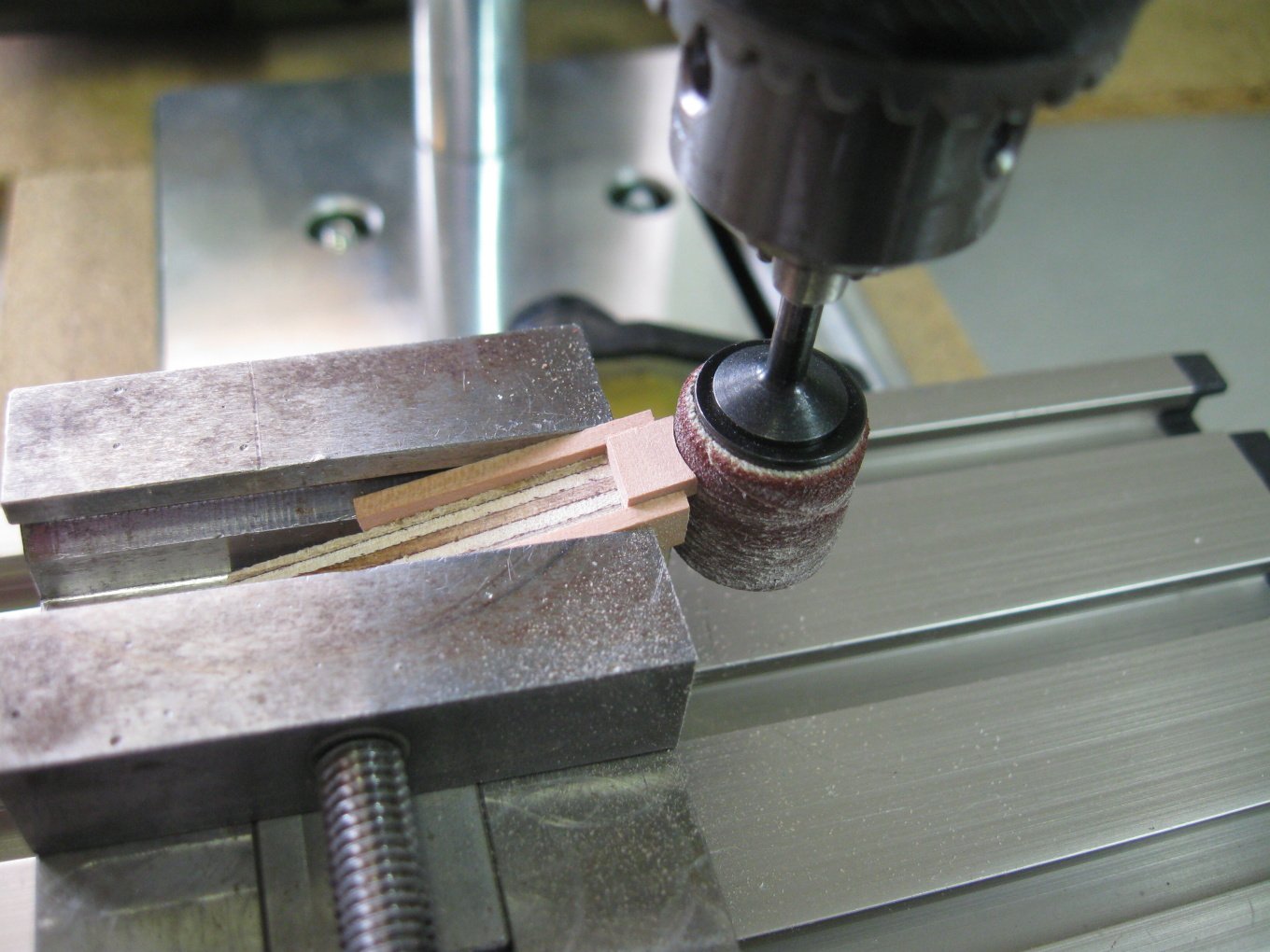

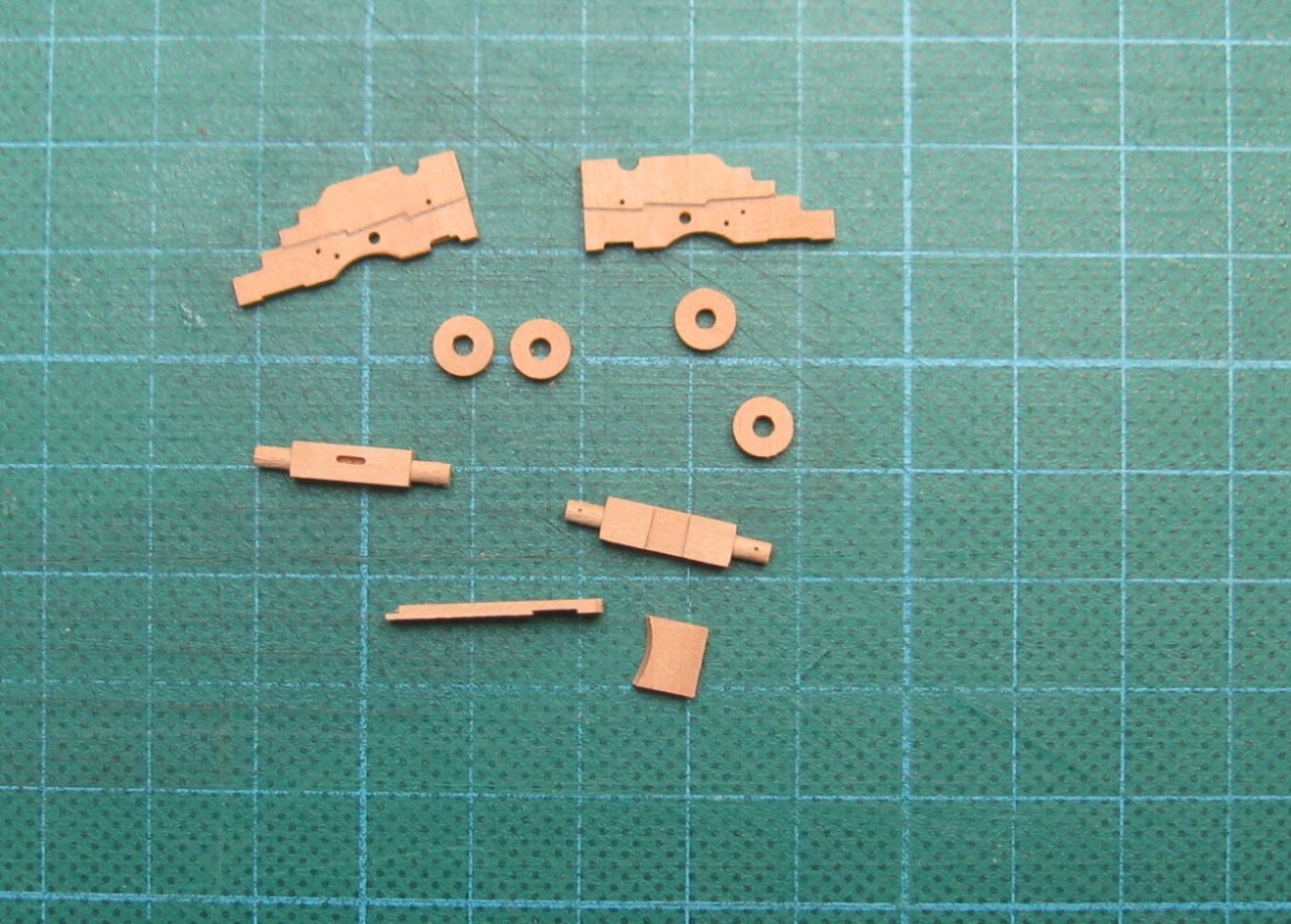

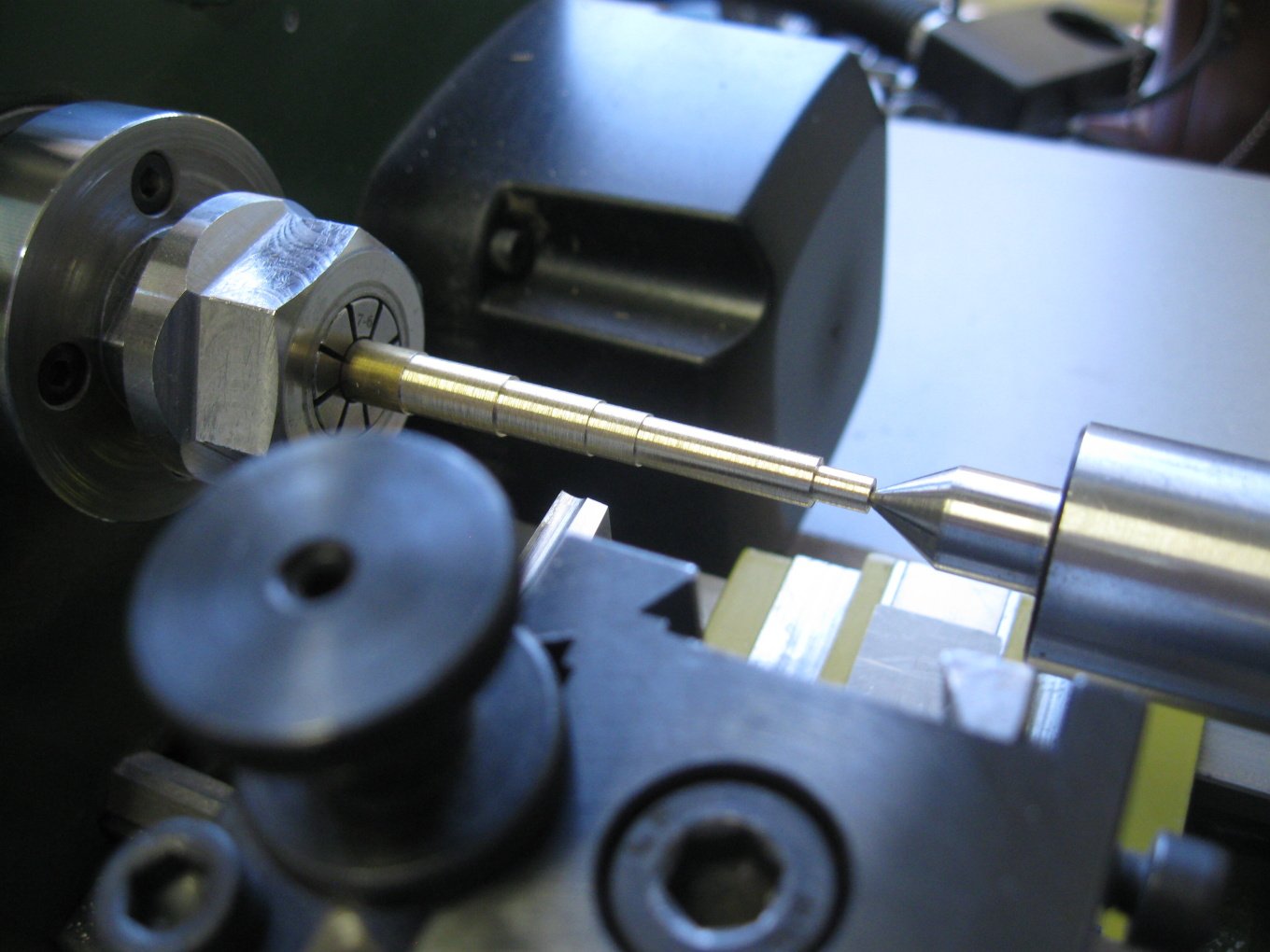

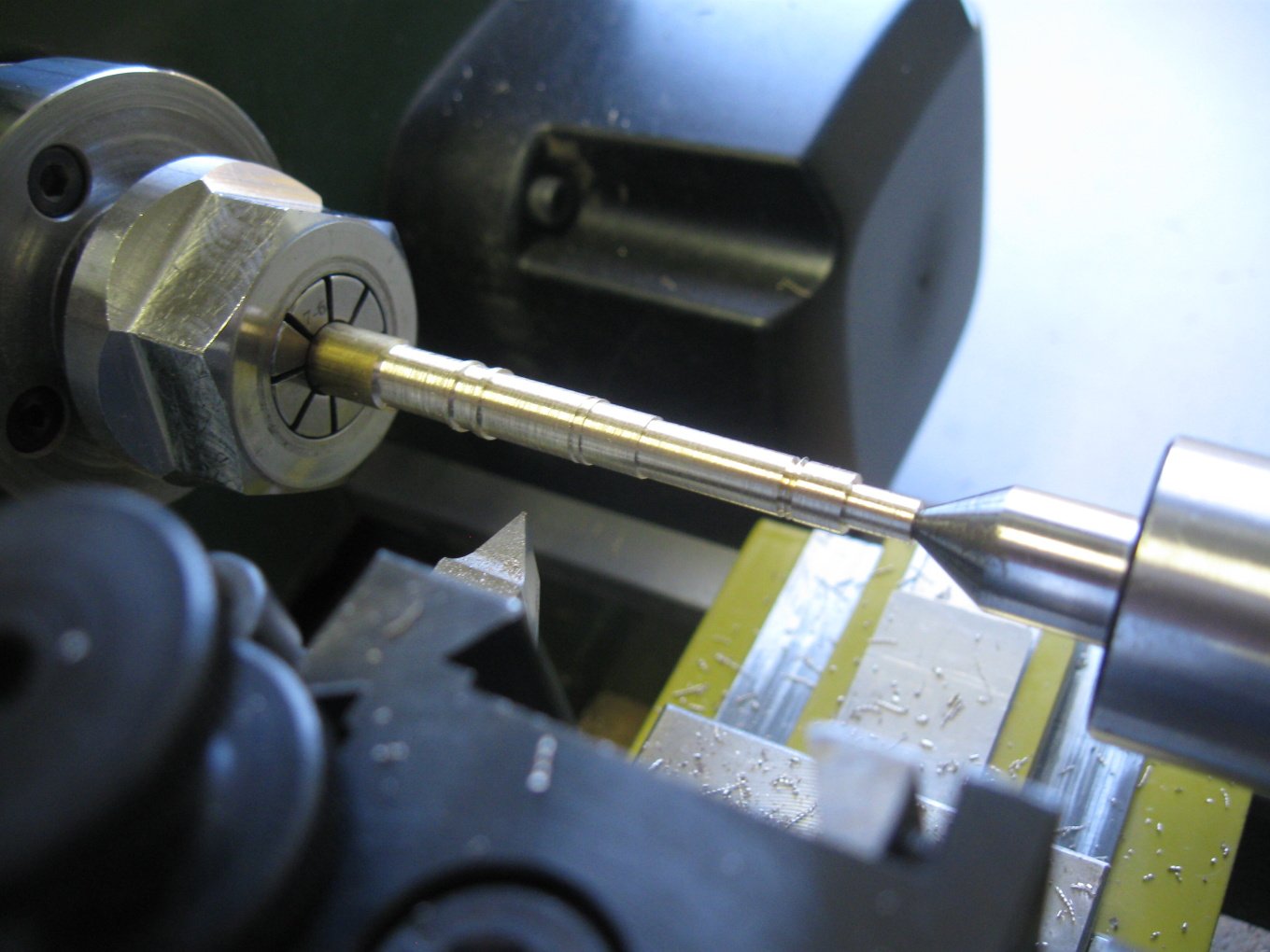

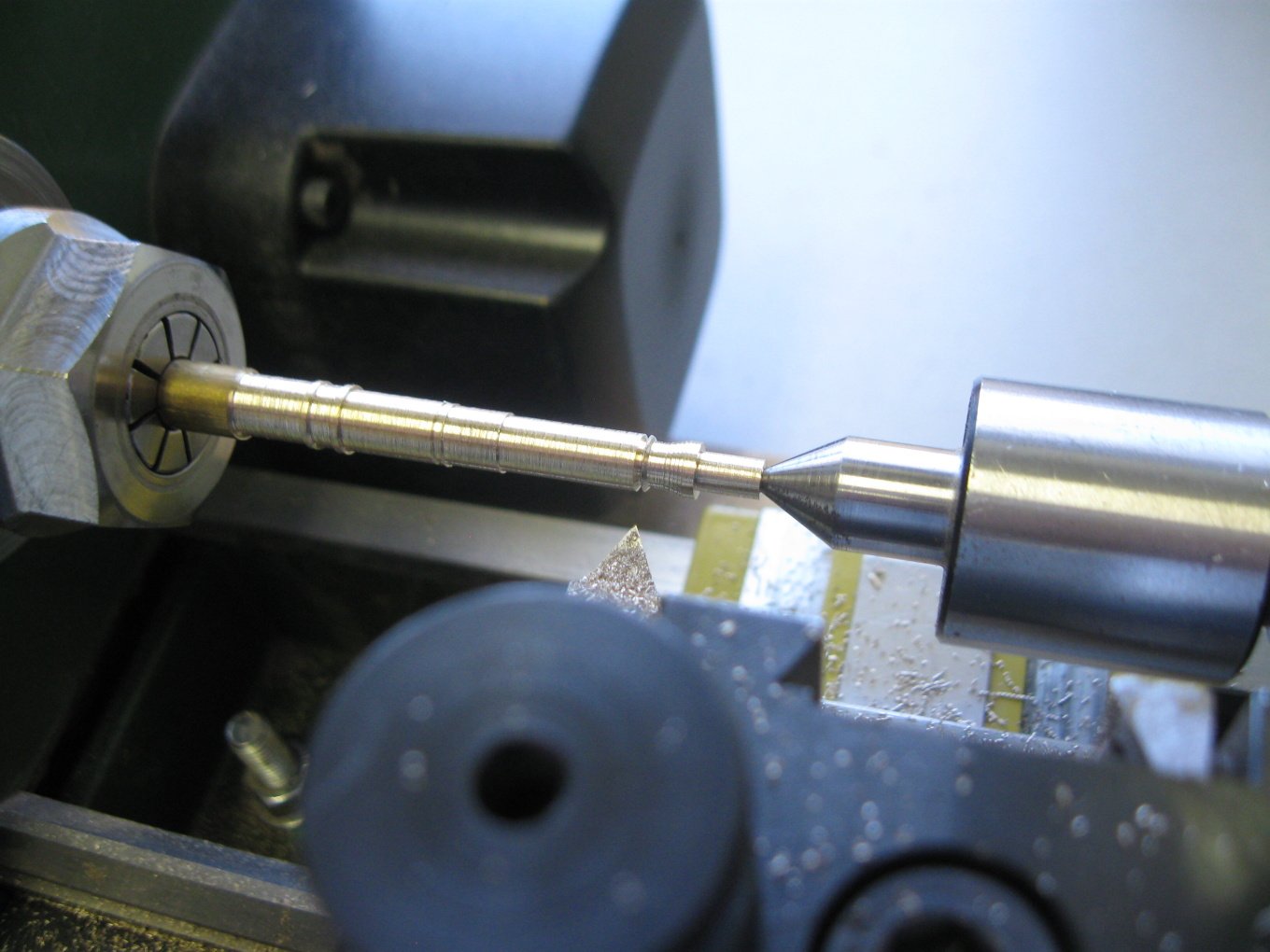

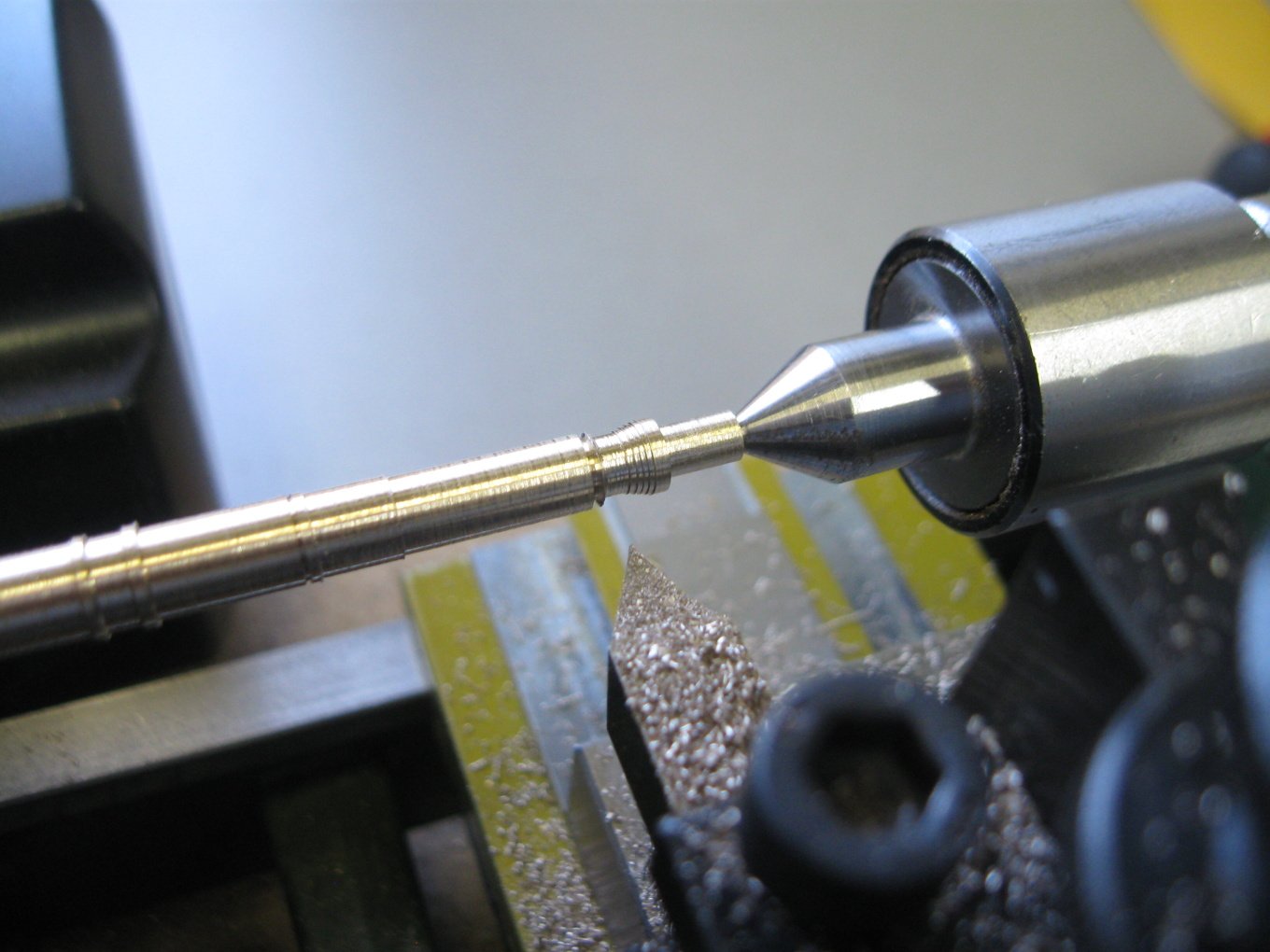

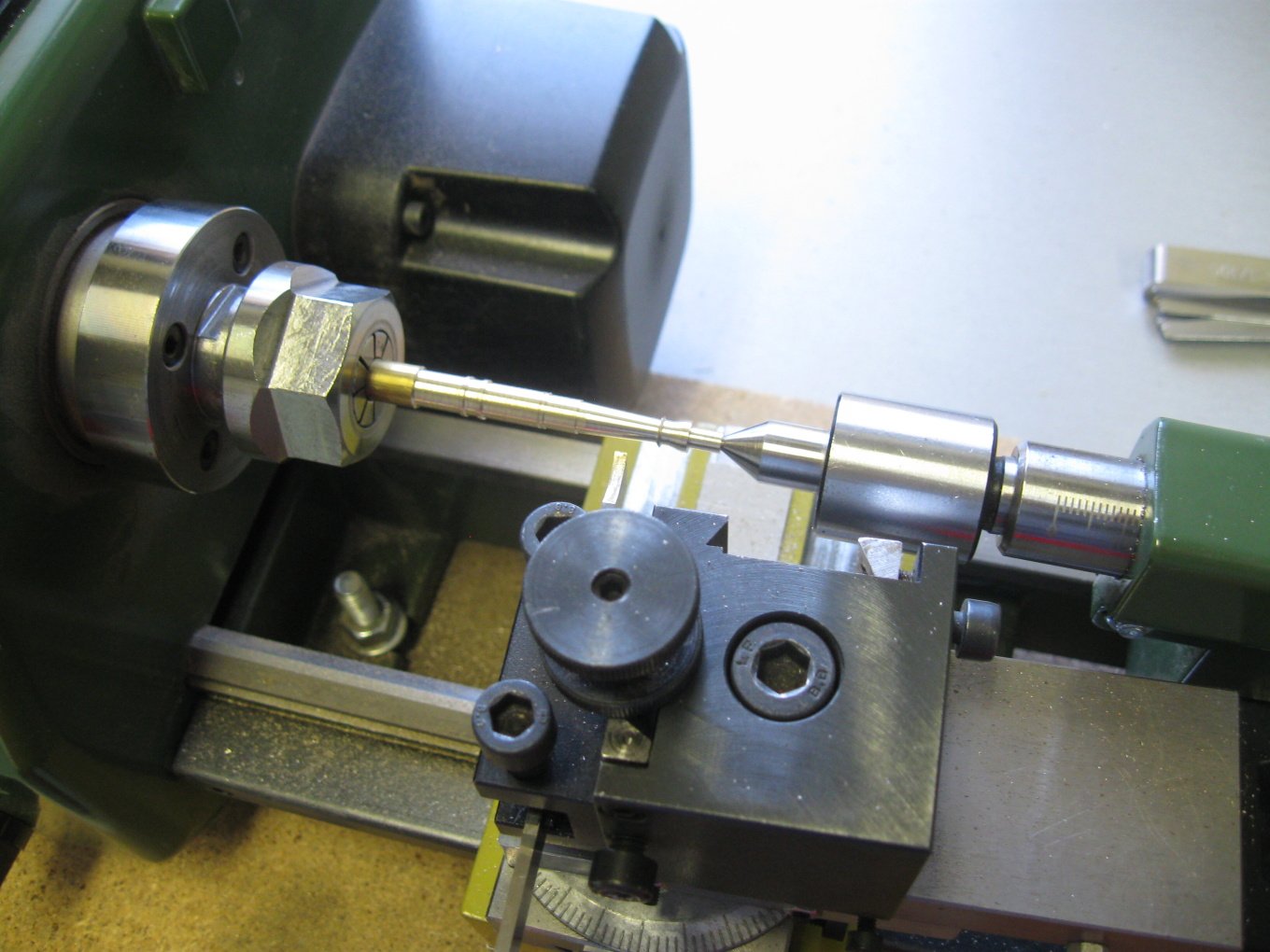

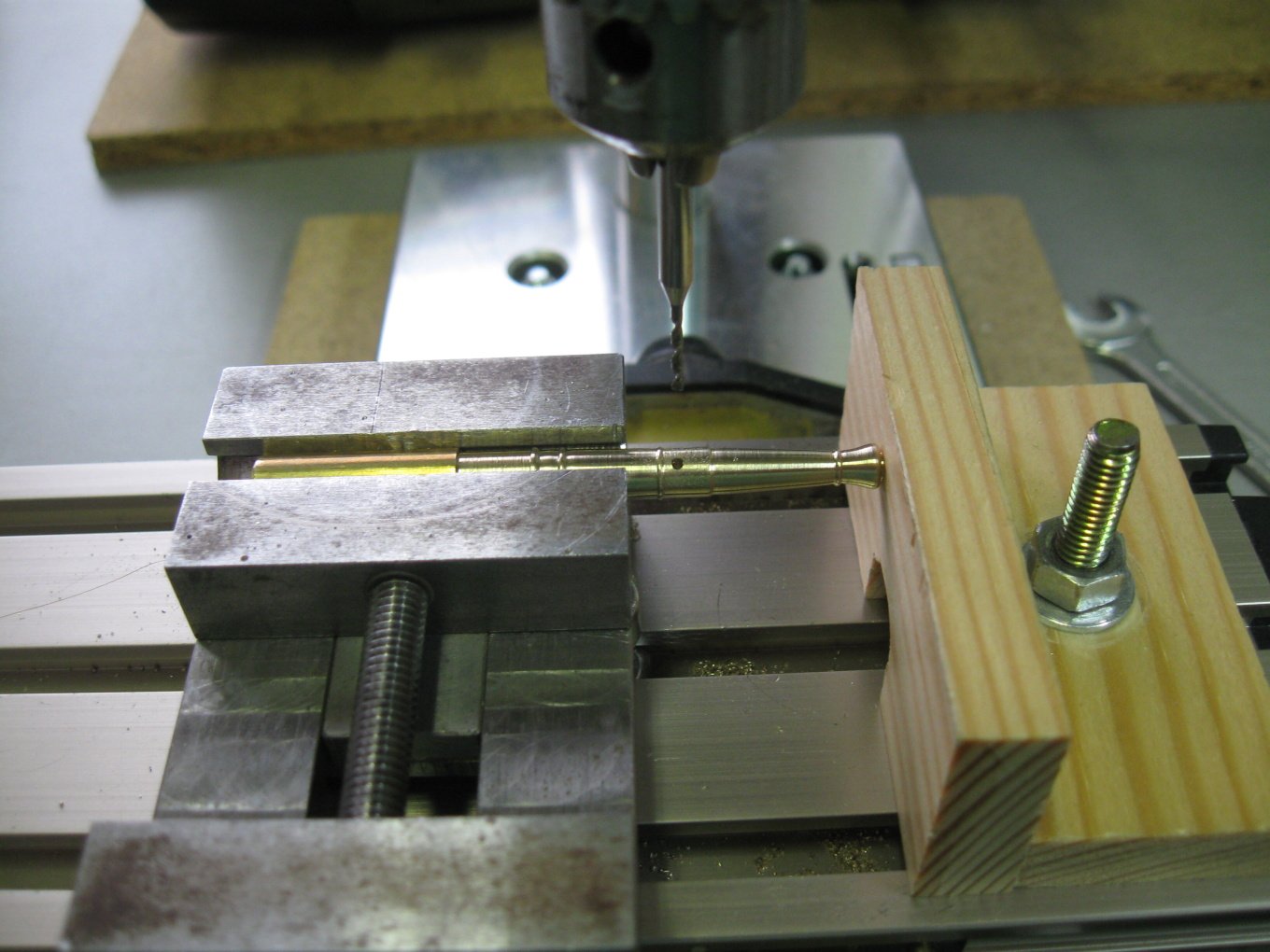

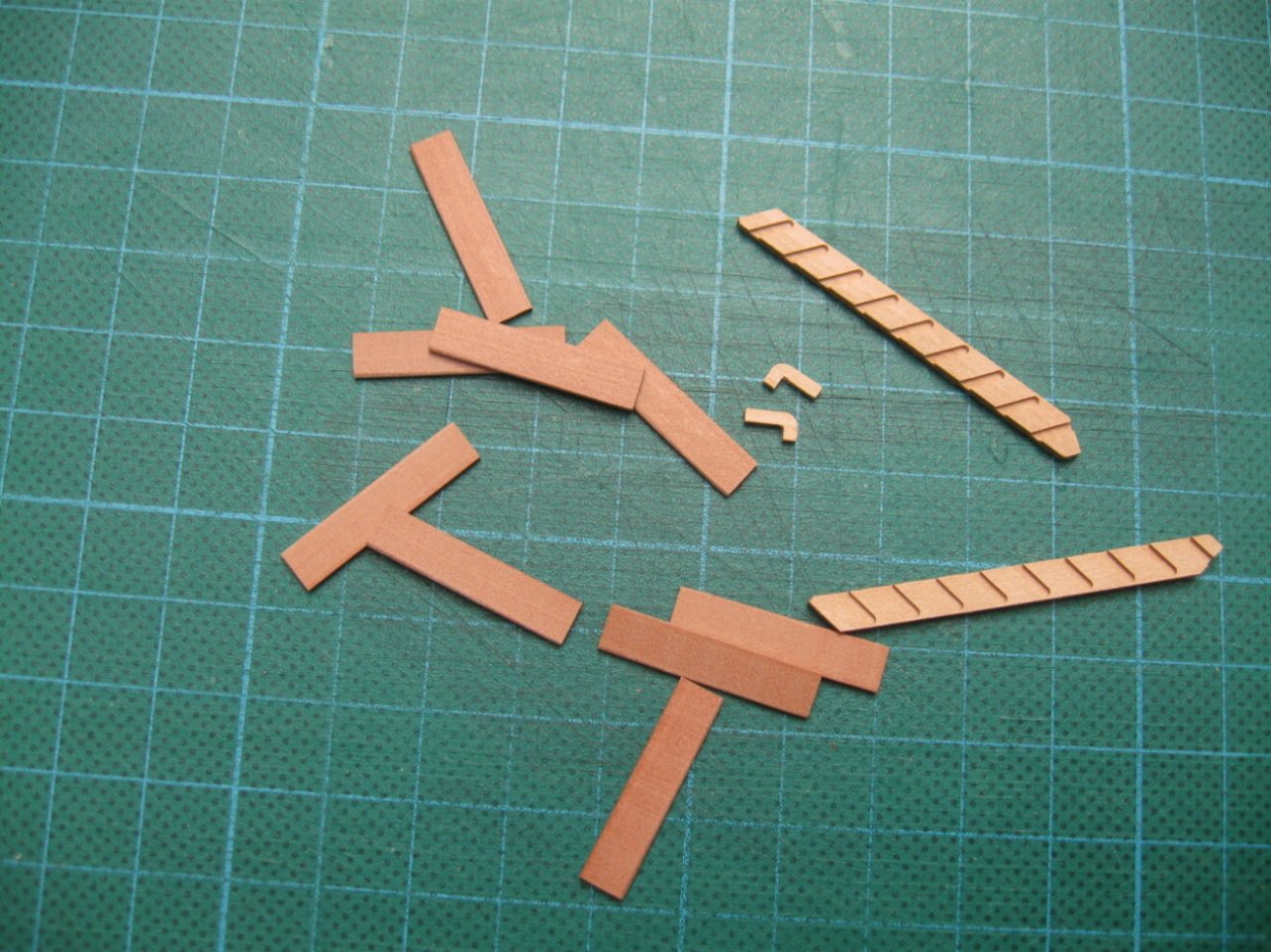

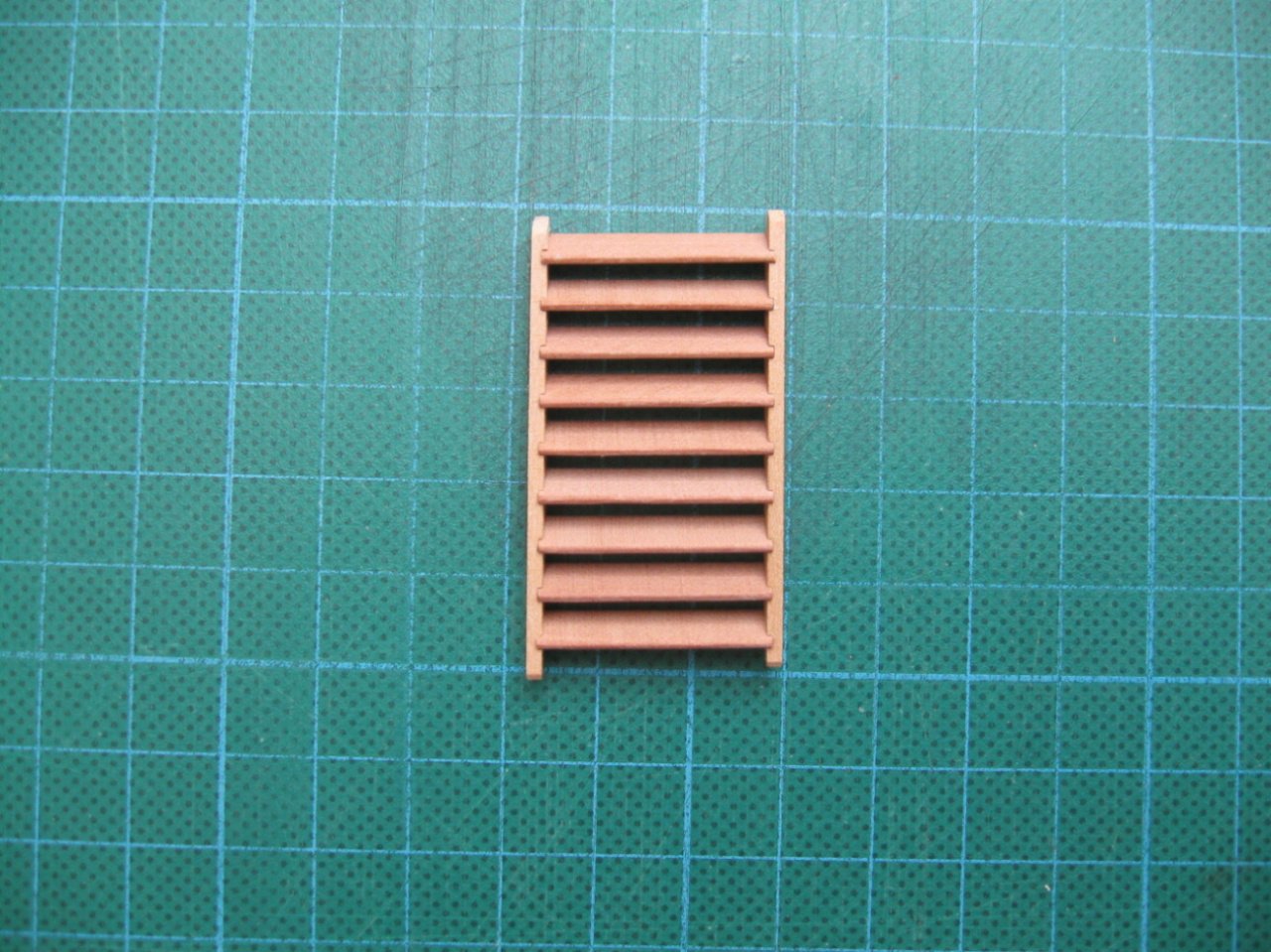

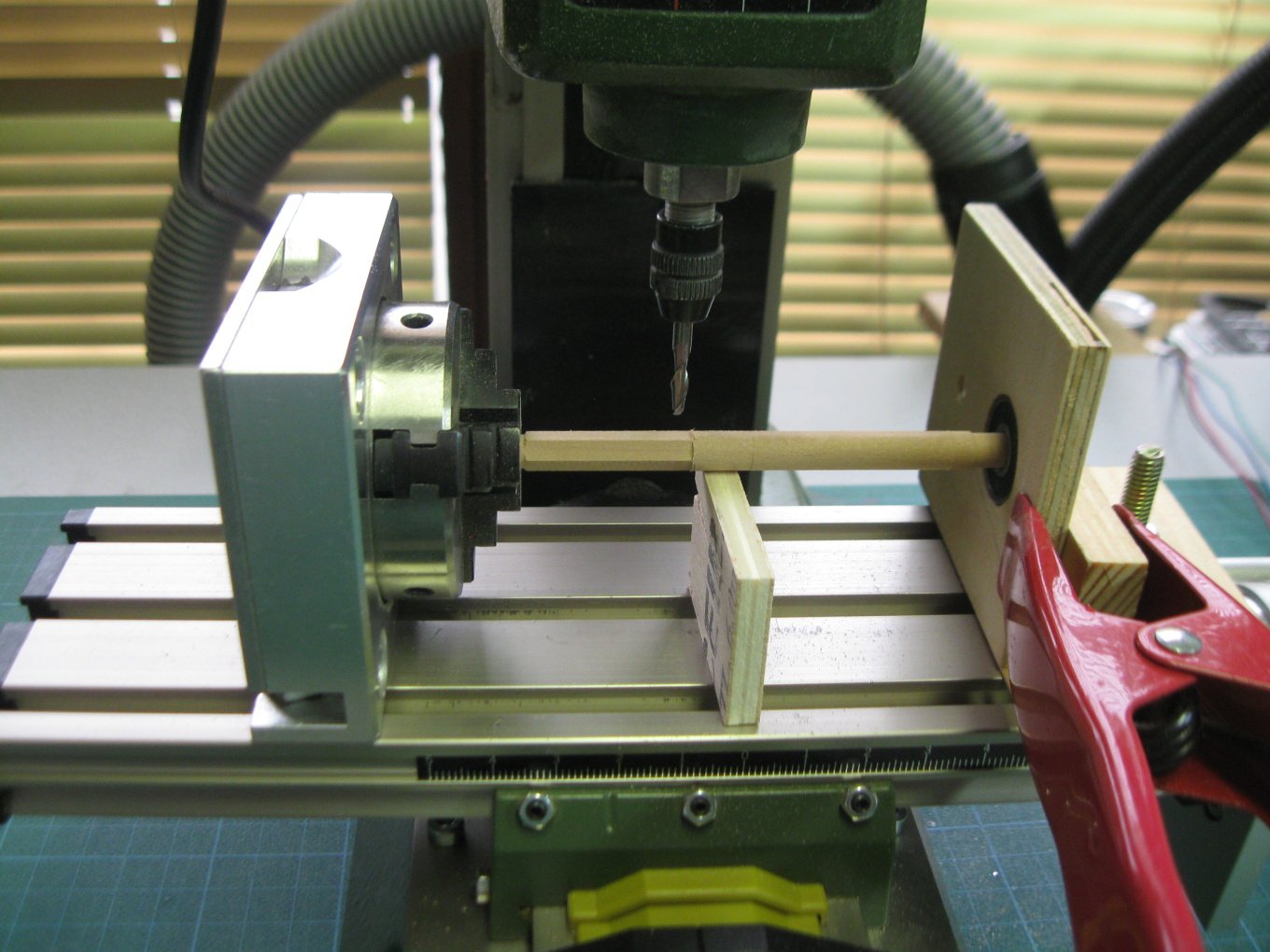

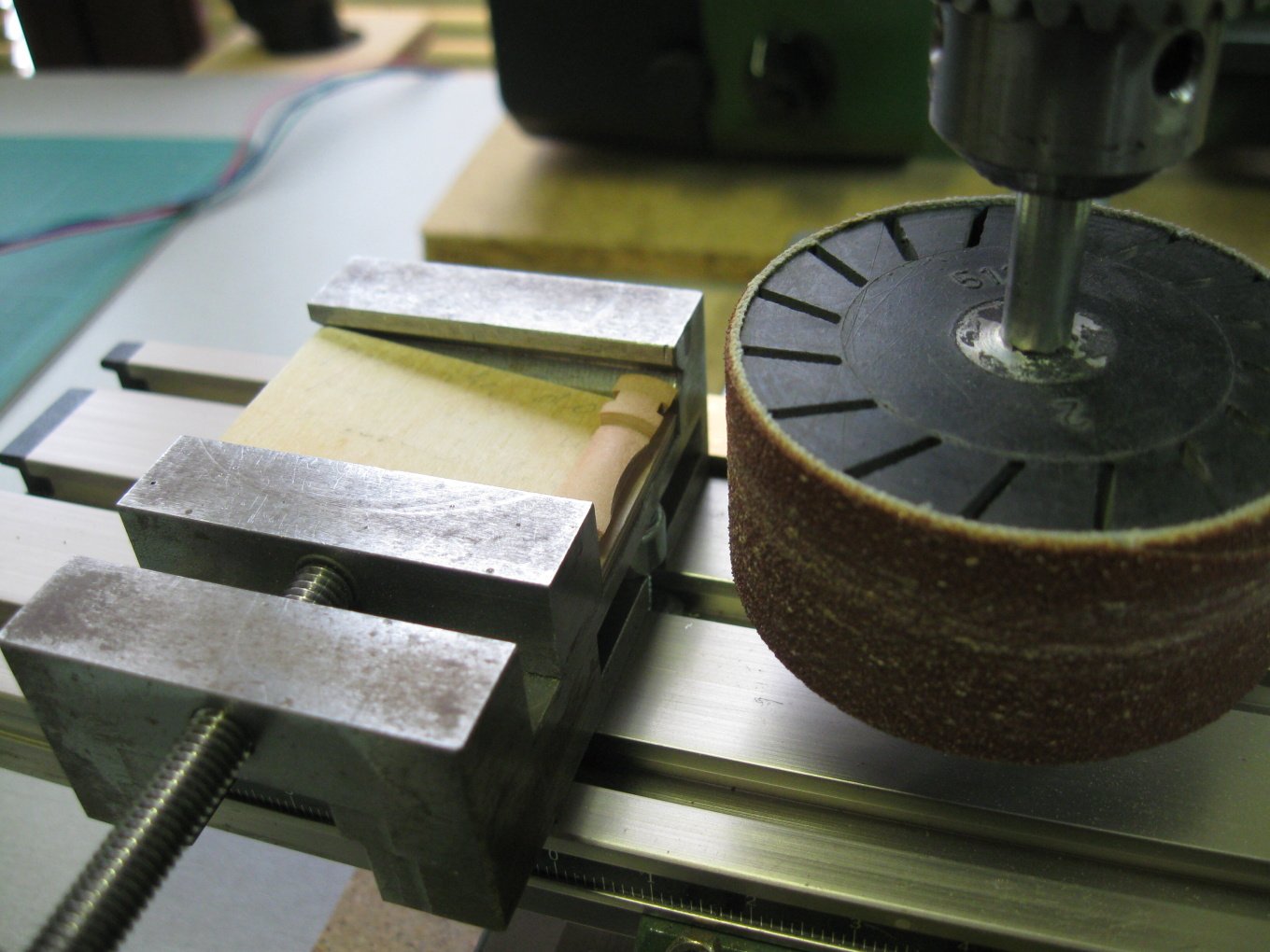

