marsalv

NRG Member-

Posts

620 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by marsalv

-

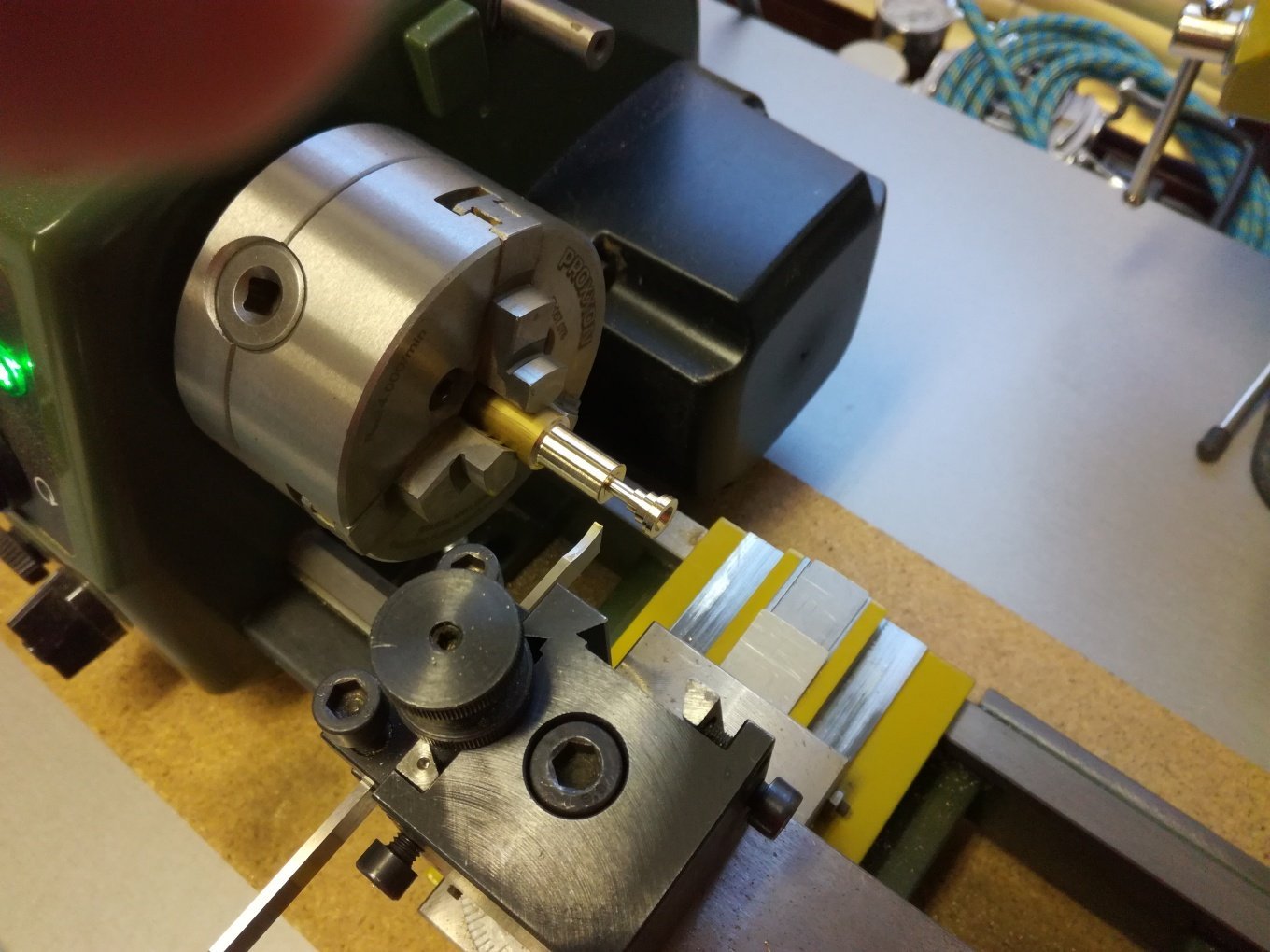

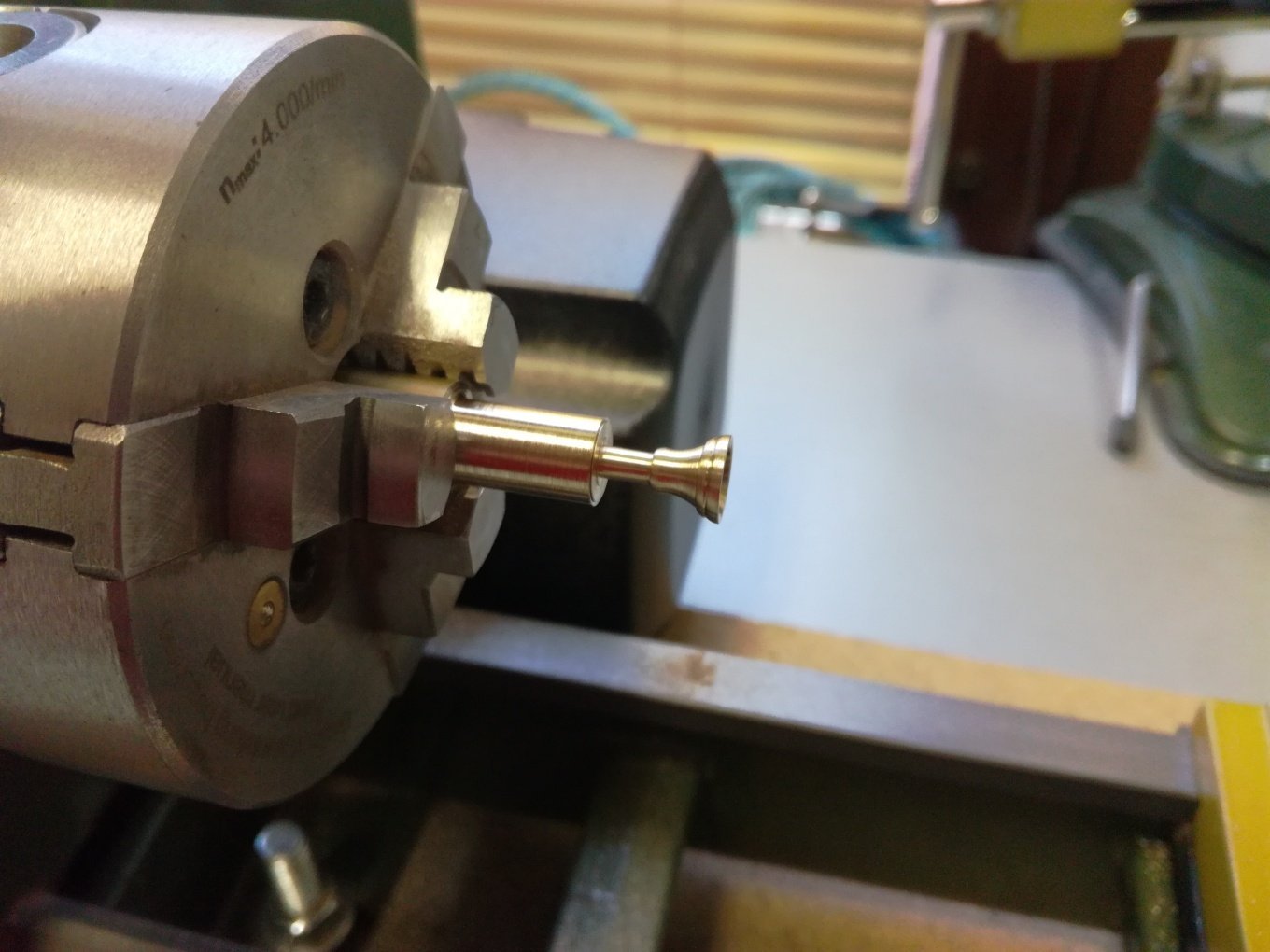

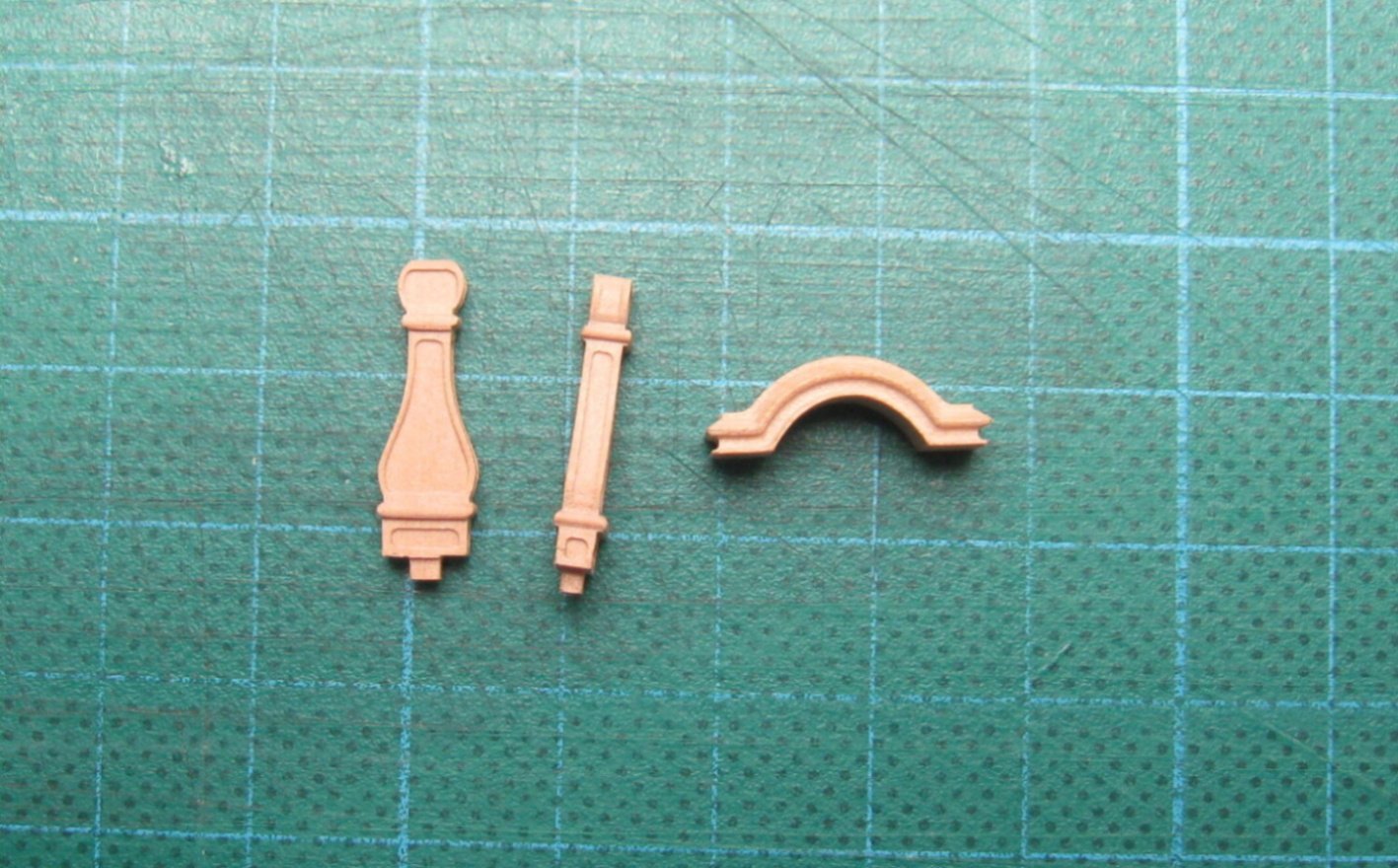

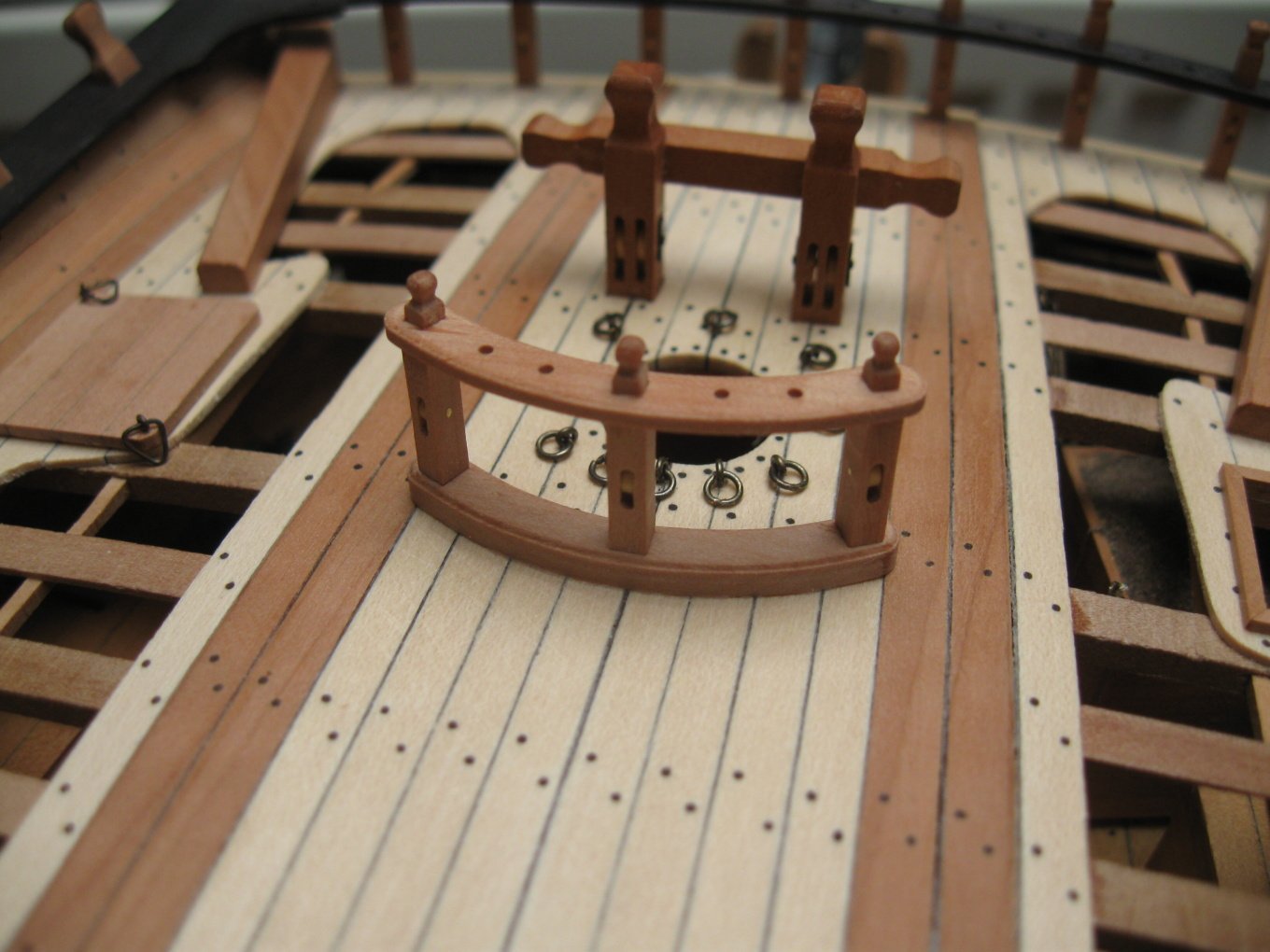

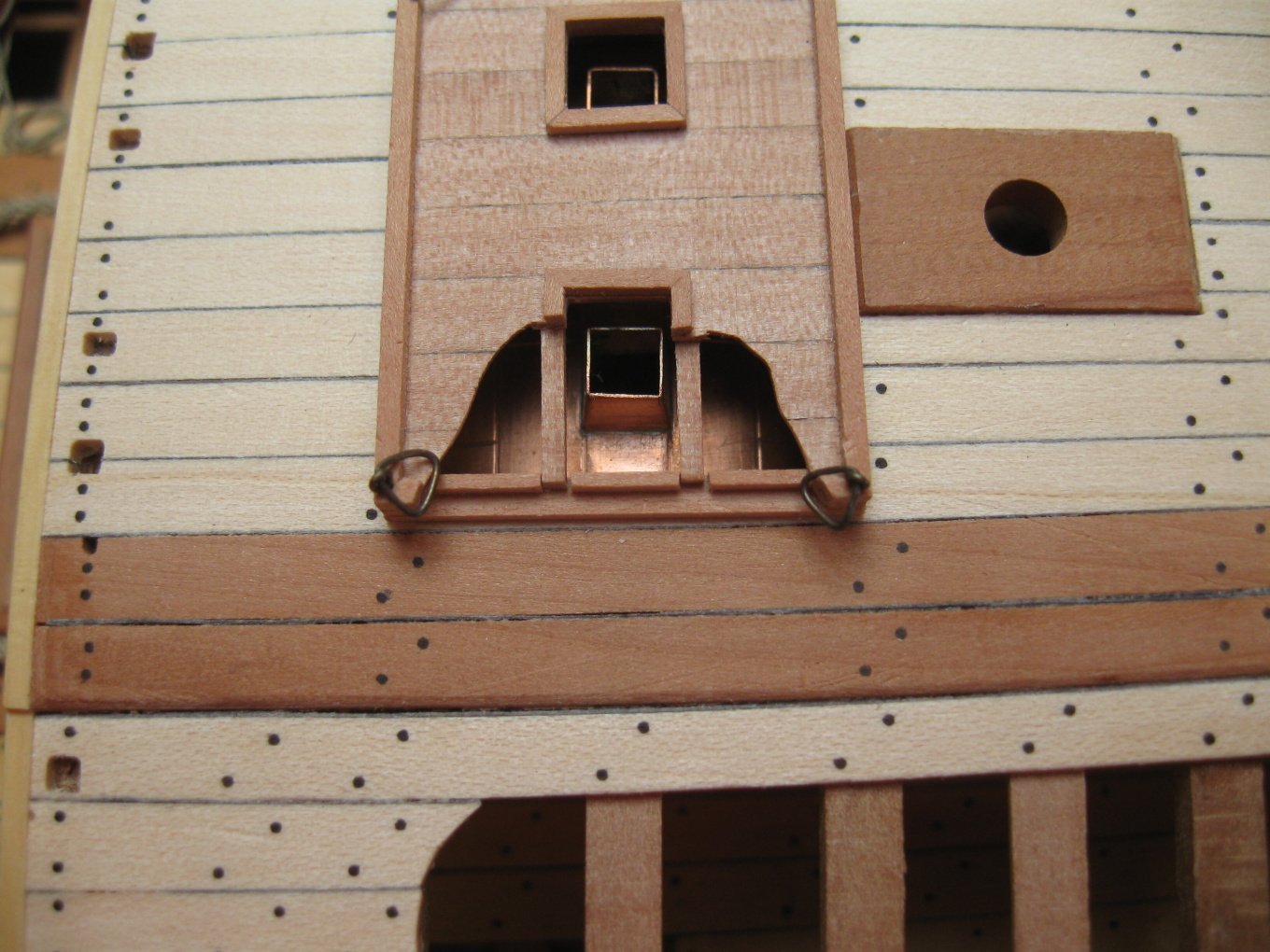

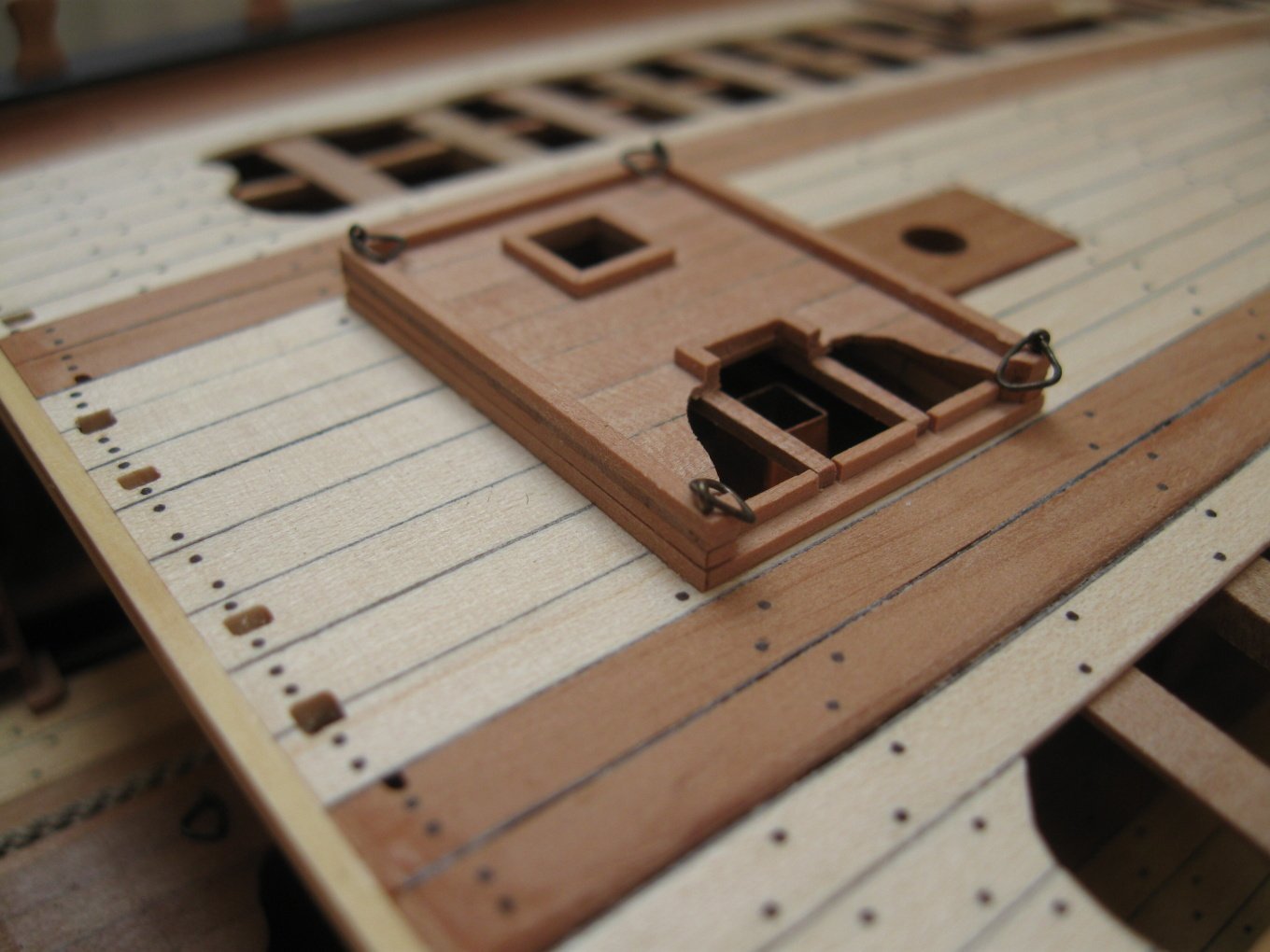

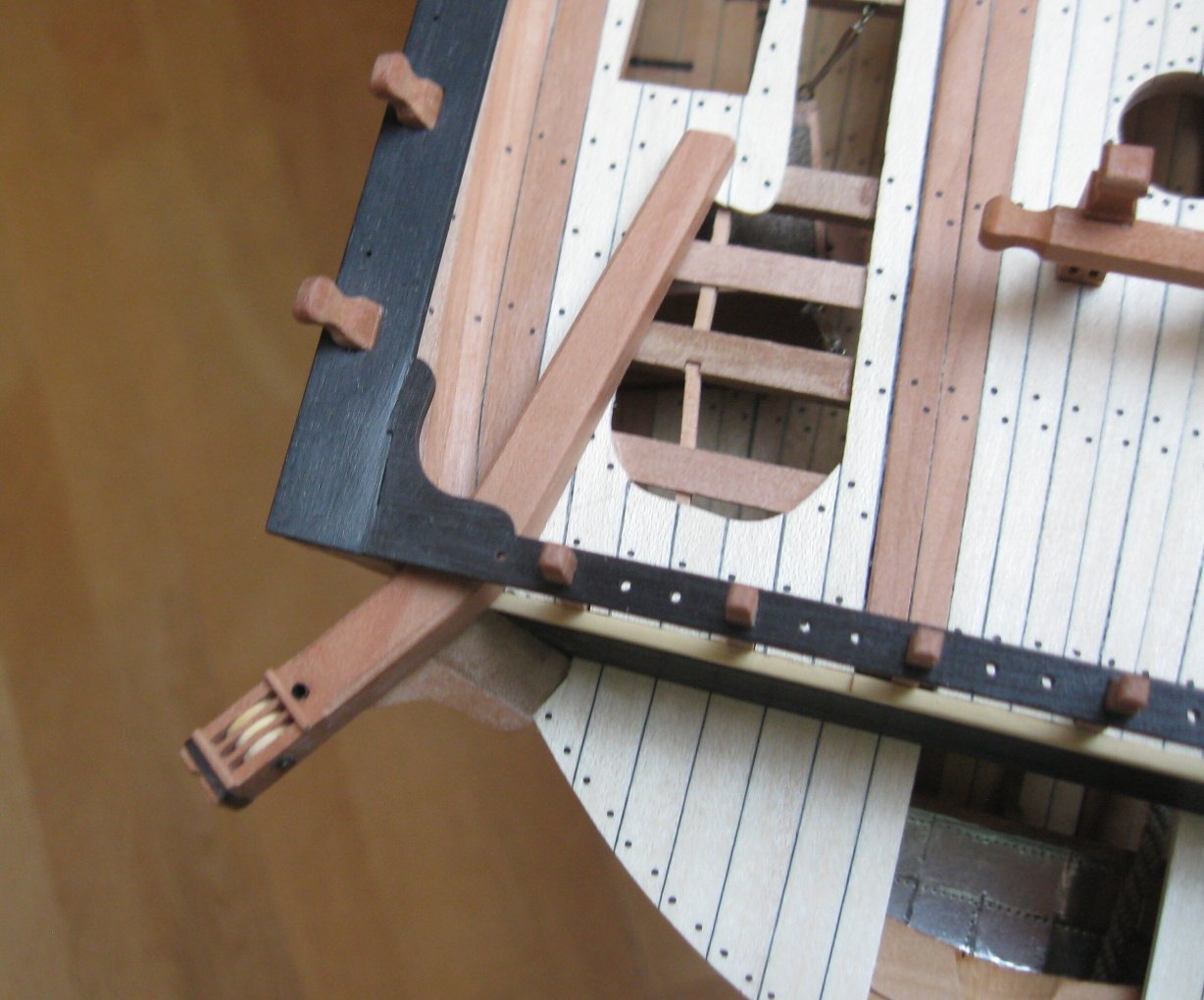

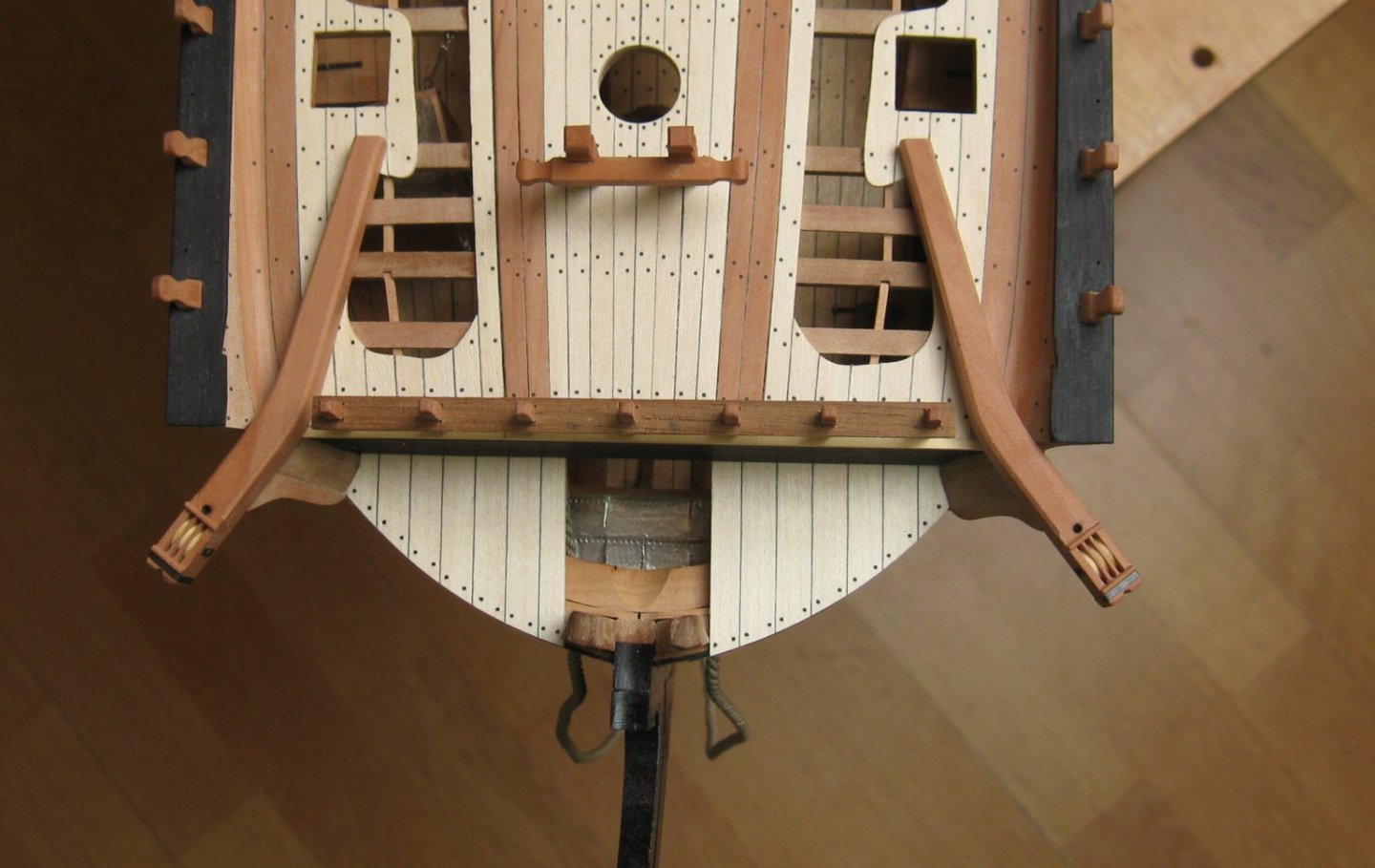

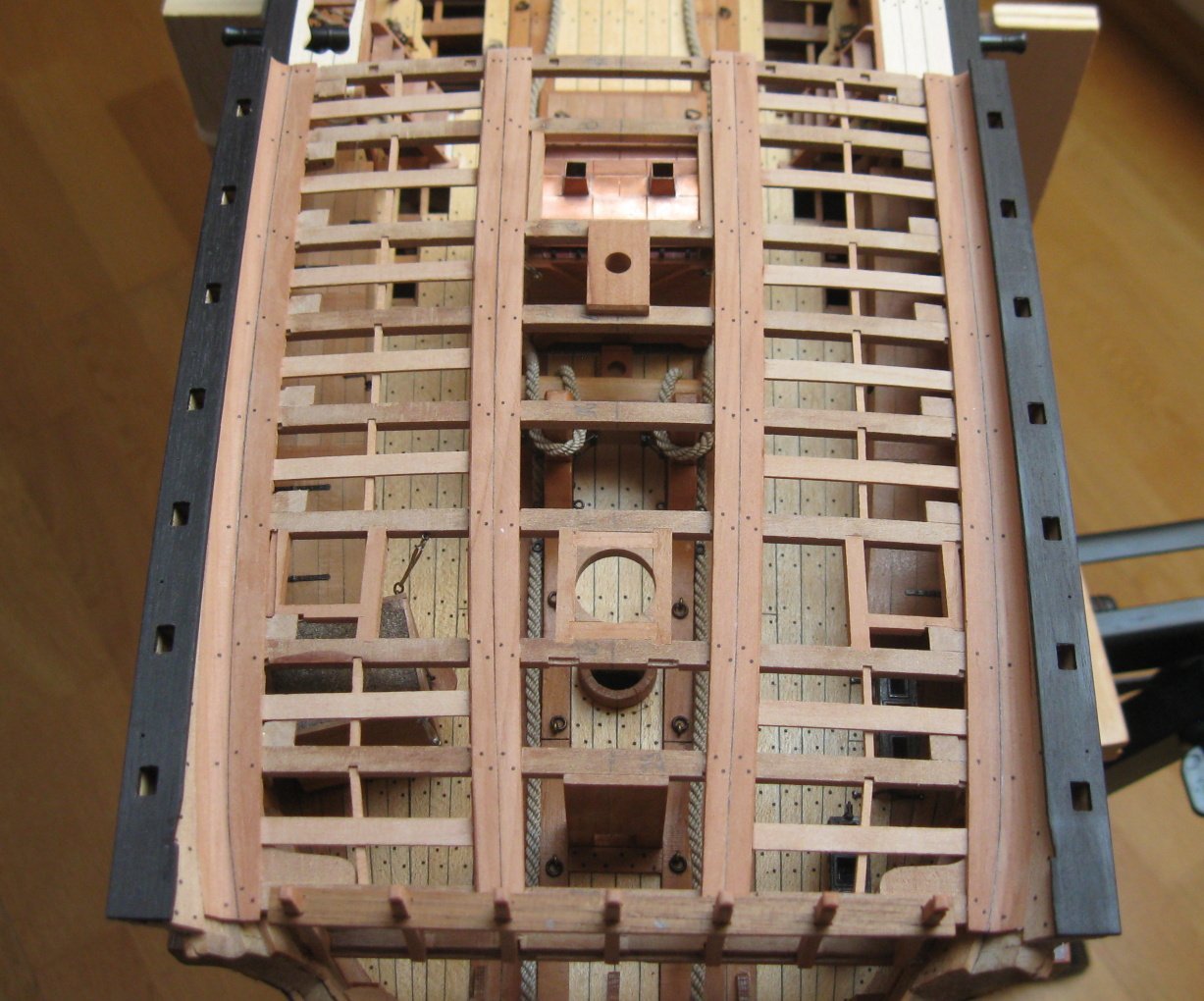

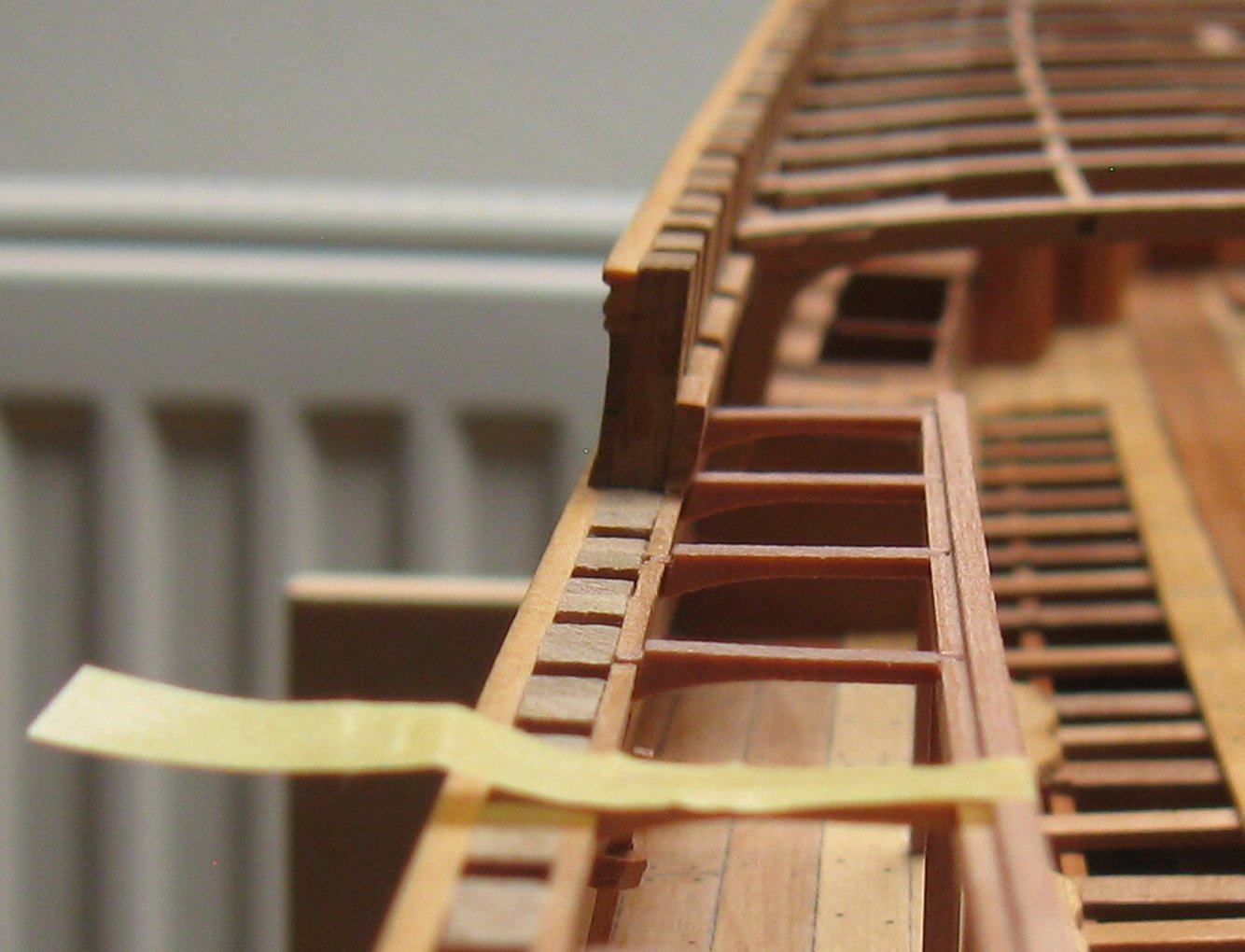

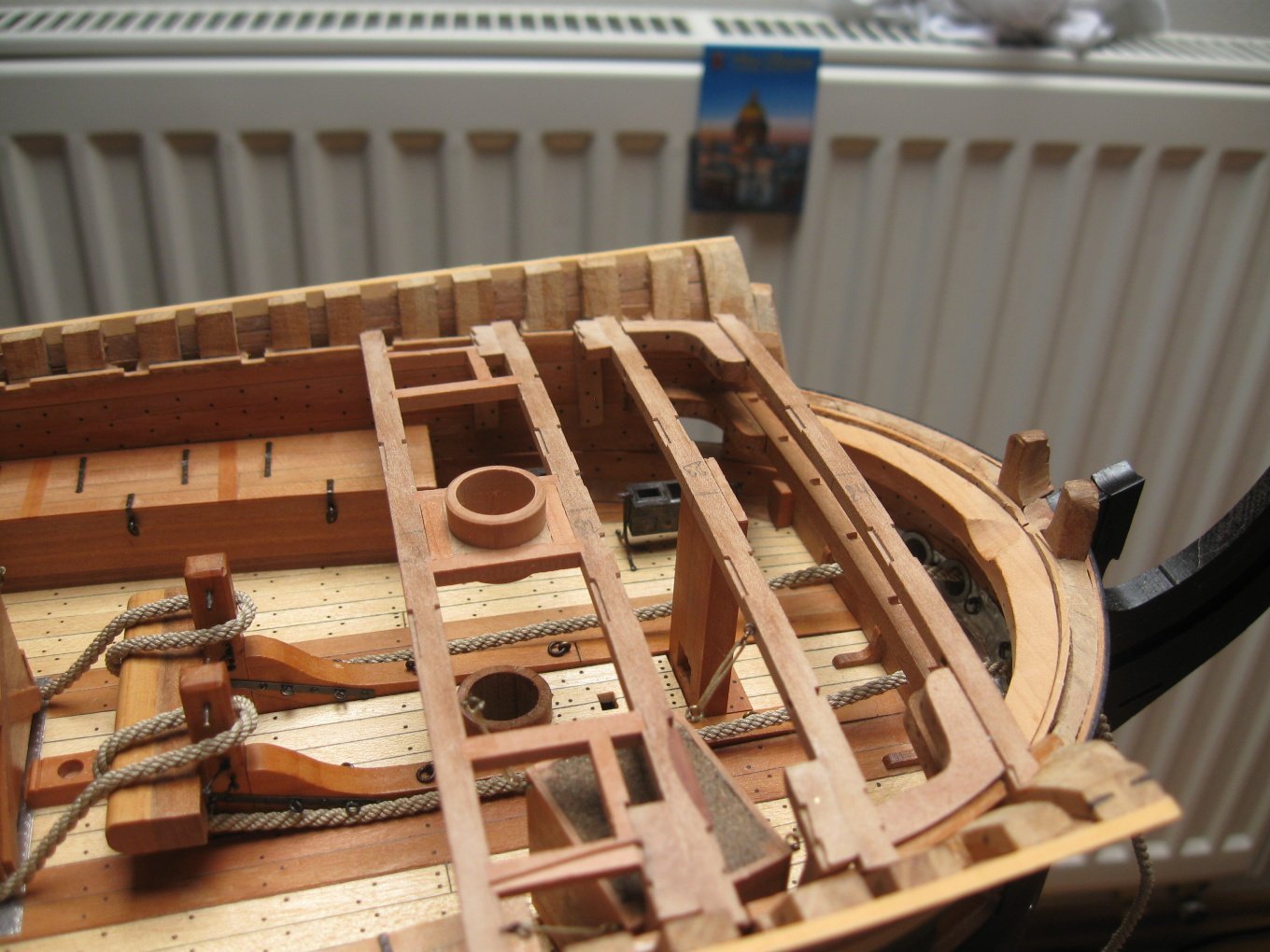

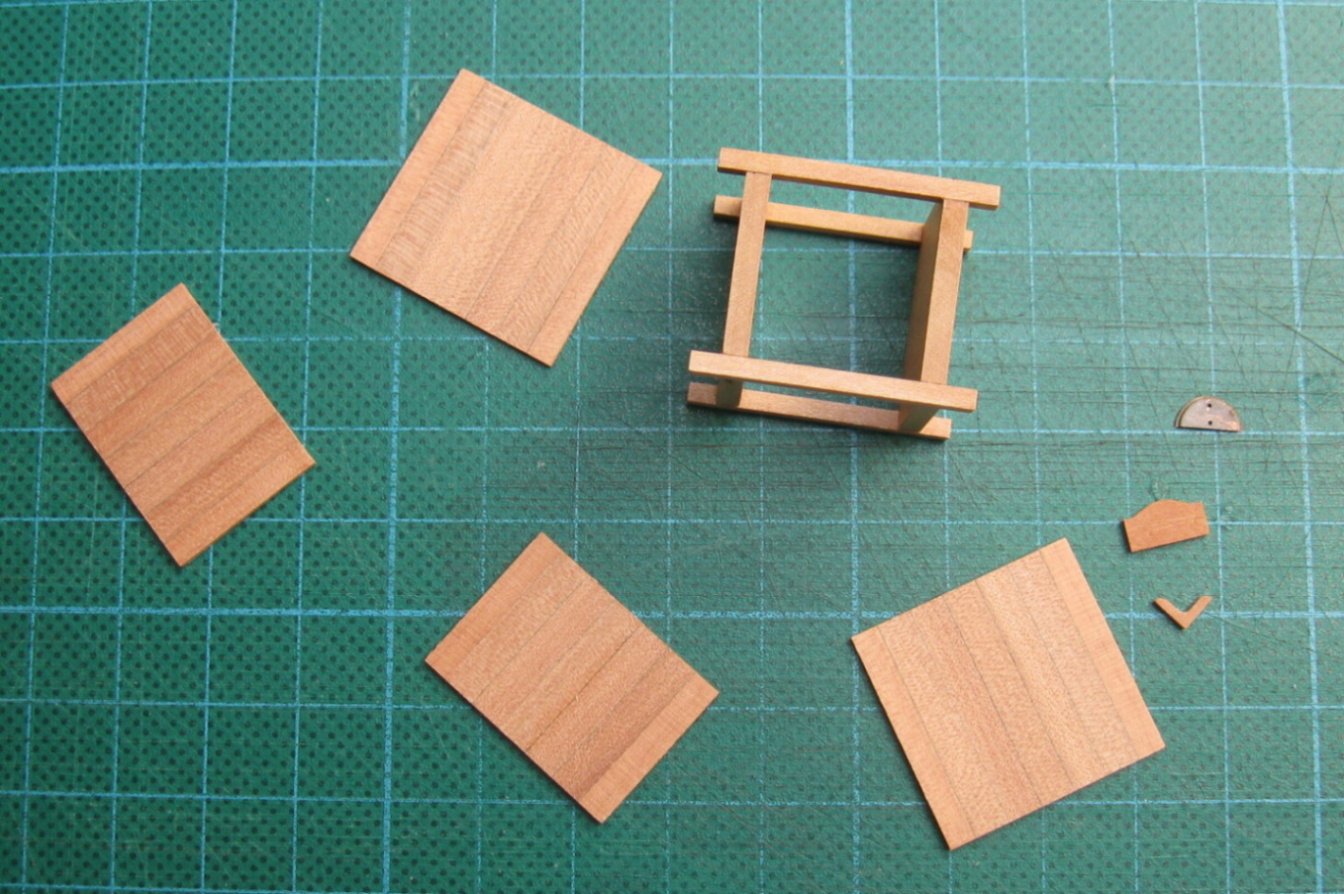

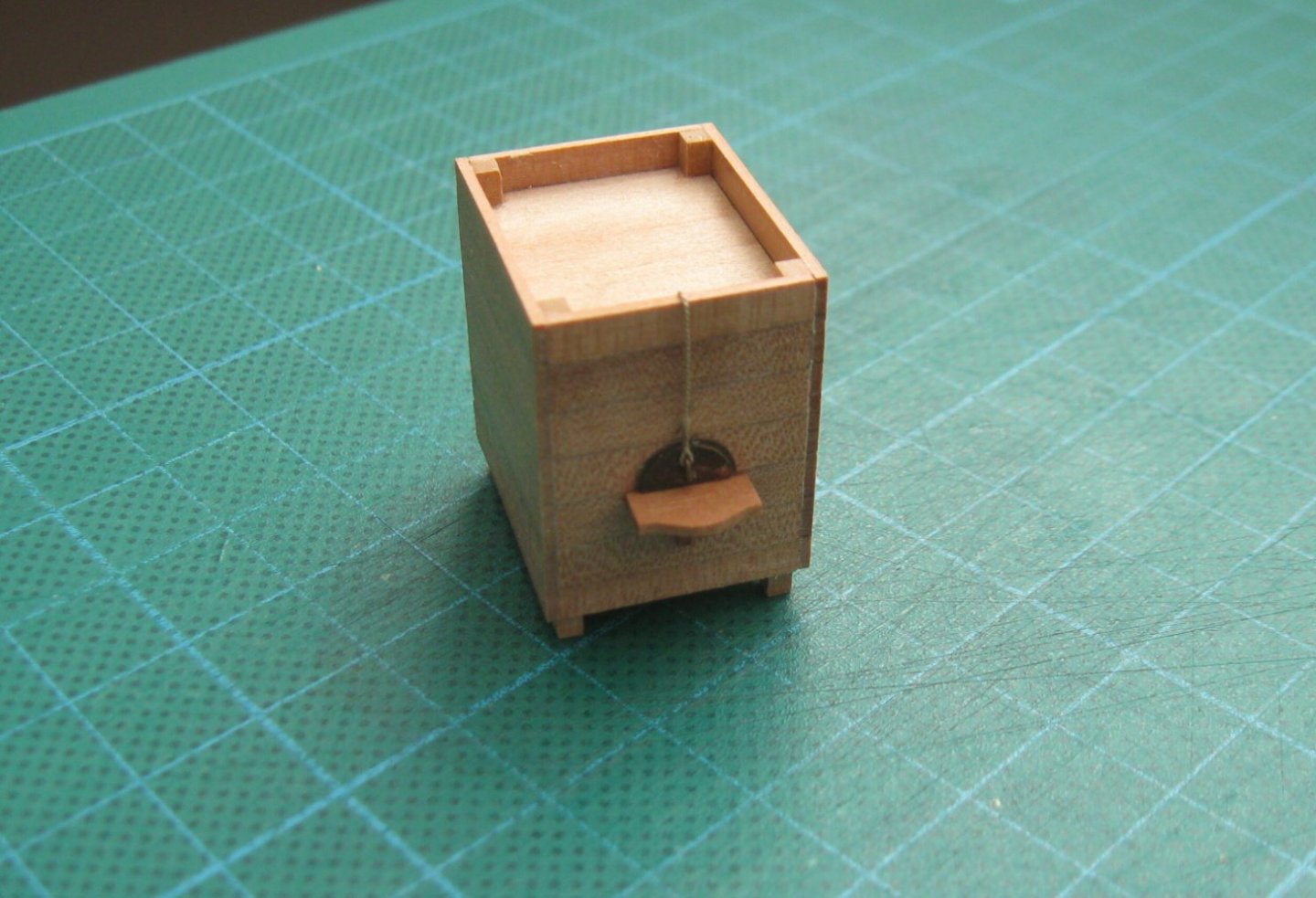

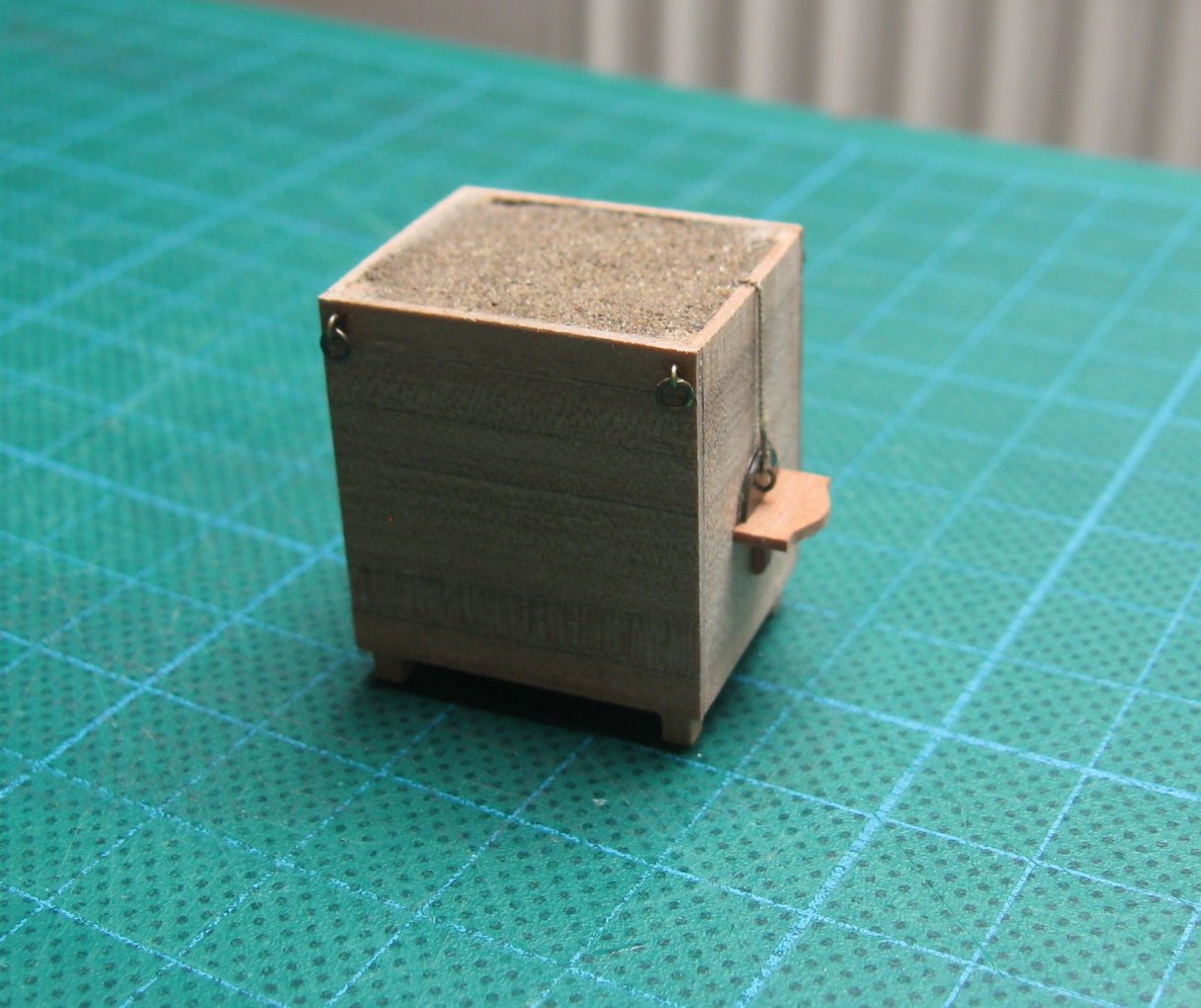

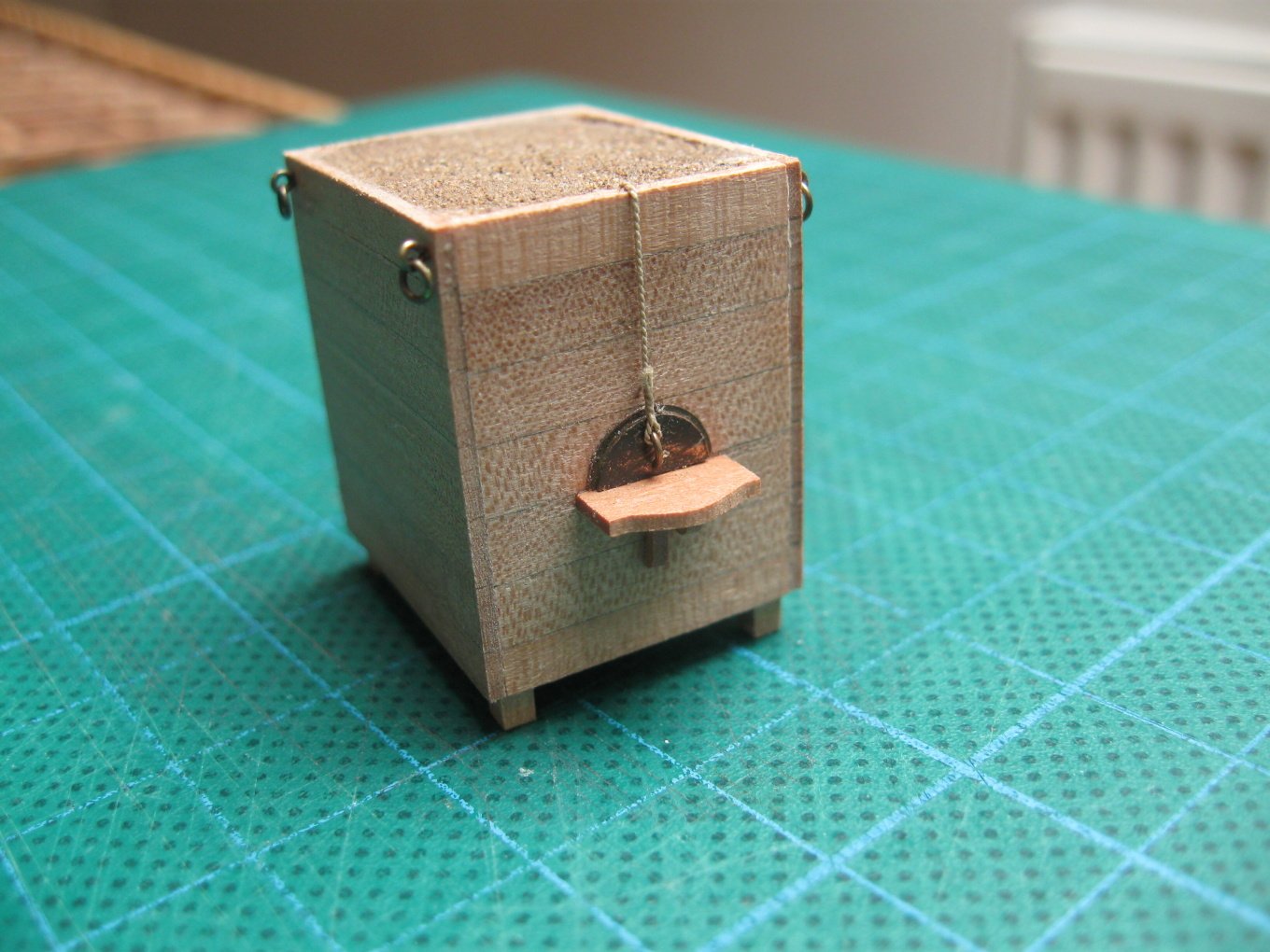

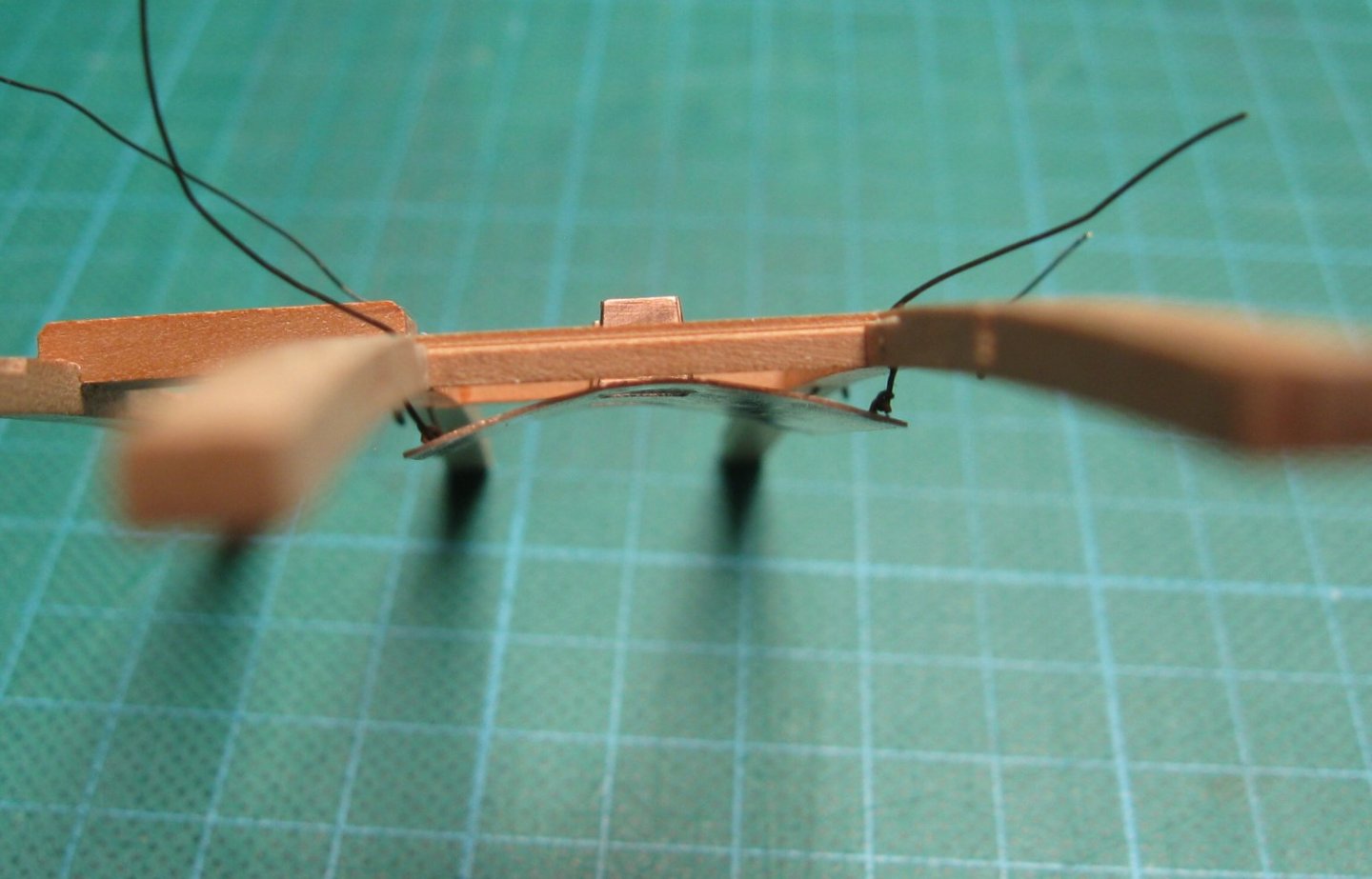

Thank you guys. To Taner Yagci: This is line nr. 8 form the Plate 3 - Hull horizontal section - the widest part of the hull. I finished the belfry.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

