-

Posts

1,984 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glen McGuire

-

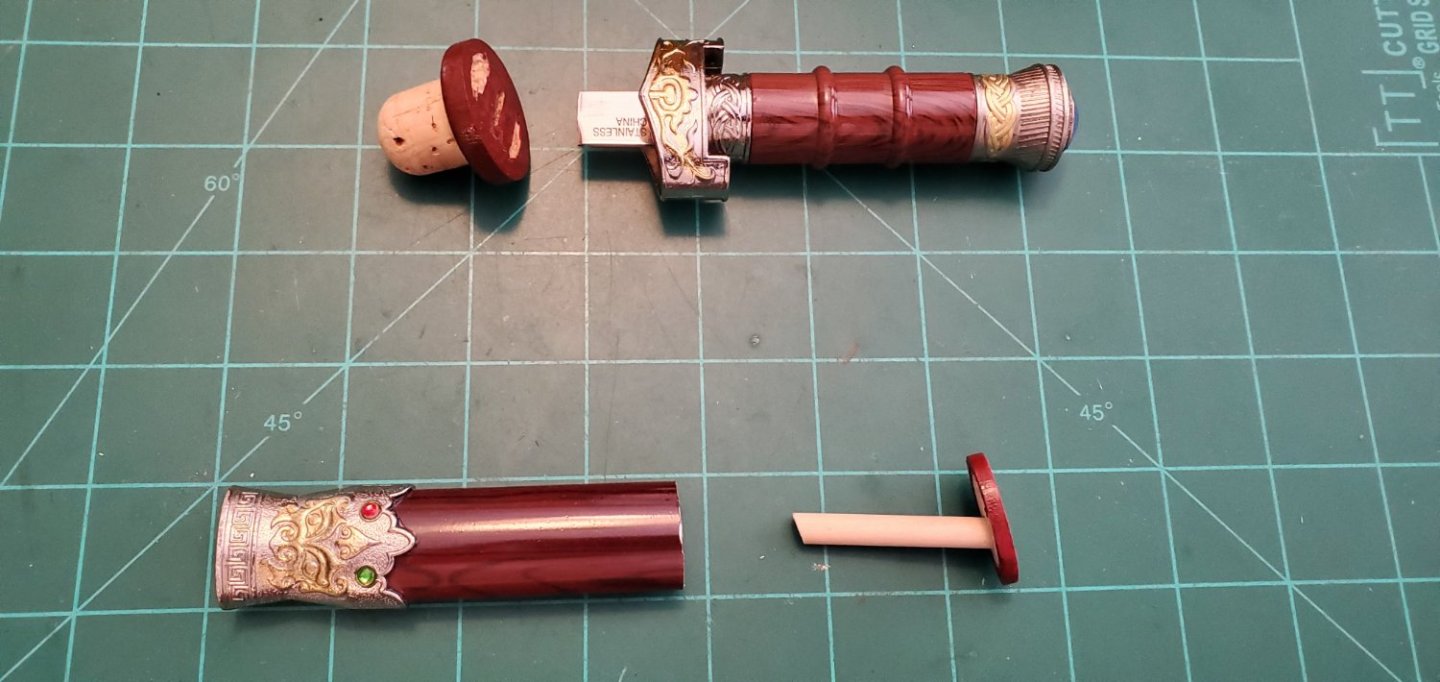

Here’s my idea for the final presentation. My thinking might be a little far out, but hang in there with me on this! Since the base is a sword holder and the bottle sits on the sword holder, the bottle should serve as the sword or at least bear some resemblance to a sword, right? So my thought was to have a sword handle protruding from the bottle opening and the end of a scabbard protruding from the bottle’s base. I was not sure how that would turn out but was determined to try. I found a smallish Chinese-style sword on Amazon and ordered it. The sword is actually a letter opener that fits inside a scabbard. To secure the sword handle to the bottle opening, I cut the sword's blade off about ¾” from the hilt. Then I found a cork stopper that fit the bottle opening (the bottle originally had a screw-on cap), sanded it down, and slotted it so the cut-off blade would fit snugly inside. Then I color matched the stopper to the sword handle’s color. For attaching the scabbard end, I could think of no option other than using epoxy to affix it to the bottle’s base. The scabbard is actually thin metal painted to look like wood. I cut it off at the length I needed to balance it with the handle. Then I carved out a little wood grommet with a small, angled support and epoxied the scabbard to the grommet. Then I epoxied the whole thing to the bottle’s end and set the bottle inside the boot holder to cure. Believe me, I was more then a little nervous turning the bottle on its end like that to fit inside the boot, but everything inside held tight! While waiting for the epoxy to fully cure, I added a few touches that a friend with an eye for details suggested. I took 2 of the small red and green “jewels” from parts of the scabbard that I was not using and added them to the hilt to match the scabbard end cap. I also highlighted the Chinese lettering on the base (“A Great Treasure in Your House”) with a paint color that matched the sword handle.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

