-

Posts

761 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ERS Rich

-

Hi Avi, Burnish is a fancy word for pressing down. Place the plate without glue, then press down with your fingers and shape it. Hold it down with one finger then use the side or point of the toothpick to press in the overlap with the previous plate. Try applying glue with toothpicks - the universal applicator. Cut a square of wax paper, and put a little pile of glue on it. Use the toothpick point to apply dots, and the side as a trowel. I use alot of toothpicks. If a plate is curled after drying, use the toothpick point and push in glue under the curl, then push down the curl and hold until the glue dries. If glue squeezes out while holding, with your other hand roll the side of a dry toothpick along the line to clean it up - while still holding down with the first pick. Try to establish an order of steps to install a plate, say dry fit and shape, apply glue to plate, install plate and hold down, clean excess glue while holding down, wait for glue to dry. Then repeat the same steps. After a while you’ll get into a rhythm. Like anything else new, start slow, figure out what works, after a awhile it get’s easier. Defects are less visible on the bottom. You’ll get better as you work towards the waterline. And take breaks, sometimes I’ll jump ahead to something else, then back to the longer job. This is a big job but worth it. Have a good one, -Rich

-

Never done this…..looks tough…. Perhaps dry fit the plate first. Use the side of a tooth pick to burnish the overlap area. Once you like the fit, glue it….. I’d consider filling in the imperfections between the planks with plastic wood applied with an Xacto spade blade. Give a bit more surface area. Next time, for a smooth surface, Gesso is a possibility. Artists use it to prep canvas for painting, it’s acrylic with a binder, water soluble, and easy to work with. Wonder about applying another coat of anything at this point - over paint. Make sure the choice is compatible with the paint. Persevere, you’re on the learning curve…. -Rich

-

Thanks Rick, hope to show simple ways to do the work. And for the next project, have a reference to refer to, when I forget how I did it…. Have a good weekend.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Welcome aboard! Always open to answer a question.

-

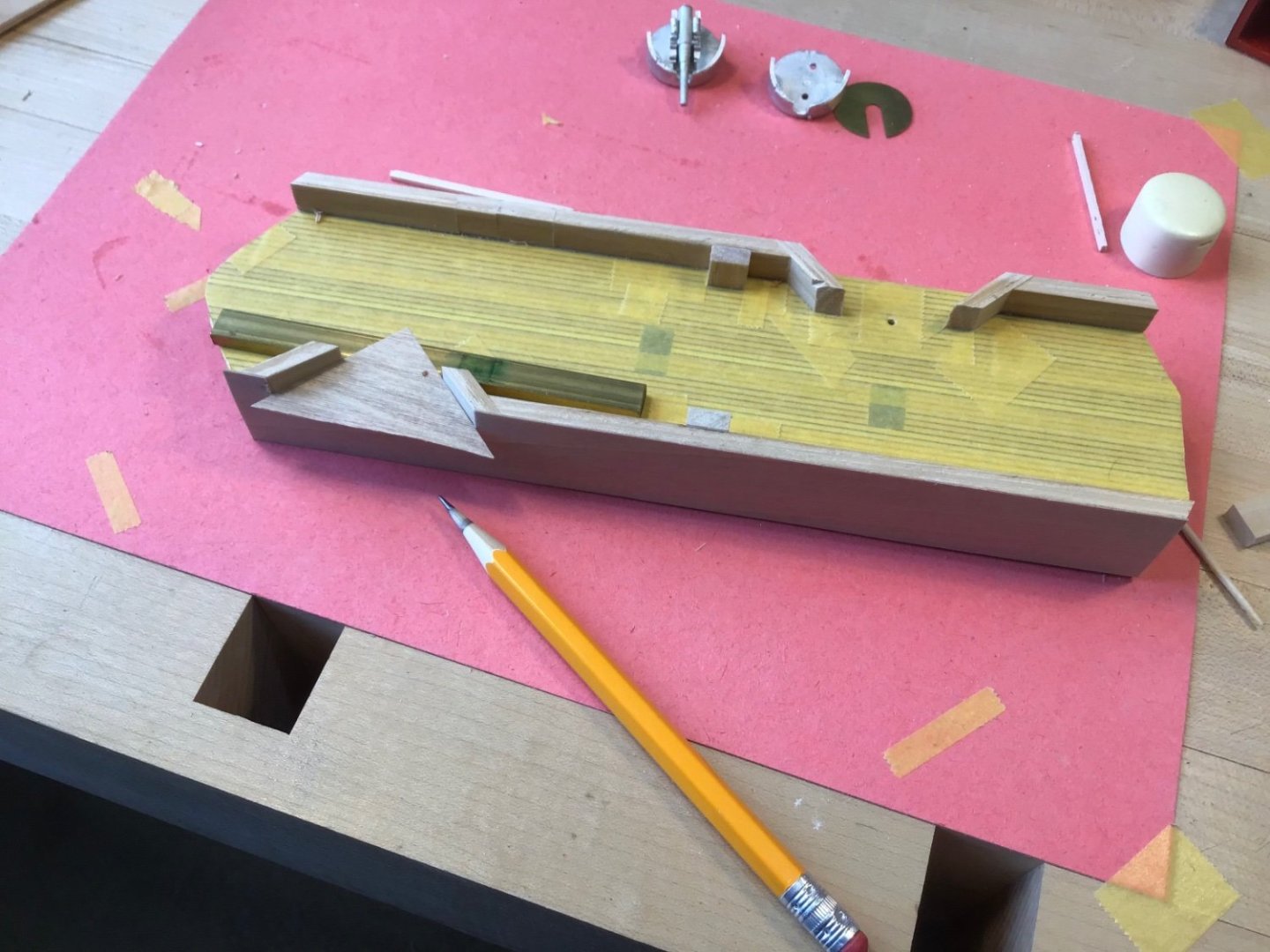

Progress Photos Not as much time for the shop the past few weeks - spring projects, trouble with the house boiler, amongst other things. Should have more time for the shop in the weeks ahead. Hoping to wrap this up by the end of May. Working on completing the mid and aft superstructures. Same processes used for the fore superstructure. And beginning to build the sub assemblies for the run up to final assembly. Ahead is the PE for the catwalks, cranes, etc. Here is the mid superstructure in the tail vise, with a plastic piece on the left acting as a caul, to apply pressure on the curved forward end plywood skin. Next is the mid superstructure with plywood installation around the perimeter complete. This picture shows applying the 3/16” half round. A spacer block is used to position the middle piece. A few of the sub assemblies - 6 pounder gun tubs note the tiny hand wheels, and the deck winch. Mid and aft superstructures dry fitted. Have a great weekend!

