JohnN

Members-

Posts

60 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Freddy Hutson reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

Freddy Hutson reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

-

Freddy Hutson reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

Freddy Hutson reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

-

Scott Crouse reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

Scott Crouse reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

-

GrandpaPhil reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

GrandpaPhil reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

-

DPhilbrick reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

DPhilbrick reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

-

JohnN reacted to a post in a topic:

Muscongus Bay Lobster Smack by GGibson - FINISHED - Model Shipways - 1:24

JohnN reacted to a post in a topic:

Muscongus Bay Lobster Smack by GGibson - FINISHED - Model Shipways - 1:24

-

JohnN reacted to a post in a topic:

Muscongus Bay Lobster Smack by GGibson - FINISHED - Model Shipways - 1:24

JohnN reacted to a post in a topic:

Muscongus Bay Lobster Smack by GGibson - FINISHED - Model Shipways - 1:24

-

bobandlucy reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

bobandlucy reacted to a post in a topic:

Norwegian Sailing Pram by JohnN - FINISHED - Model Shipways - Scale 1:12

-

oneslim reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

oneslim reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

-

I apologize for missing all your questions, I need to learn how to properly receive notifications. 🙁

- 43 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Blackreed reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

Blackreed reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

-

nehemiah reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

nehemiah reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

-

Cathead reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

Cathead reacted to a post in a topic:

Viking Knarr by JohnN - FINISHED - Dusek - Scale 1:35

-

Installed the rudder, finally, and I declare this model finished. See last photos at end of post. Summary: Overall, a satisfying project. Reasonable price for an entertaining build, a good value. For me, the choice of the 1/35th scale was correct, given my skill level and preference for larger scales. Positives: Reasonable increase in build complexity from MS Pram Good quality materials Supplied planking material installed without excessive fuss Rigging worked better than anticipated A presentable, attractive result, IMHO Improvements: Instructions are minimal, and for my skill level, lacked detail. Lots of time spent pondering build steps given above Plywood material had lots of tarry residue, sanding was laborious Largest rigging size was insufficient to complete work Mast rigging seemed to lack realism. Perhaps a trade-off for reduction of complexity. Blocks replaced with aftermarket parts. Fit of some frames required a lot of adjustments Some frames likely installed reversed, discovered when fairing for planking.

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

Very nice result @GGibson. Congrats !! I will be watching your smack build log with interest.

- 26 replies

-

- Model Shipways

- Norwegian sailing pram

-

(and 2 more)

Tagged with:

-

Yard installed as well as associated rigging. A couple hours of tidying and I think I will call this project finished. I might experiment with the sail, but, even if I do, I will not install on the model. Will summarize in a post or two. Thinking about the next project. Perhaps MS's Lobster Smack, but, the build log here and an unconvincing reply from MS customer support regarding addressing some of the major documented issues have me considering other kits. All suggestions are most welcome.

