Mike_H

Members-

Posts

240 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mike_H

-

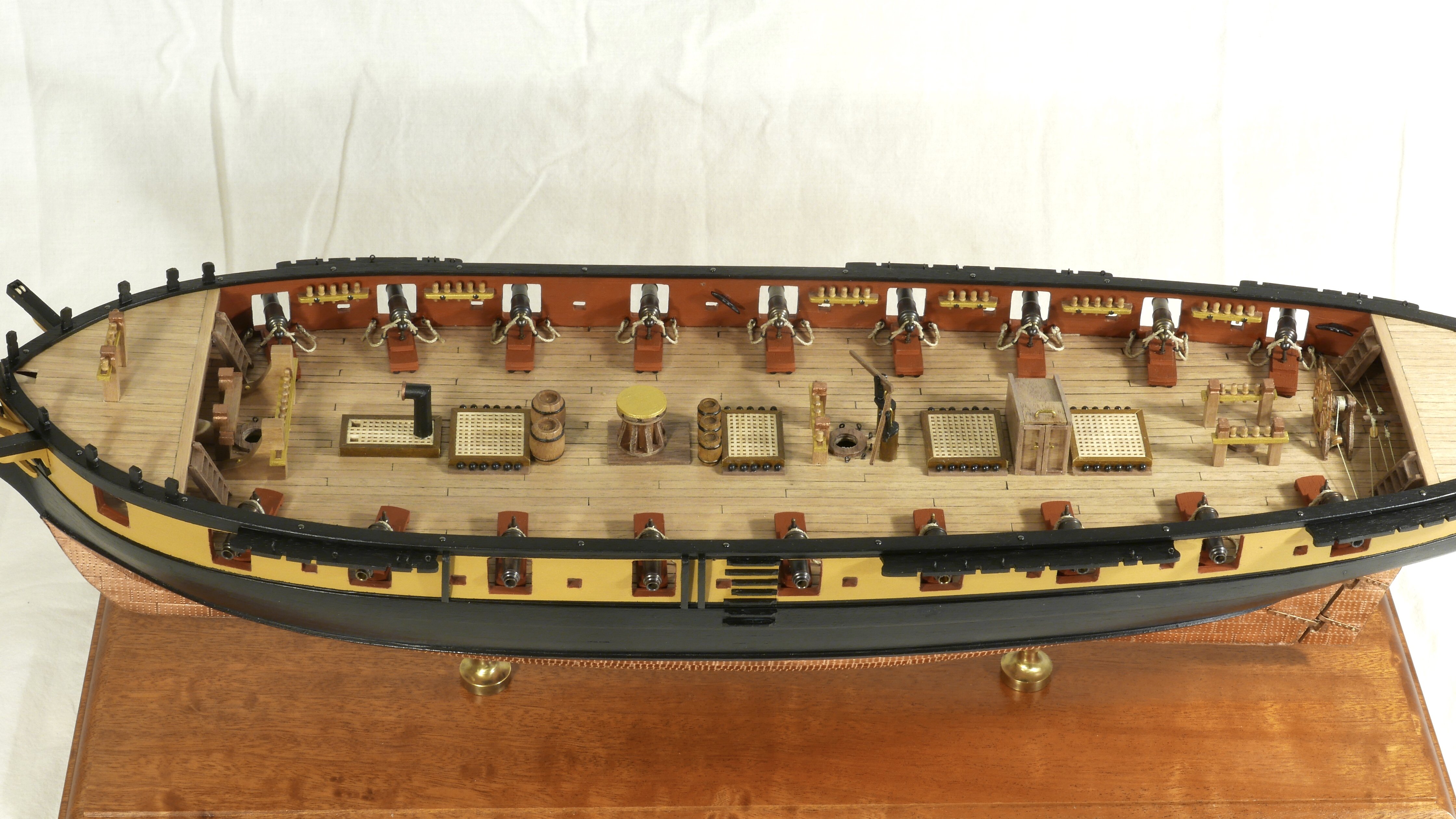

A few steps forward, a few back, and then some more forward. Finished the planking inside and out. Cut out the gun and sweep ports. The eagle-eyed might spot that the waterline batten is gone. I had placed it using the supplied drawing, matching the position at the cut-water. The more I looked at it, the more convinced I was that it was too high. Checking agains the rudder it really was apparent at the stern. So off it came. I also realised that I hadn't quite got the line of the port main wale right at the stern (not sure how). Anyway, with much trepidation I trimmed off a lower portion and spliced in a wedge-shaped piece at the top. To my great relief it worked fine. Lessons: pay more attention, and don't be afraid to remedy a mistake. Here she is with the outboard bulwarks painted yellow ochre, and then masked up for the red and black to follow. And here she is all freshly painted. Now on with the deck planking!