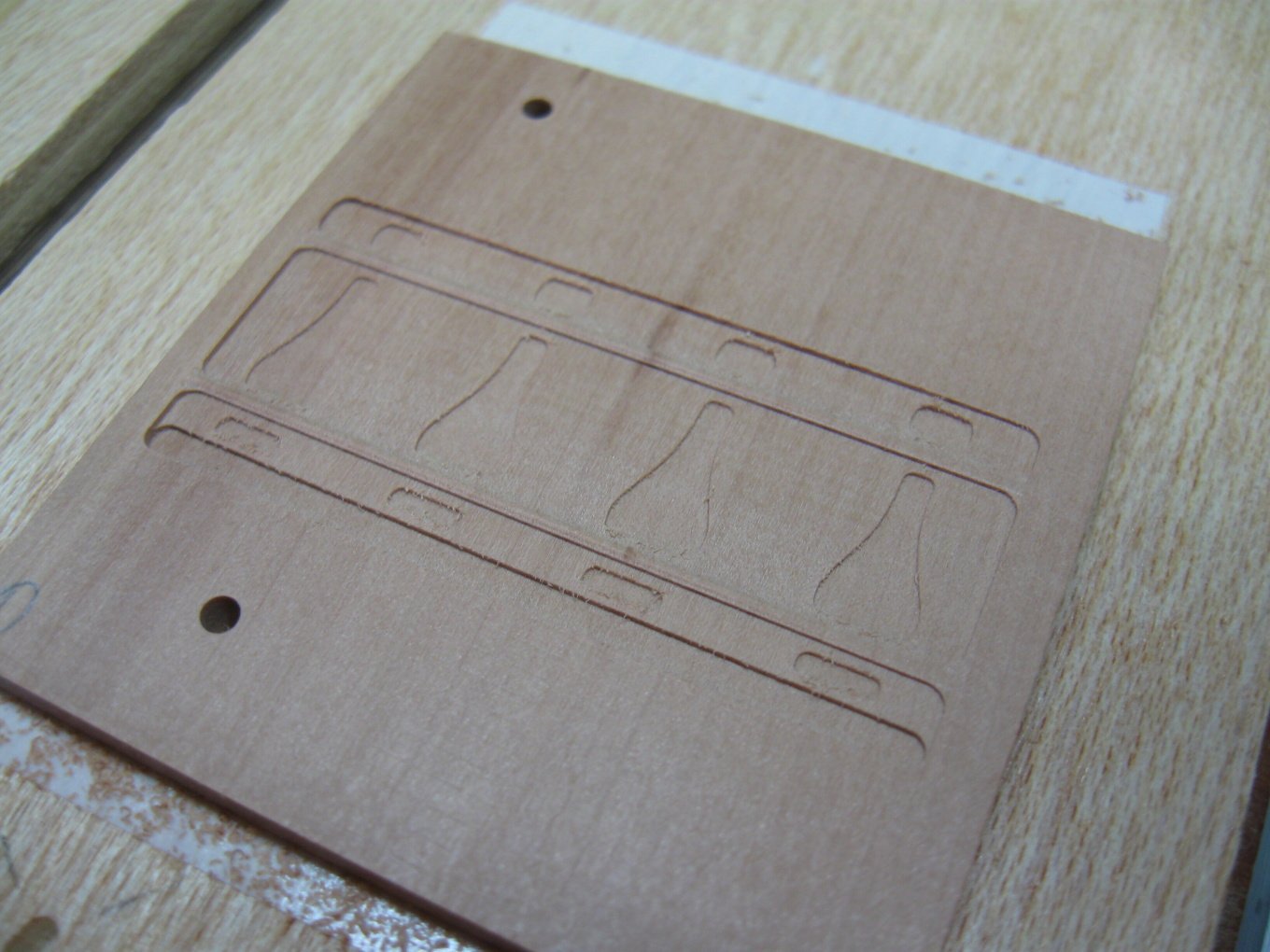

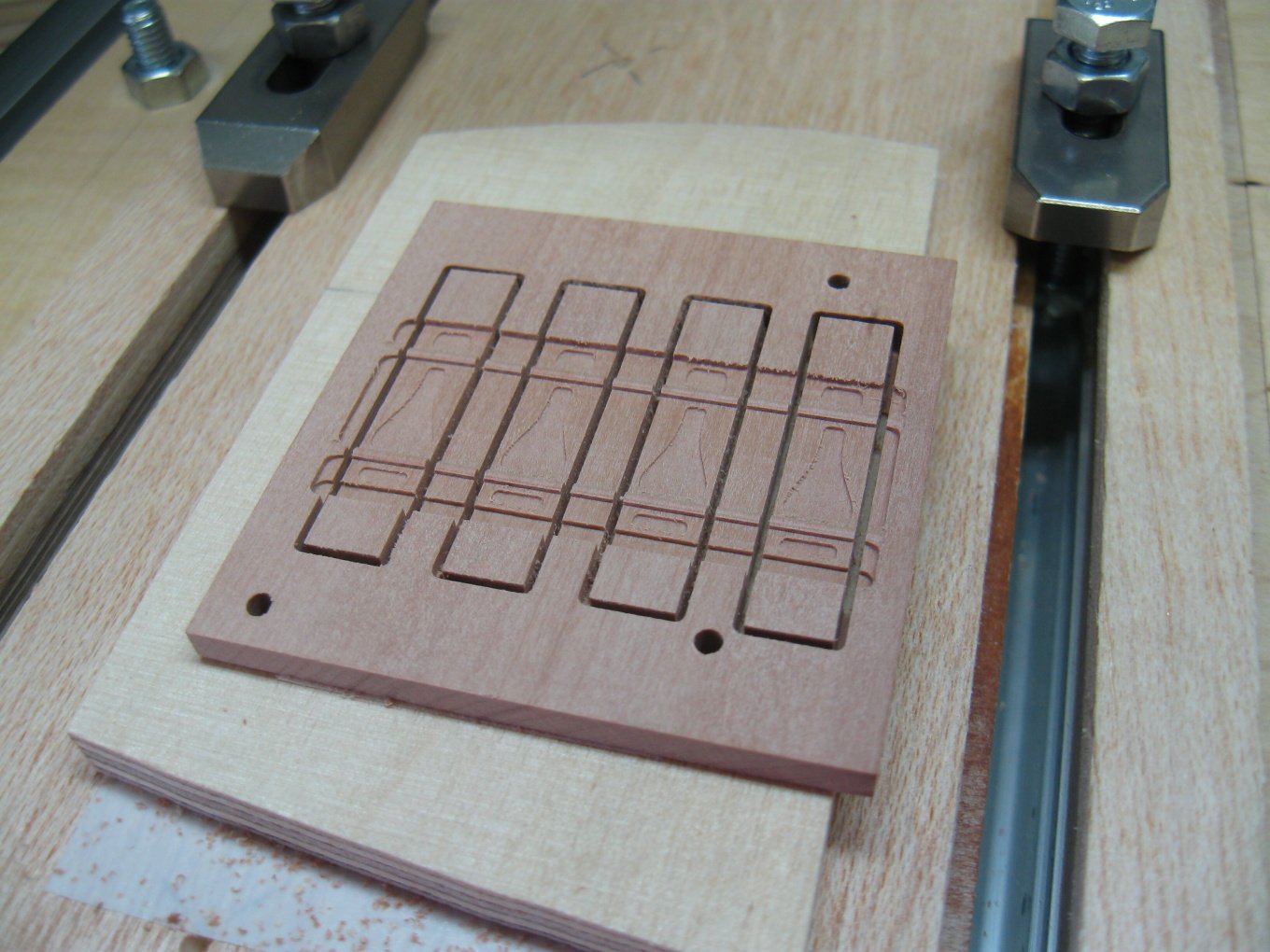

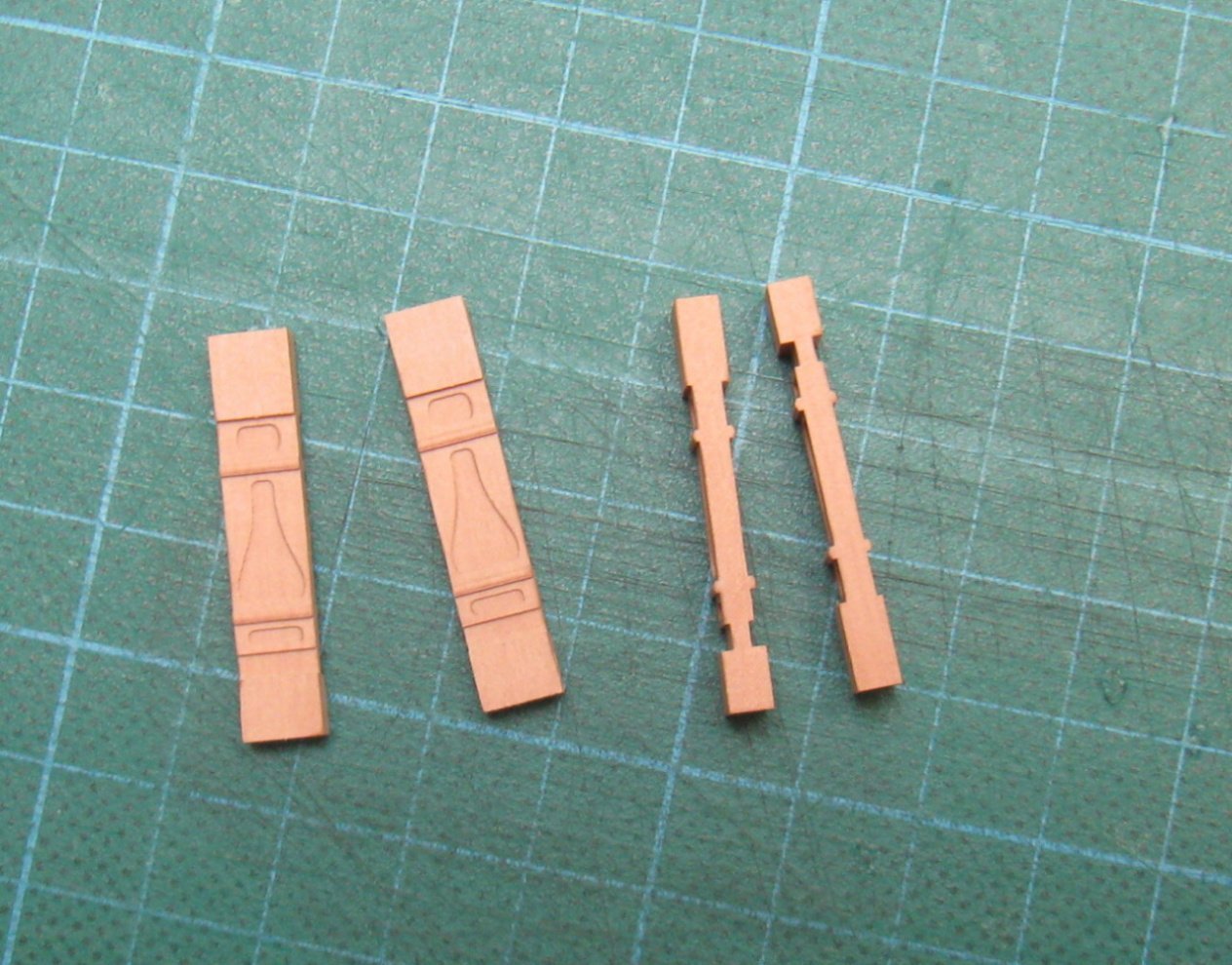

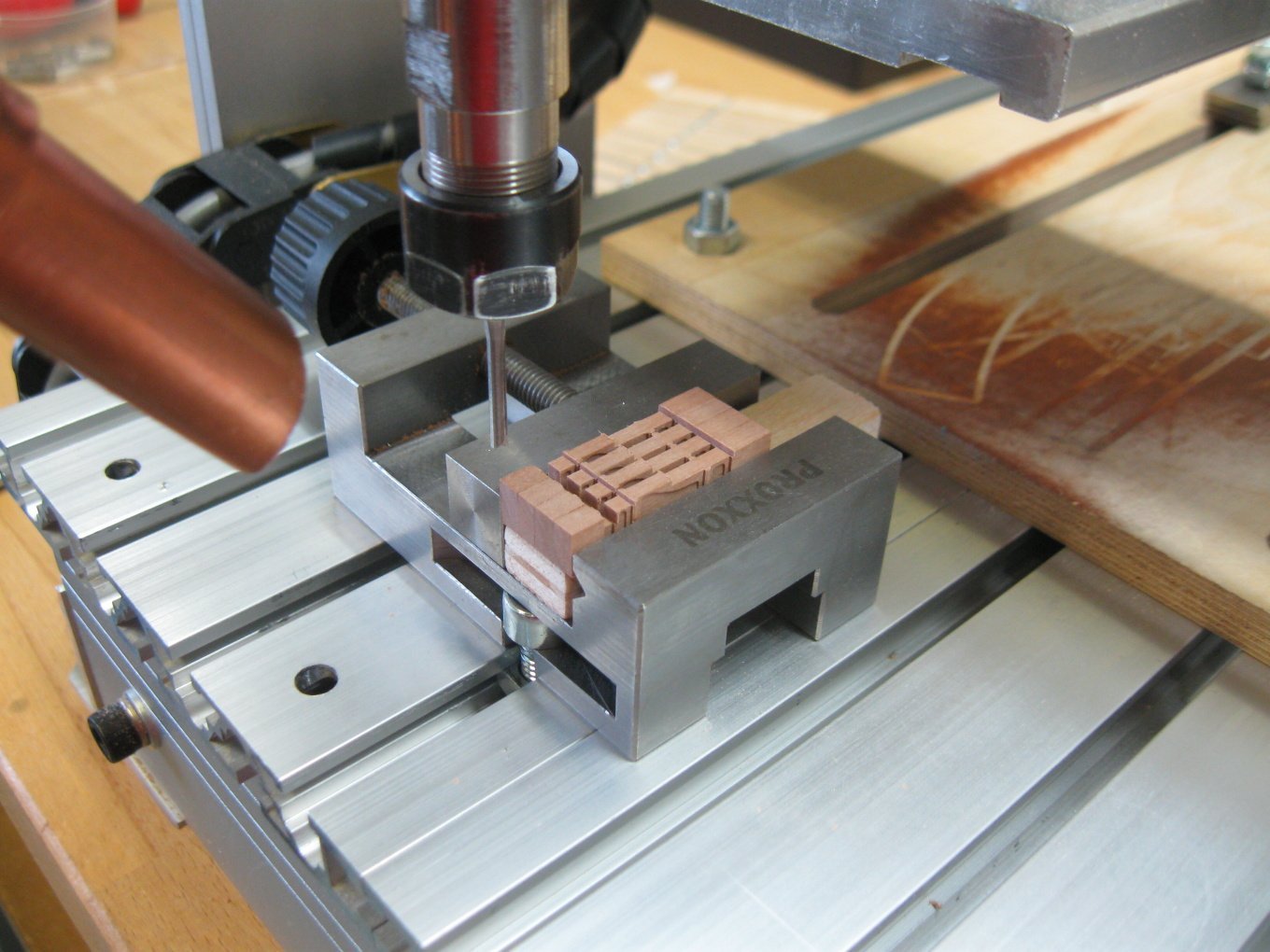

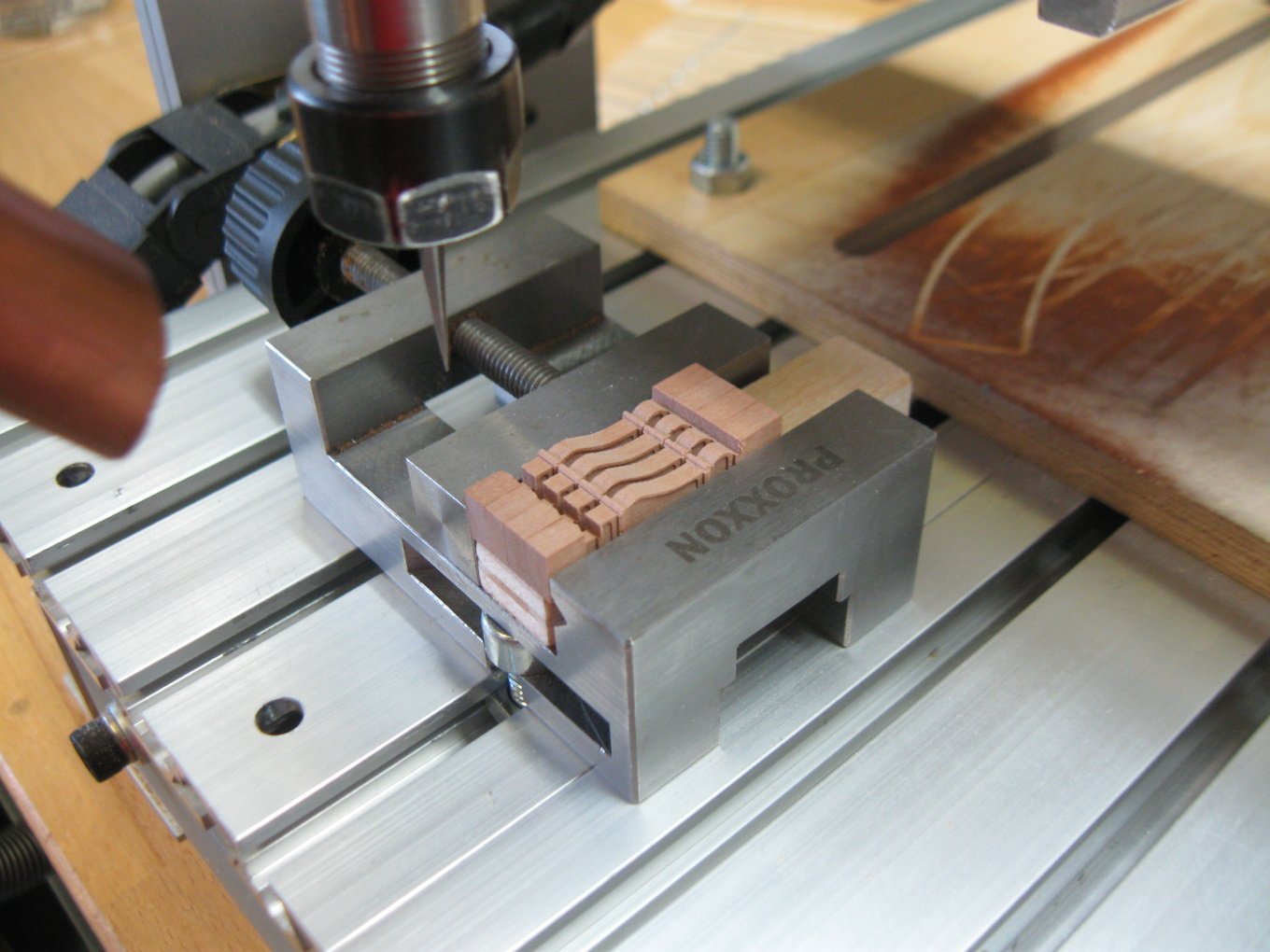

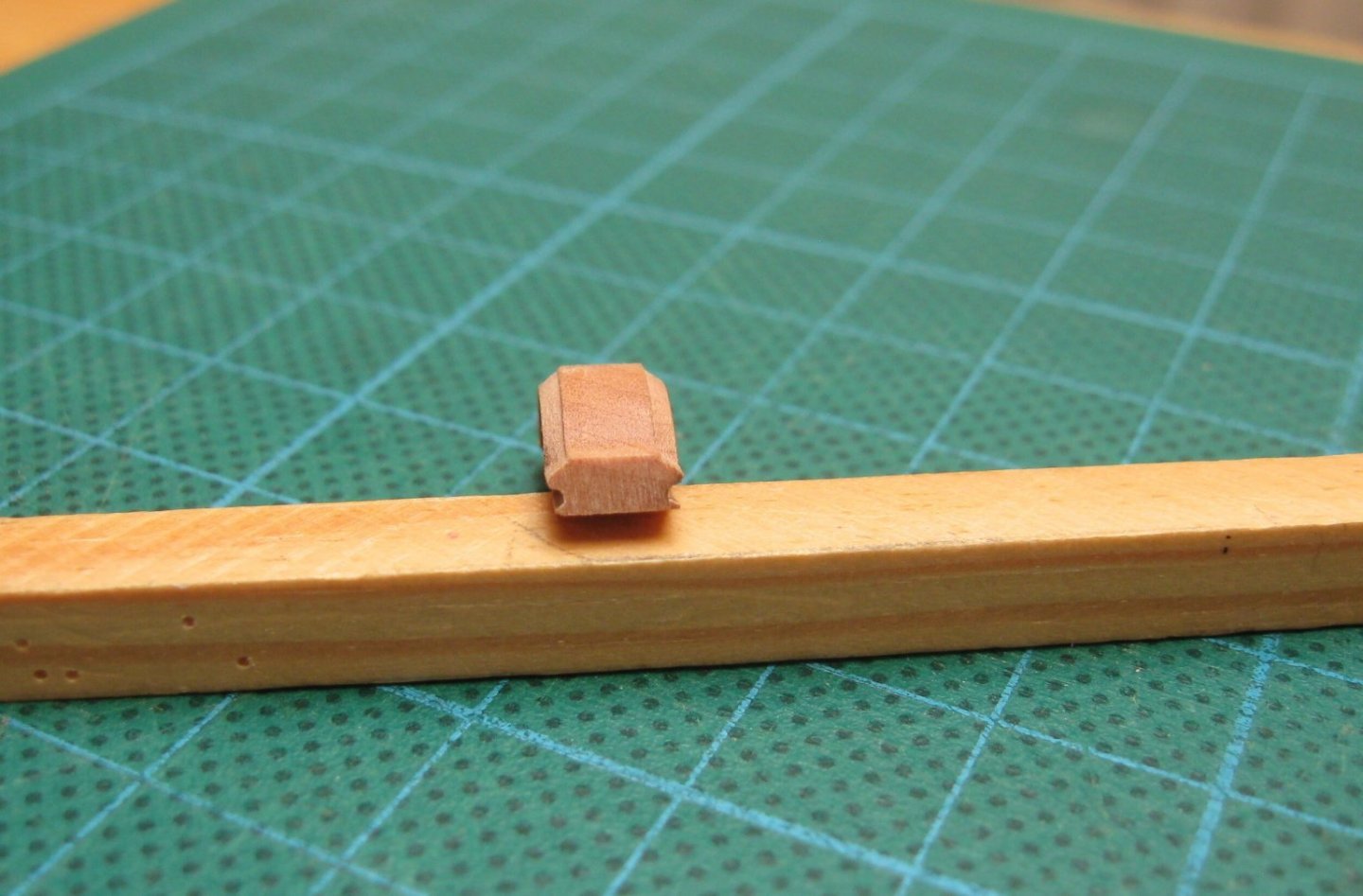

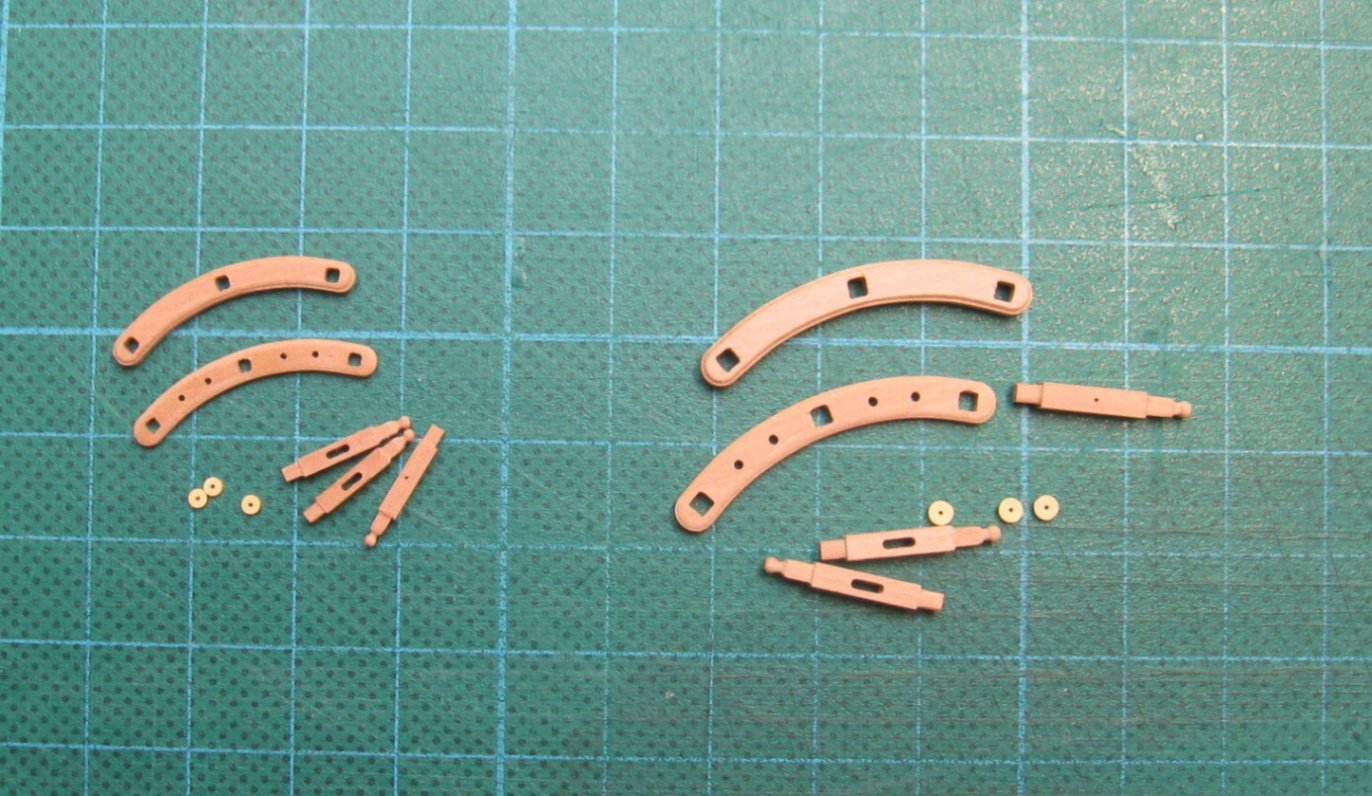

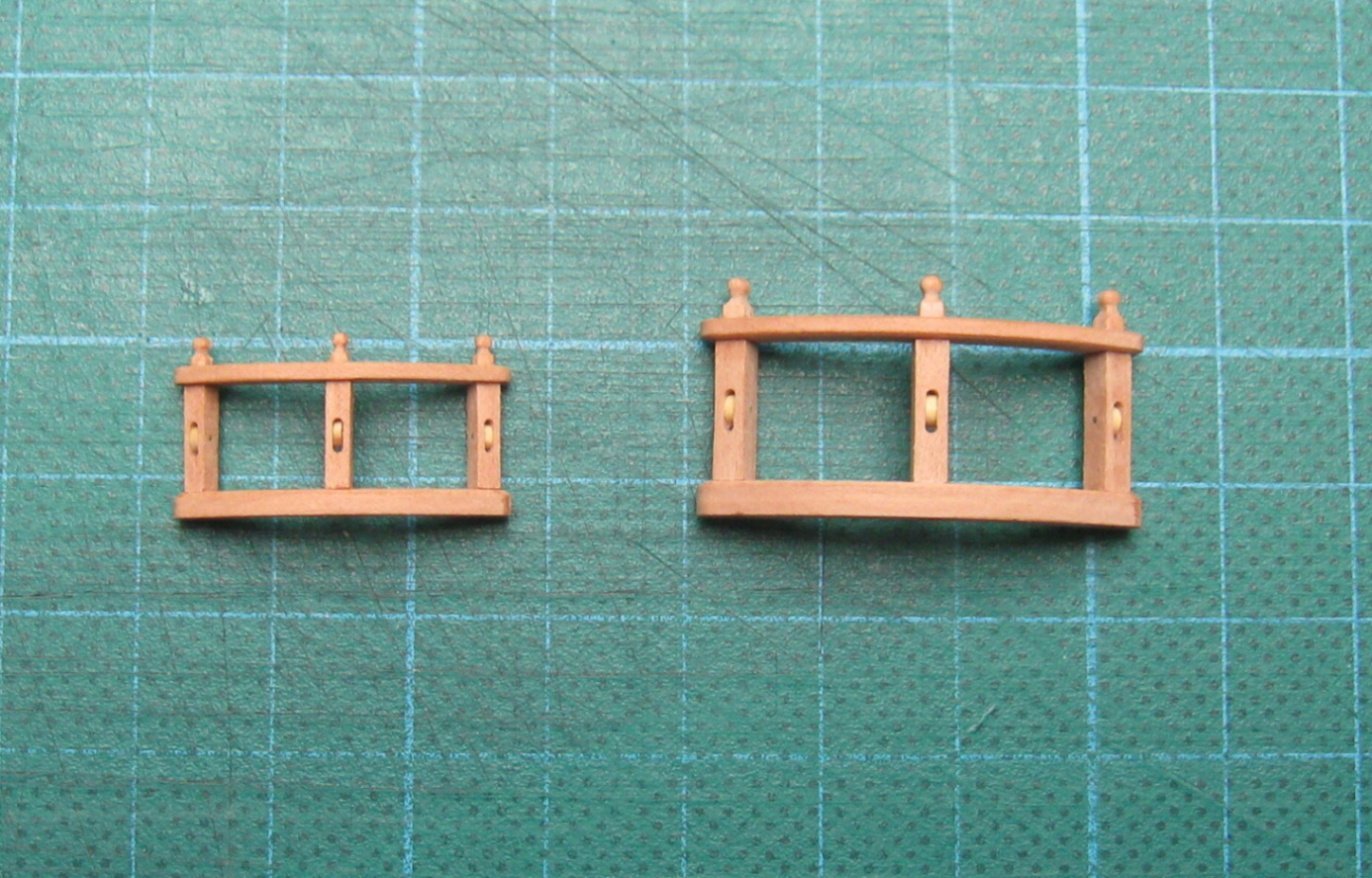

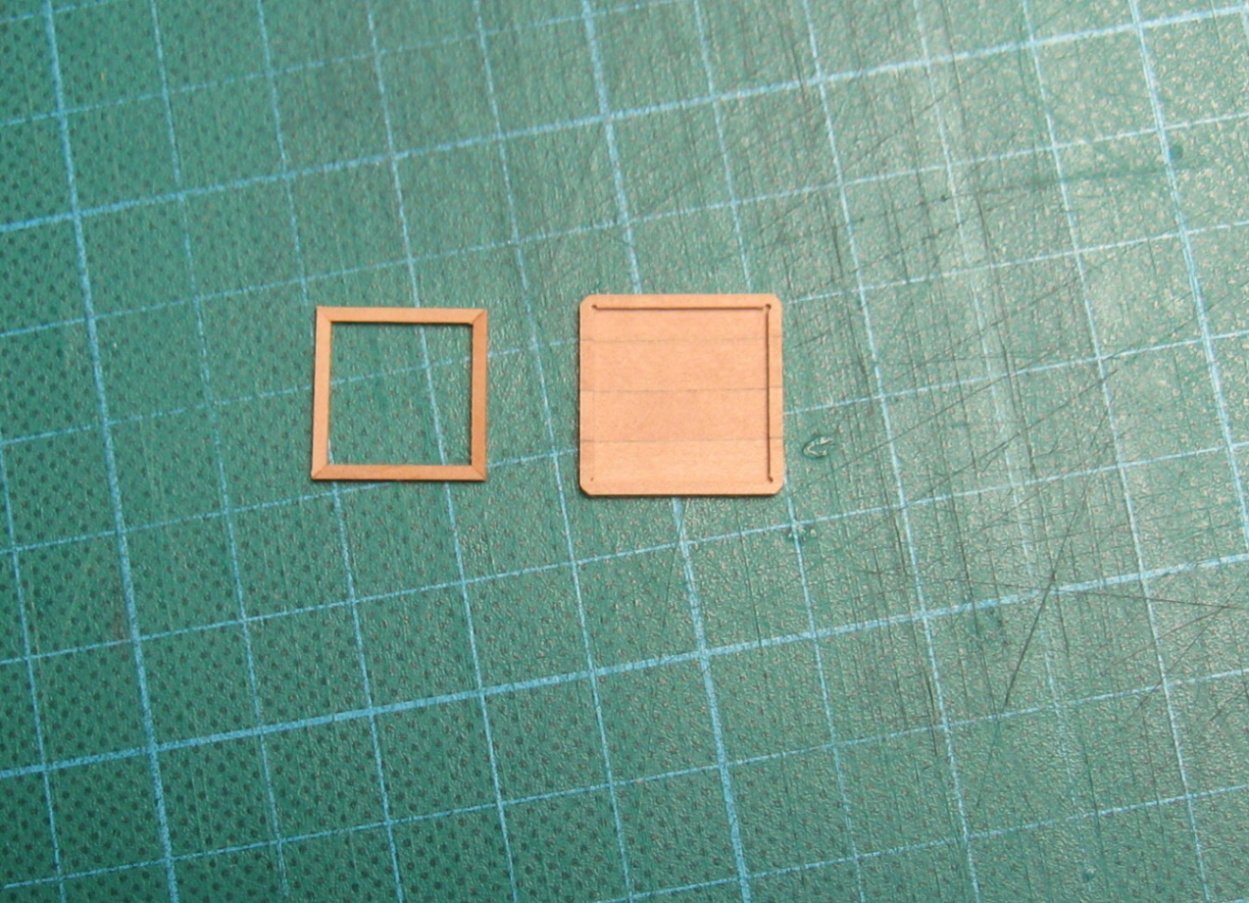

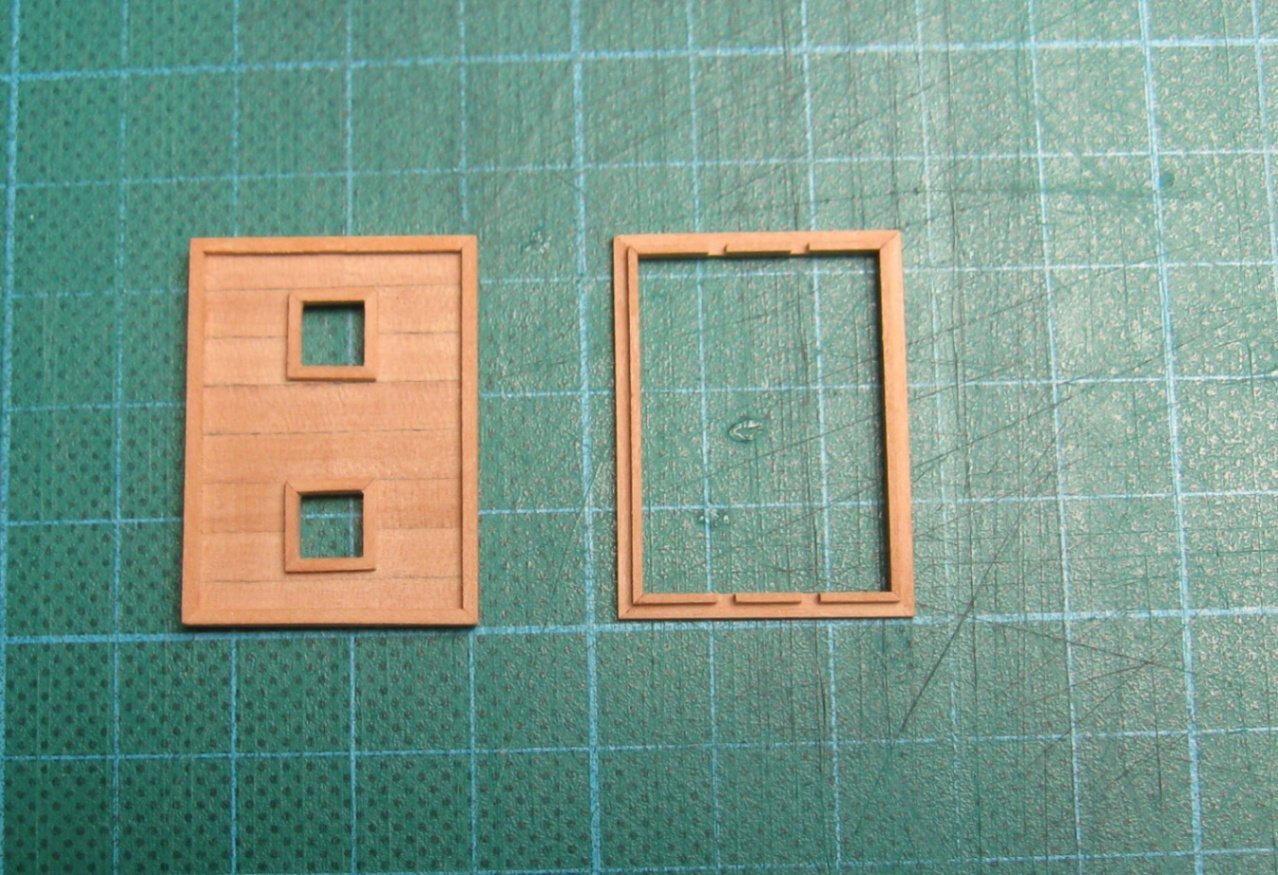

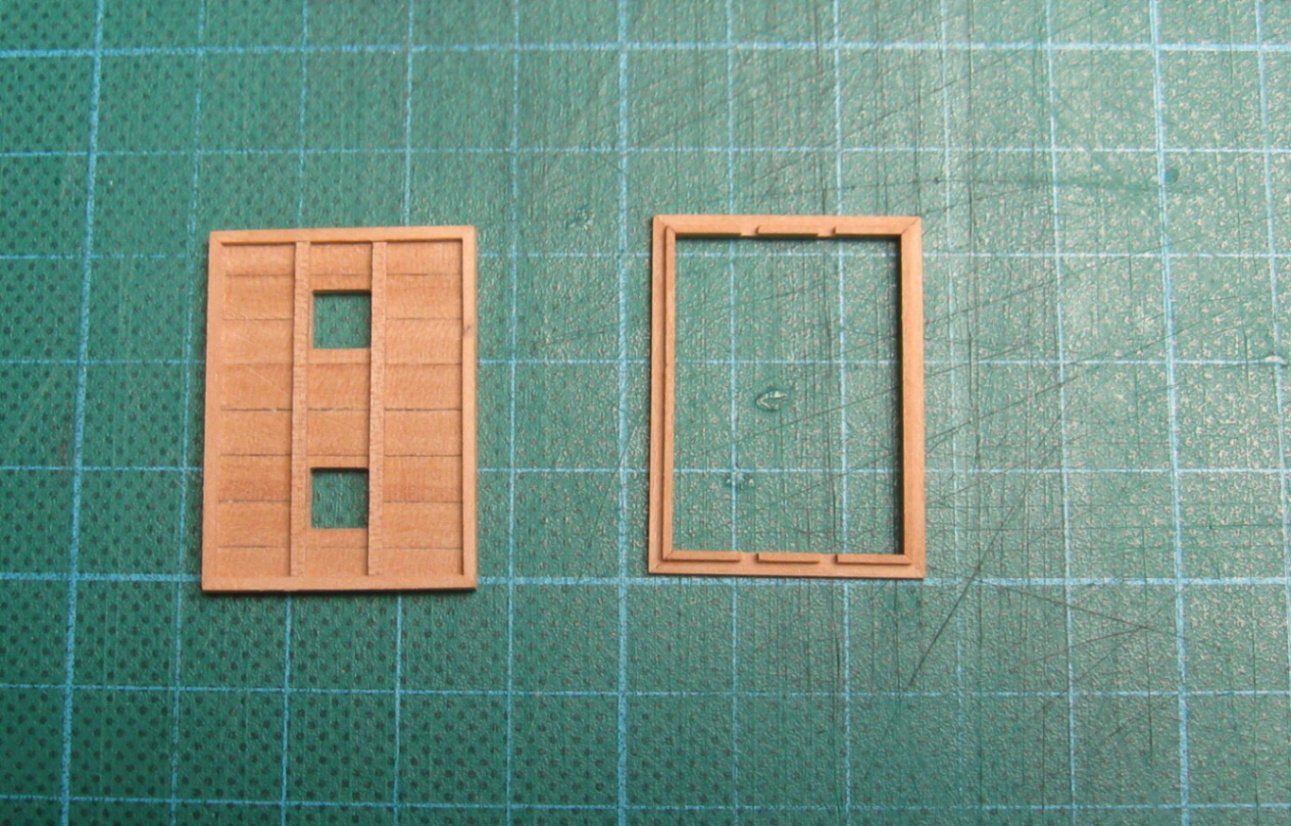

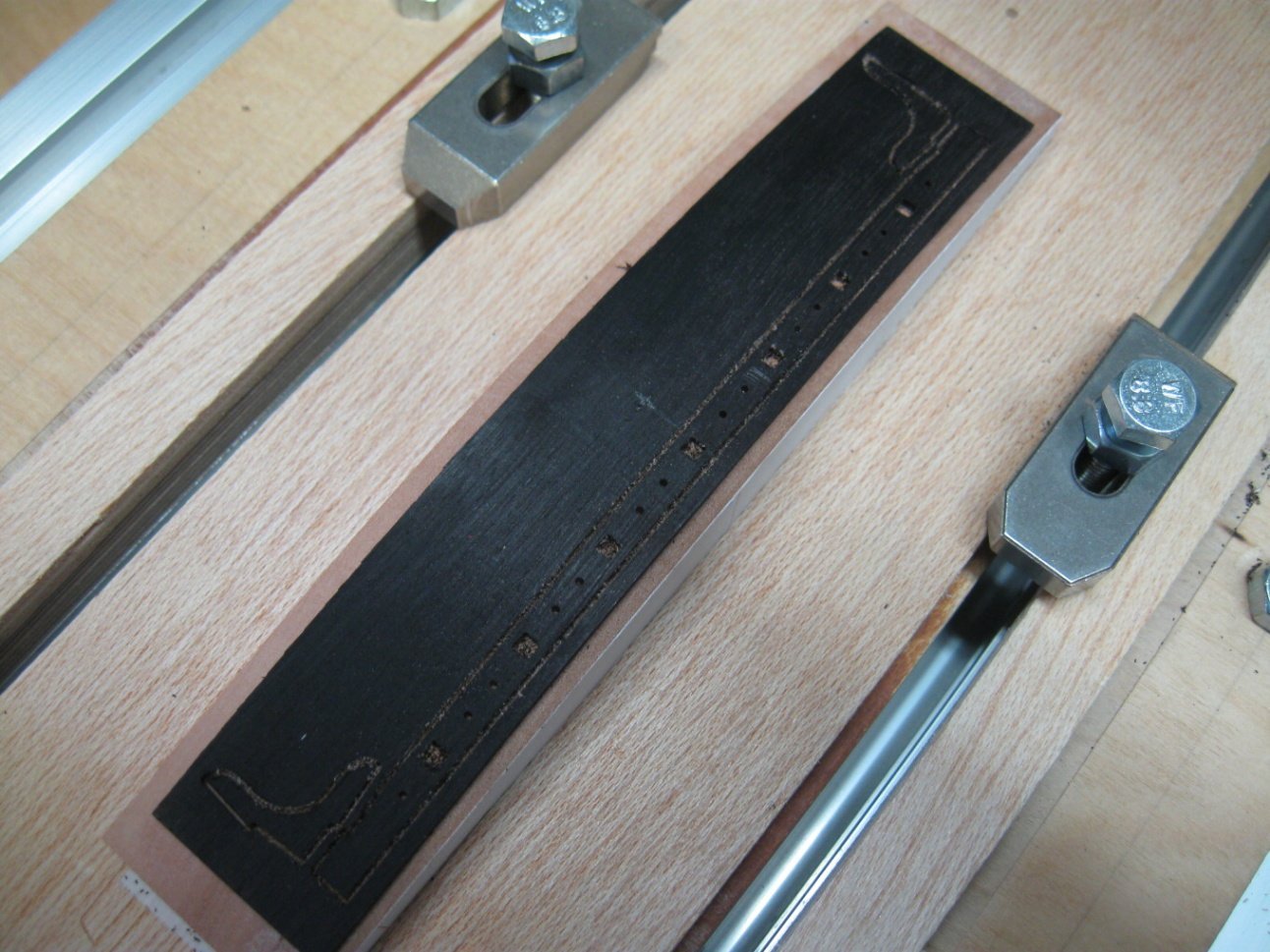

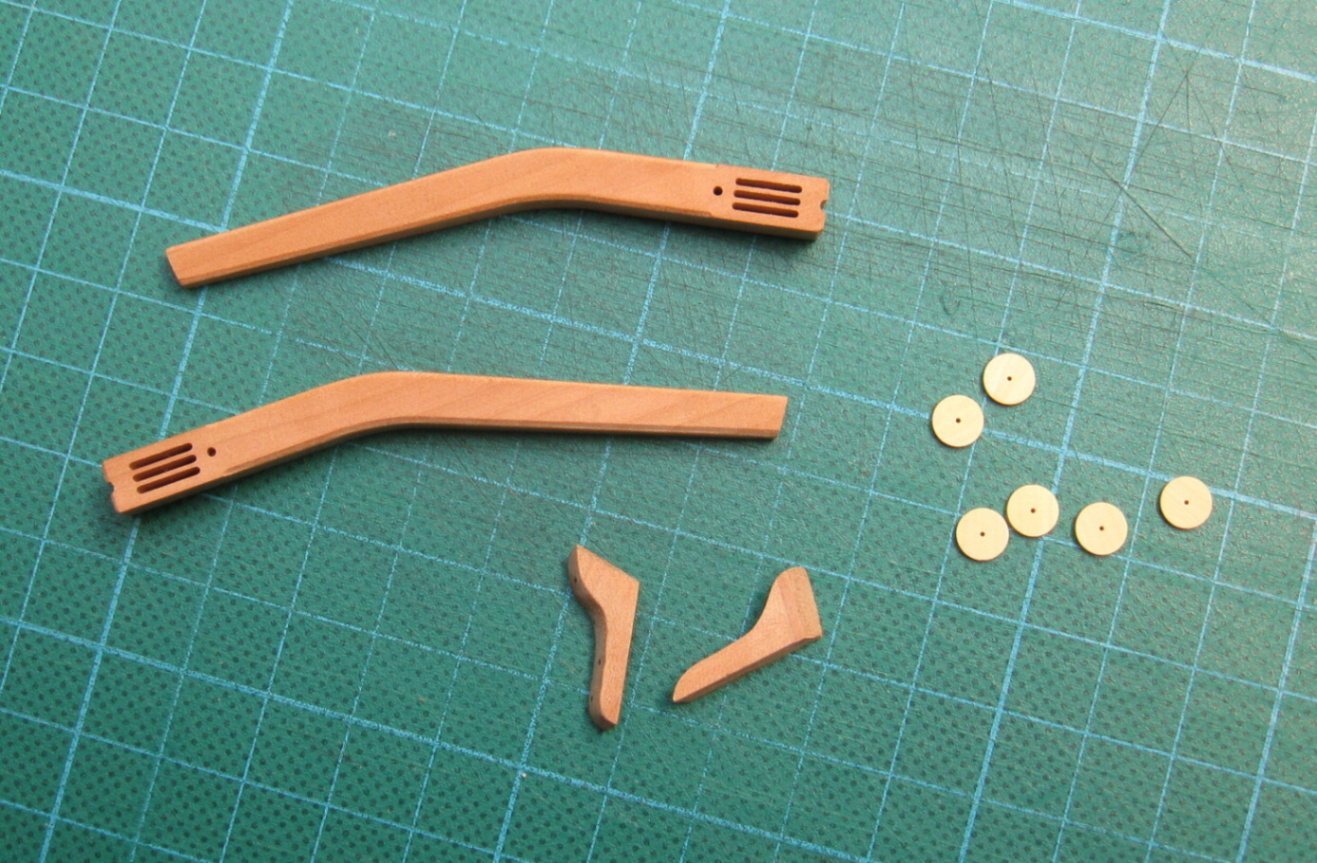

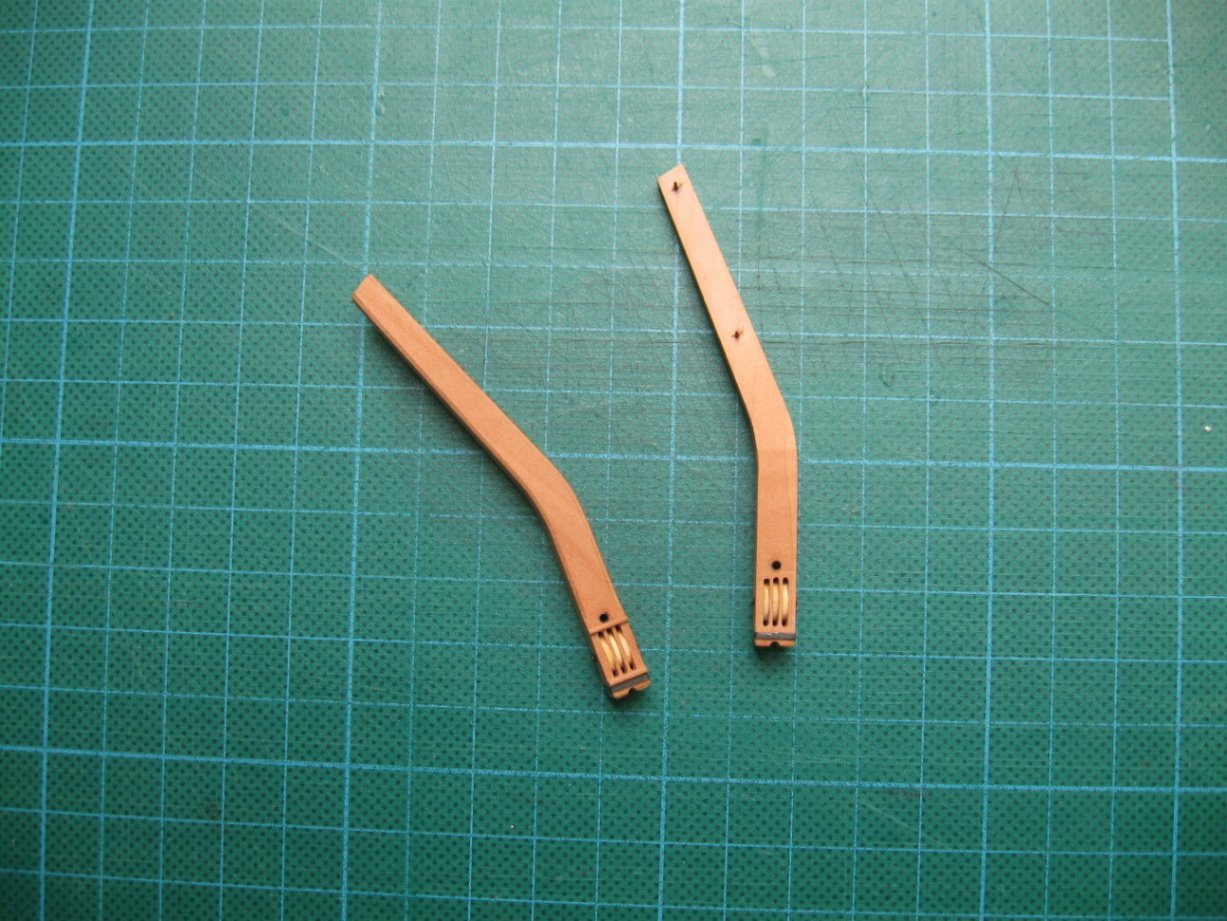

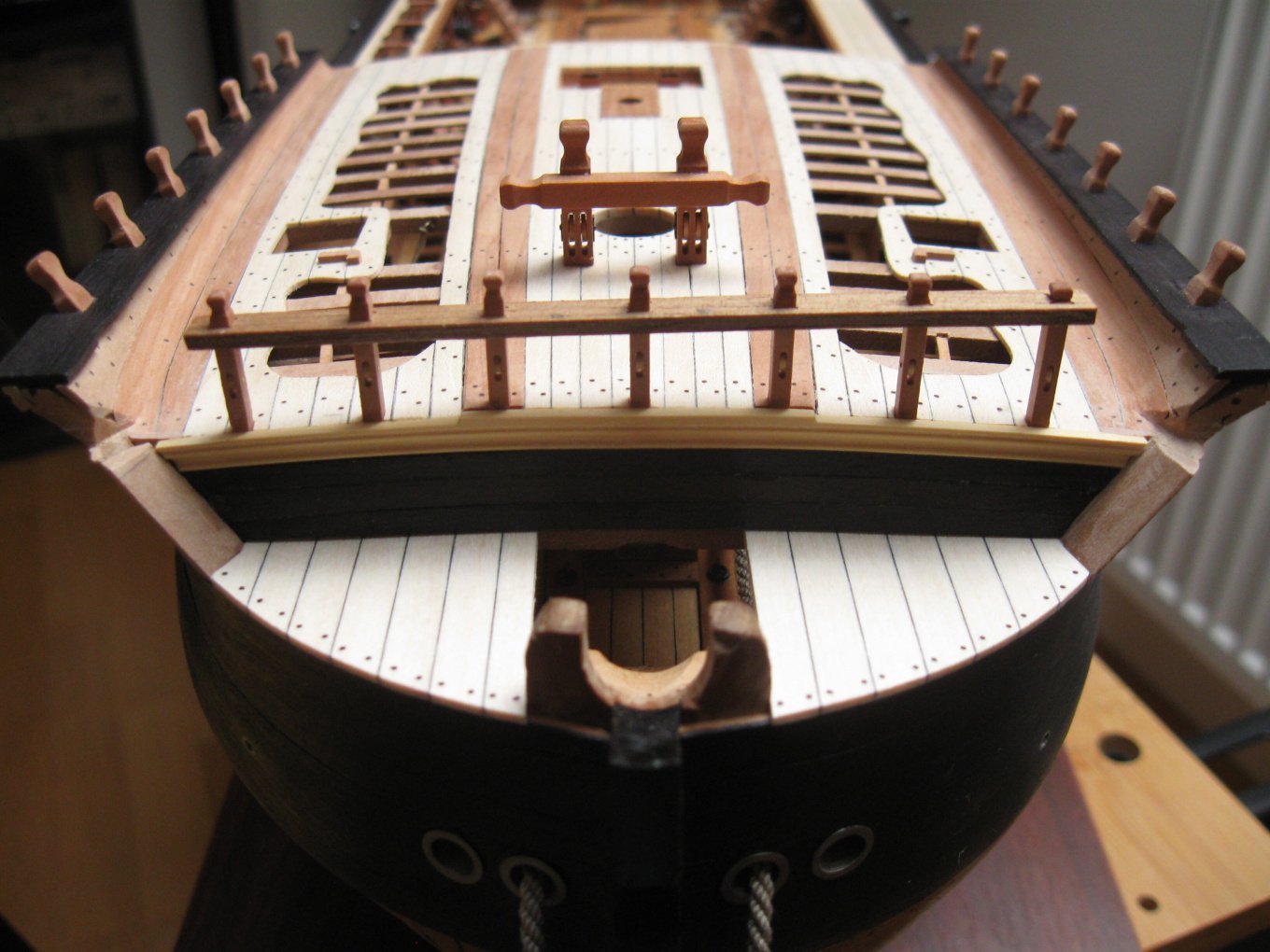

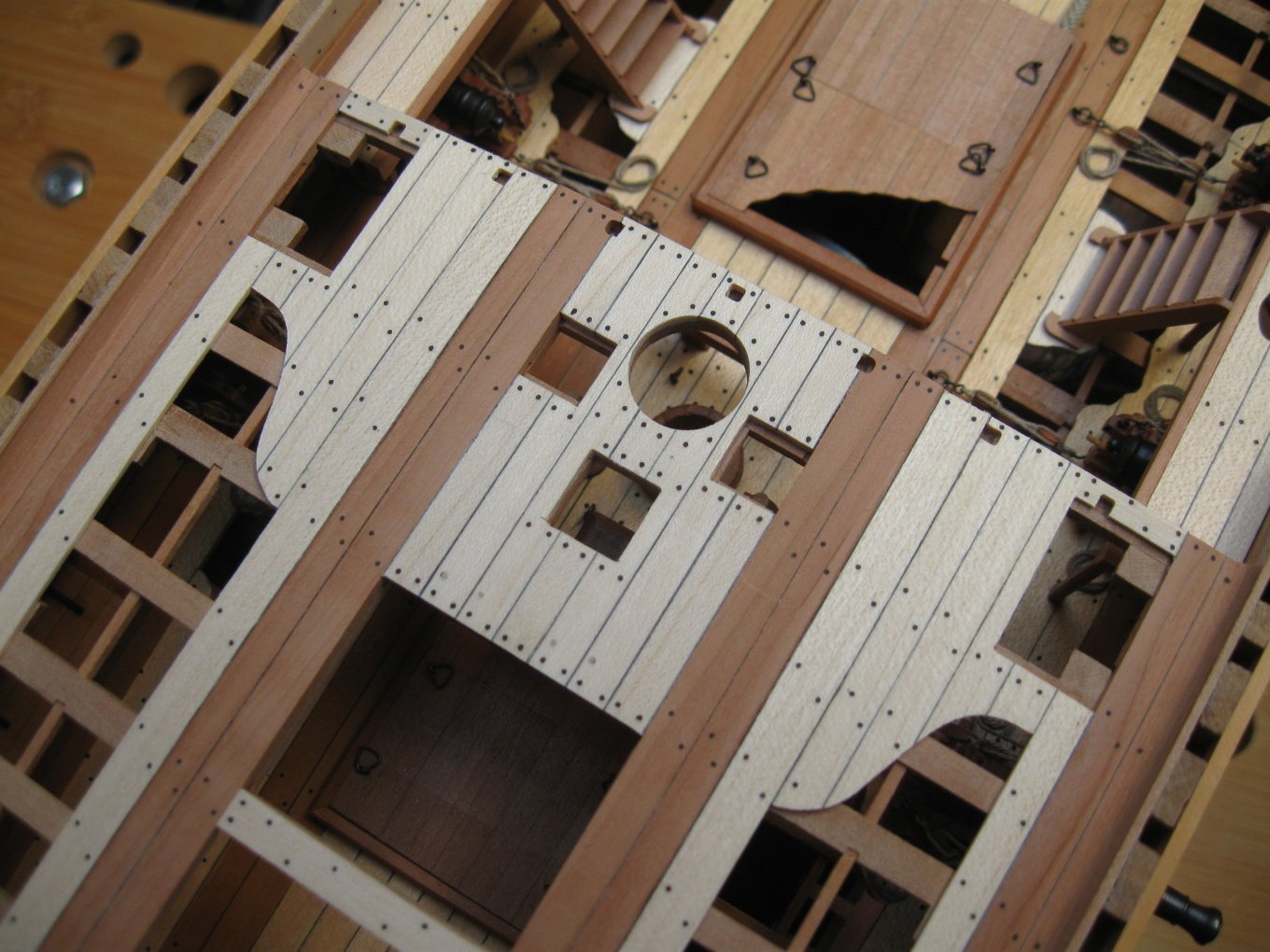

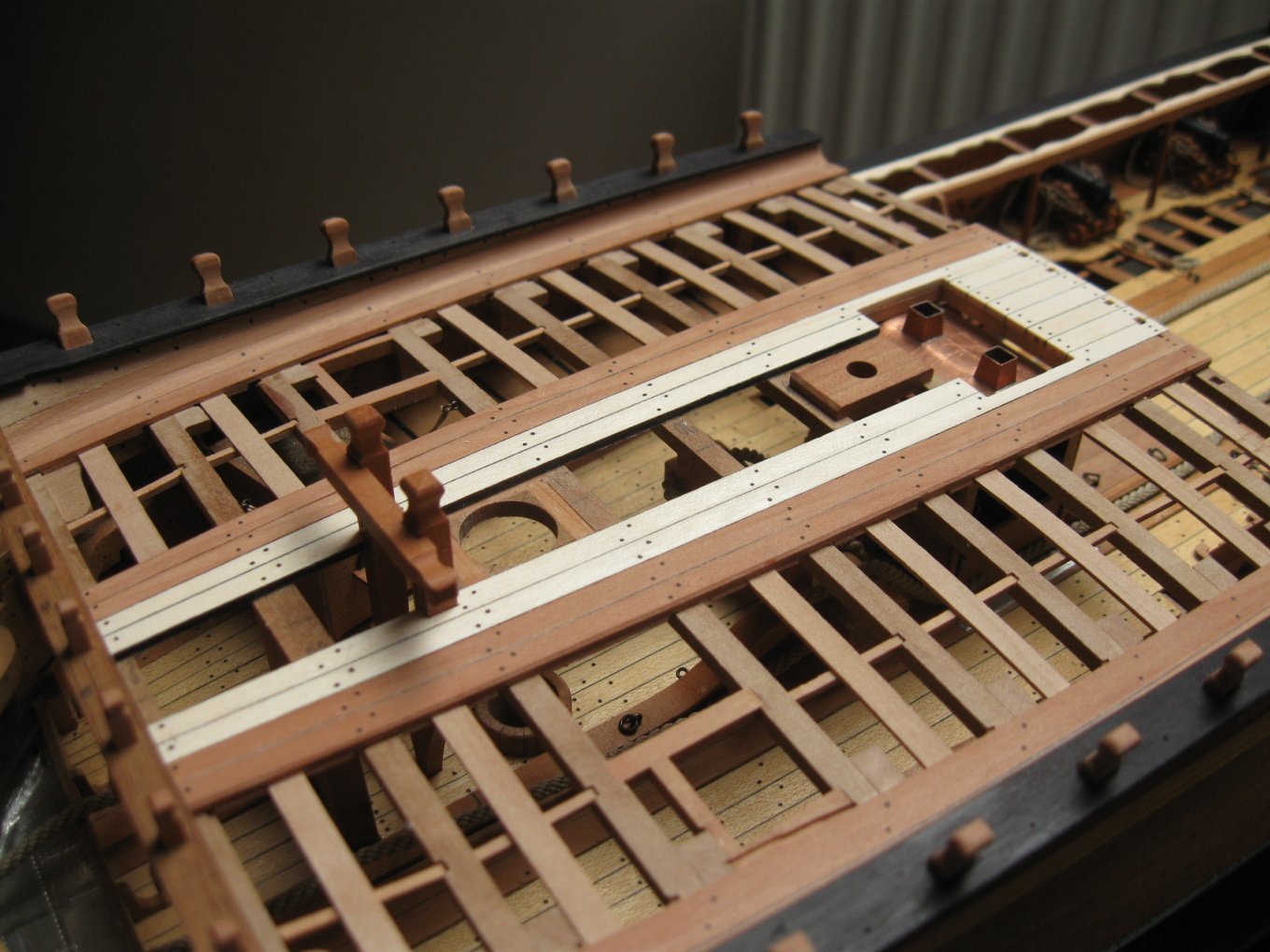

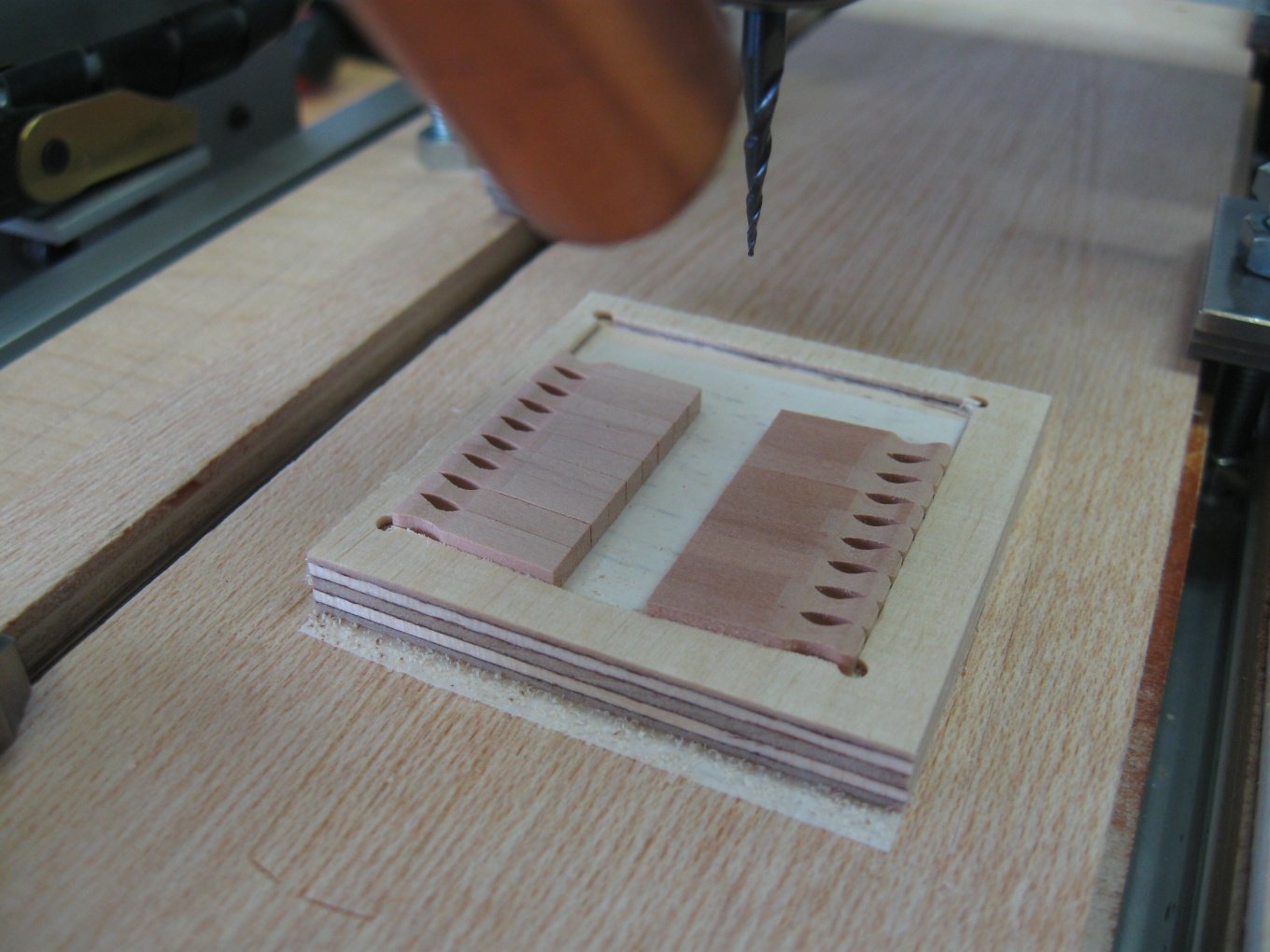

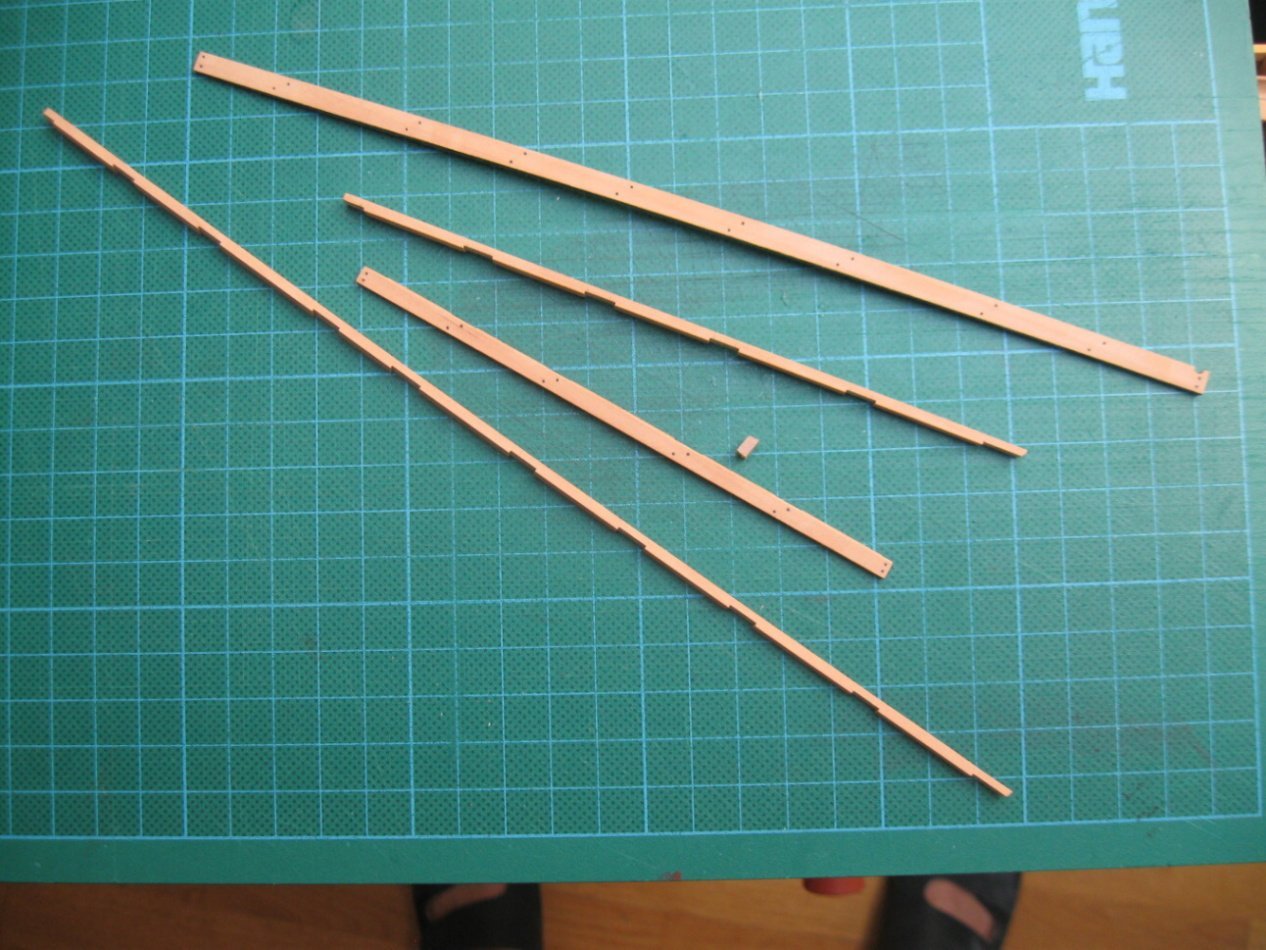

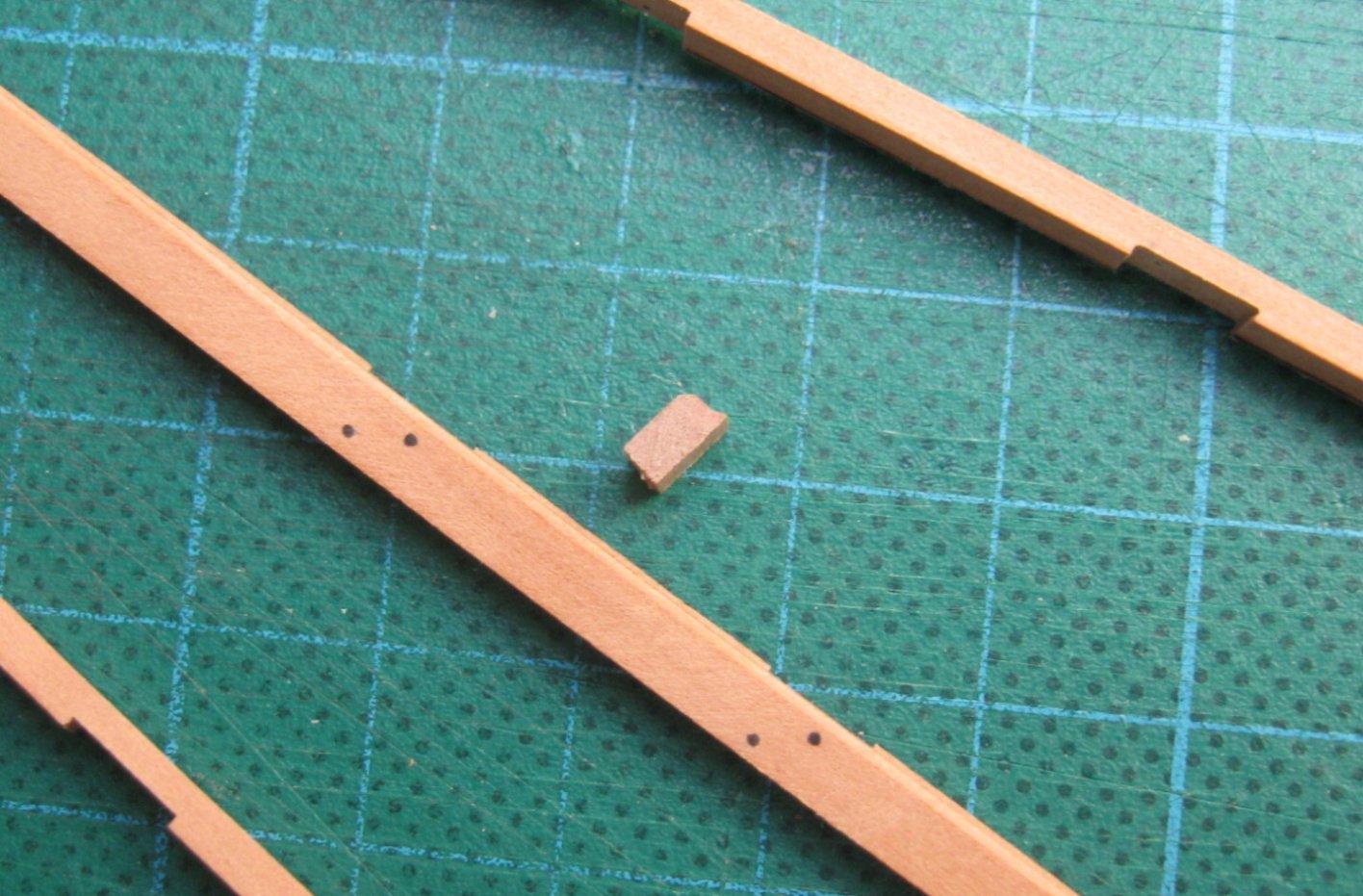

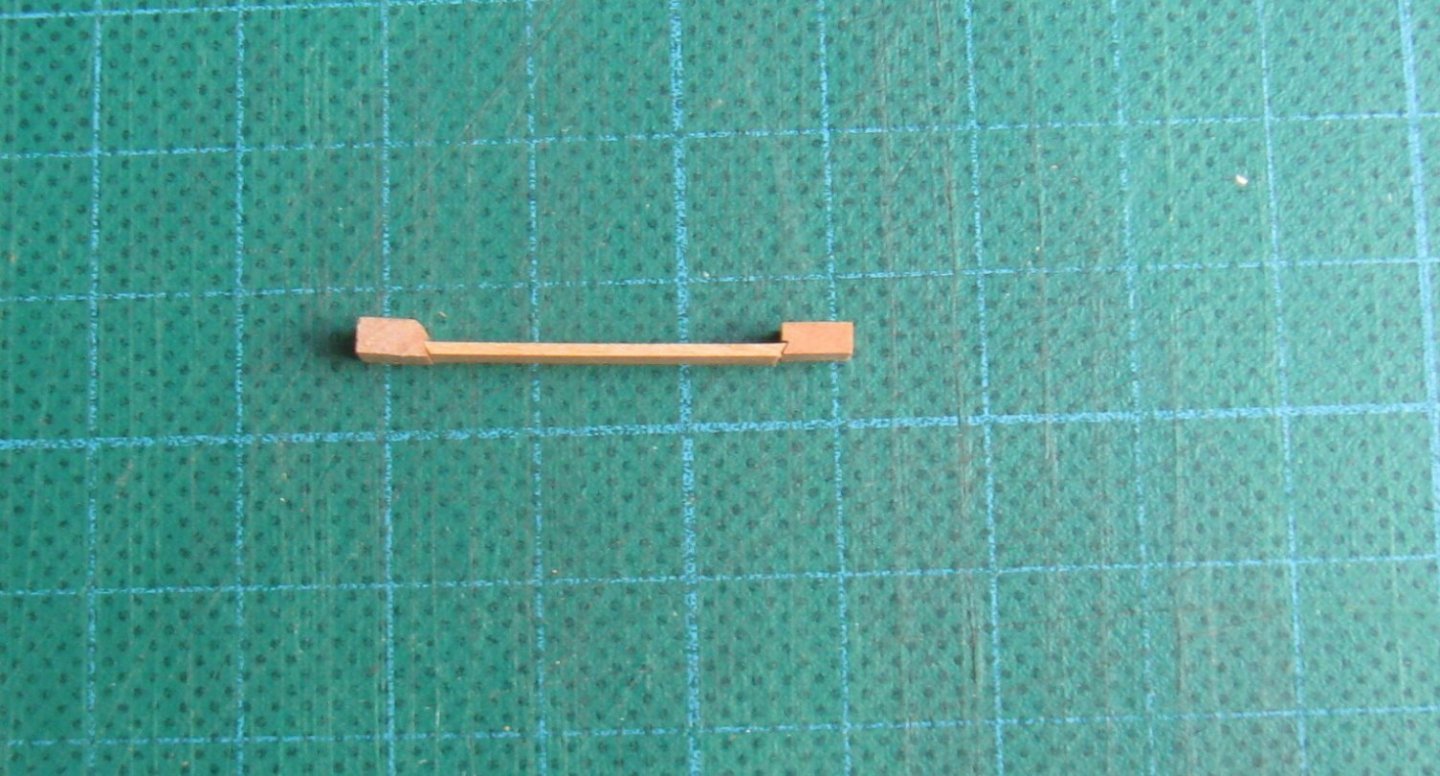