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

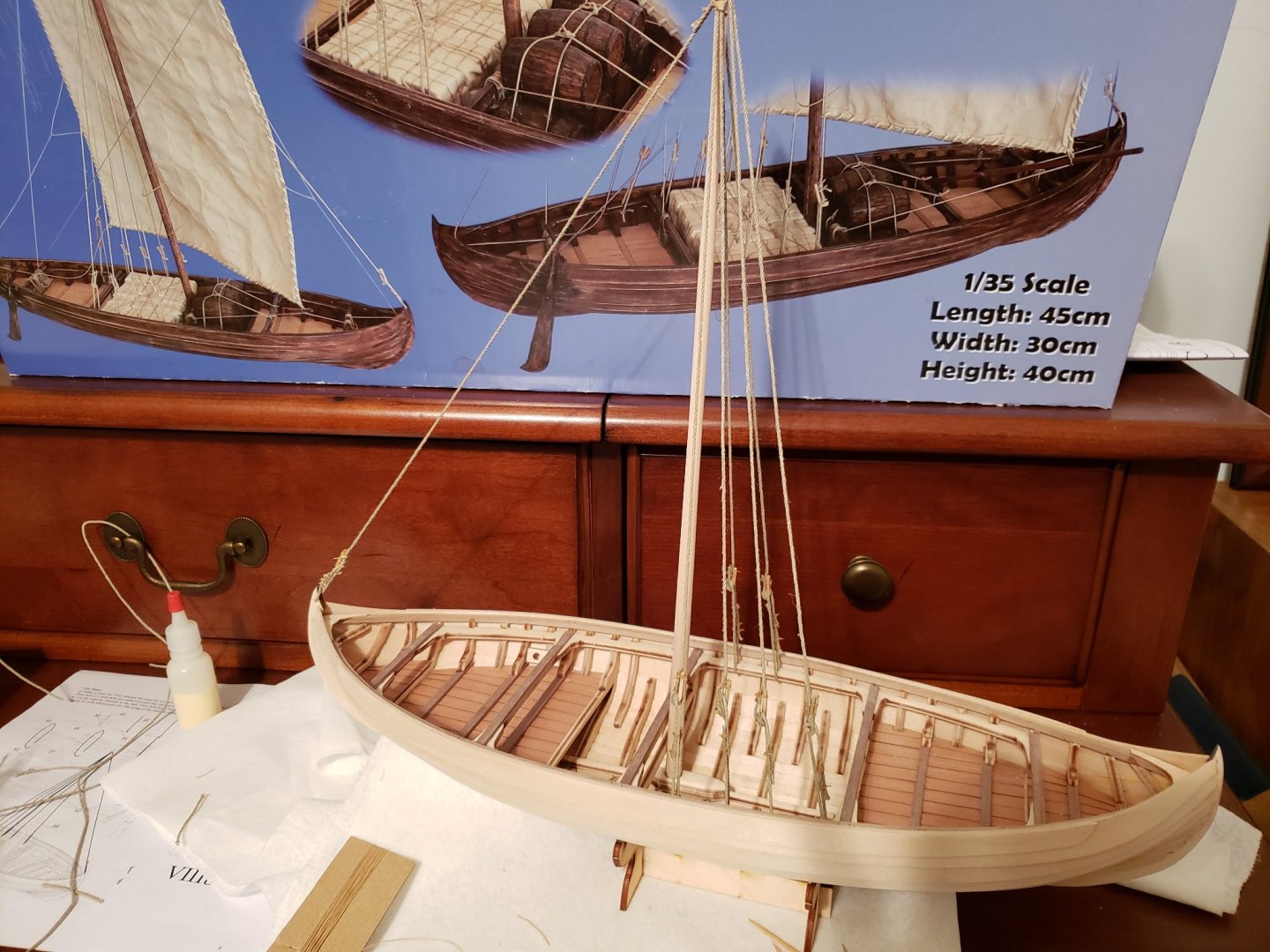

Finished first step of rigging. It would have been quite helpful if the instructions included approximate lengths for the various components, as well as more text describing a suggested process. I neglected to account for the stacking at the top of the main mast when cutting rough lengths, which added to the overall fun of this step. A couple of the stays appear slightly wonky in the photos, but did not appear so to my eye. I presumed the forestay was first, based on the instruction illustrations, then noticed @Daryl's build log (1:72 Viking Knarr) where he ran the forestay last. 🙀 Debating whether to use the sail. As I ponder, on to the yard.

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

Main mast is permanently installed and rigging has started. Photos Real Soon Now ... (edit, delivered) 🤣 The mast required a slight bit of diameter reduction at the base as well as slight flattening towards the bow, as one of the frames impinged on the mast mount. Easily remedied, but I did not notice when dry fitting. The mast was near perfectly positioned once these adjustments were applied. The fore stay is completed.