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

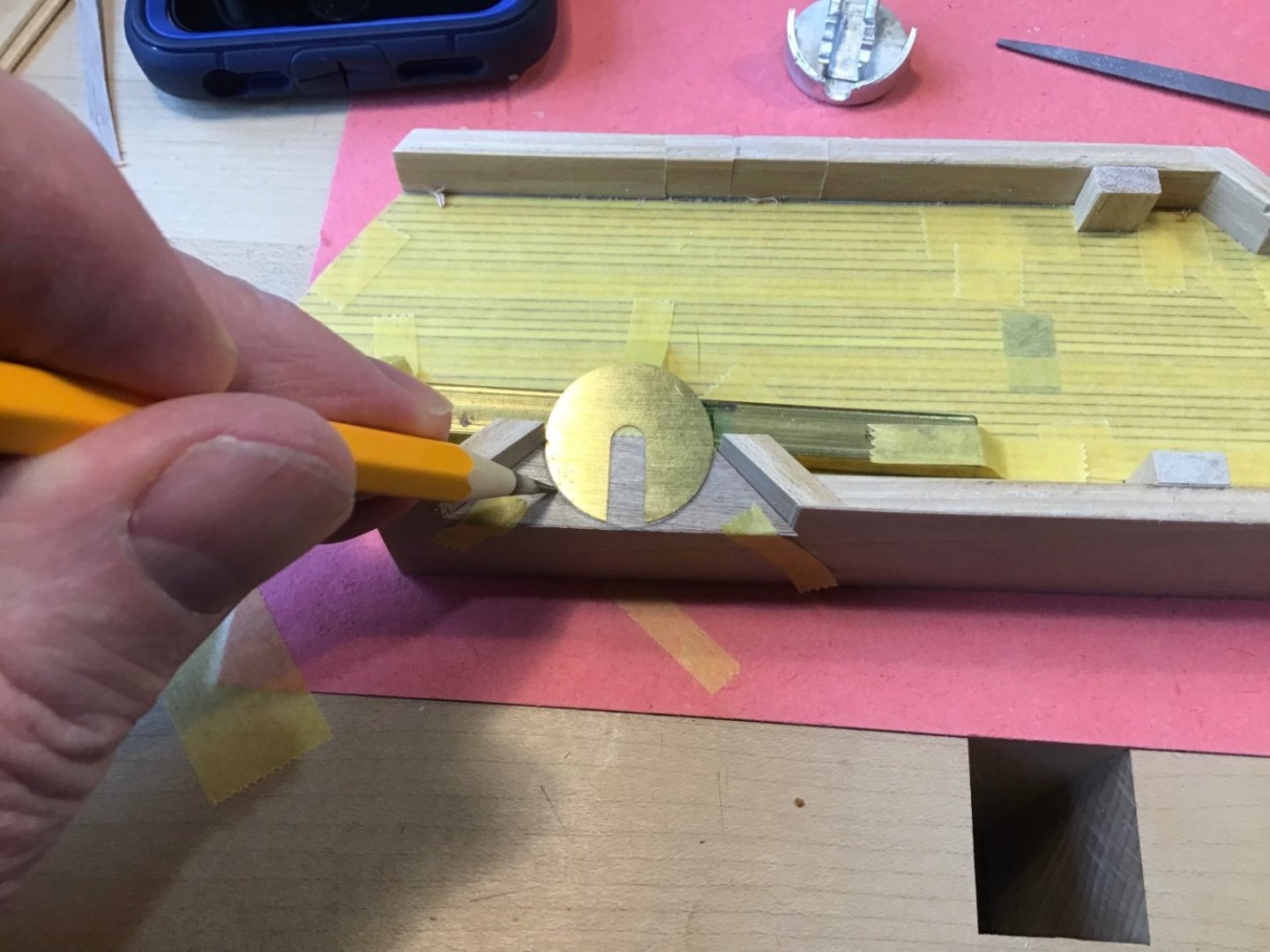

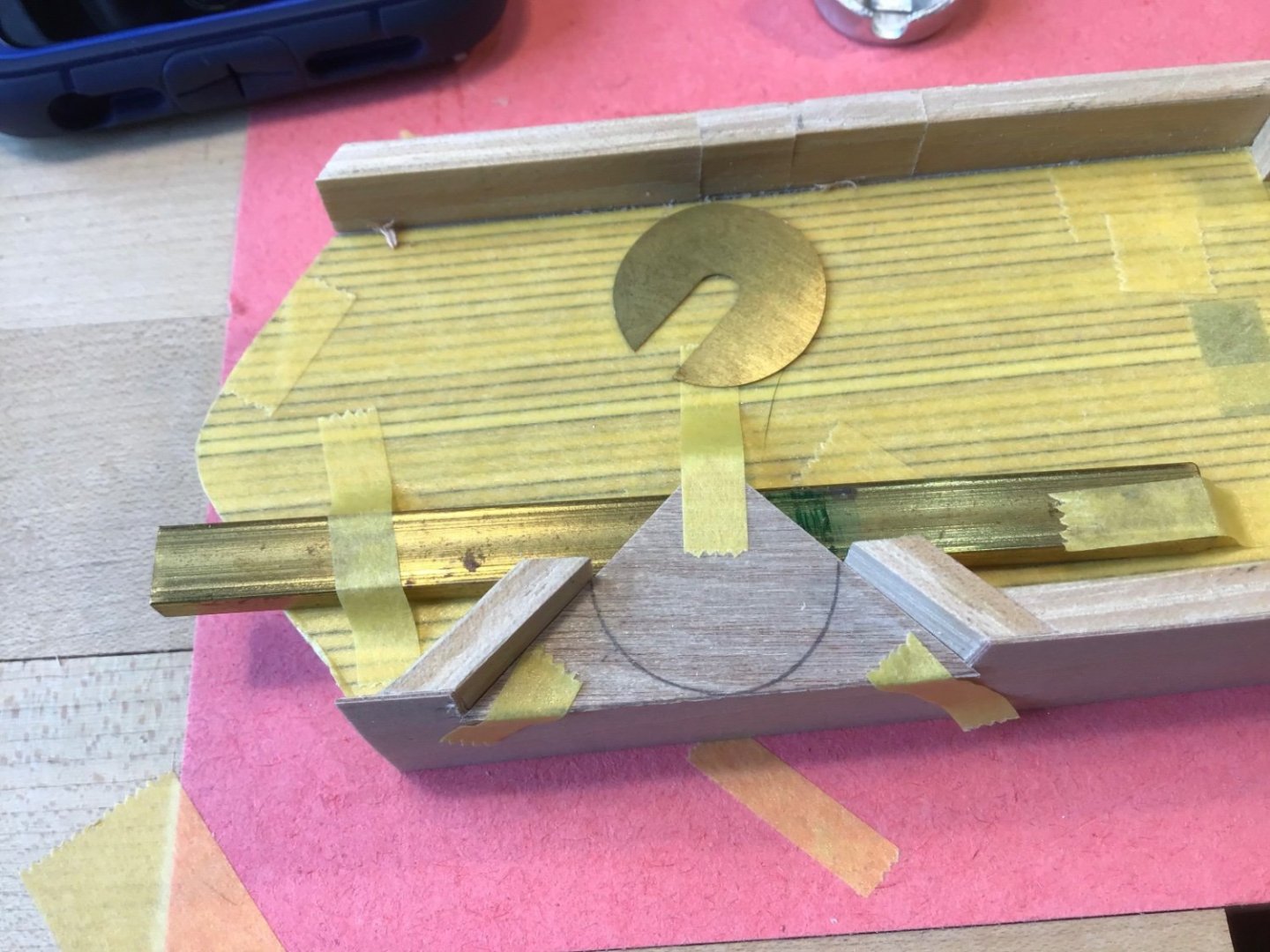

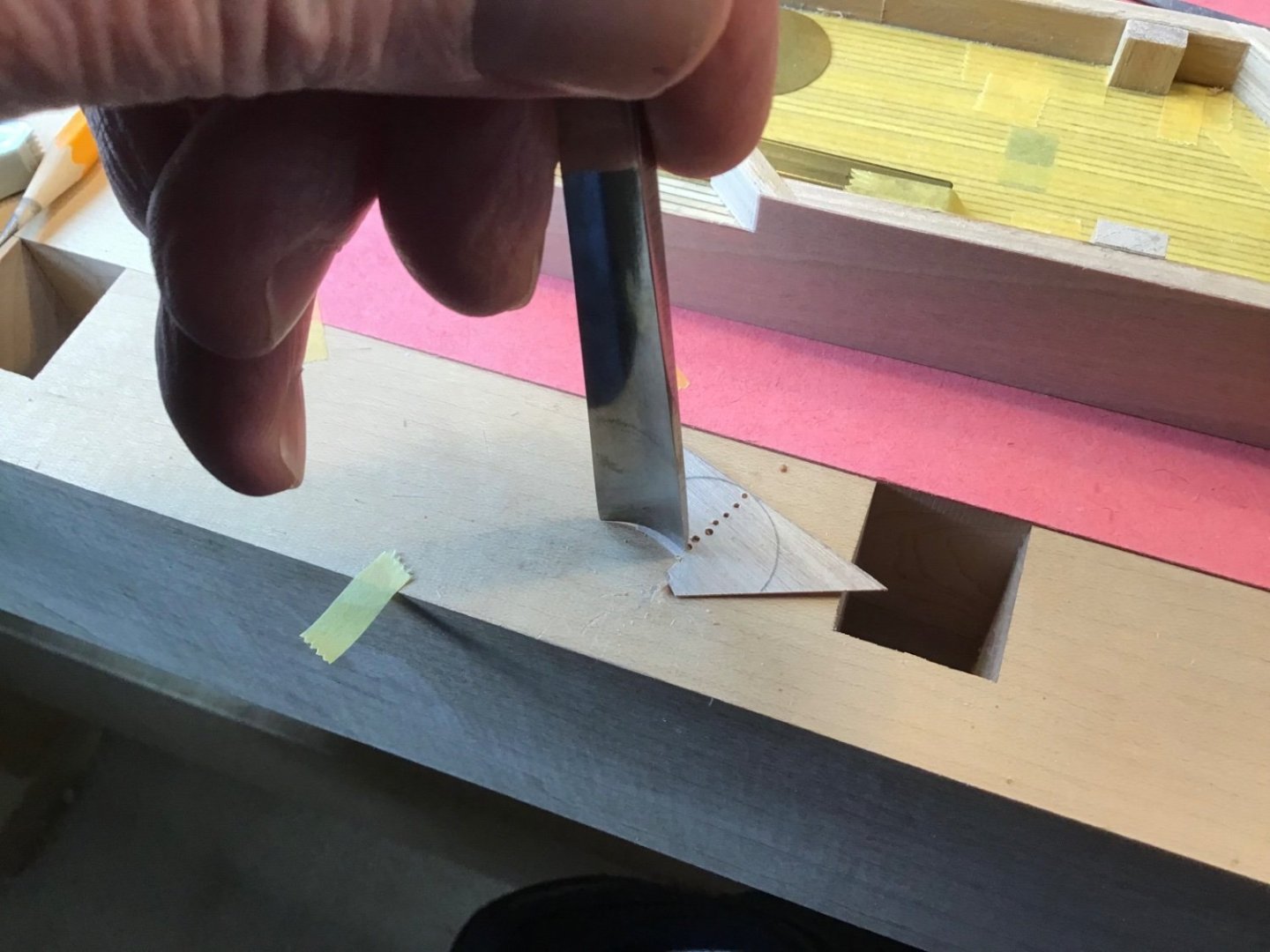

6” Turret Splinter Shield Spent time reviewing the instructions and plan to understand how to make this piece. Seems harder at first than it really is. Starting with the fore/aft width of the opening, cut a piece of material slightly longer on the paper cutter and cut a 45 degree angle at each end. The outboard sill is 3/32” high, the rise of the shield outboard to inboard is 1/16”, so the inboard height is 5/32”, the brass bar is 5/32” (part of a Standard set from Micro Mark). Marked a line underneath the shield along the edge of the bulwark, and trimmed the piece. Next secured the pieces with tape and used the turret cover as a template to mark the opening in the splinter shield. Next drilled a series of relief holes and cutout the waste. Started with larger sweep gouge. Used a the smaller gouge to approach the line, and a fine file to meet the line. The shield installed.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

