Trond

-

Posts

166 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Trond

-

-

- chris watton, AJohnson, wvdhee and 1 other

-

4

4

-

The bell is in place.

Whentthrough what size and how many deadeys I needed, more than I had. The bough a supplement package to the original kit with fittings, canons +++, but that was missing a lot and not very up to scale. So need to buy all blocks (boght some earlier) and other supplemtns for rigging.

Also startet with the figure. So this is take 1 and I'll see how many tries before I get it right. 1st time carving.

-

-

-

-

-

-

-

On 8/26/2022 at 4:57 AM, LyleK1 said:

You are gonna love it! I assume you mean the mini mill?

I use mine for a lot of things and I haven't even begun to use it for its full value!

I screwed up with my order and bought something that I really didn't need. Thank to you Lyle I did another going through my thought and what I had and what I needed. I got stop my order right before it left the shop. Know I'm going through what I really need.

So, I have a lath with a mill.

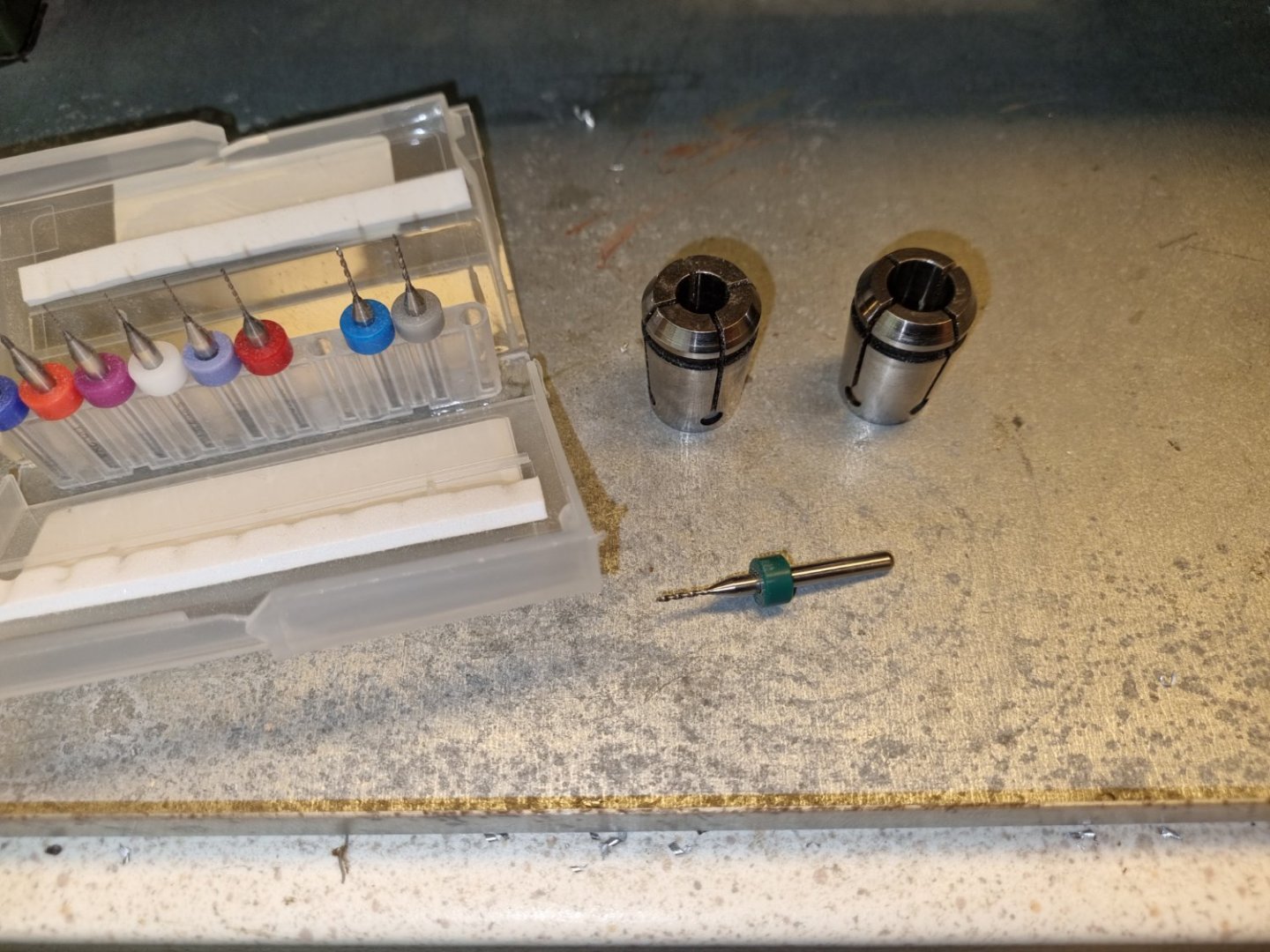

What I didn't know or though about was by getting a set of collets other than Proxxon, since what they have are to big.