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

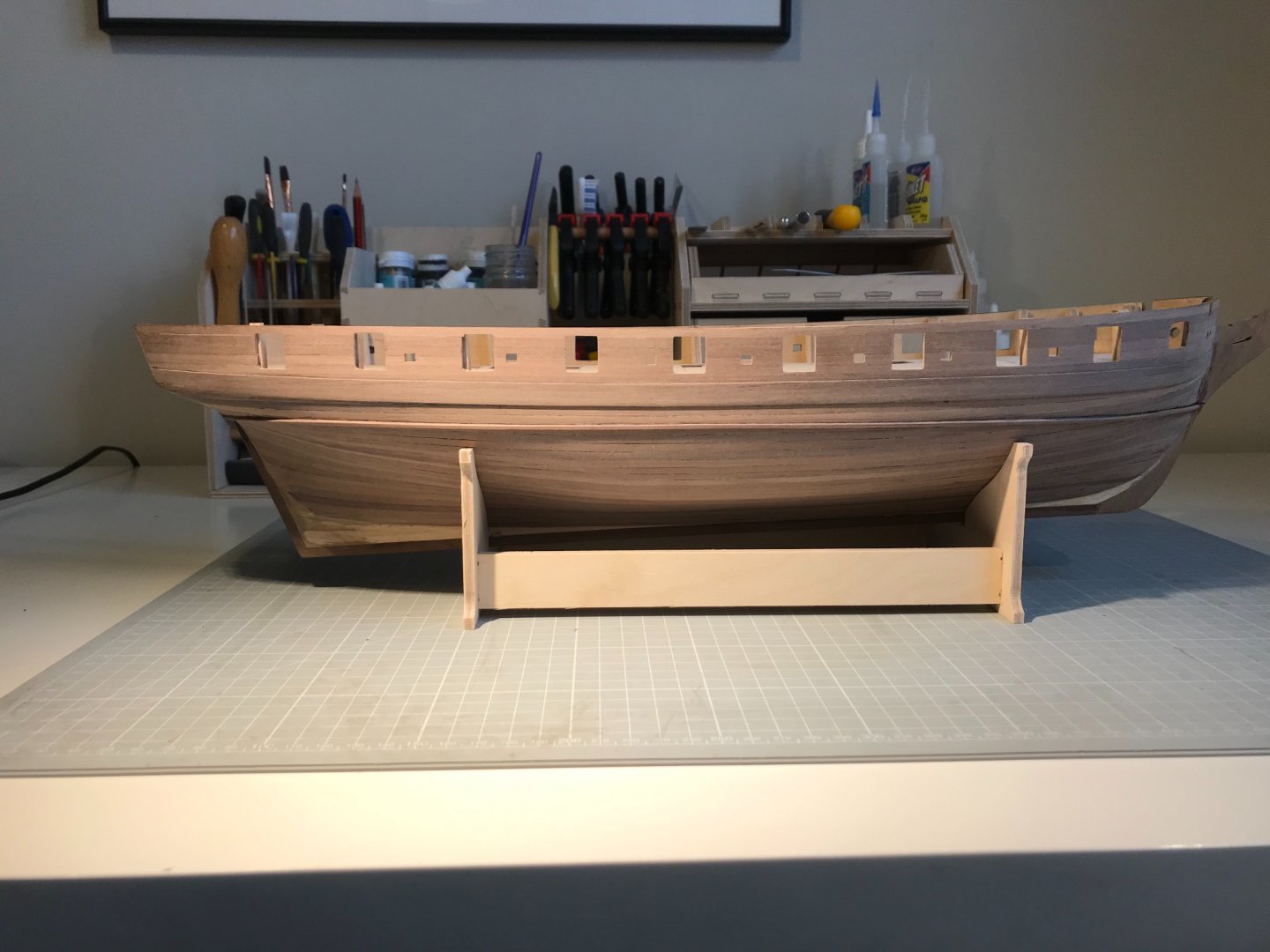

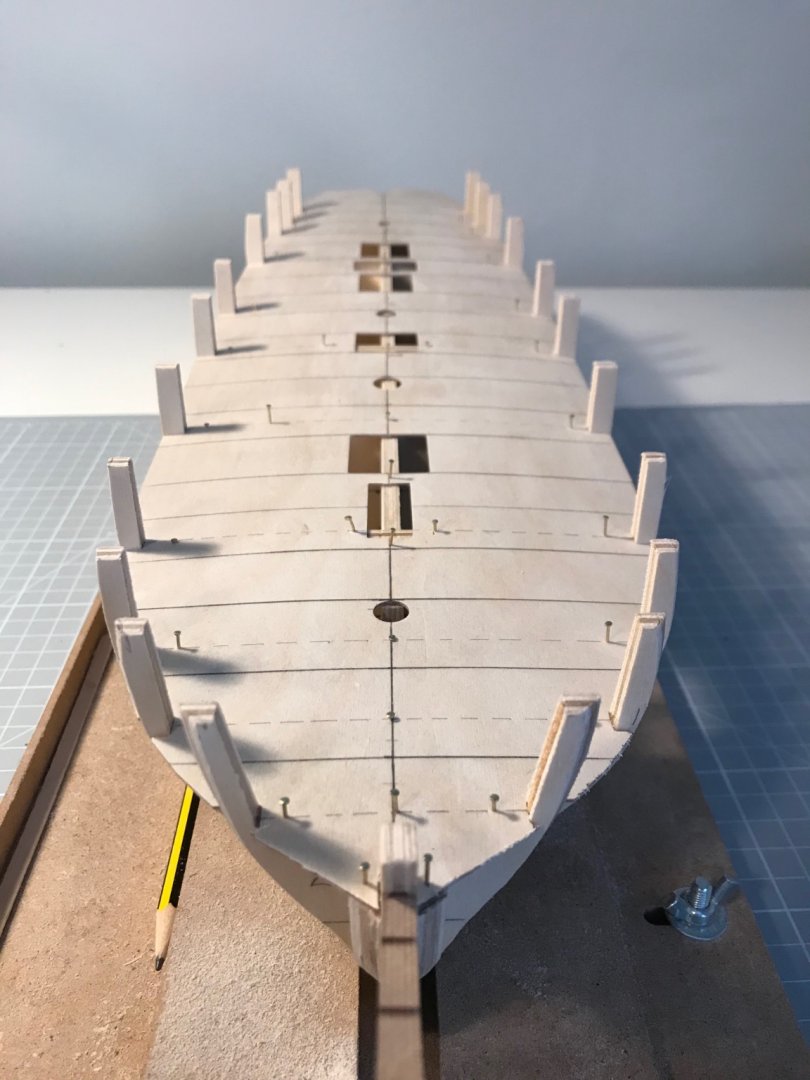

Holidays, 0ºC, occasional snow. Excellent for progress. Main wale, and water-line batten fitted. Hull sanded. Bulkhead extensions cut through and plucked out (images of self as Stephen Maturin dealing with rotten teeth) Bulwark inner planking largely done.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Breath-taking, as ever, Jason. I need to install the catheads in the nearish future and was wondering whether to drill them out. I see you have gone beyond that, but apart from the end of a pin proturding I cannot see what you have done. Is there a sheave in there?

