DaveBaxt

Members-

Posts

1,324 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DaveBaxt

-

Hounds and Cheeks for Endeavour finished in 1761

DaveBaxt replied to DaveBaxt's topic in Masting, rigging and sails

Thank you Allan but please forgive my ignorance fornot being able to comprehend your last piece as although I have read it twice I find as yet I am unable to follow that. Perhaps I need more time to follow that but for what its worth I too came up with the length of the cheeks being half the distance between the partners and the stops. I am assuming the stops are the underside of the trestle trees and the hounds are finishing at the same place. Perhaps you could clear up one matter for me is regarding the top and the cap and allowing for the rake of the mast. I am assumimg these are both parallel with the deck or waterline rather than 90 degs to the mast ? Sorry again for not following your last paragraph (Italics) Hopefully given time the penny will drop but I thank you once again for your effort and patience in trying to help me. Best regards Dave -

Hounds and Cheeks for Endeavour finished in 1761

DaveBaxt replied to DaveBaxt's topic in Masting, rigging and sails

Thank you Allan for that drawing which is further evidence showing what the relationship between the cheeks and the hounds. Interesting what that you mention the groove and that most modellers leave it out. I have neither come ocross it in photos or heard it mentioned by other modellers but interesting all the same and now knowing it is there. Much appreciated. Best regards Dave -

Hounds and Cheeks for Endeavour finished in 1761

DaveBaxt replied to DaveBaxt's topic in Masting, rigging and sails

Thank you for clearing that up for me and where to get more information. Best regards Dave -

Hounds and Cheeks for Endeavour finished in 1761

DaveBaxt replied to DaveBaxt's topic in Masting, rigging and sails

Thank you once again Druxey for clearing that up for me . Best regards Dave -

As far as I can see form Lees book" The Masting and rigging of English ships of War" for that period the Cheeks extend from the hounds to midway between the hounds and the partners, however l am unsure where the cheeks finish at the tops. Do they extend to the top of the hounds where the trestle trees sit on top of the cheeks, so that the Hounds fit over the cheeks. Or do the cheeks terminate at the bottom of the hounds so that the trestle trees sit on top of the hounds. One other way which looks to be that the hounds are part of the cheeks (Monfeld "Historic Ship Models) Seems there are a few different ways this can be achieved, but what is the most accurate for this period.Best regards Dave

-

Nice to see another recent build log of the Endeavour. Looking good so far. Good luck with this build and I look forward to watching your progress.

- 79 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

terrific looking paint job Anderw. Are you using brushes and or airbrush. If so can I ask what equipment you are using. Very professional. Best regards Dave

- 206 replies

-

- Vanguard Models

- Brixham trawler

-

(and 2 more)

Tagged with:

-

I got my order in yesterday from Timberline and I did what you suggested and gave them a call. A few hours later they returned the call and have added in the 8 mm stock and they have posted it all together so hopefully it should be with me in the next few days. So far they have been a very good service. So once again Thank you No Idea. I am sure others too will be thankful for your heads up on this one. Best regards Dave

-

Thank you Bruce and Sound advice as I am feeling a bit doped up at the moment. Just trying to go over everything I have learned in the last few days. Its like being back at school. Haha.

-

I think he meant a spacer to change the interenal diameter from the FET saw blades 10mm to the diameter of the blades used by a Byrnes saw ,so you can then use their blades. I would be interested to know a bit more about your spacer/adaptor for cutting the Castello Boxwood. I don,t suppose you have a photo ?