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

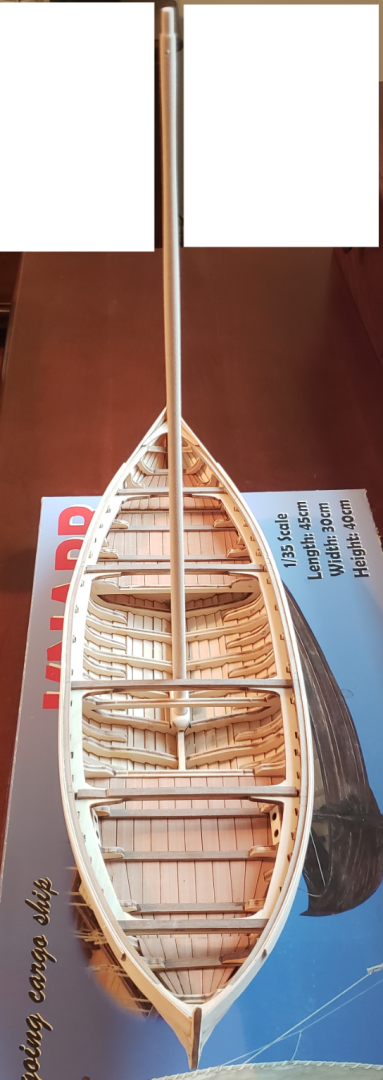

Photos of main mast finished and test fitted. Lots of life in progress presently, which has slowed progress.

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

Have most of main mast shaping completed, the step at the top and final sanding remain.

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

I have decent progress on the rudder and rudder mount, although the mount is quite tedious and not particularly well designed. I have installed the four frame tops (parts 29 and 35). I feel this was the proper order, as they add nothing to the hull shape, and might have been problematic as no reference is readily available for good installation earlier in construction. I have also made a start on the main mast, which requires quite a bit of material to be removed, and will thus take some time to shape.

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

JohnN reacted to a post in a topic:

Muscongus Bay Lobster Smack by SkiBee - FINISHED - Model Shipways - 1:24 Scale

JohnN reacted to a post in a topic:

Muscongus Bay Lobster Smack by SkiBee - FINISHED - Model Shipways - 1:24 Scale

-

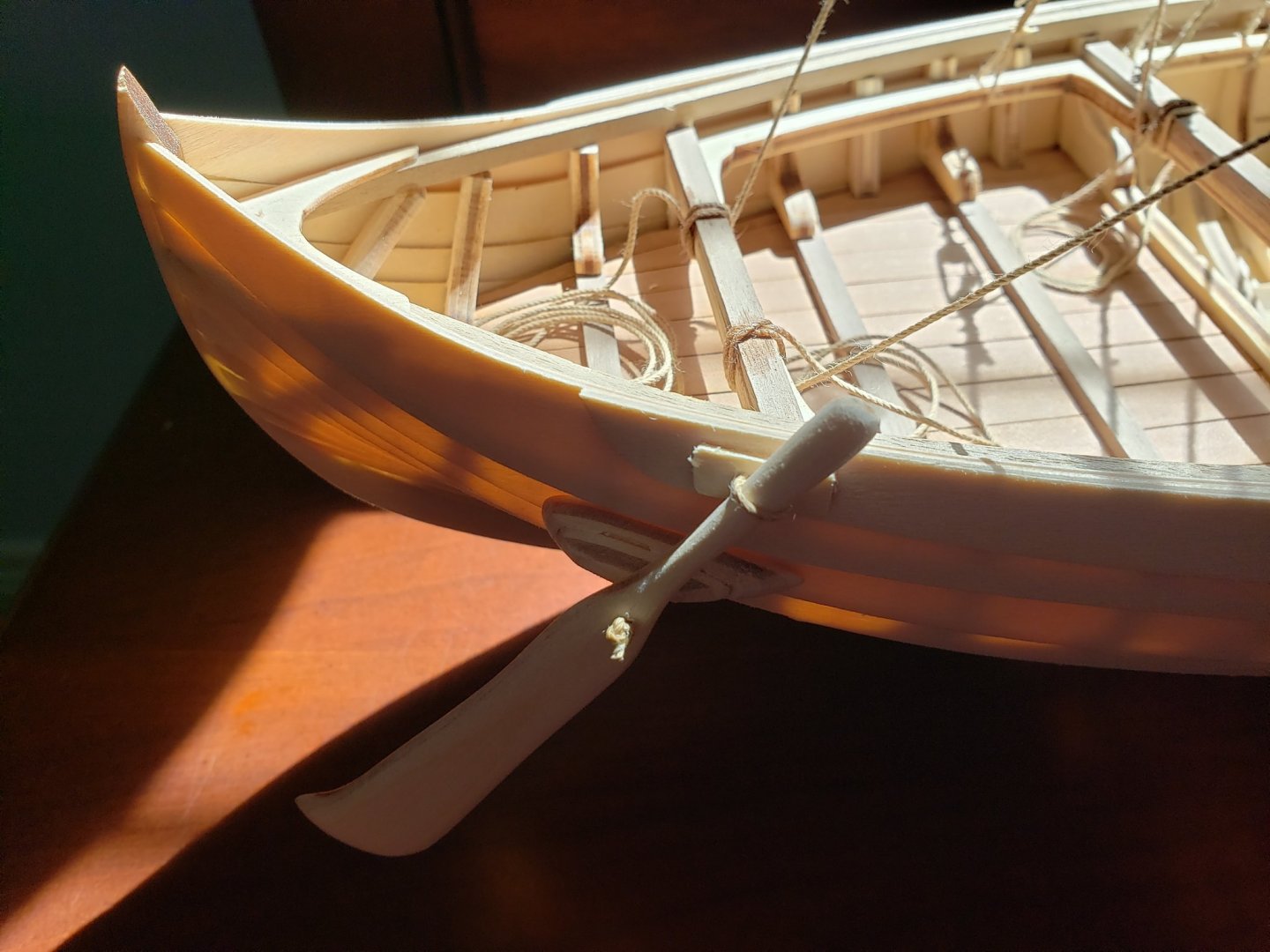

Cleanup of the bow and stern is (mostly) completed. I may spend a bit more time working these areas. I did use some filler to close gaps I am also working on the rudder and rudder mounts, more on those in a separate post. Bow Stern