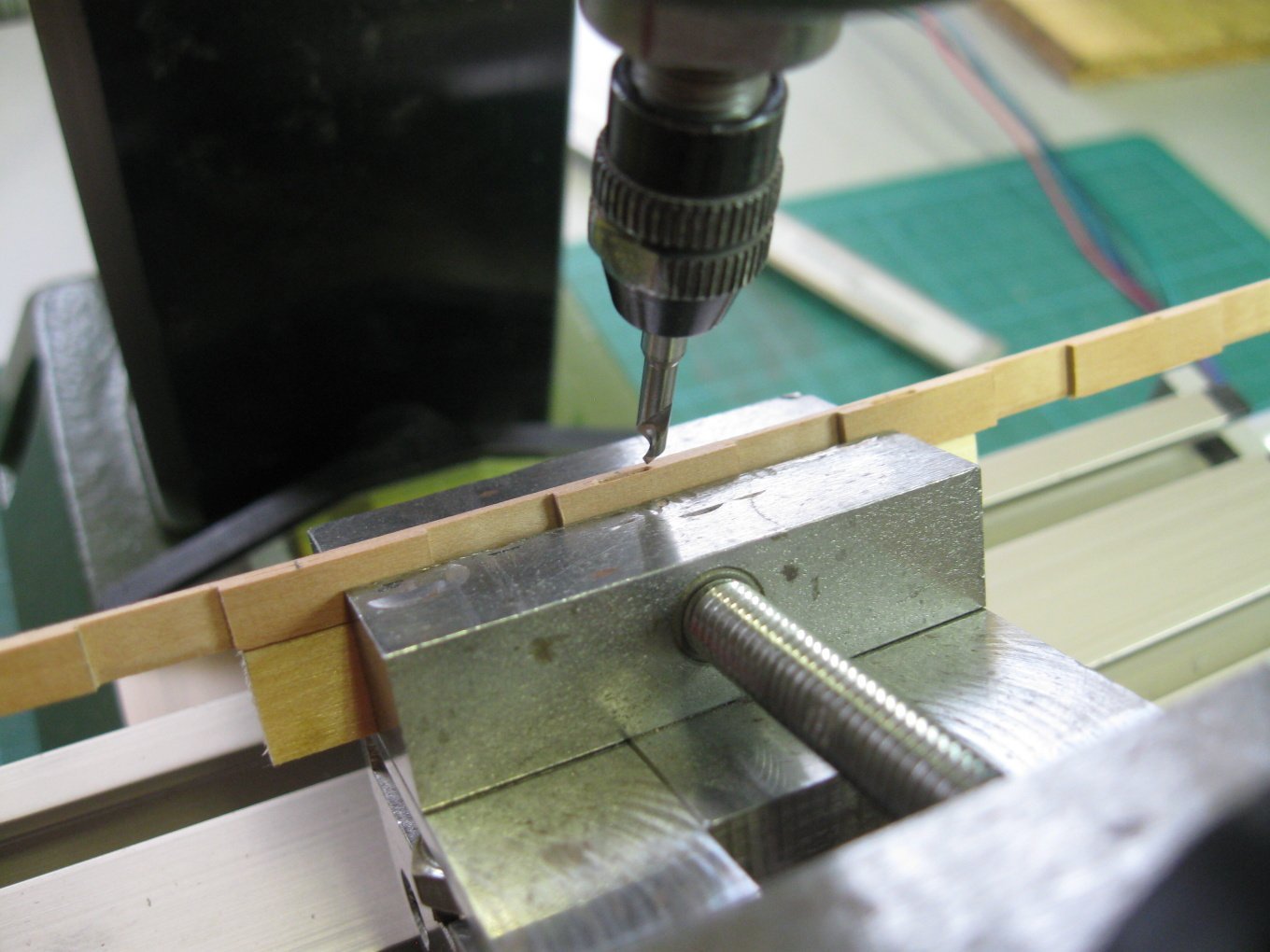

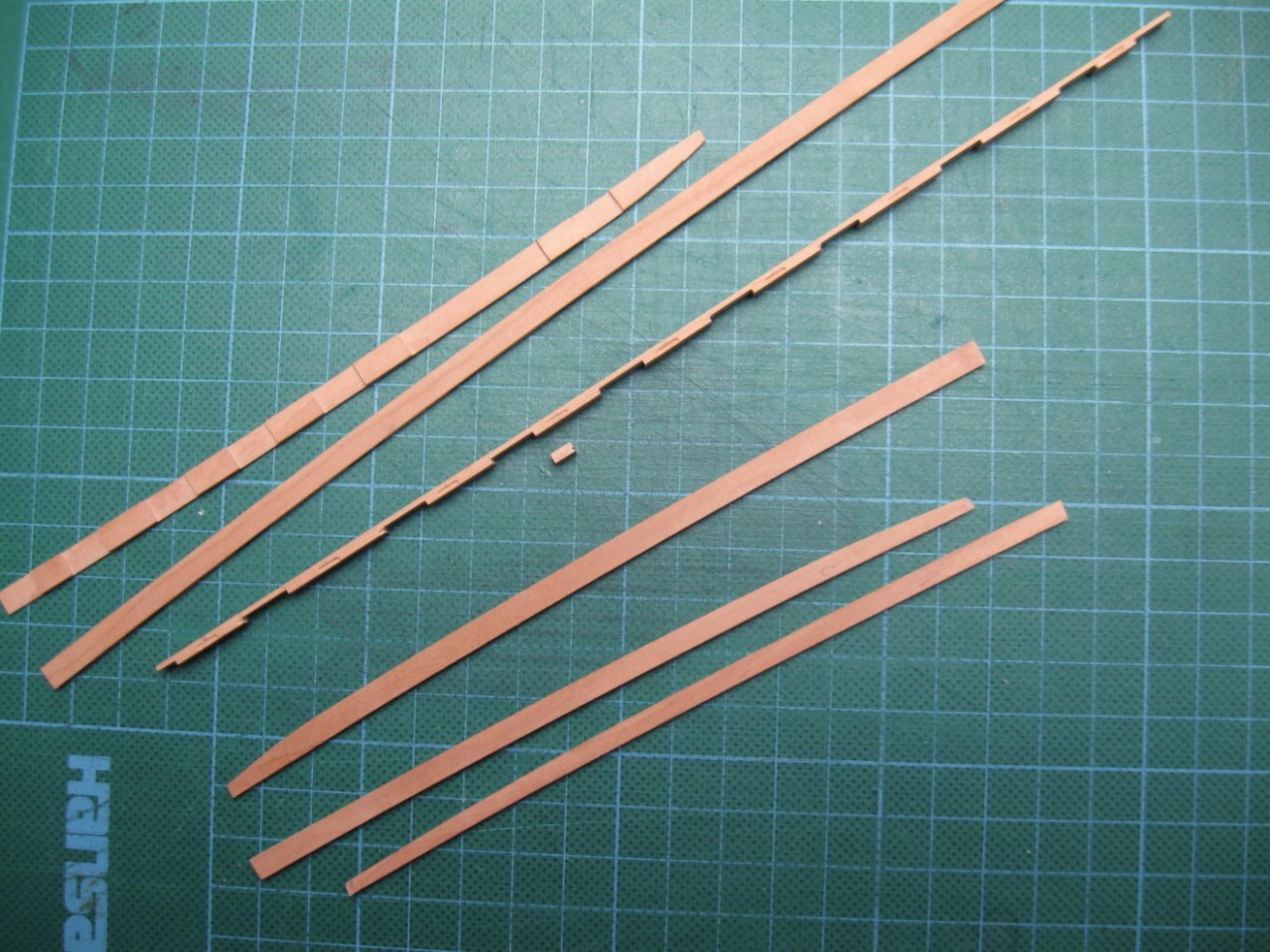

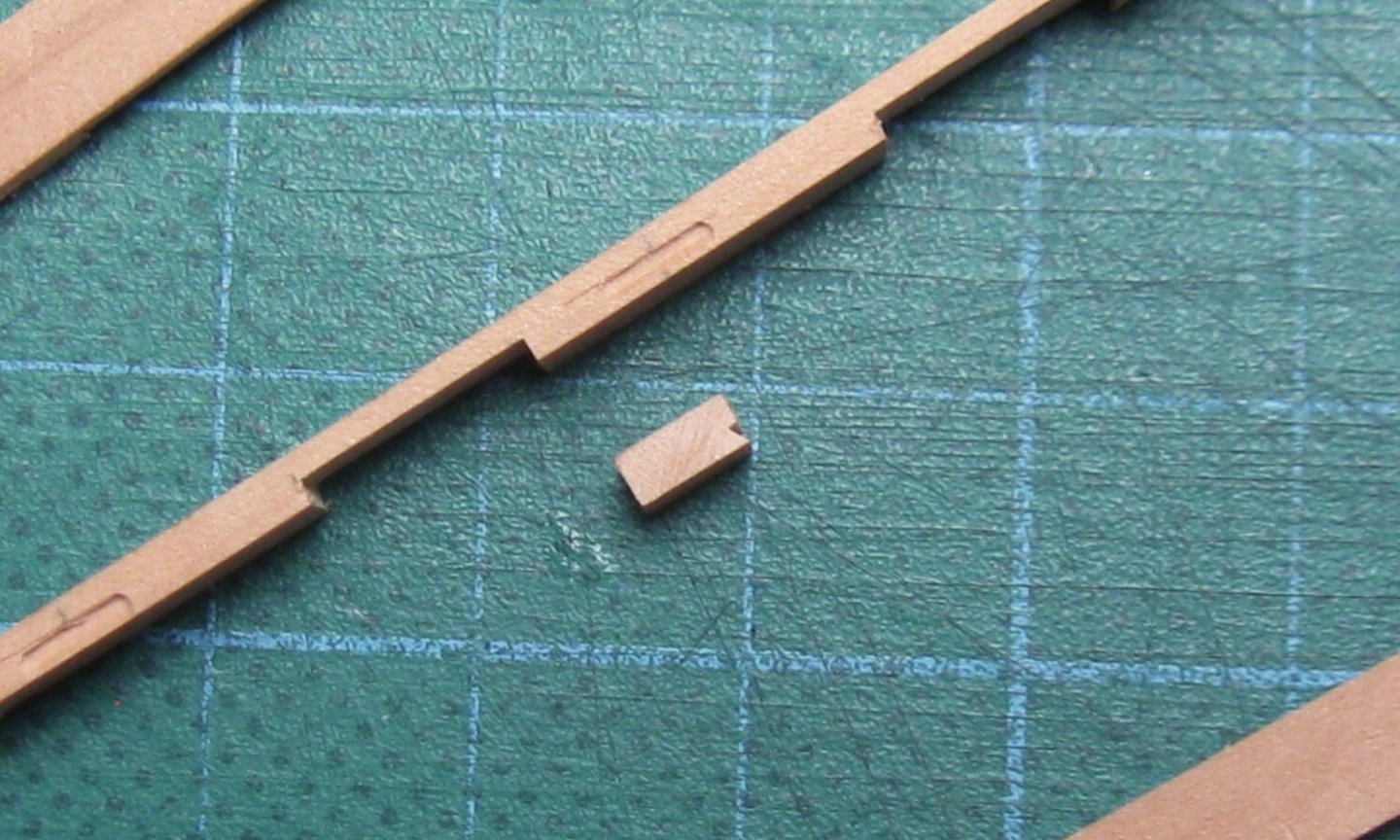

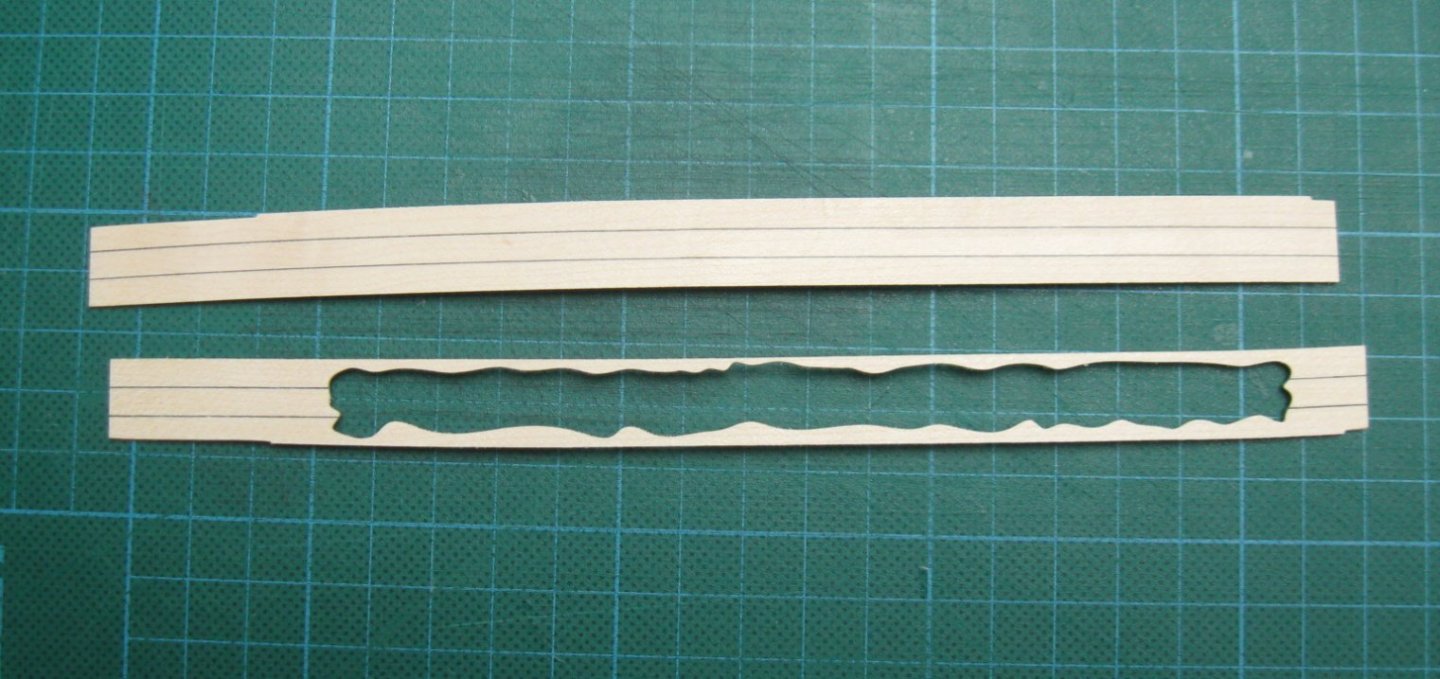

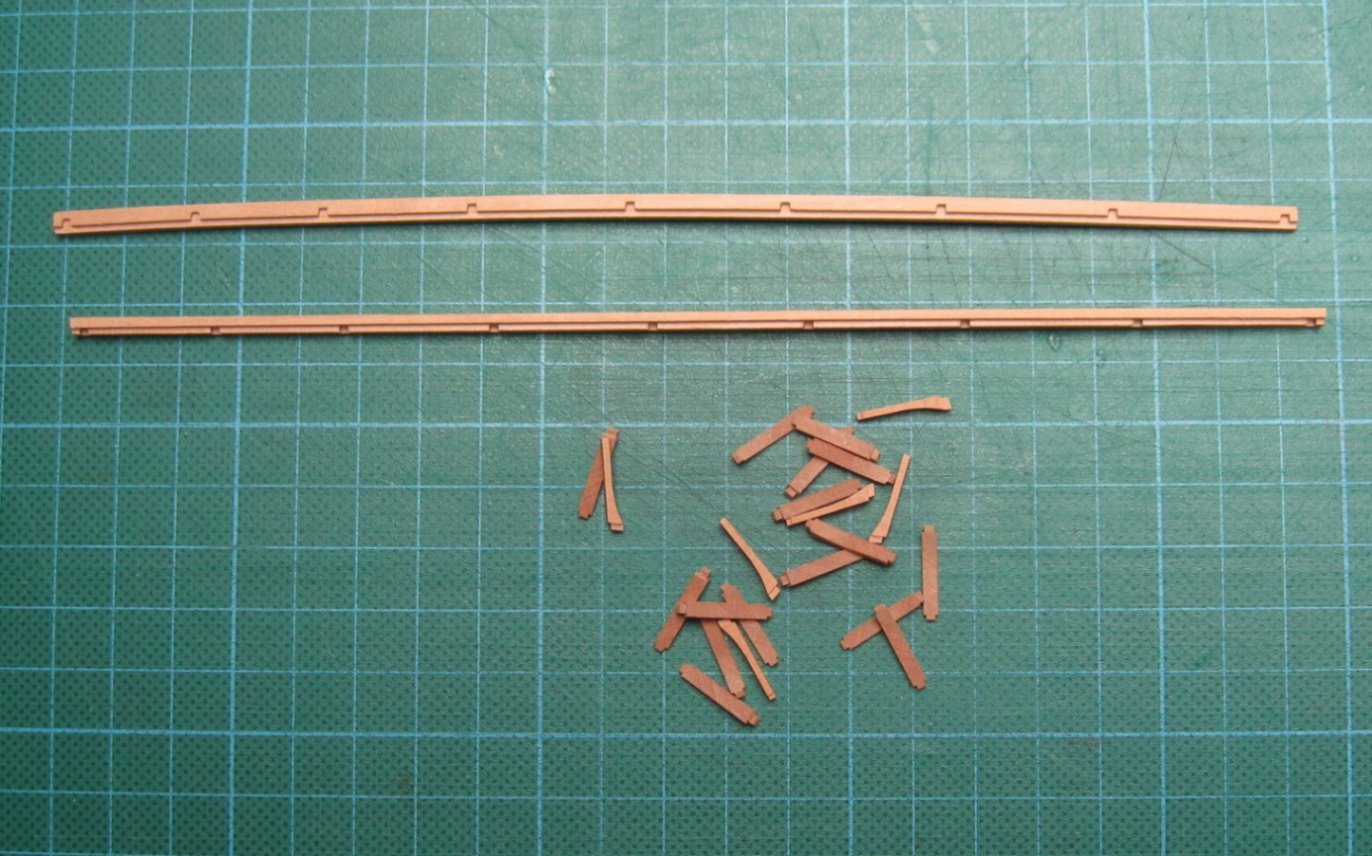

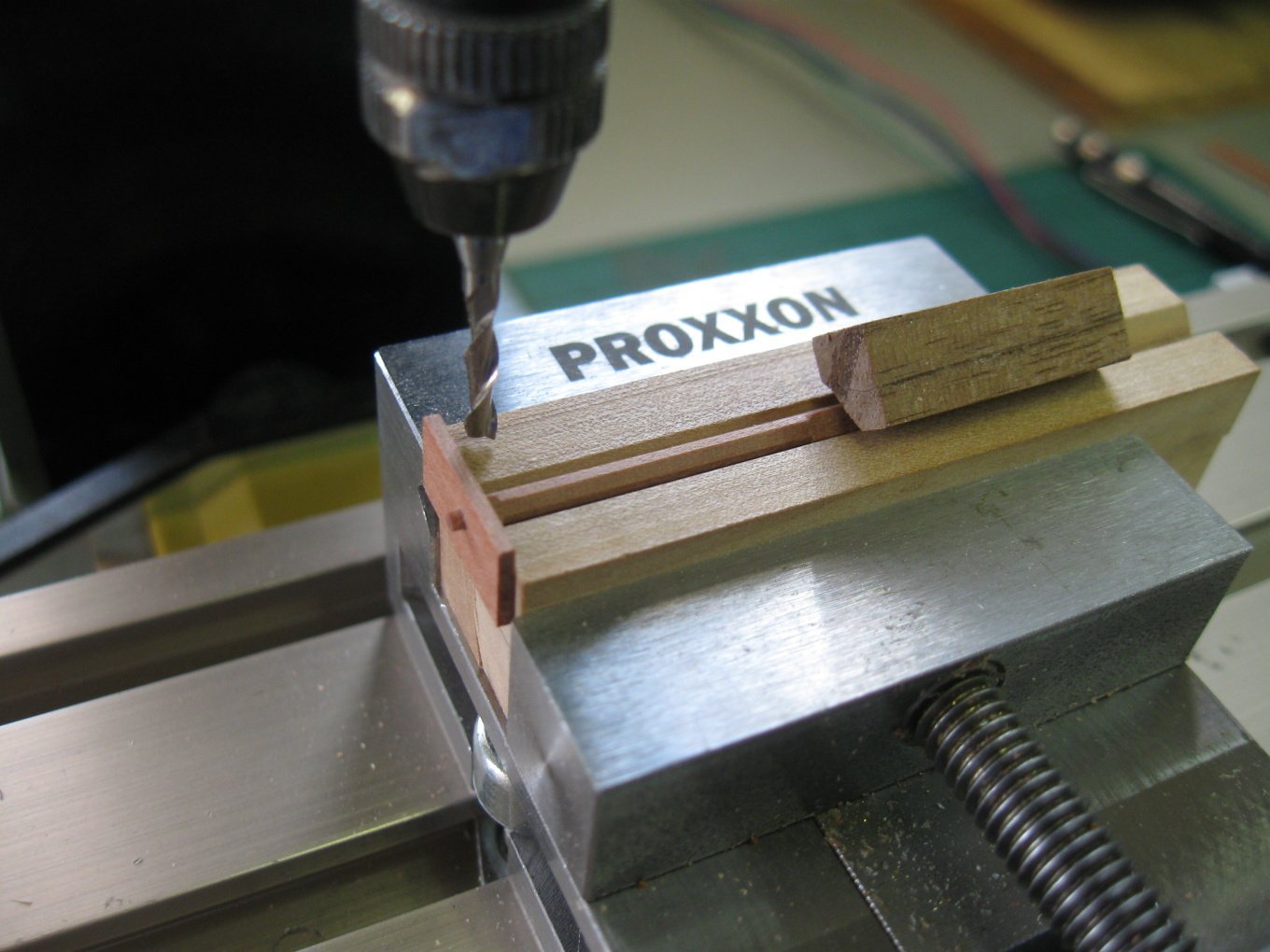

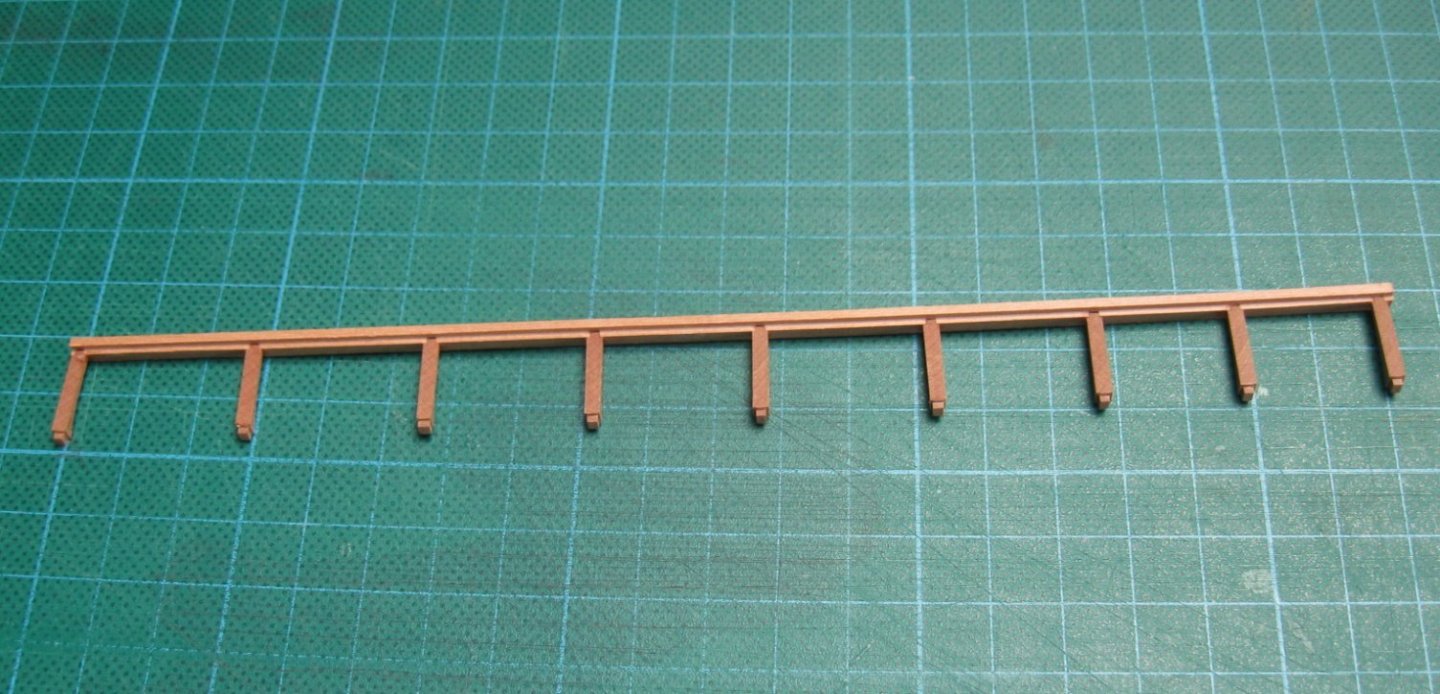

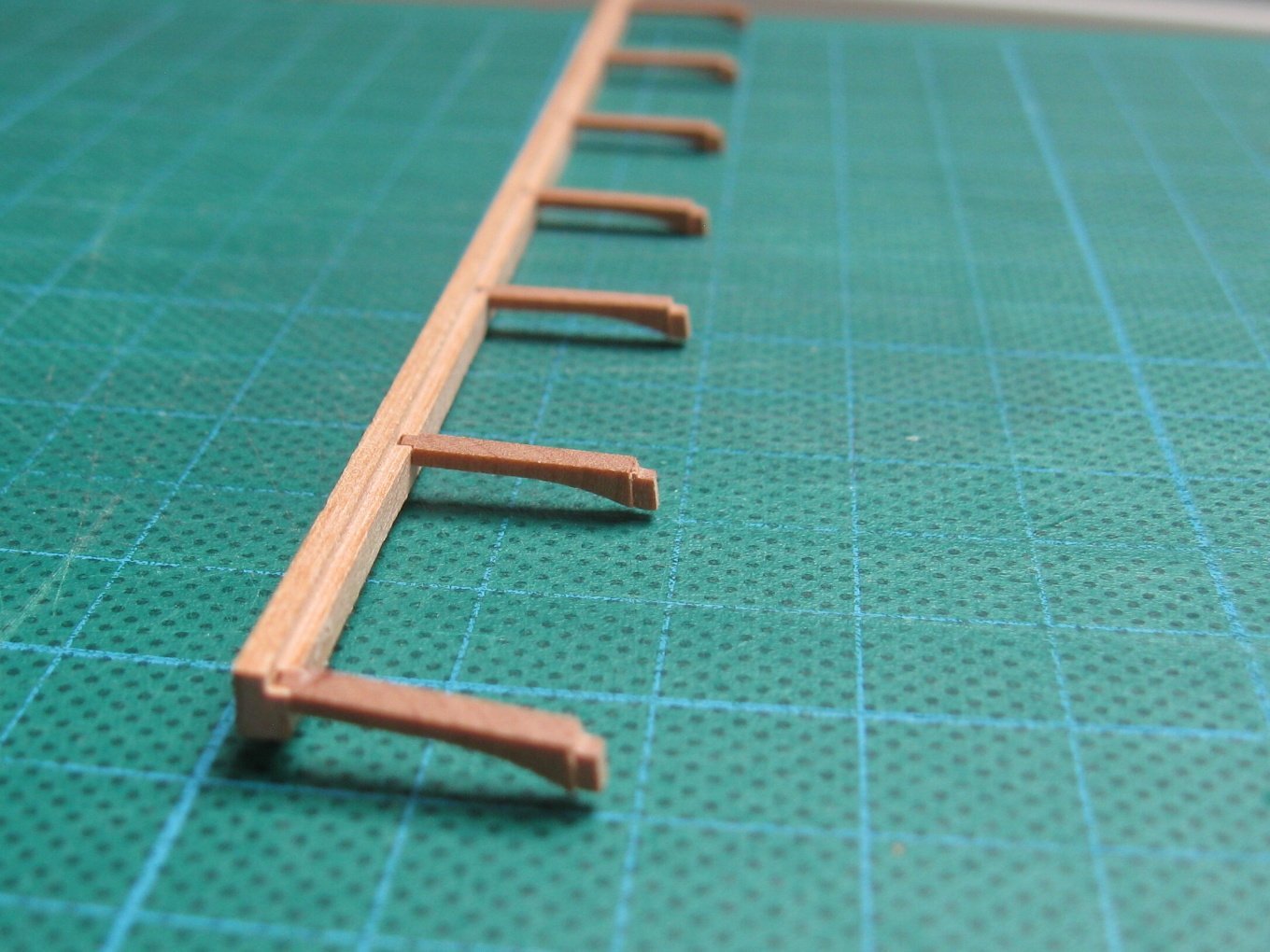

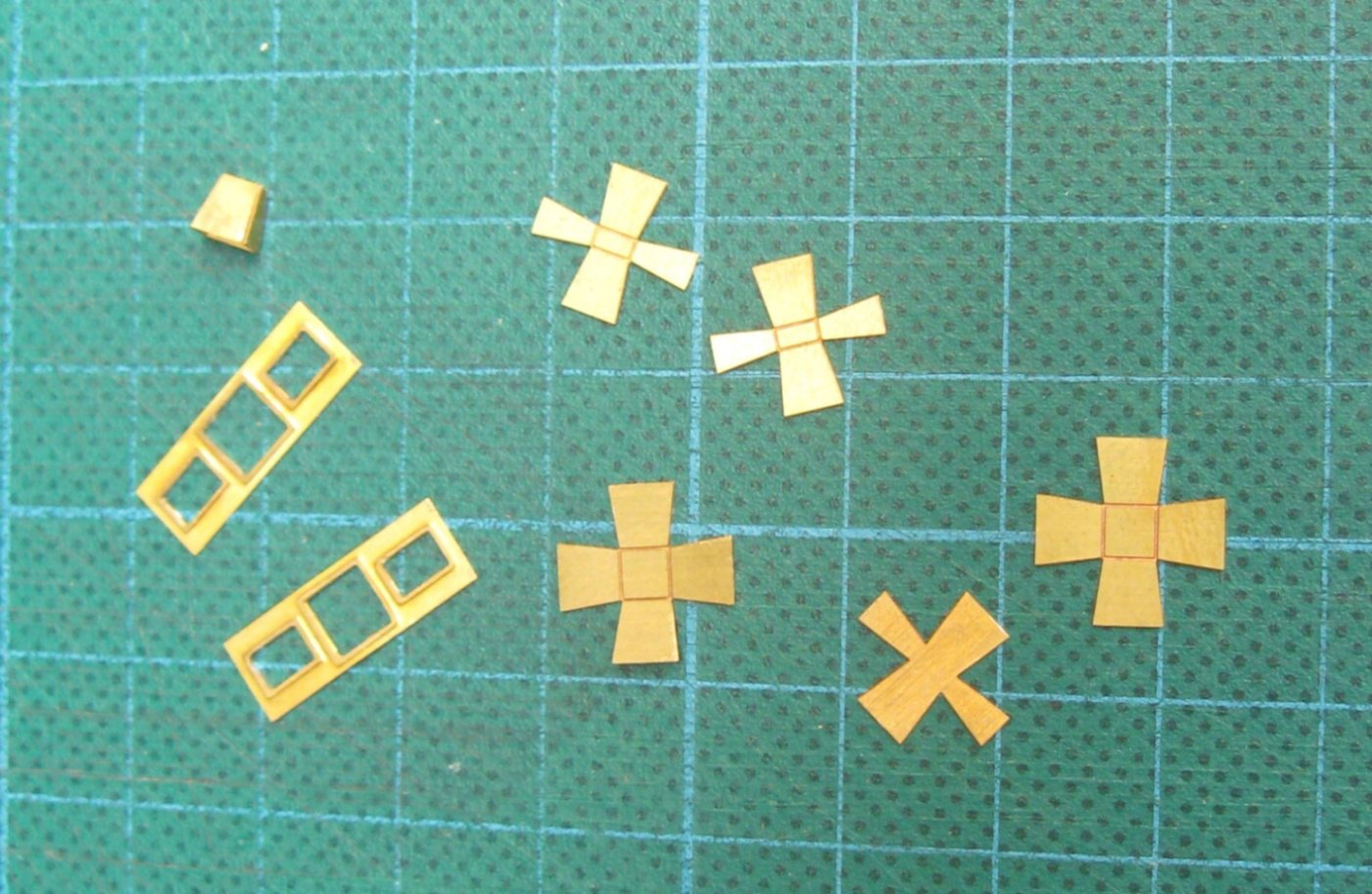

To Hsae: The square holes are made with small diameter milling bit (0,5 mm) and the rest with file. To popash42: I am using VCarve Desktop software for CNC milling. As regards Laser Engraver, I´m not sure, but the VCarve Desktop is propably not primarily intended for laser. You can find information on the optional laser add-on module on the Vectric website (https://www.vectric.com/products/laser-module). Pinrails.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

