Meriadoc Brandybuck

Members-

Posts

201 -

Joined

-

Last visited

Profile Information

-

Location

Japan

-

Interests

Ships, Tolkien, rpgs. Fluent in Japanese and relatively knowledgeable about nautical history, I guess.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

daHeld73 reacted to a post in a topic:

Fish-hooker by Ab Hoving - FINISHED - CARD - after af Chapman - how to scratch-build from paper

daHeld73 reacted to a post in a topic:

Fish-hooker by Ab Hoving - FINISHED - CARD - after af Chapman - how to scratch-build from paper

-

Meriadoc Brandybuck reacted to a post in a topic:

A Dutch 17th century pleasure vessel by Ab Hoving - CARD

Meriadoc Brandybuck reacted to a post in a topic:

A Dutch 17th century pleasure vessel by Ab Hoving - CARD

-

Meriadoc Brandybuck reacted to a post in a topic:

Ship paintings

Meriadoc Brandybuck reacted to a post in a topic:

Ship paintings

-

Meriadoc Brandybuck reacted to a post in a topic:

Ship paintings

Meriadoc Brandybuck reacted to a post in a topic:

Ship paintings

-

Meriadoc Brandybuck reacted to a post in a topic:

Ship paintings

Meriadoc Brandybuck reacted to a post in a topic:

Ship paintings

-

ccoyle reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

ccoyle reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

-

Ab Hoving reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

Ab Hoving reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

-

GrandpaPhil reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

GrandpaPhil reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

-

Meriadoc Brandybuck reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

Meriadoc Brandybuck reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

-

Baker reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

Baker reacted to a post in a topic:

Revenge by Meriadoc Brandybuck - OcCre - 1:85

-

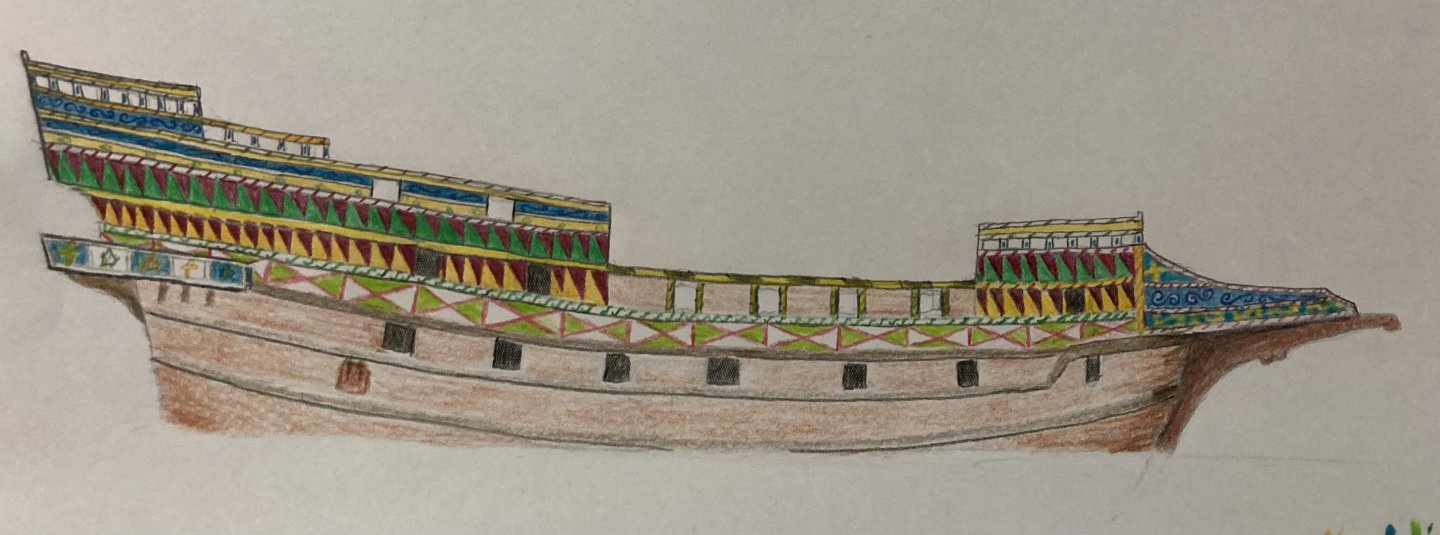

Hello, it’s been quite a while, but this spring I just couldn’t quite find the Badger energy I needed, so I took up other projects instead- starting with some 1/72 aircraft, and then was able to find my way back to the Revenge. I have a lot of progress to report. I got around to gluing my re-engineered beakhead together and started putting the rest of the wales and sheer strakes on. Then I got to thinking about where to actually go with the look, thinking about changes I could make to steer more in the direction of realism than the Occre manual. I got out my colored pencils and reference material and started visualizing. I decided on a color scheme that strikes a balance between contemporary references and how I’d actually like to paint it. Greens to maintain the Tudor connection, deep yellows and reds because they look great together, and an elegant peacock blue to adorn the beak and upper sterncastle. Inspection of the Elizabeth Jonas model in the science museum indicates a lot of little patterns to adorn every little piece of trim, and I want to recreate something remotely similar if not as perfect. I got all the sheer strakes and rails on as well as I could, making lots of adjustments to the hopelessly out-of-scale suggestions from the Occre instructions. I used a lot of 2x2 and 1x1 mm stock instead of what the kit offered. Now I have lots of leftover African walnut. I then managed to apply sanding sealer and a coat of matte varnish (water-based polyurethane) to the lower part of the hull after sanding it for several hours, working from 240 to 320 to 400 and 600 grit. Last, I present my waterline gimmick. I masked the waterline, using a Lego jig built to the right height. I also applied felt to the stand beforehand so as to protect the underside surface. After masking, I applied another coat of varnish below the waterline, this time using gloss varnish. It worked well enough, but the difference isn’t as stark as I had hoped. Still, it delineates the waterline if one wants to see where it should be, and displays the sapelli grain in the planking that took so many hours to do. Sorry Kirill4! I know in reality it would have been painted off-white in a wavy pattern. Ultimately, it’s more a piece of furniture than a scale replica, and I am happy enough with the look. Well, I am looking forward to your thoughts and comments if you have any! Meriadoc

-

GrandpaPhil reacted to a post in a topic:

HMS Badger by Meriadoc Brandybuck - WAK - 1:100 - CARD - serenely taking in sails

GrandpaPhil reacted to a post in a topic:

HMS Badger by Meriadoc Brandybuck - WAK - 1:100 - CARD - serenely taking in sails

-

JacquesCousteau reacted to a post in a topic:

HMS Badger by Meriadoc Brandybuck - WAK - 1:100 - CARD - serenely taking in sails

JacquesCousteau reacted to a post in a topic:

HMS Badger by Meriadoc Brandybuck - WAK - 1:100 - CARD - serenely taking in sails

-

Ab Hoving reacted to a post in a topic:

HMS Badger by Meriadoc Brandybuck - WAK - 1:100 - CARD - serenely taking in sails

Ab Hoving reacted to a post in a topic:

HMS Badger by Meriadoc Brandybuck - WAK - 1:100 - CARD - serenely taking in sails