- 800 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

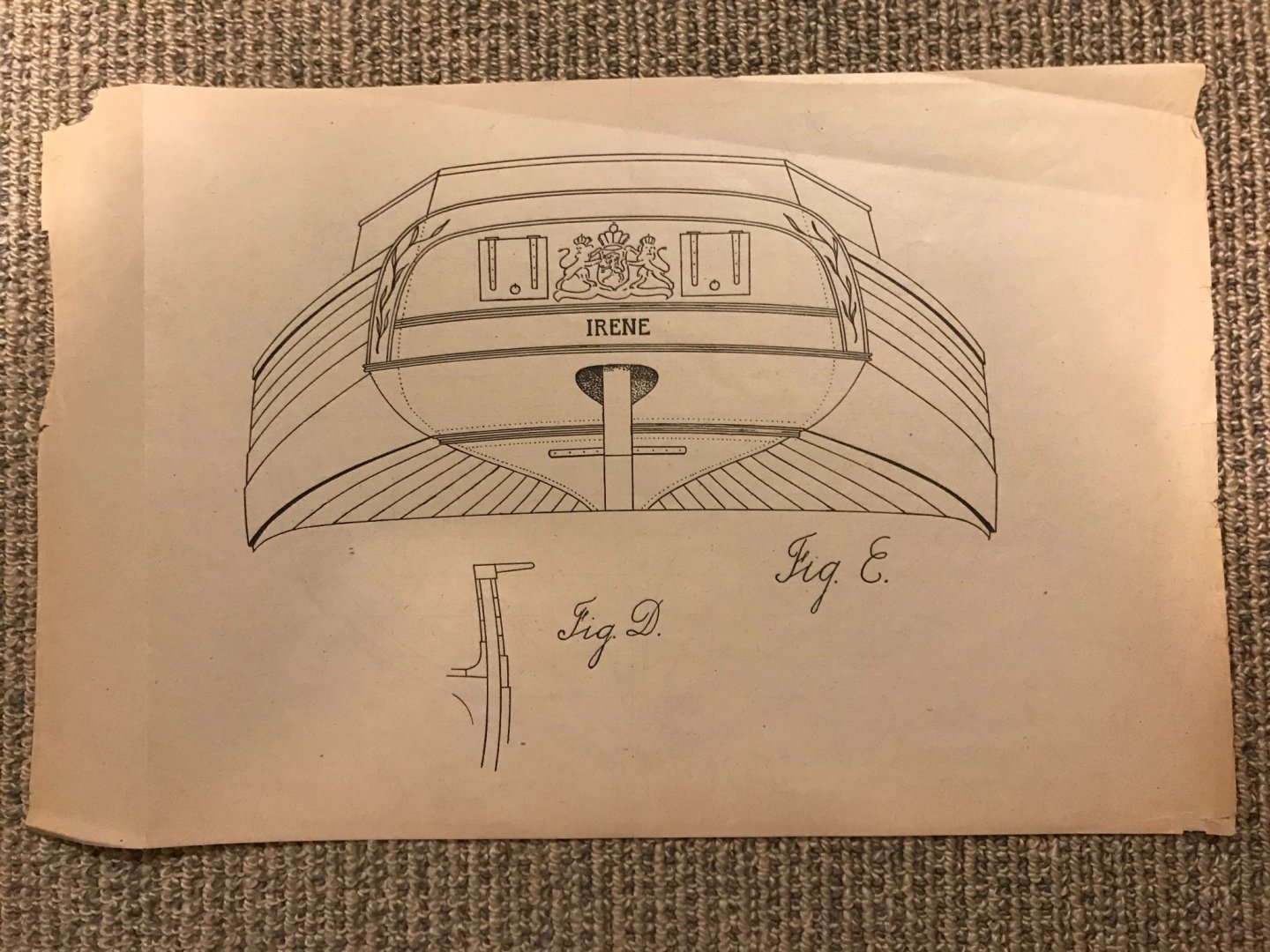

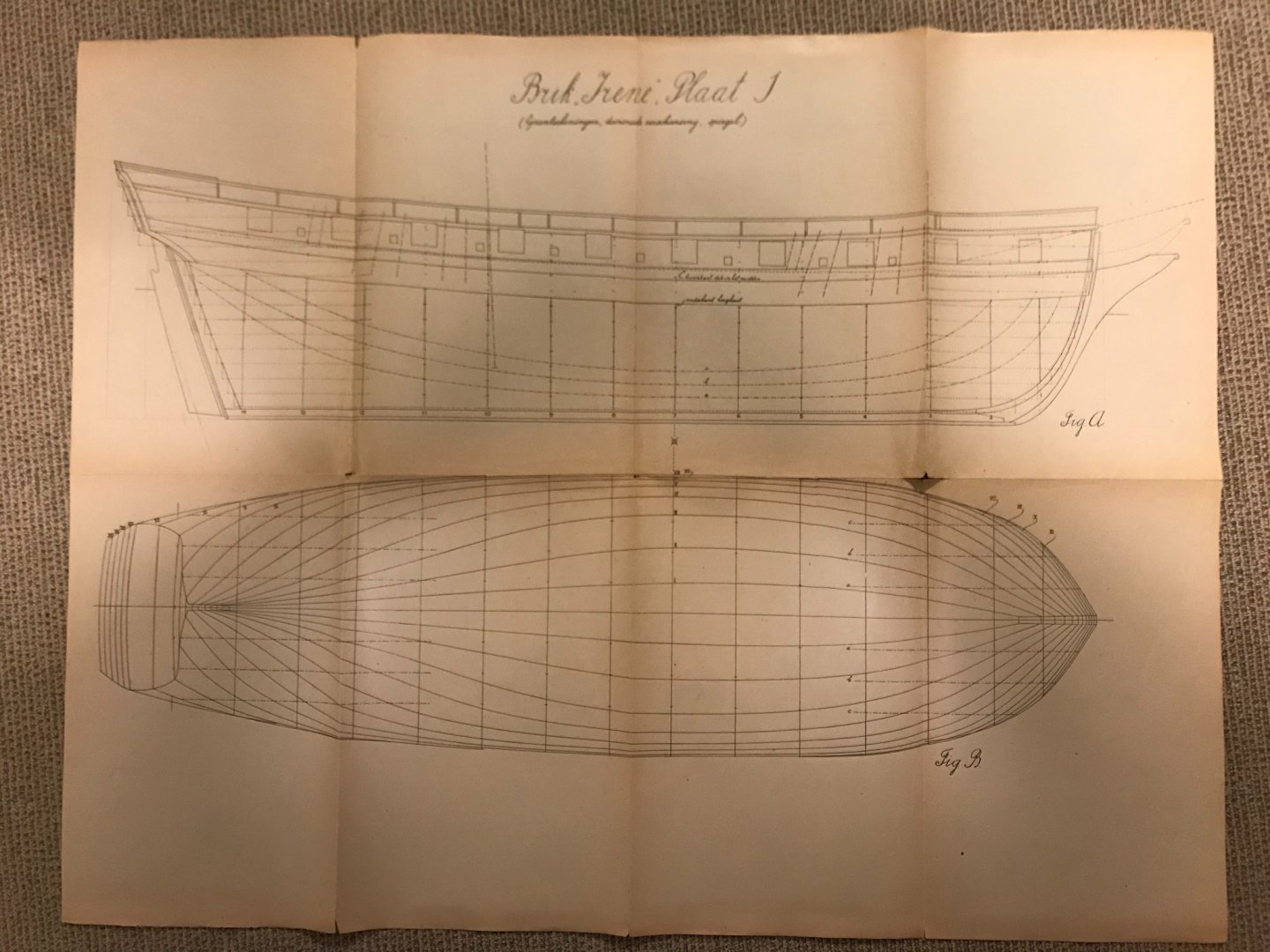

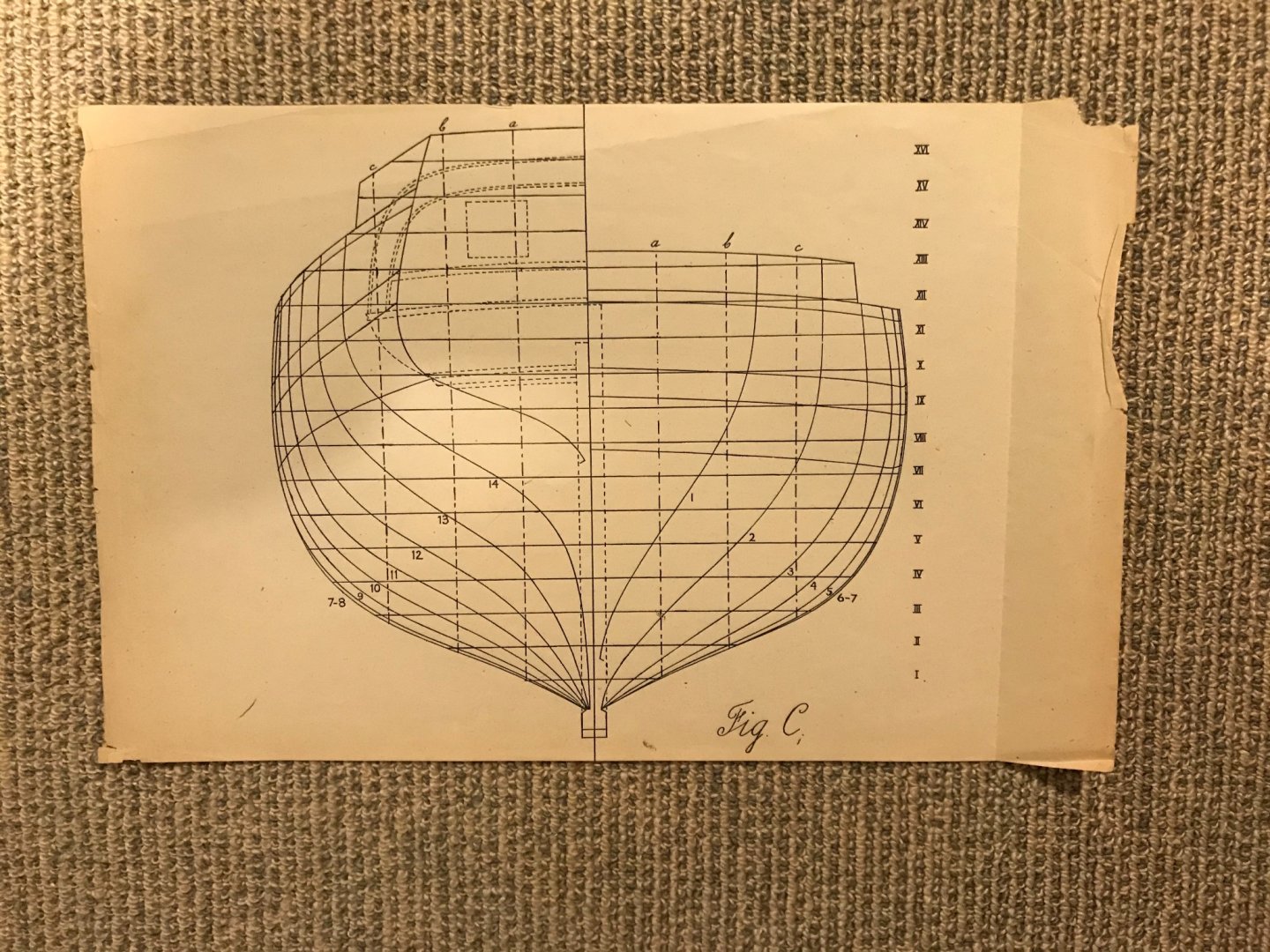

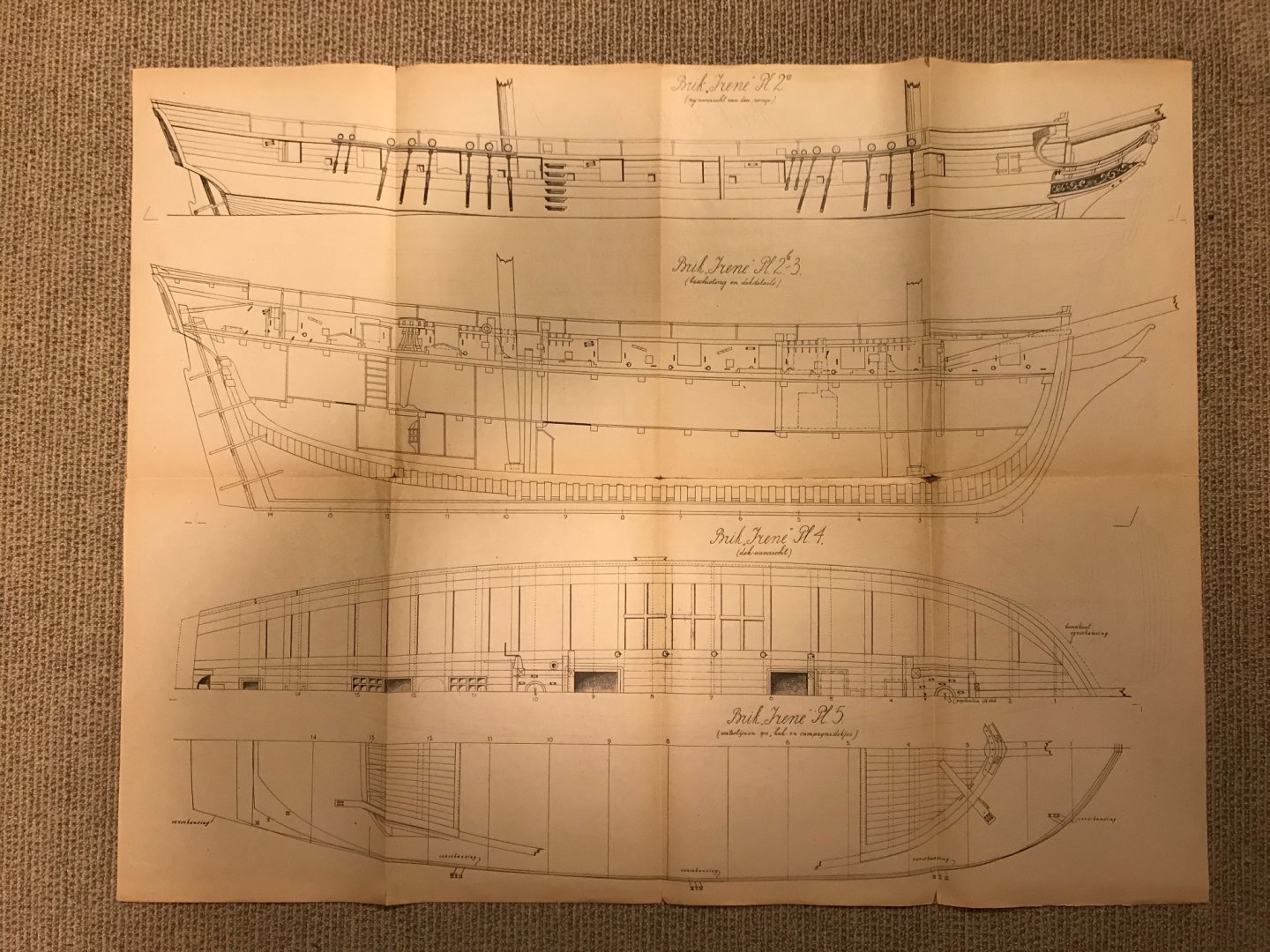

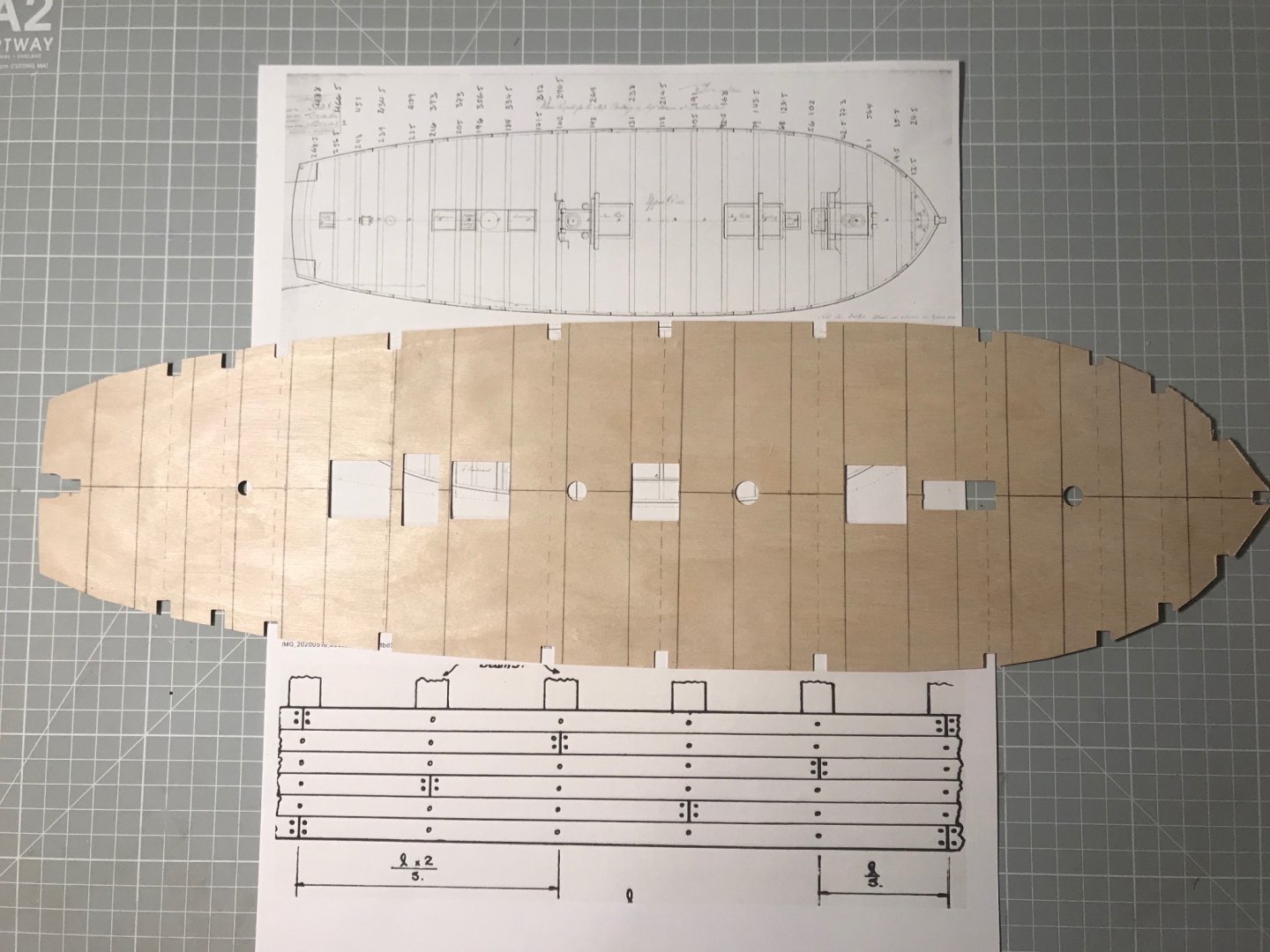

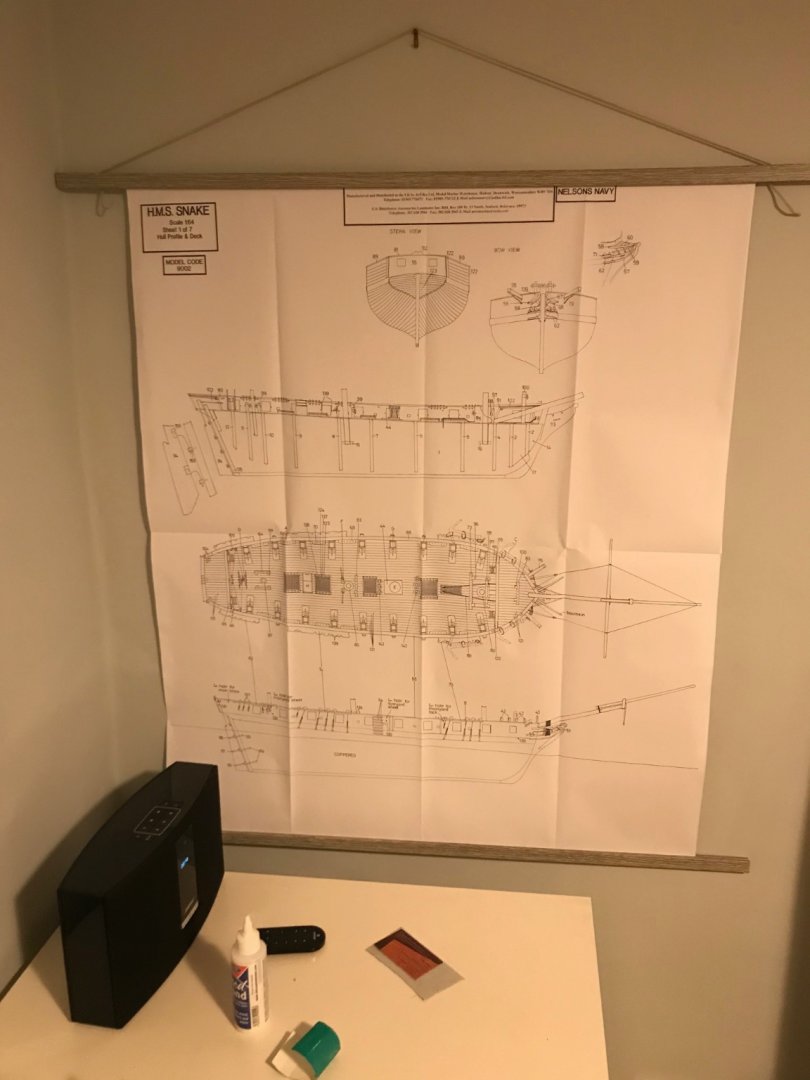

Well, I knew there were some plans slipped under the dust jacket, but I only got round to checking them today - what glory!

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Christmas brought new storage and relocation of the Shipyard. Hull pretty-well sanded now. Fitted the keel and sorted out the display stand. Feels like it will be some time before it's needed. And marked the water-line.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

HMS Snake by Liam - Caldercraft - 1/64

Mike_H replied to Liam's topic in - Kit build logs for subjects built from 1751 - 1800

Hi Liam. I’m building a Snake at the moment, a couple of hundred miles north, and about 2 months ahead of you. You can see my build log here: I give some links to some builds more advanced in time and knowledge than me. They are well worth browsing if you haven’t already. I’m having a great time, and learning a lot. Have fun. Mike -