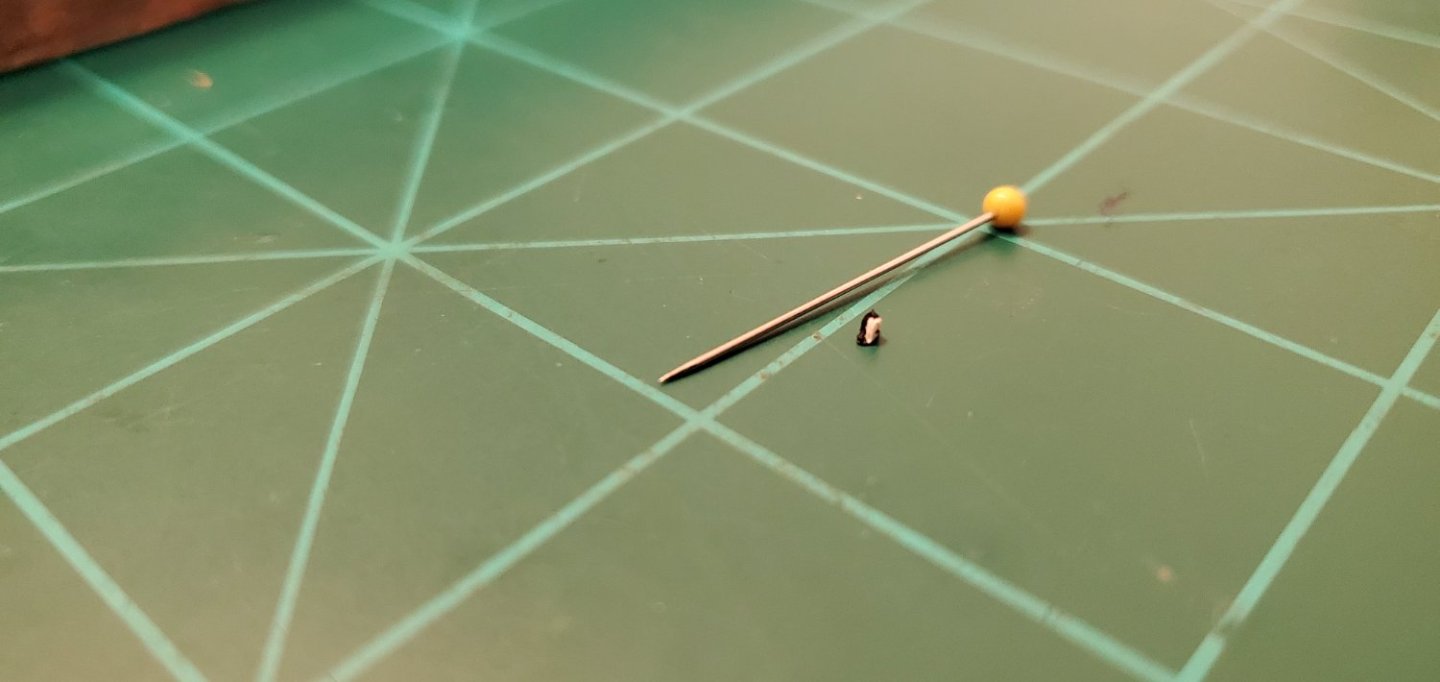

While waiting on an Amazon delivery so I can complete the treasure fleet base, I decided to see if I could actually make something resembling a tiny penguin. Since the longhorn herd turned out pretty well, a penguin shouldn't be too hard, right? So here he is. He's 1/16" tall. That scales to about 1/750 based on a 4' tall emperor penguin, so it's definitely a reasonable size for one of my SIBs. I may open up the Aurora bottle and try to mount him on one of the broken ice floes. If that doesn't work, I'll save him and maybe do an Endurance down the road. Oh, and I named him Keith.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Welcome aboard, Steve! Looks like you've got a flair for western art as well based on other things in your work area!

-

Thanks, Grant. The base is a sword holder shown in one of the early posts. I've got a couple of things in mind to do to it to try and make the whole thing look better. We'll see how those turn out. Keith, you have now joined my son on the list of people no longer allowed to suggest new SIB projects! 🤐