-

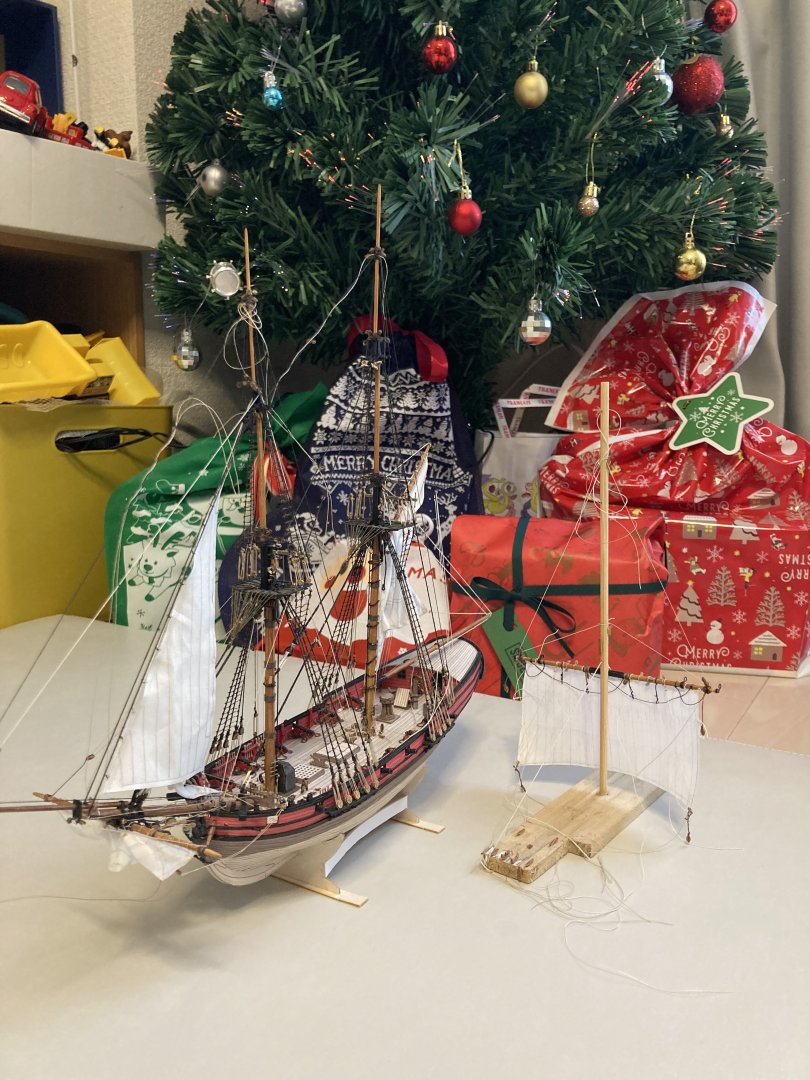

Happy holidays! The Badger has progressed, ever so slowly. I have fitted out almost everything on the fore course yard & sail. Getting ready for sculpting and mounting. I’ve also attached the jib and spritsail- the first of the square sails. Much of my time has been spent learning to draw ships and nautical scenes, which has been quite fulfilling. I’m waiting for the foremast sails to be installed before finalizing the jib and flying jib; they’ll get in the way of slackened bowlines. Photos below. -Meriadoc

-

Hello, Well, happy late summer- or winter. I hope everyone is doing well. Standing rigging has been completed! It was quite a slog. It’s easy enough to get in the zone hitching ratlines, but shrouds and stays involve lots of preparation, guessing, measuring, finagling seizings, adjusting tension, and readjusting tension for every single line. Thus it is probably about right that it took so long, but now it is time for the fun part- rigging and sculpting sails! I’ve already begun with the fore staysail. Almost every block for the entire rig has been attached to masts, stays, shrouds, etc. Spars not so much. Things should proceed nicely if time can be found. Cheers, Meriadoc

-

Hello, sorry for not seeing this earlier. The “deck” you refer to is just a base plate to hold the frames while you plank the boat. You’ll note little notches near the top of the frames. This is where you cut the boat free of the base when it’s done. I haven’t tried this step yet, but I fully expect the plywood to break and crumble while trying to fair the frames. Good luck! Meriadoc

-

Hello, An update on standing rigging. The first tier of shrouds and stays has been finalized (ratlines going on currently behind the scenes). Photos below showing the progress as well as the completed mainsail miniproject. Below: the messy state of affairs before balancing and finalizing tension, with lanyard excess hanging everywhere. Below: the mainmast, rope horse, and the snipped ends of all the falls of rope. Coils will be made and stuck onto the pins and cleats later. Below: all the excess falls have been labeled to get the right diameter and length into the final coils. Below: the brailed-up mainsail, with all its rigging finalized. Below: views of the head and bowsprit with the bobstays, martingale stays, and gammoning. Below: overall views of the rigging progress. That’s about as far as I’ve gotten; today I got on the futtock staves and a decent number of the ratlines. Maybe another month and I’ll have the standing rigging completed at this rate? -slow but sure Meriadoc

-

Thanks; though I think in this case the hard part will be getting the stuns’ls to hang just right. When we get there. Better do some experiments. Meriadoc

-

Interesting choice. I can’t wait to see it take shape. I have the book; it’s one of my most prized possessions with all its magnificent plans. Given enough time I’d like to build everything in it and make my own variations like Ab does. For now I’ve started preparing to build a little kaag and pink sometime this year or so. Perfect little finishable projects, unlike my Badger. Meriadoc