By that I mean my very small drills 0.1-1.0mm which have a base stem of 3mm, which is to small for what Proxxon supplies or what I have. I also saw that it is possible to get a gear tooth chuck (10mm) with adapter that I can fit into my mill.

So I've asked for price and delivery of small collets and a gear chuck. It saves me a lot of money and is more accurate than what I've used so far.

-

20 hours ago, LyleK1 said:

Lots of pictures going forward on the masting and rigging. I've looked at numerous sources for the little details that are just not well pictured or explained.

So, going forward, I will attempt to make it bit easier on the next builder!

I went back and reattached the anchor rodes in the mid-bilge area:

Figured it would be easier to do now when the masts are not on the boat!

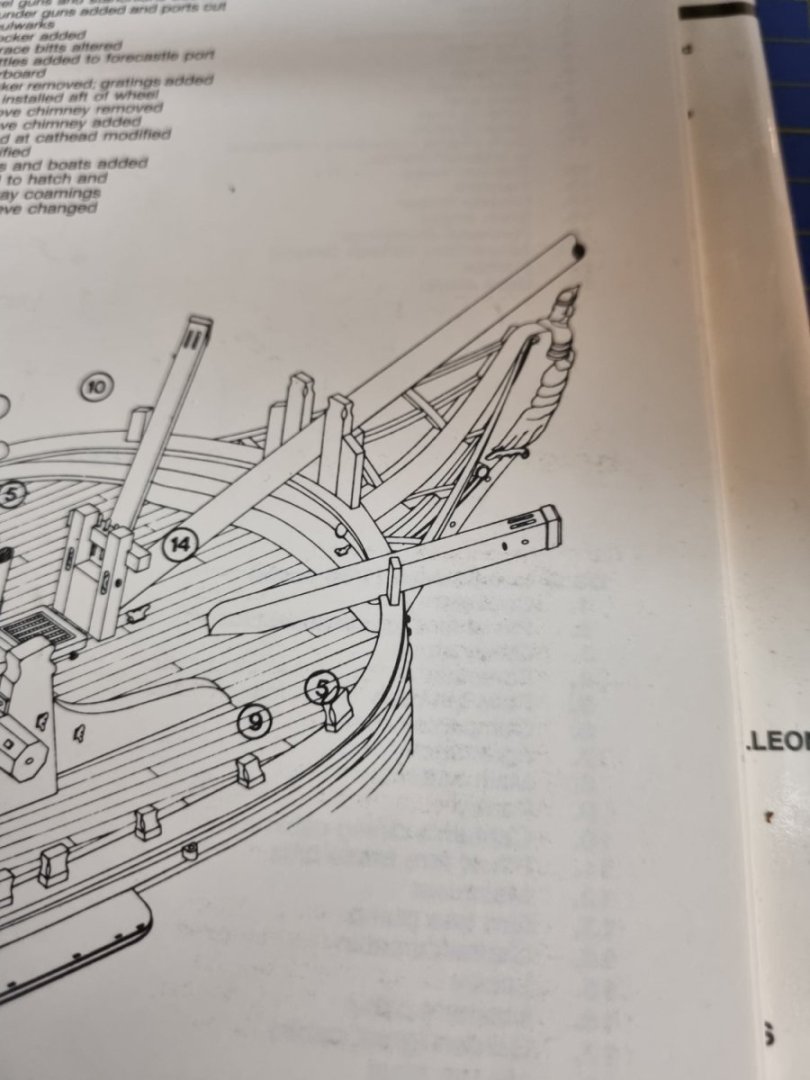

The rigging attached to the bowsprit was very hard to follow but I am confident I got most of (if not all) it right. As mentioned nothing gets done until I've researched it first unless it's REAL obvious!

The next series of pictures is that rigging being incrementally installed:

The Traveler was an item that took me a ton of time to figure out! Again, based on several sources, here is my rendition:

A tad out of round! But trust me, that was my best one! That was really tough to make and harder to find a decent picture of one!