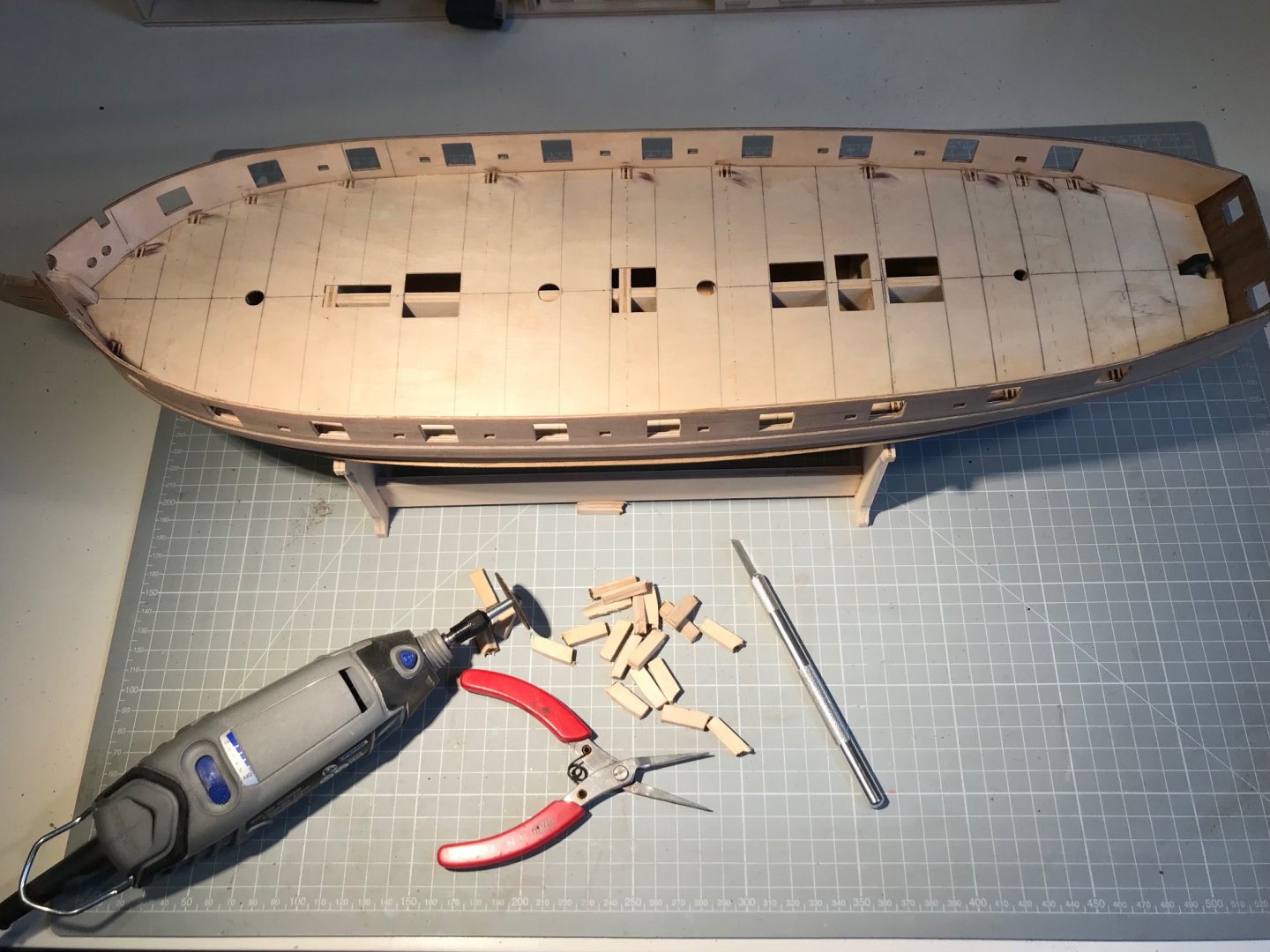

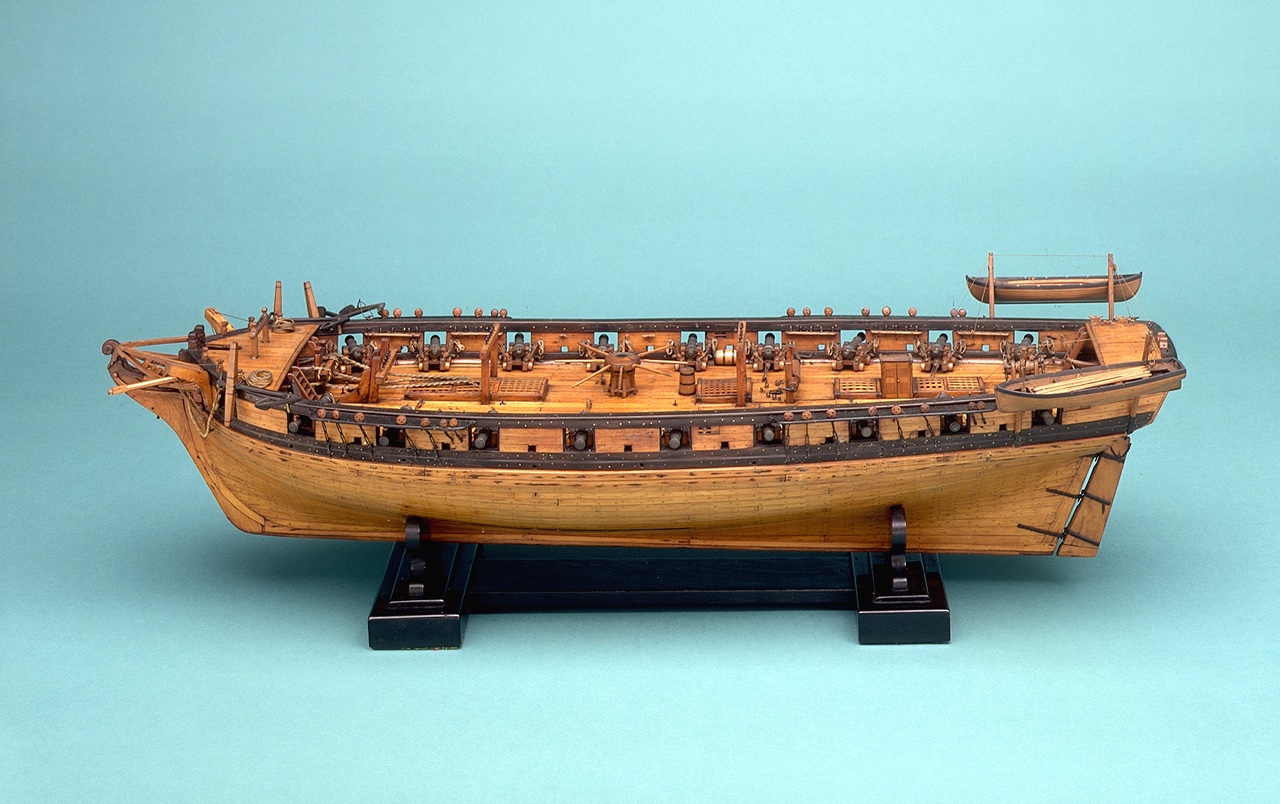

So, been planking. This shows the results with no sanding yet. I spiled with some care down to the waterline, and set a sheer line using a thin thread of masking tape. I had planned to stop there and just slap them on, but thought this a good opportunity to improve my skills so carried on. I really should have put in another line at around the belly of the hold - but, well, I'm going to copper them, so thought I'd just use the one plank geometry and as a consequence the line of the planks is not quite as graceful as I would like . I inserted a couple of stealers, and I think it came out neat enough. I didn't plank the stern first, as I want to add the stern post and the keel after I have sanded - though I think it would look better to have the side planks ( there must be a technical term for those) overlapping the stern planks. The Cruizer brig model in the NMM (photographs above) has a neat solution, but I'm not sure that I could execute it accurately enough. We'll see. I do regret not cutting a rabbet at the prow (or should I say stem?) since gluing the planks there was challenging - sanded, filled and painted or coppered probably means it does not matter. I am pleased I did not cut a rabbet along the line of the keel or seek to plank the deadwood on the false keel as once sanded I think the lines will be smooth and pleasing to the eye. The two holes showing on the false keel and the hex cutout s around them are for a pair of M3.5 machine screws that will attach a pair of brass columns once the hull and deck are done. A pair of hex nuts will sit in the holes and be held captive between the keel and the false keel. It was fun getting the spacing on the holes right (genuinely; and if you didn't enjoy that kind of fiddling around, model ship building would be a challenge) to give the keel the correct dip, and drilling the holes at the correct angle, was similar fun. The only unknown is by how much the thickness of the second planking has changed the overall "elevation" of the keel on the columns since the planks are at different angles at the two hole. I won't know the answer until I've sanded. I think the sequence from here is cut out the gun and sweep ports (possibly cutting our a couple of frames where they get in the way) . Sand the planking completed so far. Fix the keel and sternpost. Plank the stern. Sand some more.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Quite remarkable rigging and photography, Jason.

- 800 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Joe, I suspect your advice to track down Petrejus's book could be the best piece of advice I get in this whole build! Copies are few and far between in the UK- expensive and usually missing the large plans. There was one on ebay - at half the price of most suppliers. So I bought it half expecting it to be any or all of: in Dutch, falling apart and missing pages and plans. It arrived yesterday in close to pristine condition, all pages and plans intact. And, to my relief, in English. Not only is it entertainingly written and illustrated, it is a fount of detail. I am now much more relaxed about doing the rigging - though that is some time away at the moment.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks. Sadly, I think AL have gone bust, certainly no-one seems to stock their stuff at the moment. I think I can adapt what I’ve got, or alternatively I’ll get some time on a lathe at work and make my own, and then either learn how to use a modern milling machine or ask a friendly tech to mill a slot in the top

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks Joe. Your Sophie looks a treat. I tell myself not to obsess about correctness - after all there were so many of this class, there is no correct. And really correct is 64 times bigger. However, every time I see something that wouldn’t work in a model it winds me up. I will be searching for “Irene” straight after hitting return!