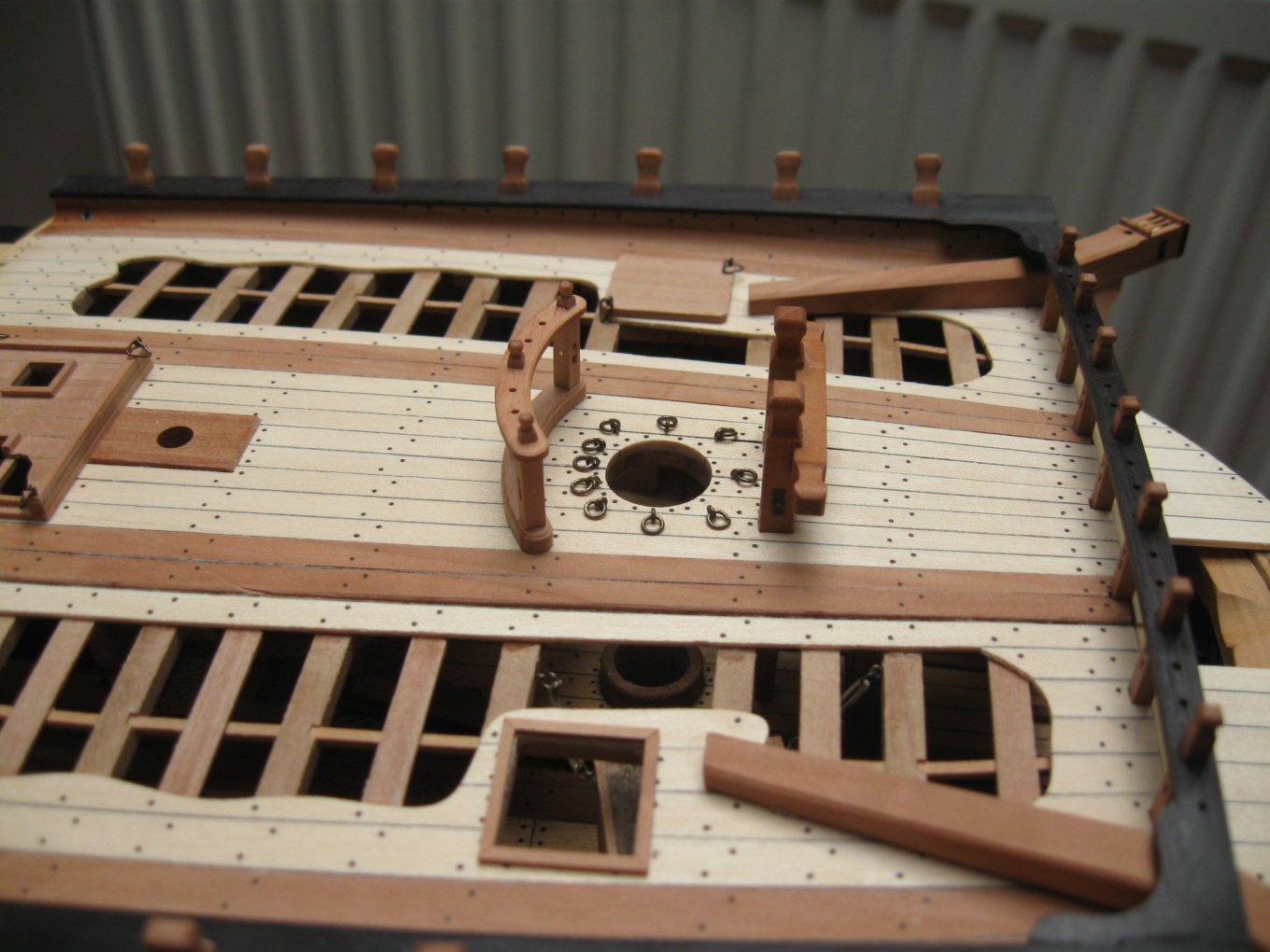

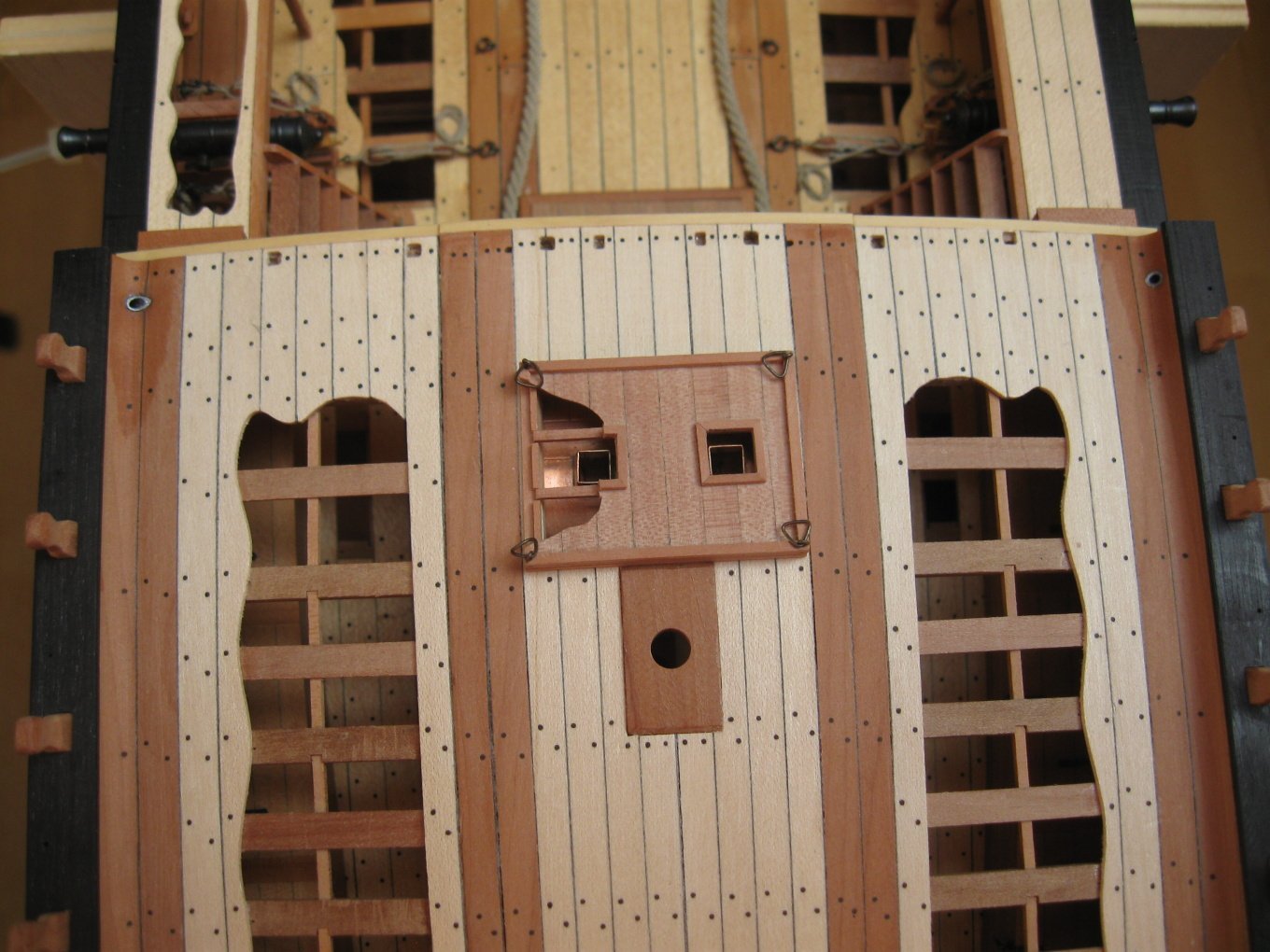

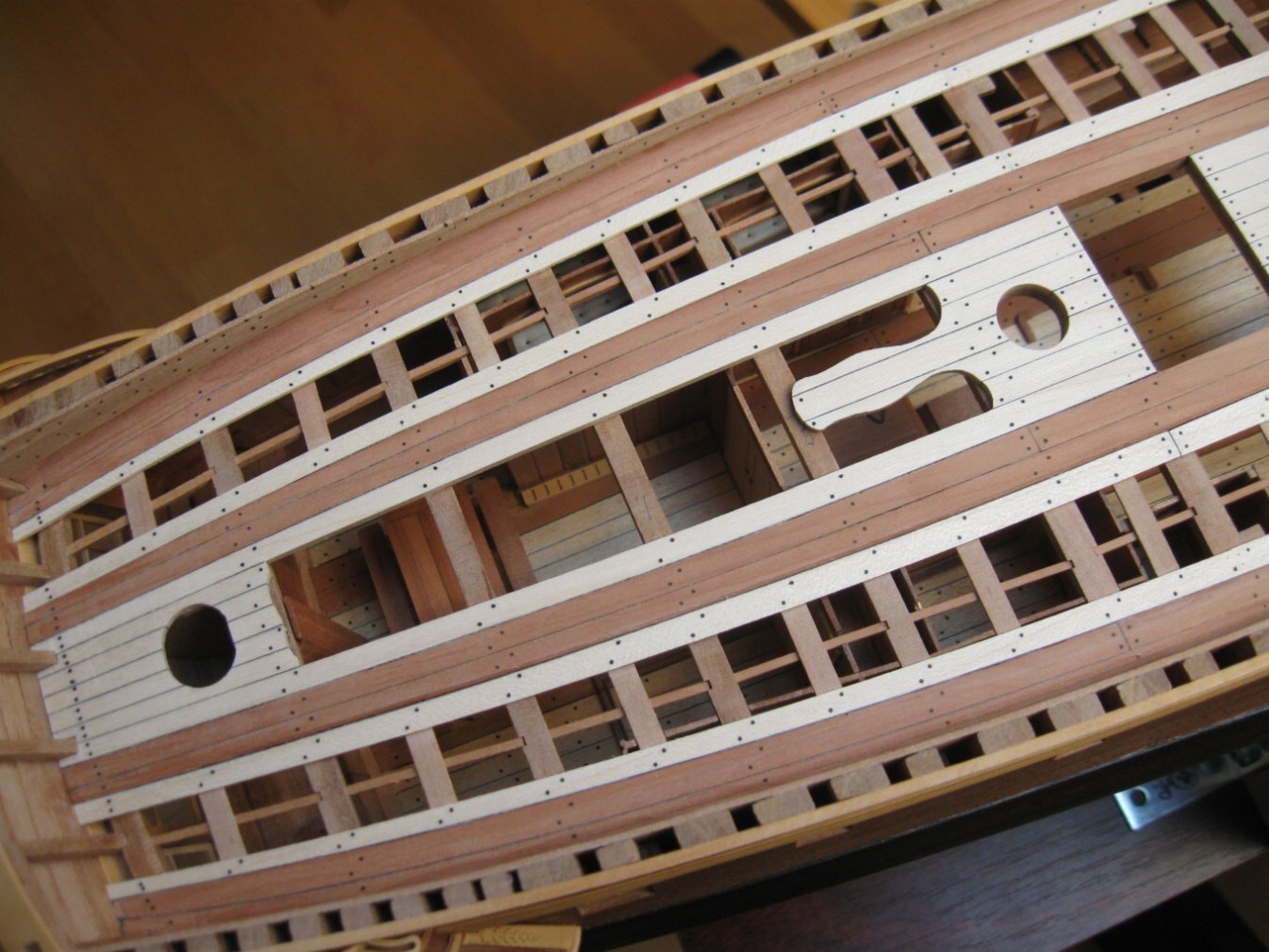

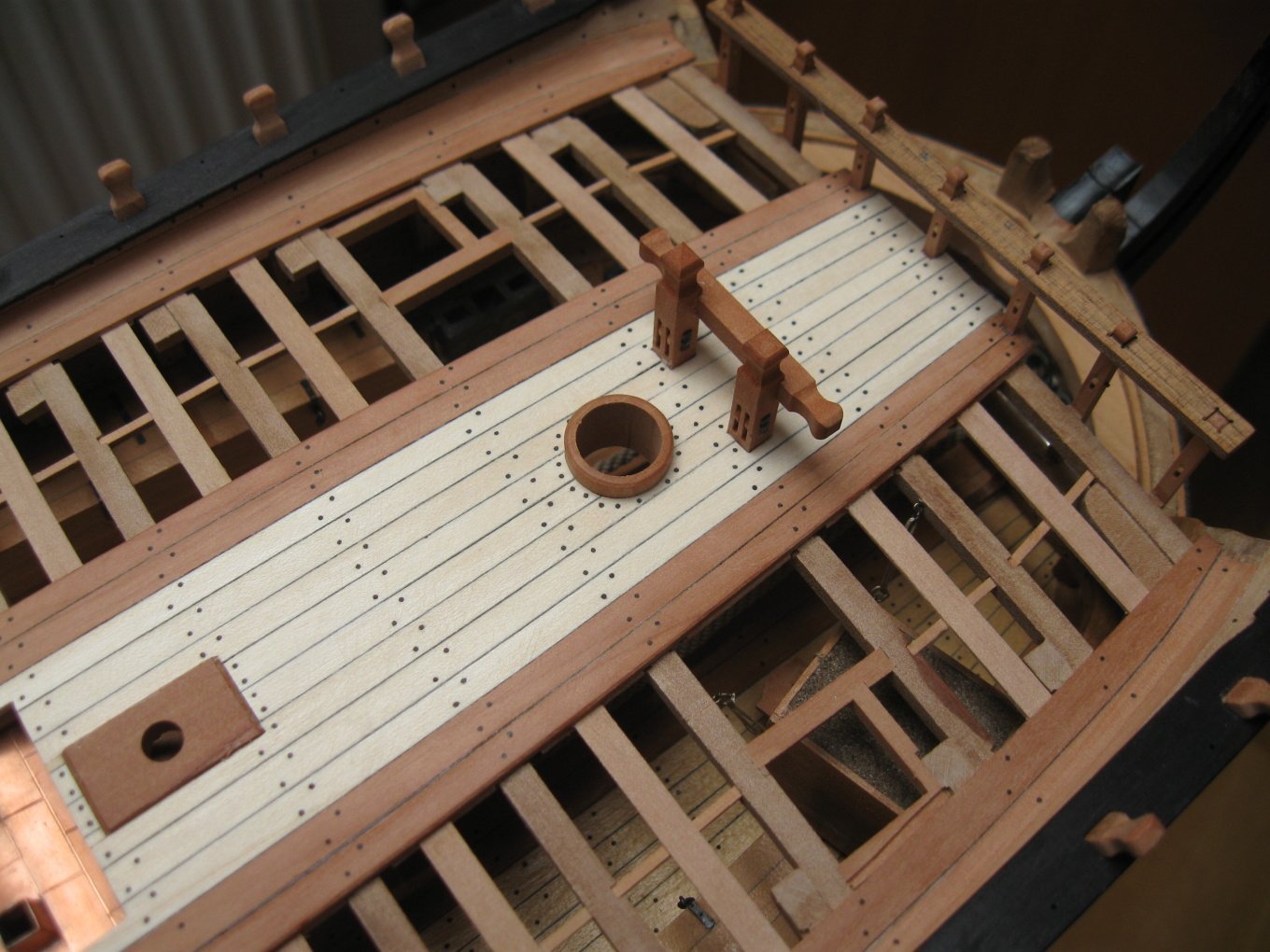

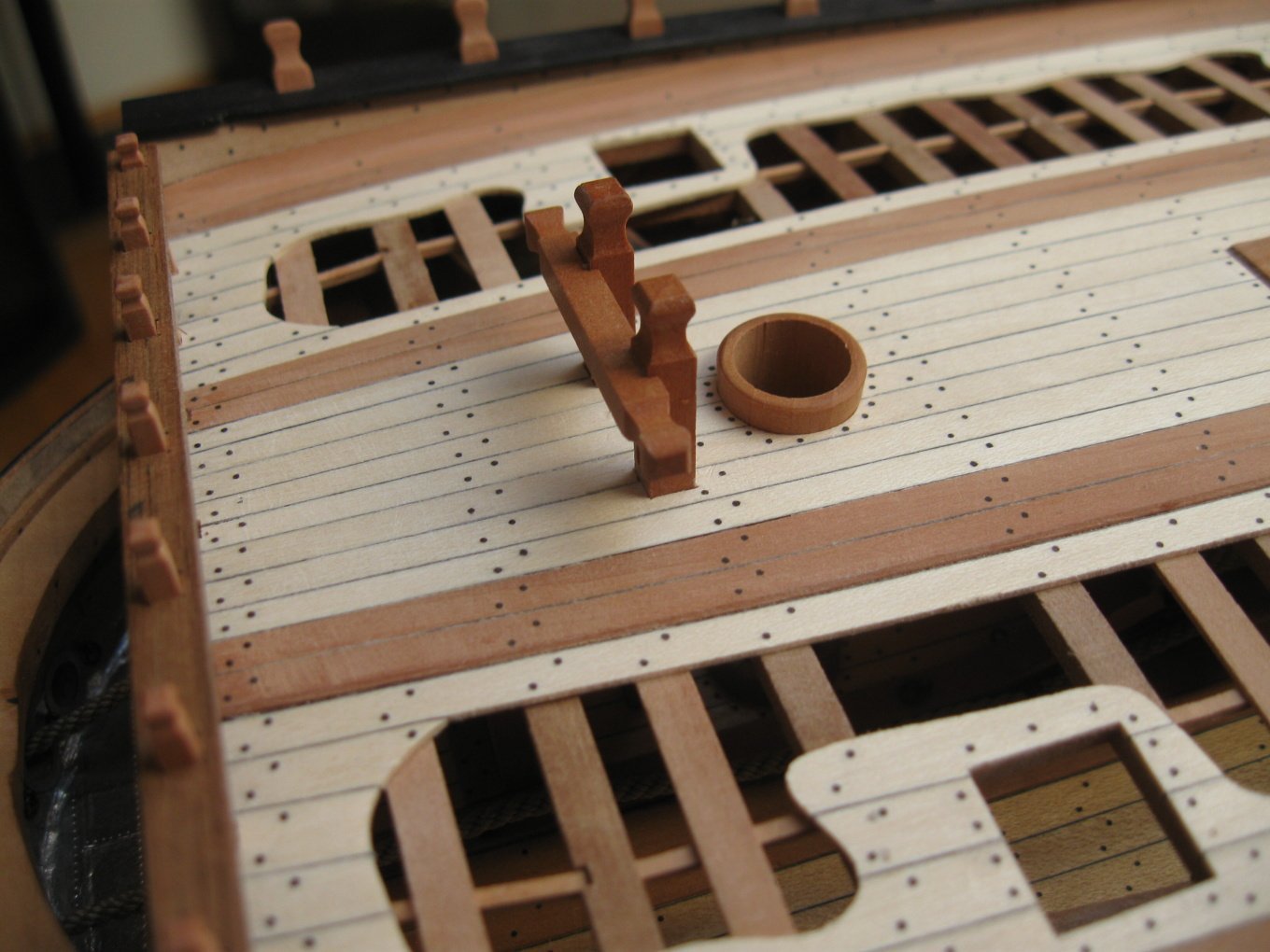

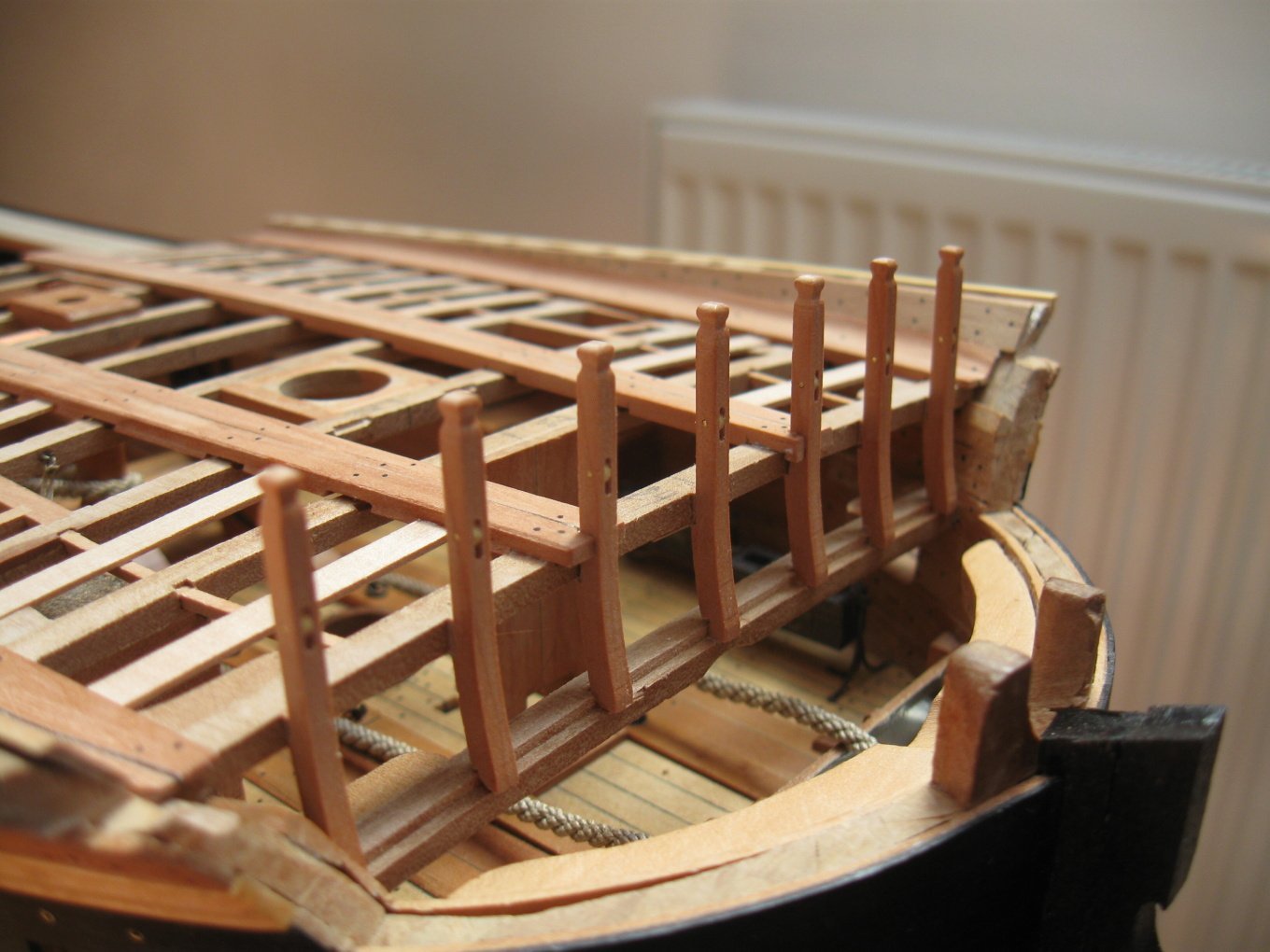

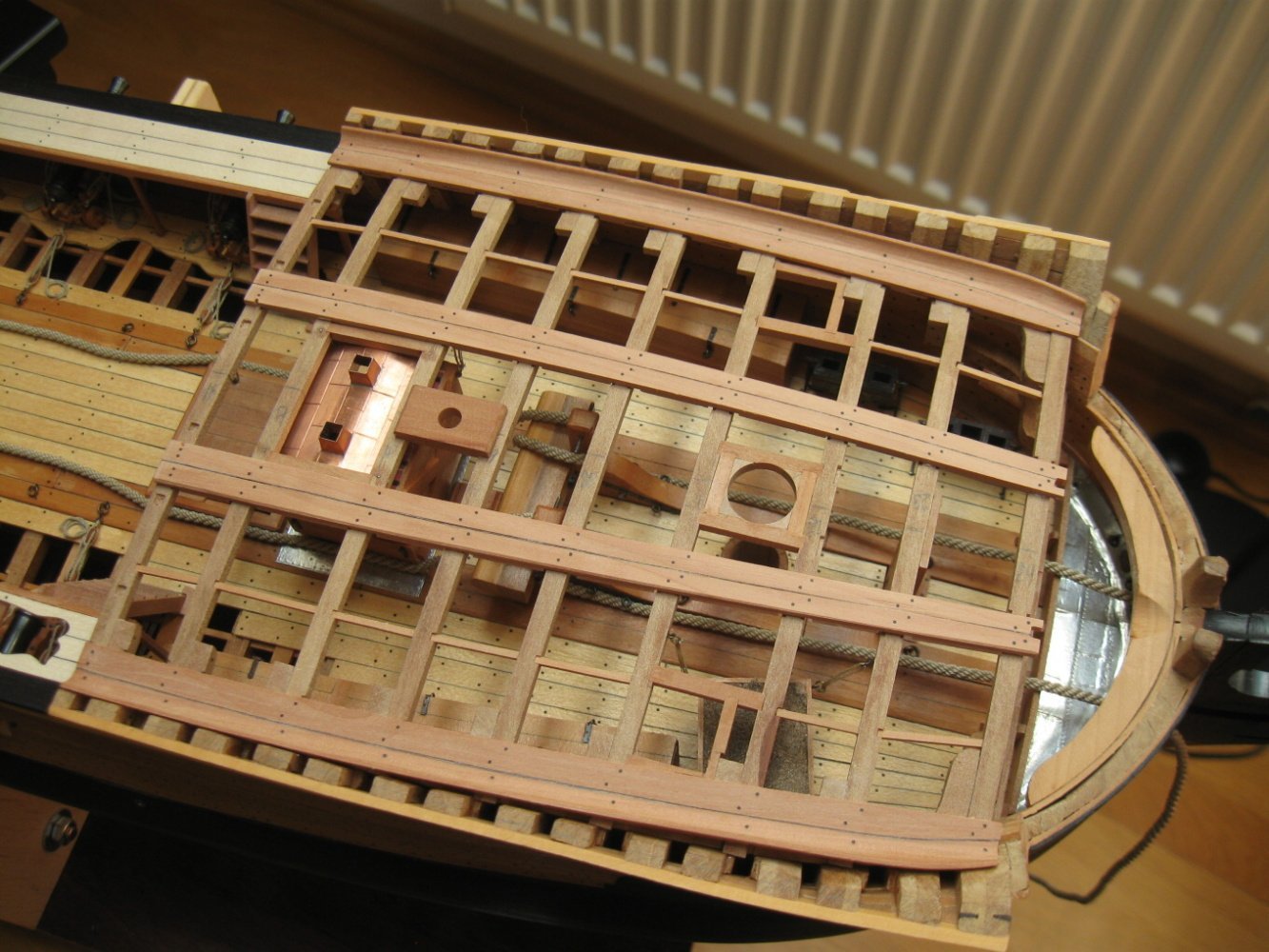

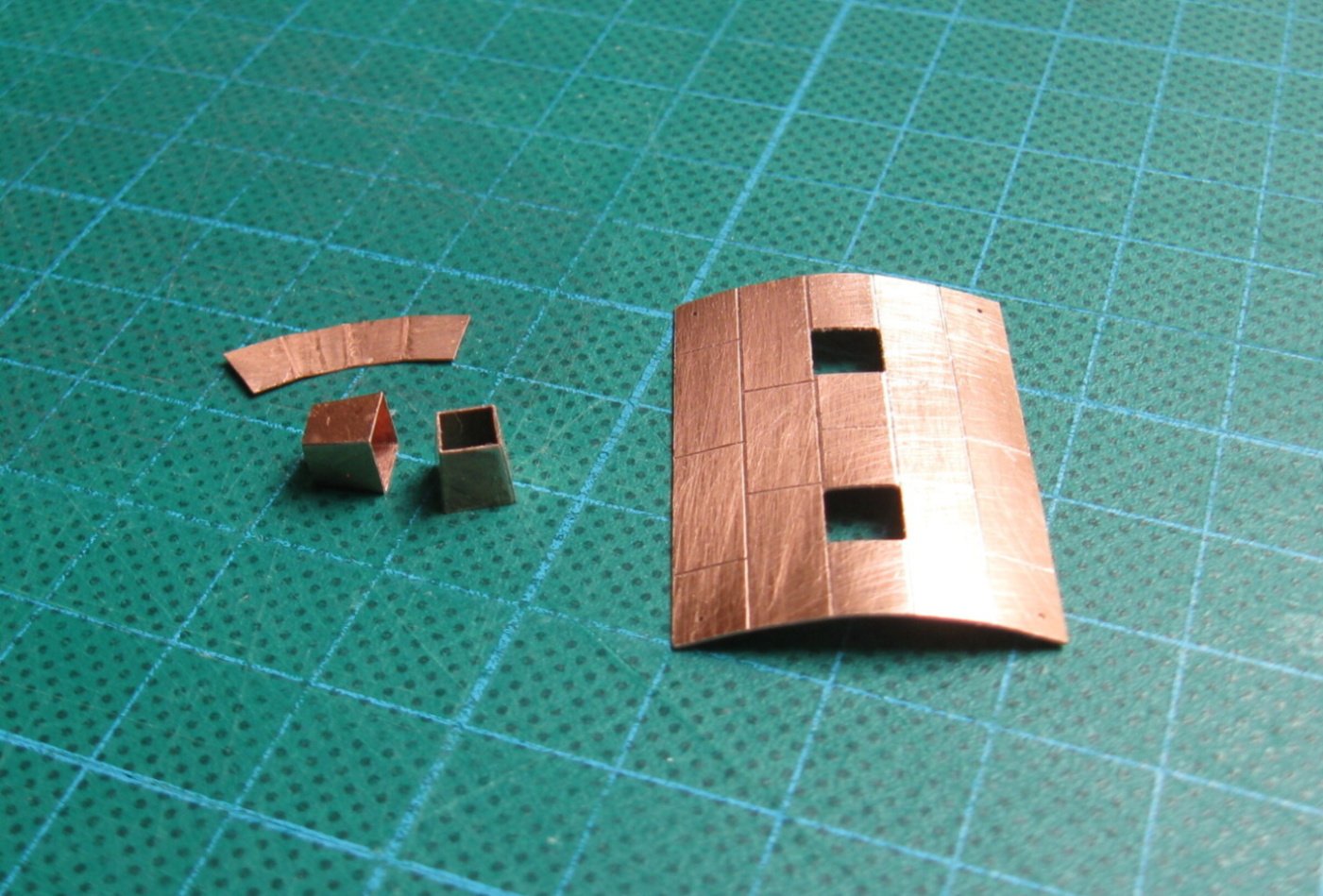

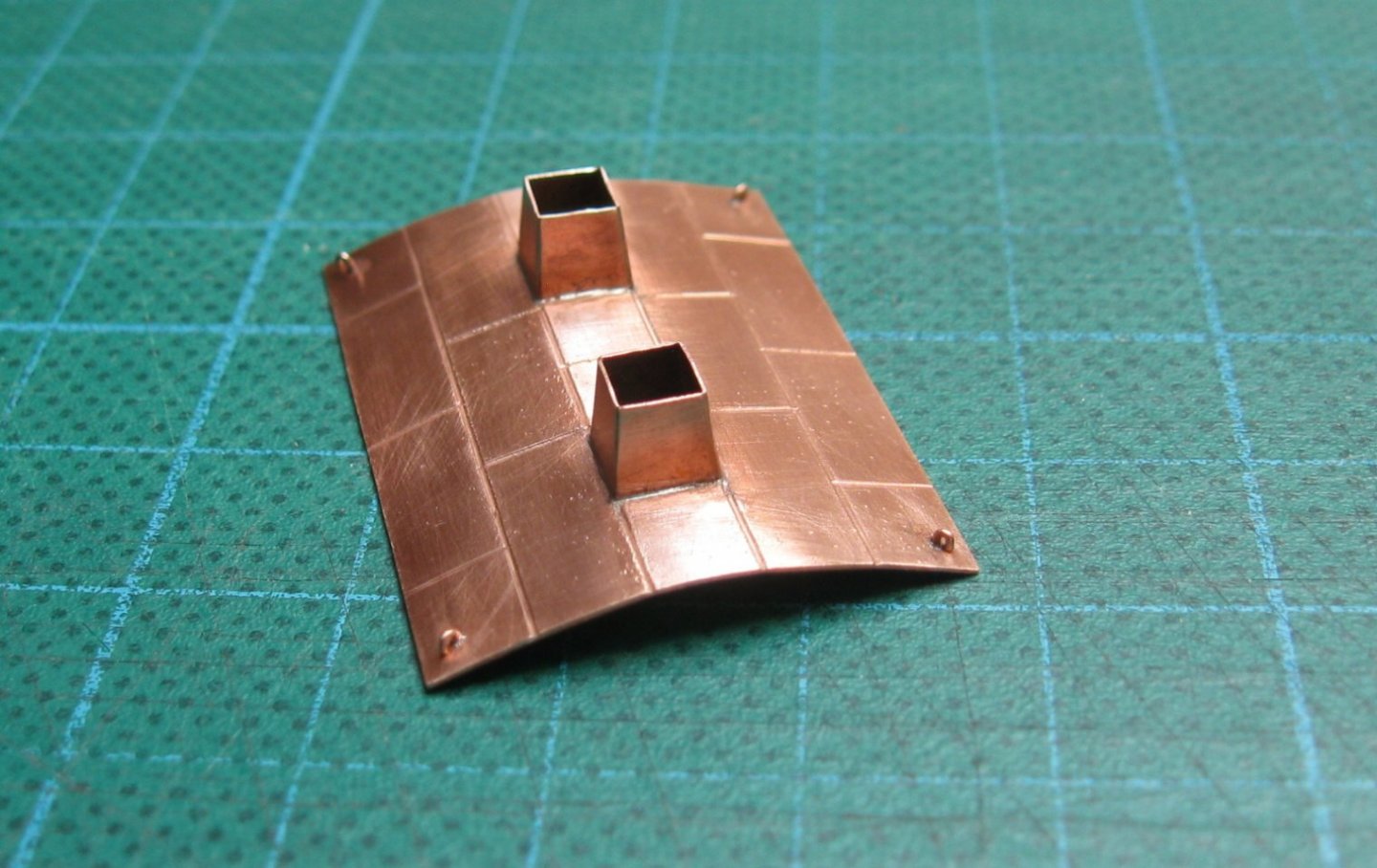

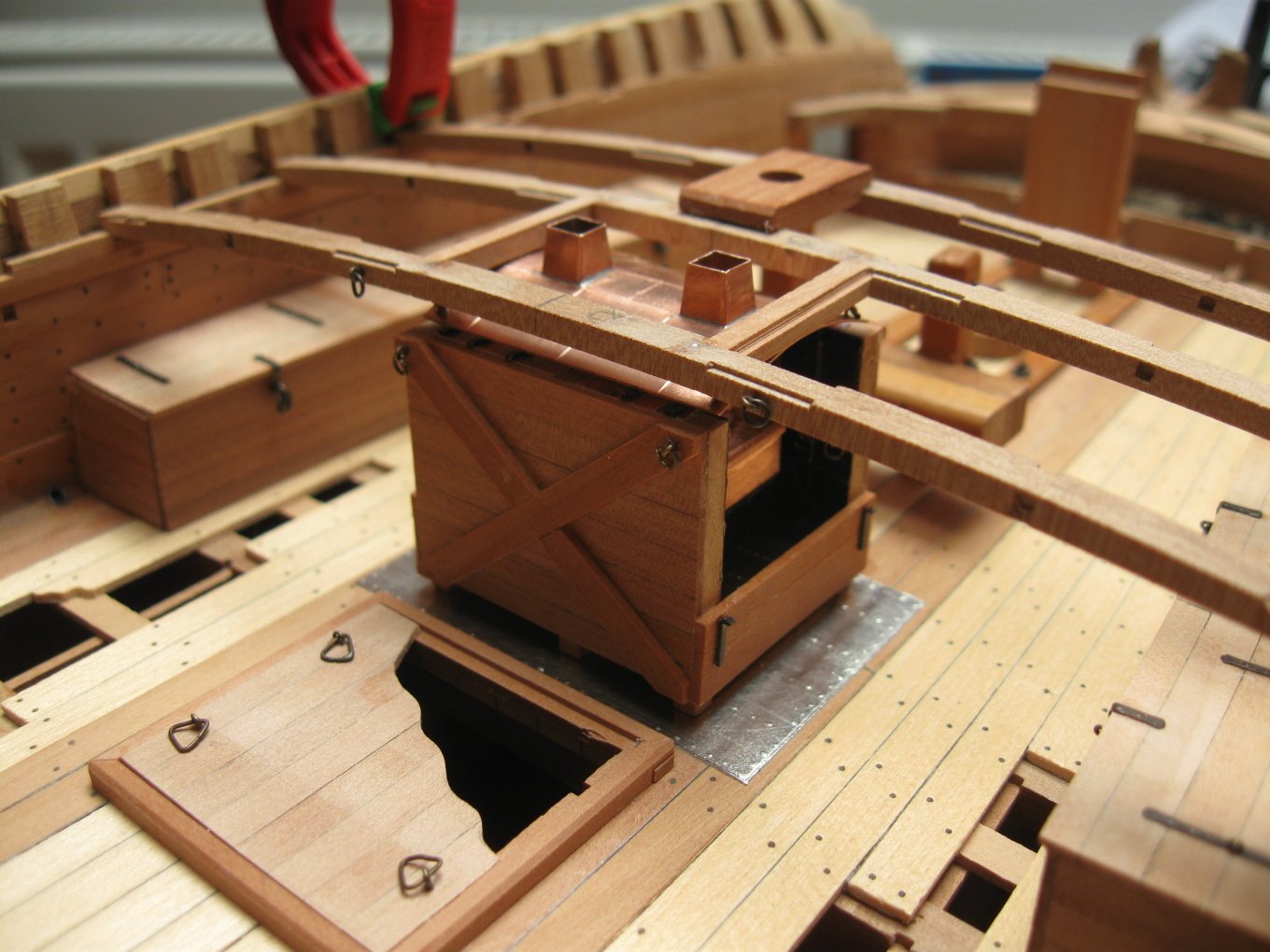

Thank you guys. I continue with some details on the forecastle deck. As the first ones - scuttles and the galley´s hatchway.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