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

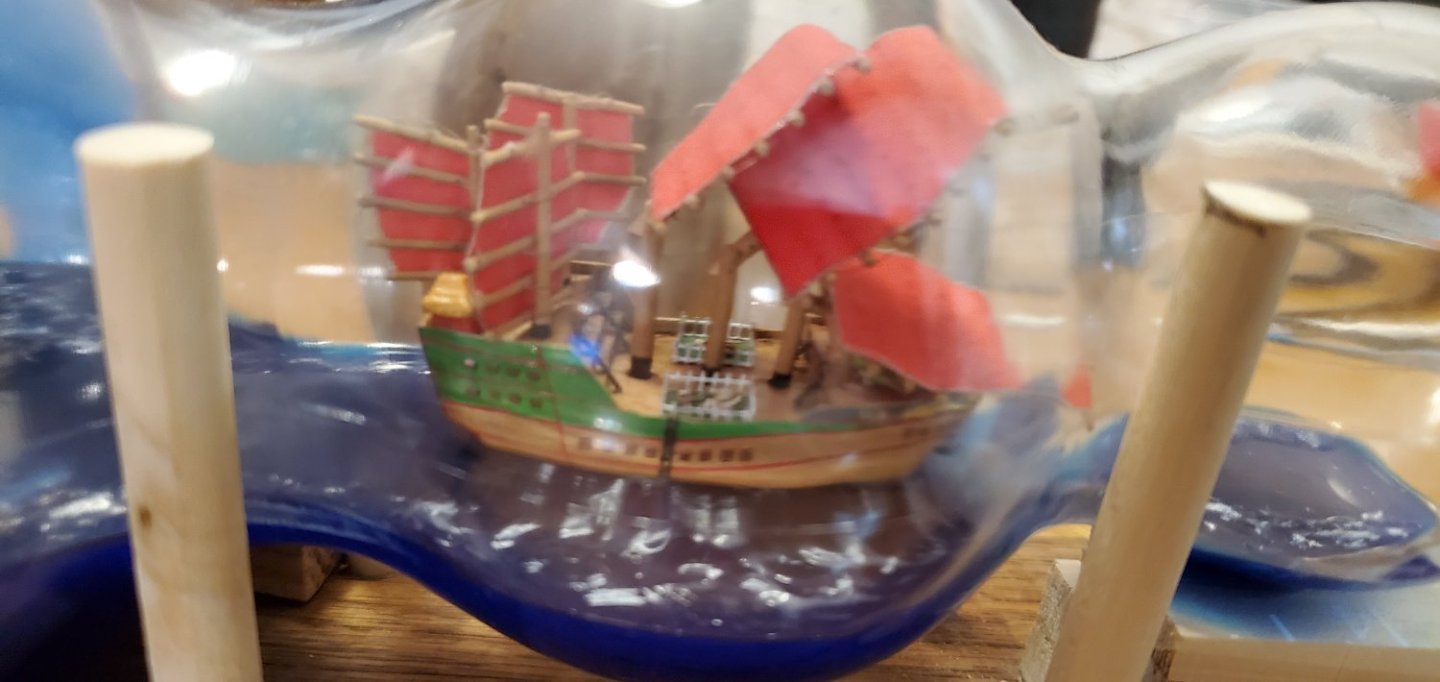

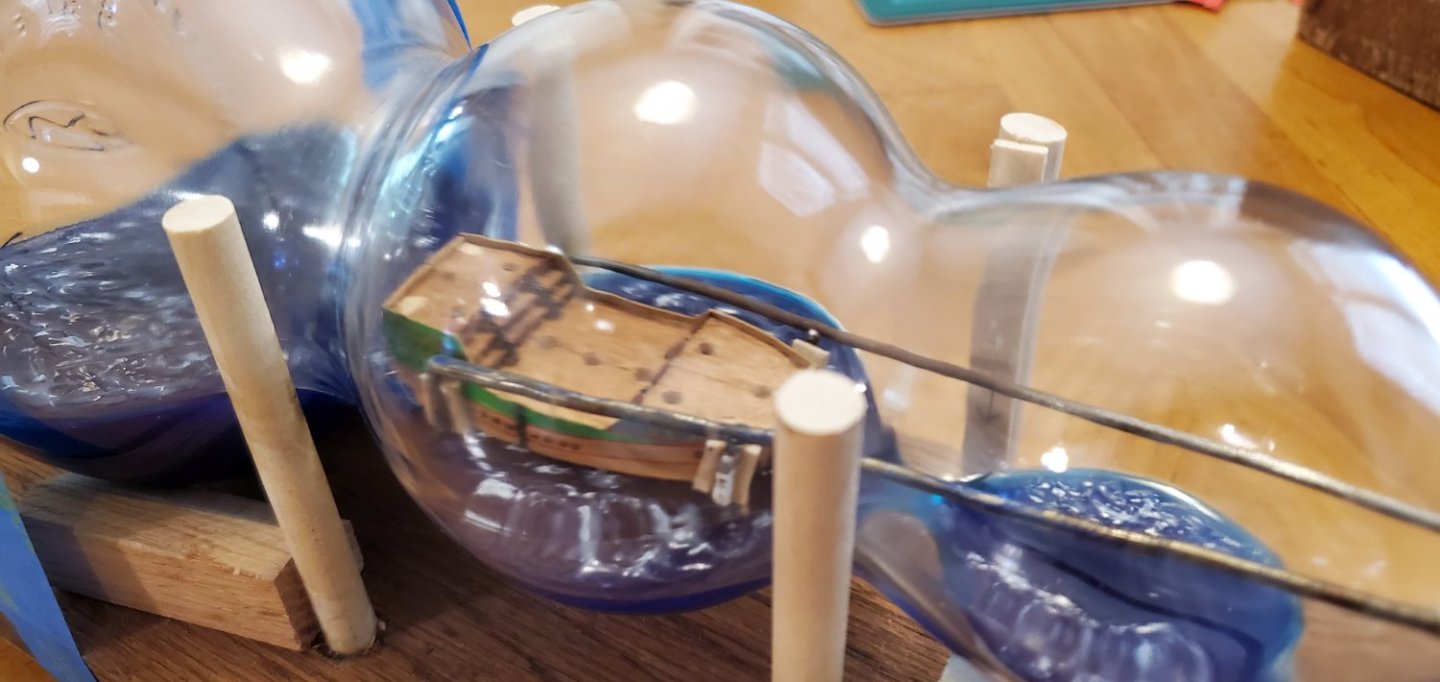

The third and last ship is in the bottle! The mini Treasure Fleet is afloat!! Now I've got some work to do on the base for the final presentation.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Thank you, Keith, SH Johnny, Mark, Roger, and Grant! Yes, huge sigh of relief here!!! On the home stretch now. Hopefully I did not jinx myself as Keith alluded to earlier!