-

A little update. I managed to get all the rigging for the gaff and boom set. I wanted to get this out of the way before main shrouds got in the way. I don’t think the net tension of the standing rigging will affect these lines much. You can see the vangs, topping lifts, sheets, halyards, and even an inhaul-which I’m wondering is even necessary. All lines except brails are belayed and fastened permanently; later I will snip off the excess and turn it into hanks. Not sure how the halyard falls should look. That’s a lot of rope. The mainsail brails are still tied off at the foretop as they will eventually terminate at main shrouds cleats. The first set of main shrouds is going on now. I made a twisted wire guide to hold the deadeye at the right height, but it always wiggles loose somehow. I have better luck just judging the length by hand and using my four hands and mouth to try to seize the shroud around the deadeye while holding it all in place somehow. I don’t even know how I do it but I have gotten better at it. I cannot wait to get the standing rigging on her and start sculpting the rest of my sails. Anyone think I’ve made a horrible mistake by finalizing the mainsail rigging before the standing rigging? Meriadoc

-

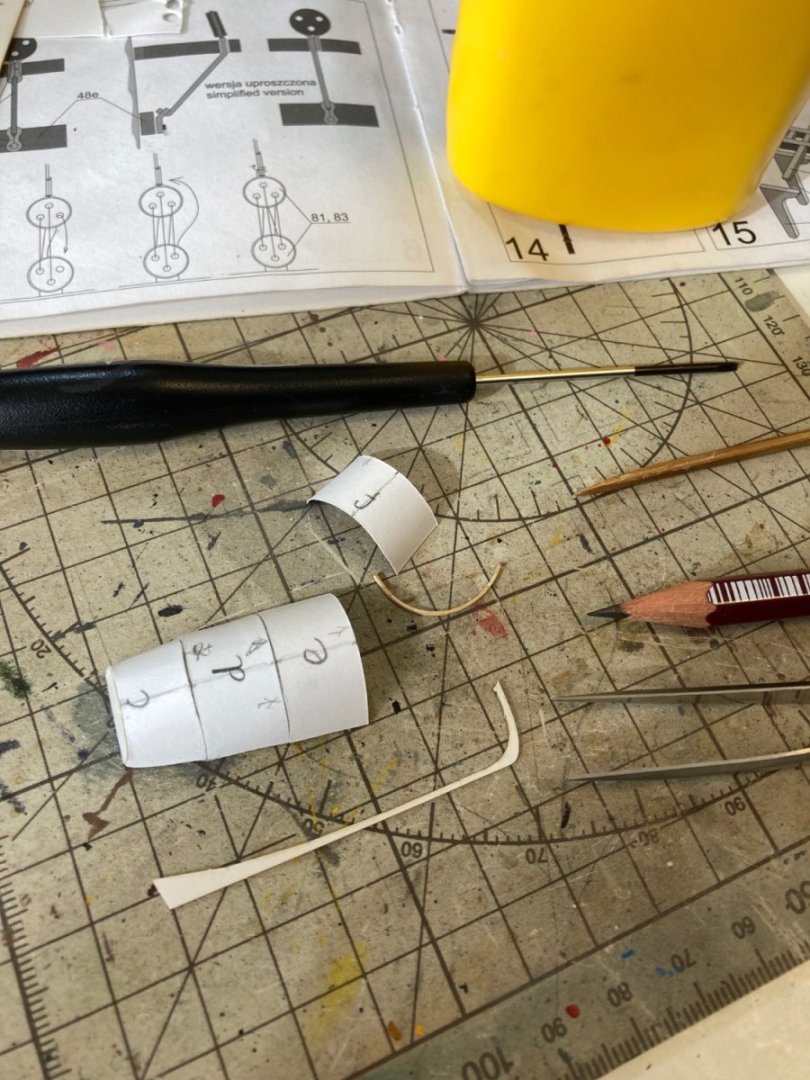

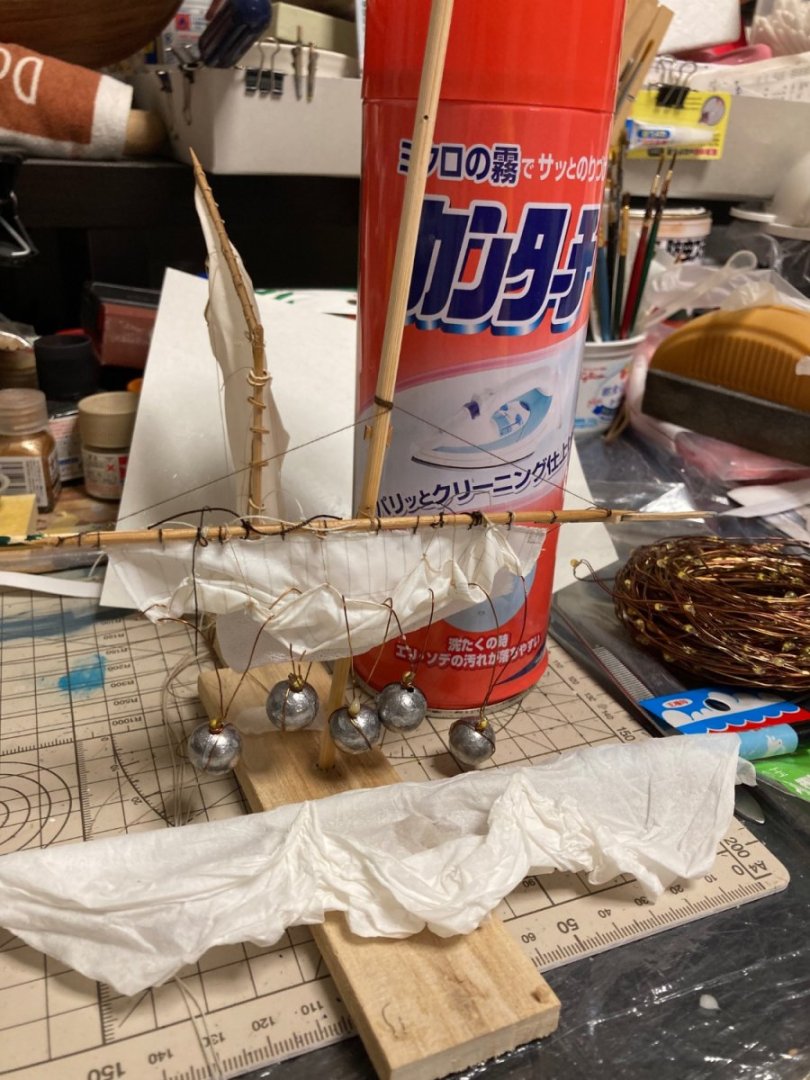