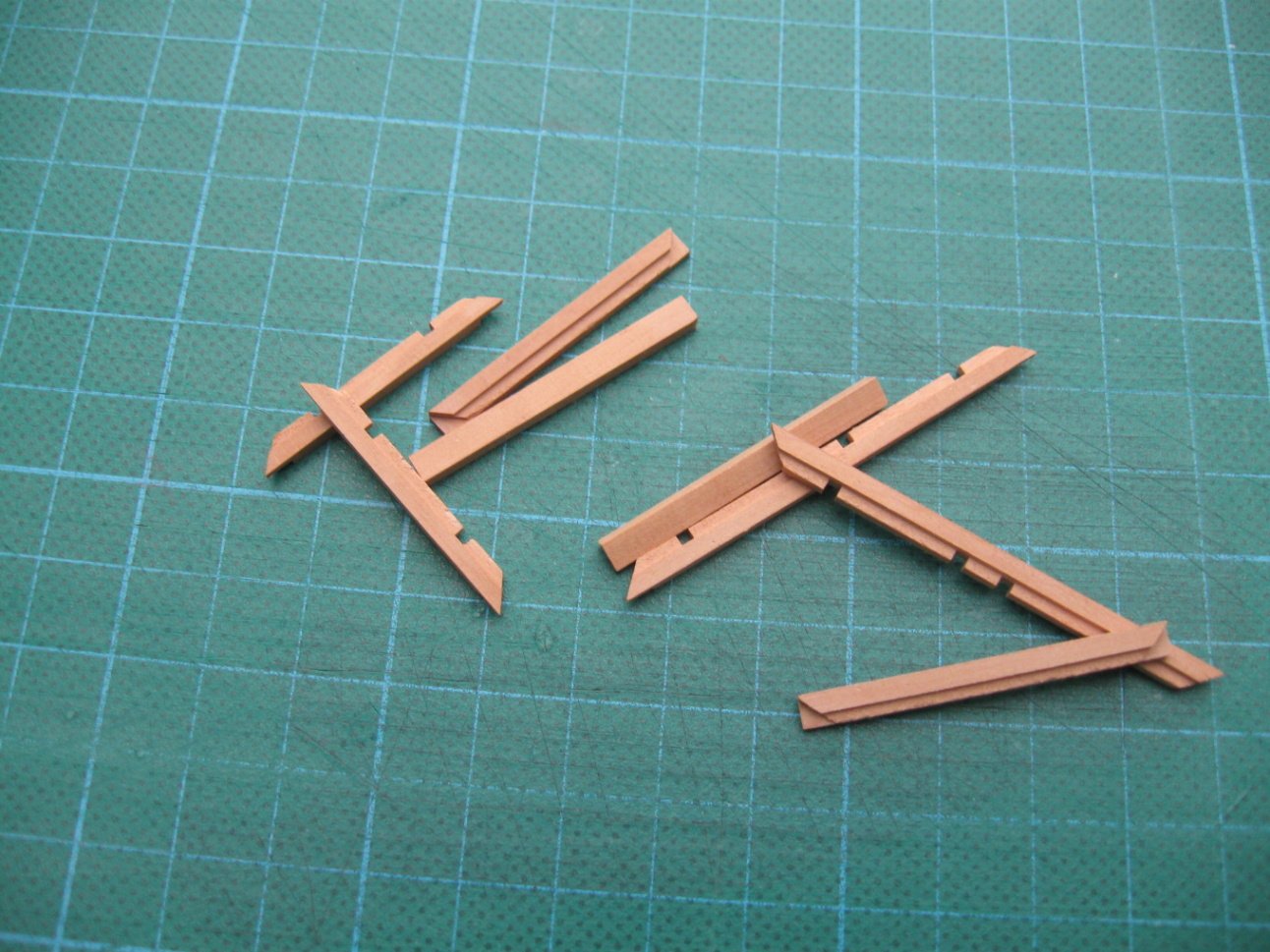

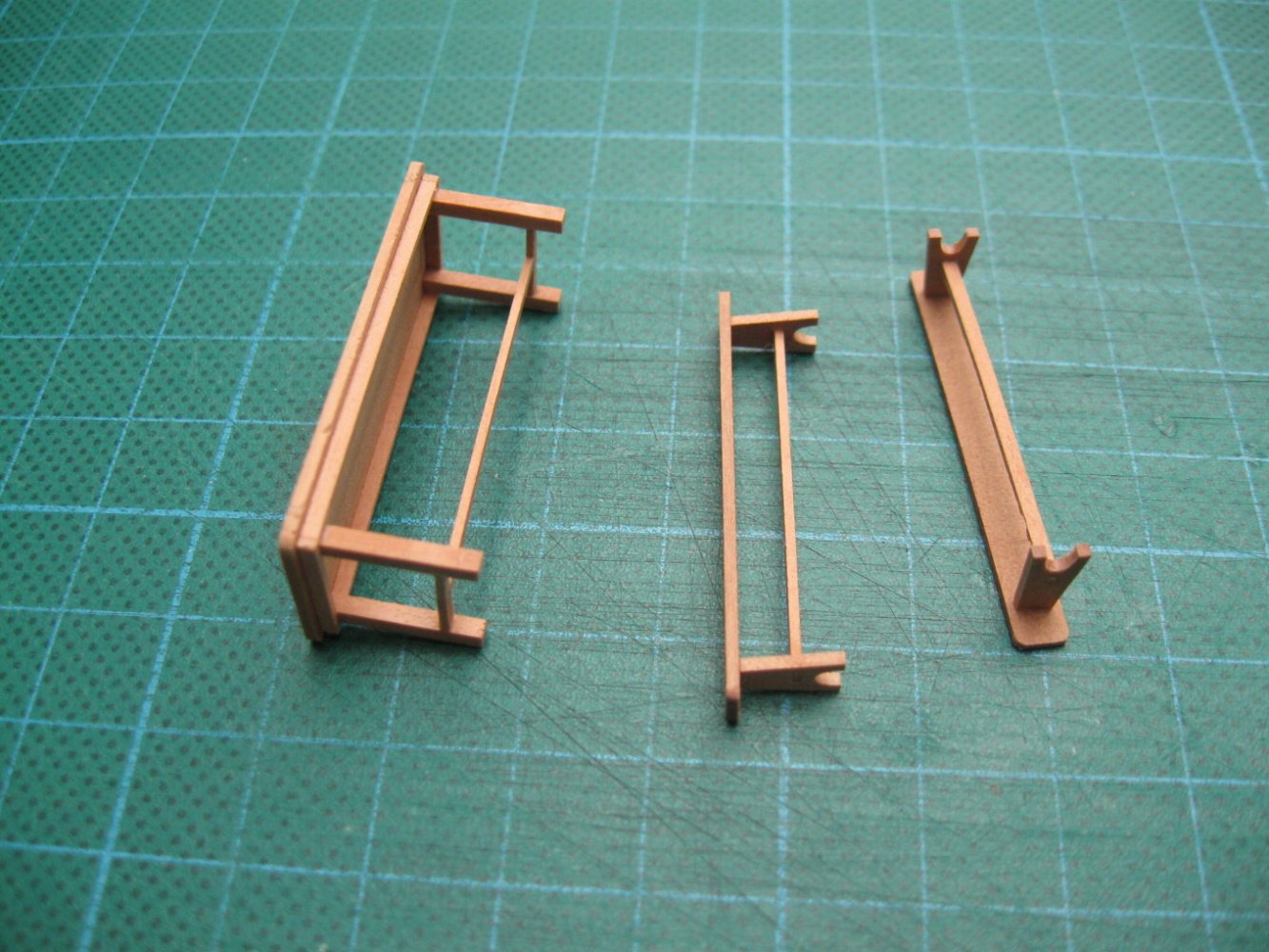

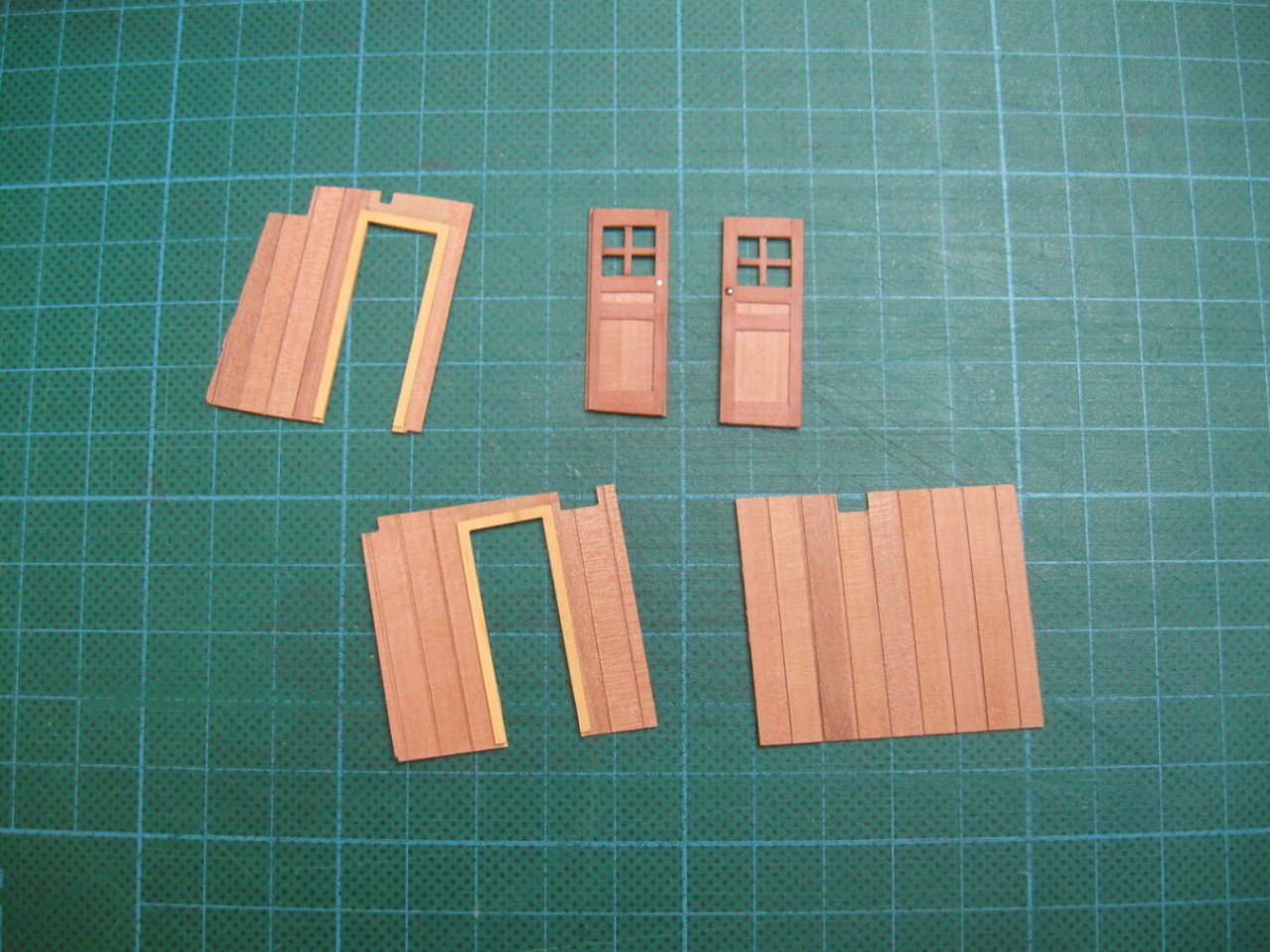

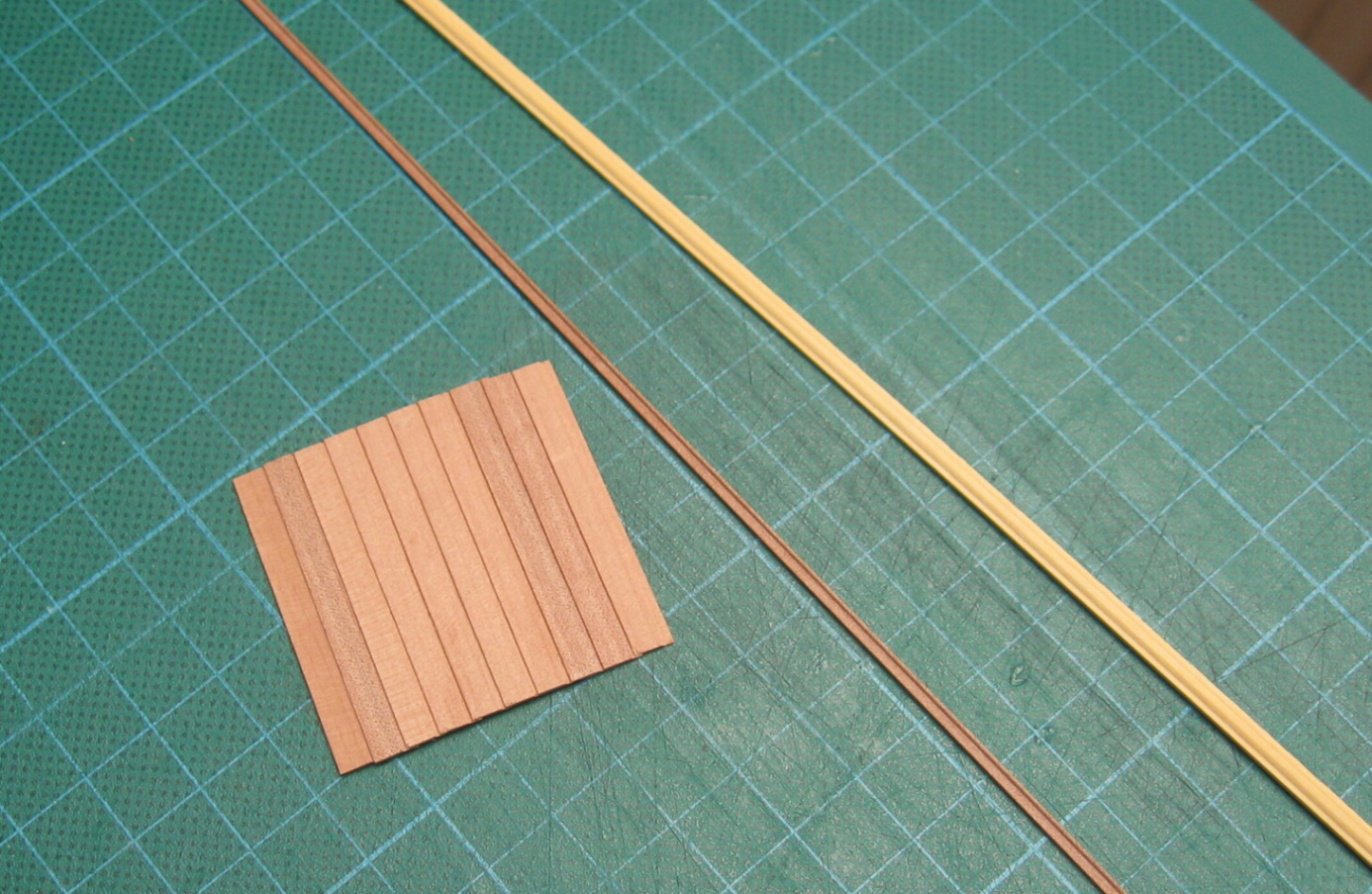

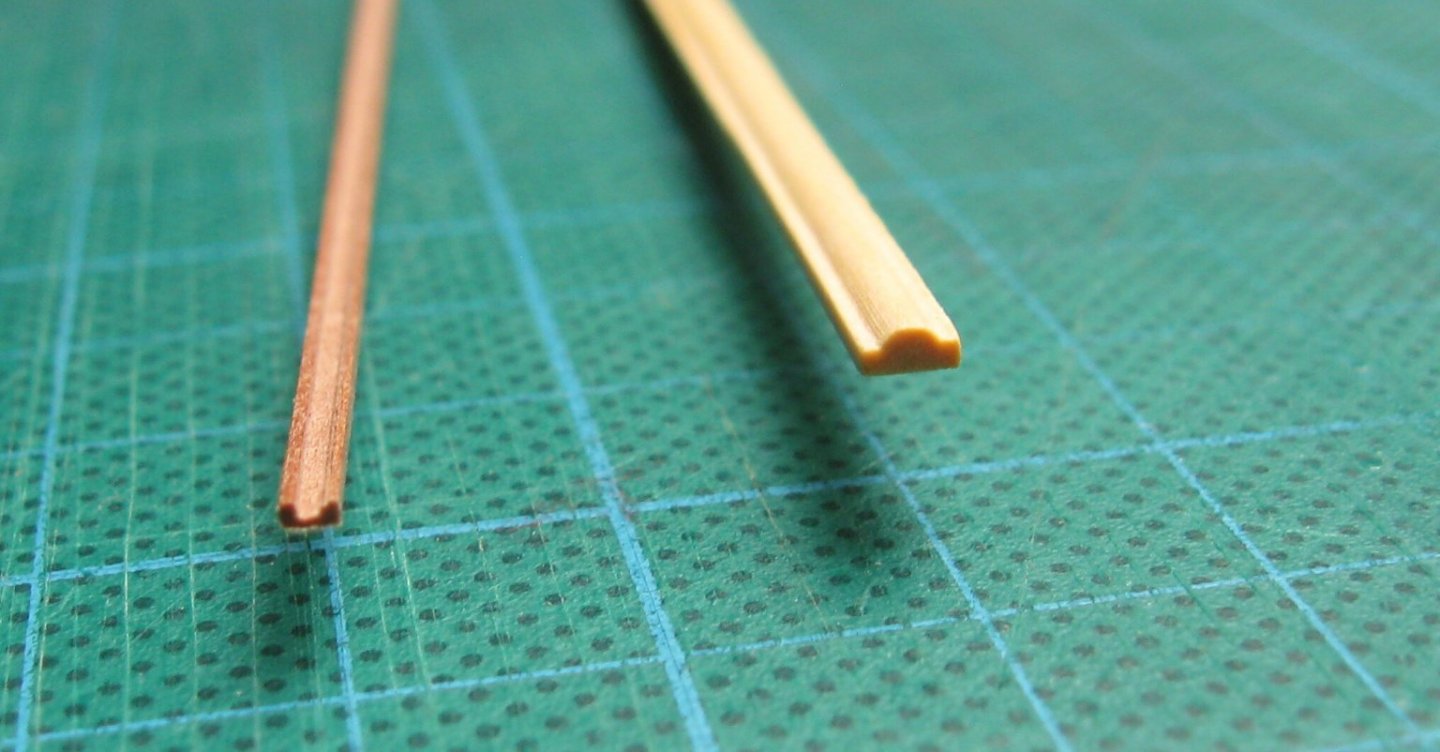

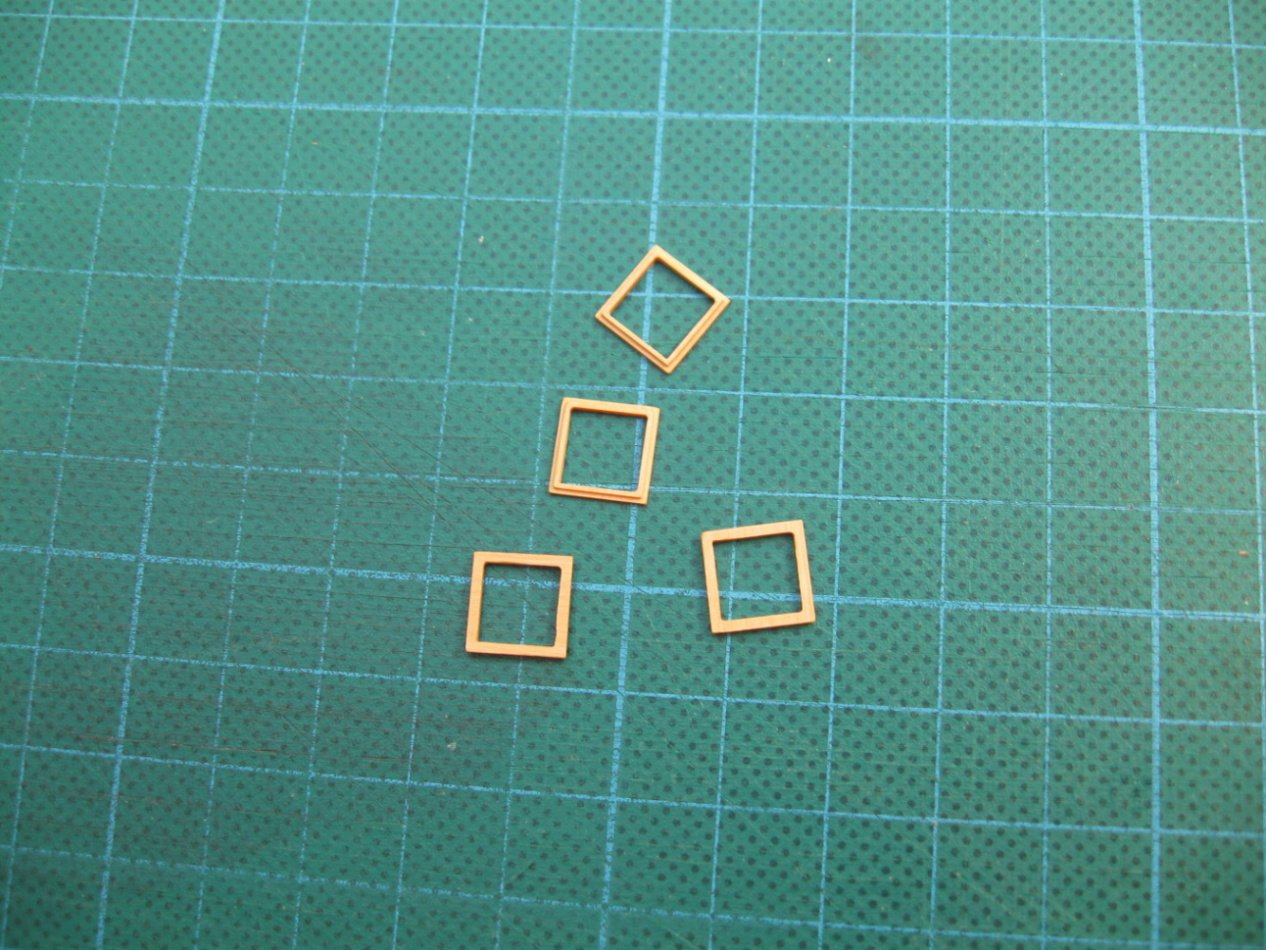

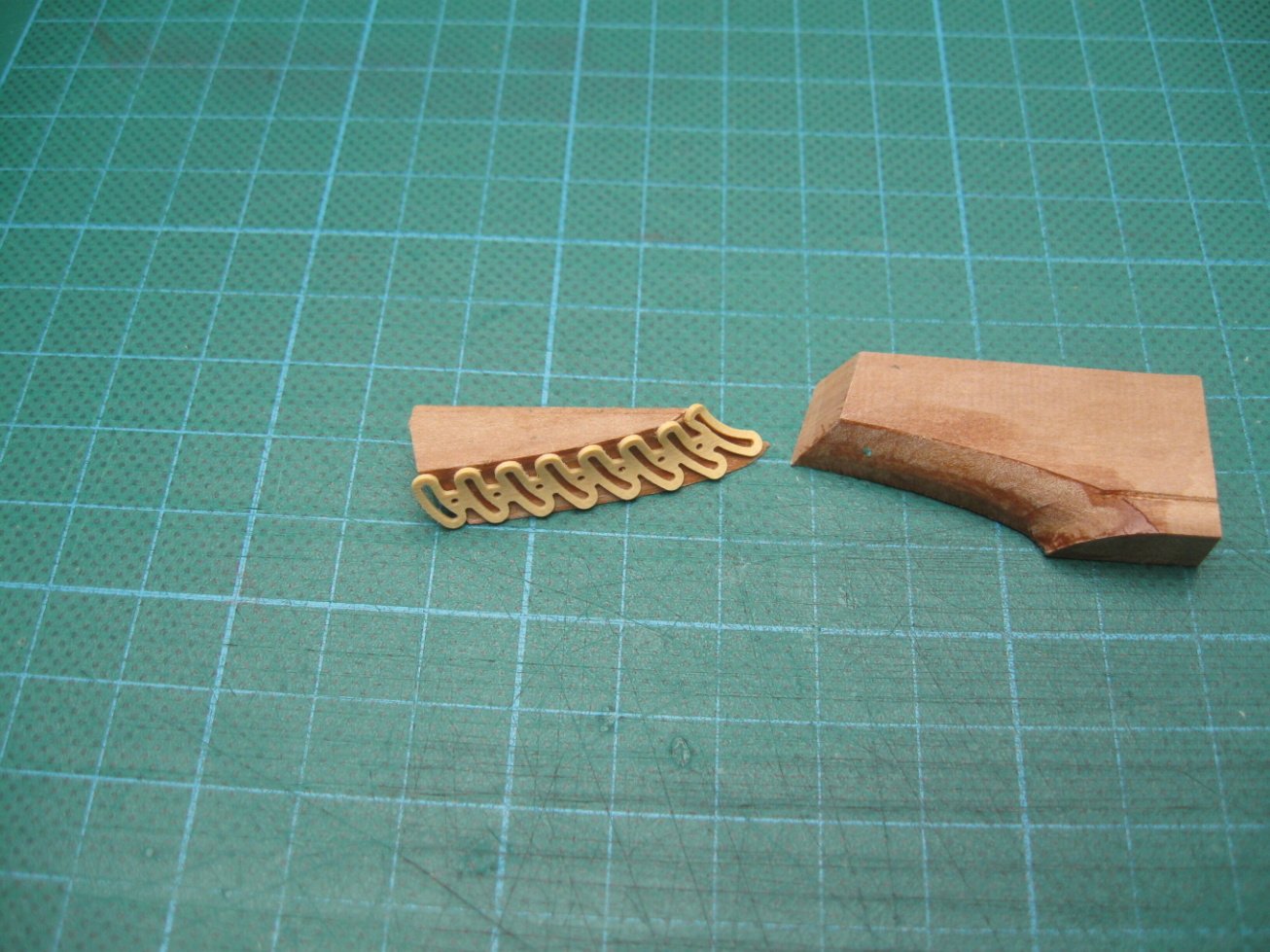

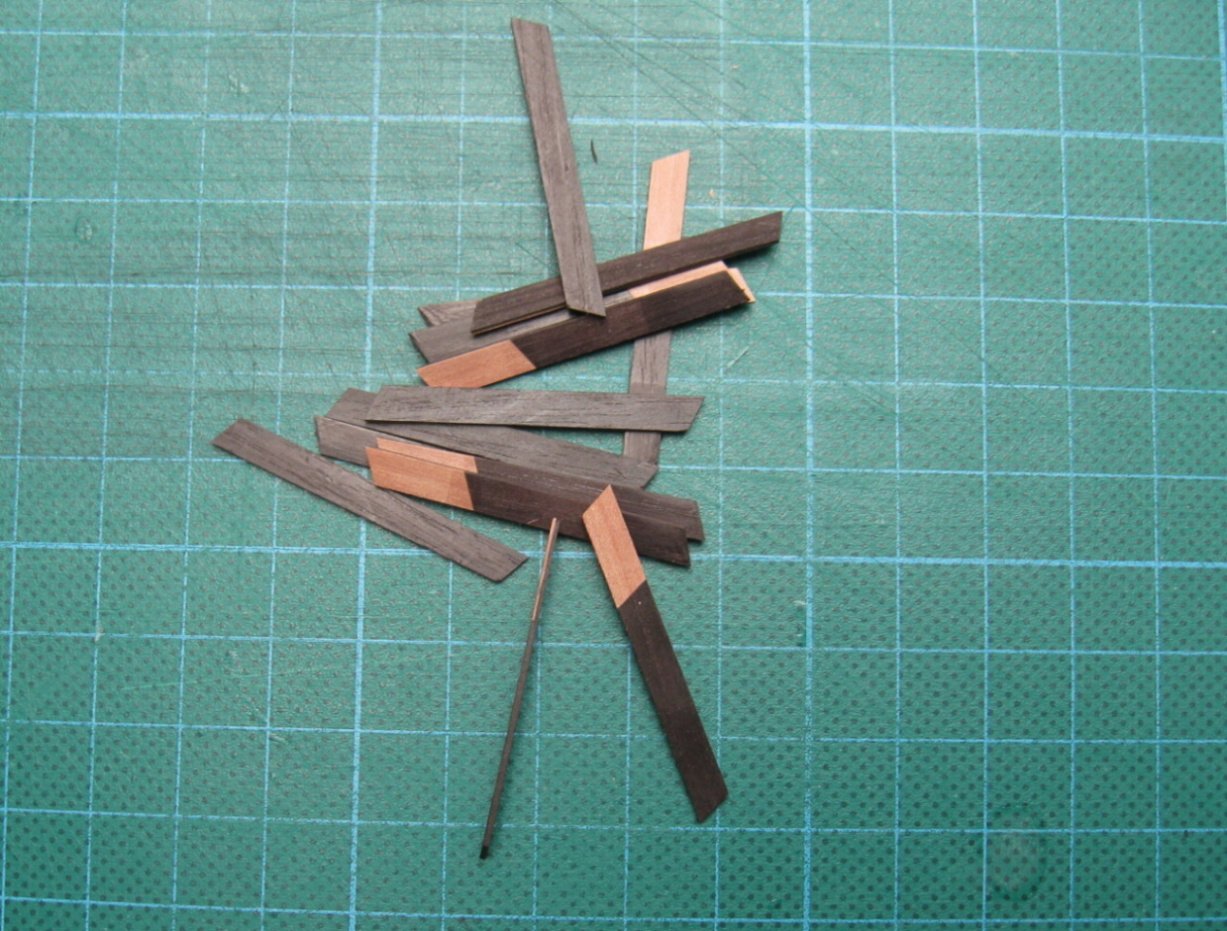

To Dowmer - all cannons are made by hands (it means with no CNC feature or replicator) Preparation of parts for the production of gun-carriages.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