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

While working the masts/sails, it dawned on me what the best thing about these junk ships is - no ratlines!!! 😍 Anyway, it was a long but successful process Friday night and Saturday installing the 6 hinged masts with sails. I started with the ship resting in the middle bulb. Here was the process for each mast/sail: 1. Scrunch the sail up the mast, insert into the small bulb, and push it off to the side oriented where I could easily grab the mast with long tweezers. 1. Mix some 30 minute epoxy and start a timer (it's really only about 20 minutes before it becomes too gummy to work with). 2. Dab a bit of epoxy into the targeted mast hole. 3. Grab the mast with tweezers and work it a bit to get it hinged at a good angle for inserting into the mast hole. 4. Make a bunch of stabbing attempts until I finally hit the hole (trying to ignore the ticking timer). 5. Using another way-back tool, straighten the mast upright and maneuver it around until the whole thing looks like it rests at a 90 degree angle bow to stern and port to starboard. 6. Let it sit for 2-3 hours, then rinse and repeat. During the whole process I was really worried about the mast hinges. They were getting a lot of work as I was repeatedly having to push the sail up and down to make room for each successive mast/sail. But they held up quite well. I was terrified that one would stress and break which would have been a catastrophe. After all the masts/sails were firmly in place, I slid the ship into the back bulb, pushed it to the side as far as possible (maybe 1/2"), dabbed some epoxy on the water, and slid it back over the epoxy to lock the ship into its final resting place. Once that round of epoxy was dry, I carefully raised the folded part of each mast/sail till it was upright and straight. Then I dabbed a touch of epoxy onto the hinge to lock it and moved on to the next one. Distorted pictures follow...

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

You and me both! I am not a patient person so this is testing my limits!! If I can get the next 6 hinged masts in place and raised on the treasure ship I'm home free. The 2 smaller ships will be relatively easy.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