-

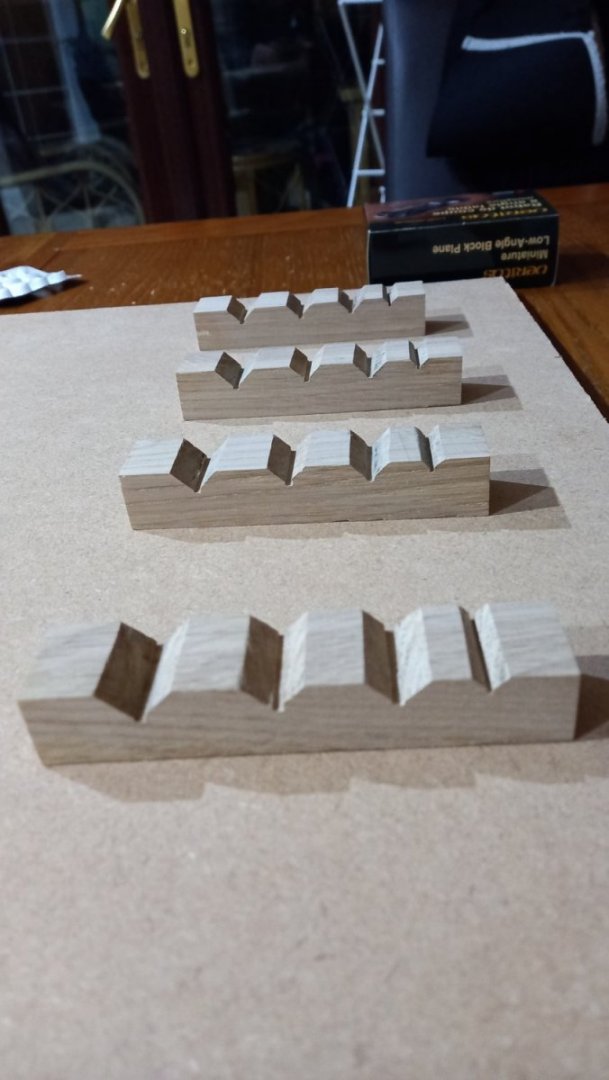

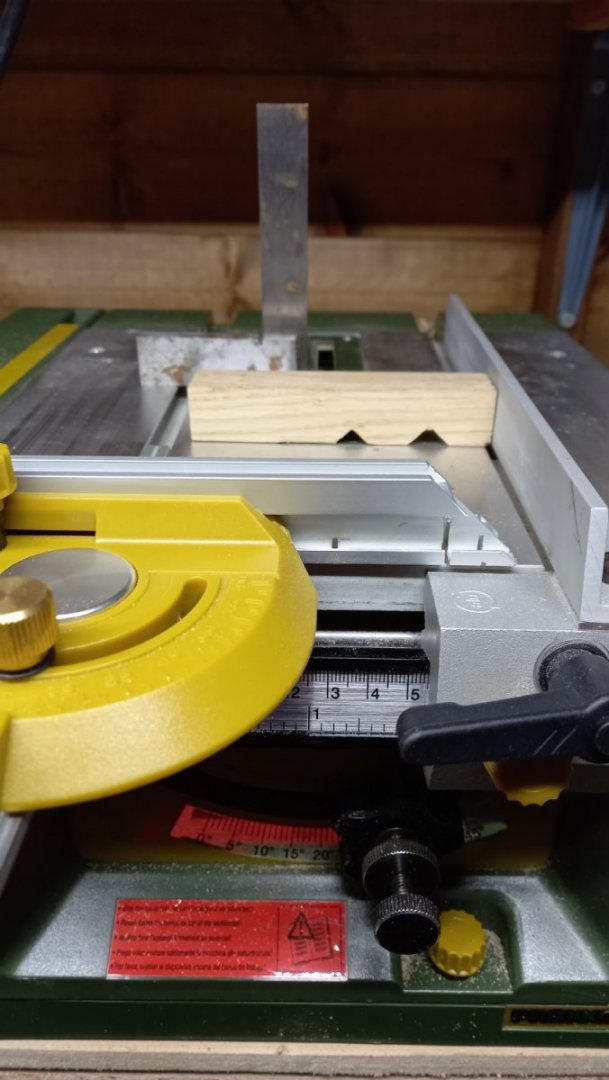

Not been on for a while but haven't been idle. Tried my hand at making the long boat and still working on the pinnace. Not too bad for very first attempt at building such a thing but still want to use Chris Wattons boats when they arrive I have also been looking ahead to constructing the masts and have decided to use square stock instead of dowel and also use castello boxwood which is readily available here in the uk. I have also made a station for turning the square stock into an octagon section and bought myself a decent miniture Veritas plane to carry out the finer work on the yards etc. This is the first time I will have tried this, so hopefully it turns out ok. Here is a photo of my station. It will also double up as a honing station , once my guides turn up for my planes. The 90 deg grooves on the blocks were produced using my Proxxon FET table saw and the long small 90 degree V was produced using the Proxxon 90 deg router head.