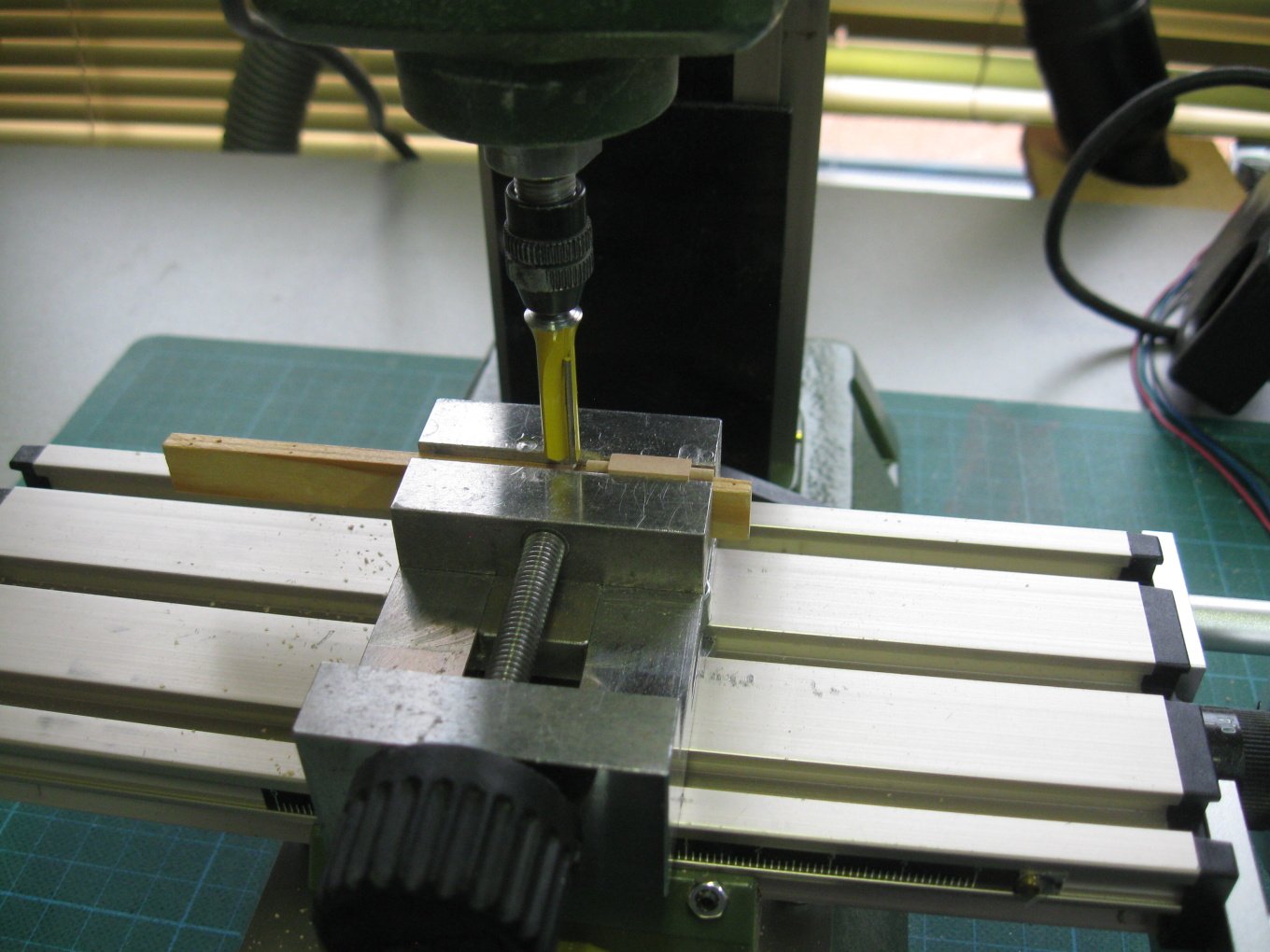

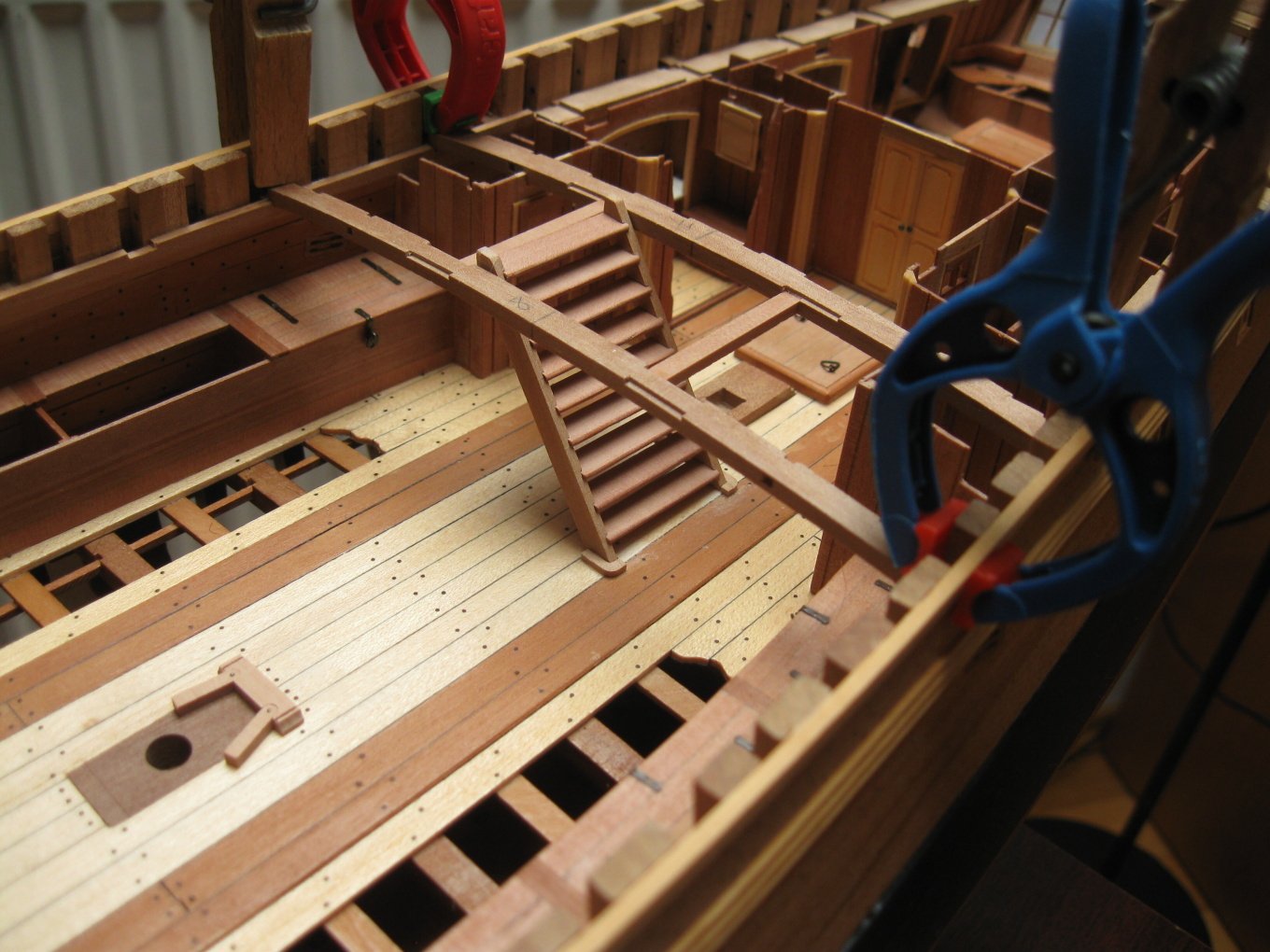

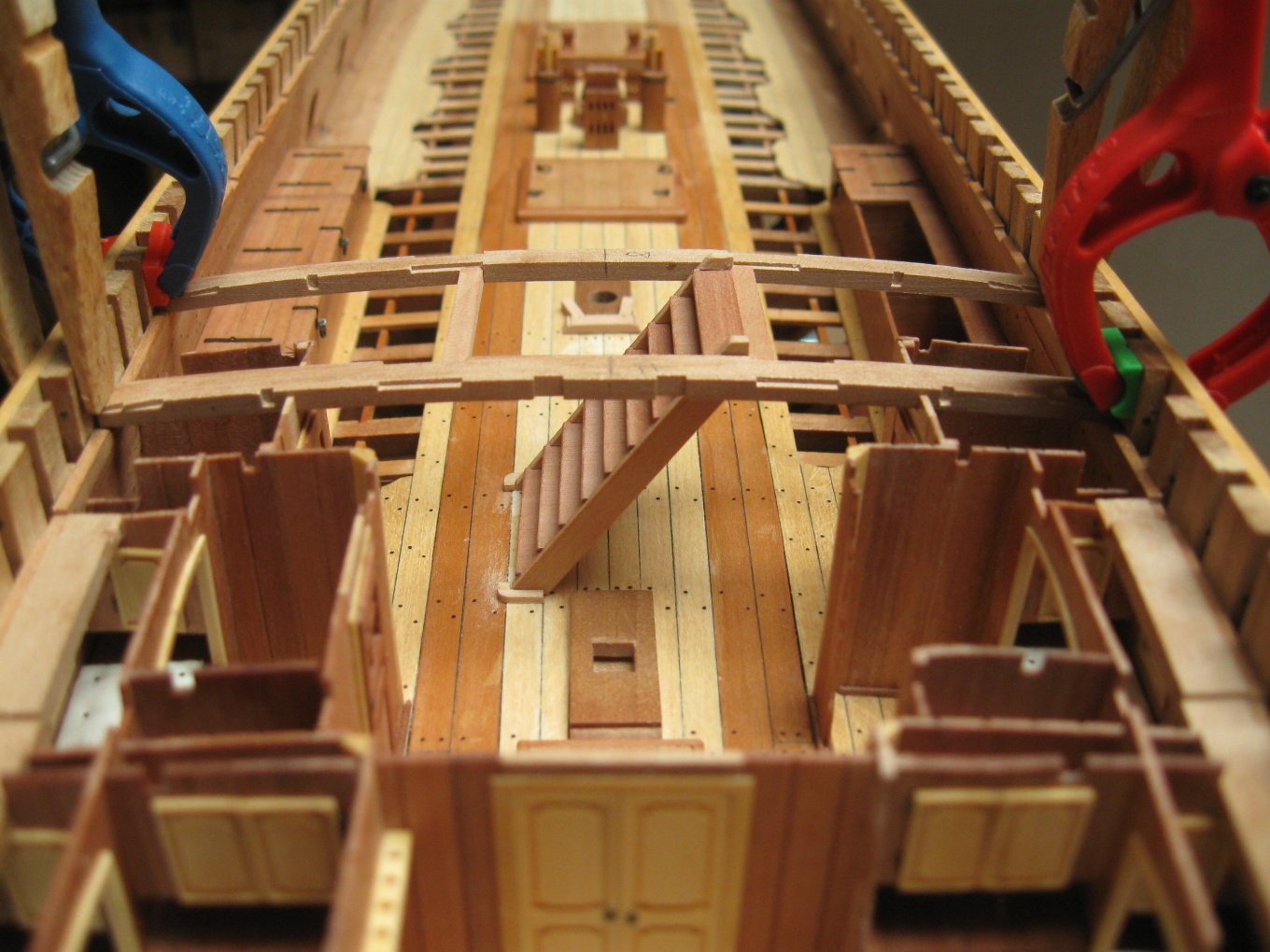

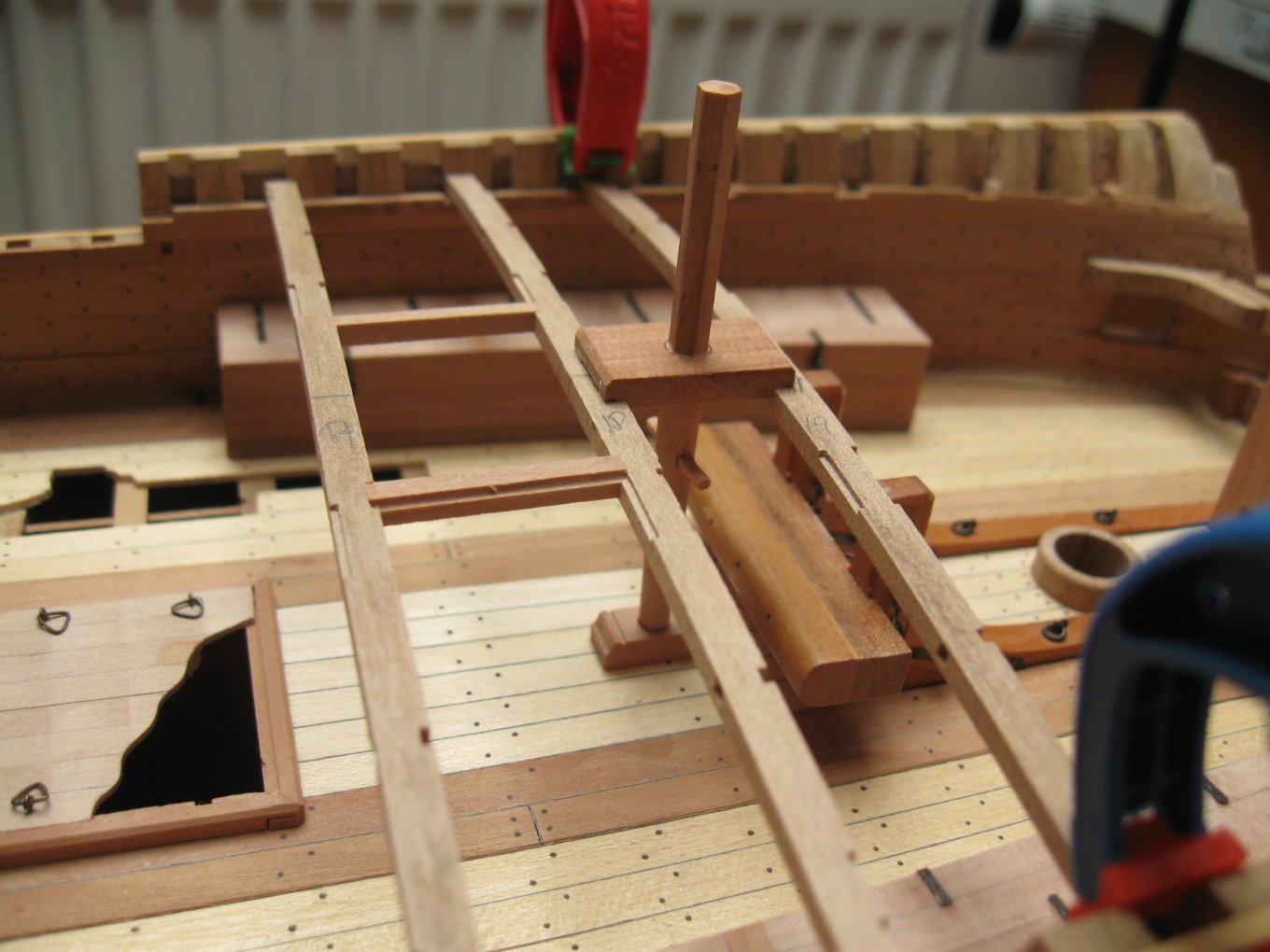

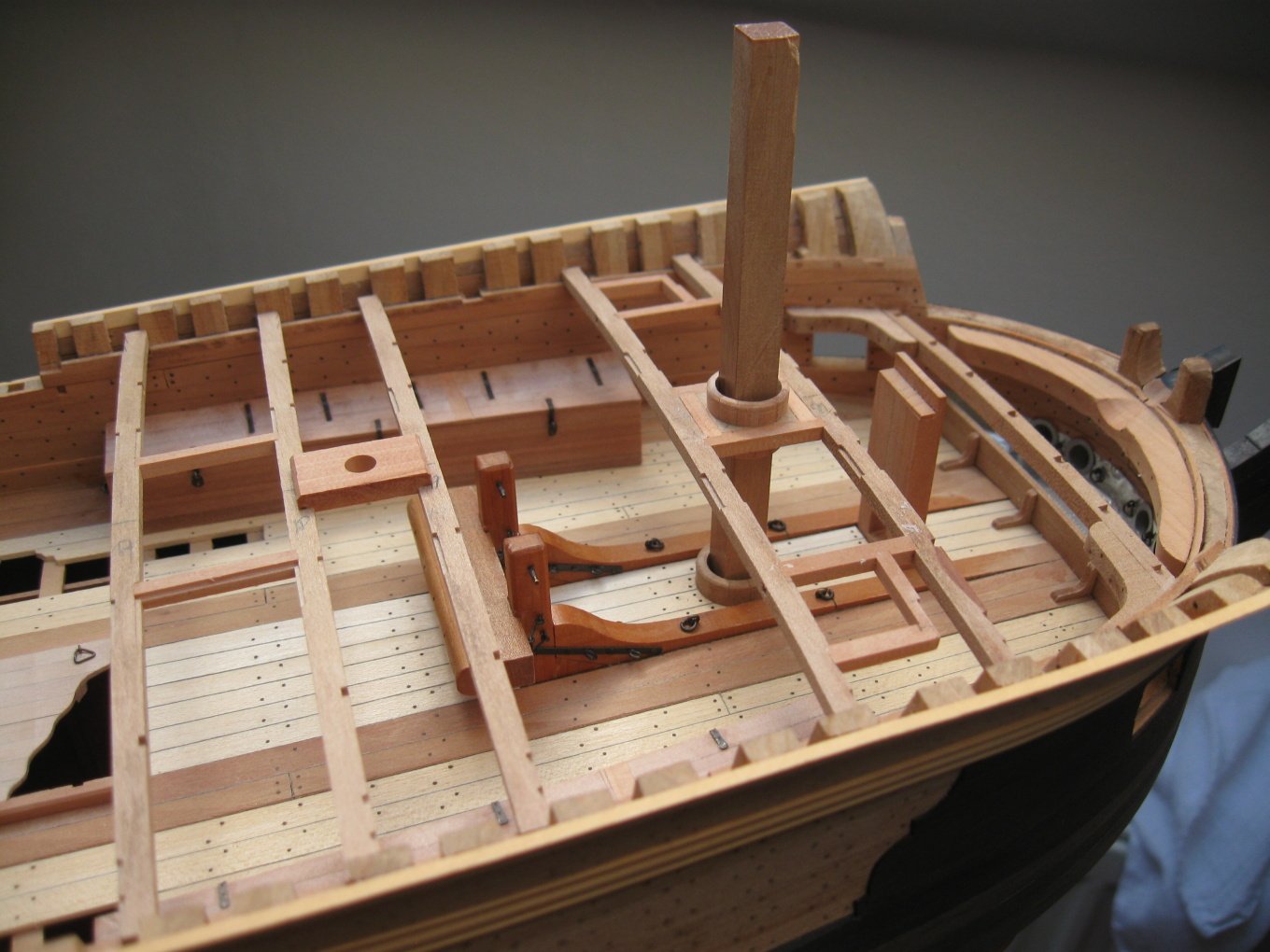

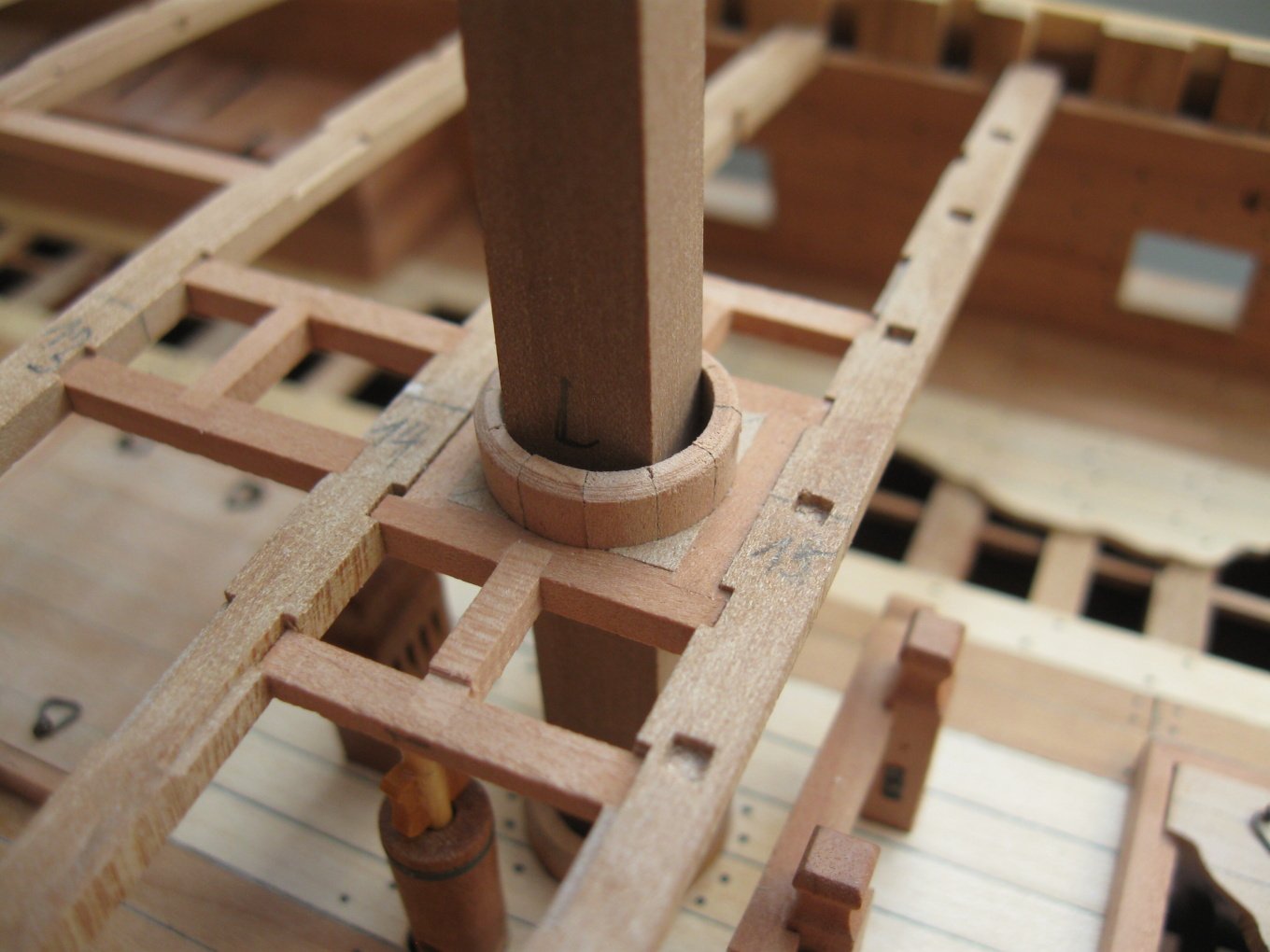

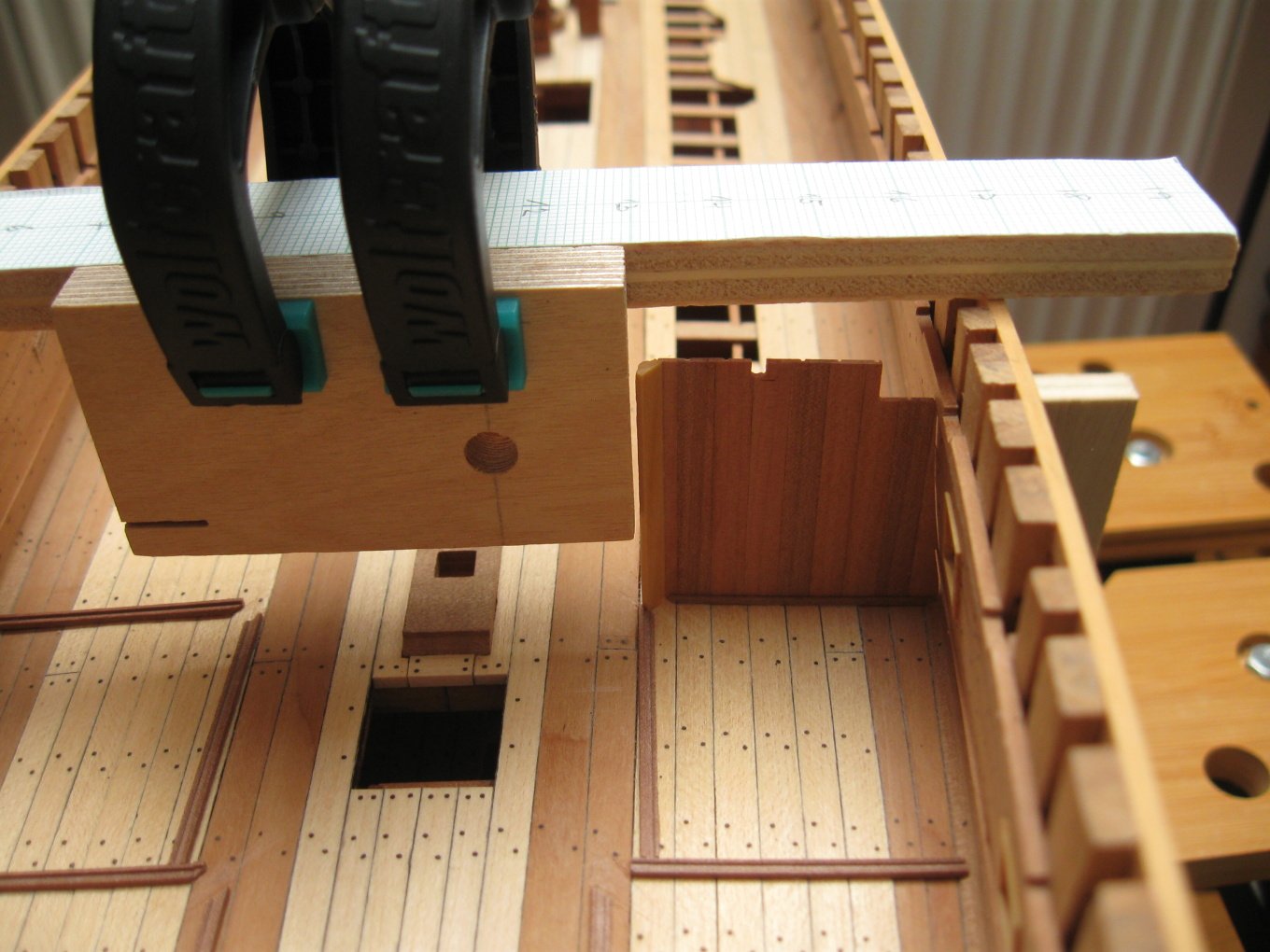

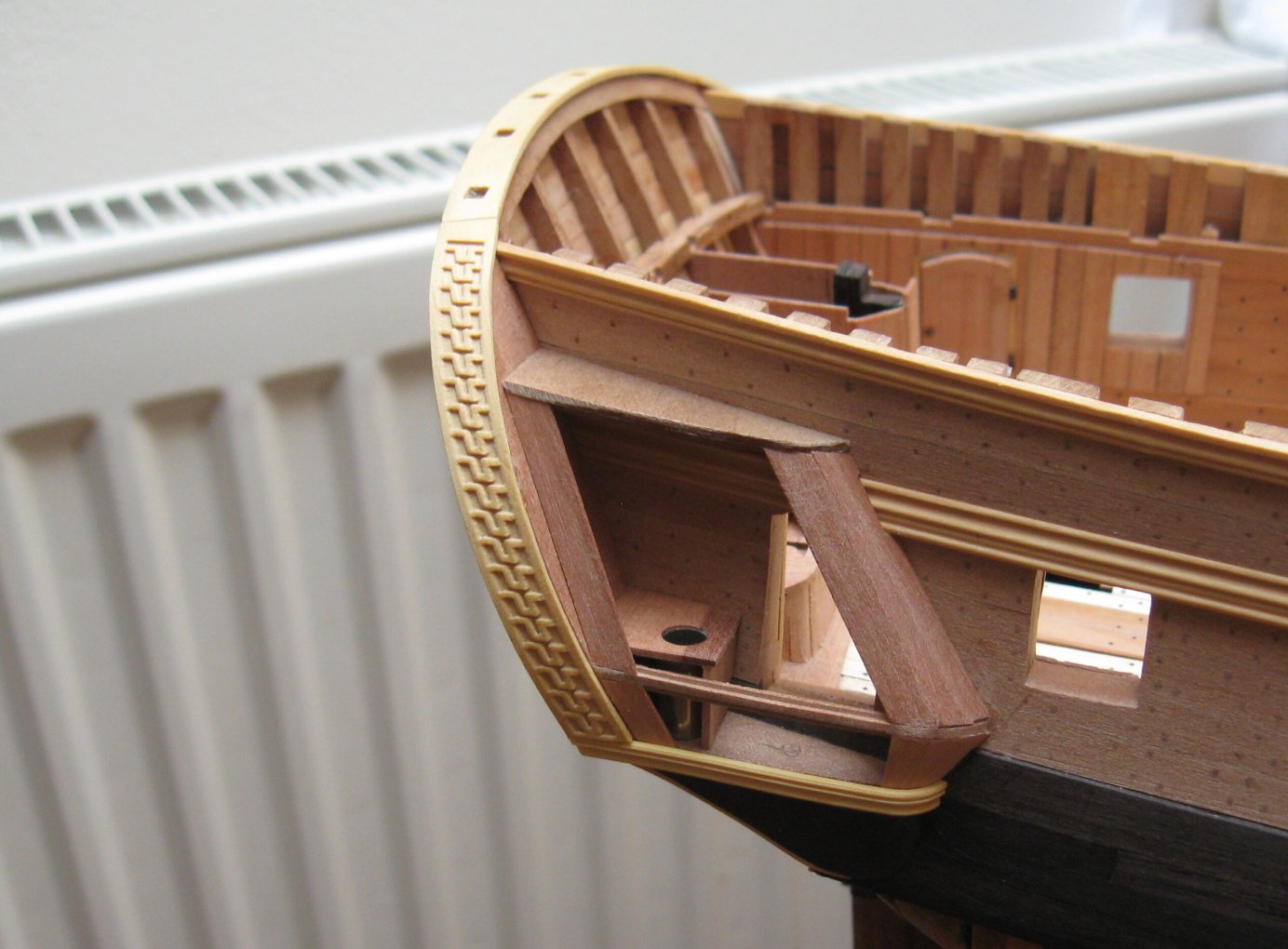

To claybaker and garyshipwright - These milling cutters are manufactured by a number of manufacturers in the world, so it does not matter which manufacturer you choose. There are several of these manufacturers on aliexpress. I myself chose the "Chinese variant" because it is significantly cheaper and will do the same service as more expensive milling cutters. Installation of quarterdeck deck beams.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