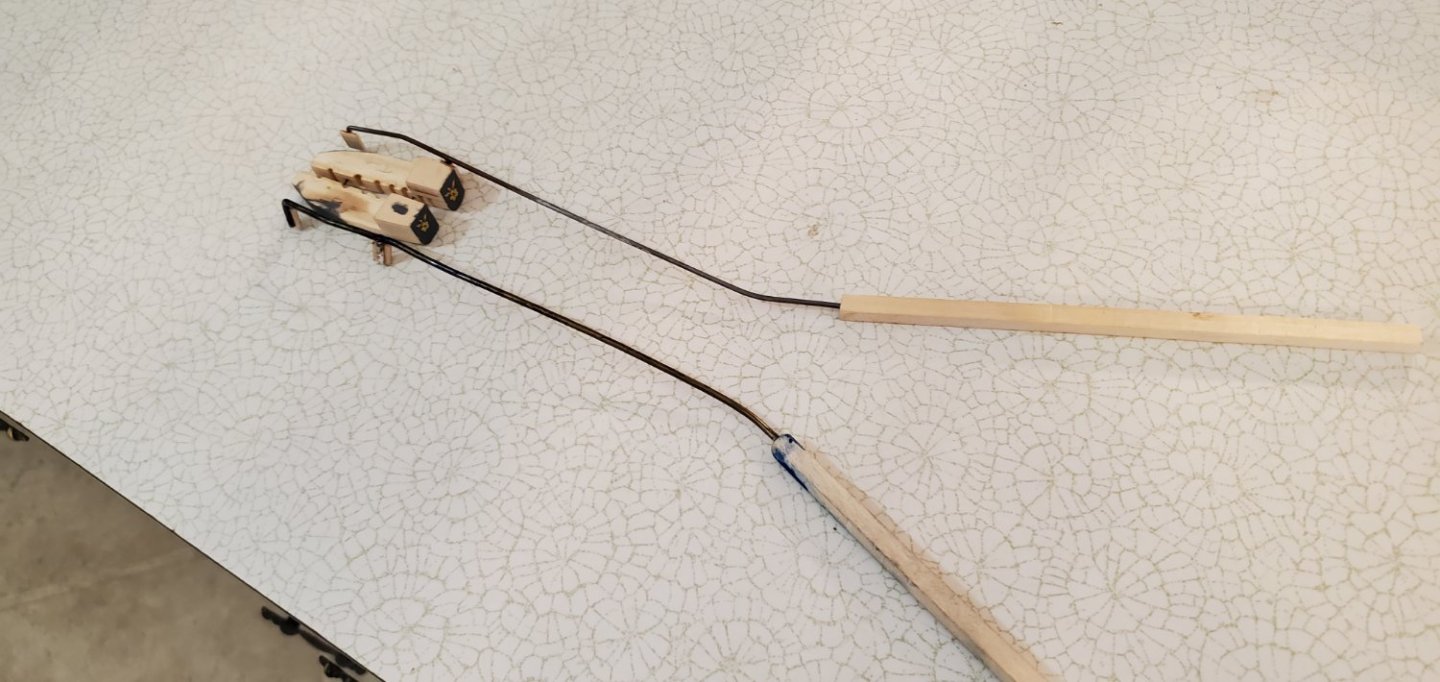

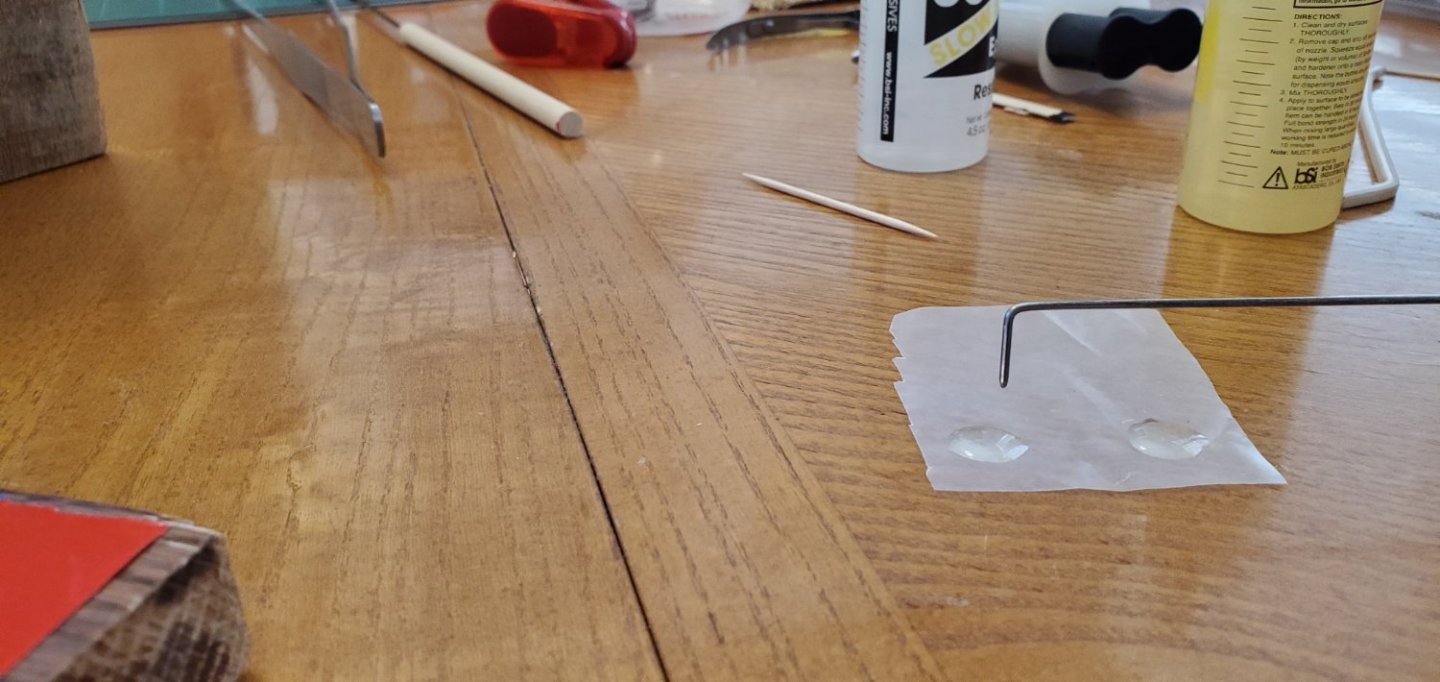

Game time!! Unlike my previous builds where getting the ship in the bottle was the moment of truth, this time that will be the easy part. The real challenge is assembling things inside the bottle. It’s going to be a slow process as I’m using 30-minute epoxy for each step (hopefully that’s sufficient time). So there will be long waits for the epoxy to set between each step. Here’s the starting point – with waves and whitecaps added to the water. I left a smooth channel down the middle so I can slide the ships as needed during the assembly process. When I get the furthest left ship glued in place, I’ll add some texture in the narrow water before I put the middle ship in place. Here’s the tool I made to push the 2 halves of the hull together and hold them in place till the epoxy dries. I got the 2 halves of the hull inside and glued together. No turning back now as the boat is not coming back out of the bottle!! After the hull epoxy set, I needed a way to hold the hull steady while I inserted the masts and added fittings to the deck. So here’s the tool I came up with. It’s a brass rod with two prongs that fit inside two mast holes on the forecastle. Secured of course with duct tape. For placement of epoxy to exact spots on the deck as well as inside the mast holes, I use a long, thin metal rod with the end filed to a point. The 2nd pic shows placement of two small shelters on the rear corners of the quarter deck. The 1st pic below shows successful installation of the first mast and sail in the rearmost hole on the quarterdeck. The 2nd pic shows successful installation of the other two quarterdeck masts/sails as well as the longhorn corrals and corn field. Next up is the real test - adding the hinged masts...

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

WOW! That is amazing stuff. Her work requires real artistic talent which automatically disqualifies me. For the most amazing miniaturist I've ever seen, check out my addition to MTaylor's post on Impressive Miniatures: https://modelshipworld.com/topic/32342-impressive-miniatures/#comment-929824

