-

Posts

325 -

Joined

-

Last visited

About Gabek

- Birthday 06/21/1961

Contact Methods

-

Website URL

https://sites.google.com/view/hms-triton-ship-model/home

Profile Information

-

Gender

Male

-

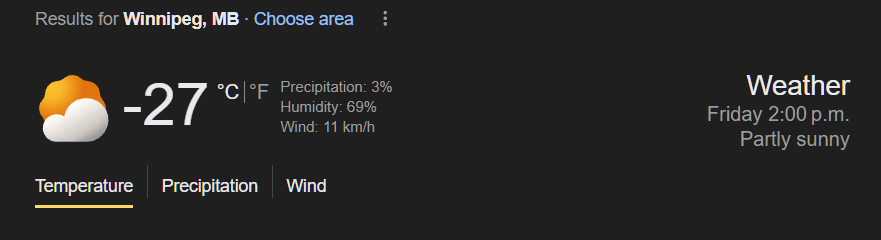

Location

Winnipeg, Canada

-

Interests

Fishing, painting figurines (Warhammer), wood carving, fly-tying, reading, baking (cheesecakes a specialty), turning pens. Newest hobby: 3D resin printing (I love it!)

-

Gabek reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

Gabek reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

-

Keith Black reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

Keith Black reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

-

AON reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

AON reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

-

Just wonderful work, Bruce! Waiting for the reveal of the entire model in display! Clear skies and sharp tools! - Gabe (Although, we both know what clear skies in January on the Canadian prairies really means)

-

Gabek reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

Gabek reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

-

Gabek reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

Gabek reacted to a post in a topic:

St Roch by Lecrenb - 1:48 scale - RCMP Schooner rigged as schooner c. 1930/35

-

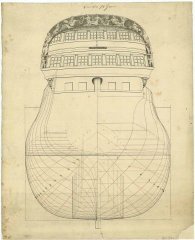

Triton by Jerzy

Gabek replied to Jerzy's topic in HMS Triton - 28 gun frigate's Cross Section Build Logs for HMS TRITON

Beautiful work, Jerzy! But I have to laugh a little. It has warmed up a little since this morning (-32C): Clear skies and sharp tools! - Gabe -

Gabek reacted to a post in a topic:

Triton by Jerzy

Gabek reacted to a post in a topic:

Triton by Jerzy

-

Gabek reacted to a post in a topic:

Triton by Jerzy

Gabek reacted to a post in a topic:

Triton by Jerzy

-

thibaultron reacted to a post in a topic:

The Matthew c. 1497 by Gabek - 1:175 - Resin/3D-printed - plans from Matthew Legacy Project

thibaultron reacted to a post in a topic:

The Matthew c. 1497 by Gabek - 1:175 - Resin/3D-printed - plans from Matthew Legacy Project

-

Gabek reacted to a post in a topic:

The Matthew c. 1497 by Gabek - 1:175 - Resin/3D-printed - plans from Matthew Legacy Project

Gabek reacted to a post in a topic:

The Matthew c. 1497 by Gabek - 1:175 - Resin/3D-printed - plans from Matthew Legacy Project

-

Introduction With my son nearing the completion of his Masters degree I decided to build a ship model for him. Being a Canadian boy named Matthew, what better ship than The Matthew - the first documented European ship to land in North America, as a gift. I have taken pictures of the whole journey but I didn't post them. Time was short so I blasted through this build as fast as I could. I did, however, create short videos for the model group I belong to: The Model Shipwrights of Niagara. I will post these short videos rather than a painstaking day-by-day log and will respond to any and all questions with additional pictures if necessary. I hope you enjoy. Clear skies and sharp tools! - Gabe K.

-

Casks - hollow with separate head (lid)

Gabek replied to Gabek's topic in 3D-Printing and Laser-Cutting.

Glad you are using them, Tillsbury! Please send a photo when you have them installed. Sharp Tools and Clear Skies! - Gabe -

Bravo, Michael! Very nicely done in every aspect. Encore! Encore! Clear skies and sharp tools, Gabe

- 61 replies

-

- Agamemnon

- Ardent-class

-

(and 2 more)

Tagged with:

-

Great job, Bob! Can't wait to see her in person on my next visit! Clear skies and sharp tools, my friend! - Gabe

- 207 replies

-

- vanguard models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Heyo folks, I haven't really done much with the model, but I took a step towards my final presentation: I created a YouTube livestream and a companion website: https://sites.google.com/view/hms-triton-ship-model/home I still have more grandiose plans for the final product, but I have to settle for this for now. For one, I would like to slow down the turntable! I hope to actually work on the model and post an update soon... Clear skies and sharp tools! - Gabe

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.