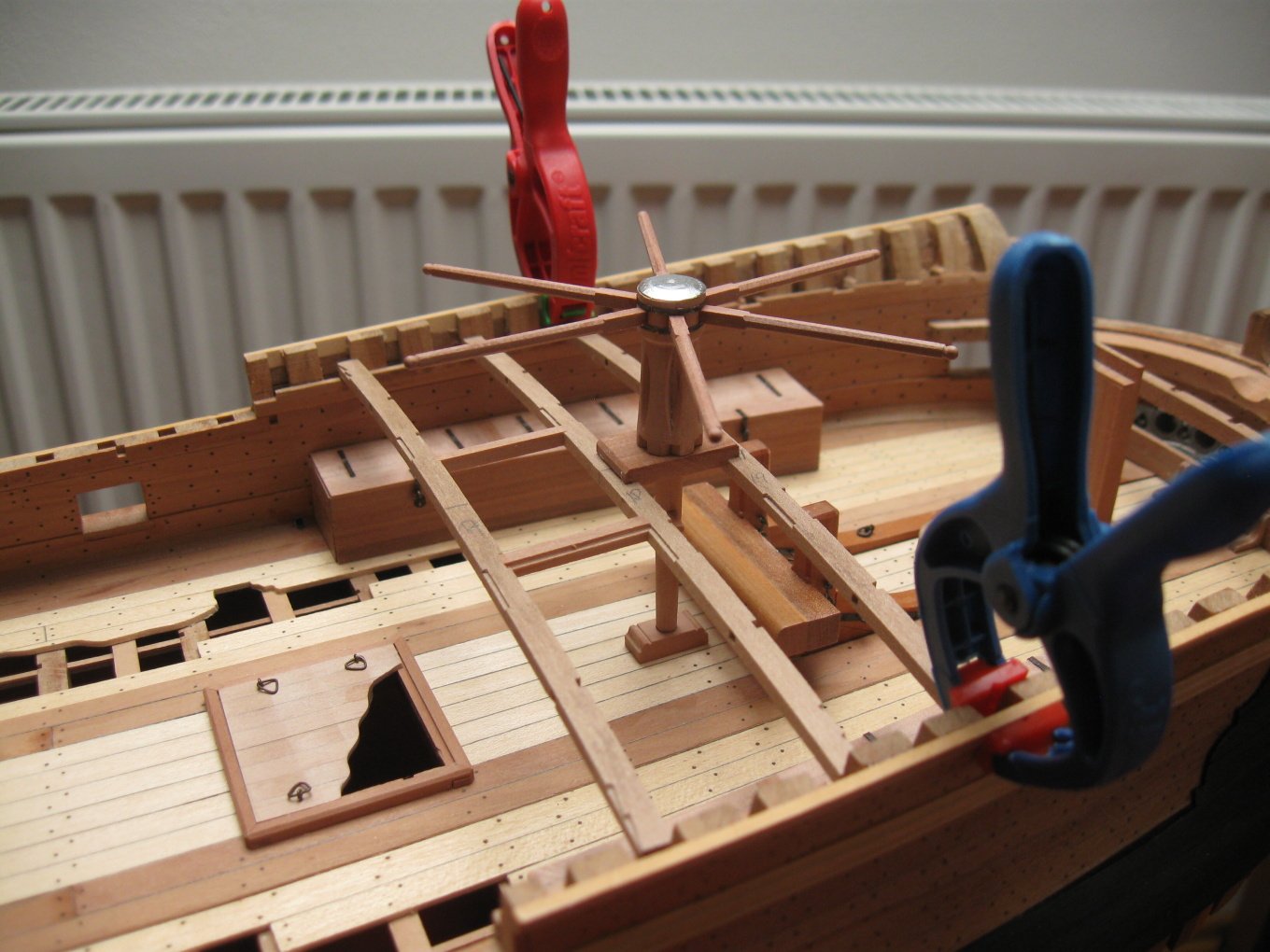

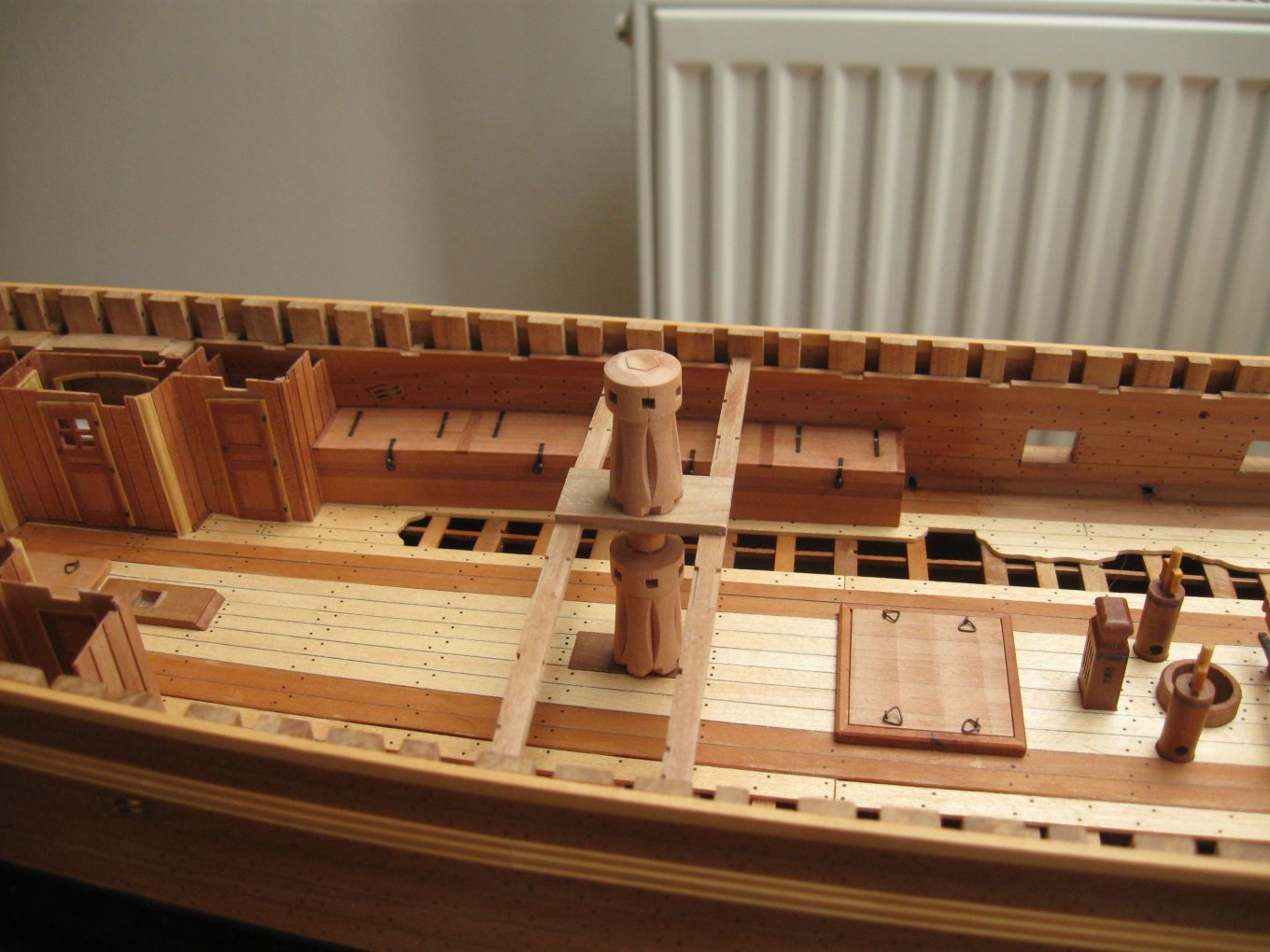

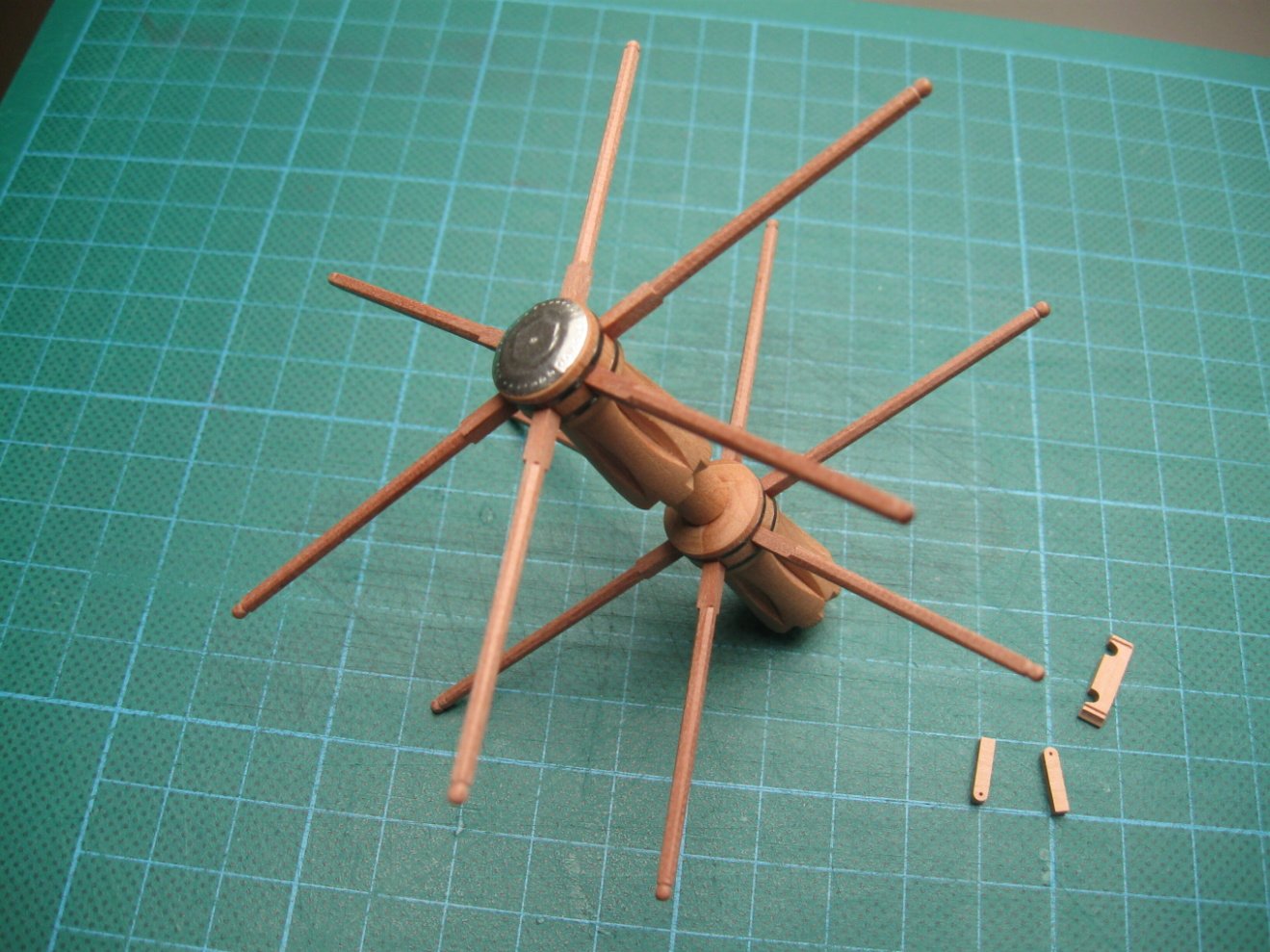

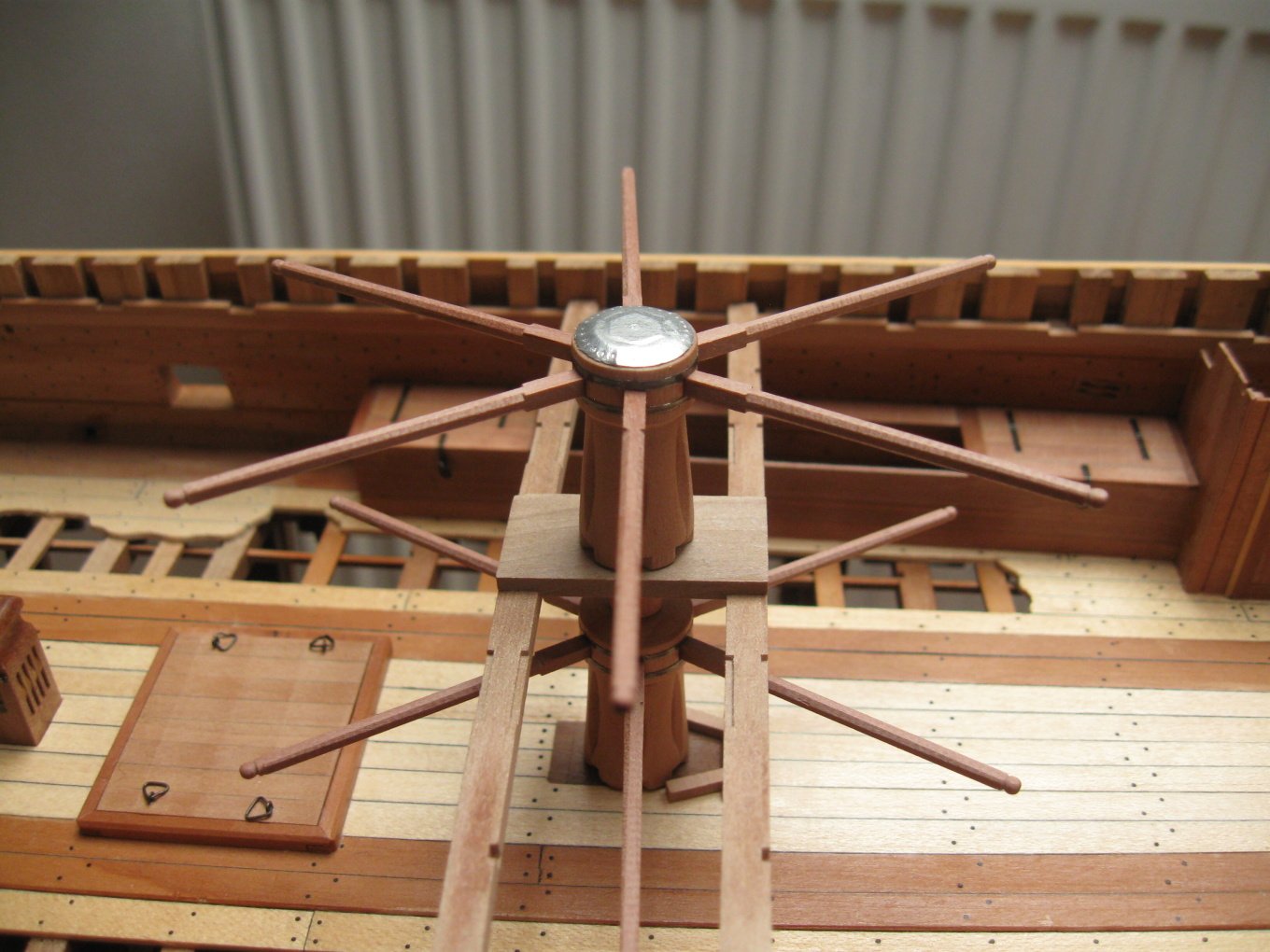

To G. Delacroix - thanks for the info, I made the new one items with no wedges To garyshipwright - I am using "10 Degree 0.1mm Tip Carbide CNC Bits Flat Bottom Milling Cutter V Shape" (https://www.aliexpress.com/item/852725456.html) for most of CNC 3D carvings. Question about tutorial - I am so sorry, making a video tutorial would be too time consuming and my knowledge of English is minimal. I continue with the assembly of the capstans.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