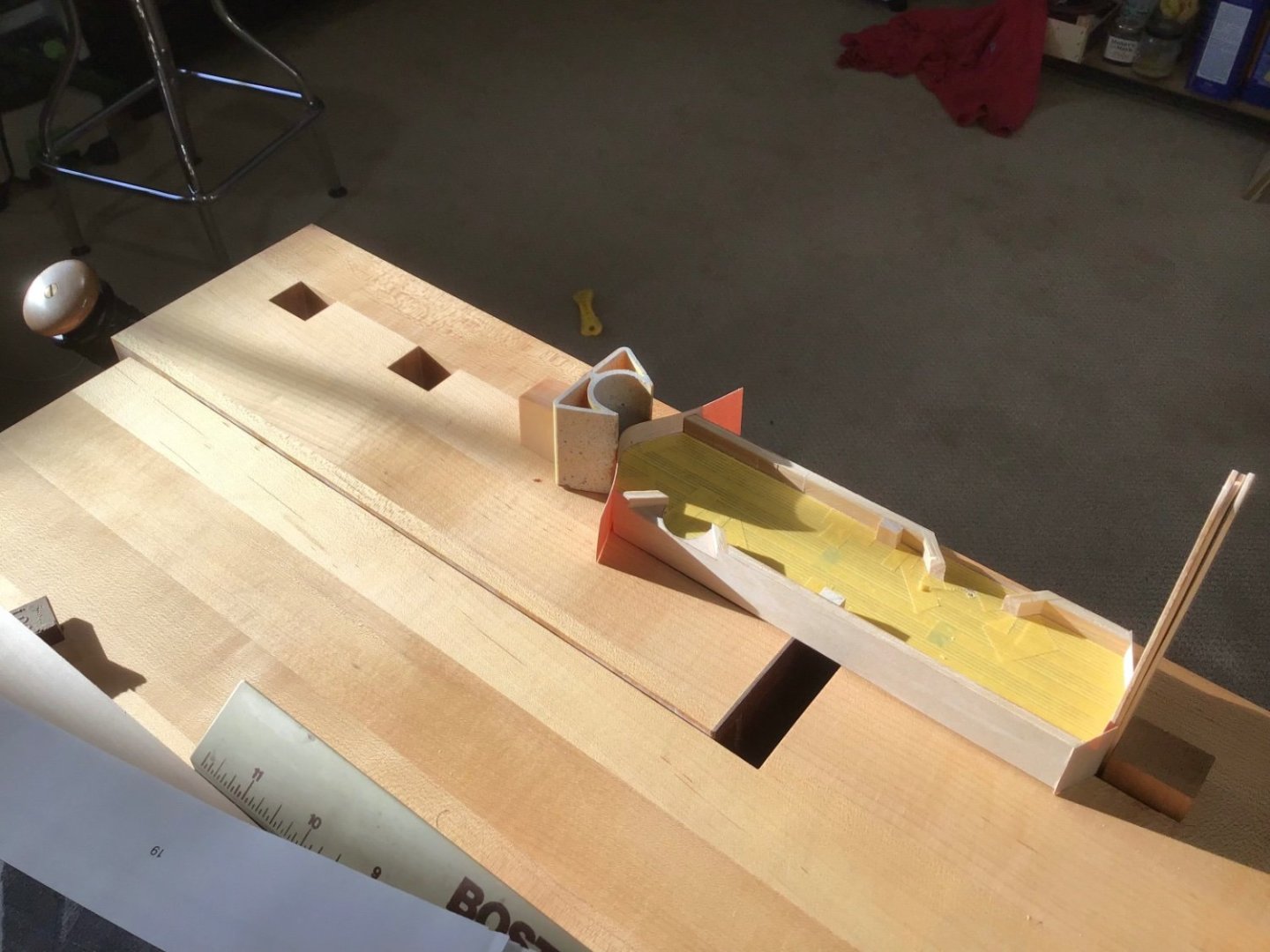

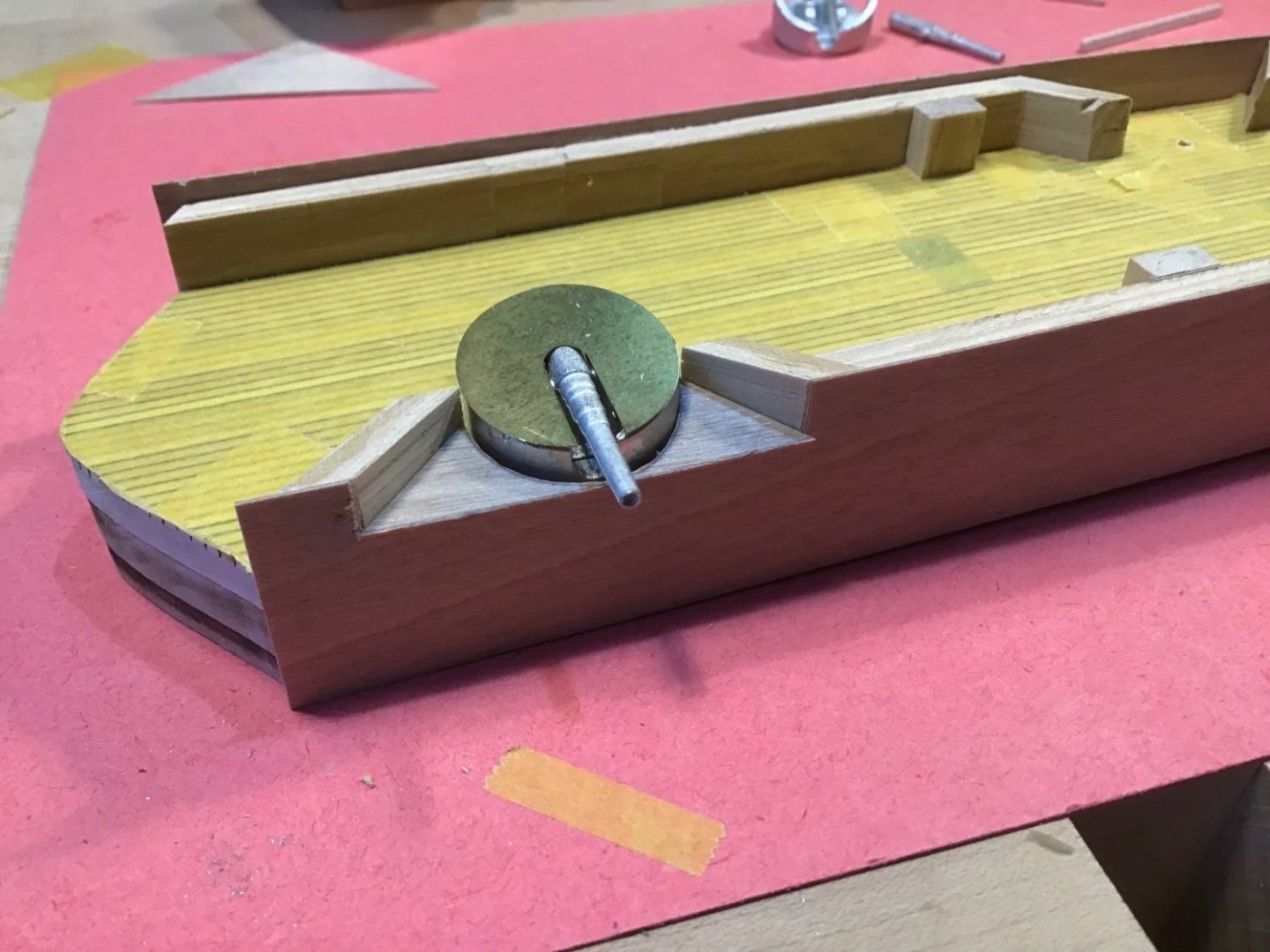

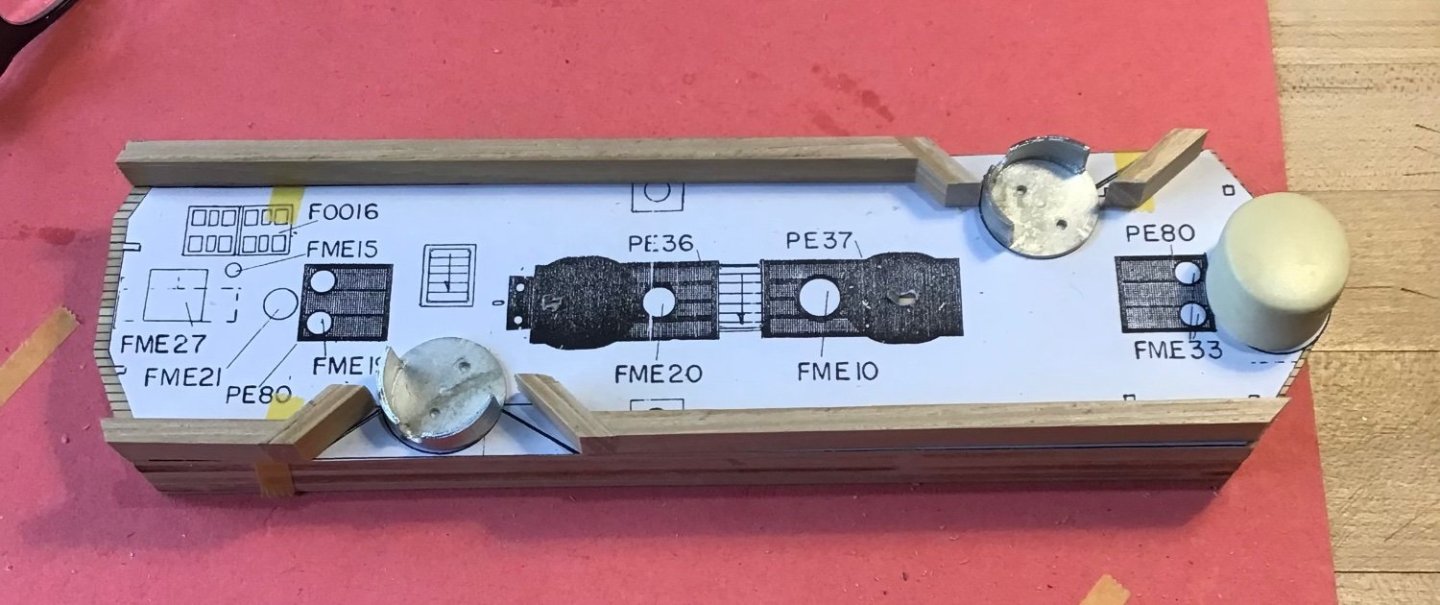

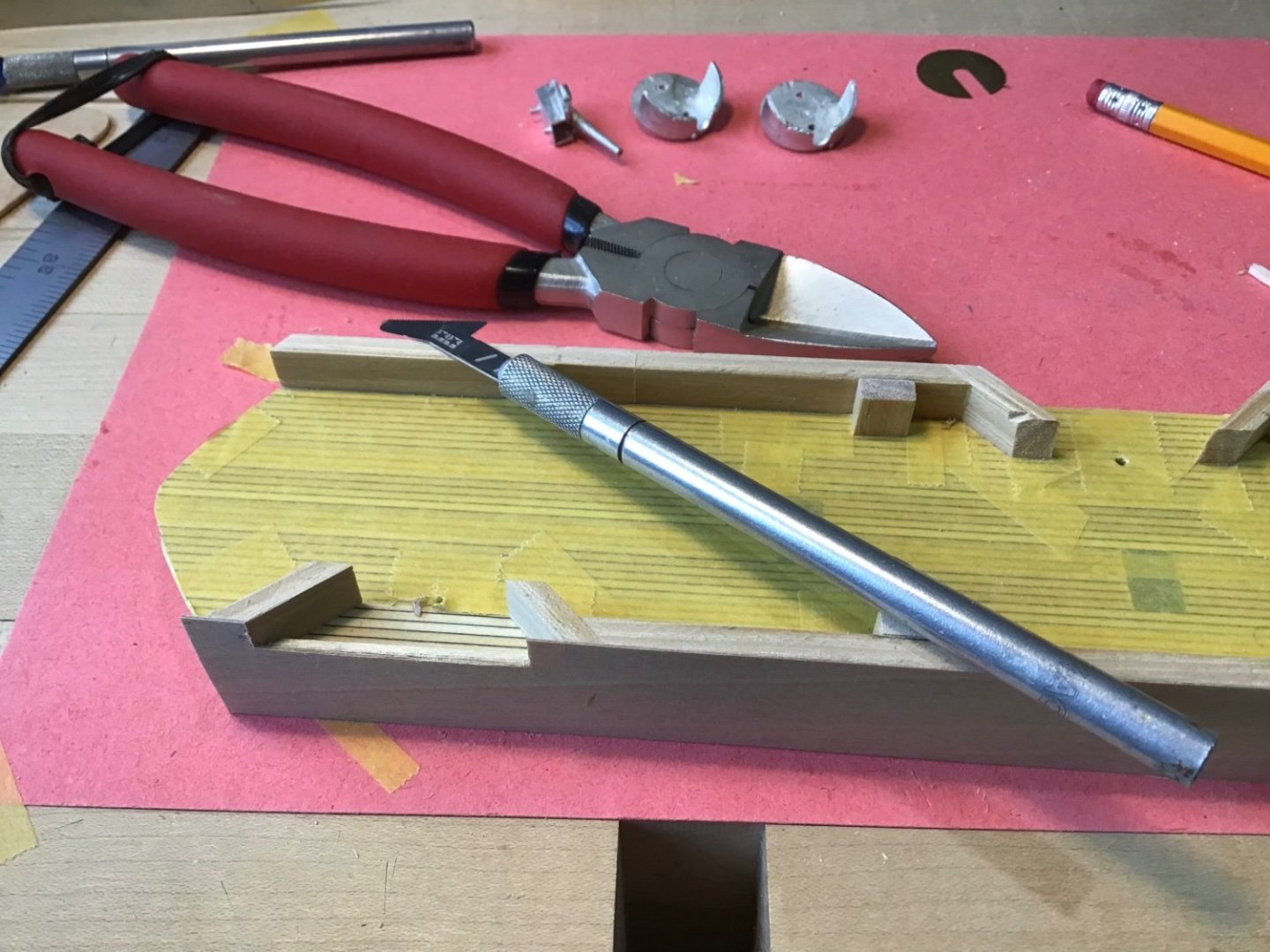

Midships Superstructure - Part 1 First made a photocopy of plan for a template. Reckoned that the position of the gun turrets drives the assembly so fitted the turrets first then built the hammock lockers. Cut stock with a Byrnes table saw. Rough trimmed the plywood pieces for the bulkhead sides with a papercutter. Then glued to block. Trimmed the bulkhead bottom and top flush. Used a 5/32” wide piece of stock as a temporary sill for the horizontal bulkhead cut In front of the 6” turret. Trimmed with Tamiya precision saw in an X-Acto holder. The red handle tool is a flush cutter, typically used to cut veneer or plastic board edge banding, sourced from Fastcap. Turret dry fitted.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Thanks Rick, it did take awhile to get the hang of it….