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I'm happy with the planking. Could have done better in a few places, but sanding and a fairly modest mount of filler should fix that. Decided to plank the stern counter as the simplest way of closing up with the hull planking. It also means I can repair a flaw in the curvature of the counter. Apart from trimming the planks at the stern to get at the counter, and the counter itself, I've not sanded anything yet. I have not fully planked the false keel as an alternative to rebating the planks. I'll see how that goes. I soaked the planks and was surprised to see how much they swelled, and then shrank on drying. Thinking that I might pin the second planking (Horror!) as it will all be painted or be beneath the copper - would welcome views on that.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

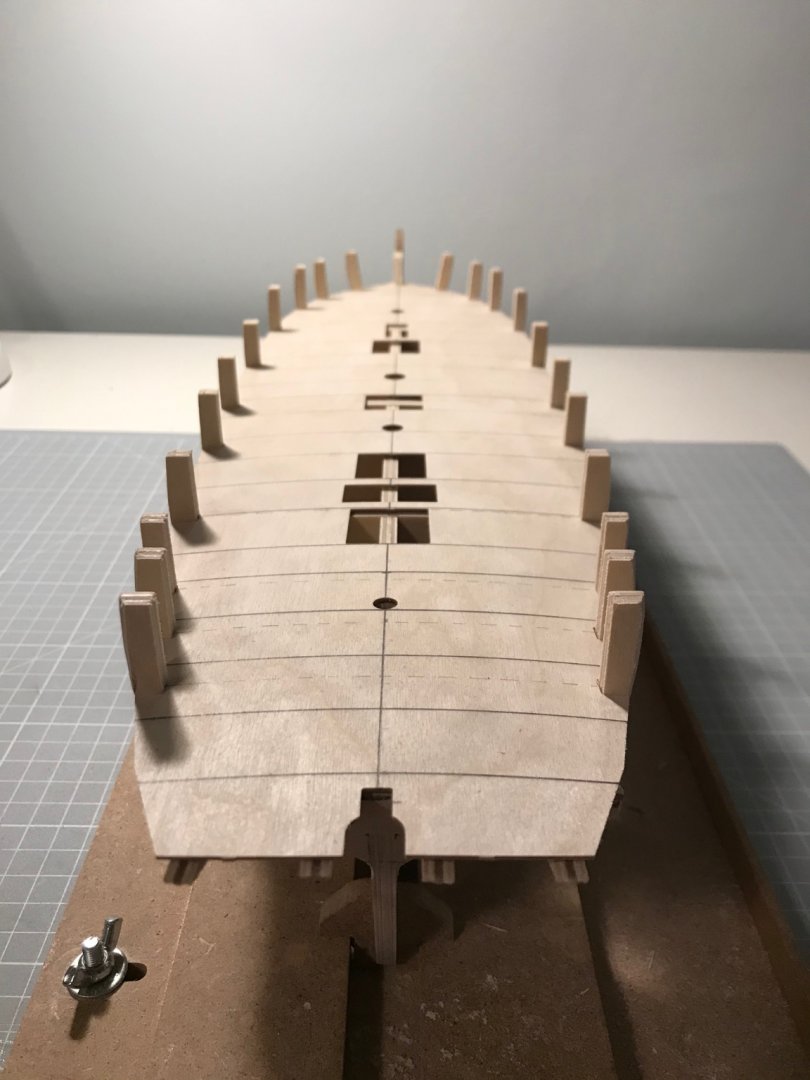

Fair bit of progress in the last few weeks. Bulwarks fitted and first planking done. I soaked the bulwarks for a couple of hours and then formed the round a conveniently shaped bowl. Clamped and glued them without too much difficulty. Was obsessively concerned with making sure the ply of the bulwarks extended down to the deck ply so that it could bond to it, since at this stage it's hard to believe that once the bulkhead extensions are snapped off that there would be much attaching the bulwarks. For this reason I didn't pin them since the tumble-home curvature would have pulled them away from the deck (I worried). Actually once it's glued on it feels very solid, and once the first planking is done, it's hard to see why I was worried. If I did it again, I'd pin to allow easier positioning.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi Jim. Just had a look at your log, and your Snake looks a beaut. And there is a nice symmetry to me starting and you slowing - our youngest has left home and now I have her room as my work area. And since you offer, I have a question. Your Snake is mounted on a display board by brass columns. These all look remarkably similar to the Amati products that I have just bought from CMB - I plan to install a pair of captive nuts under the keel (which might have been your idea, I certainly saw in somewhere on this site). An issue with the Amati columns is that those of differing heights are also of differing diameters. Did you use Amati's and did you use the differing sizes? Do they look OK. Or did you find another source?

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Your rigging is a sight to behold, Jason. Well the whole build is, really. Keep posting so we can watch an learn

- 800 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I gave quite some thought to planking before fitting (it was suggested in one of the downloadable manuals from Jokita - not for Snake though). Decided not to, mainly because the deck has quite a camber which varies fore and aft. Planking while the deck was flat would make it very stiff and I don't think it would bend enough for installation. It might be possible to set the deck up in a jig, but given how tight a fit it is, I wasn’t willing to risk it. As Jason says, there is pretty good access once installed.

- 800 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks Jason - started the planking today - need to take it slow, but it’s going well.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

While waiting for glue to dry, I was looking through the NMM collection of photographs of models, specifically to take a view on layout aft of the mizzen. I found no Snake, or three masted sloops of the Snake vintage. There are quite a number of models of ship sloops from later in the 19th century, but they are typically quarter-deck sloops. However searching through brigs I came across this: https://collections.rmg.co.uk/collections/objects/66309.html which looks very, very familiar. The accompanying text says that "the design and layout suggest ... one of the... 'Cruiser' class", of which the Snake is, of course, a member. Is very useful for my purposes, and interesting to see the size of the platforms. To my eye the aft platform on the model looks smaller than as provided with the Snake kit - and I will look to adjust. Also to see the two boats on davits - which look relatively easy to retrofit - so I might. Being brig-rigged there is no direct information on the layout around the mizzen, but I'm surprised to see no obvious binnacle. Edit: just been browsing and @Beef Wellington was there 7 years before me with the model from the NMM. I must have seen it when I first looked through his log.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

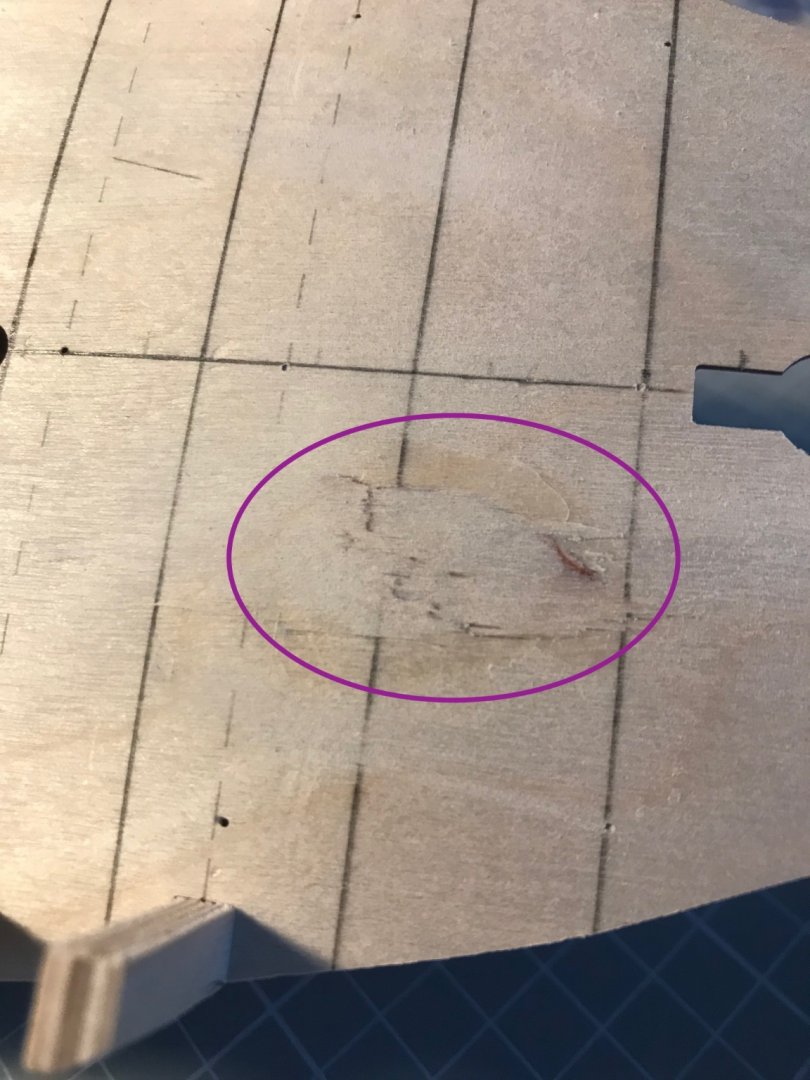

And so here comes the calamity and the consequence of the slight kink in the level of the false keel, or rather, the other way round. When doing the first rough sanding of the bulkheads I did the inevitable present-a-strip of planking, and something towards the stern was not quite right. At first, as many who have come before me have said, I thought frame 9 was toolow. But after prodding it for some time I came to the view that in fact frame 12 was too low - which I now attribute to the false keel being slightly too high at that point. Anyway this shows clearly enough that on a smooth curve, the strip sits away from the frame. But there's a simply remedy to that. Attach a couple of strips of wood either side, sand down to the correct thickness. Easy. But not quite. The tightness of the curve meant that the strips needed to be pinned in place, and, for whatever reasons the pins did not want to go in (I have a theory that 0.5 mm diameter in wet wood was not large enough, or that I was cocky after the success of drilling and pinning the deck), one of the pins bent, the PIN PUSHER SLIPPED OFF THE PIN, DOWN THE SIDE OF THE BULKHEAD AND SMASHED A HOLE THROUGH THE DECK. I may have called out as the Admiral came running upstairs to enquire after my health, and when I explained, she asked what the second noise was - err, throwing the tool across the room. I was so distressed I couldn't bring myself to photograph it until I was half-way through repairing it. The result was a jagged hole about 20 x15 mm with the layers of ply torn apart. I pulled most of the plies out, coated each with PVA, re-inserted them and then clamped the whole mess between two piece of scrap, each wrapped in sticky tape. The result, amazingly, is this: Lucky boy - larger drill bit next time, and a gentle touch with the pin pusher. So to complete this post, the extra thickness on frame 12 has done the job,