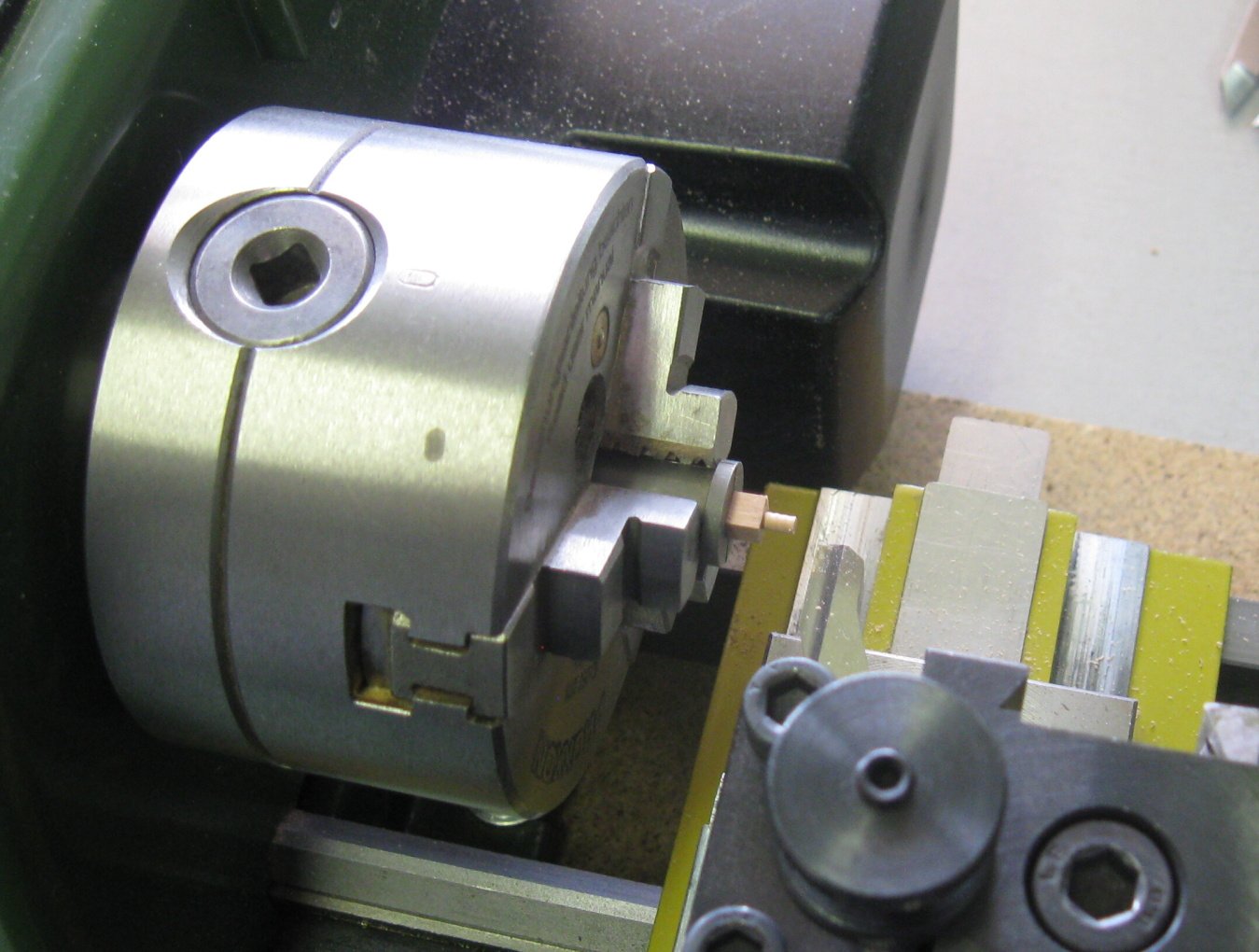

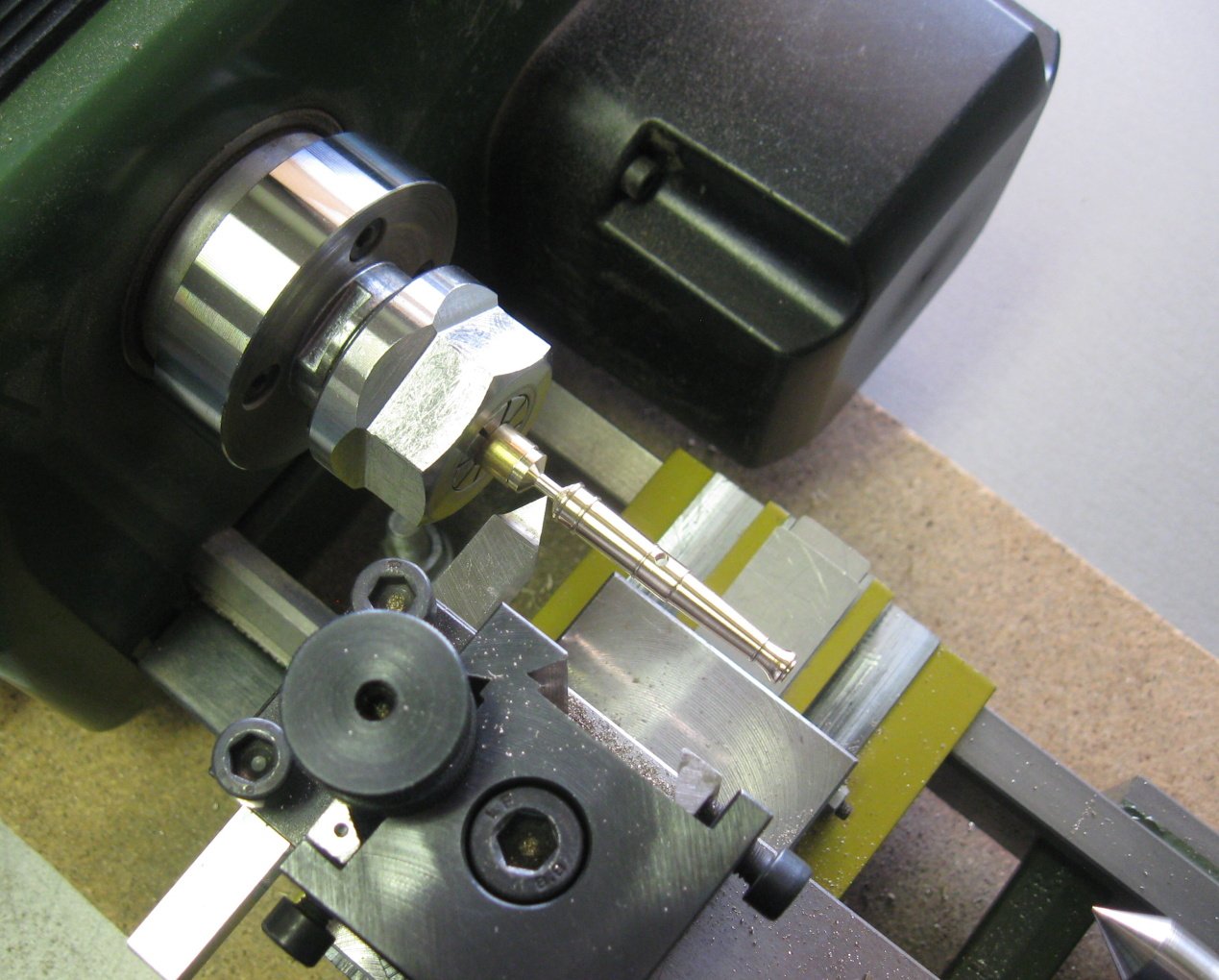

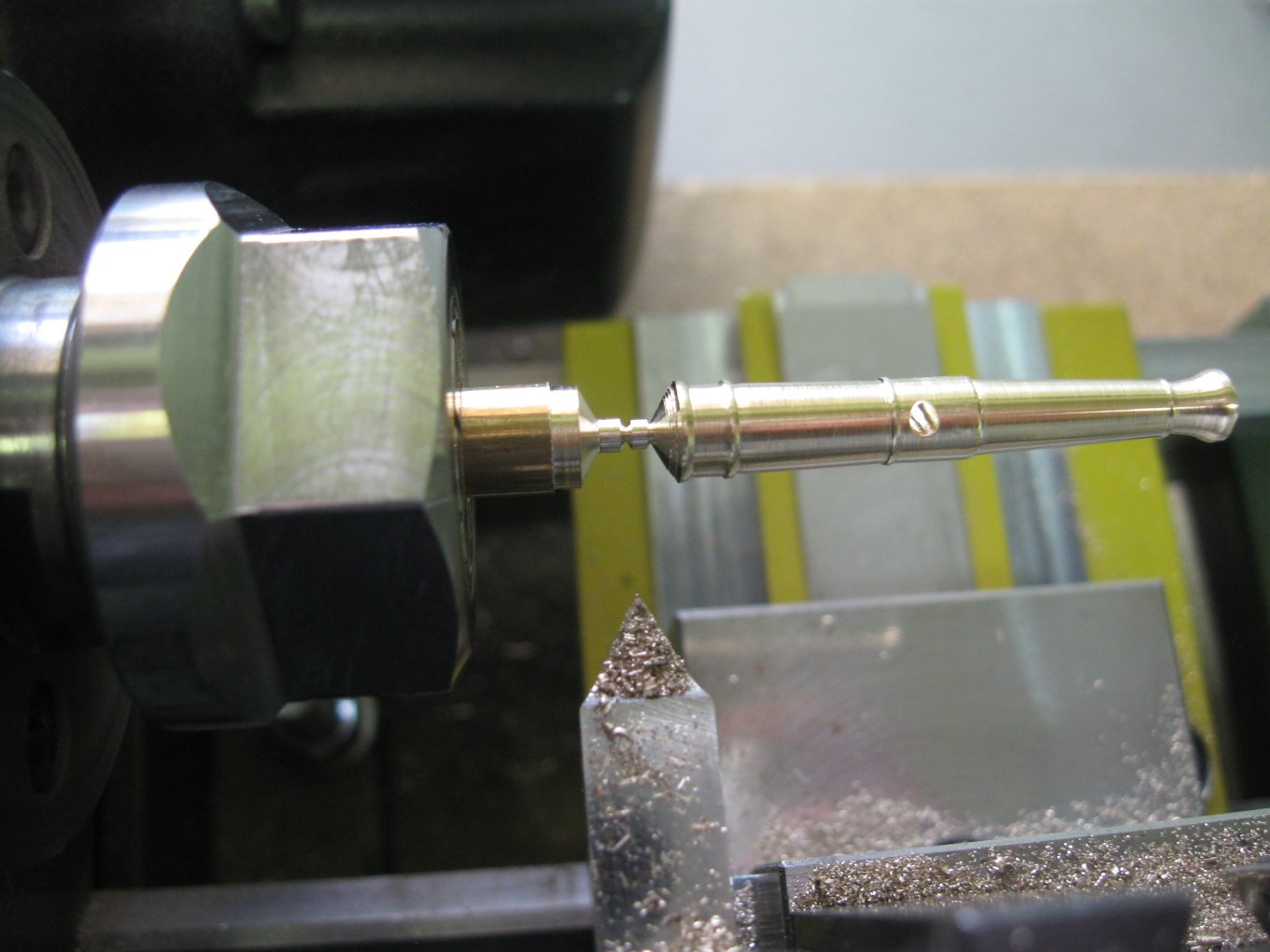

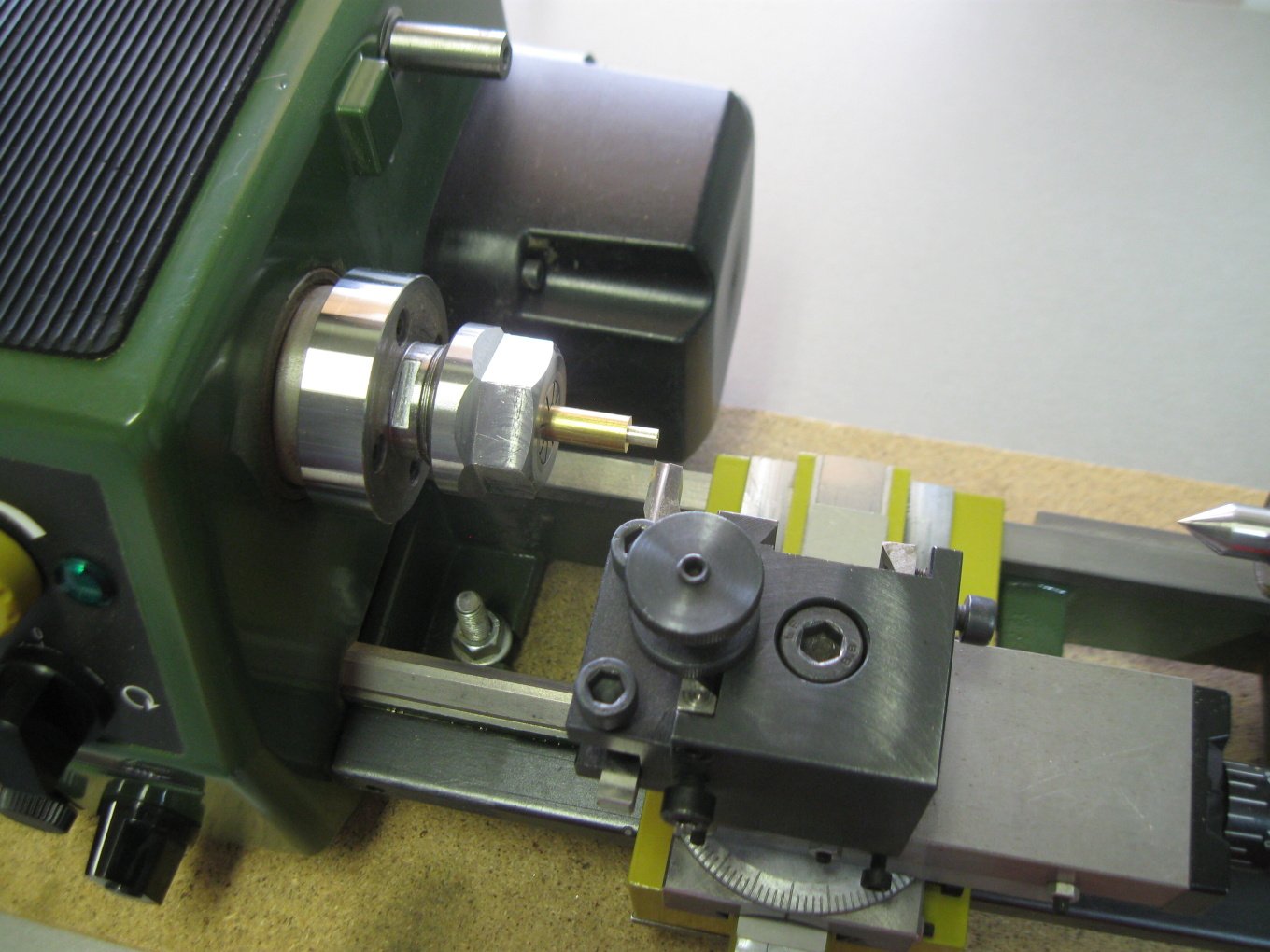

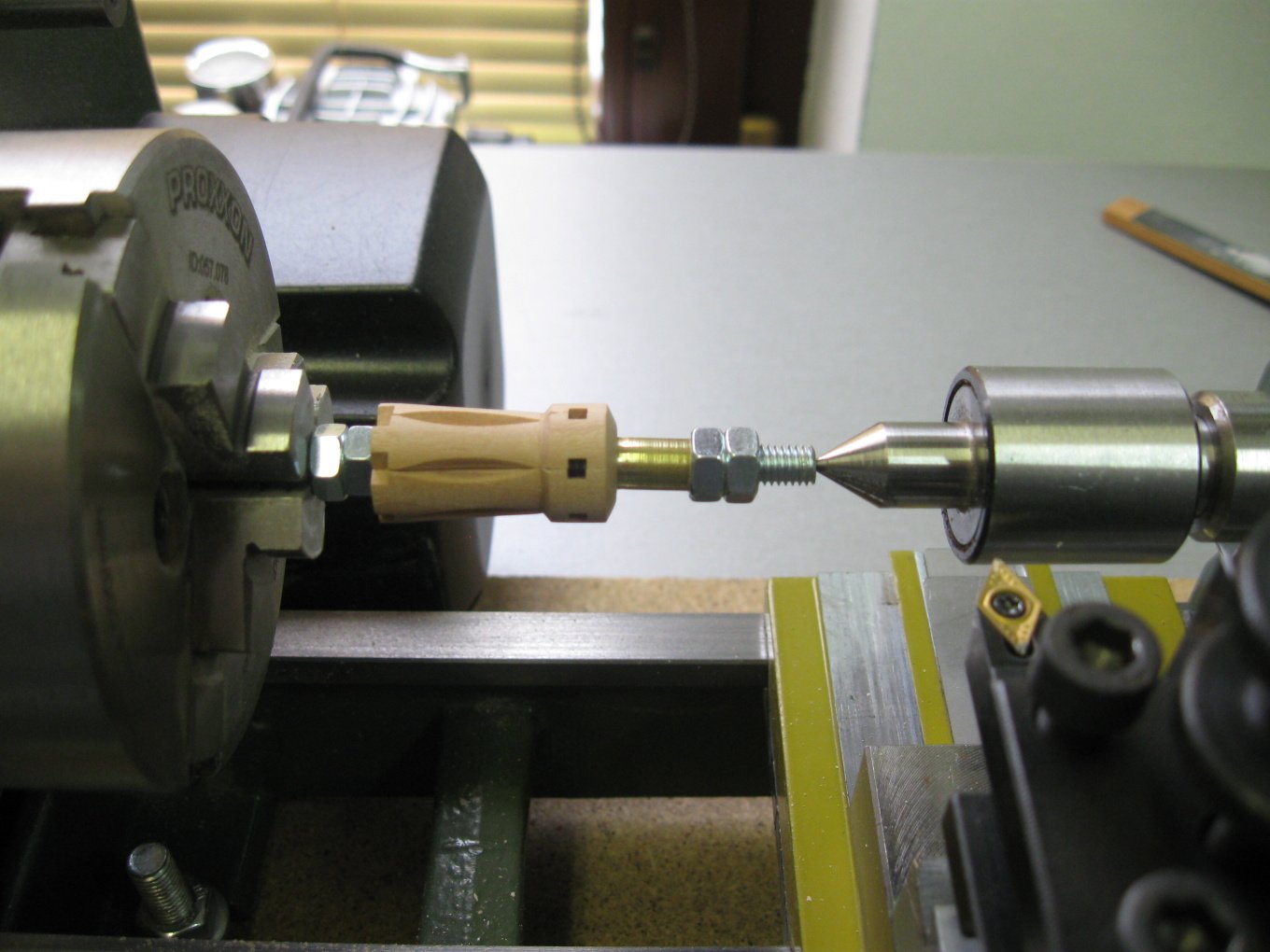

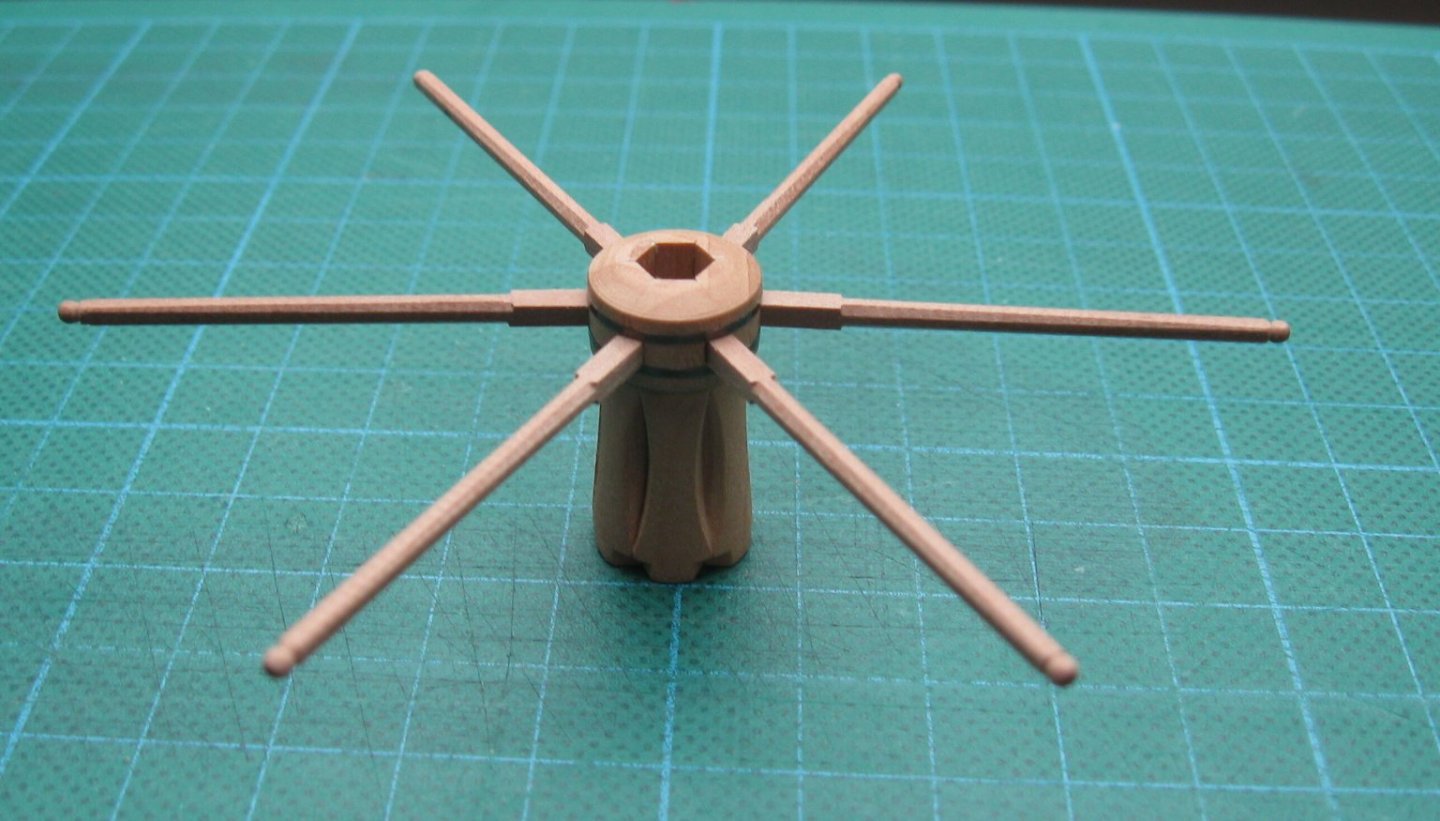

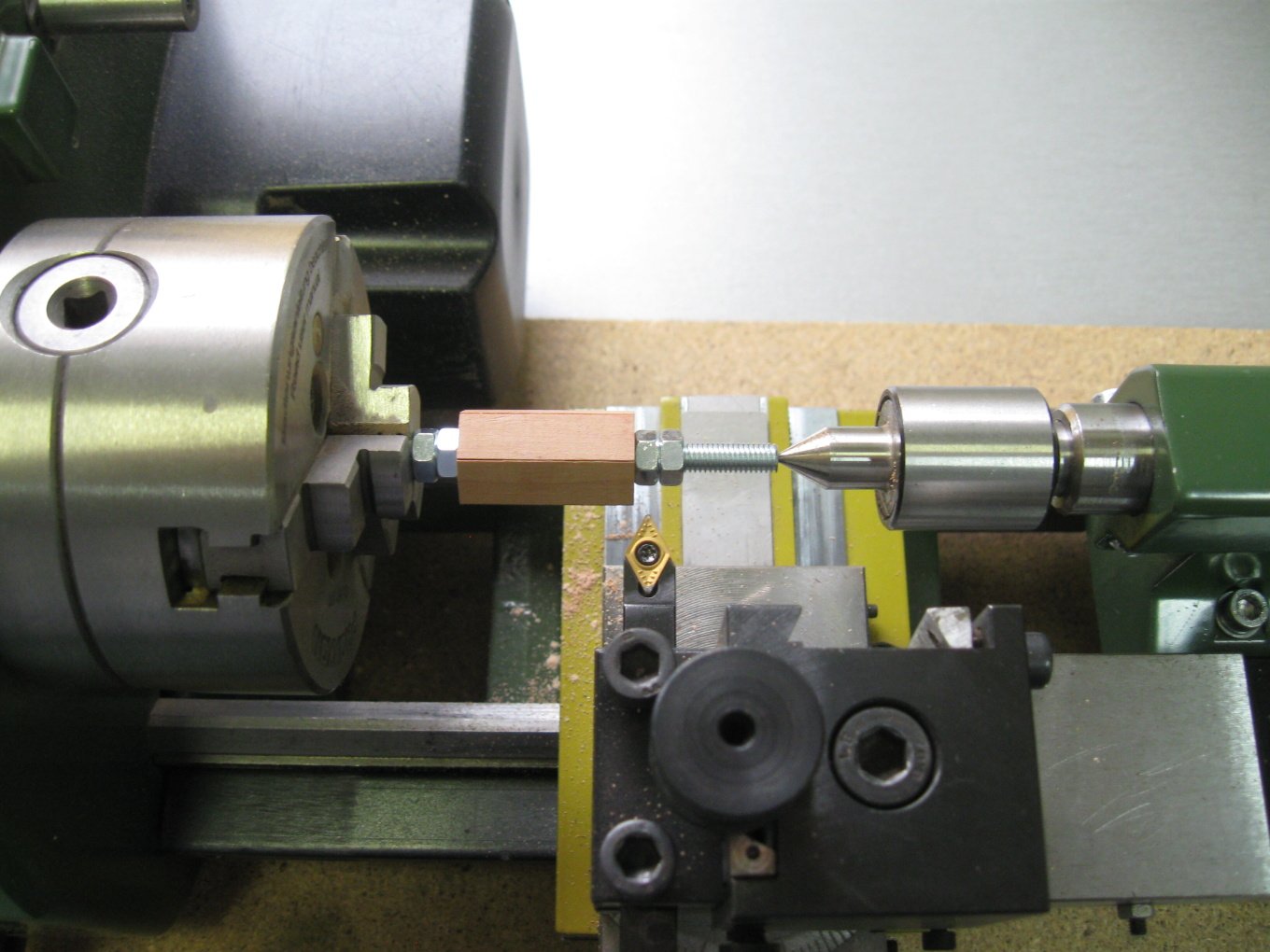

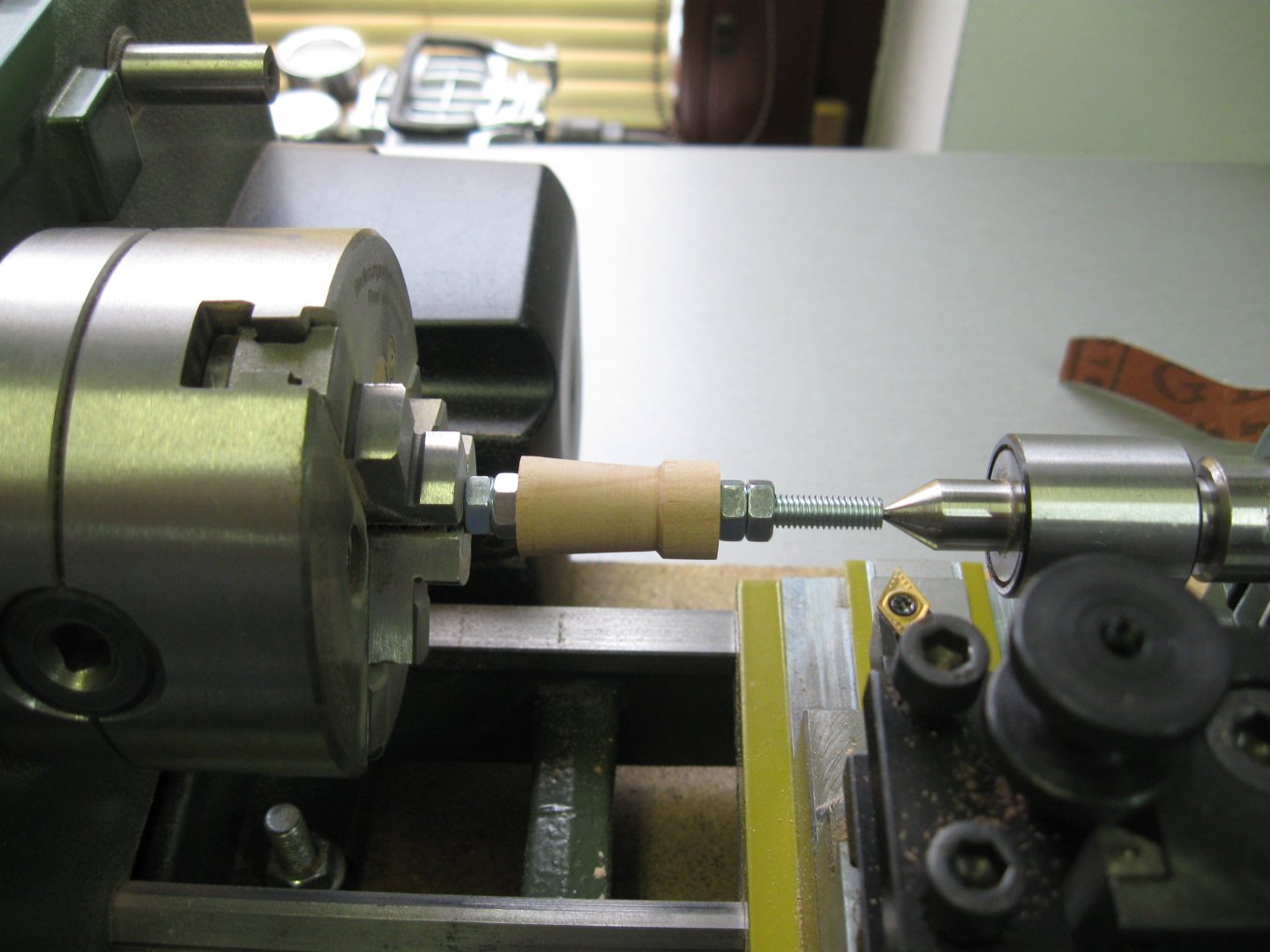

Thank you guys for all likes and comments. I understand that for some people, the use of CNC machines is a somewhat controversial topic. On the other hand, I remember how I started modeling about 40 years ago with a hand saw and a set of files. Today, no one dares to use various electrical devices that make it easier for us modelers to work. From this point of view, the CNC machine is just another evolutionary step. To garyshipwright: I am using VCarve Desktop. I am starting work on main capstan parts - some pictures from production.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

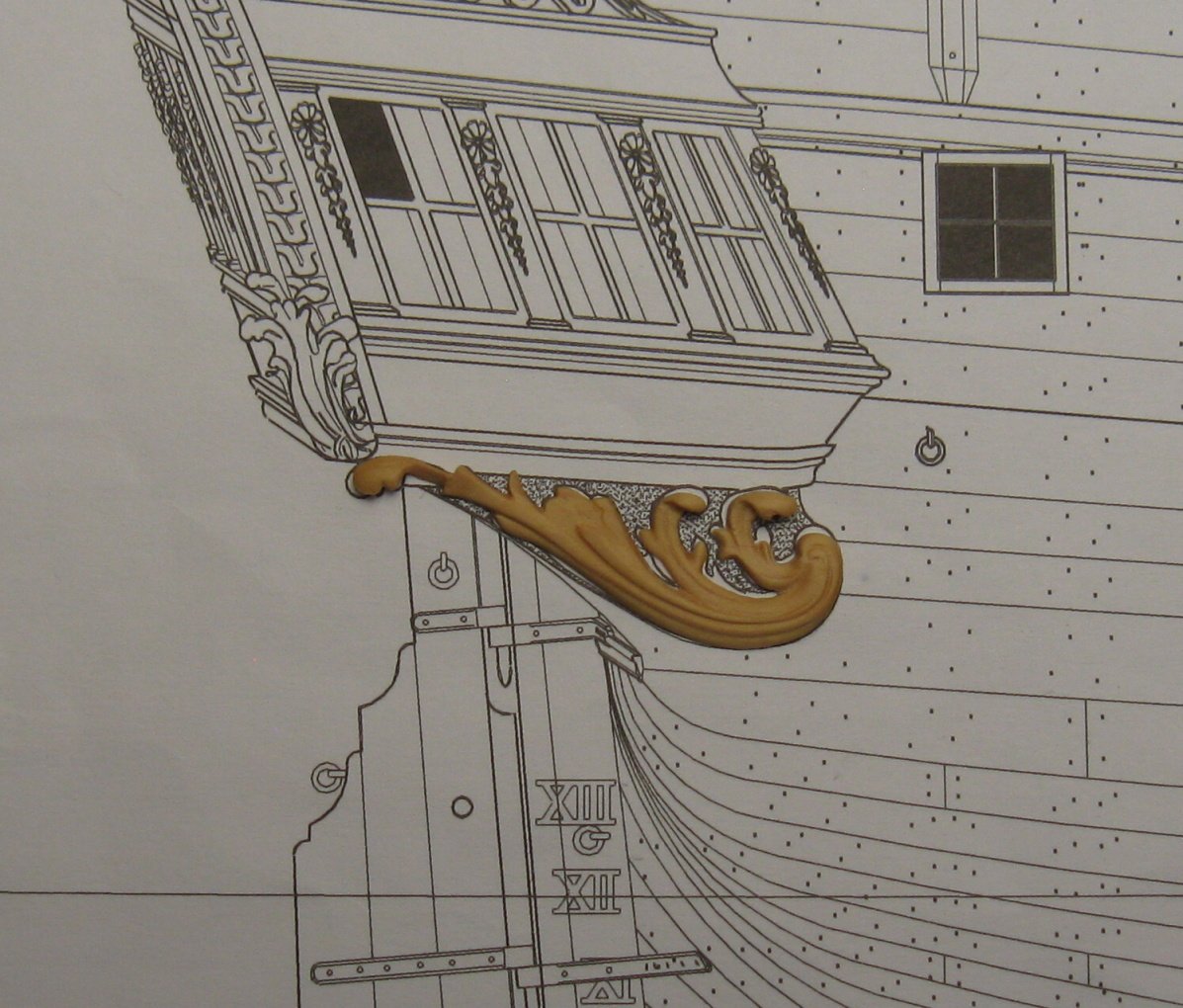

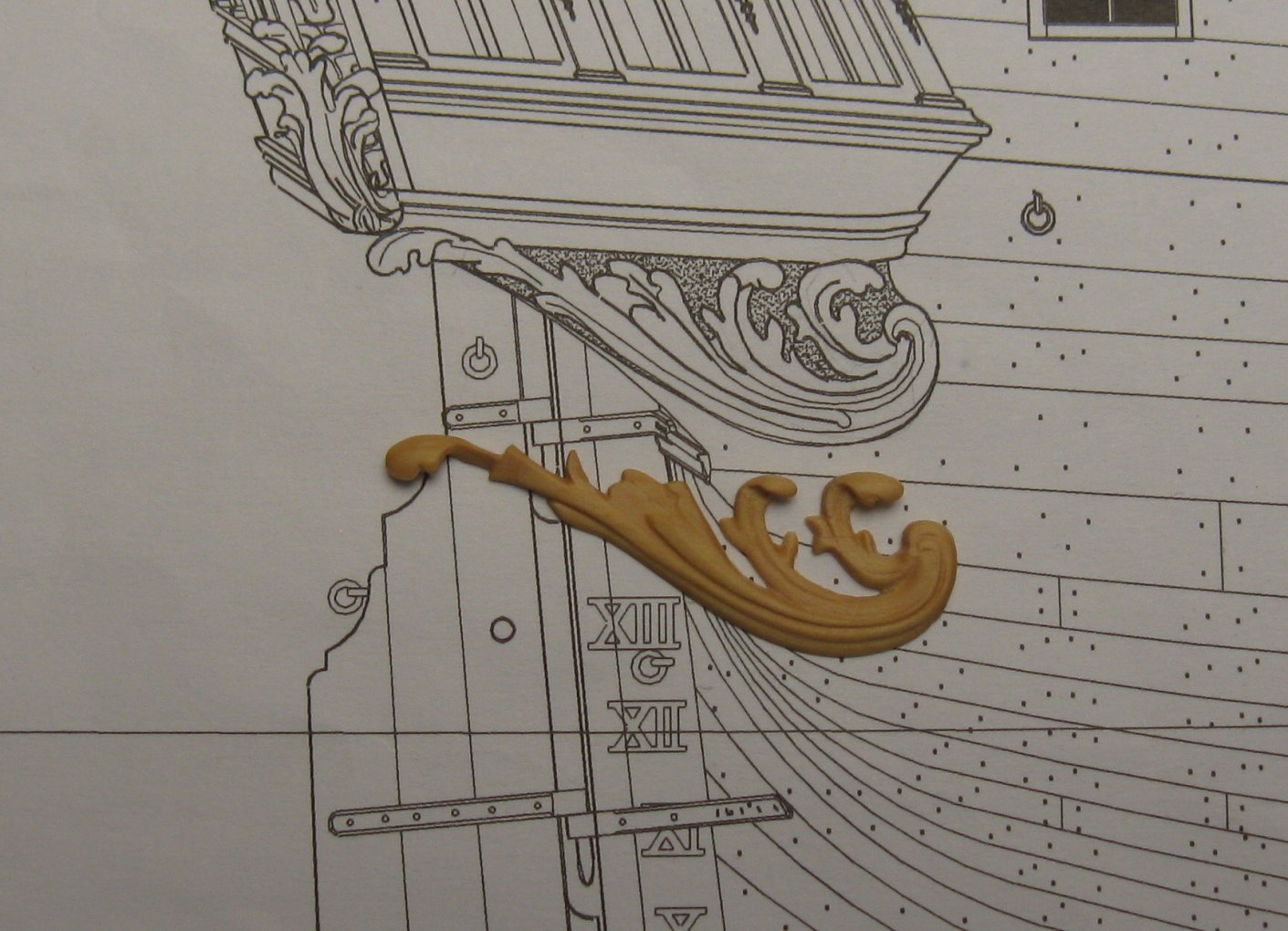

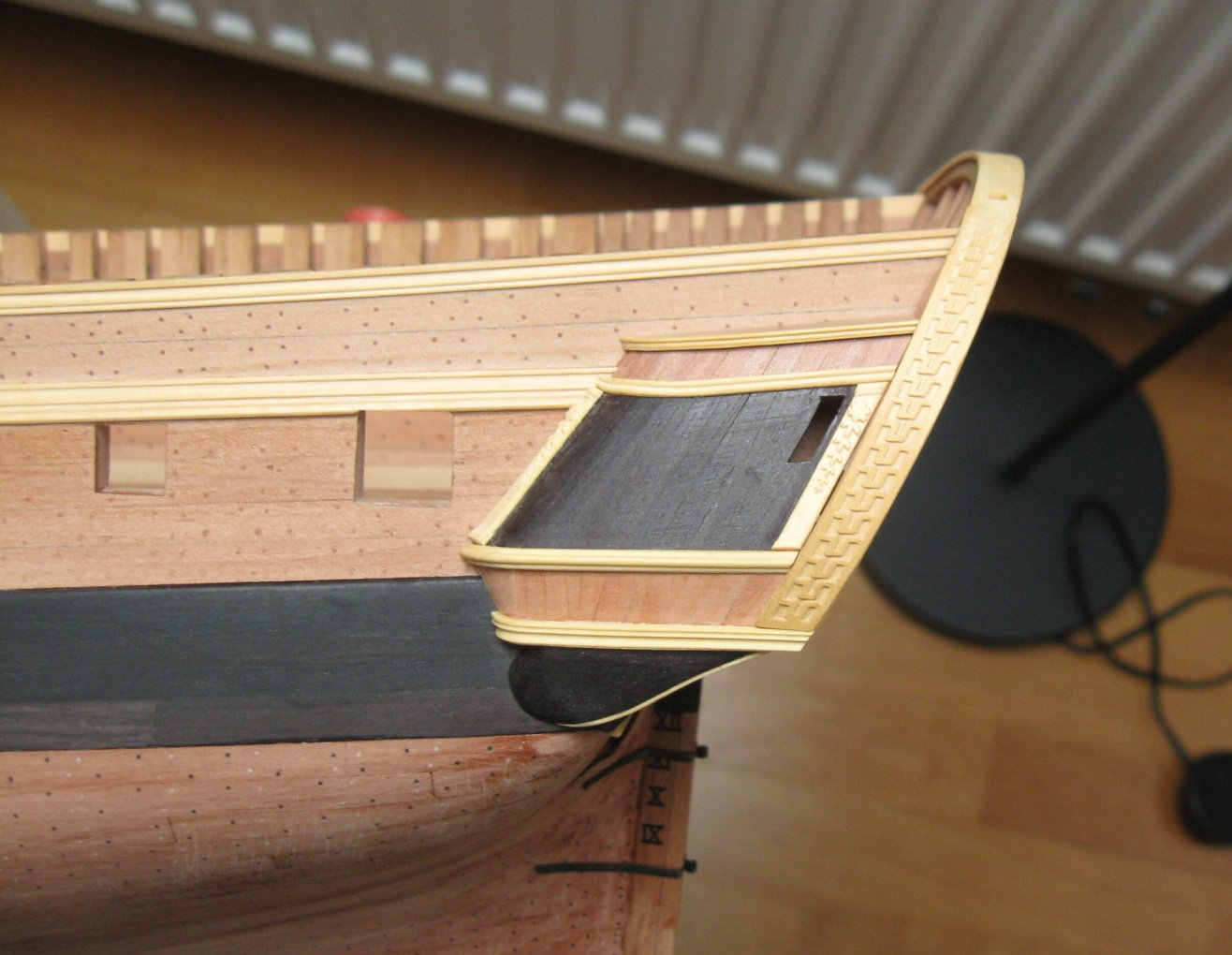

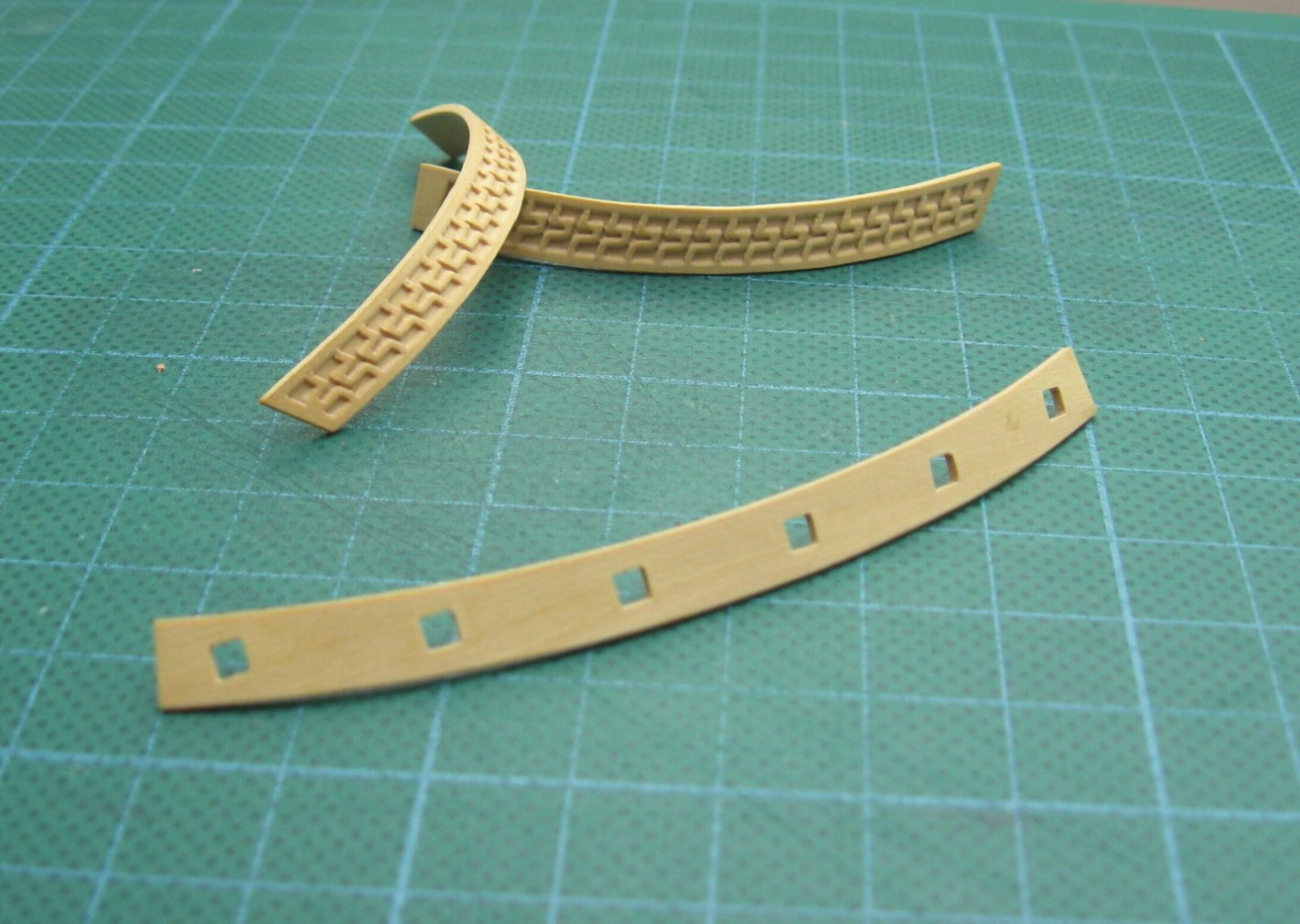

To PeteB: I used the black translucent paper for the caulking. The last stem decorations are added. All carvings are made with CNC milling maschine with small manual corrections.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Pandora by marsalv - FINISHED - 1:52

marsalv replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Hi Siegfried, you can follow my next project here - -