Well back to business. I started doing shrouds on the foremast, but decided to get the gaff sail all set up before putting the main shrouds in my way. The boom, gaff, and sail went on in about a day’s work. I discovered that I forgot to prepare the boom sheets and peak halyard so there was some catching up to do. Also had to get all the lines on the sail- brails, sheet, and inhaul. Bending it to the gaff and mast rings (which were prepared with wire) took a while because all the little ropes get in each other’s way. Then illness struck and things took a long pause while I recovered. Today, I prepared everything for the final gaff sail sculpting: a jury lift and stay to stabilize the gaff and mainmast because of all the fishing weights to be strung from the sail, and several more weights had to be set up with wire hooks: See the operation below. In the end the heavier weights are more useful (about 10 grams each or so): Brail lines are temporarily made fast to the foretop pins for convenience. The sail is wet by fingers (using a dripper just runs water down the sail) with paper towels below for safety. Weights tend to fall off and threaten to break the tiny pump handles on the quarterdeck. I got lucky. When the sail dries, I can blast it with starch a few times to get it to retain the shape. With the sheet line pulled a bit, it should look much like the paintings. With that done I can proceed with the main shrouds and complete the standing rigging, and on from there. I’m happy with the look so far. Hopefully the rest of the sails go well too. That’s all for now! Stay healthy! -Meriadoc