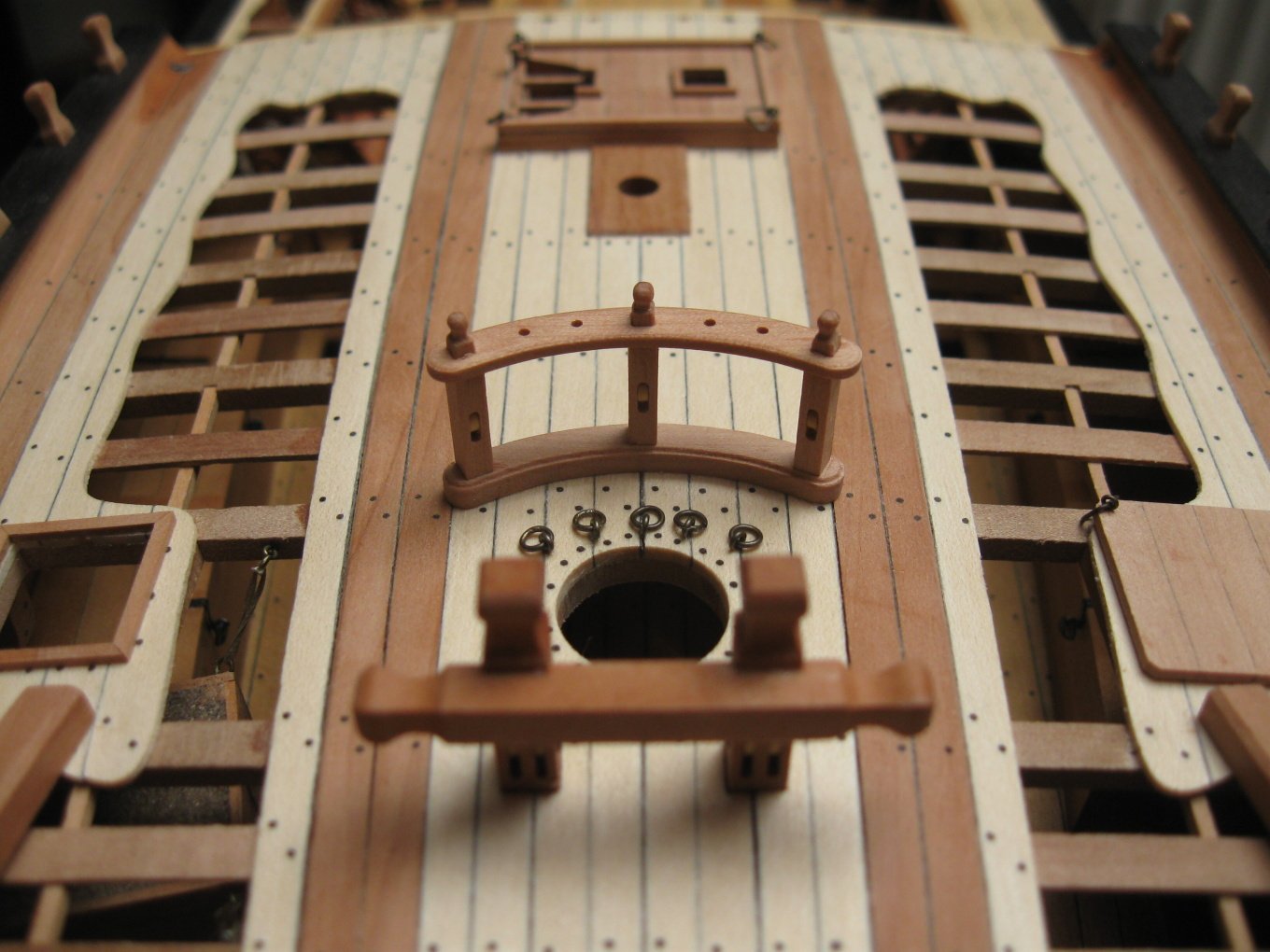

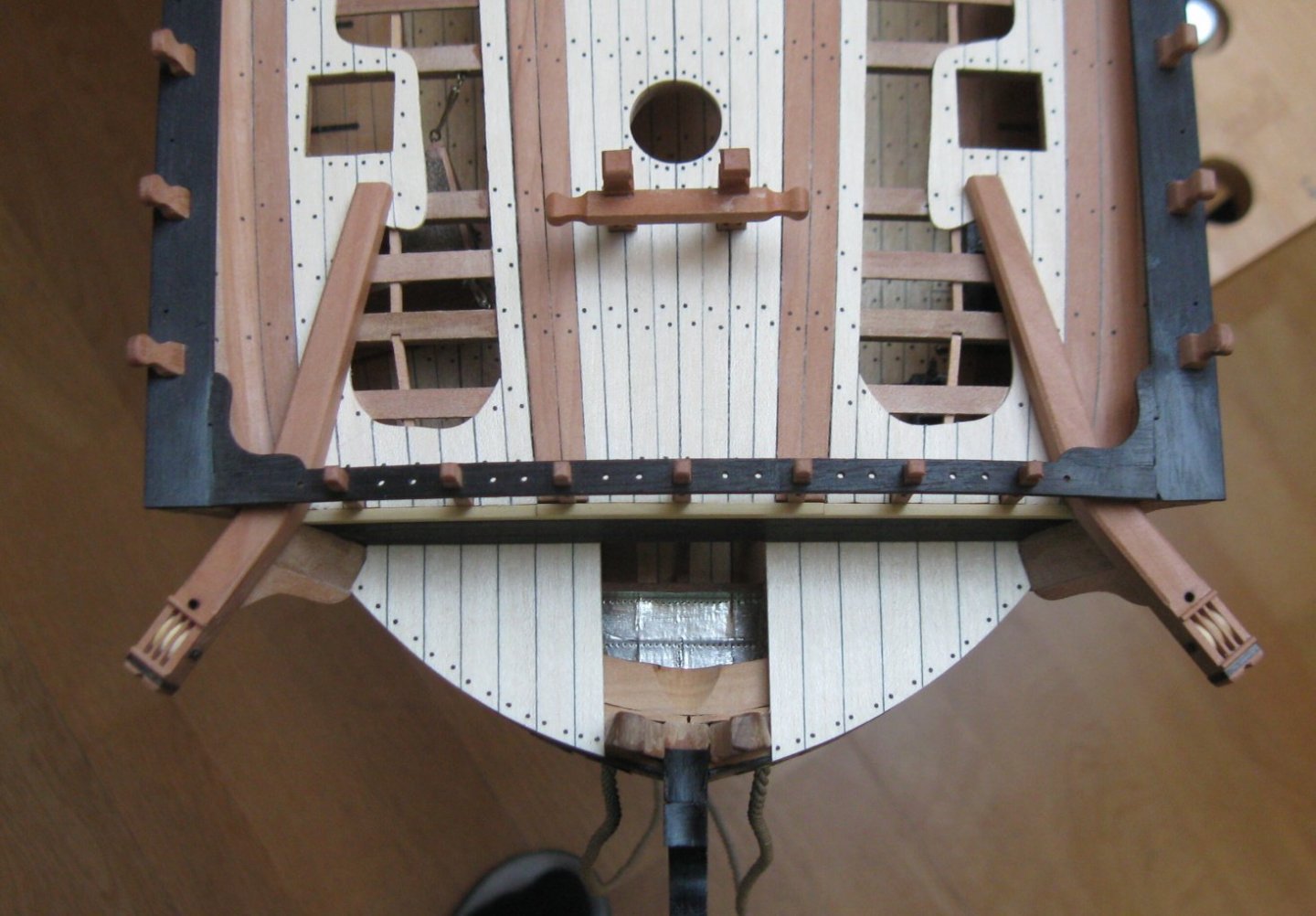

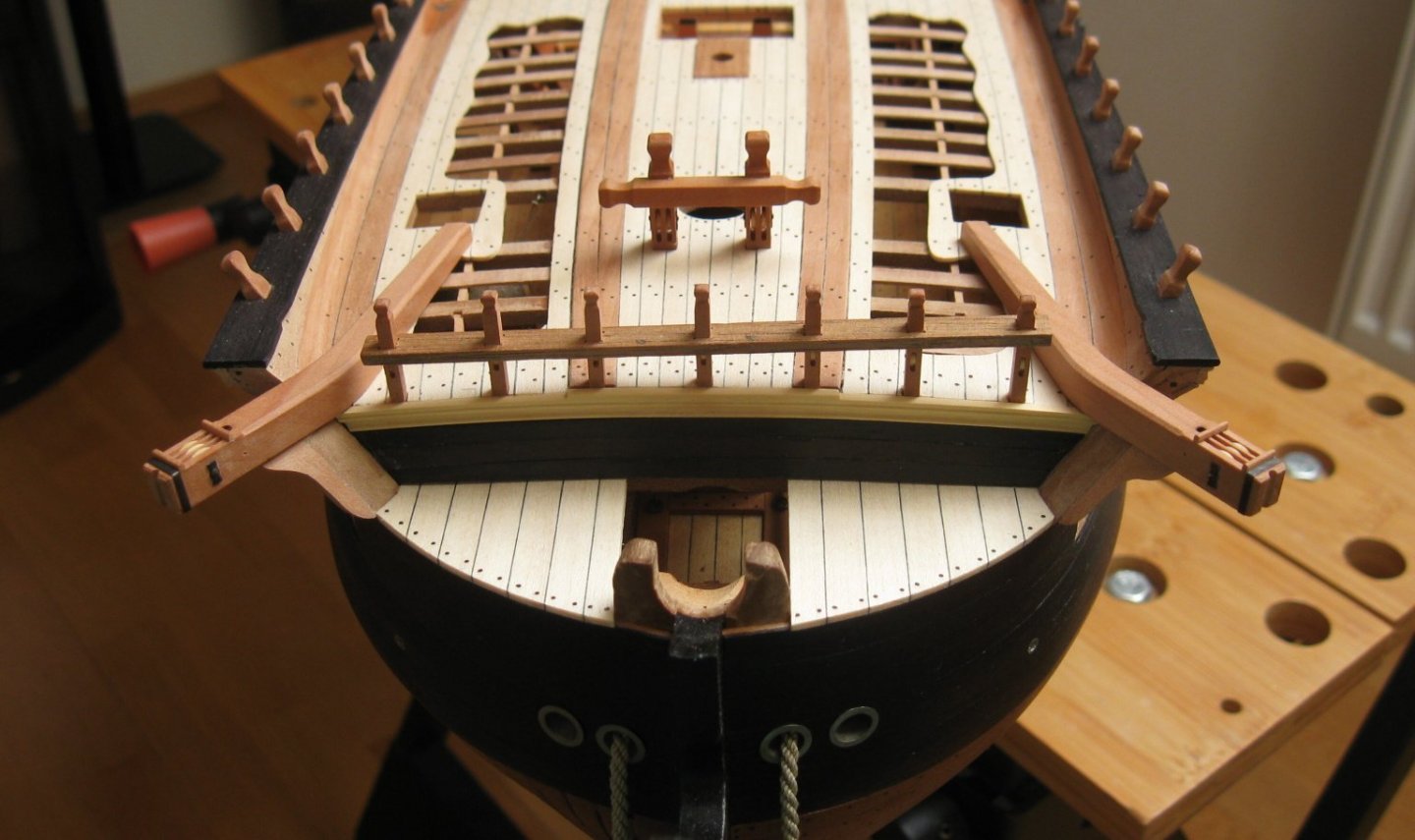

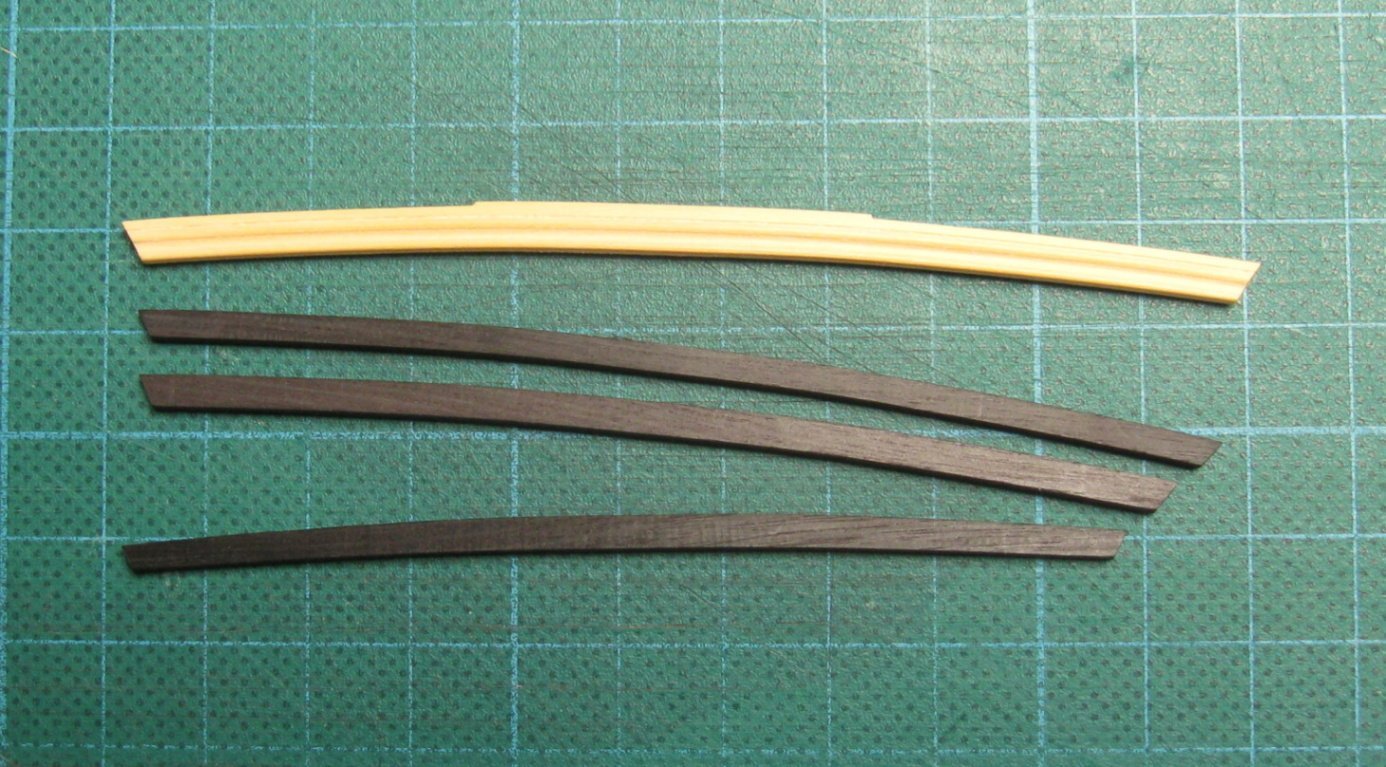

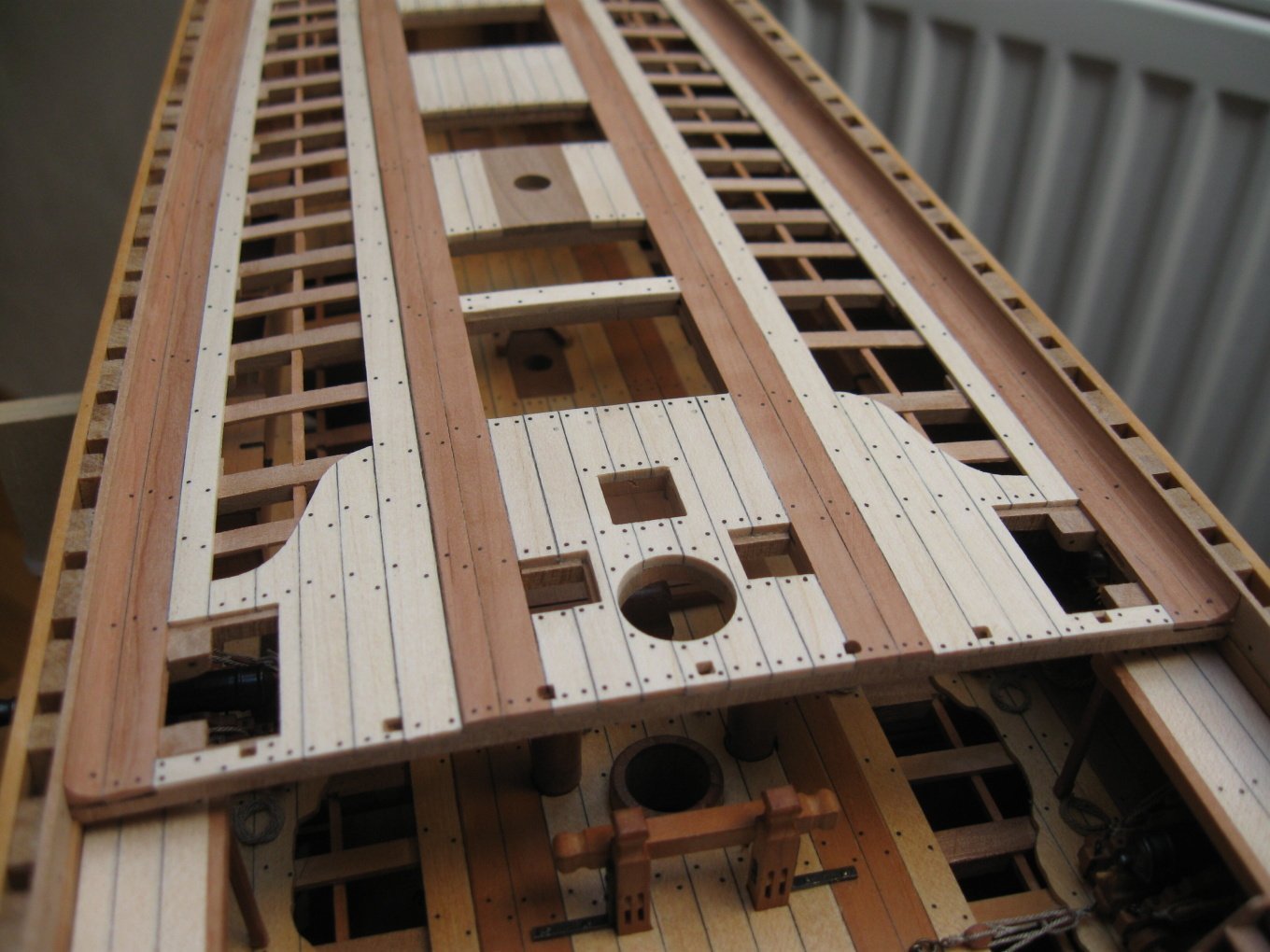

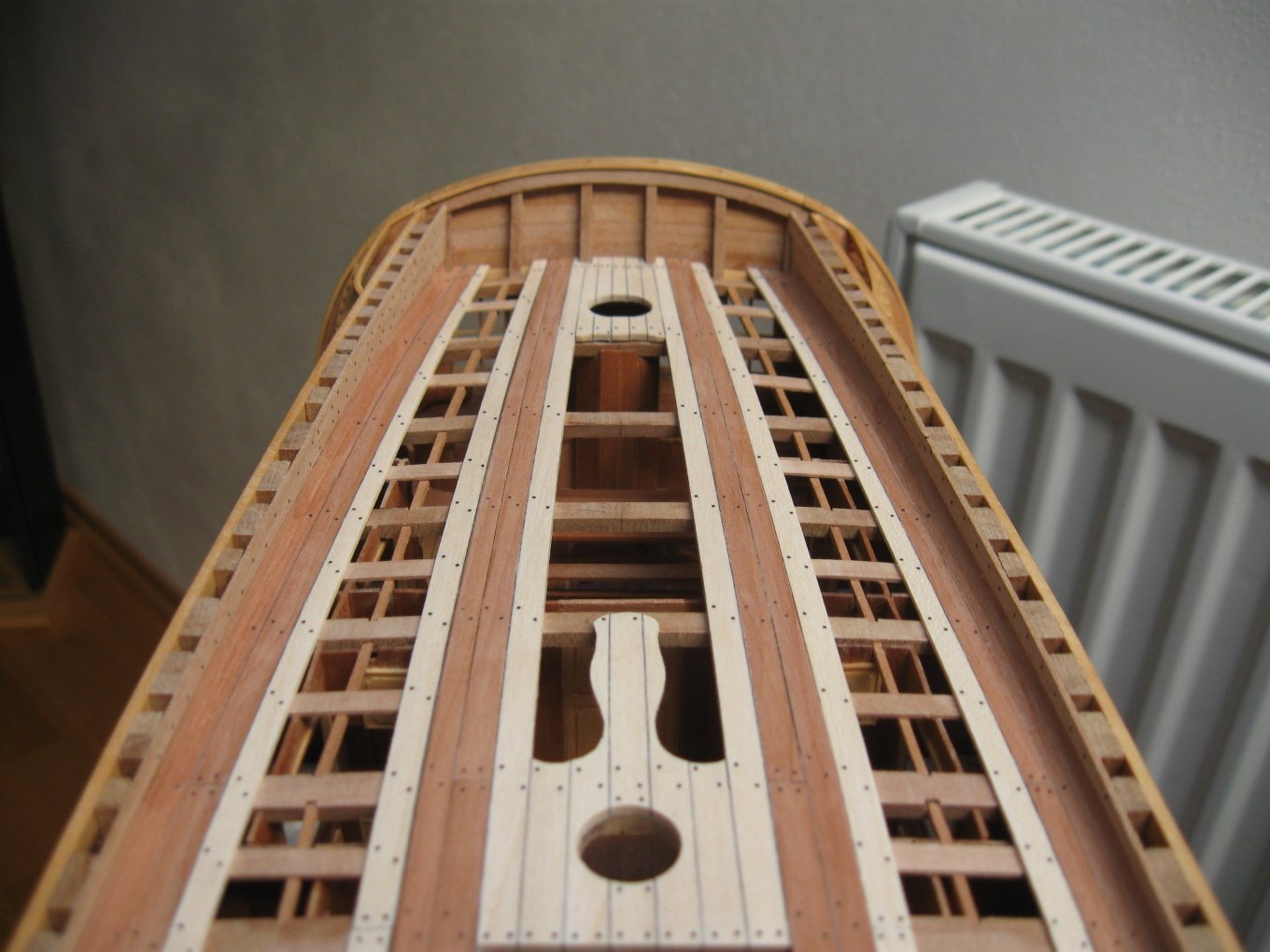

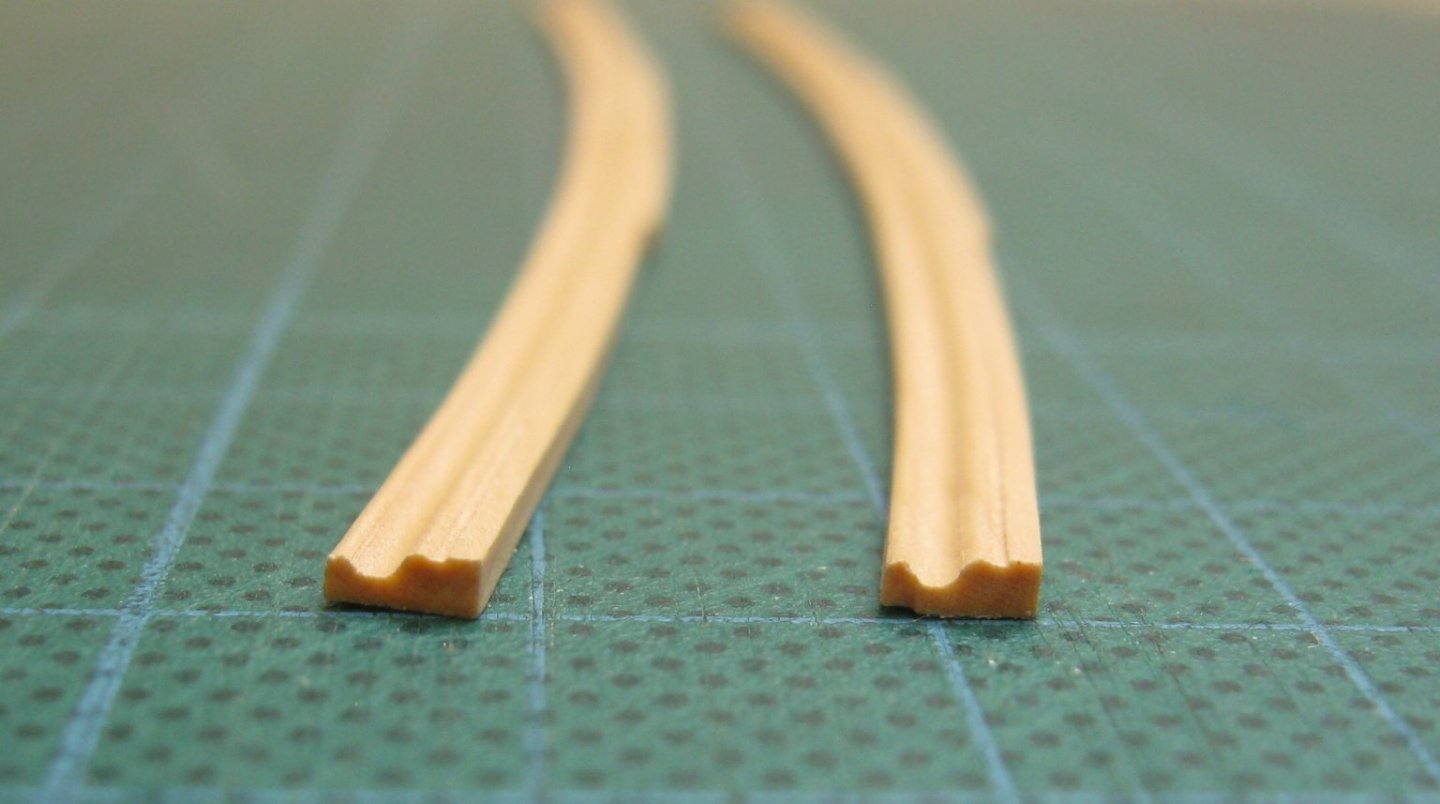

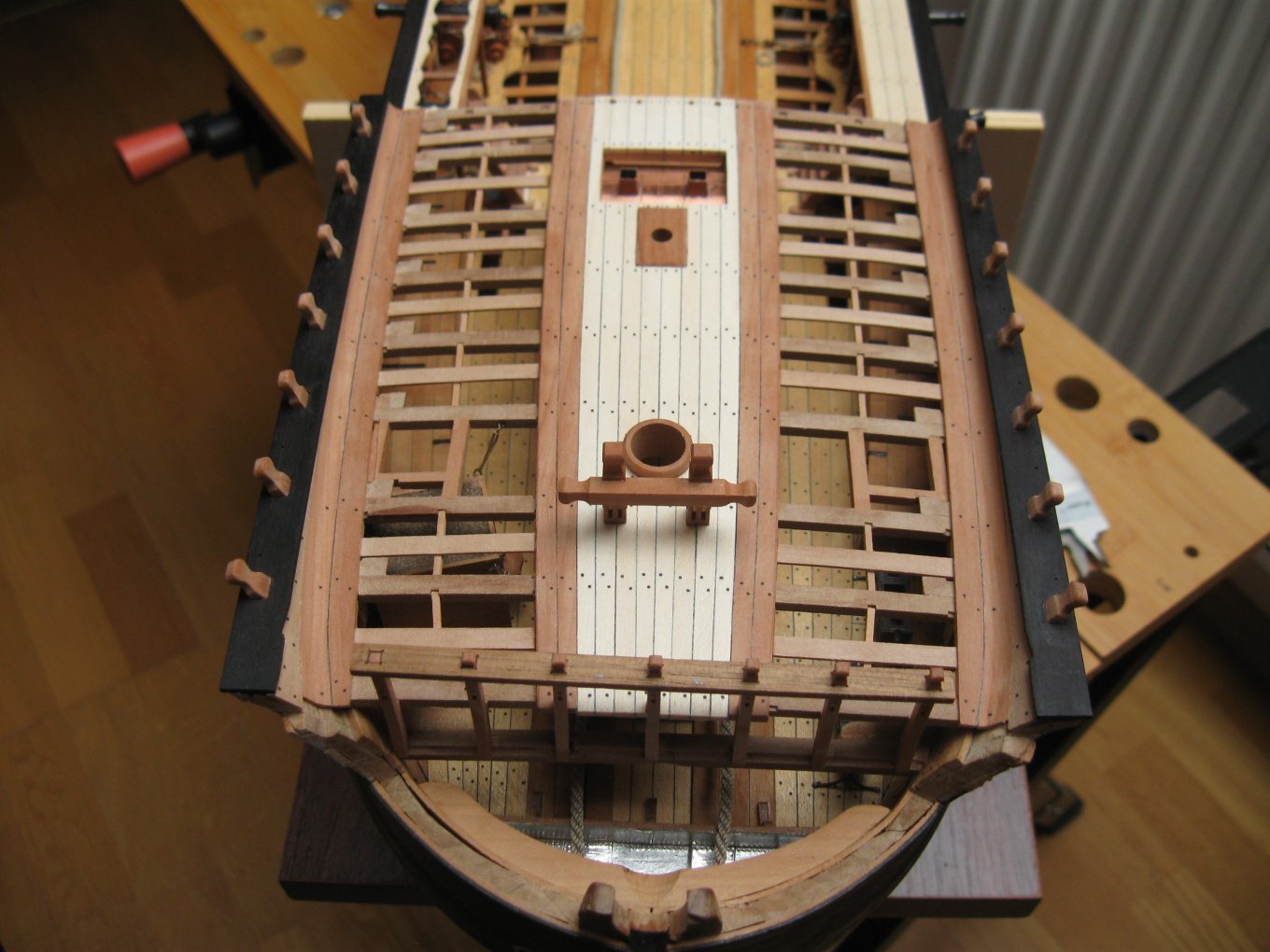

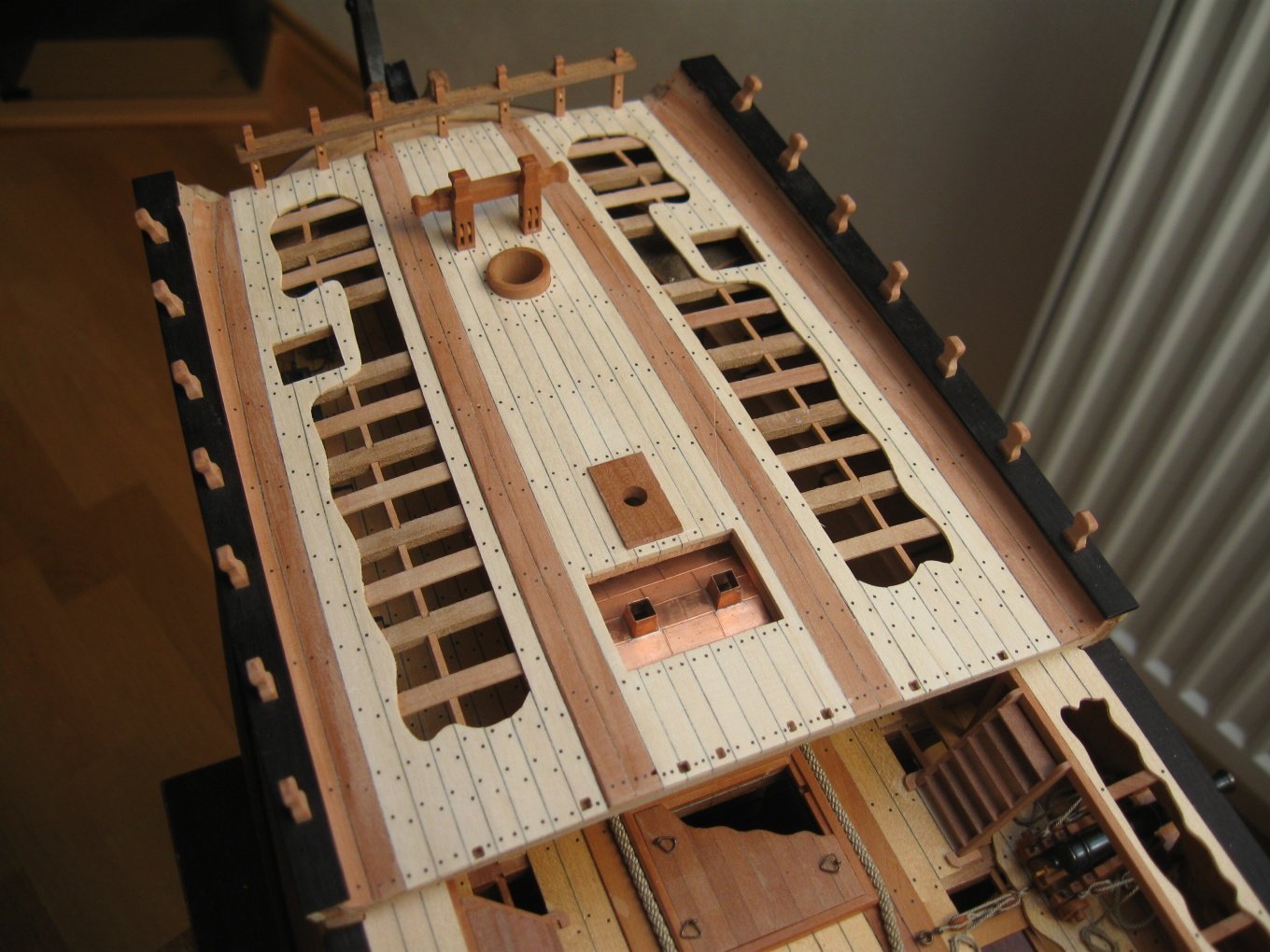

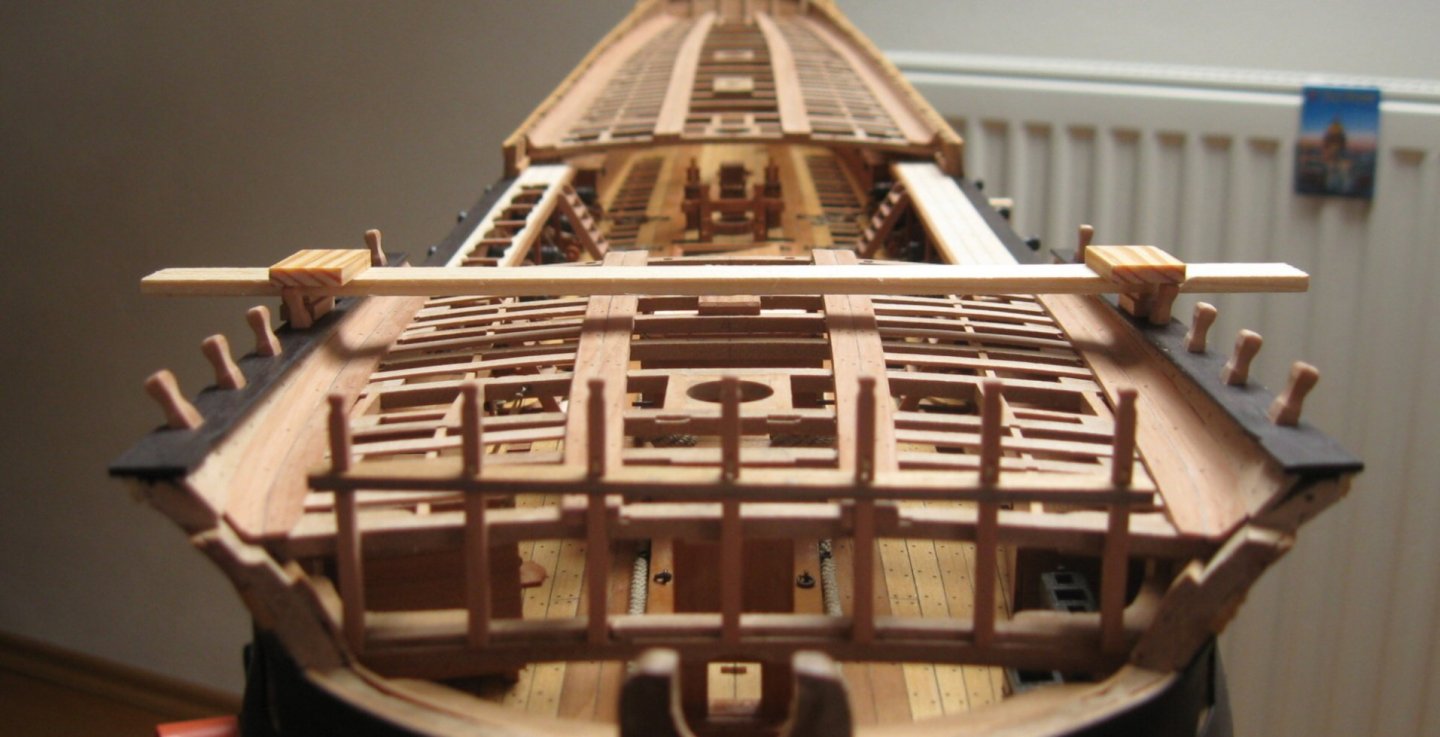

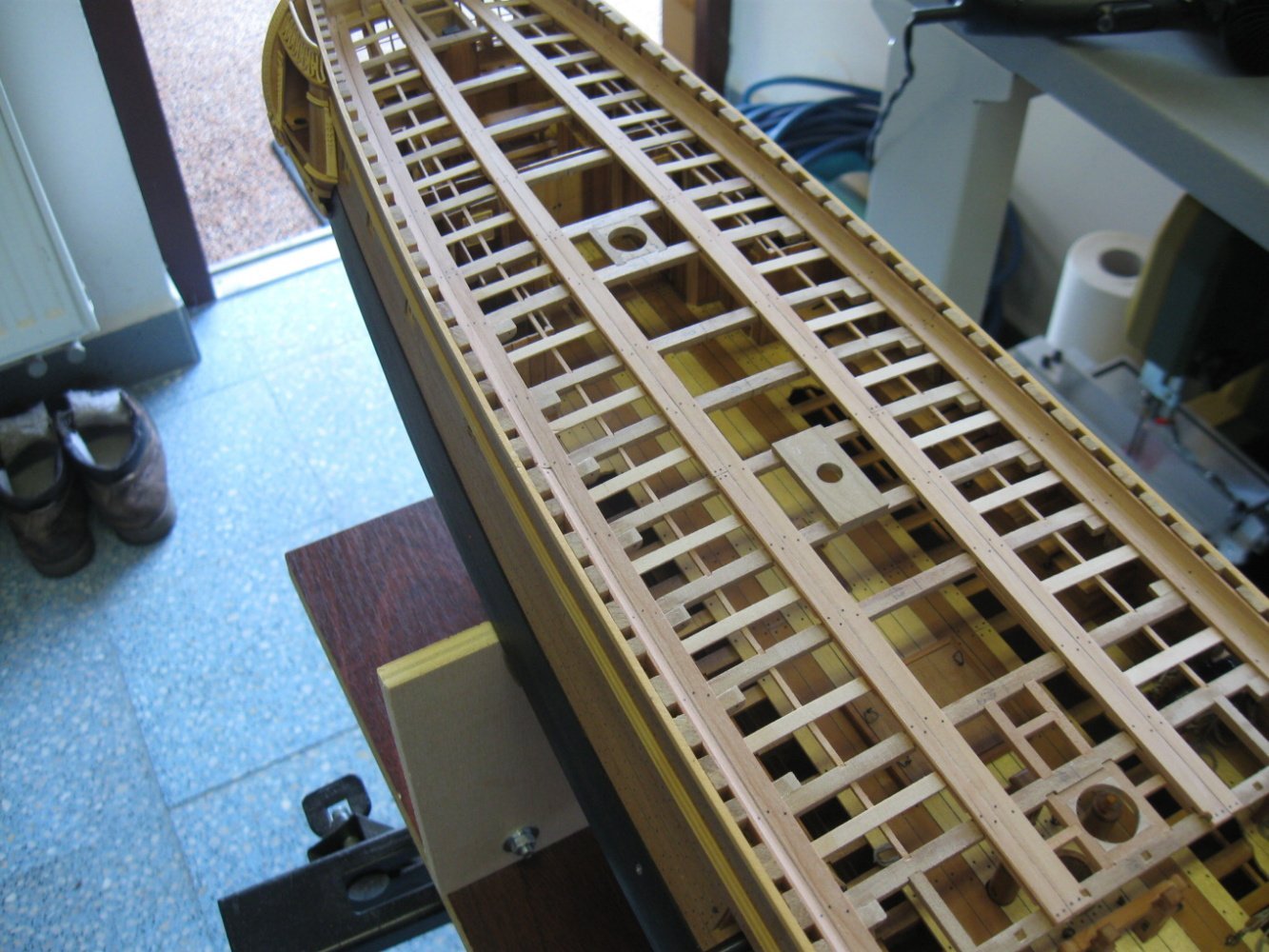

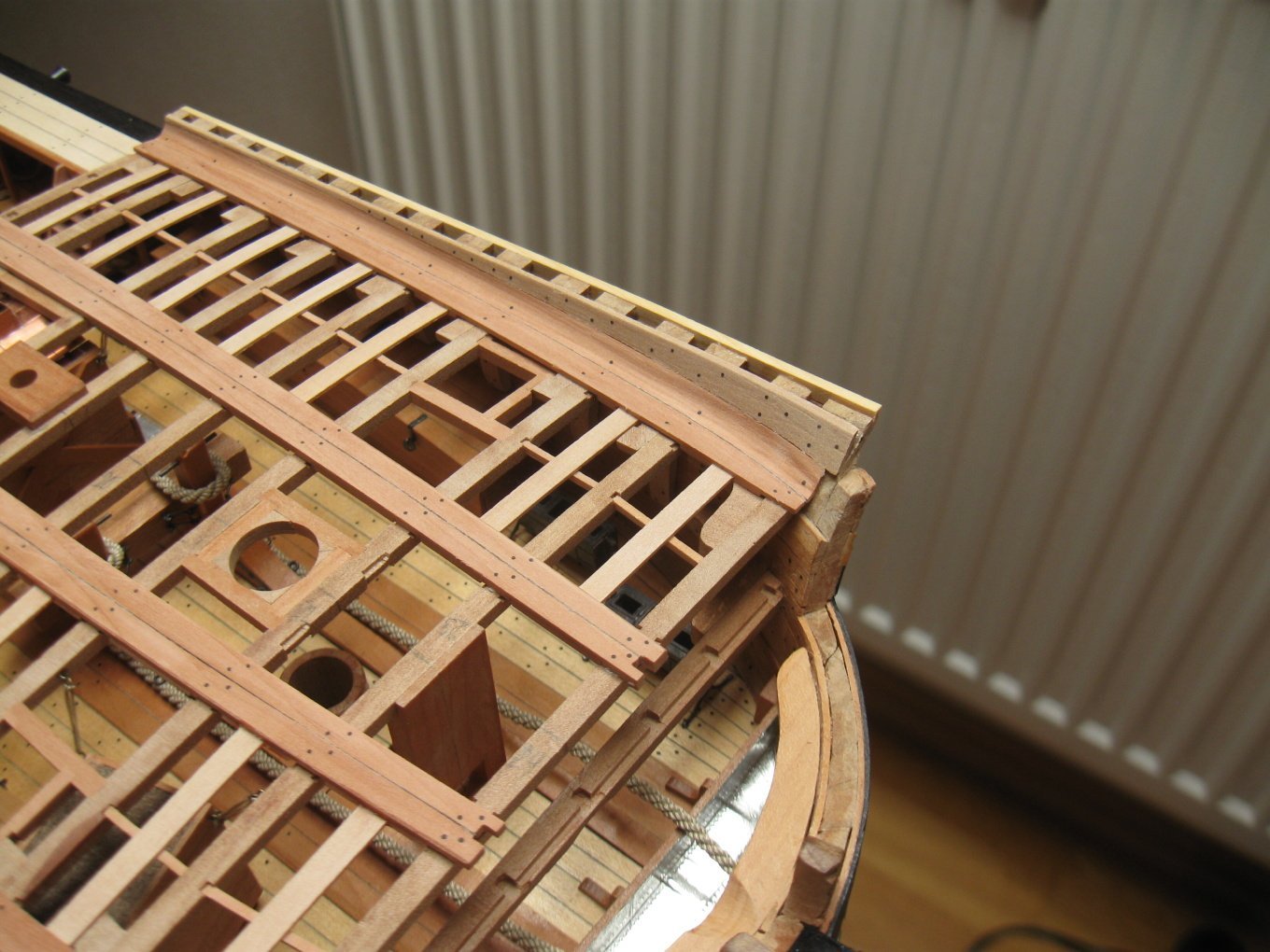

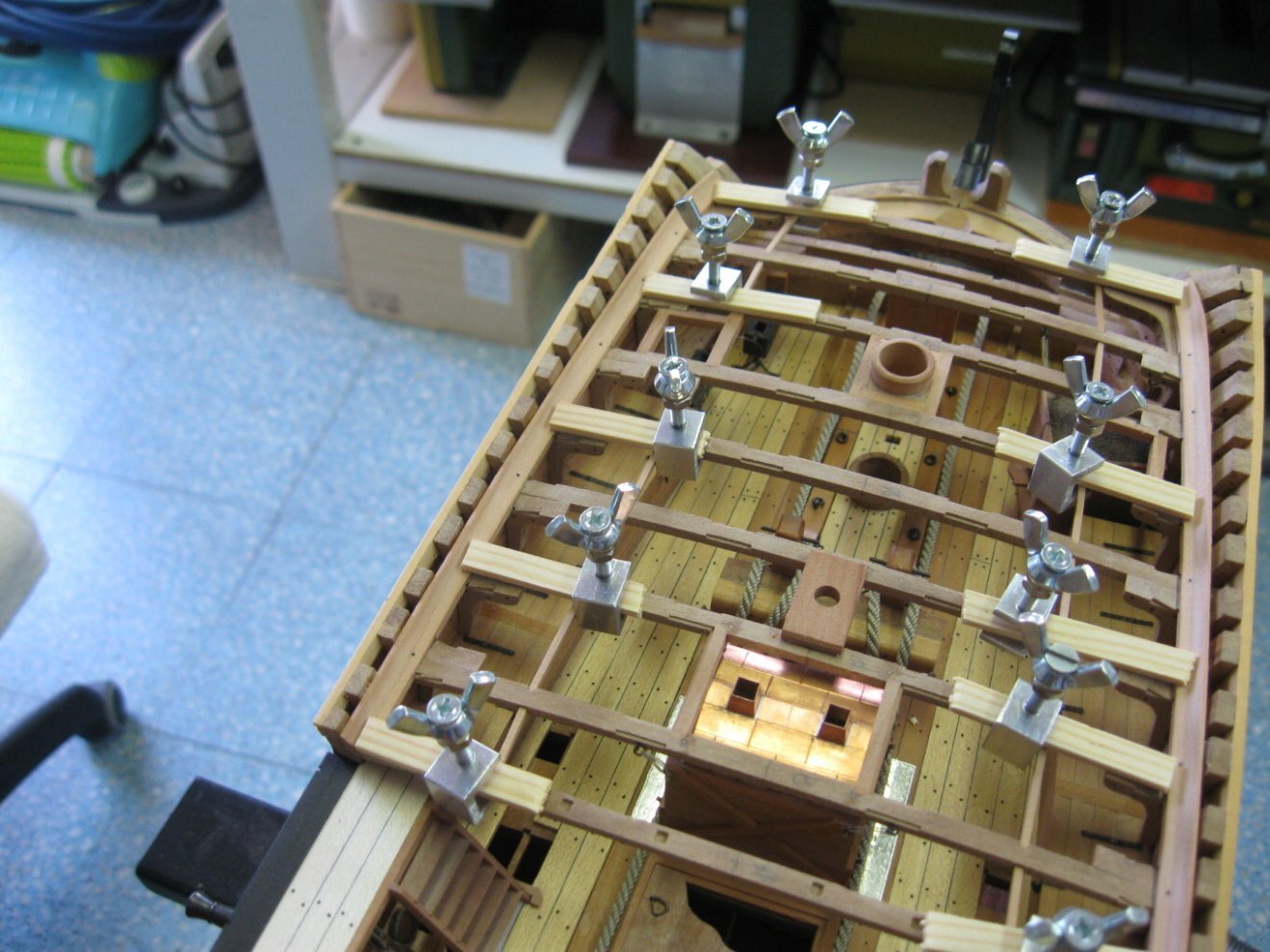

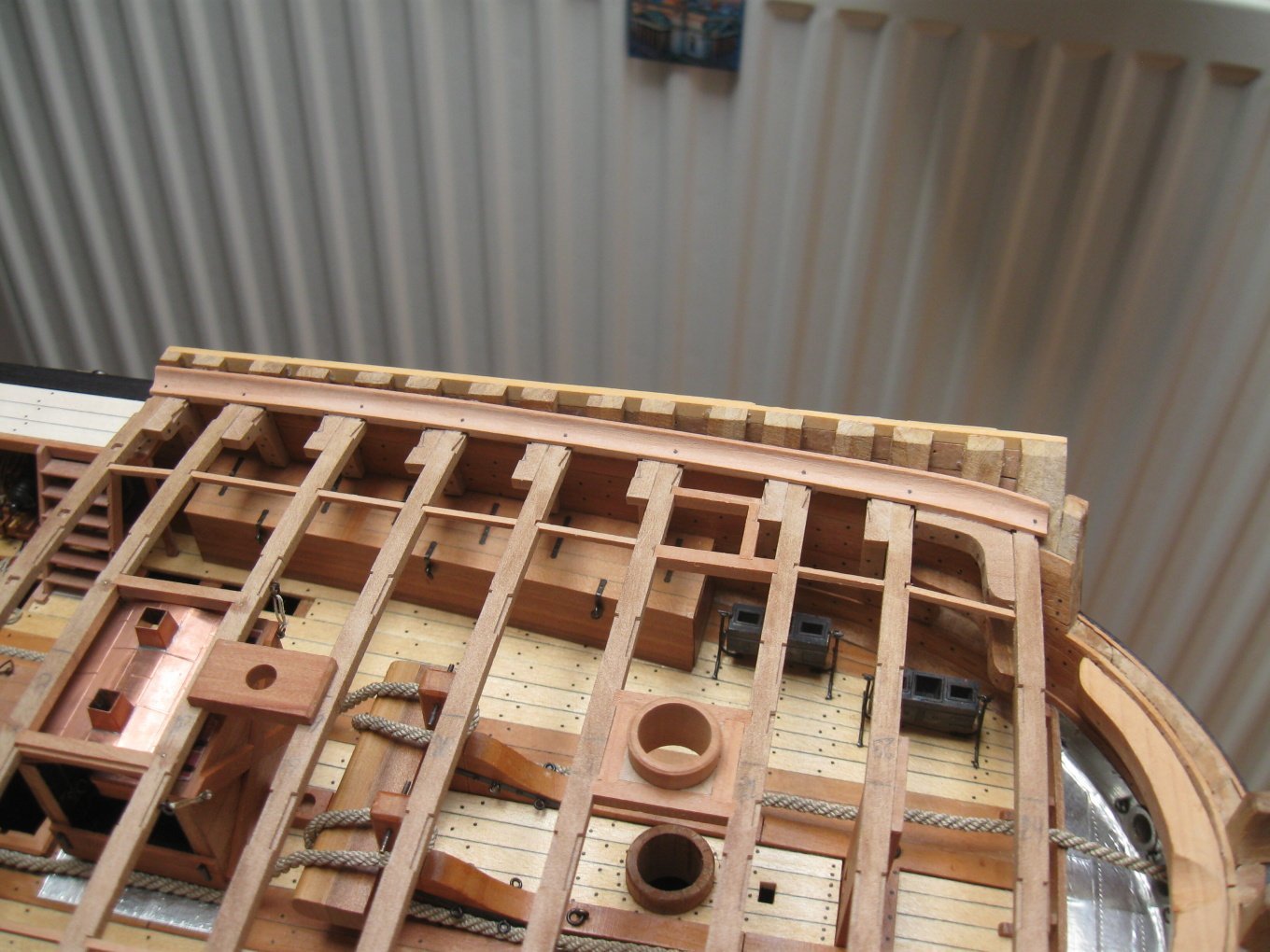

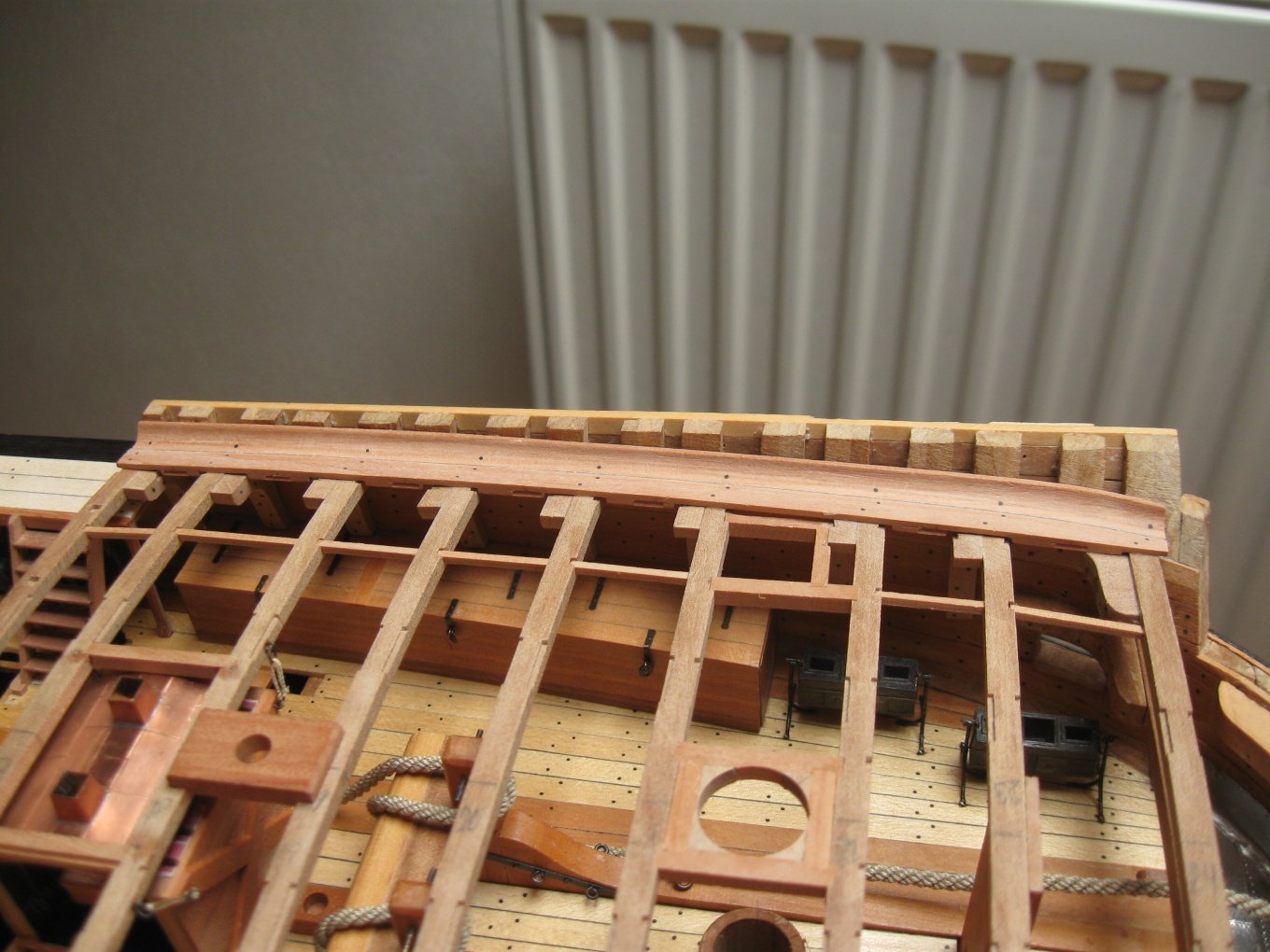

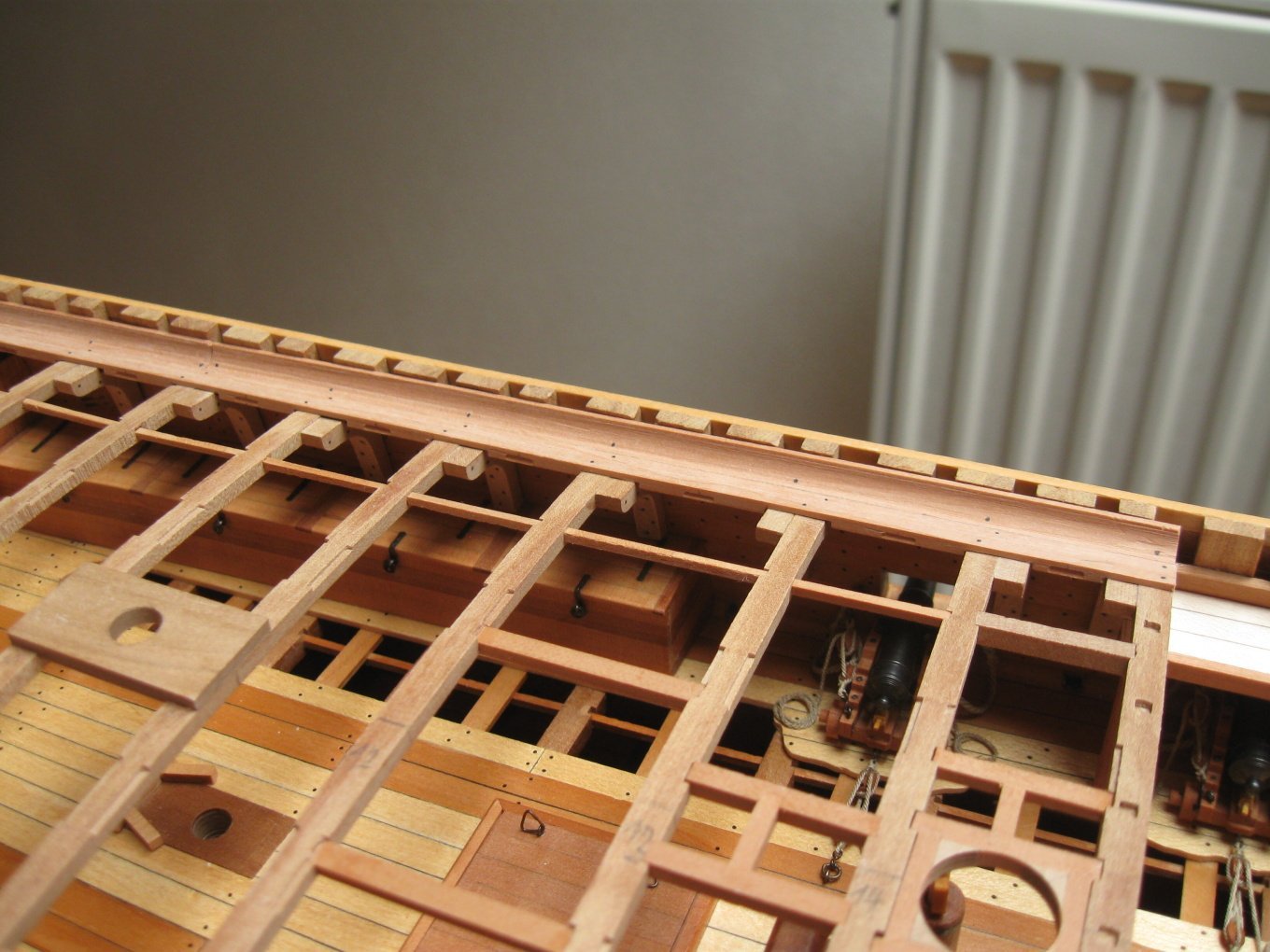

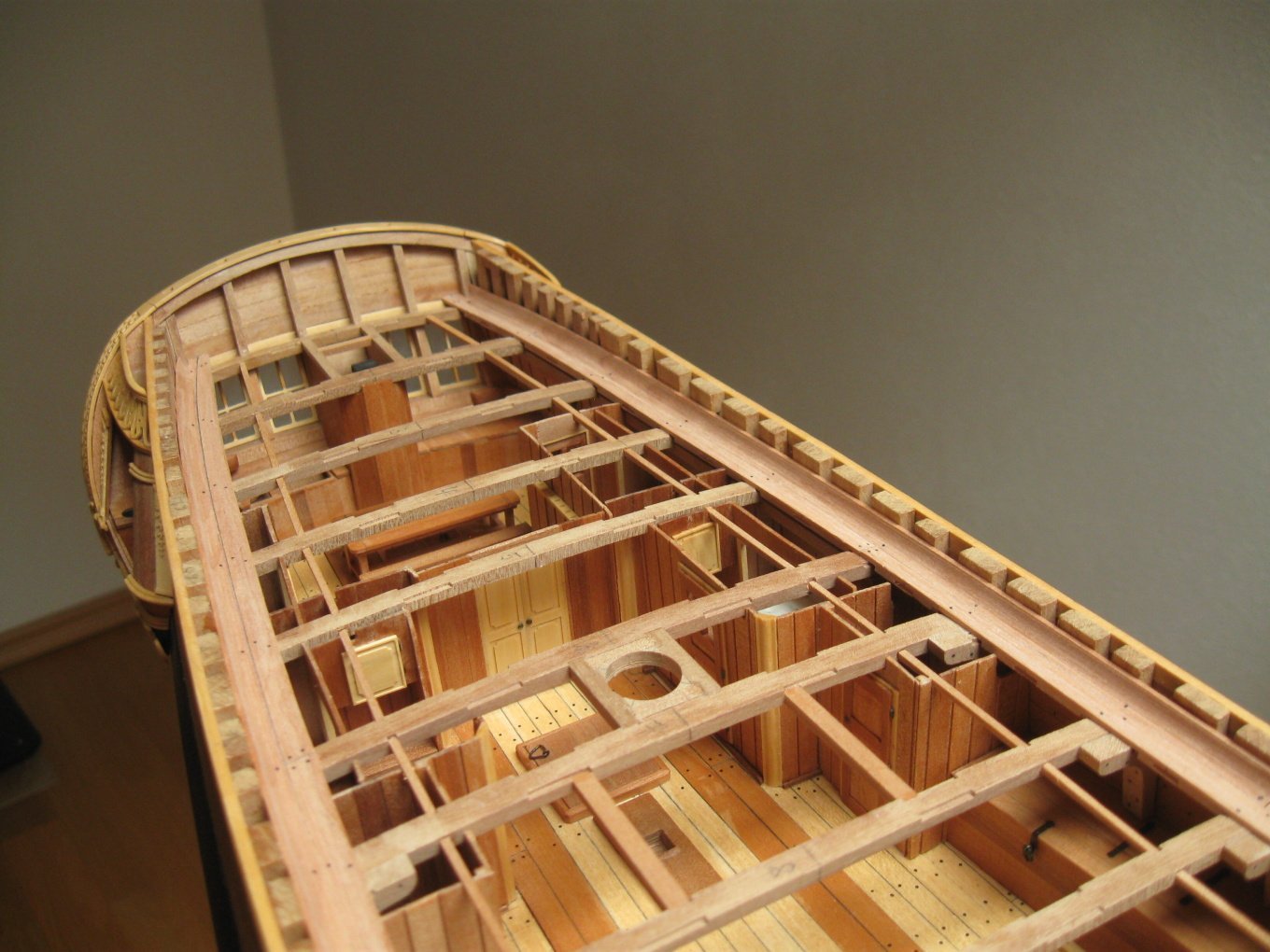

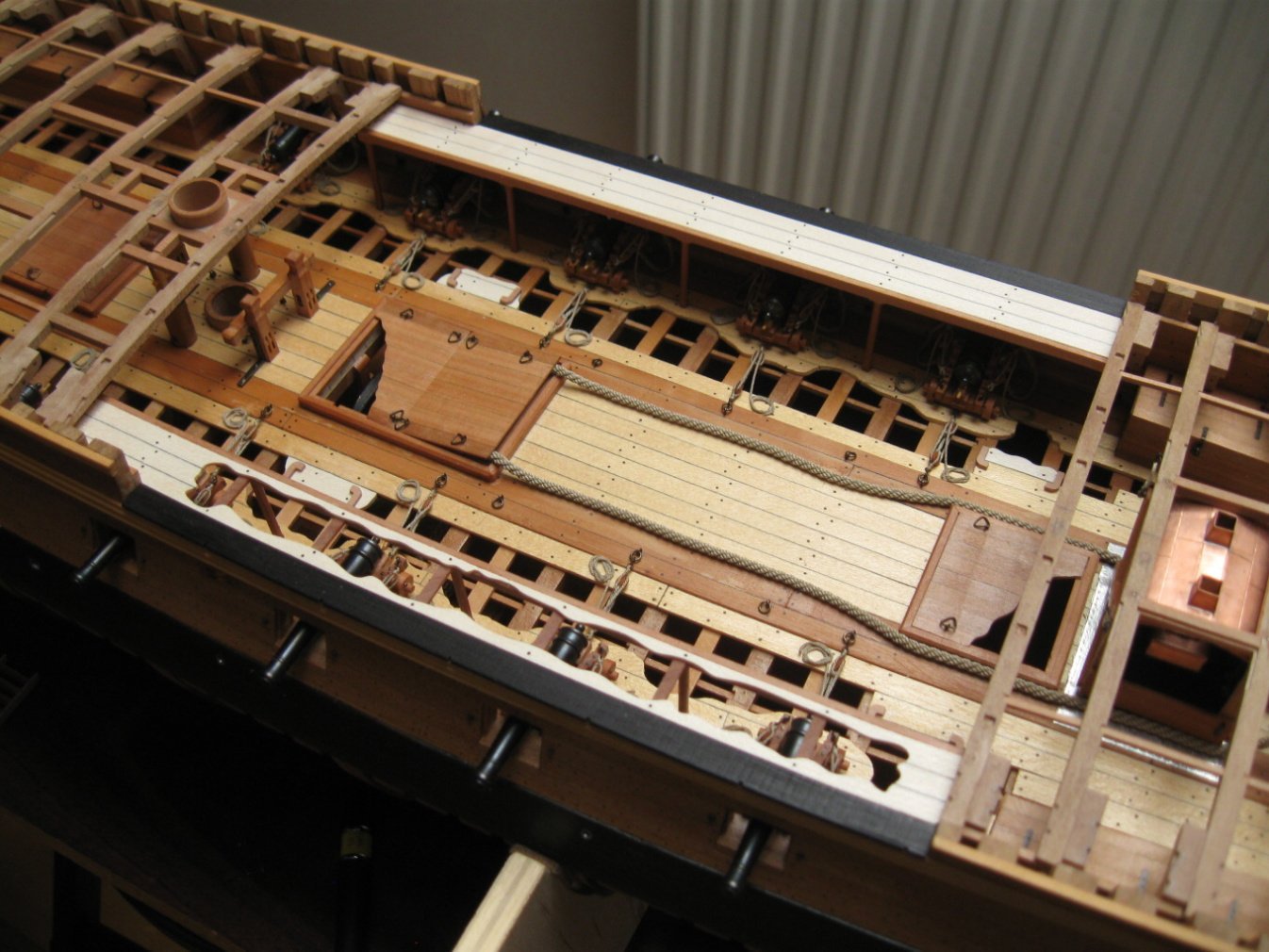

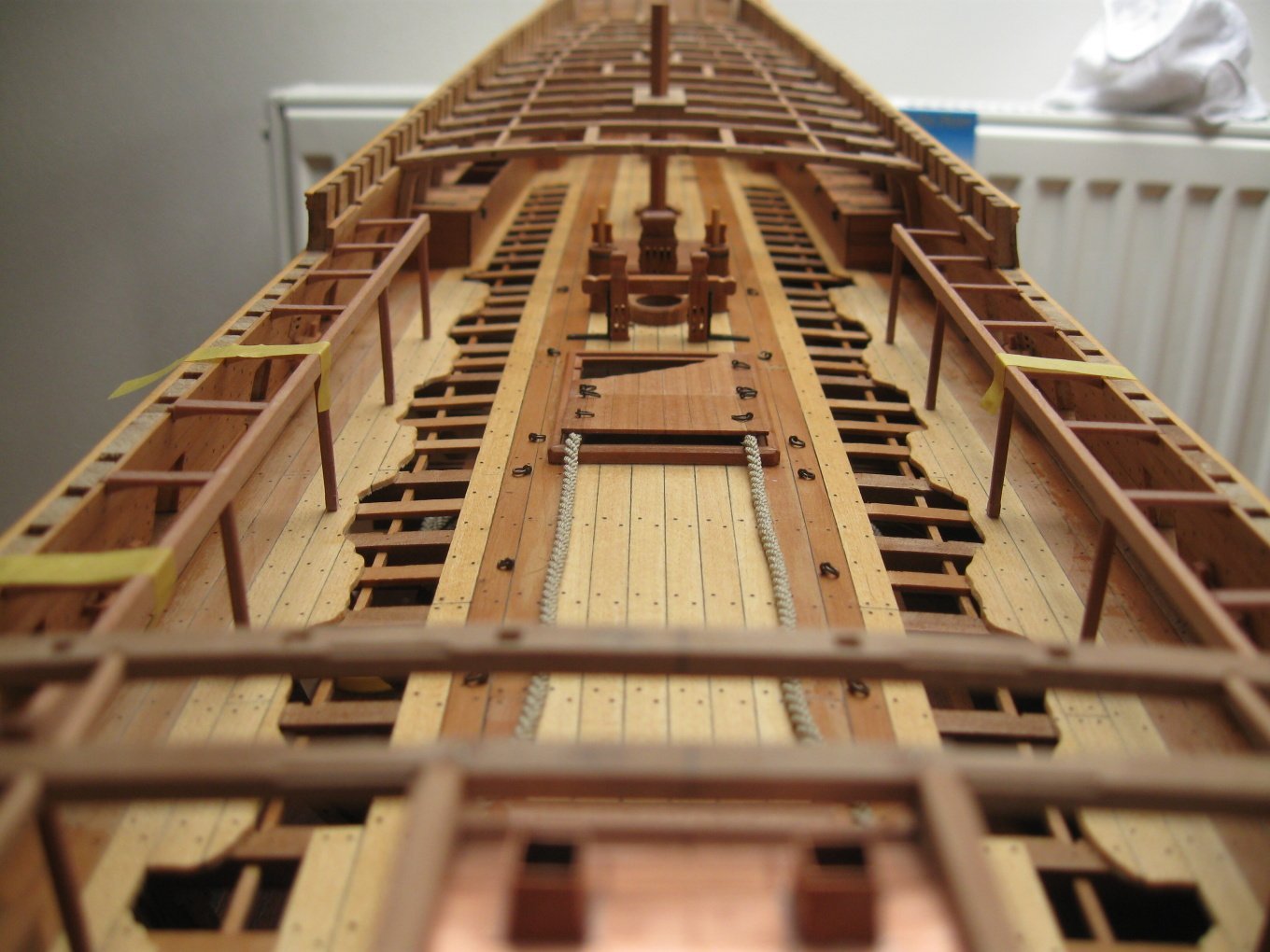