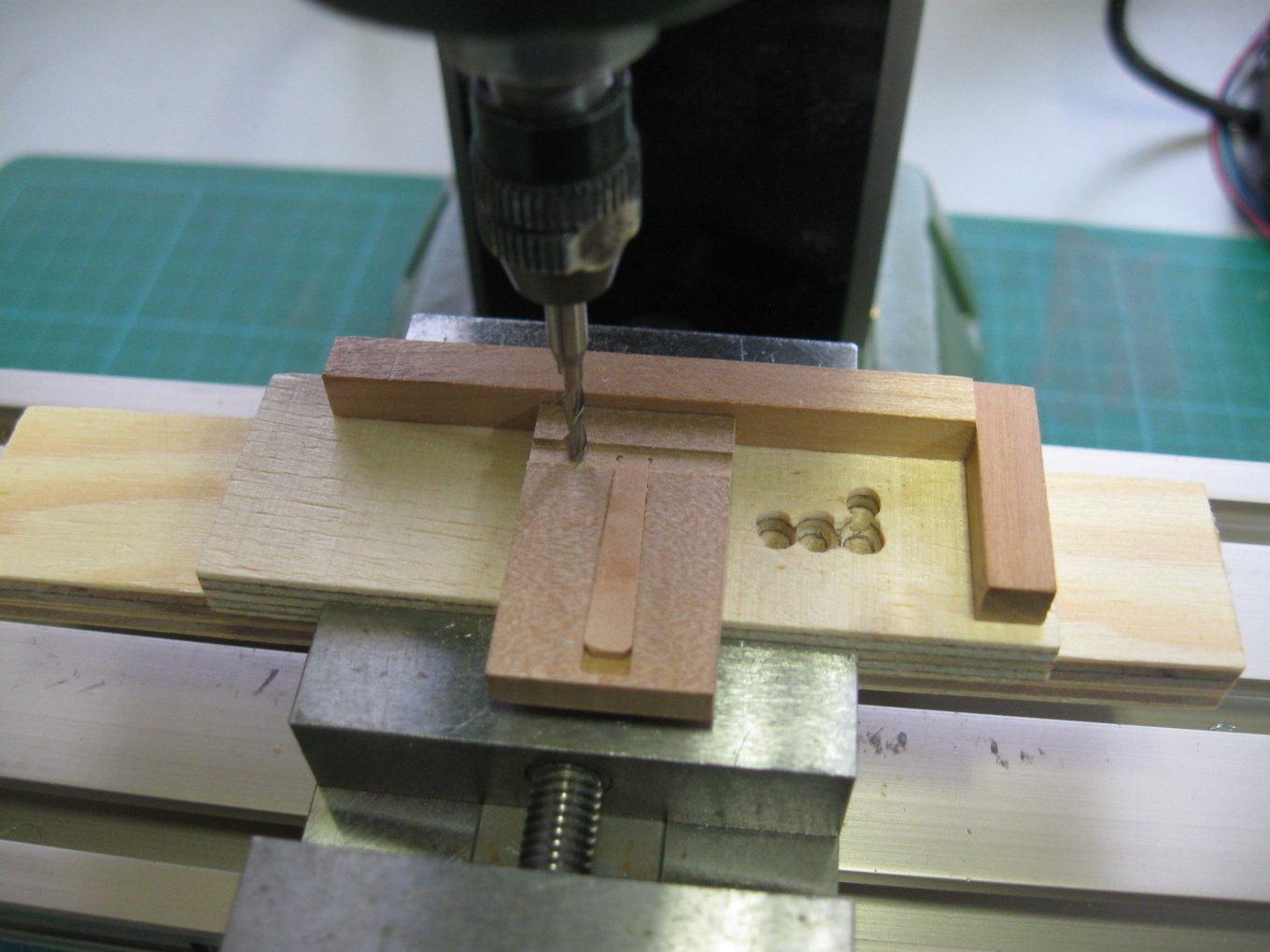

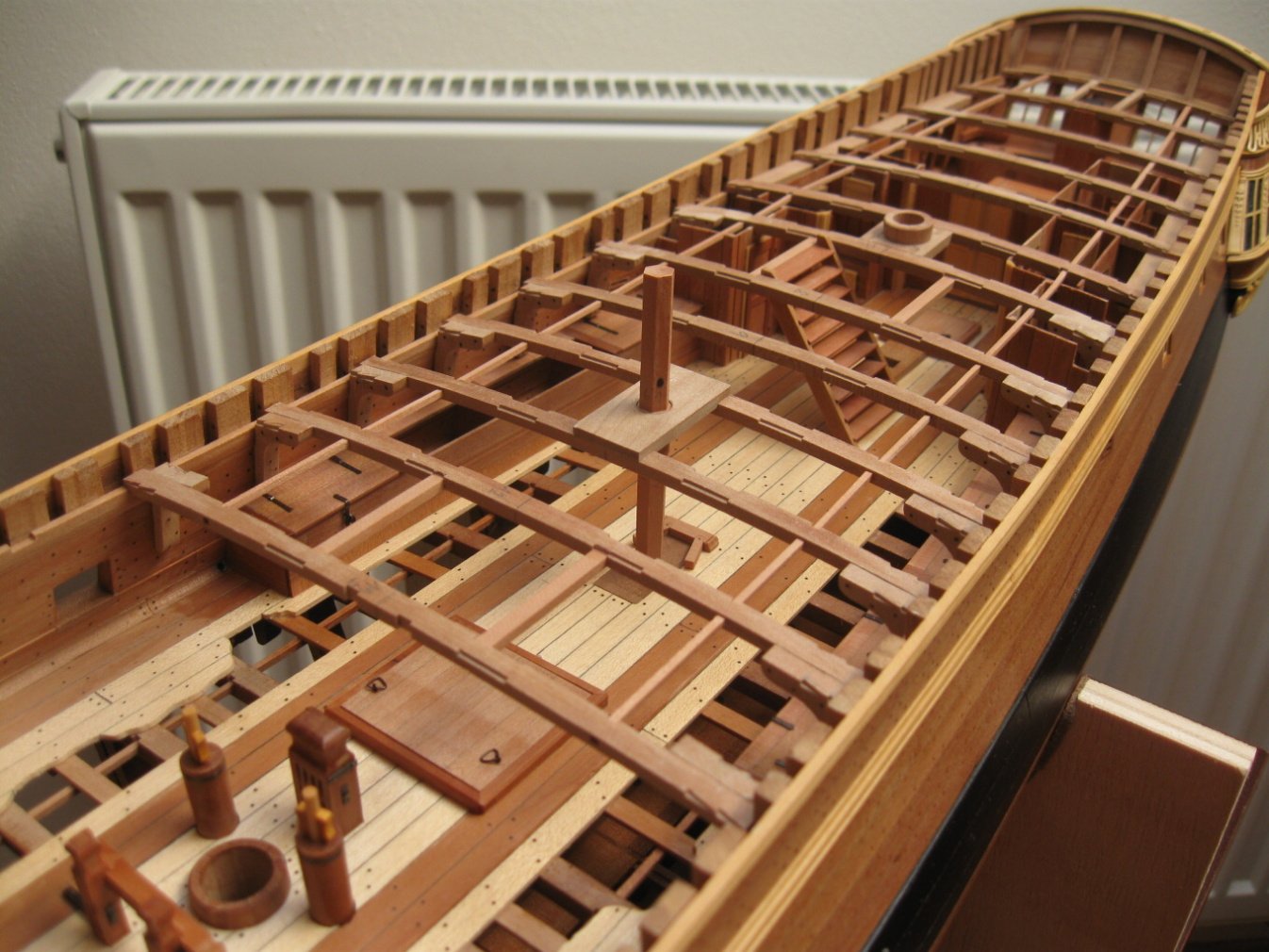

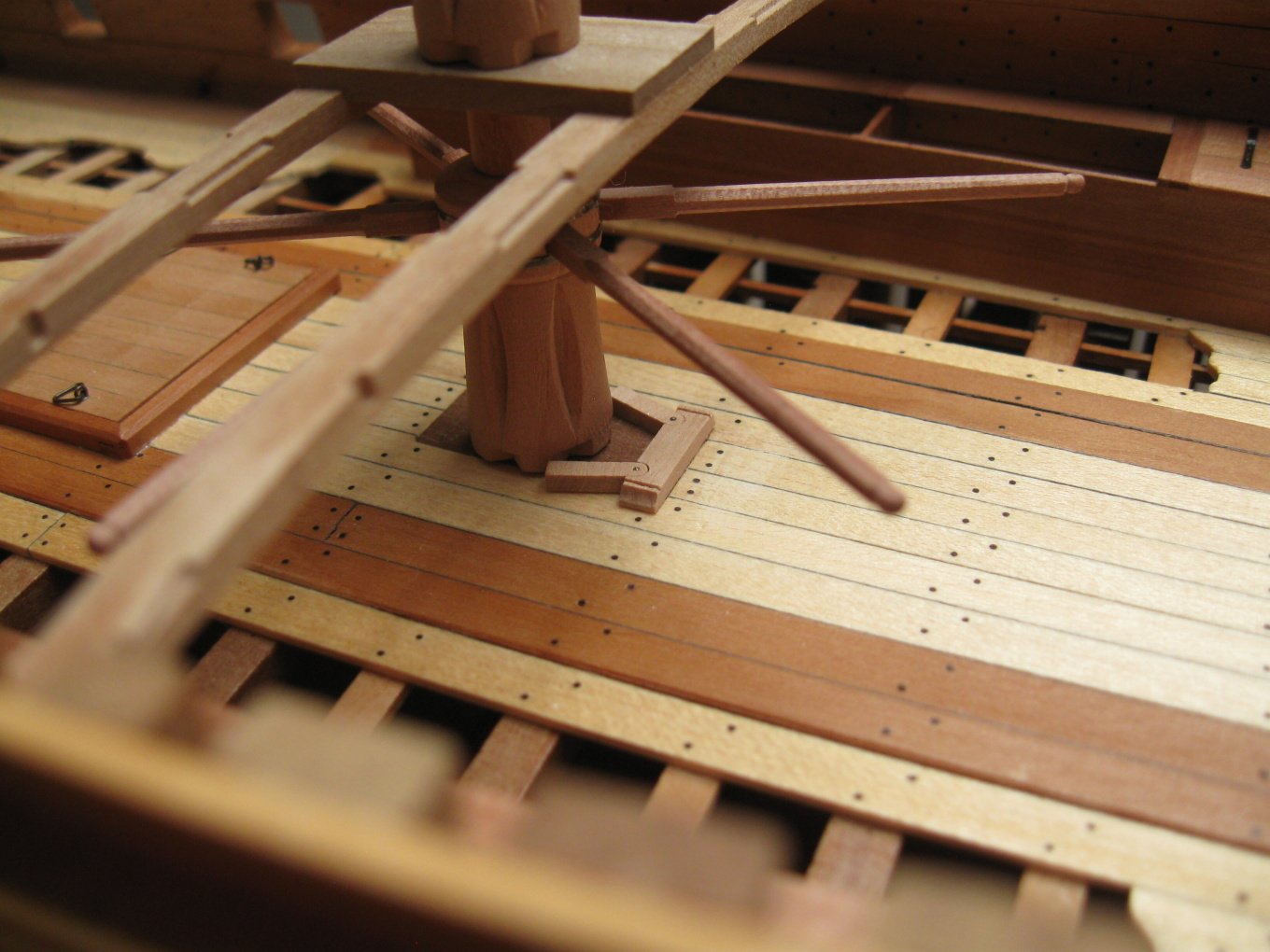

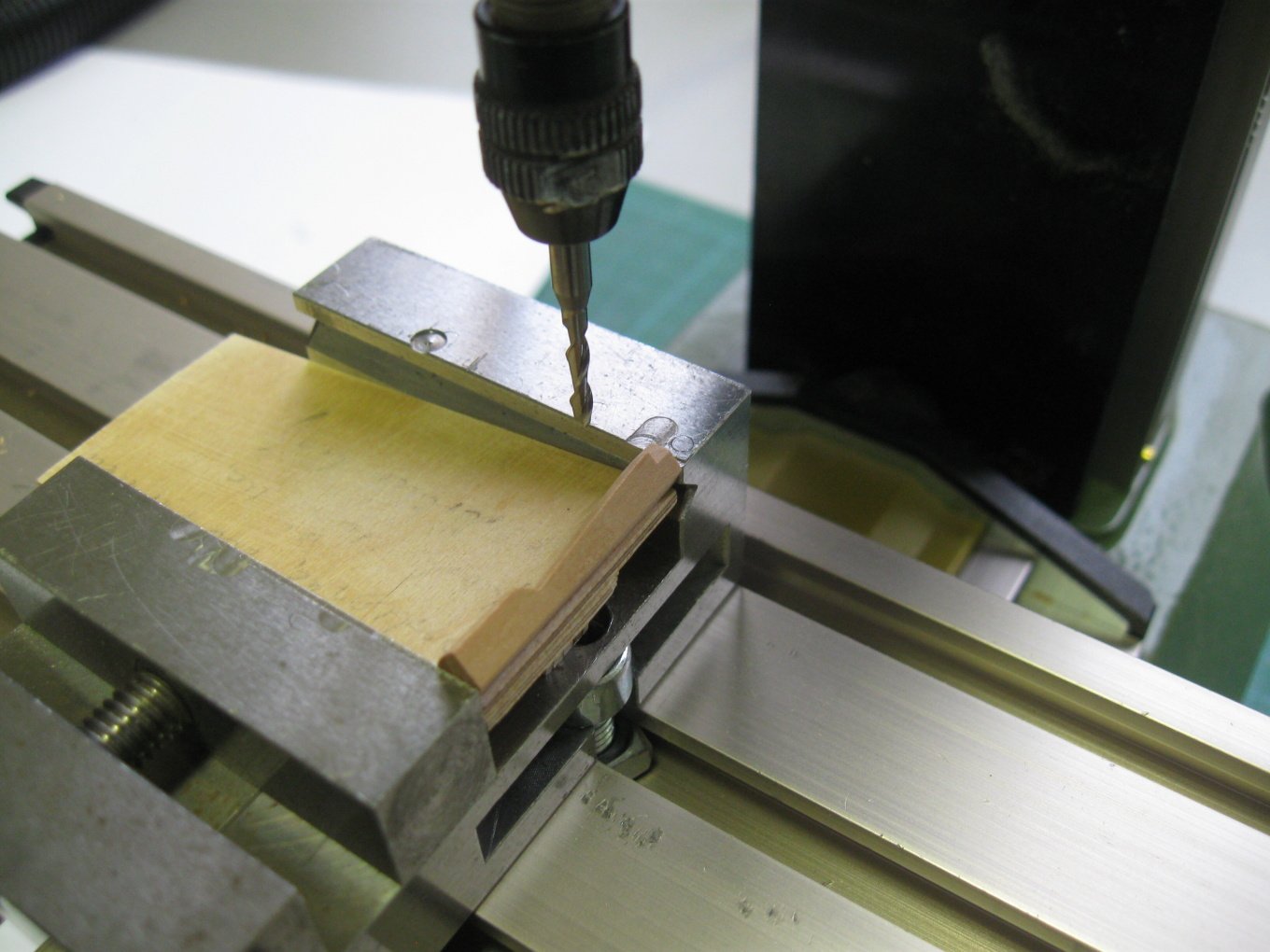

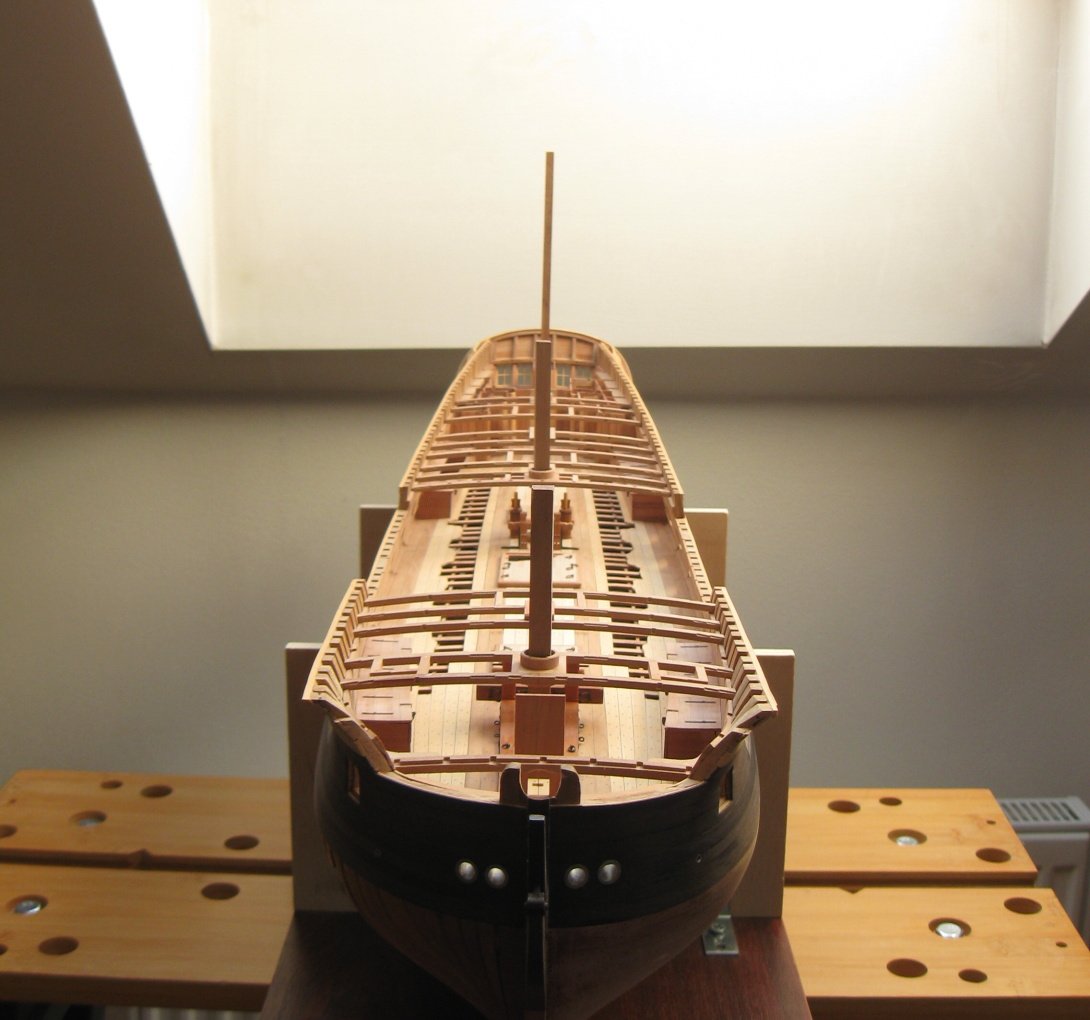

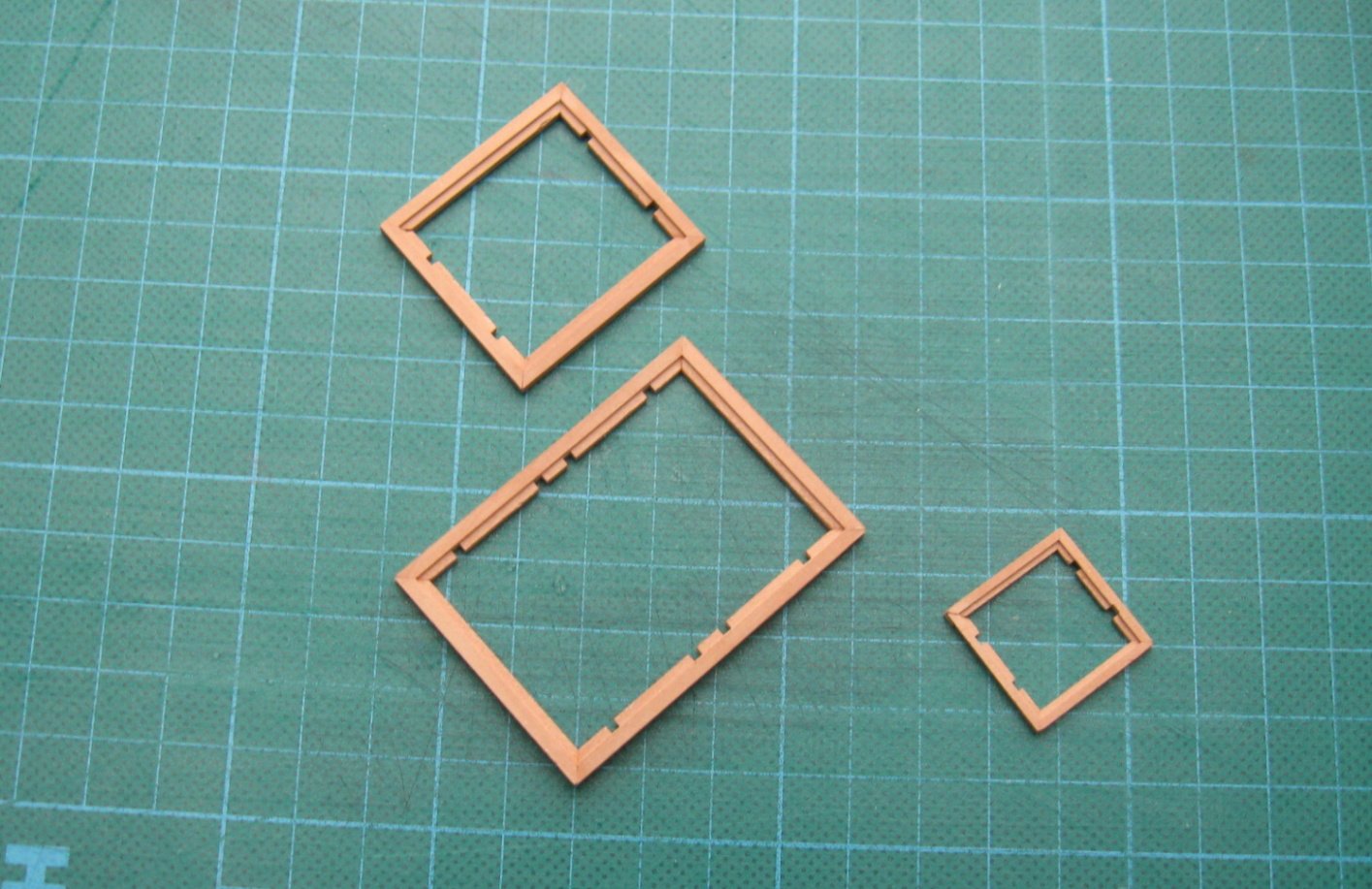

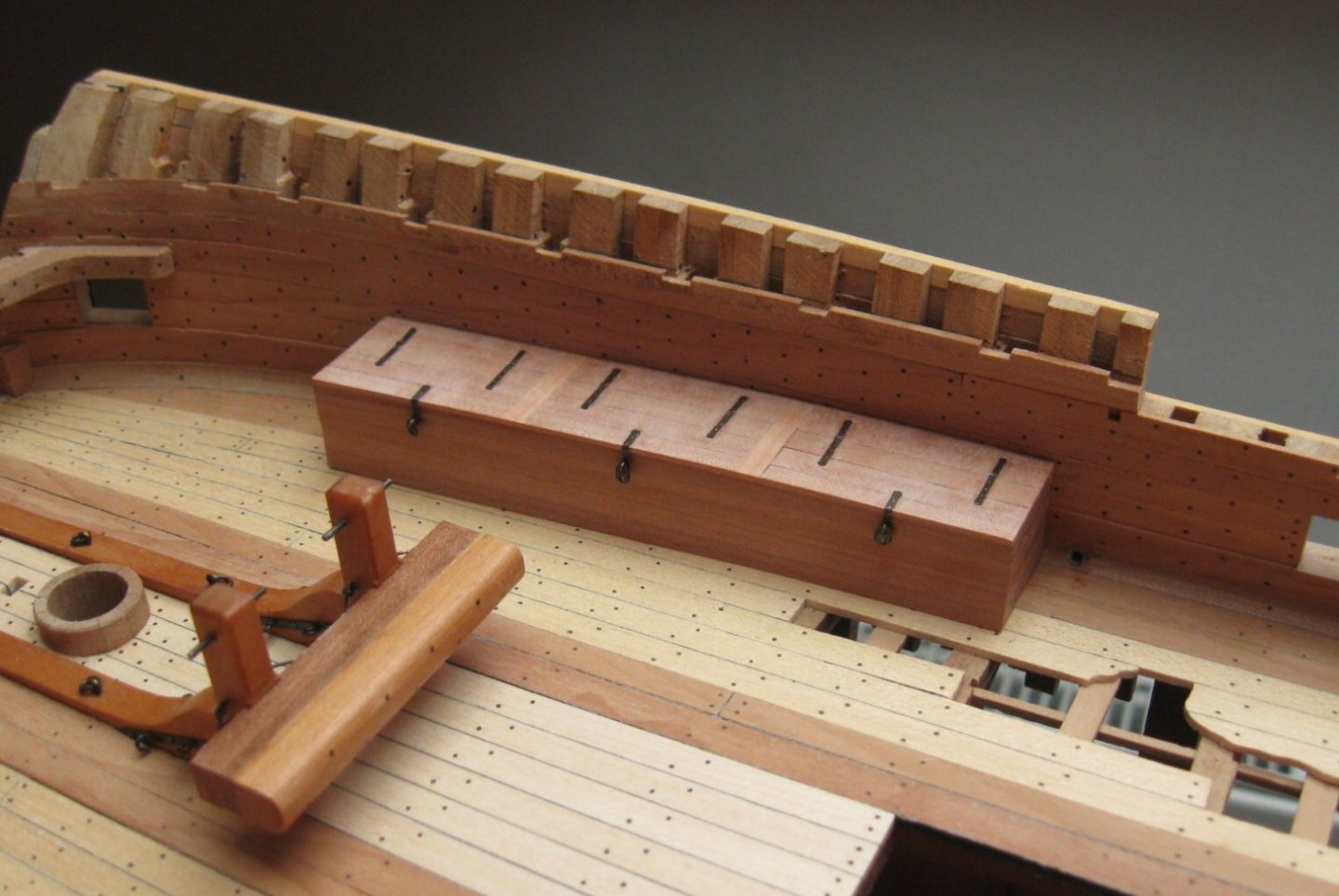

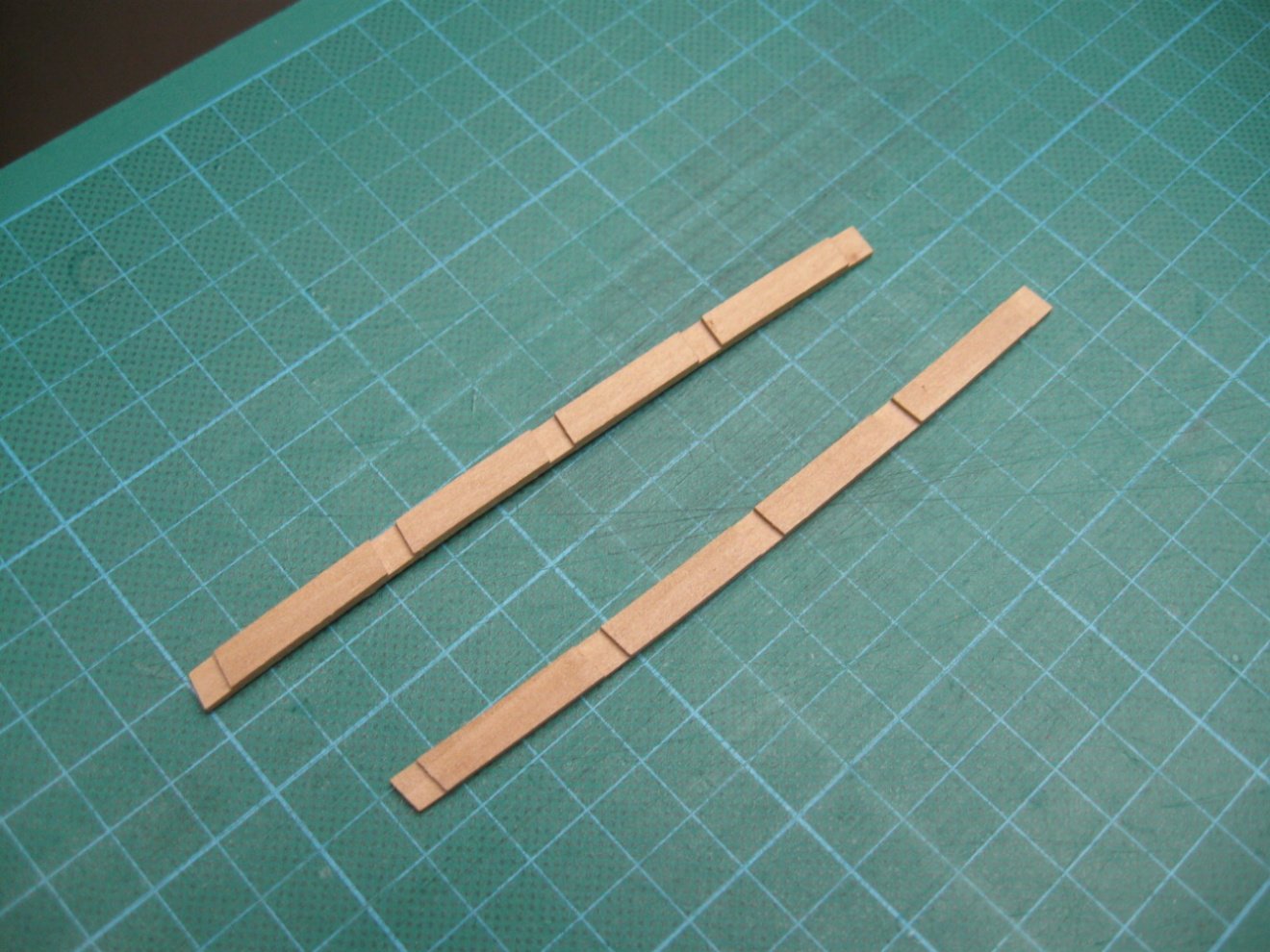

Thank you Alex M, I have to say I learned many things from you. Forecastle and quarter deck beams preparation - hatchway openings, capstan steps and mast wedges.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