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

And what is this calamity? I'm coming to that, but before I do there is the vexed issue of deck planking layout. As @BenD explains, the original ship did not have evenly spaced deck beams, and if you look at his, or just about anyone else's logs, having the joins in the deck planks line up gives a very pleasing effect, but they are meant to line up where the beams are. So, choose an arbitrary beam spacing - and then struggle that the implied positions seem to go straight through the hatch openings - or try to recreate the original? I printed out the plan from the NMM (or RMG as they want now to be known - bah!). Measured the distances of the beams from the bow then scaled that to the length of the deck of the model. For the fore-part of the ship that worked just about perfectly and the lines drawn on the deck below are pretty-much what I calculated and give excellent registration with the hatches and masts. The beam at the main mast was a little off and things got further off from there on. However a little bit of adjustment gave a reasonably uniform pattern as shown. With 22 spans and a deck length of 32 m, that gives a span of 1.45 m, and using the 1-3-5-2-4 pattern shown, that's an average plank length of 7.27 m or 23.9 ft, which the historians on this site seem to think reasonable So, deck marked up, I'm good to install Fits tightly, but well. Doesn't lie snug against the bulkheads without downward pressure, so at least 3 pins per are needed. Which is a lot of 0.5 mm holes to drill, and I only have one drill bit. Fortunately there's a tool for that: It's an attachment for a Dremel - or should I say the Dremel is an attachment for it - making what I would call a drill press, or the English, a pillar drill. 33 perfectly vertical hoes drilled, no bits broken. Compare with my last project where I went at about one broken bit per hole, this is progress. And there they are. Note, I put in a few extras without drill, and each went in crooked emerging from the side of the ply bulkheads