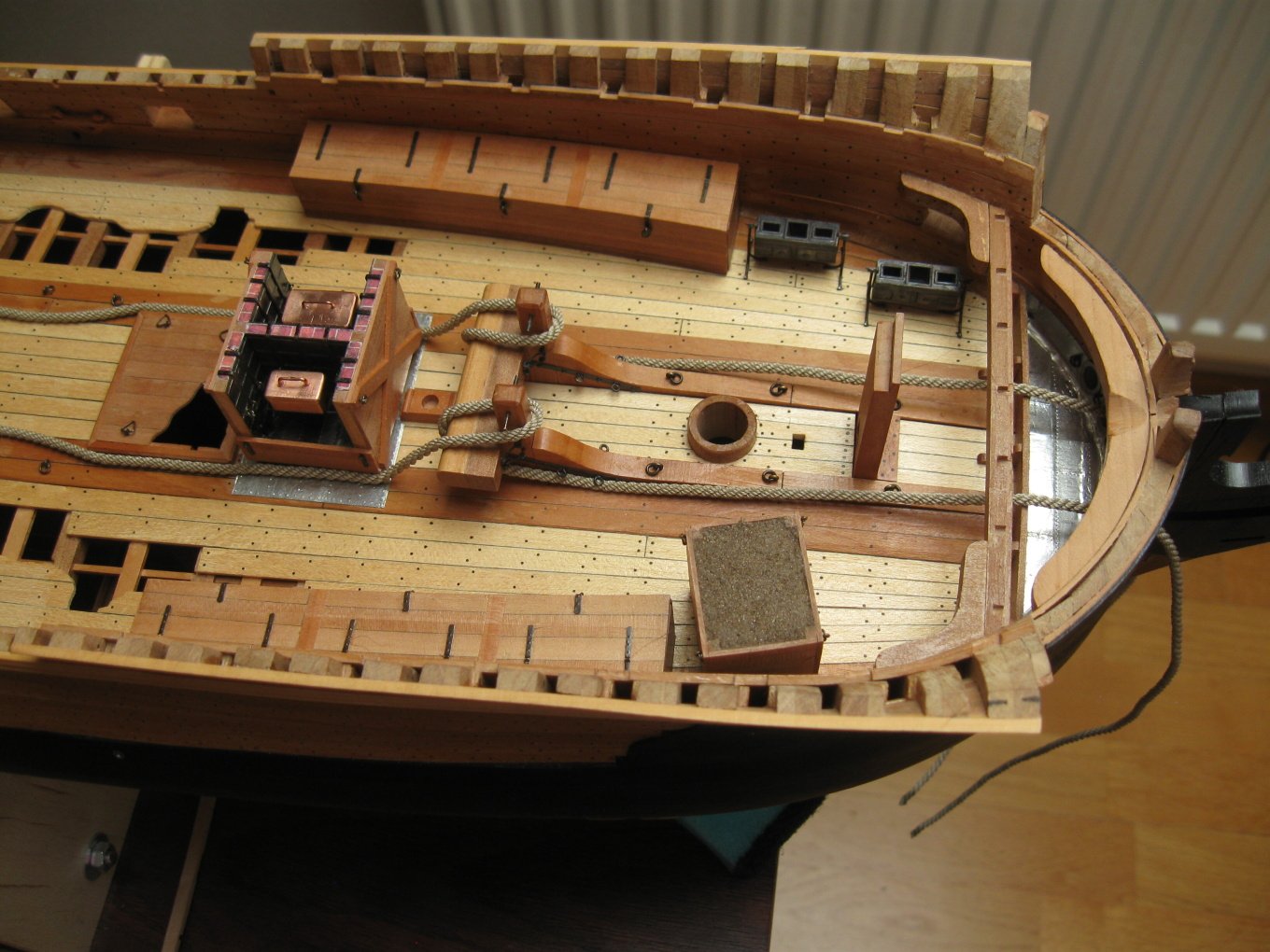

The planking of the quarter deck is completed, decorative mouldings are added at the end of the quarter deck and forecastle deck.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

To Dziadeczek: The used wood for deck planking is maple.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Thank you guys for answering daniel.b question and for the compliment my work too. Forecastle deck planking on the pictures is before waxing. After waxing get the wood little bit yellowish color so the contrast between maple and pear is not so big. On the other hand, I must say that on uncolored models, the color contrast of different types of wood is very important. Otherwise, the model is too dull from my point of view.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