-

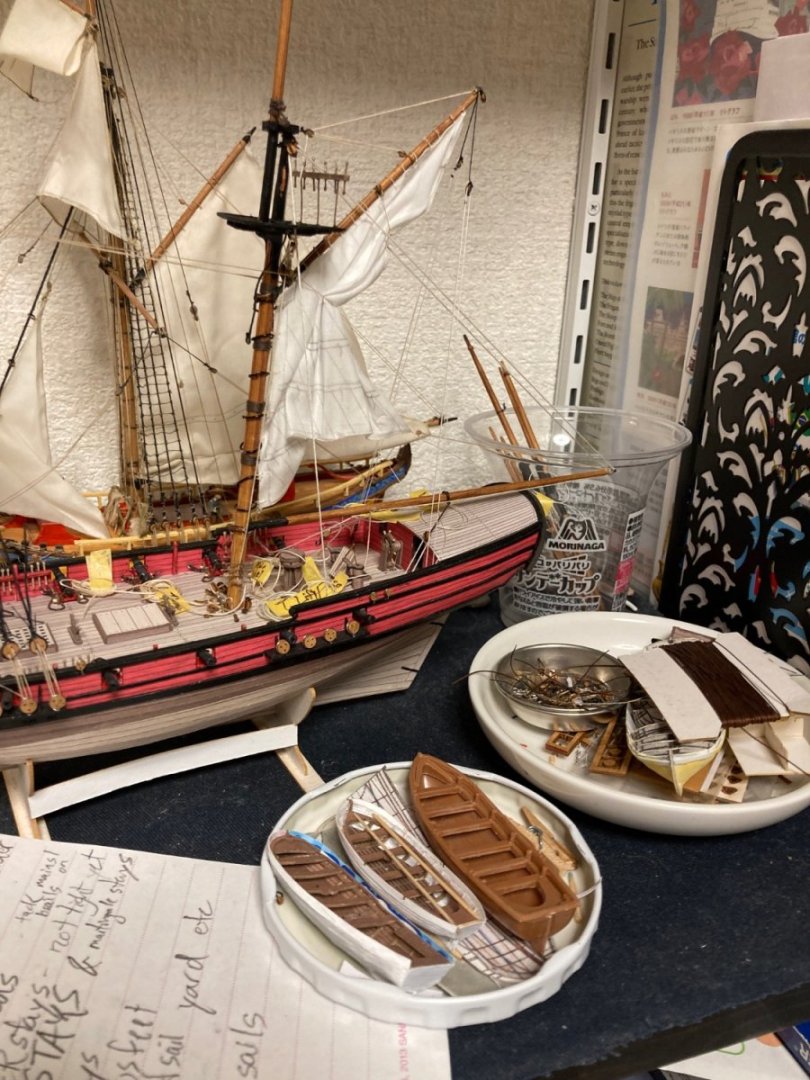

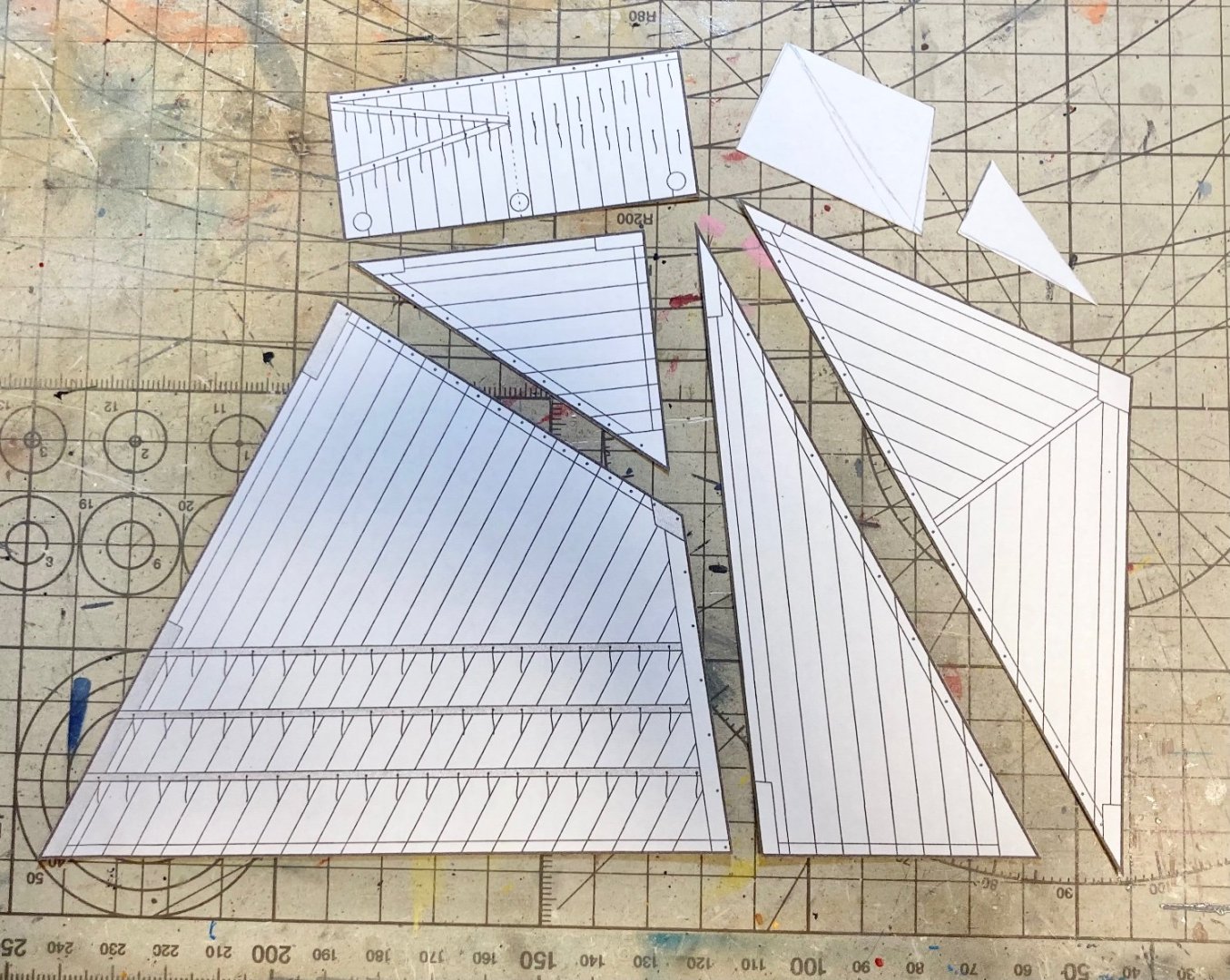

Well, I hope everyone is doing well. I haven’t been; in keeping with the recent theme of nothing going to plan, I ended up sick with pneumonia for about three weeks, stayed a spell in the hospital and finally got out alive. It’s good to be healthy again. Really good. I have lots of unreported progress. So I guess I’ll get to it. Boats. The kit includes two boats, a 16’ cutter and an 18’ launch, though the instructions are a bit unclear or mistaken about how they are to be planked. In any case I proceeded to assemble them, along with a scratch built 25’ longboat for fun since I’ve wanted to try building one for some time. Above: test fitting my thwarts in the launch. I added thwarts along with a hastily scratch built windlass. The kit wants you to leave the thwarts out and stack the cutter inside, but that was not the usual British practice. Also I have other plans for the boats. Above: cutter taking shape on the right with its clinker planking and my longboat (from Chapman) with its frames finally glued together. Above: planking on the launch displaying the hungry horse effect. I found this difficult to avoid with the soft paper employed: in retrospect it would have been best to find more rigid planking even if it was a bit too thick. I can try to stick this side out of sight in the finished model; the other side isn’t as bad. Above: added my own washstrakes. Longboat coming along with filler. Needs another go. Above: final verdict for the kit boats- I find the launch far too blunt-bowed for 1776. It seems a bit more 19th century. In any case it manages to fit in the narrow space available aboard the little brig. I plan on having it suspended from the main & fore tackles and yard tackles, being swayed out. Though that might prove too ambitious and incompatible with the sailing activities going on. It would be a fun visual effect though. The cutter ended up a bit too big as the clinker planking had trouble meeting the frames. It looks alright though and will go in the water with a spritsail and jib. You can see the templates I made for those sails below, along with a first batch of sails to make for the ship. For some reason sailmaking is enjoyable, even though it shouldn’t be. It takes too long. But I got the first batch ready. Next post, we will talk about the status of the ship itself. -Happy to be functional again Meriadoc

-

Merry Christmas, happy New Year, and congratulations on finishing your lovely 74 before the year ended! This was quite the project. Can’t wait to see the victory album! Meriadoc