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Speaking of impressive miniatures, have you seen this? It's the most amazing miniature art I've ever run across. The Mount Rushmore carving is inside the eye of a needle. The BMX rider carving is on the tip of a dog's hair. The skateboarder is on an eyelash. Yes, an eyelash!! https://www.willardwiganmbe.com/

-

Thanks for checking in, Mike! Yes, the pressure and suspense is mounting as I impatiently wait for the texture I added to the water to dry. I know you understand what it's all about!!! 😬 Regarding the Dimple products, looks like my local stores hear carry them so I will check them out.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

I echo what Tom, Brian, and Mark say above. Your additional progress on the Tennessee is fantastic, but the best part is seeing you back and working on it.

-

HAHAHA!! Keith, I'm pretty sure there is professional help available for people with minds like yours!!!

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Thanks, Grant! I checked out your diorama beginnings. What a cool project you have chosen. I'm on board to watch that one come to life.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Here's closeups of each ship. In case things go south, at least I will have record of what they were supposed to look like! 😃

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Well heck. I thought I was done with the ships, but when I posted the picture of the Model Shipways bow I noticed there were 2 hanging anchors that I never noticed before. So it was back to work to make a couple of small anchors and complete the treasure ship. Also, since I really liked how the fingernail decals turned out on the treasure ship, I went back and added some ornamentation to the first 2 ships. And with that, the ship construction is complete! I am going to go add a little bit of texture to the water inside the bottle. Once it dries then it's go time! Anxious moments await!!! The last picture is a bit of a preview.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.265a7cb011ed1d9a2056c8c18c087197.jpg)