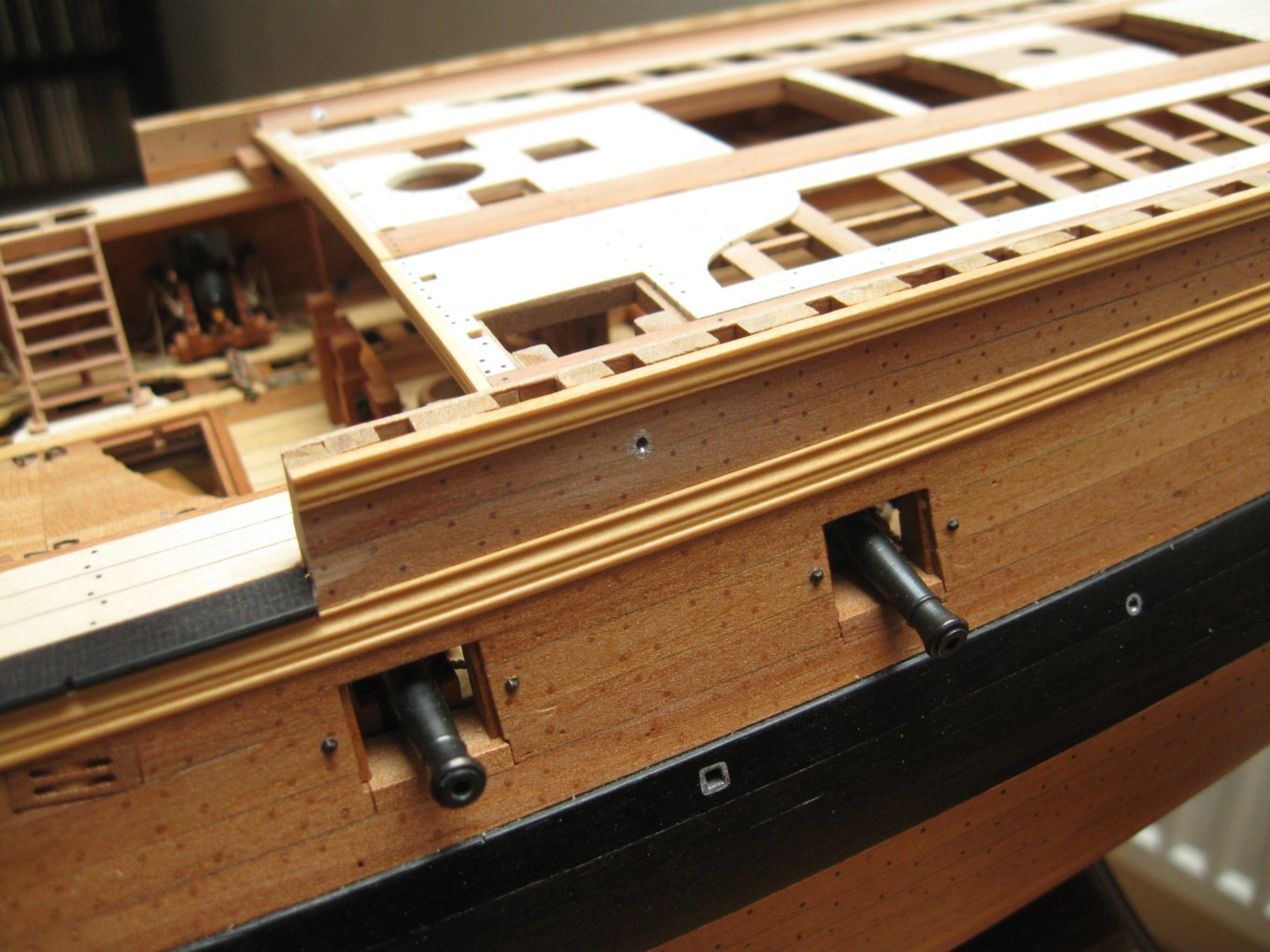

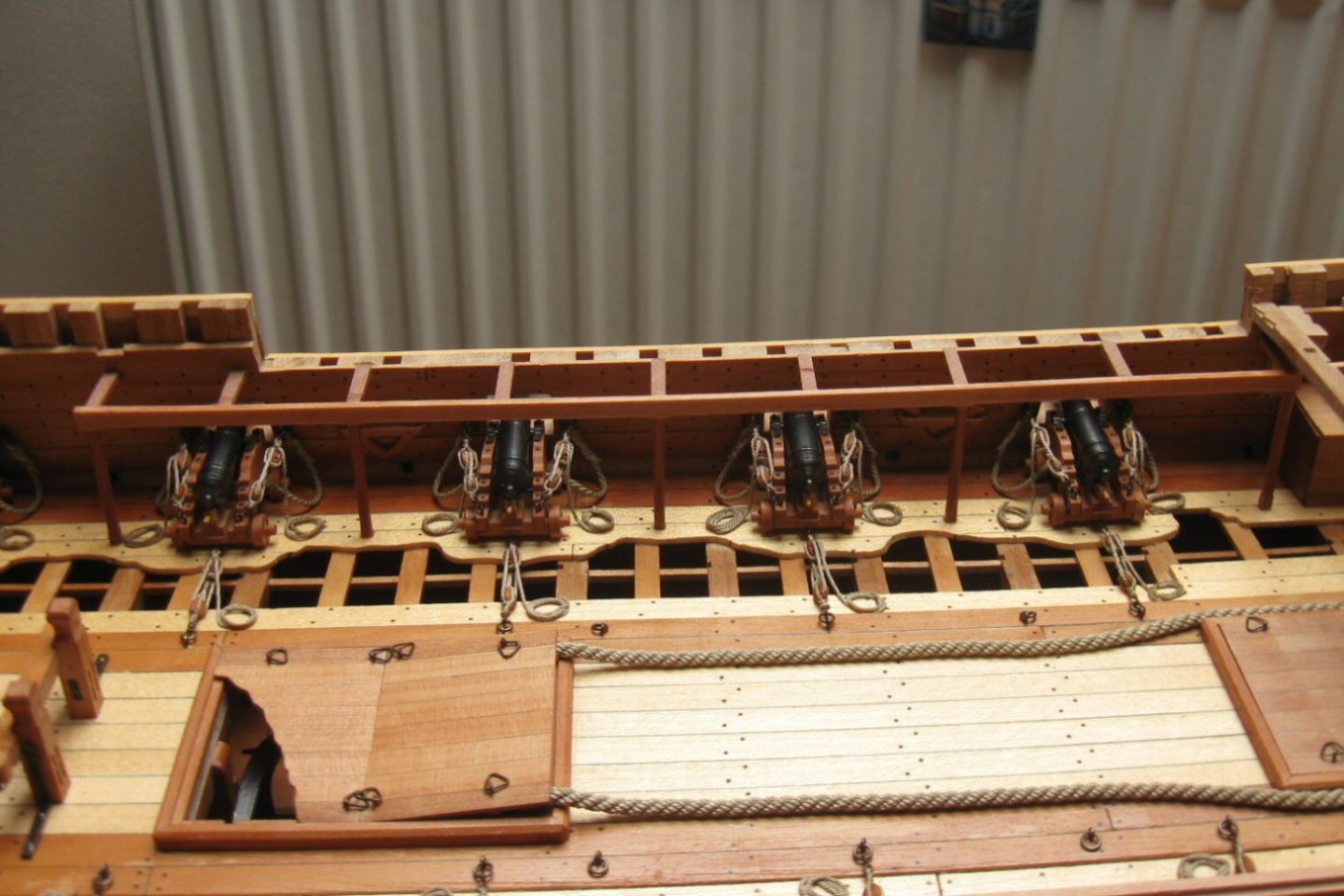

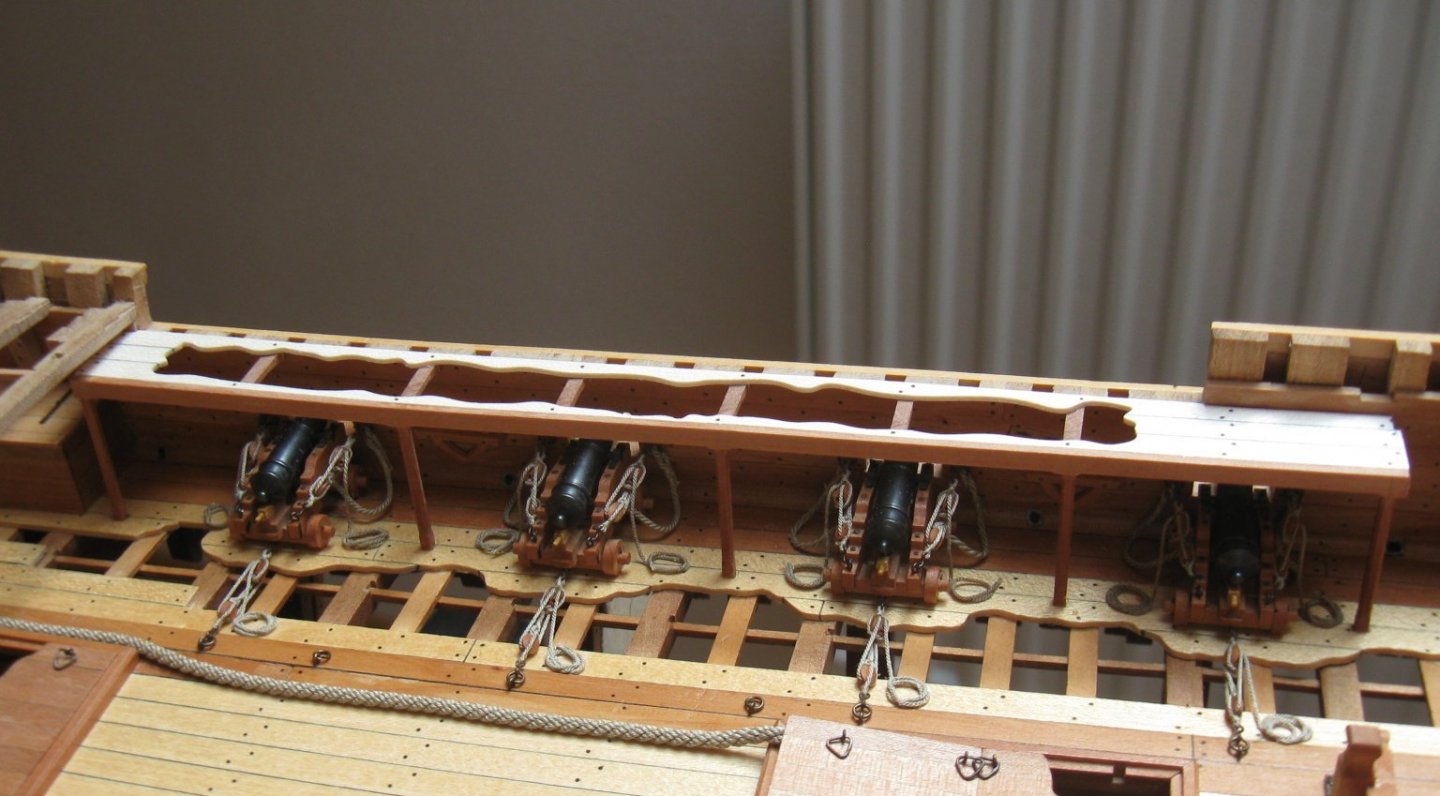

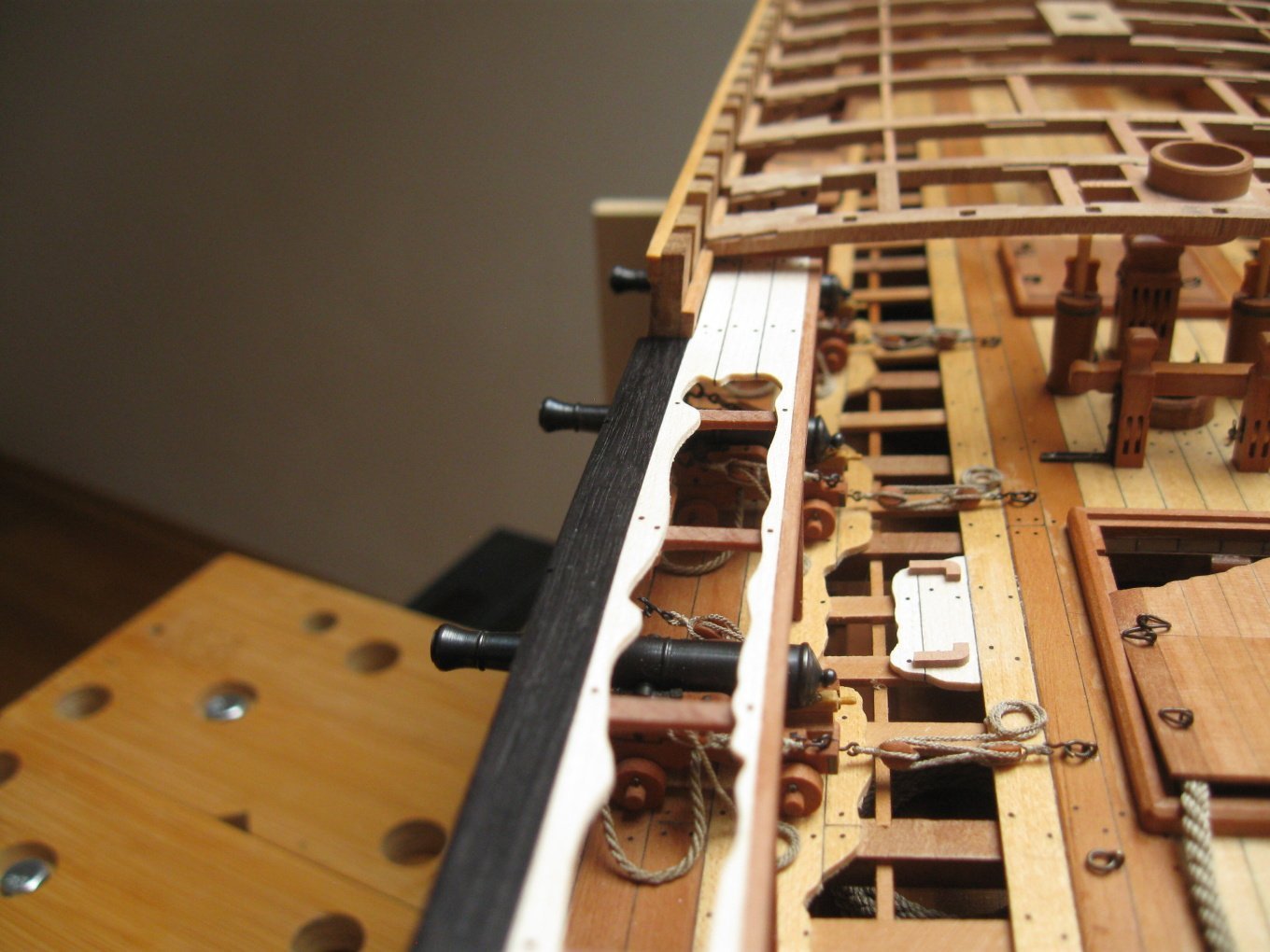

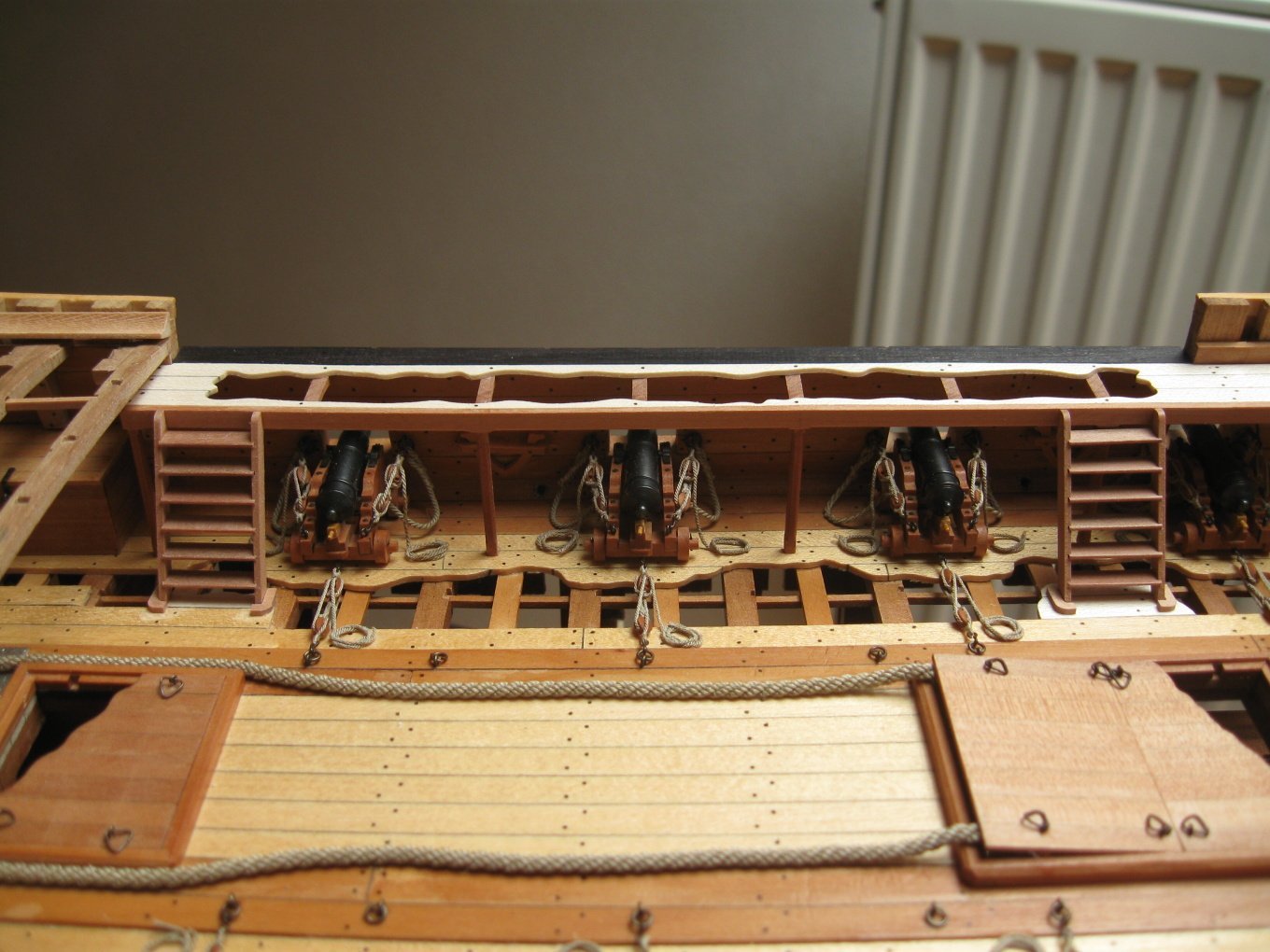

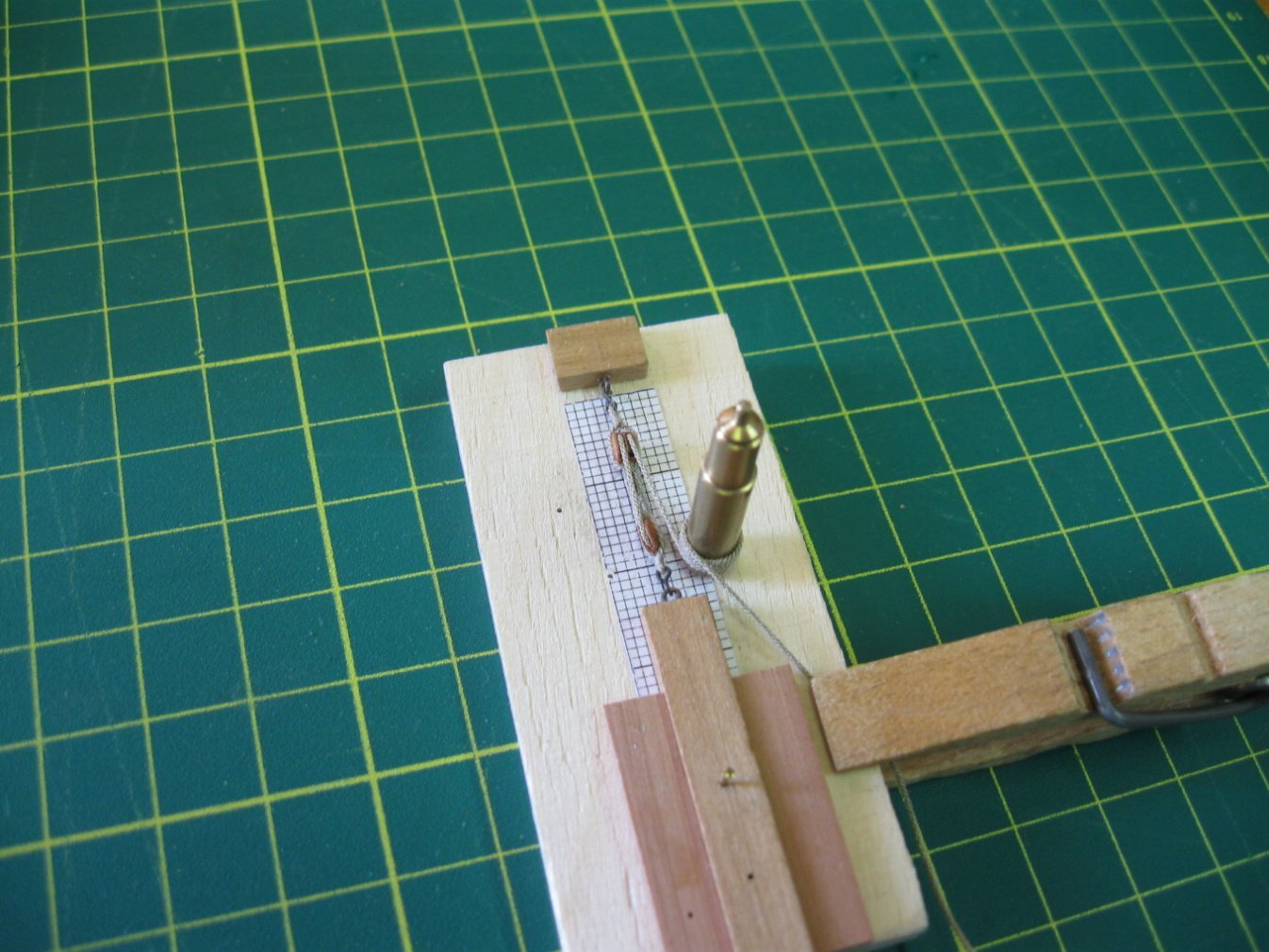

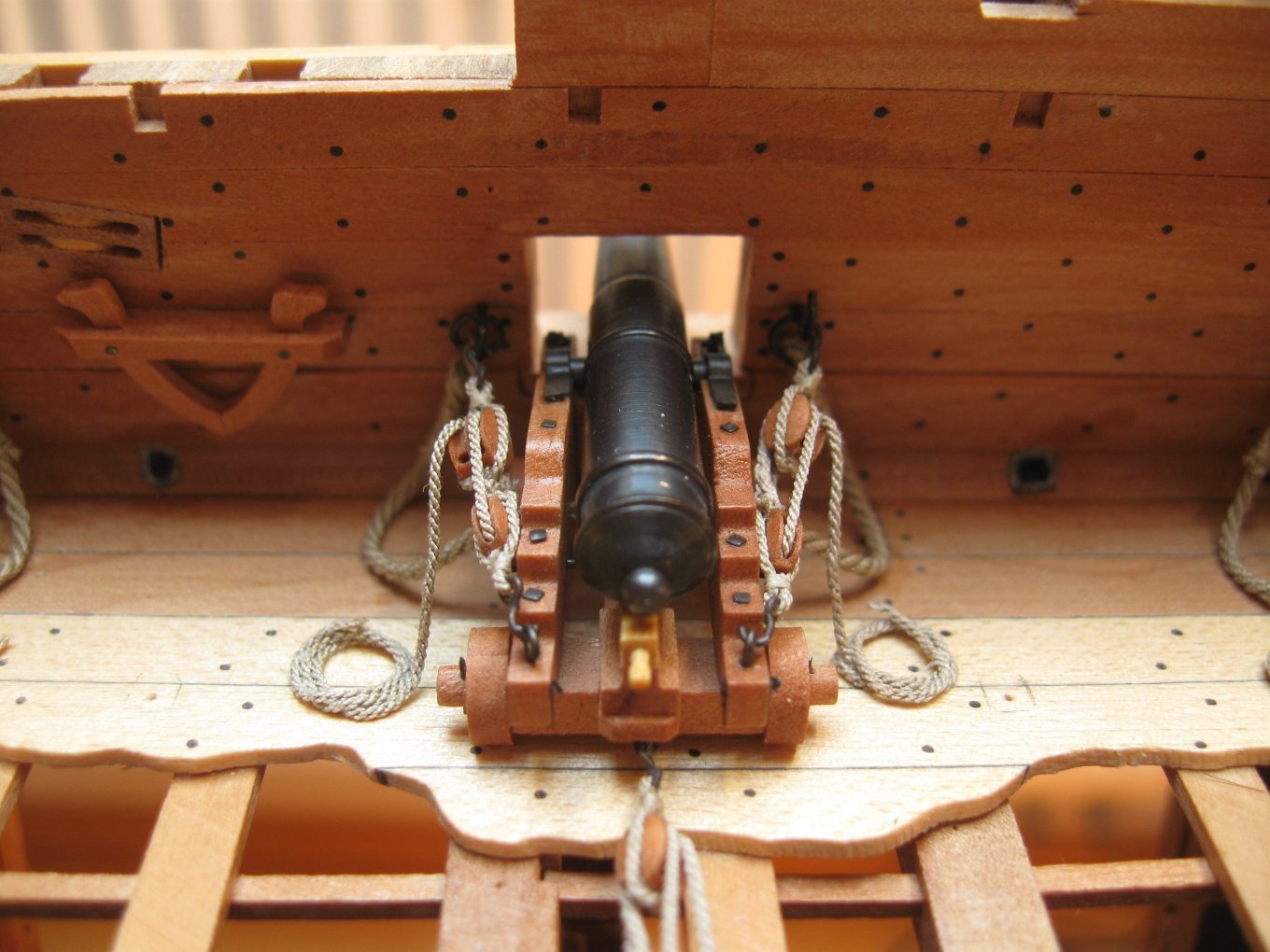

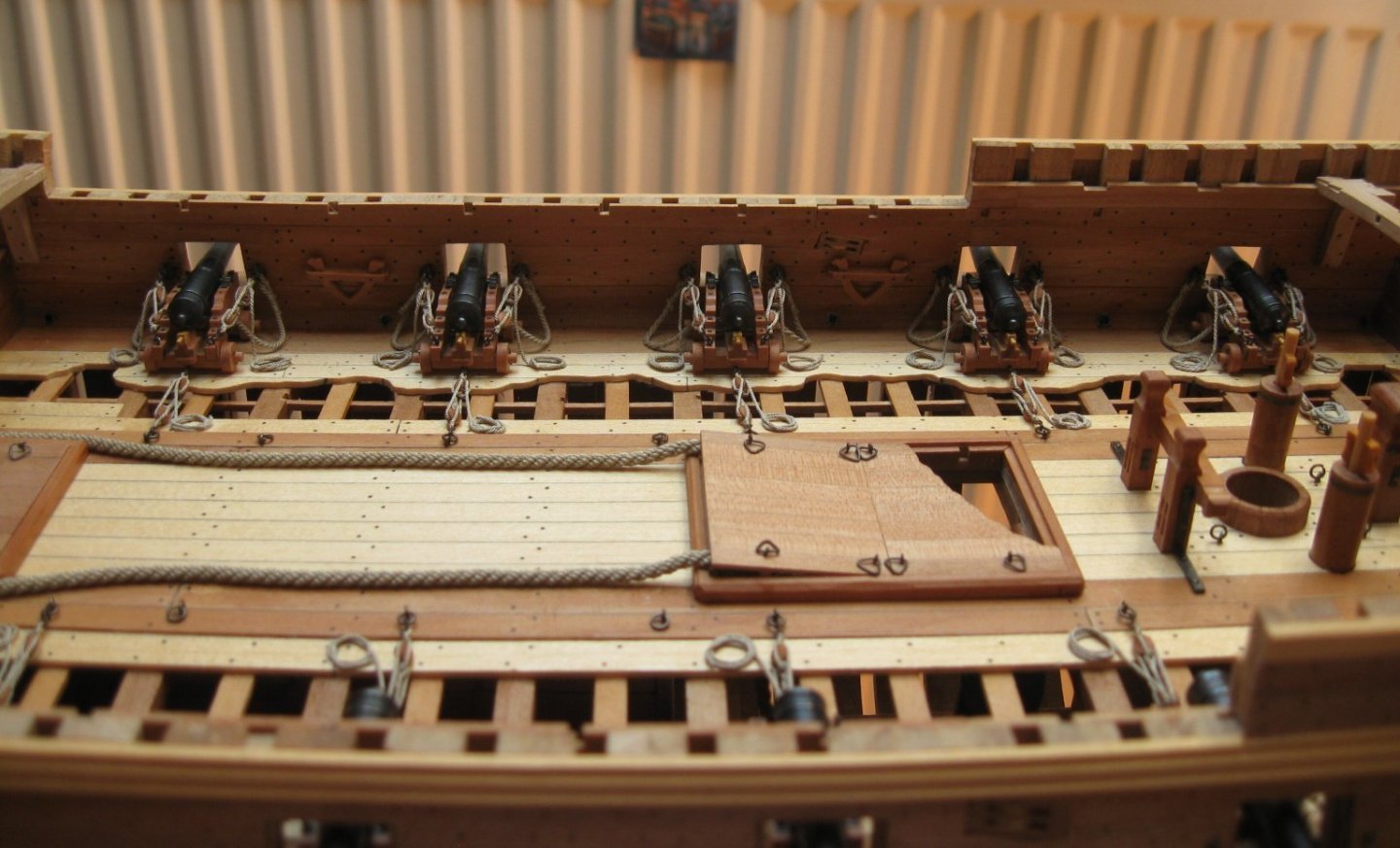

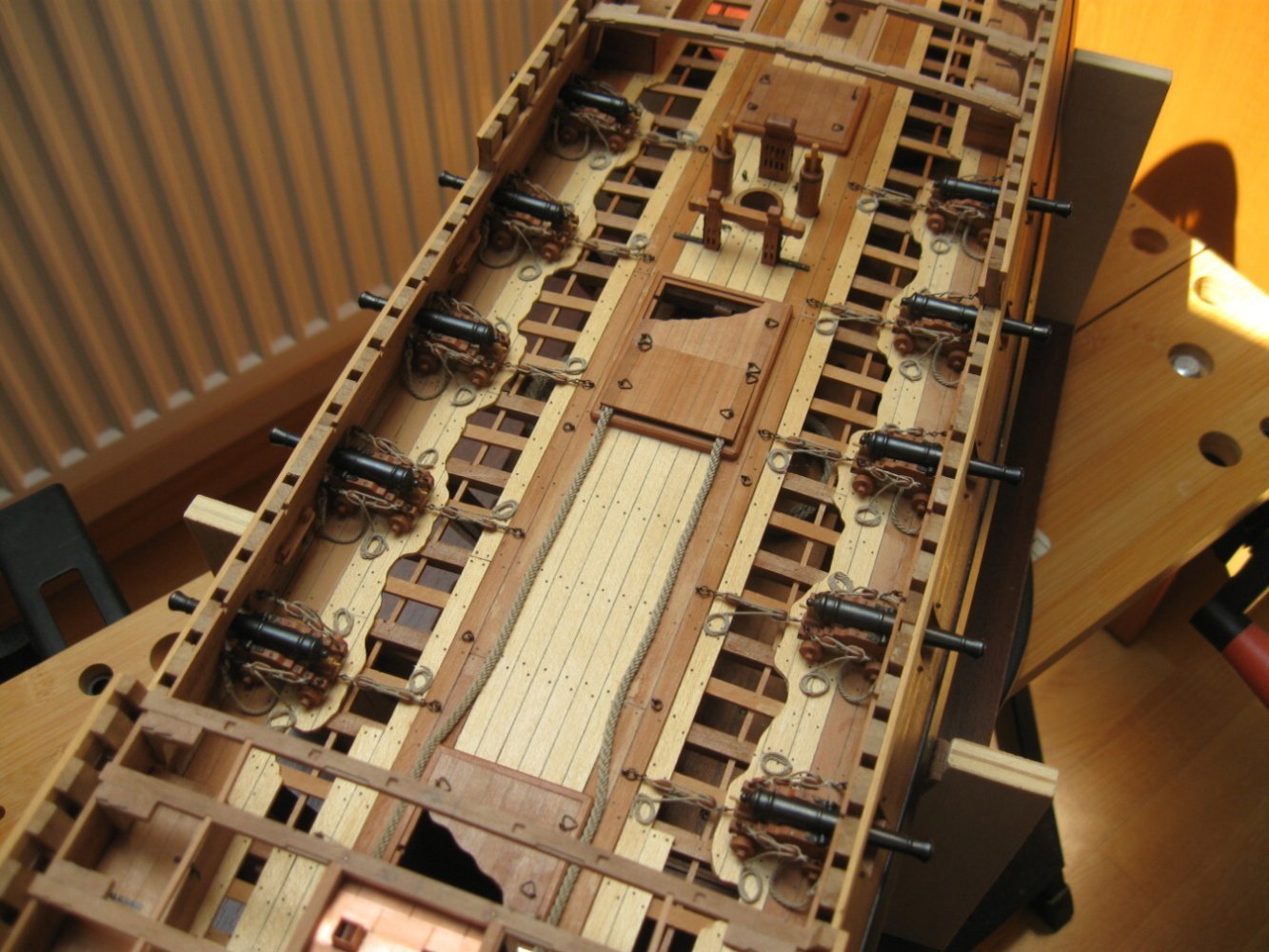

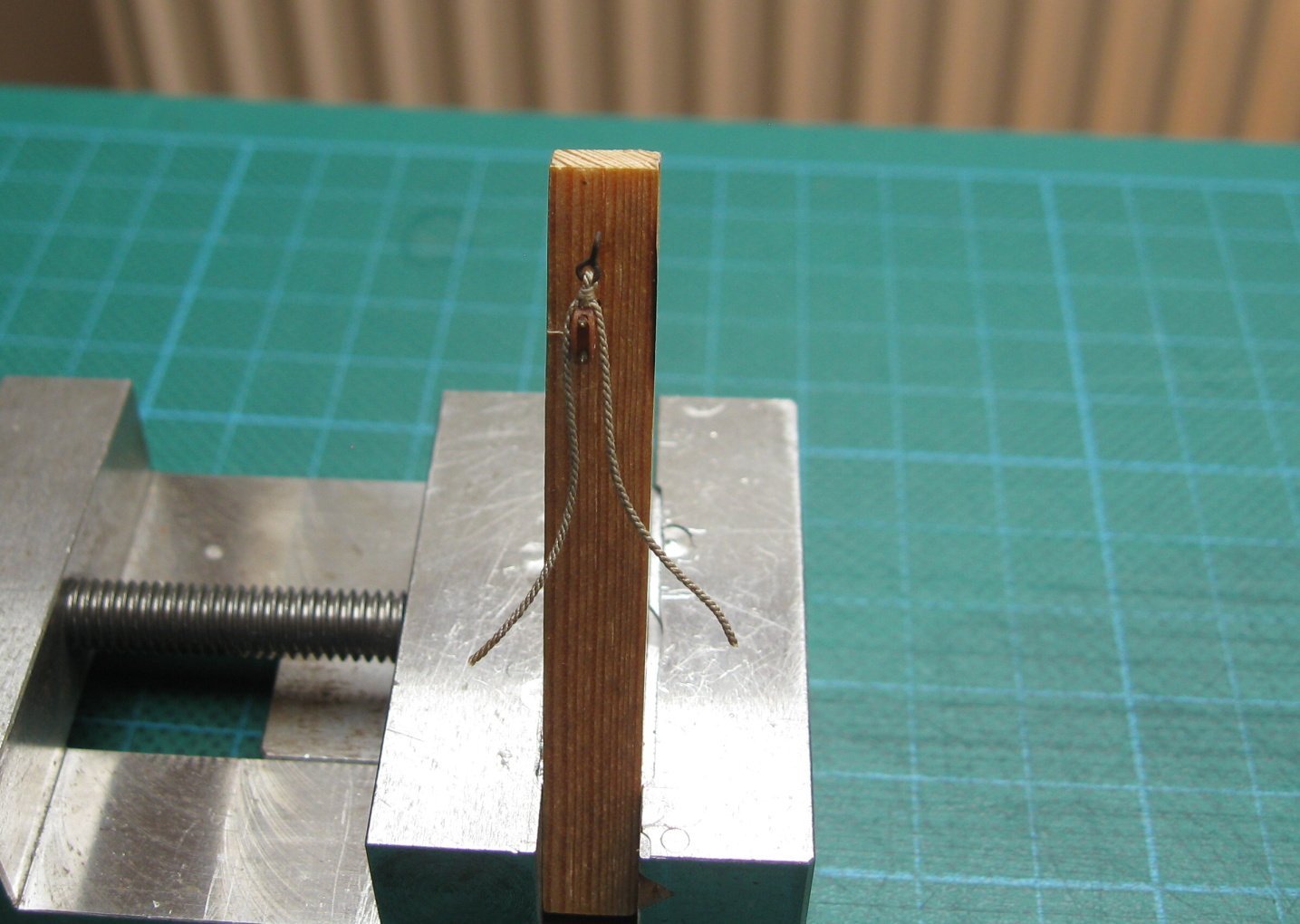

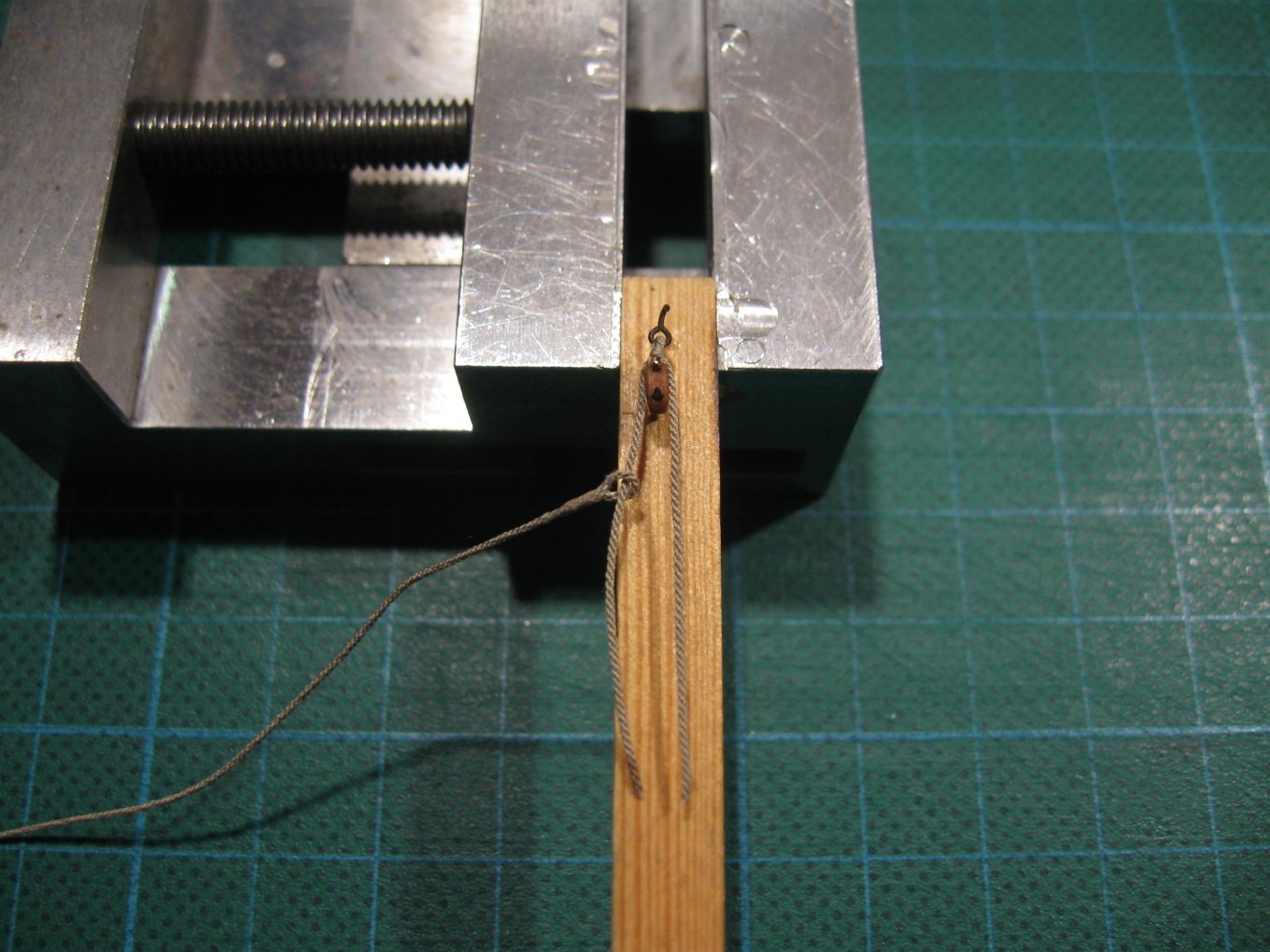

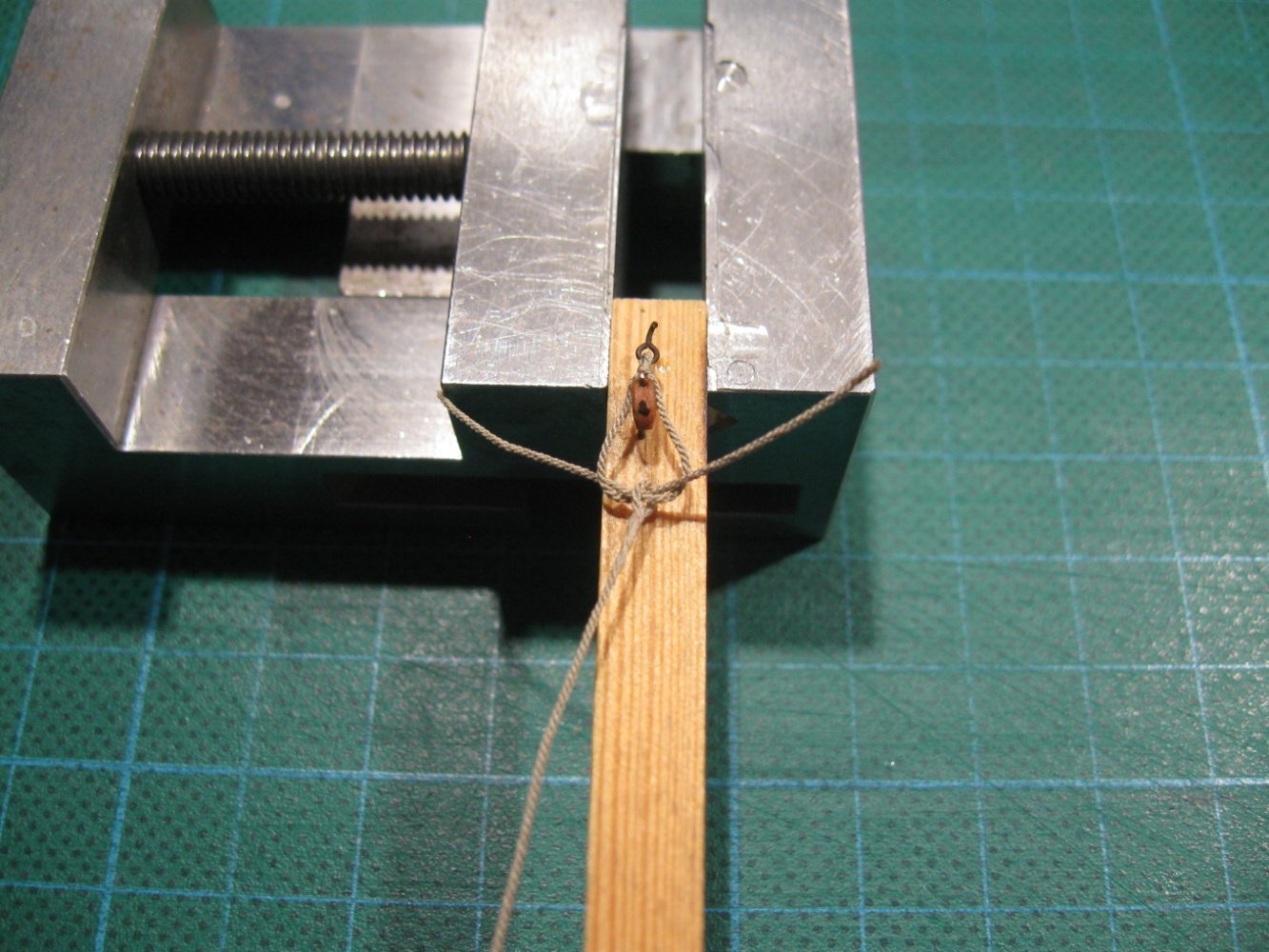

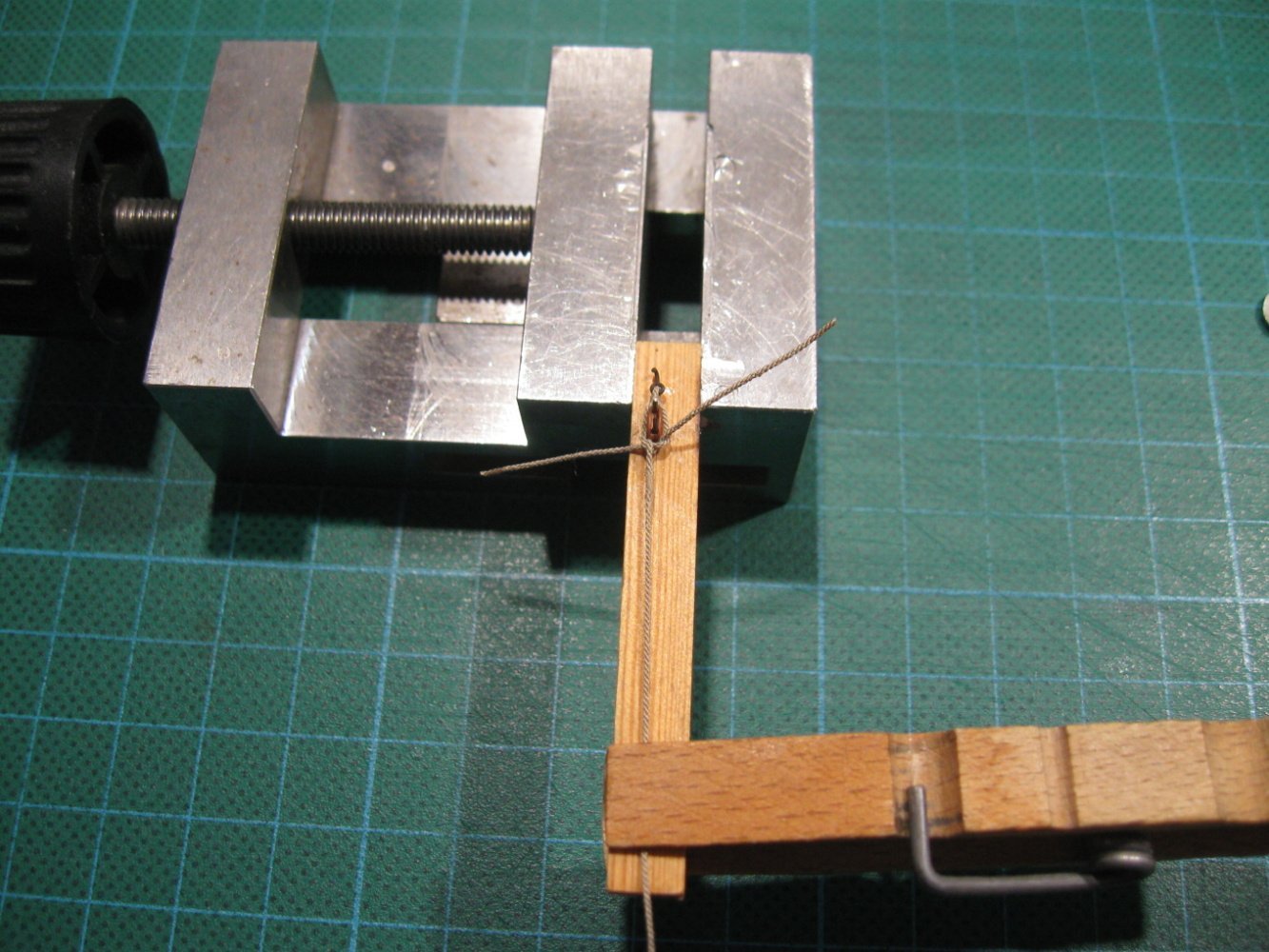

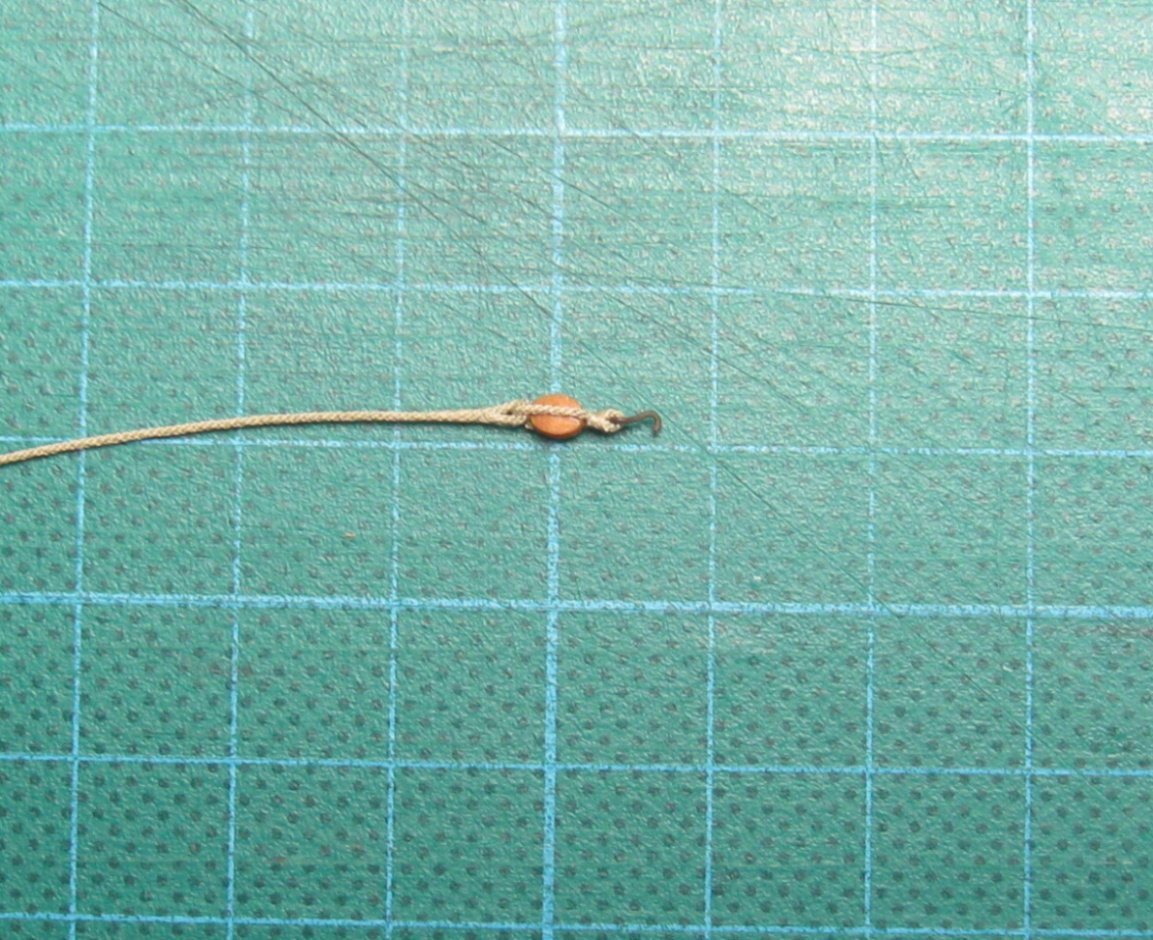

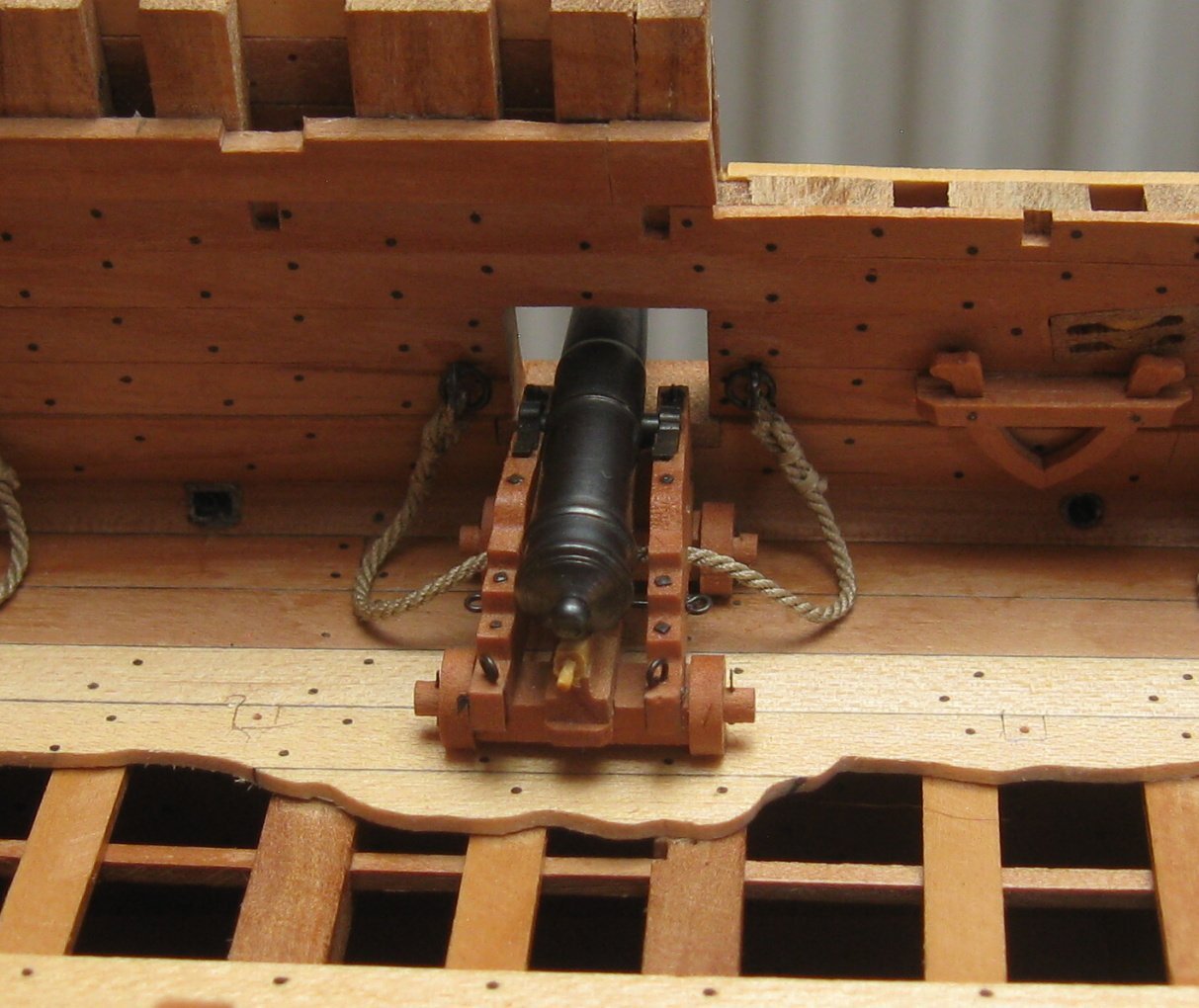

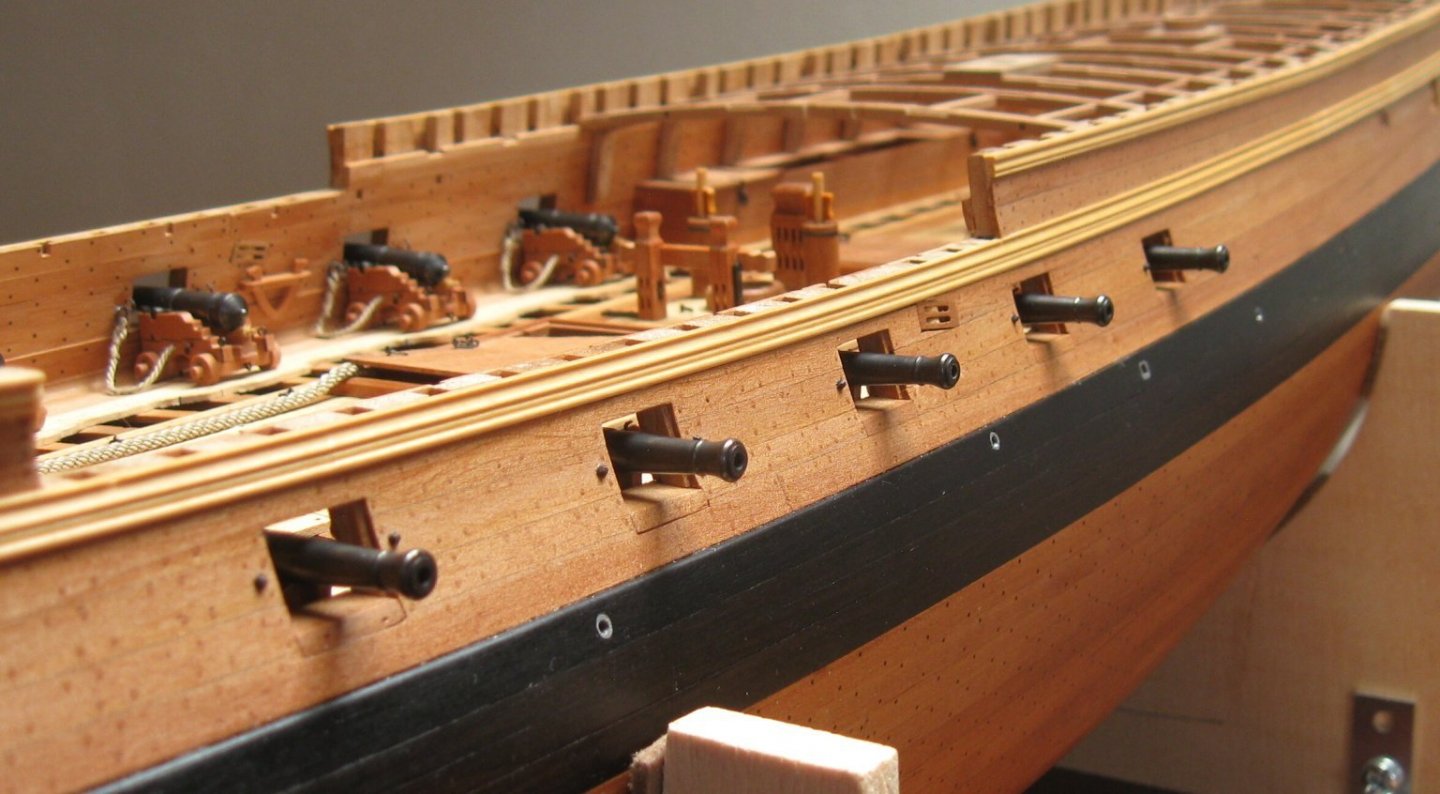

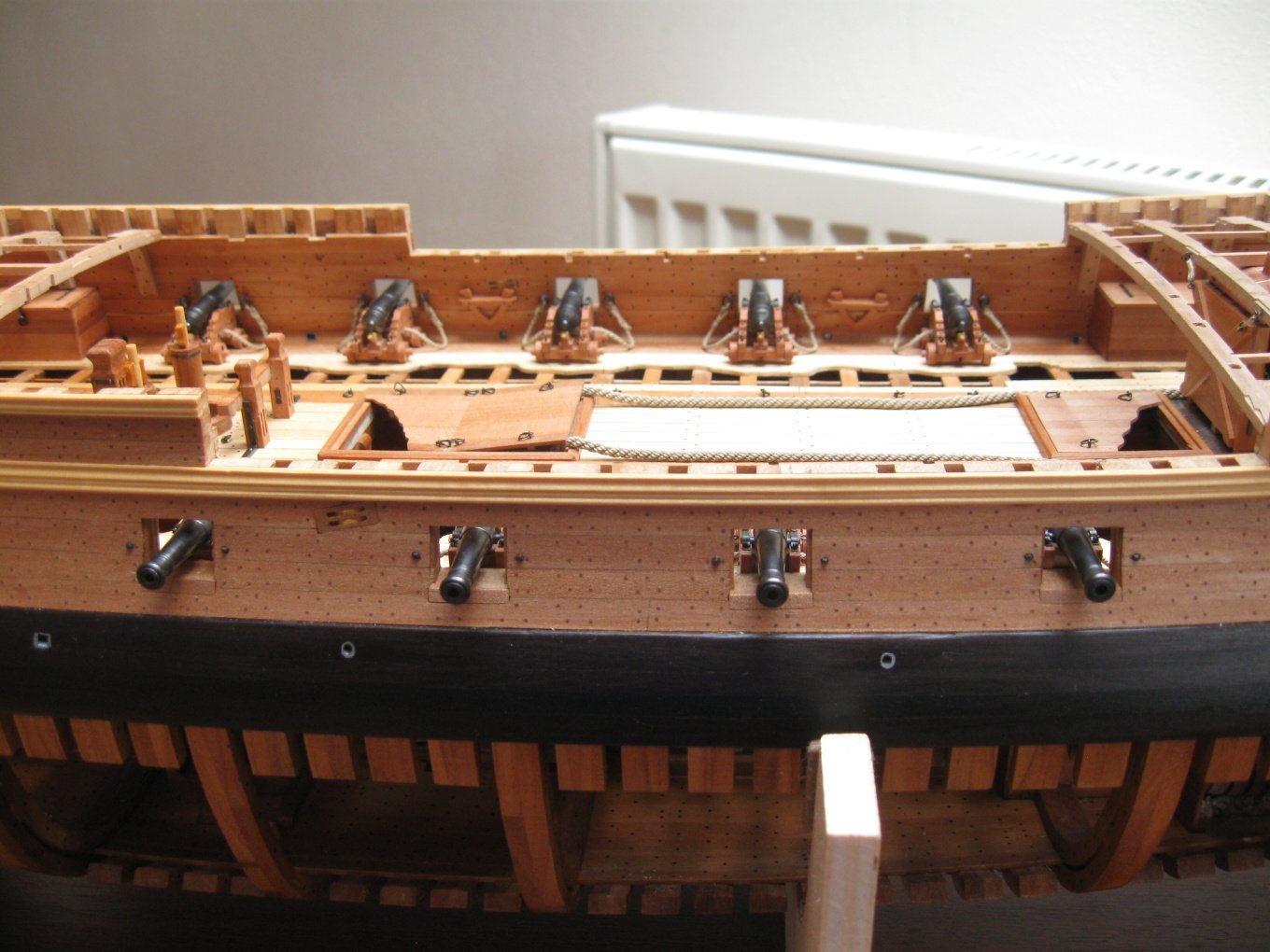

To stuglo: I got this device from a friend, but the equipment was made to order by another company. So I have no way of getting another one. I´m sorry. Installation of guns. It remains to complete the side nd train tackles.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

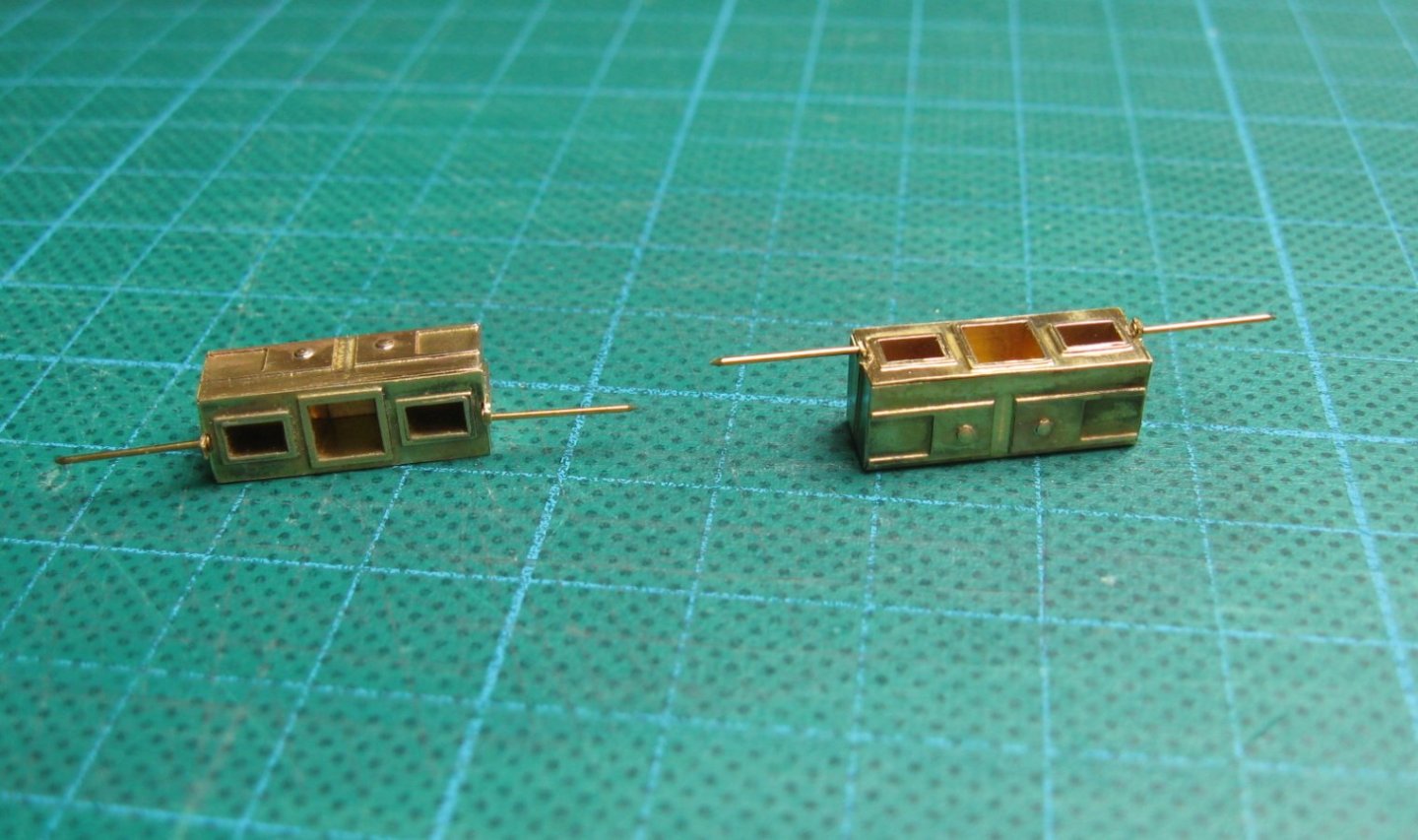