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

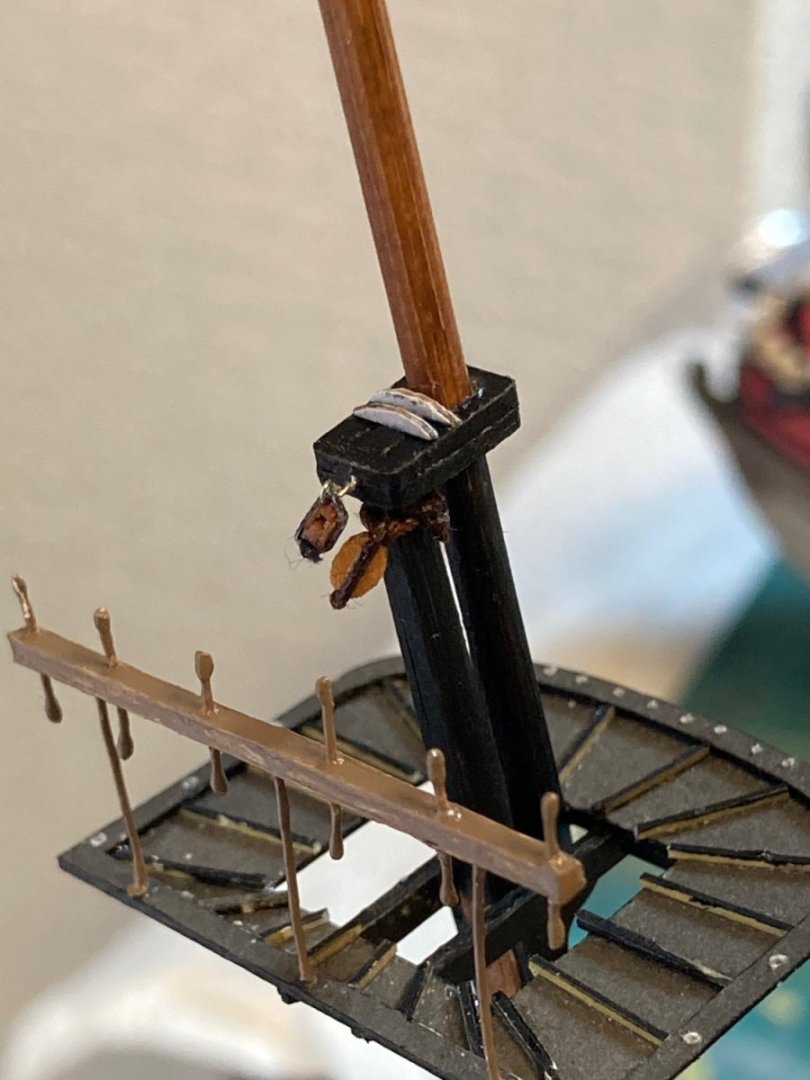

Well, I have much to report. I ran out of things to do that aren’t rigging-related. Rigging is my favorite part, but I wanted to make sure everything was ready to go so it will go as smoothly as possibly. Masts have been finished with all blocks and fittings (except jeers yet) and when all was finished on the hull, they were finally glued in place and await shrouds. I also experimented with sail manipulation and achieved decent results. Please see below. Above- lots of subassemblies and two sails I prepared for practice and experimentation. Above- masthead sheave blocks (going to check that terminology when my dog gets off my lap) for the running lines of the headsails. Above- no way to reasonably hang these blocks from the tiny paper-construct fore top, so they are simply attached with a drop of CA. Above- I decided I needed a saddle for the halyard of the flying main course crojack yard. The regular jeers will hoist the full-diameter main topsail spread yard. Above- speaking of so many yards on the mainmast, I installed extra cleats and blocks to handle them. The kit doesn’t include jeers or even halyards for the main yard but I decided to use jeers for ease of hoisting. Slings were not quite yet in use at this time, so something robust would be desirable to hold the weight of the yard. Above- a couple experiments. The cloth course was rigged to a jury setup with all its clews, bunts, and leech lines and hauled up. This looked completely unconvincing but I remembered to try fishing weights, so after wetting the sail I used weights to give the sail scale gravity effects. When it dried I used laundry starch in a spray can a few times to stiffen it before removing the weights. There is also a brailed gaff sail and a tissue that I tried “clewed up” around a chopstick. Not bad if I knew what to coat it with for stiffening and longevity. Above- the result of my sail experiments. I also did a topsail, less tightly hauled up. It was made of a nylon blend fabric that feels nice but isn’t as workable. For one it’s nearly waterproof and thus difficult to soften. I used weights to obtain the curves, and lots of starch to hold it but it’s still pretty pliable since the starch can’t soak in. Acceptable result though for loosely hanging sails. Based on these results, I will use the cloth from the lower sail (a fine lawn if I recall) and a diversity of fishing weights to sculpt each sail on yard with my jury rig mast before final installation on the model. Above- my little figurehead painted with little head knees installed on each side. Also boomkins to handle the foresail tacks and timber heads made of Proxxonned 2x2mm stock. Also I went ahead and stuck in the boom topping lift so the ship looks that much more believable. Now for standing rigging and methodical spar work and sail sculpting. Happy Thanksgiving! Meriadoc

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.