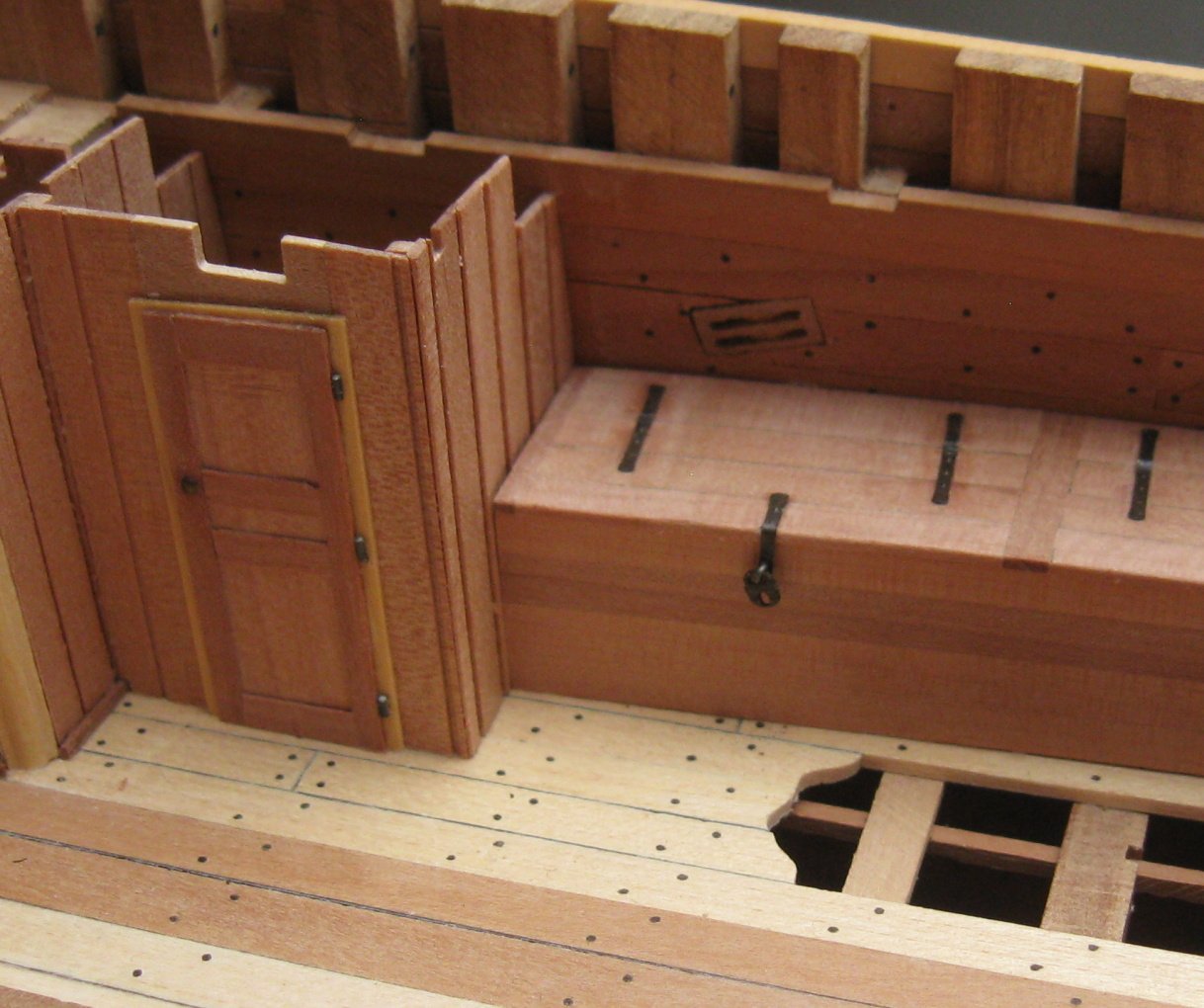

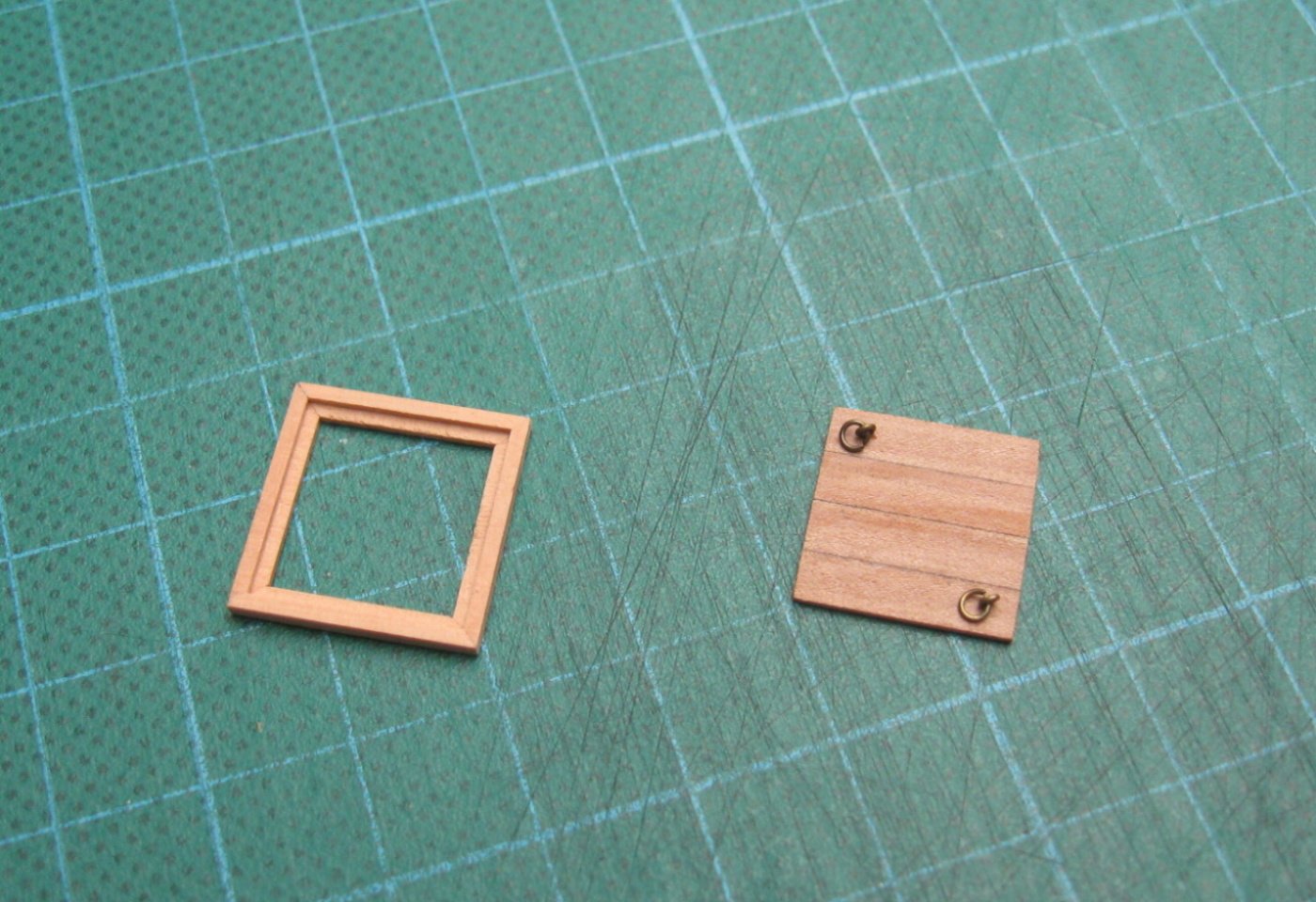

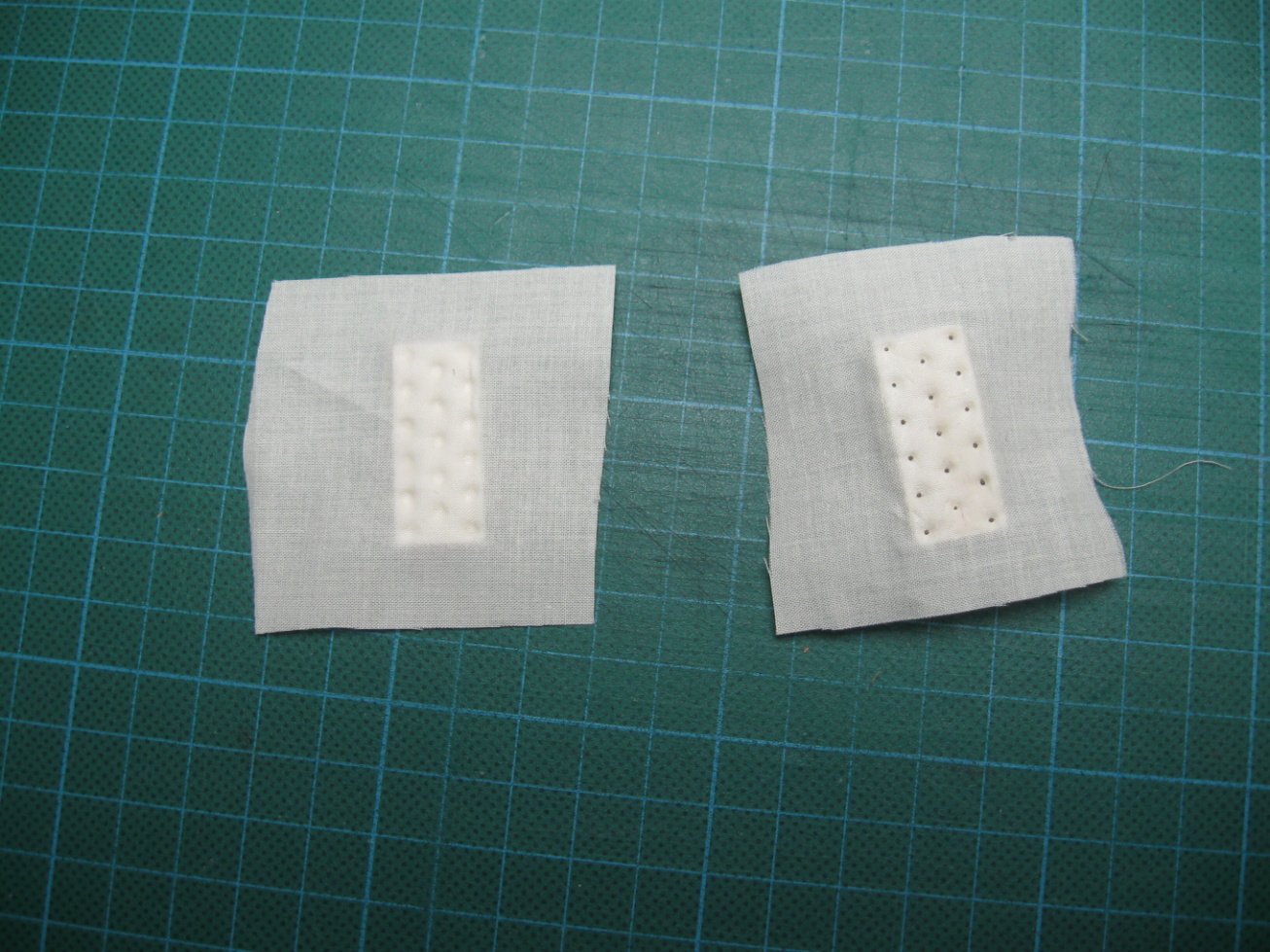

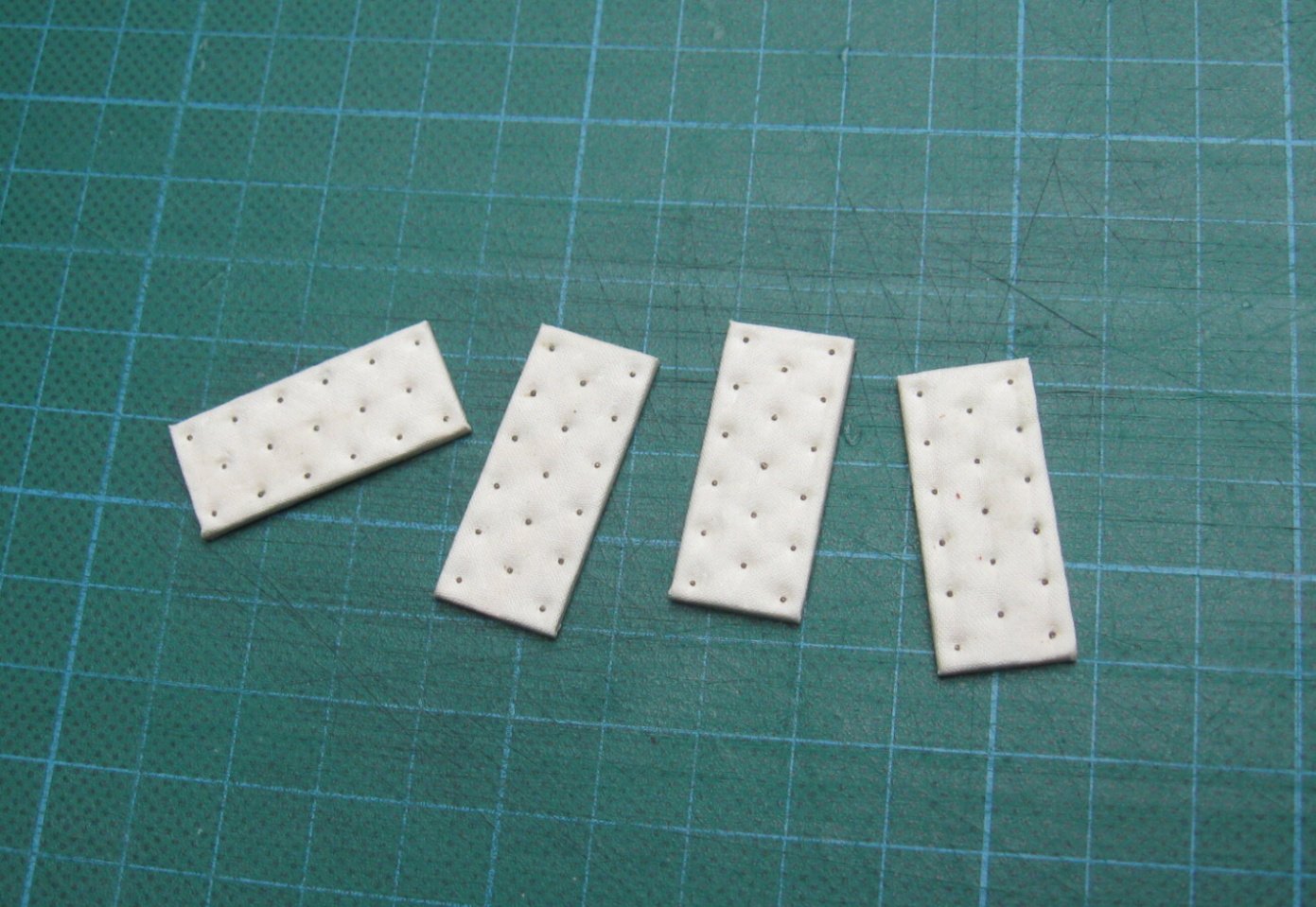

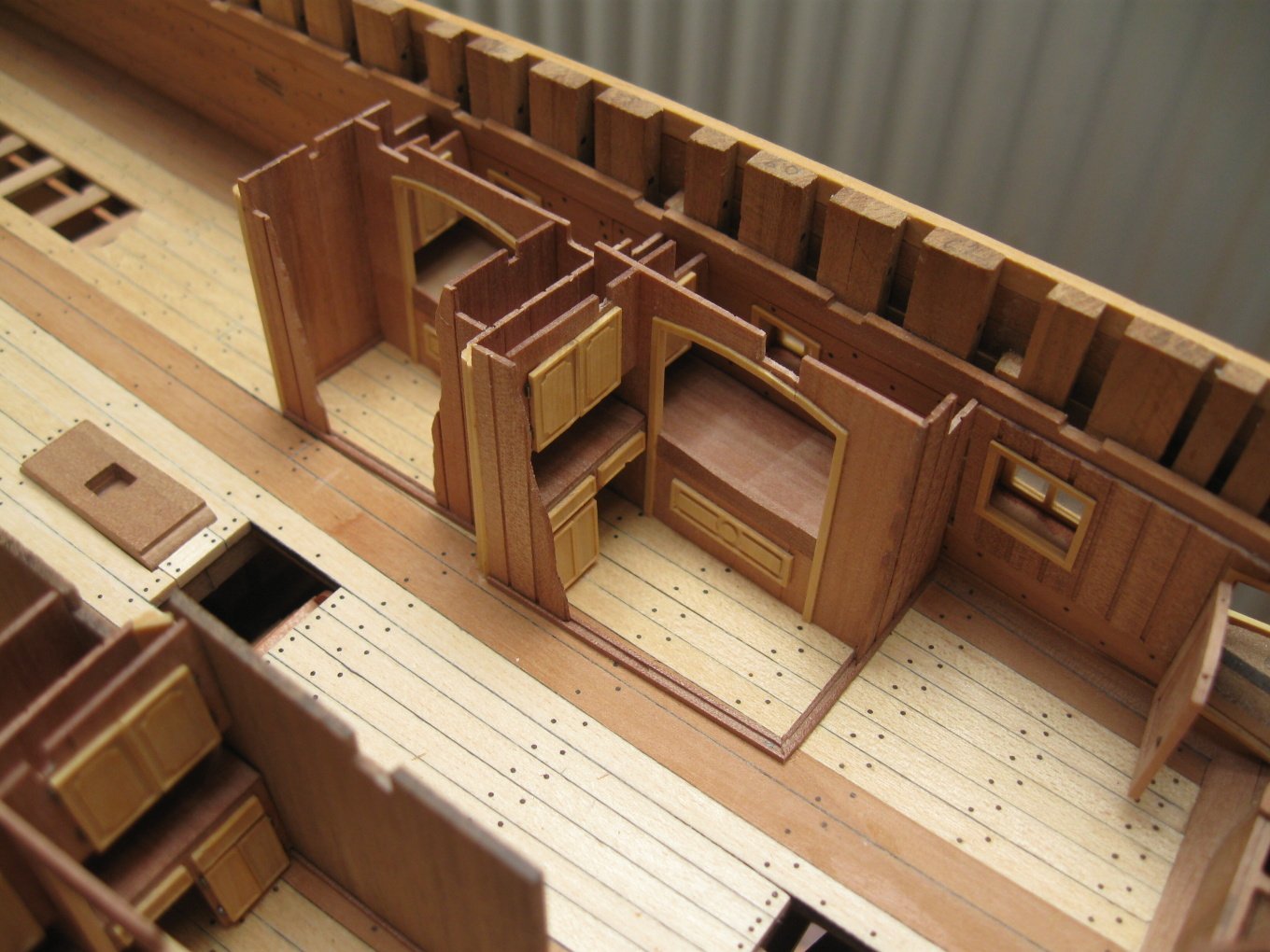

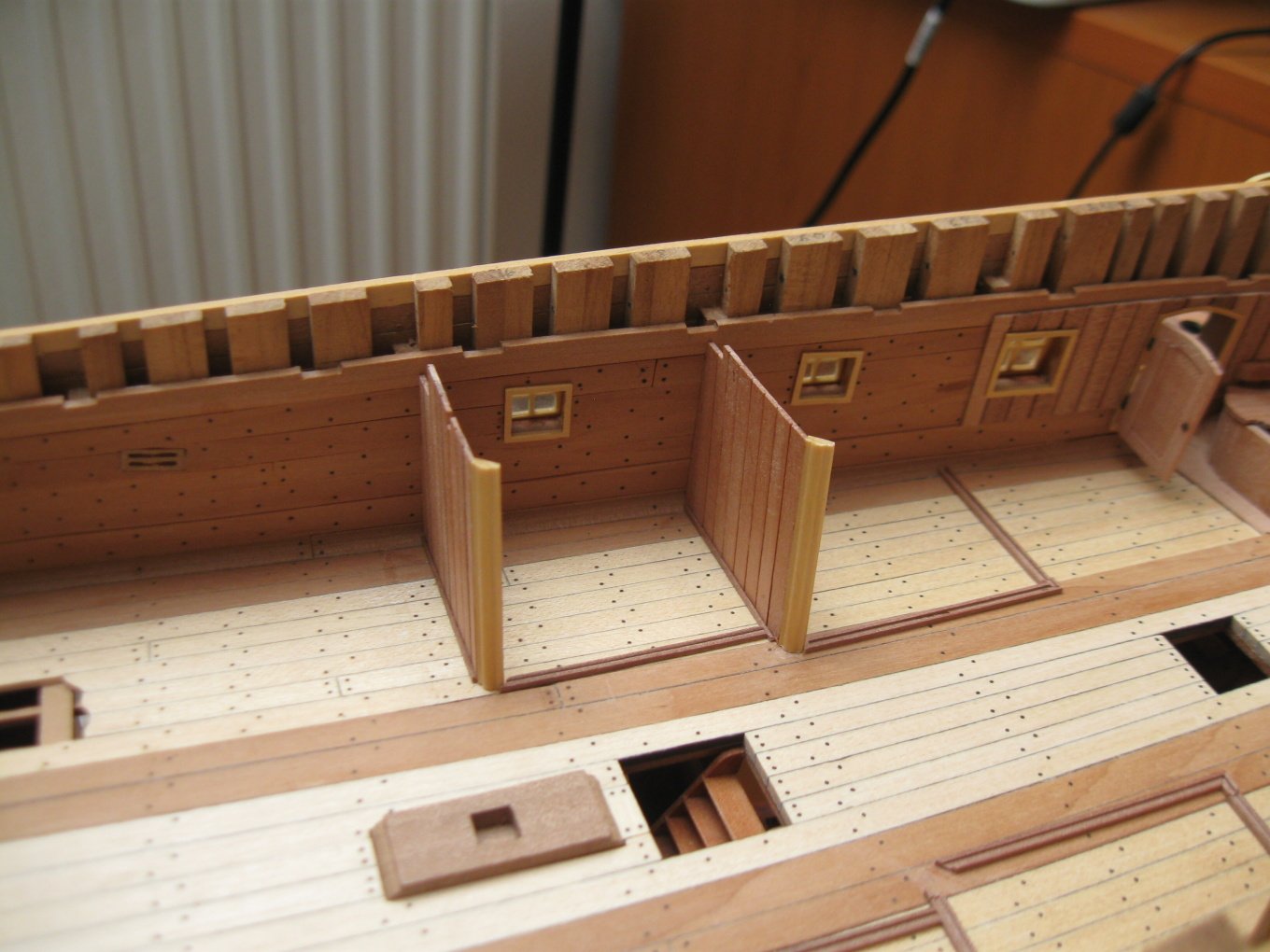

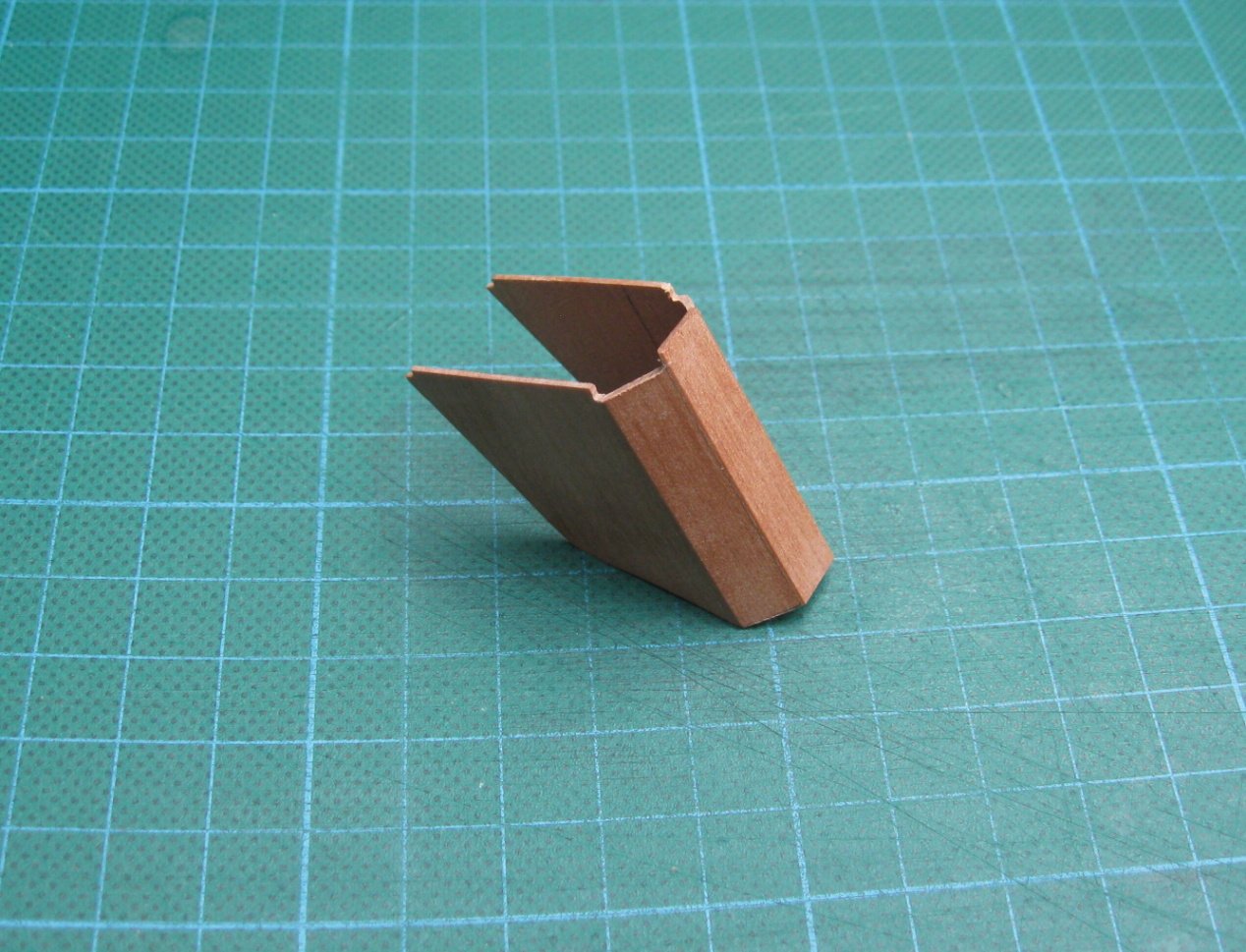

Thank you guys for all likes and nice comments. The next task on the gundeck were trunks (or chests?).