And finally, the completed bowsprit from several angles and close-ups:

On to the spritsail yard.

Nice work Lyle and great pictures. Just had a more detail look in the book and I agree with you that drawingsit are complicated. So thanks for sharing good pictures. A very good reference when I get to that stage (some time in the future)

-

-

-

Nice work LyleK1.

In the Armed transport Bount book there is detailed rigging and the figure is descibed as a women in riding clothes.

I'm following the book as good as I can, but must admit I'm not sure how accuret the book is since from my understanding there is not to much detail from the real ship building.

-

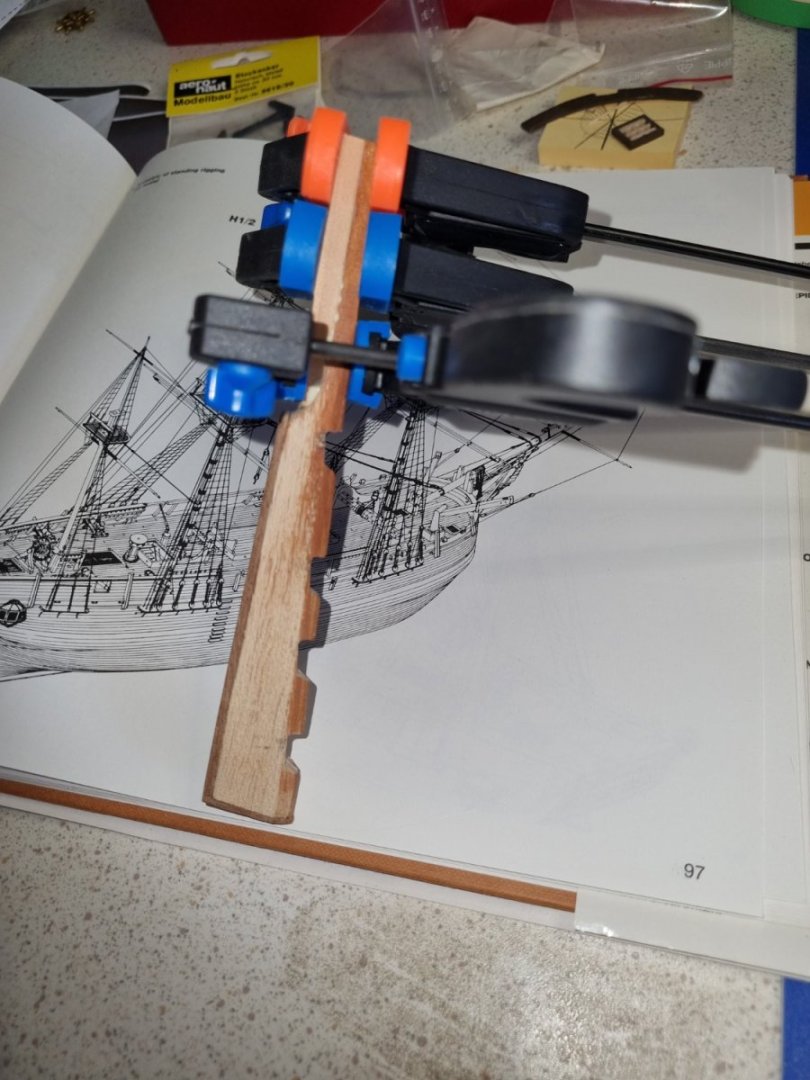

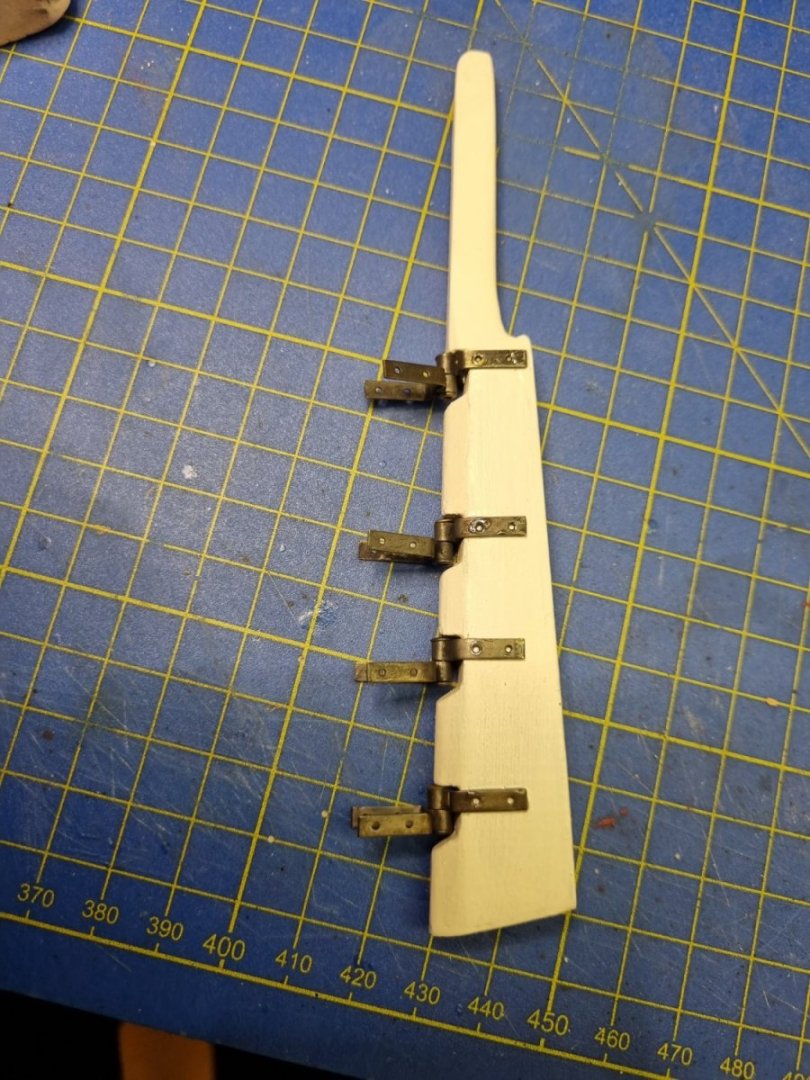

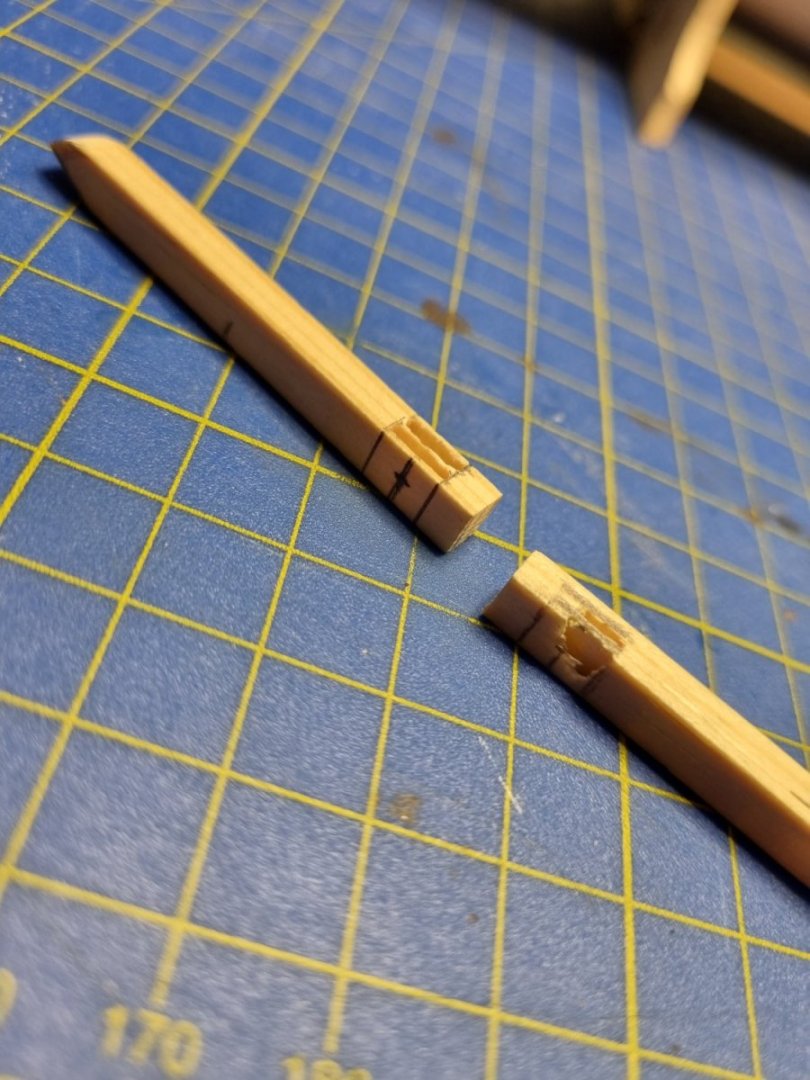

Next is the rudder. I accually could use the on in the kit with some modifications. Added on some wood and made som notches for the hinges.