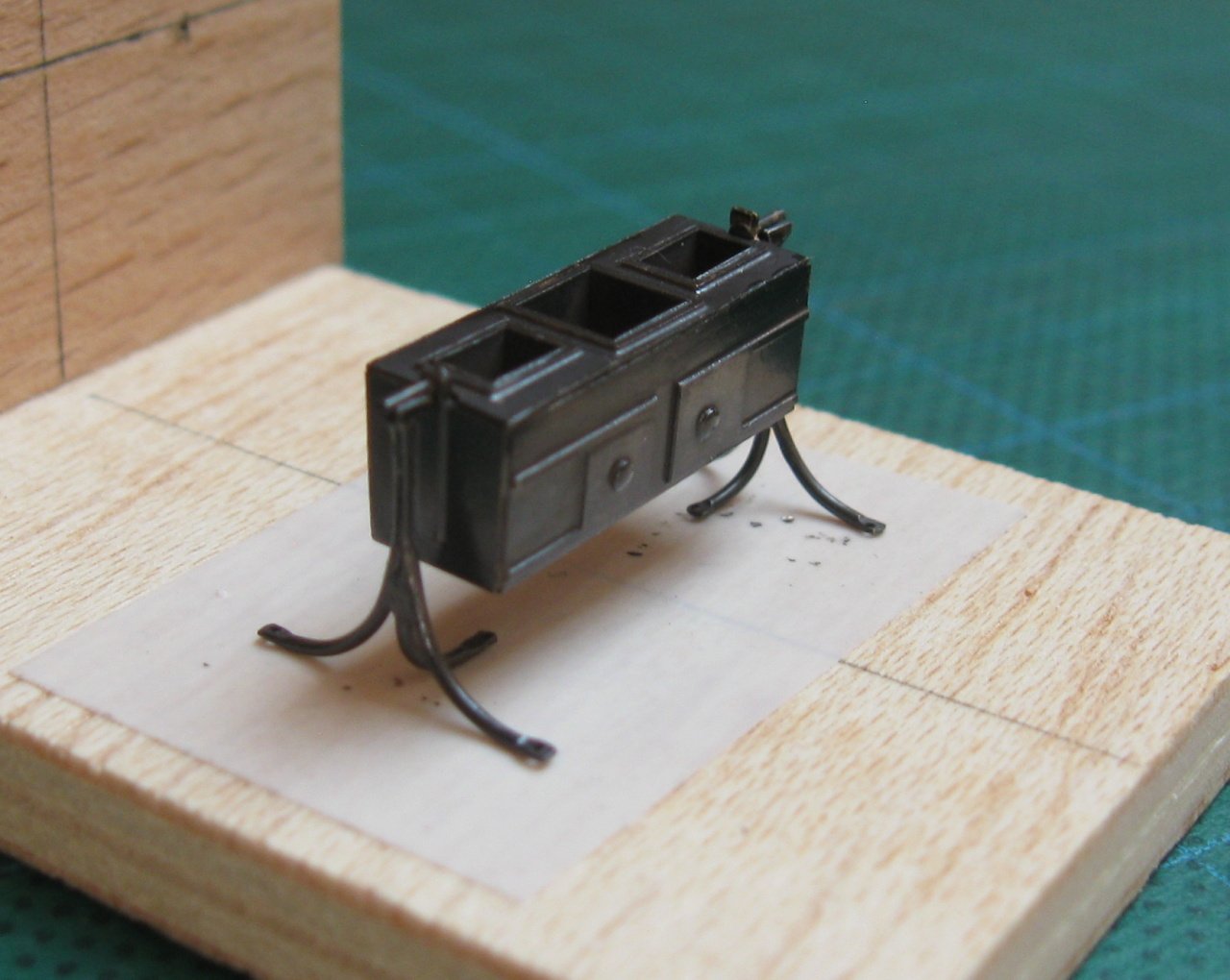

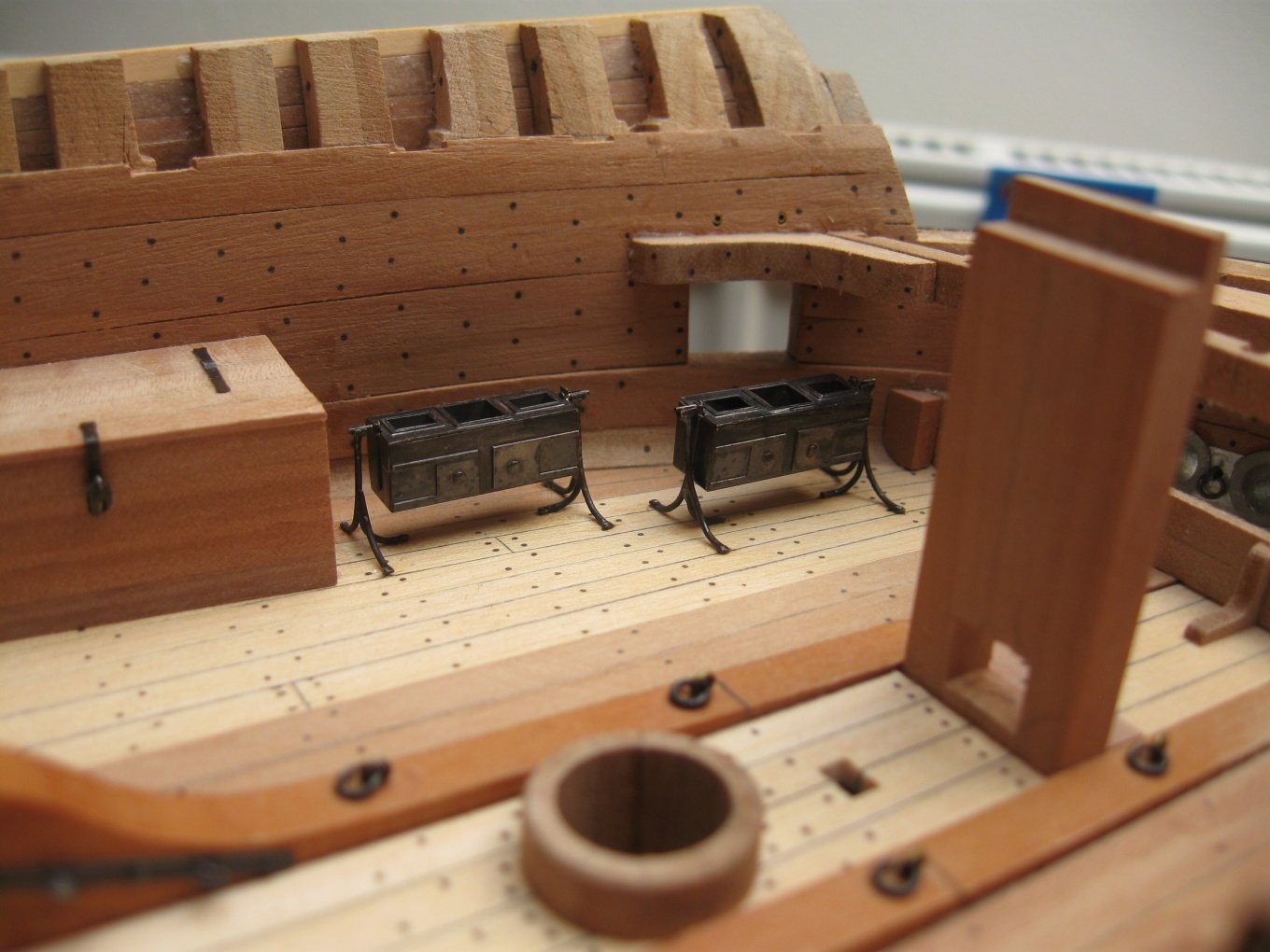

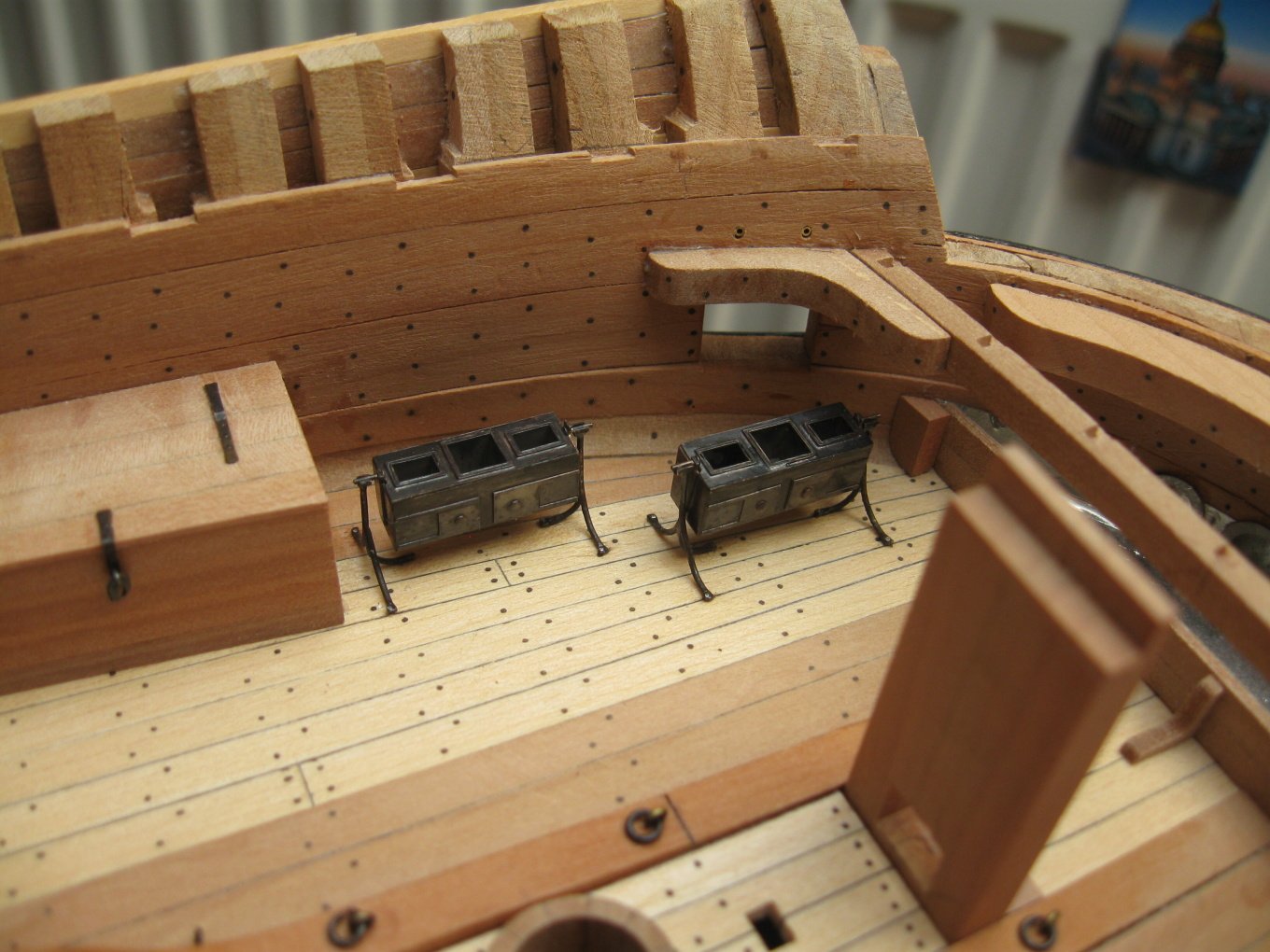

Glenn, thanks for your warm comment. The charcoal stoves are done.They are made of etched parts, so their assembly was not so difficult. Making tripods was much more complicated and demanding. But I am satisfied with the result.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

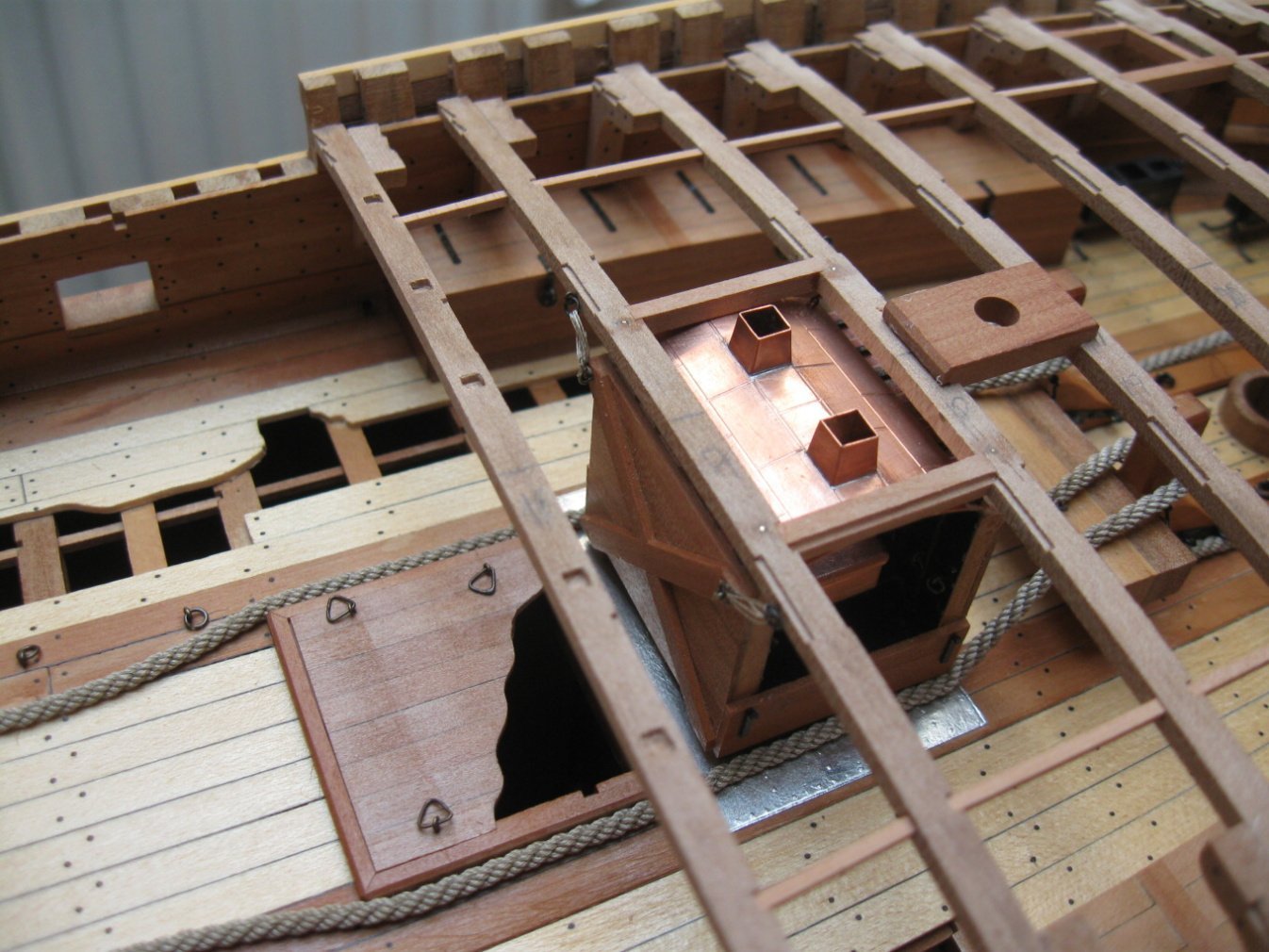

Baker´s oven. Two more charcoal stoves remains to be made. It will be quite a challenge at this scale.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

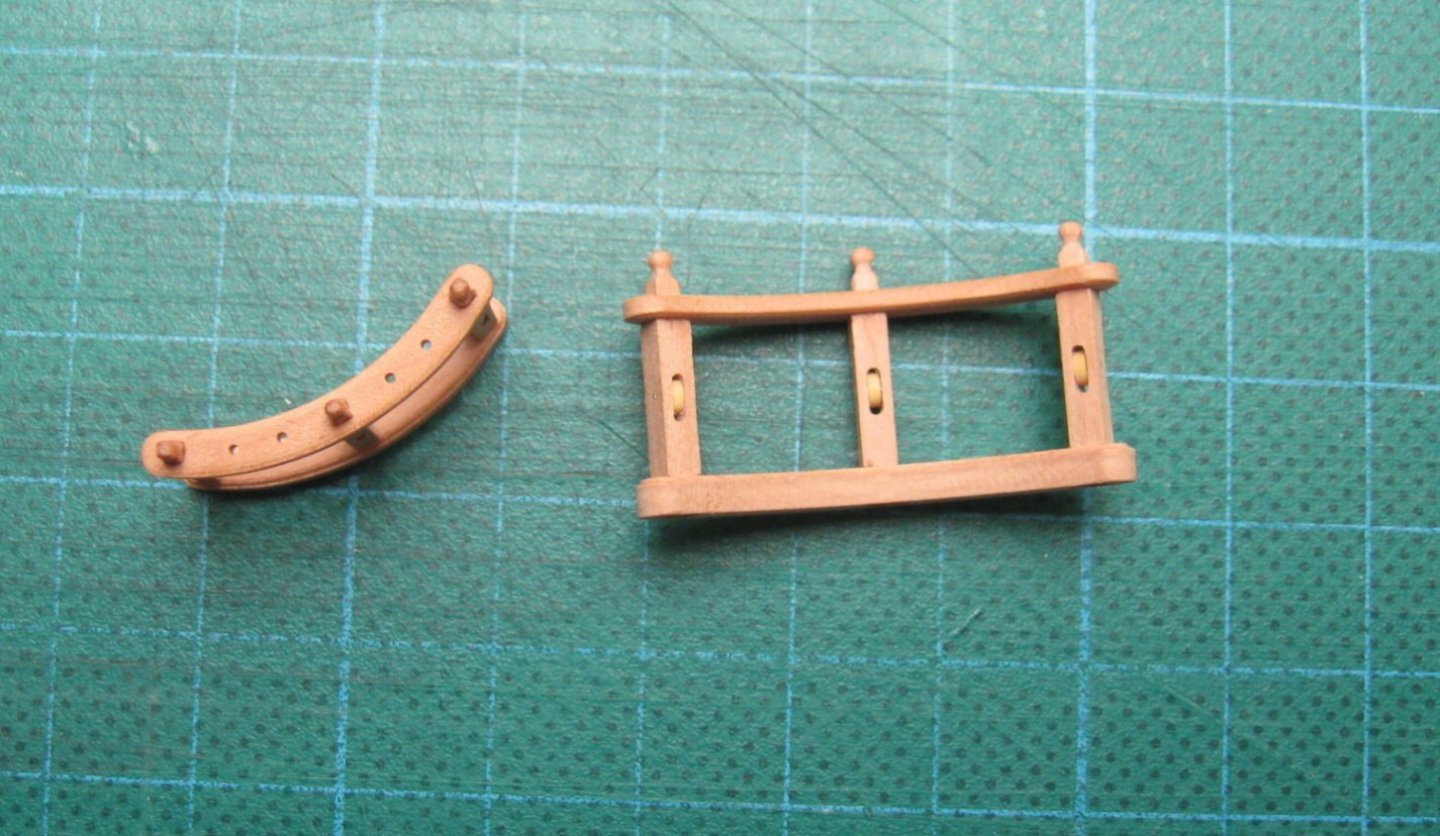

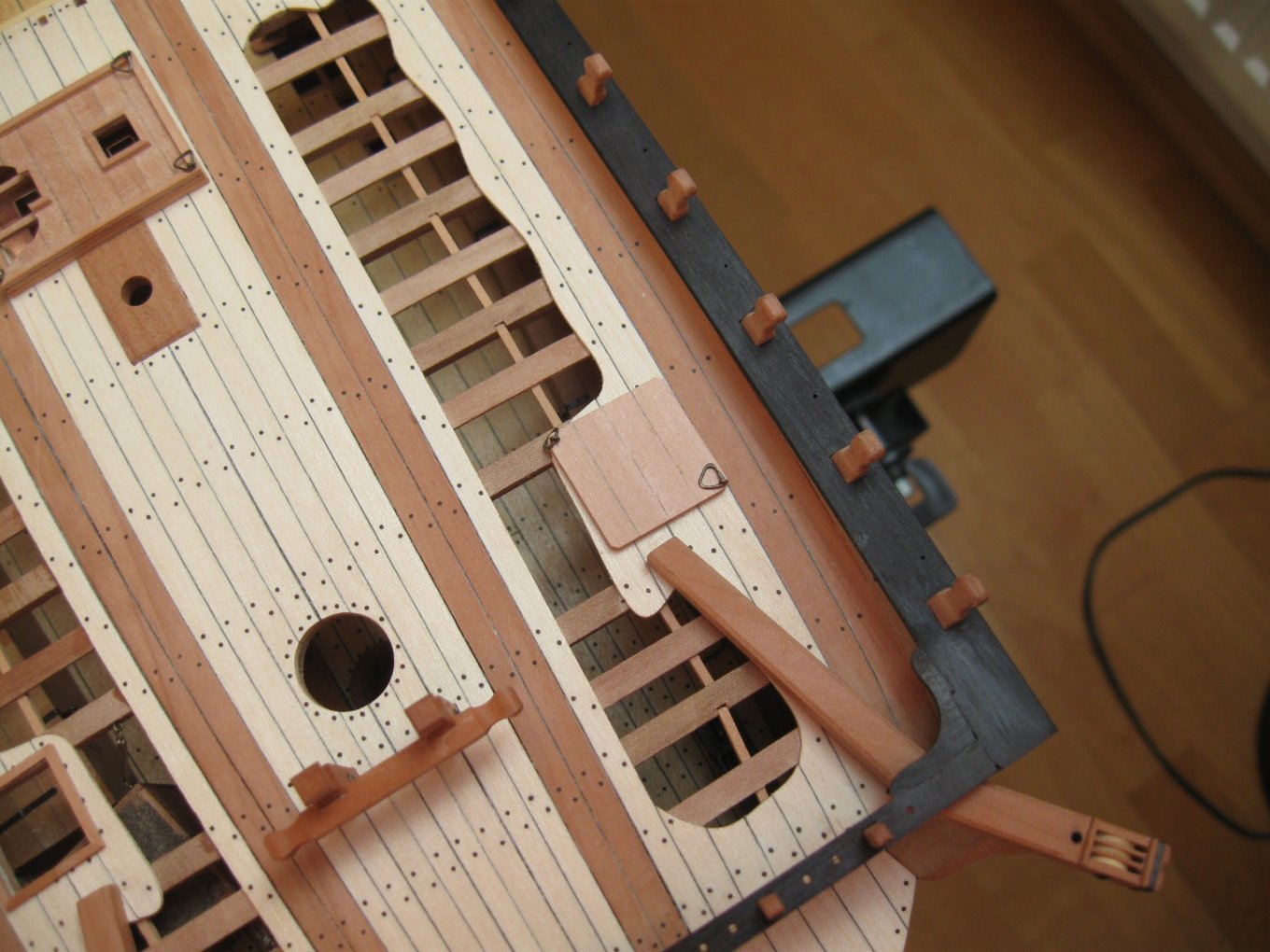

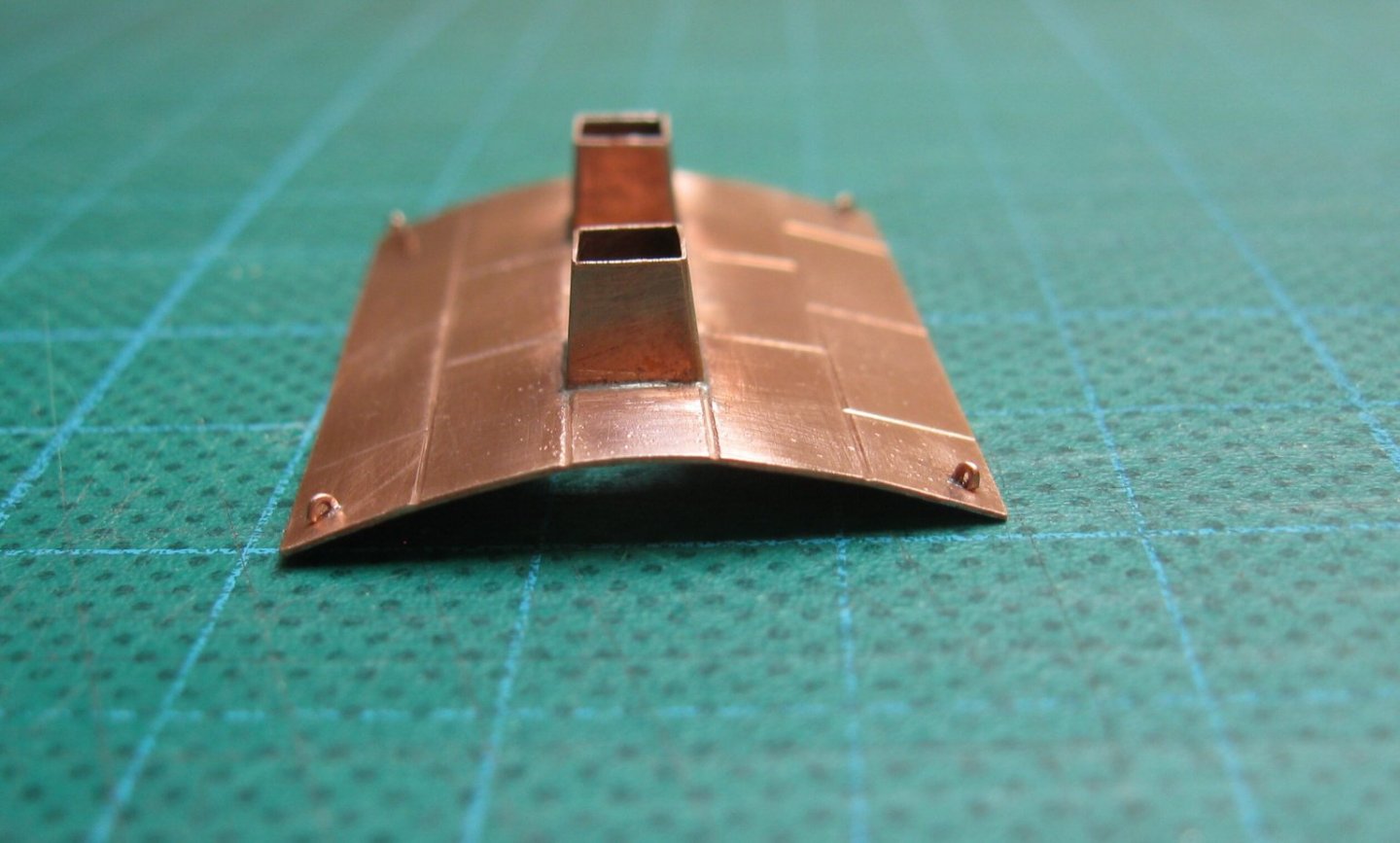

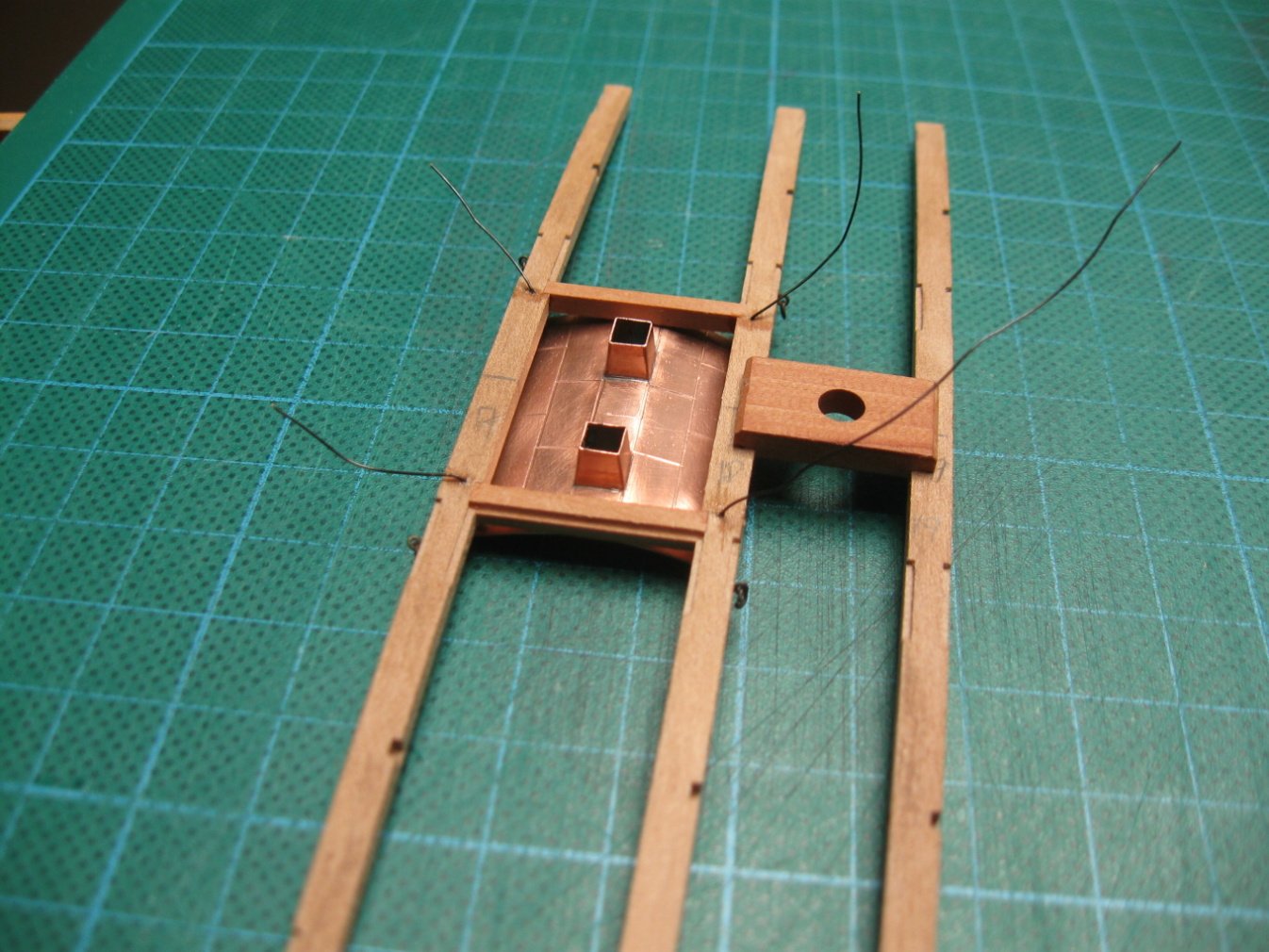

Druxey, you're right. But no one would say how much time these details will take. I continue with the roof of the galley. Due to the small space, I simplified the attachment of the roof a bit (this detail will not be very visible in the final).

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.