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

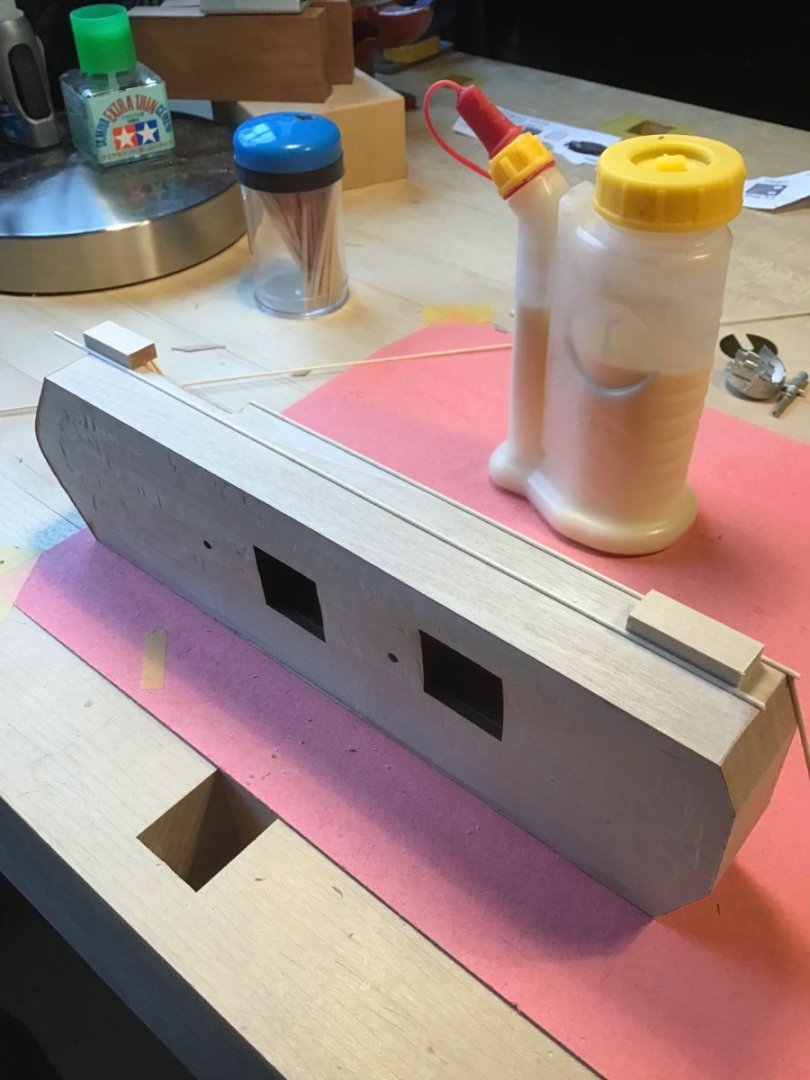

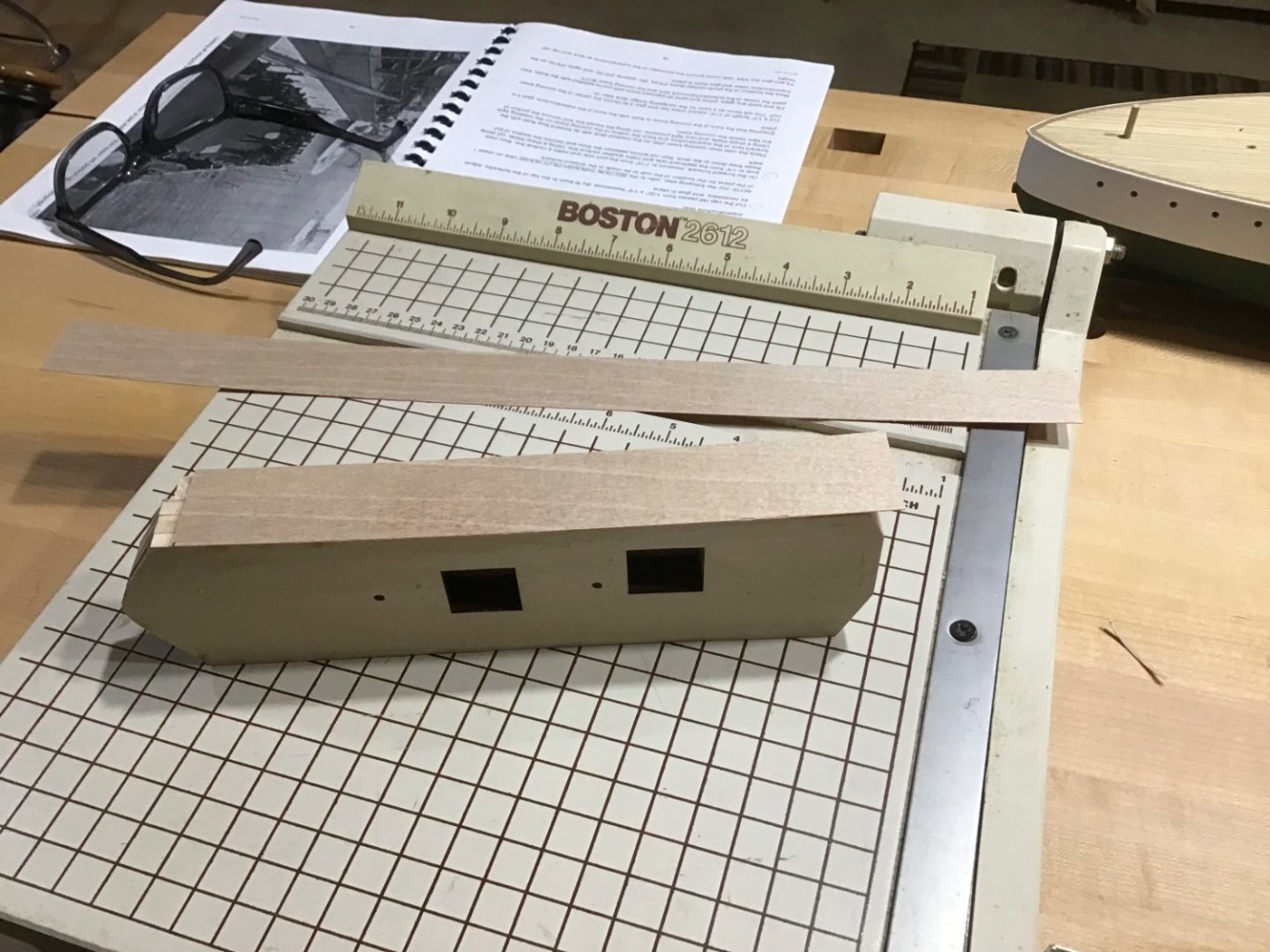

Middle Superstructure Fitting Have to fit the superstructure to the deck camber. Started by planing the bottom with a plane with a convex sole. Plane sourced from Veritas woodworking. Planed to as close to the edge without going over. Next is to scribe the sides so they fully contact the deck. Here I used a pencil to mark where the the part touches the deck. Then the convex plane was used to carefully remove marked wood, planing along the edge and from outside to inside.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