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

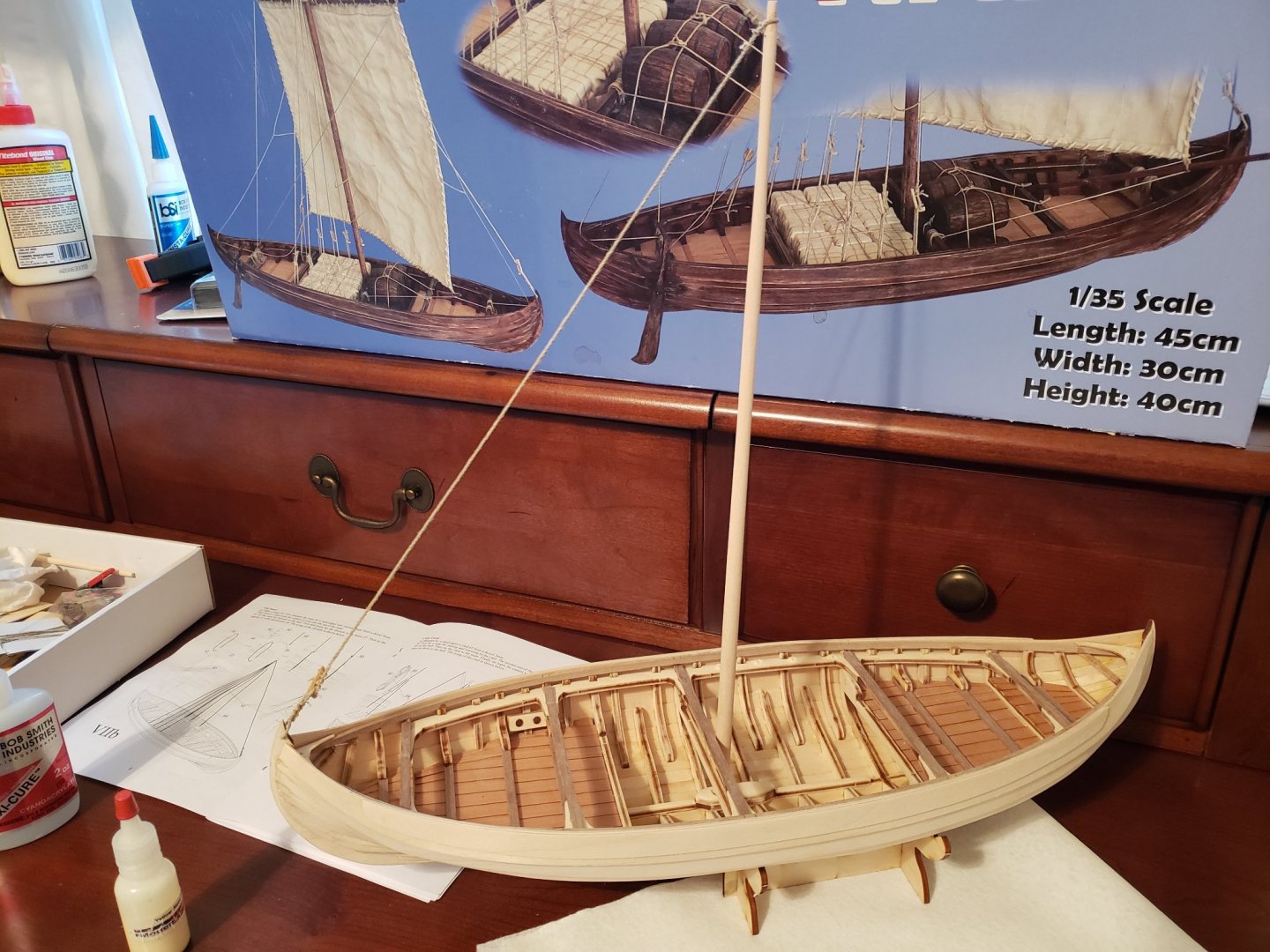

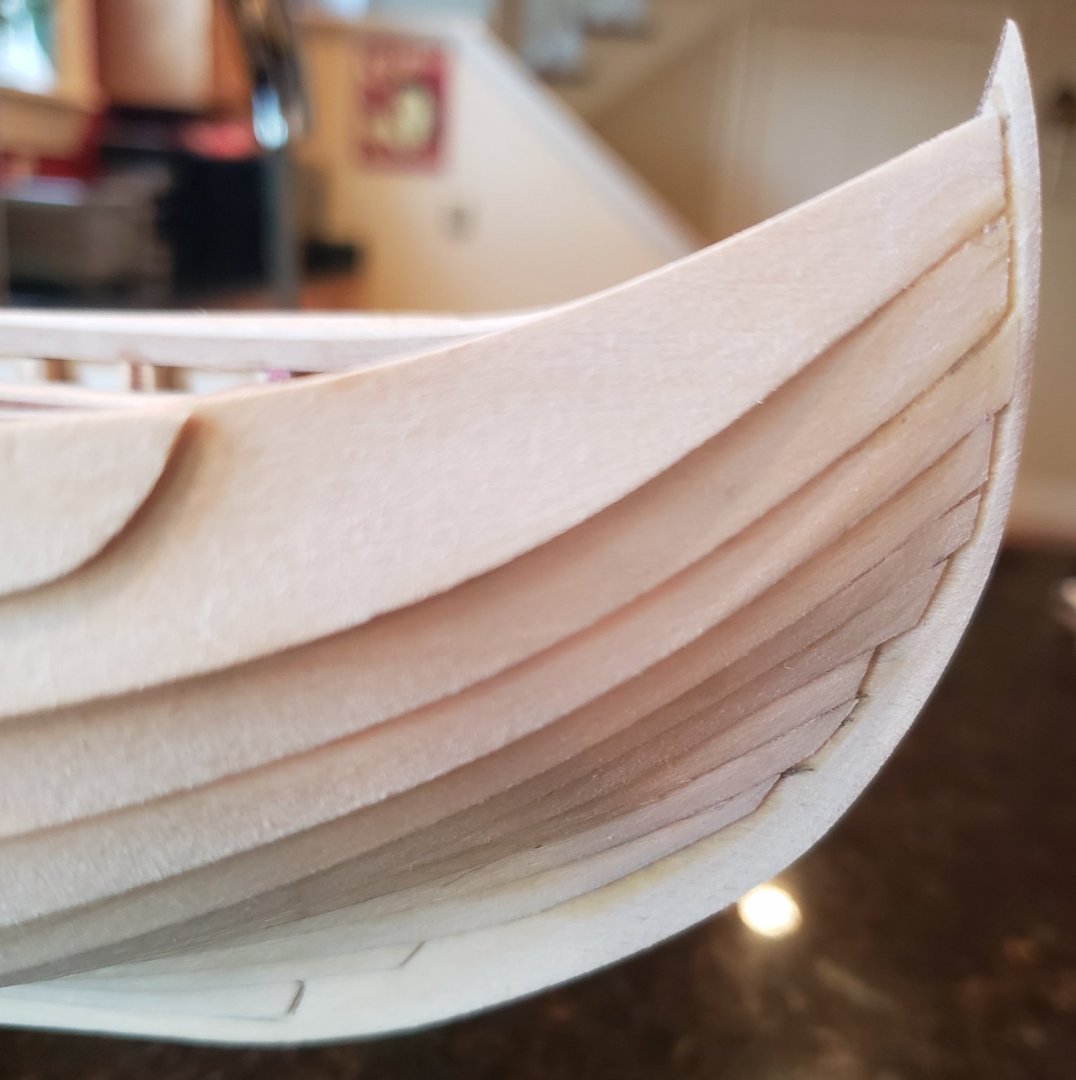

All planks have been attached. Still to do is final sanding and clean-up of plank attachments at bow and stern. The process was smoother than anticipated. However, placement of planks is a fussy process, and it is difficult to determine proper bow to stern placement. I do have some mis-alignment, and hopefully this will not be very obvious once I have finished clean-up. During planking, especially the final two planks, some of the frames required removal of quite a bit of material, which, in retrospect, was the correct approach. The final two frames, both at bow and stern, do not align well with the overlying planks. The frame profiles need adjustments that are not parallel with the provided notches. I am unsure if I installed the frames incorrectly, or if the root cause of this mis-alignment is due to some other issue. It seemed the frames may have had a bias bow to stern that I missed during assembly. About half way though the planking, it seemed several frames may have been installed backwards. There is no obvious problem at this stage, but I am left wondering. For the cap rail, my assembly approach seems correct, or at least useable, as it resulted in a lot of bonding surface for the last two planks. The instruction illustrations seemed to indicate a gap between these parts and the keel, which I think would have resulted in quite a mess if followed. The hull is quite solid and stable, and I was able to handle it without issue as I was working the last planks. The last planks are slightly proud of the cap rail; I have not decided whether it is worth the effort to level them amidship as shown in the plans. I knew this as i assembled, but it is requiring more effort than anticipated to remove the excess material. There is a small bit of mis-alignment at the bow; it seems the keel is off perhaps 2mm port to starboard.

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

-

Interesting. My current project required removing substantial material from some of the frames during planking. I'll be updating the build log soon. Seems as though you have (or had) a similar situation.

- 62 replies

-

- muscongus bay lobster smack

- Finished

-

(and 1 more)

Tagged with:

-

My opinion is the frame 10 and transom alignment is not similar to the instruction photos, as you say, @SkiBee How does the transom bottom align with the frame bottoms ? Perhaps dry fitting the stern post pieces as shown in step 10 will provide more information regarding transom alignment.

- 62 replies

-

- muscongus bay lobster smack

- Finished

-

(and 1 more)

Tagged with:

-

Cap rail installation went smoothly, and is finished. I decided to attach them to the keel at bow and stern, as shown below. I think a bit of sanding will be required to properly attach parts 55 and 56, that will need to wait till tomorrow. Bow Stern

- 48 replies

-

- dusek

- viking knarr

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.