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

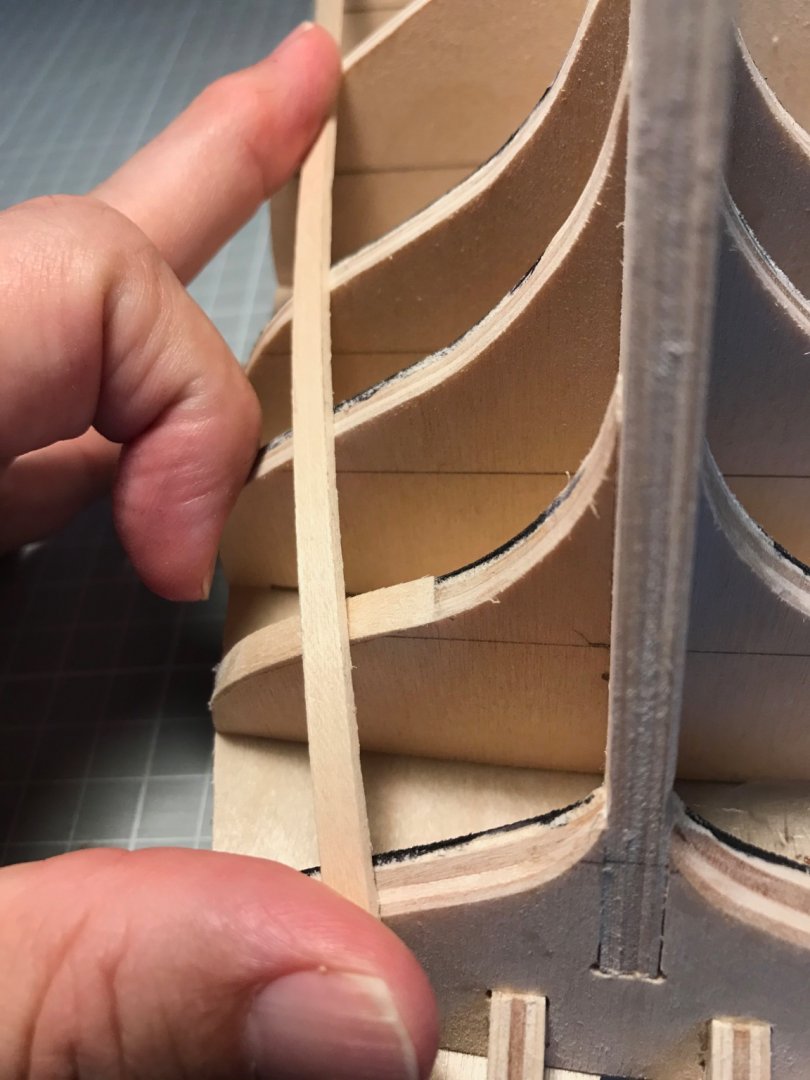

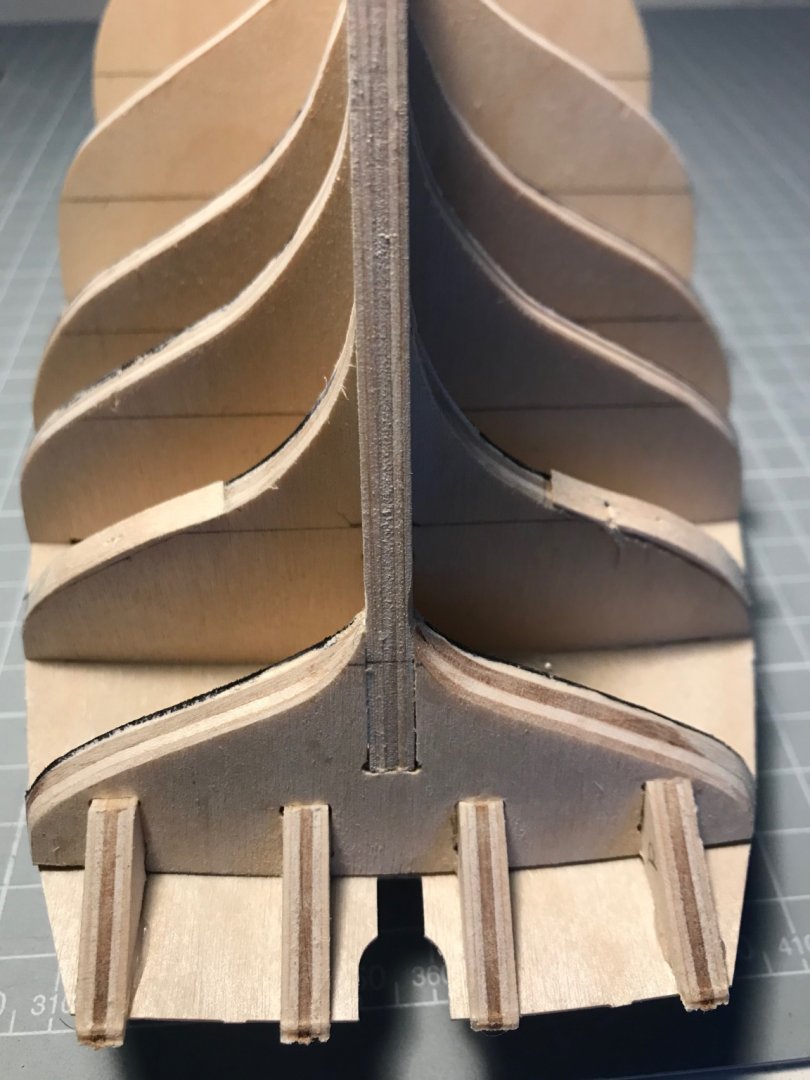

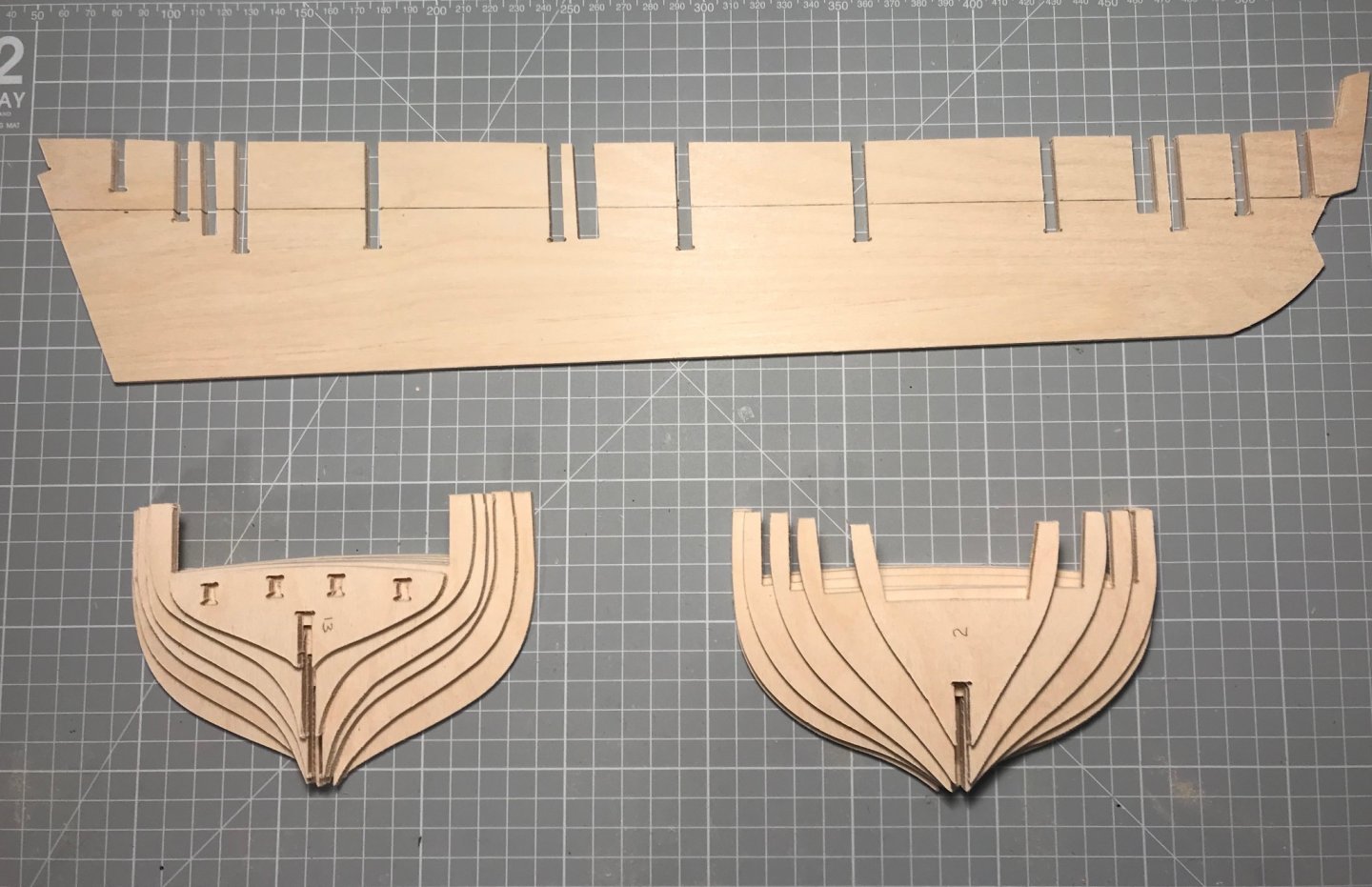

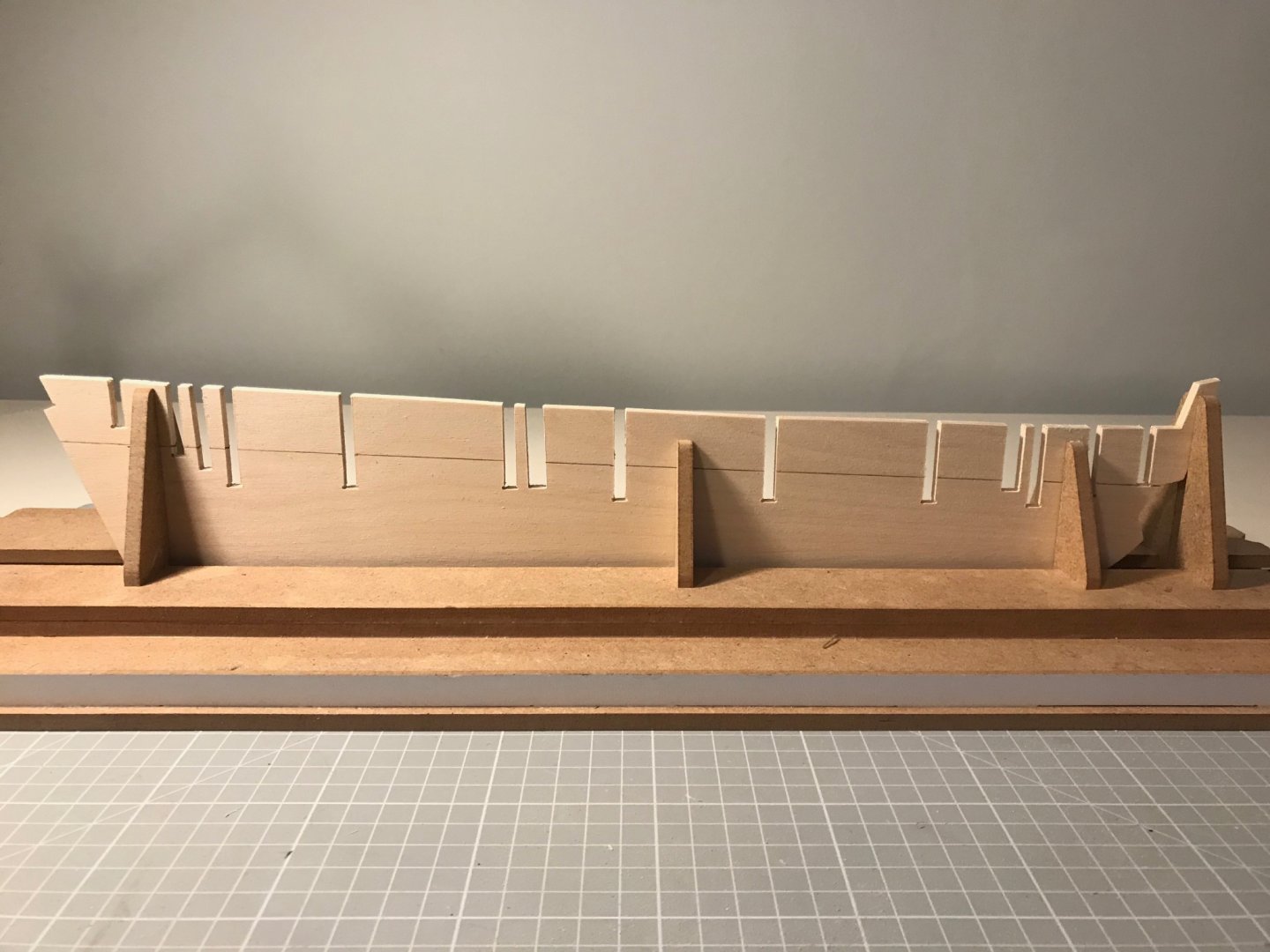

Some progress and one calamity to report. Cut out the keel and bulkheads - all very nicely machined, perfectly flat and reliably symmetrical. The slots were all slightly too tight even to dry fit, let alone assemble with glue. An hour with a file sorted that almost without problems. You can just see in the images of the (false) keel that it has a slightly surprising change of slope along the top edge around the aft vertical bulkhead (12). Wish I had noticed that before, as will become apparent. I say almost without problems because with a file 15 cm long crating exactly flat and square surfaces is beyond my craft skills so a couple of the bulkheads didn't fit exactly square. Loosening them up a little more to give some play, clamping them with lego blogs (duplo in fact), and and checking that every angle was right, very often, in all all directions, (a geo-liner is the tool for that), and then when gluing them planning to do it in such an order that you can get in and check those angles are 90º did the trick. As I found on my first build, get this wrong then, at best, you have a load of fiddling ahead of you. Attached the fore and main mast alignment blocks (both of which has to be trimmed to fit between the bulkheads-, then glued the bulkheads to the keel (with all the care I can manage) and installed the plank termination patterns and the stern counter frames. Cranked up the Dremel and sanded... a lot!

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

HMS Snake by BenD - Caldercraft - 1:64

Mike_H replied to BenD's topic in - Kit build logs for subjects built from 1751 - 1800

Excellent, thanks - more work for the Dremel. -

HMS Snake by BenD - Caldercraft - 1:64

Mike_H replied to BenD's topic in - Kit build logs for subjects built from 1751 - 1800

Hi, wonder how your Snake build is coming on? Your build log is my goto for foreseeing challenges. And I will post later today about my internal debates on how to lay-out the virtual deck beams which you will find very familiar. And I think I'm about to carve a rabbet on the bearding line, so thought I would get your opinion on something. It looks to me that you 2nd-planked right down to the keel, stern post and prow, but I can see your rabbet at the stern sits at the bearding line. My concern is that the copper plating clearly has to sit directly on the stern post to give a good match to the rudder, and I think it makes sense that the plates should fit direct on the keel and the prow. So, I think your approach was to carve a rabbet deep enough for the first, lime-wood planks, and at the stern that followed the bearding line. How did you then finish the second, walnut, planks to leave them flush with the stern post etc? Thanks in advance! -

Just dropped in as part of preparing to build Snake (following your visit to my log). Great to see you resolving your issues leading up to planking. I'll focus on those for a bit. Mike

- 102 replies

-

- cruiser

- caldercraft

-

(and 1 more)

Tagged with:

-

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.