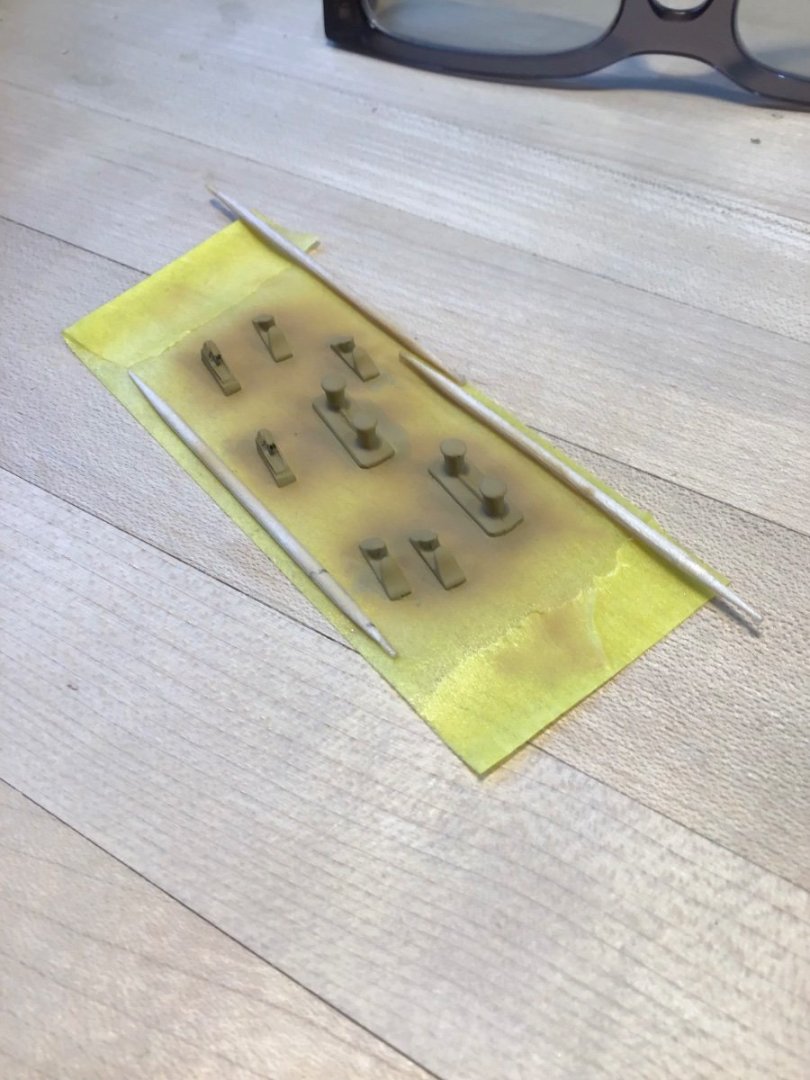

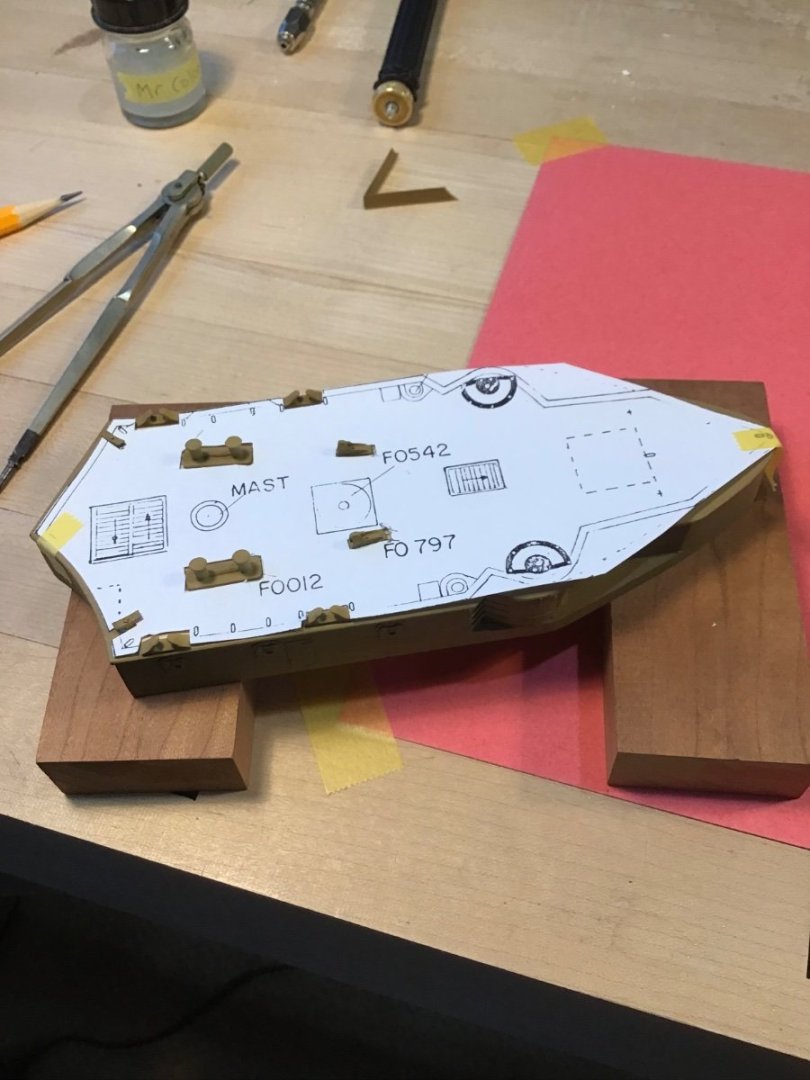

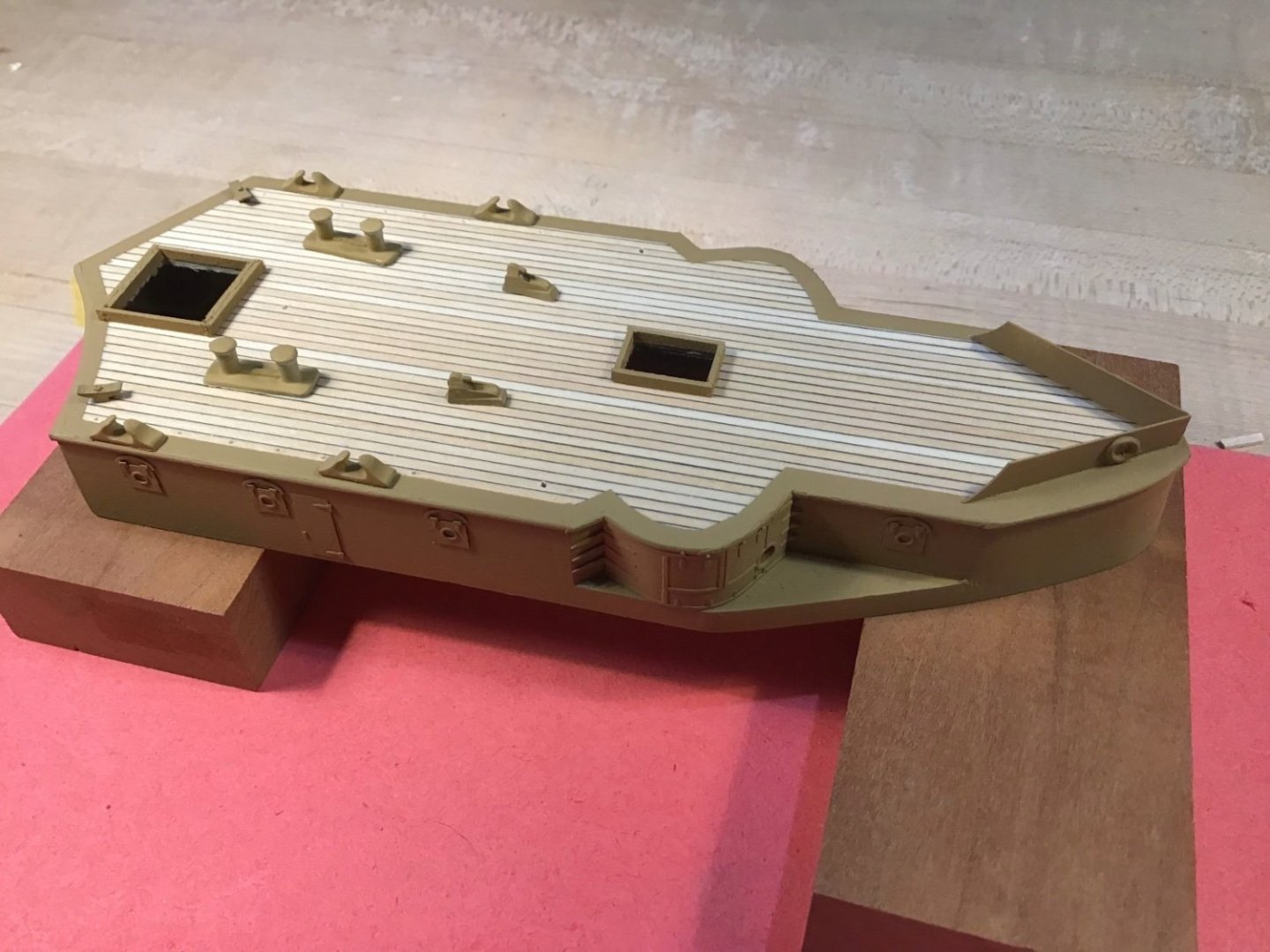

Finishing the Forward Superstructure The completion of these steps bring us to page 16 of the instruction book. Filed the parting lines from the metal fittings. File set purchased at Home Depot. Next primed the fittings with Mr Primer, thinned with Mr. Color; then painted with XF-26. Next made a photocopy of the deck, cutout the openings for the fittings, and installed them. And removed the template. Next installed the bow break. The challenge here is to get adhesive on the thin edge of the styrene without a mess. So dry fitted the break, applied tape on the deck along the edges, removed the break, applied adhesive to the deck, reinstalled the break, slowly removed the tape before the adhesive dried. Finally installed the hatch coamings, and cleats. Cleats by Syren Ship Model Company