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

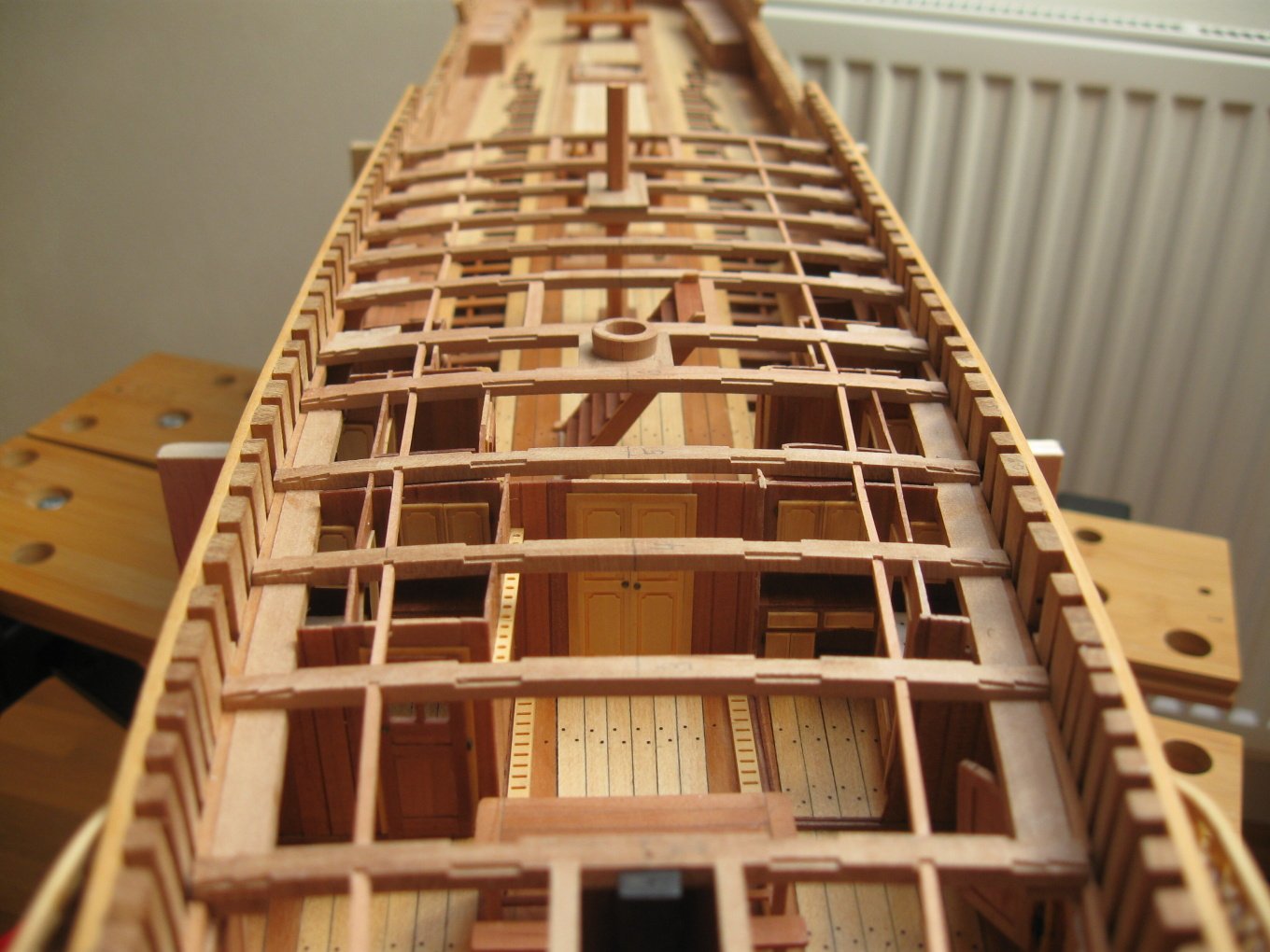

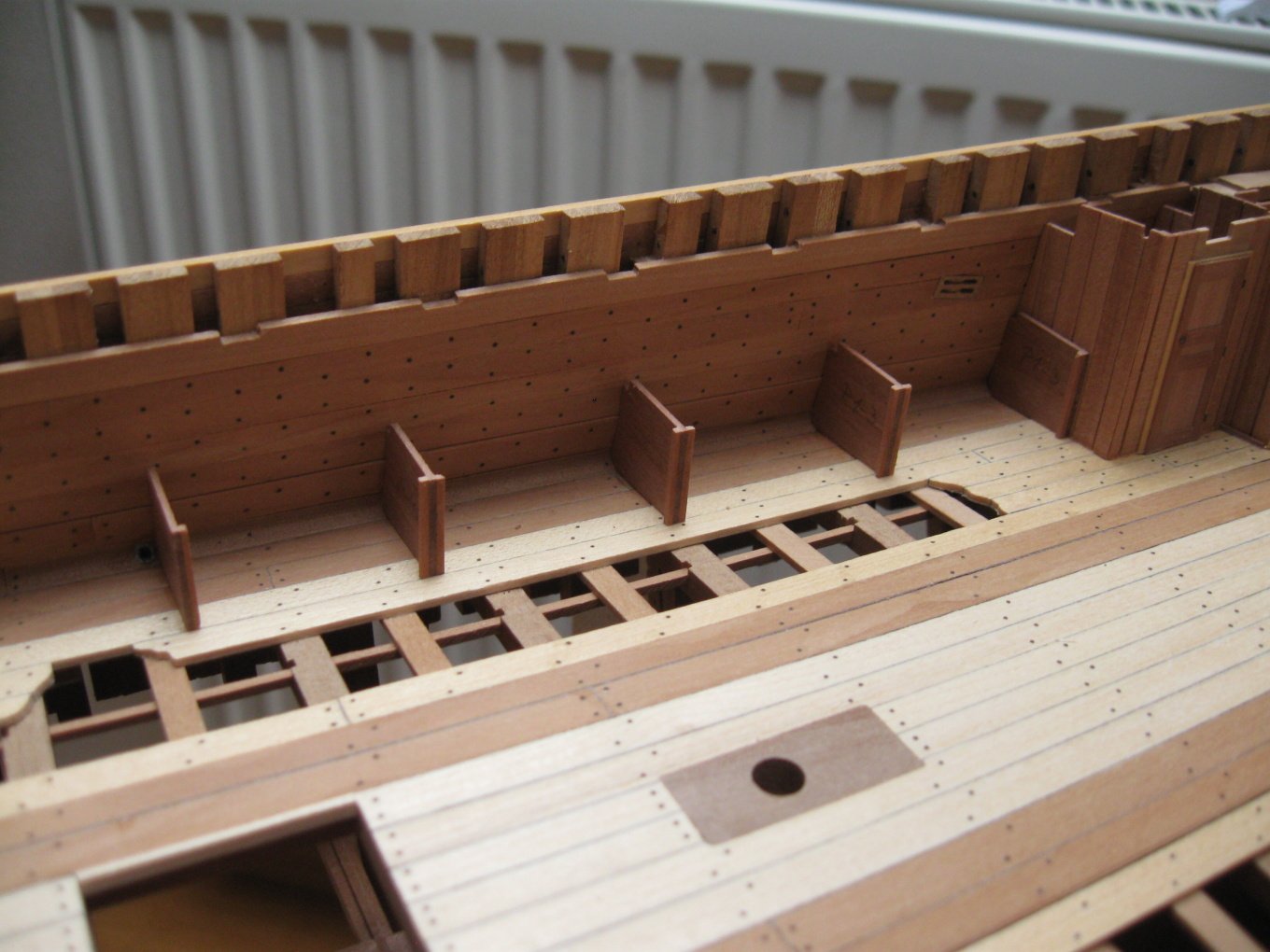

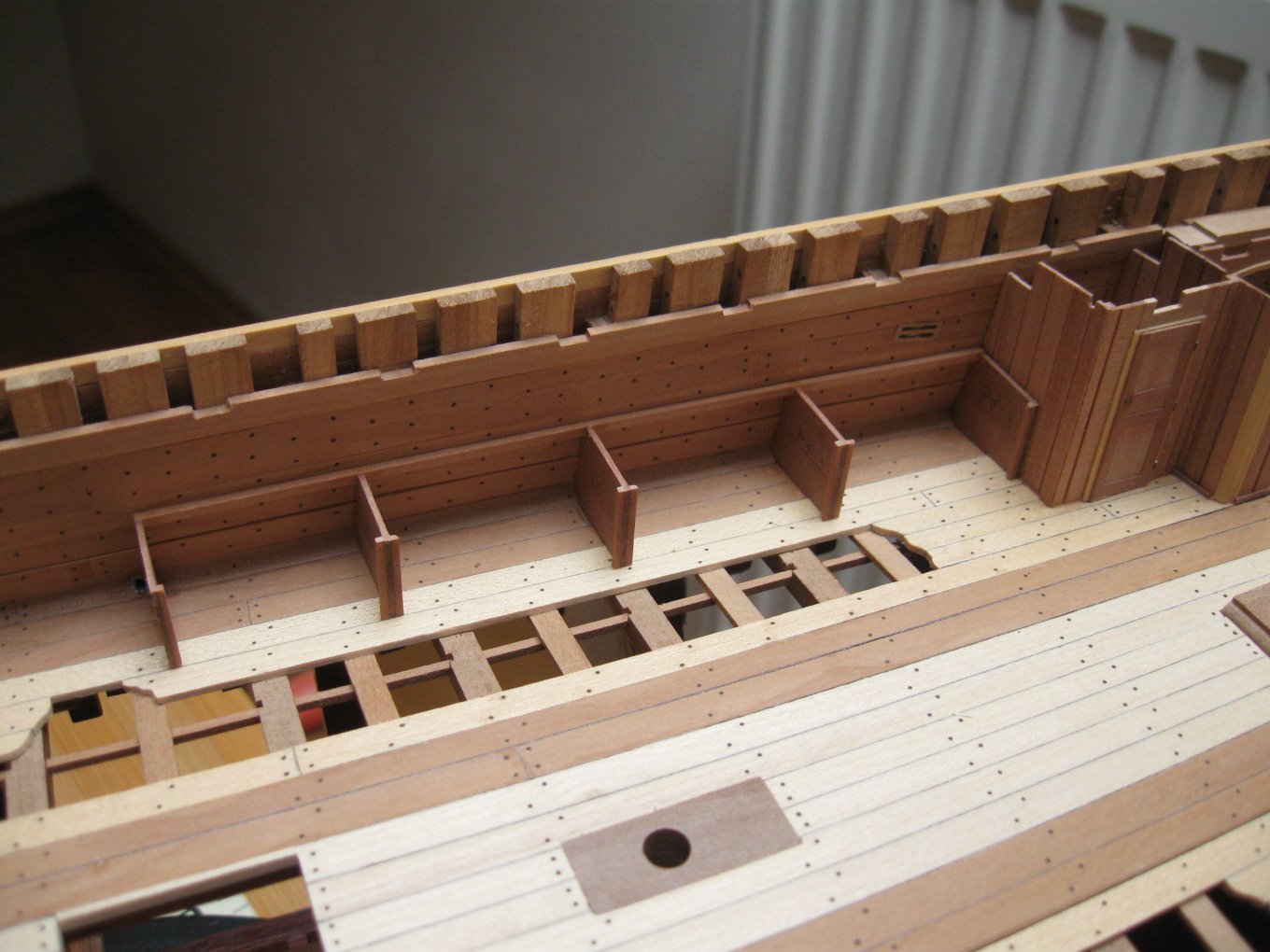

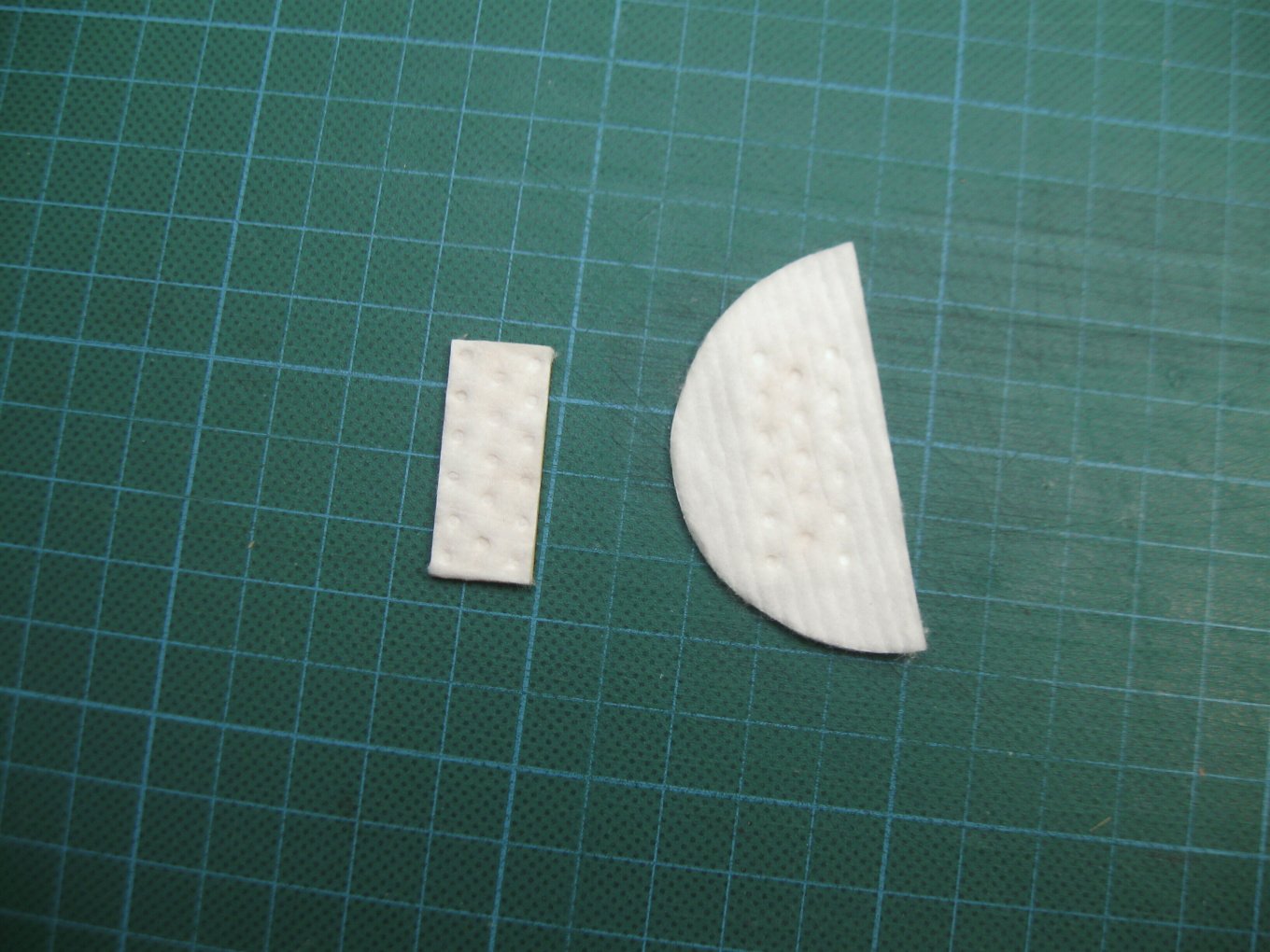

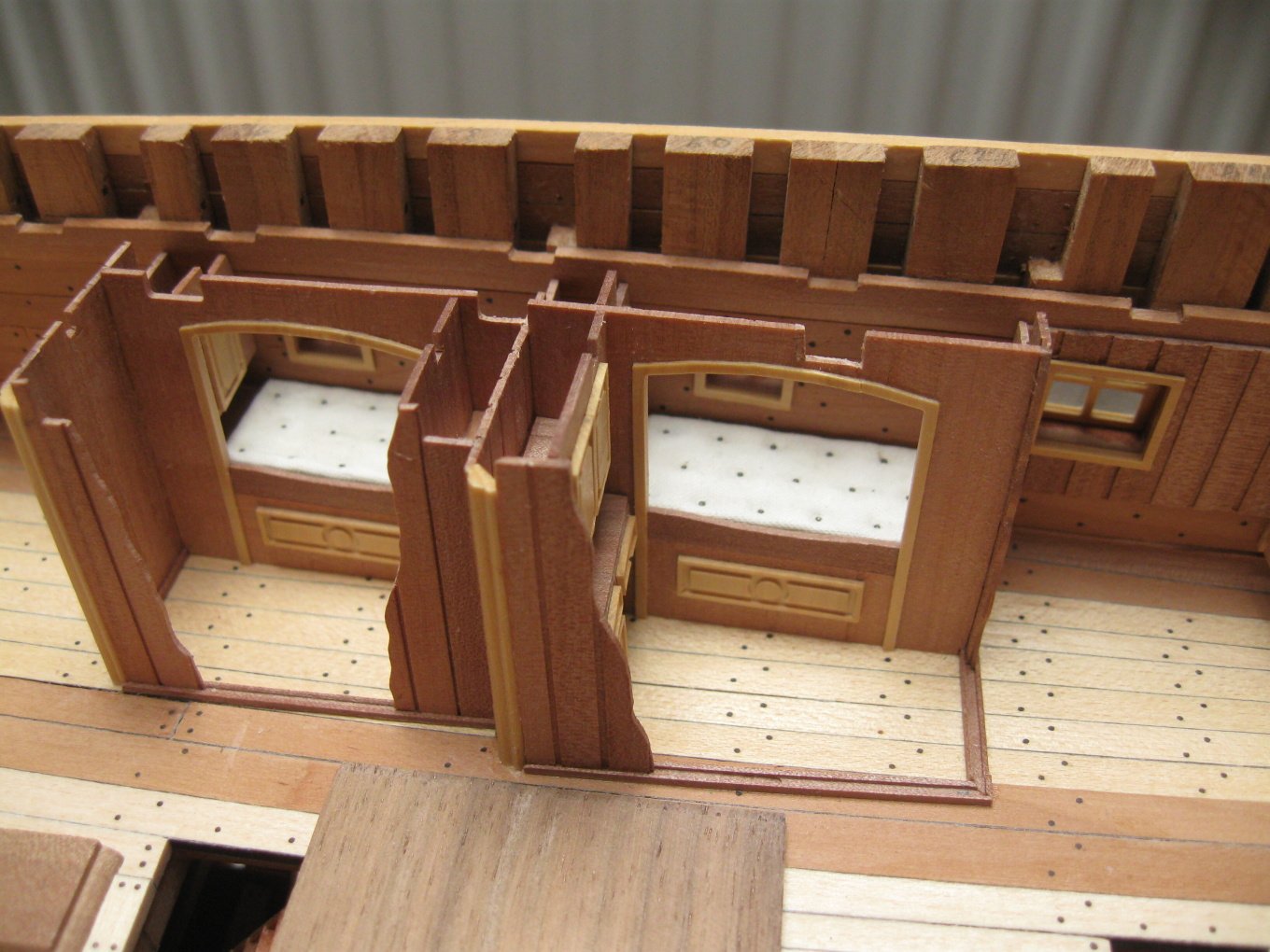

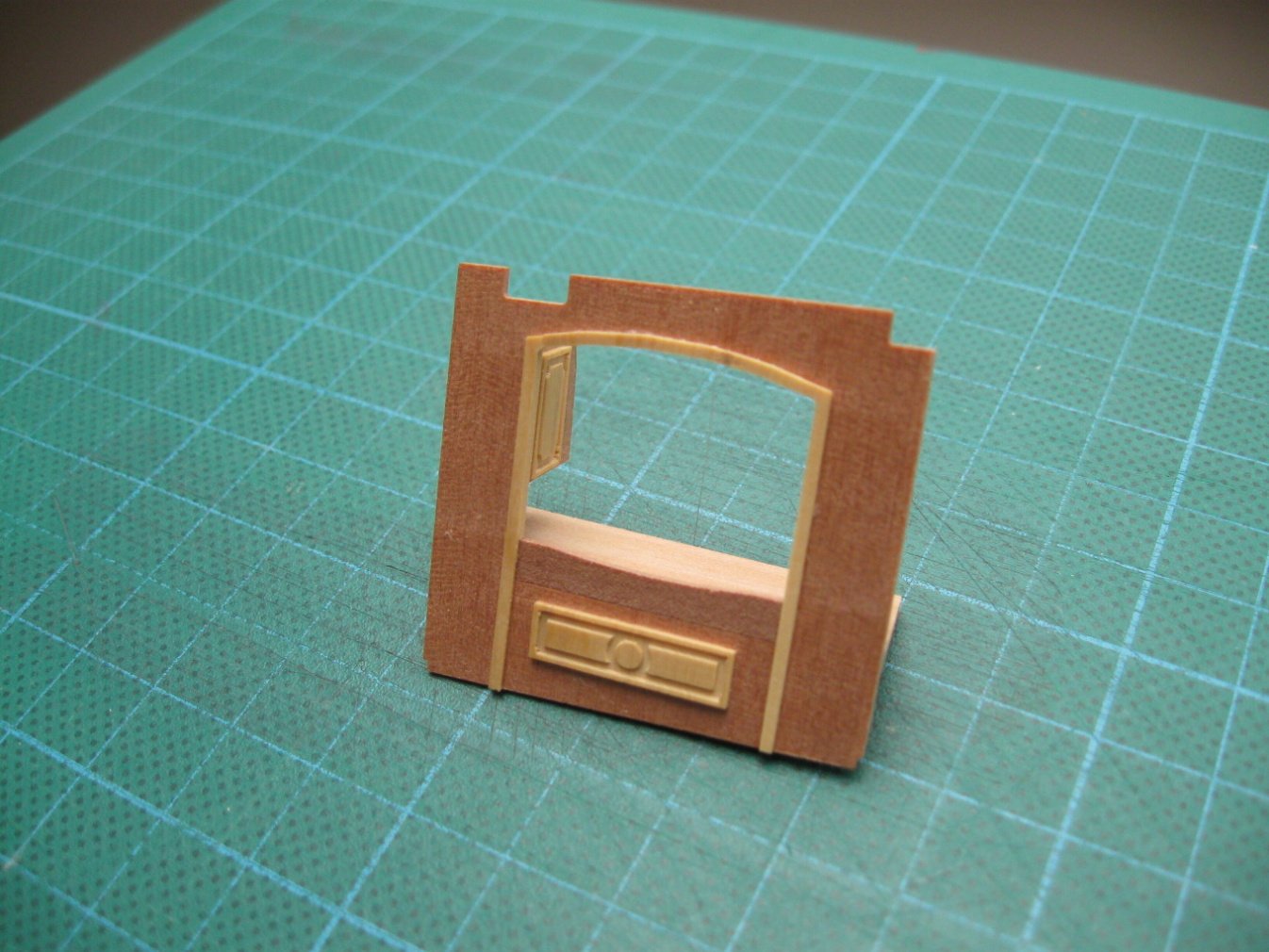

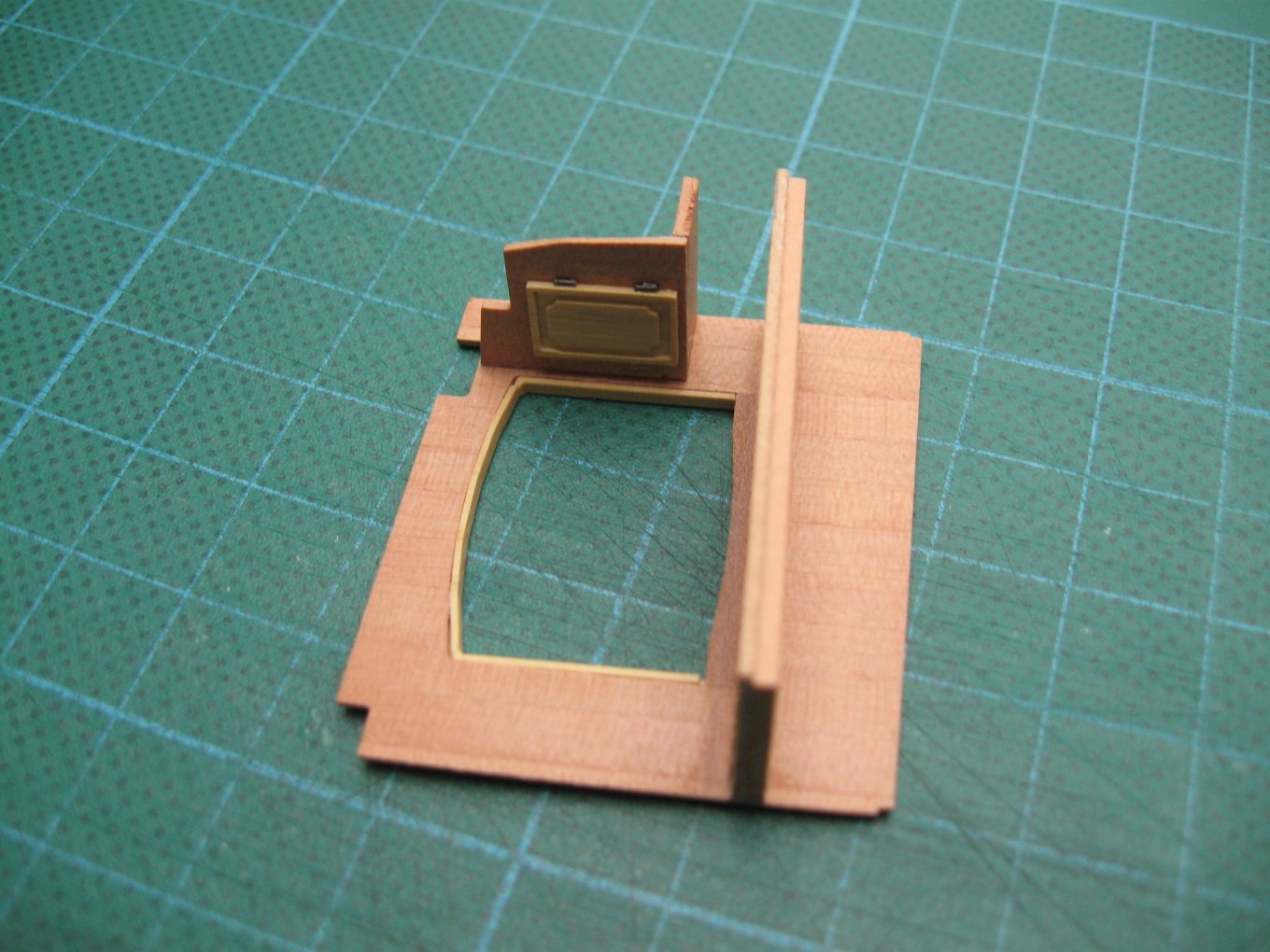

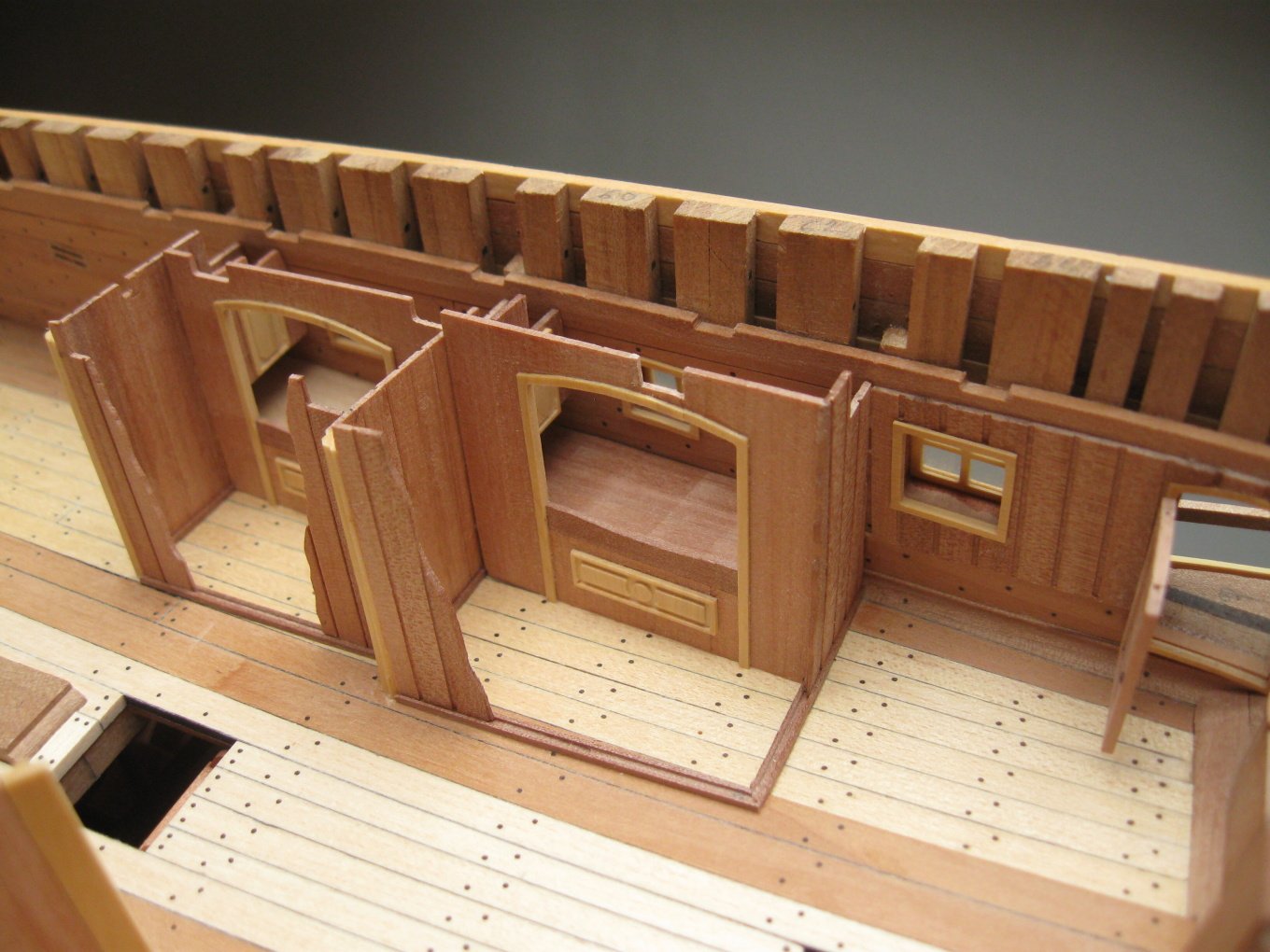

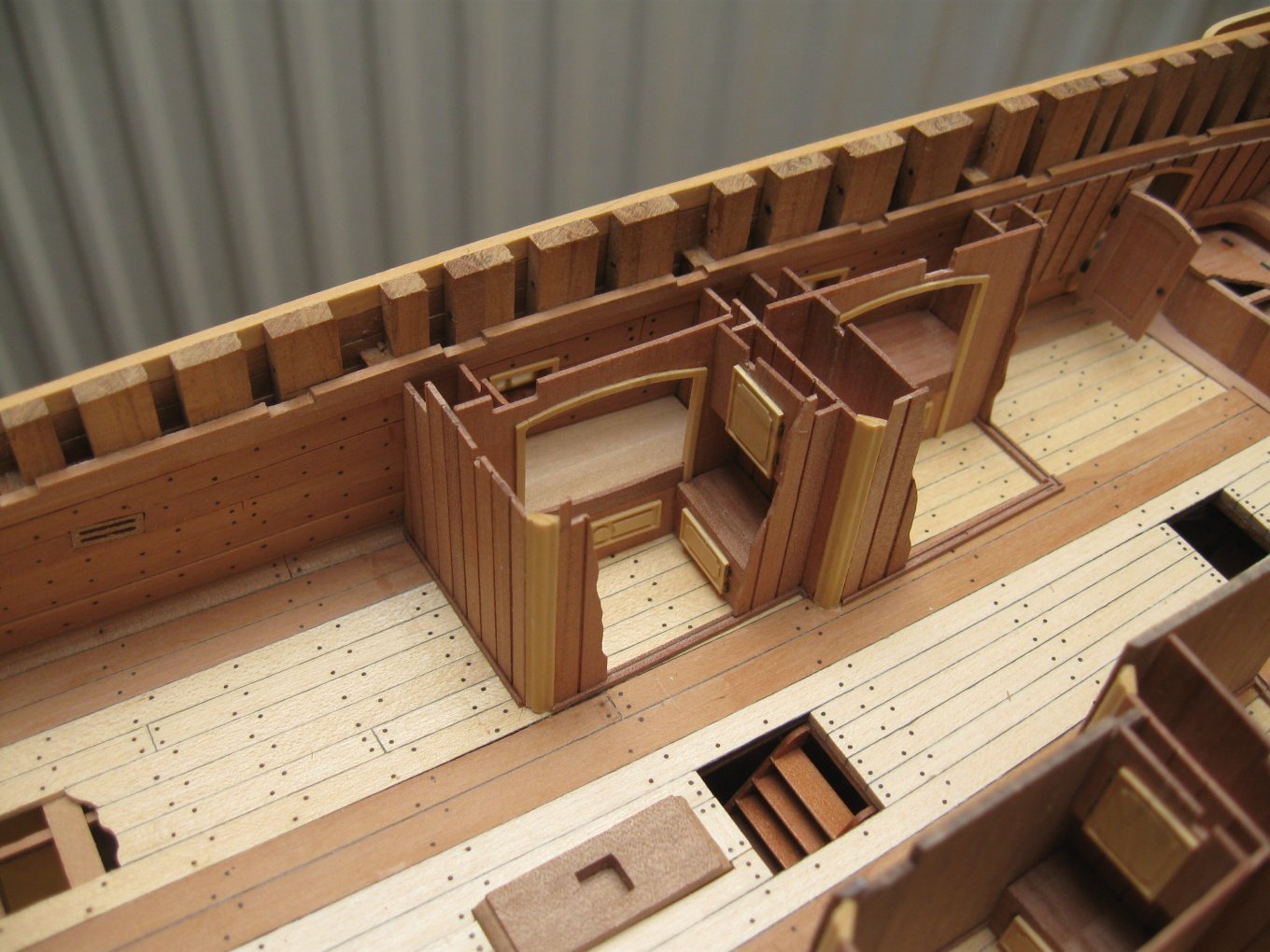

To the learner - The basis is a wooden plate into which depressions are milled and holes for nails are drilled. A cotton pad (a make-up cotton pad that I borrowed from my wife) is glued to the plate prepared in this way. Push the cotton into the recess with the end of the brush nozzle. Glue any suitable cloth and push the material into the recess again. Finally, thread the nails with small heads through the cloth and cotton into the holes in the wooden board, glue and cut. Glue the ends of the fabric over the edges of the wooden board and you're done. Inner bulkheads - continuation part two.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

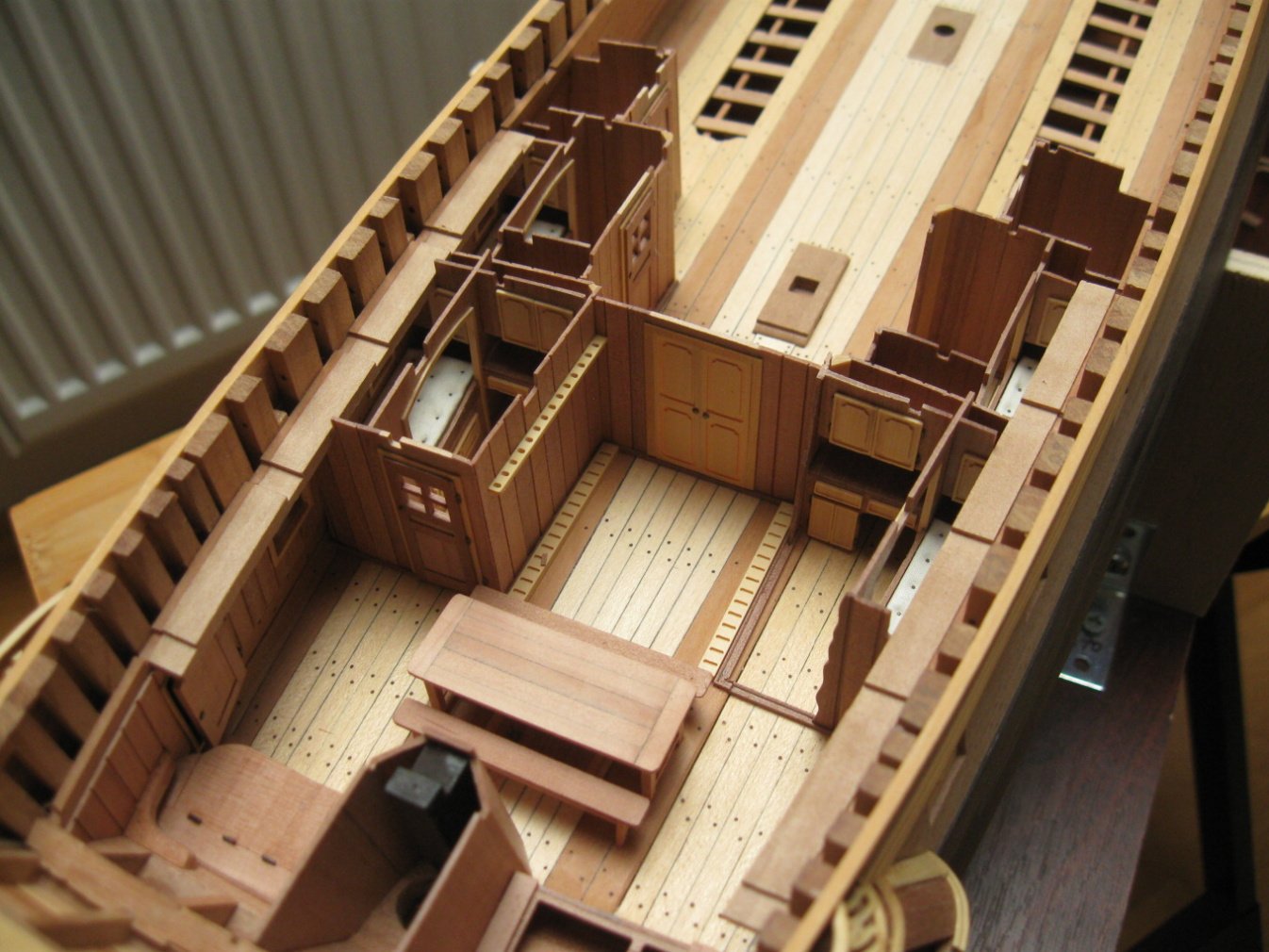

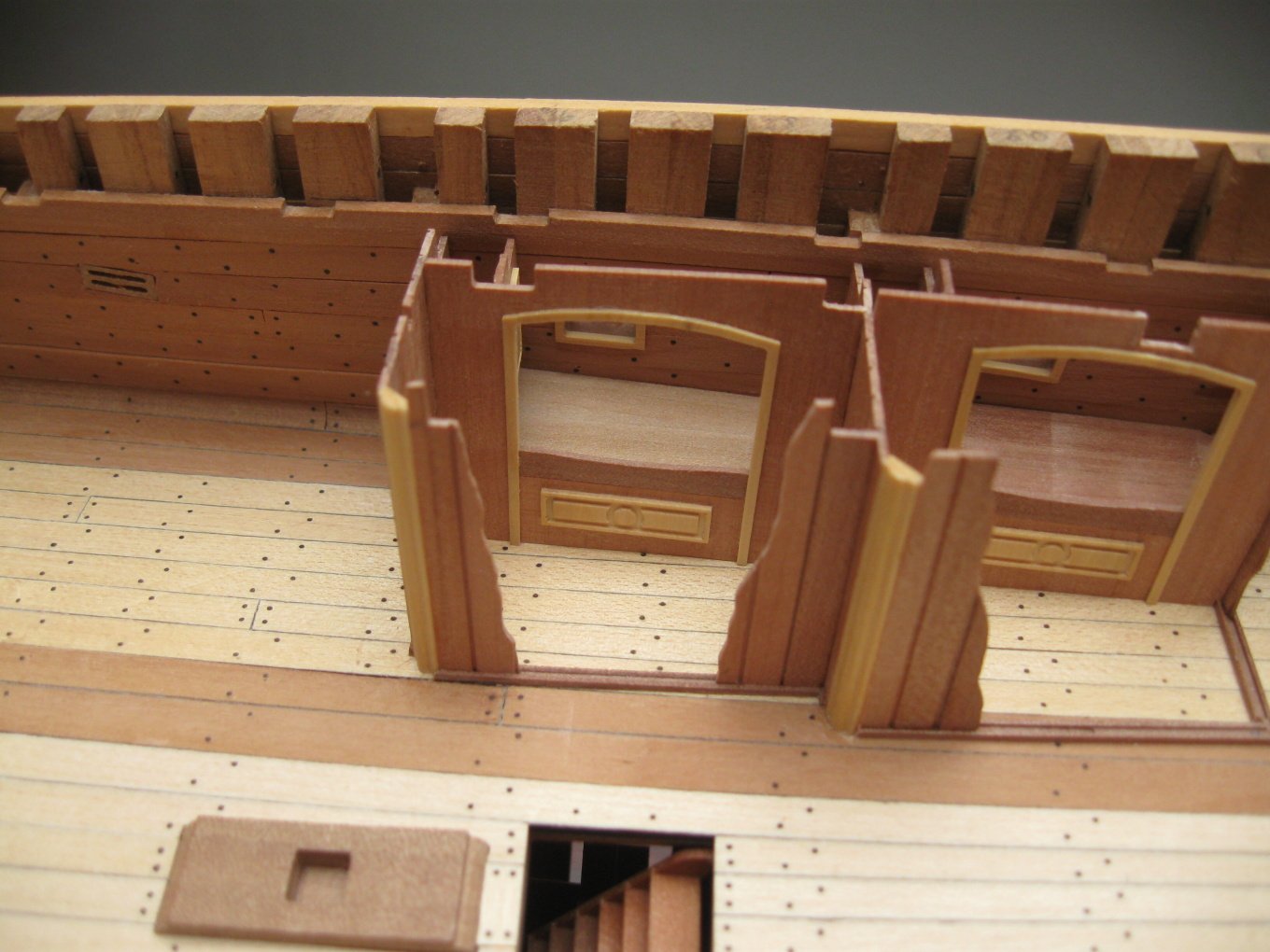

Thank you guys for all your comments and likes. To scrubbyj427: I am using CNC maschine made by China, these maschines are avaiable worldwide (see the picture). I started works on inner bulkheads.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Scrubbyj427 - I am using pear wood (steamed and not steamed - different color) and black hornbeam. Completion of the quarter gallery.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.