-

I will give it a quick run through some wood and see how the square masts sit in there . Maybe I should have tried this before posting this thread and wasting every ones time. However I have no regrets starting this discussion as it has lead me into all kinds of directions and to some great information. For the moment however I have just tested positive for Covid and feeling a bit rough. Fortunately I have had three doses of vaccines so hopefully will be well enough to carry on modelling and it will be an excuse to self isolate in my workshop for 5 days or more. So hopefully something good will come out of this pandemic or at least for me . Best regards Dave

-

Mark I already own this set. However when I measured the angle of the cutter it is quite a bit less than 90 deg. But wondering if it may work anyway ? Thank you once again for all your help. Best regards Dave

-

-

Great stuff and thank you for your help. I have just had a quick look and they offer 40mm diameter which I assume will be fine even though it is half the size of the Proxxon saw blades (80mm) .Best regards Dave

-

-

Fantastic. Just had a quick look at the Castello Boxwood. Lots of data/information. A lot of which went over the top of my head, However a least I can make a few comparisons. At some stage I will need to find out what the different terms actually mean. But once again thank you for all your help. Best regards Dave

-

Thank you once again Gregory. I have just had a quick look and they don,t seem to have anything with a 10mm bore. So unless I have a spacer. I will however do as you have suggested and send them an email and see what they come up with. I do have in my spares a rotary saw blade with 300 teeth . So would this be classed as a slitting saw and could be used for the likes of Castello Boxwood? Just a thought.Best regards Dave

-

Thank you for that fantastic information and something I can now keep for reference. For the record I believe Maple is readily available here in the uk . So I see I could consider that as hopefully a cheaper alternative to Castello Boxwood which I found to be quite expensive , although it should hopefully go along way.. One more question if I may. Is the wood Database on this foorum? Best regards Dave

-

I am assuming you made the spacer on a metal turning lathe . Unfortunately i do not own such a machine but sounds like I could do with a few slitting saws for the Castello wood which I have just ordered. By the way how do you store the wood . End up or somewhere flat. Just want to make sure it doesn't warp?

-

Thank you again for helping me out. Funny you should mention Timberline . I have just ordered some Boxwood from them. I have also be getting quite a lot of help from people who I have been following their blogs. One person in particular has build his mast like in the old days and is truely inspiring and hopefully one day perhaps I will get somewhere near. I might try a search before starting another thread but thanks for your advice anyway . Best regards Dave.

-

Thank you Gregory I will give this a try. I could do with a few more spares anyway and that is so much less expensive than the Proxxon equivalent.. Best regards Dave

-

Thank you Bruce.Thank you for your prompt reply and coming up with a possible solution. Its obvious that I need a lot of practice in the use of this machine and trying your idea might be a solution. The oak was just a give away by a plumber who thought it might be useful. I have other woods at hand such as bass wood. Its is my intention to try lime wood for my masts but eventually thinking of moving onto box wood but the postage fr om Europe to the UK is very expensive. So need to wait until I know how much I need, hence using the lime as a trial run, plus I need the practice. Thank you one again for your time and patience. Best regards Dave

-

I apologise for adding more questions to this thread and sorry if this question has been asked elsewhere. When using a Proxxon FET table saw for cutting 45 deg slots I am getting quite a bit of burn. I have tried a medium cutter wheel and a low teeth cutter which has a cutting edge on the side too. Even when cutting at 0 degs I am still getting some chatter,I think its called. Is this purely down to cutting to0 large (20 mm ) a piece of oak , which I think is a very hard wood.Perhaps its just too much for the machine or should I use a different cutting wheel, perhaps with more smaller teeth. I am hoping if anyone has experience with cutting oak or using a Proxxon FET saw. Best regards Dave

-

Thank you for the above. I think I get your meaning and I ended up trying something similar, So perhaps I wasn,t accurate enough with measuring the blocks and I did each one seperately and may not have applied the same pressure on each block. It may have been esier if I made individual blocks instead of grouping them all together. I don,t think the 45 deg setting was bang on either.I ended up cutting a groove in the bottom of each slot using a miller.I clearly need to have more practice at using my Proxxon FET table saw as there are probably no end of different applications. Again I would like to thank everyone for time and patience. Best regards Dave

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.7e38c54e98b50544c3a1f9aa2830a35c.jpg)