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

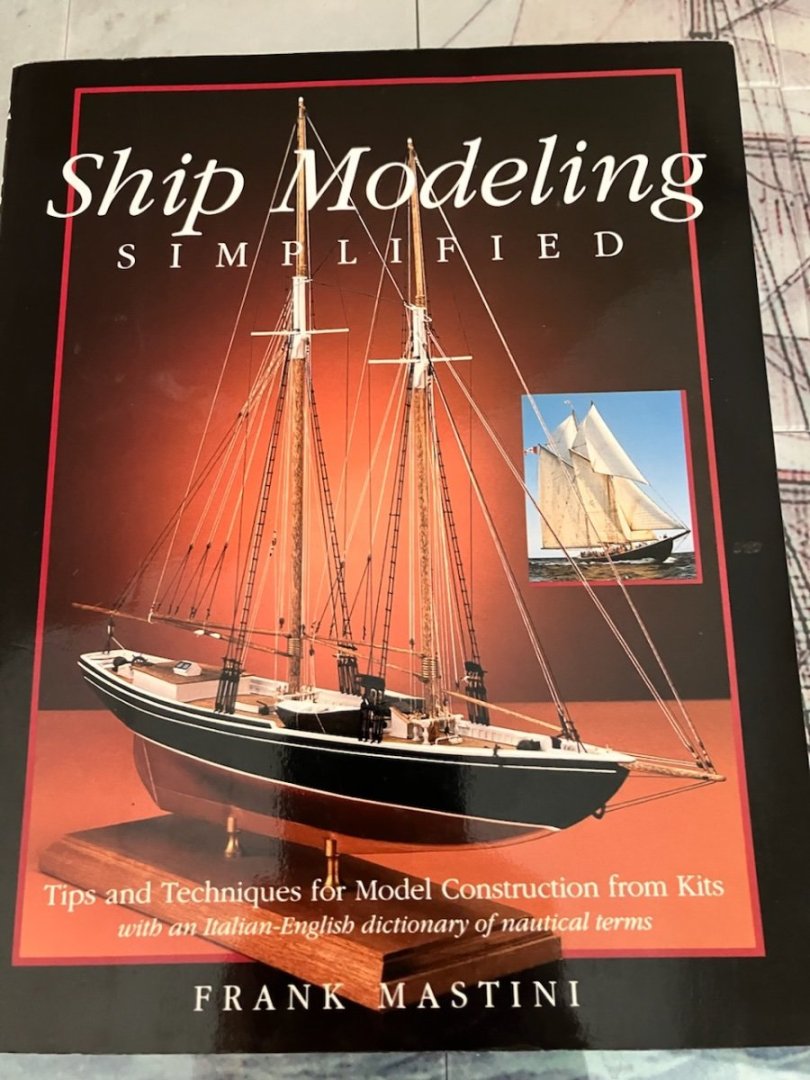

Hello and welcome to the forum. I’m always available to answer a question. Please take a look at a build log to learn the ropes. Logs can be accessed from the home page. There is a link to my Constitution log below my signature. As for tools, super special tools aren’t needed. Suggest a chisel or two, a set of small files, and a block plane for plank tapering. Learning the techniques of woodworking is important. How to sharpen and use a chisel, understanding wood grain, how to work wood with a plane and files. Plenty of YouTube videos out there. Or a basic woodworking course. Finally grab a book.. In my opinion the best book for beginning is “Ship Modeling Simplified”. Shows all the major steps, how to do it, and a glossary - the terminology is half the battle. Good luck on your shipbuilding journey.

-

Gluing on planks

ERS Rich replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

Checkout this build post: -

Gluing on planks

ERS Rich replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

Hello Rudy, Not sure how long the plank being installed is. Working with short planks is easiest. My preference is a plank that spans four bulkheads. And Titebond wood glue with Locktite superglue. Apply Titebond with a toothpick along one edge, set the plank aside, then a dot of super glue on each bulkhead. Place the plank and push the edge with Titebond against its neighbor. Apply pressure at each bulkhead until the superglue sets. The superglue will fix the plank in place, while the Titebond dries. Use a scrap plank to scape any squeeze out. Checkout my Constitution Hull build log for more planking examples- link in my signature below. Cheers -

Finishing the Hull Last steps to finishing the Hull are drilling the holes for the deck stanchions and turnbuckle eyebolts; and anchor bill top plates. This brings us to the top of page 14 of the instruction book. First photo shows drilling a hole with an Amati pin vise with #76 drill bit. Stanchion hole locations were marked off using plan sheet 2, starting from the forward superstructure and working aft. Second photo shows painted anchor bill plates in place.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Welcome aboard Senior Chief; always open to answering any questions shipmate!

-

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

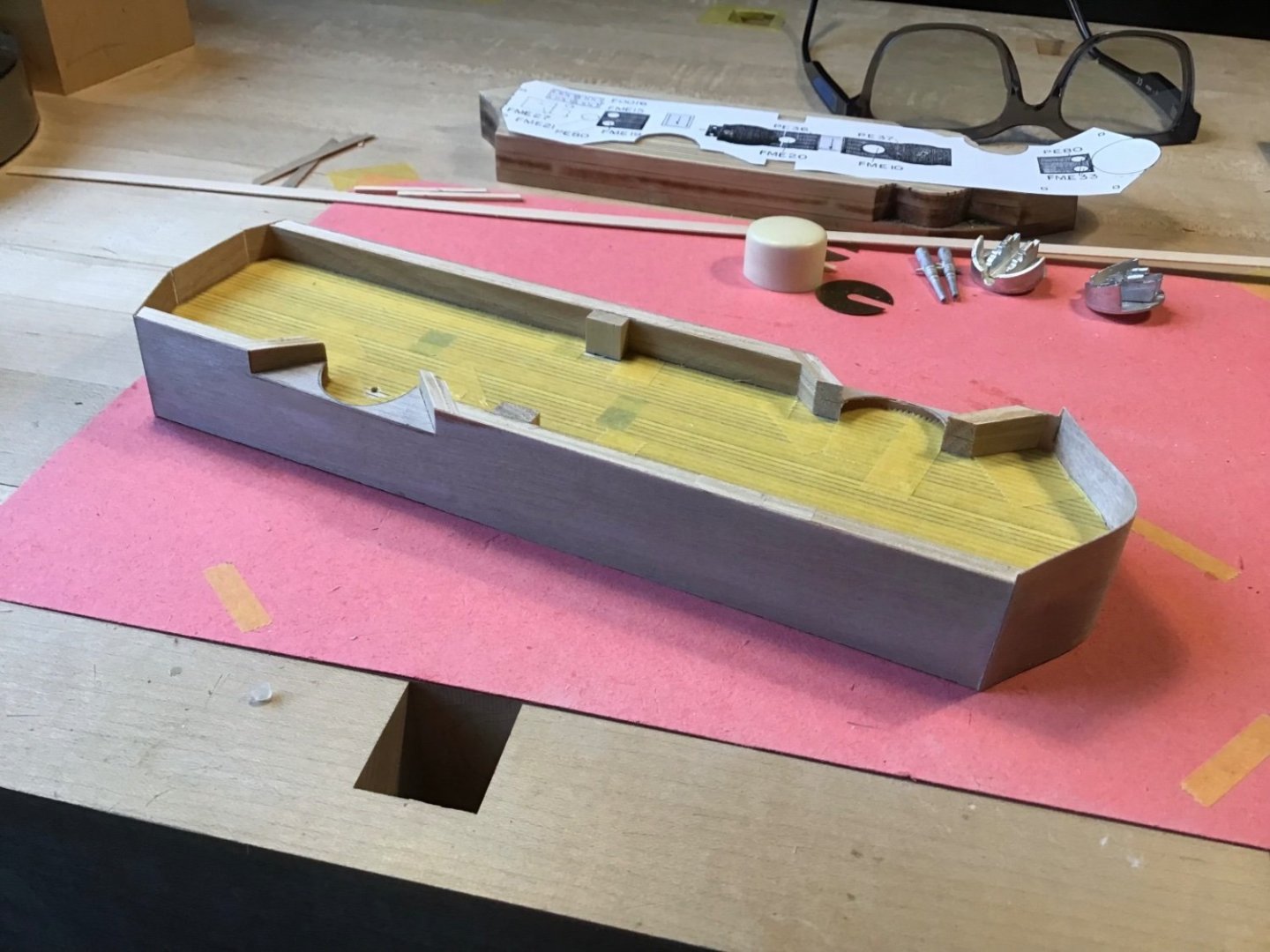

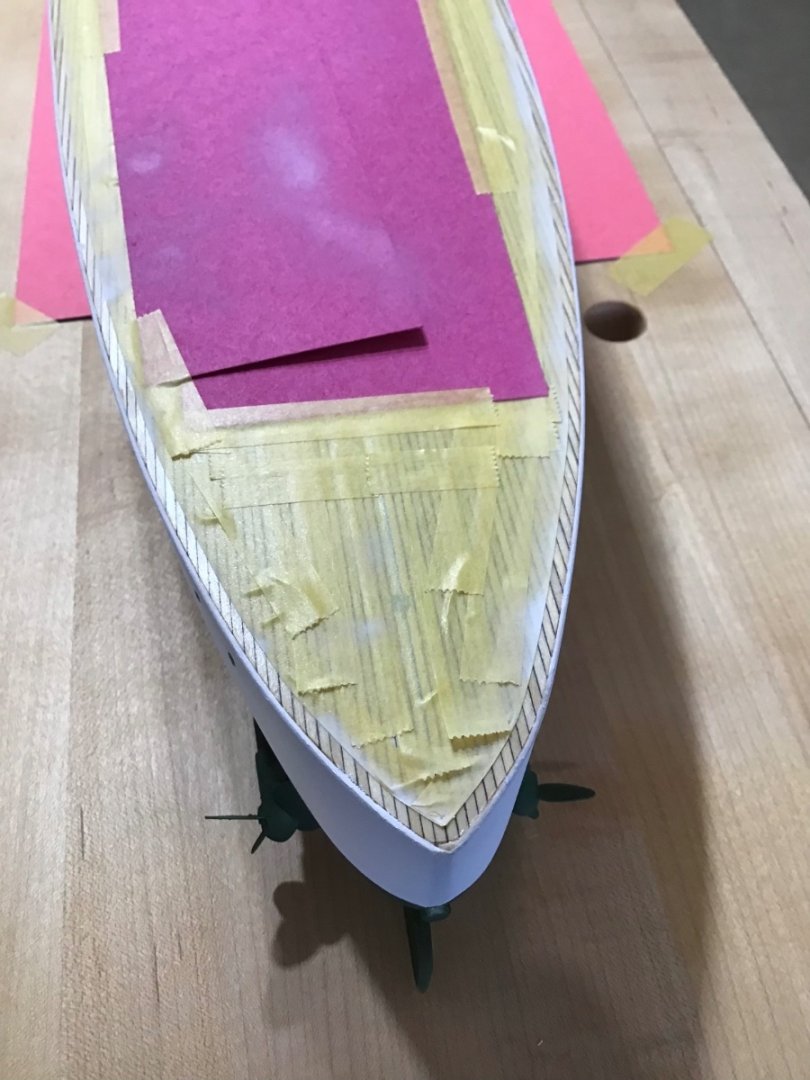

Painting the Waterways An exercise in masking…. Used Tamiya 3mm tape as a spacer at the edge half round hull trim, then masked along its inside edge, and construction paper to mask the remaining deck. Then removed the white tape. Not shown is I masked the top edge of the half round. Then painted the waterway Tamiya Desert Yellow XF-26, with Paasche Talon #2 tip. Next masked over the waterway and painted the top edge of the half-round white.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.