I cheated and bought the hinges.

Had to paint it several times to get an ok finish.

At the same time I'm working on the Timberhead. The challange has been making the hole at the tip. My drill jig is not stable enough.

The with of the holes are 1.2mm. So I need to figure how to make them even and parallel.

I definitely should by my self a good columnar drill. Need to look around.

Anybody have any referance on good ones?

- AJohnson and Keith Black

-

1

1

-

1

1

-

- Keith Black, AJohnson and Mr Whippy

-

3

3

-

All the top fitting is scratch build and will be. The only thing I can use from the kit now on is 3 types of rope and maybe the mast and spare.

So It is sometime frustrating, but at the same time satisfying. I learn alot and it's fun to see the ship beeing built kind out by my self, using HMS Bounty book.

- Keith Black and AJohnson

-

2

2

-

- Keith Black, dunnock, AJohnson and 1 other

-

4

4

-

- AJohnson, ccoyle, Keith Black and 1 other

-

4

4

-

Thanks AJohnson.

I think I will raid my wife hobby room and see I can find som black thread to use for securing rope since I don't have a rope making machine?

Is there anybody that has bought a rope machine and have experience with it?

-

No apologize needed Gregory. I'm new to building wooden ship in scale and my learing curve is preatty step, so all commetens are welcomed to help me learn more about ship building and their history.

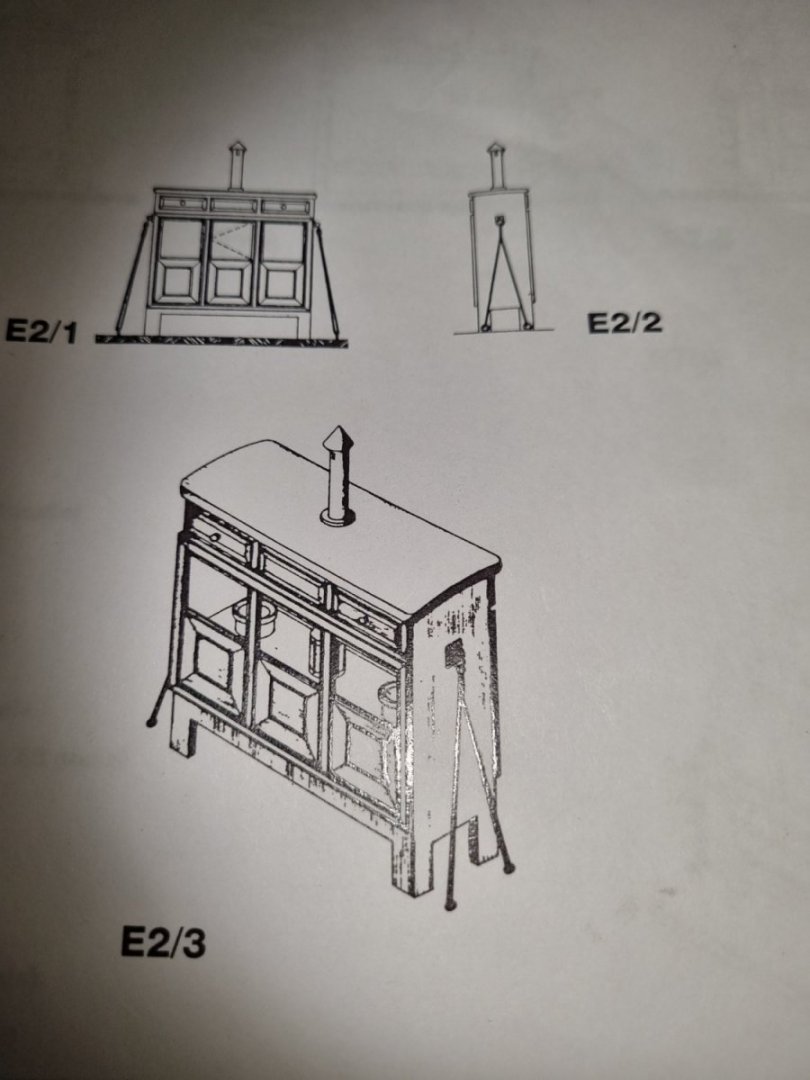

Another dumb question is the binnacle used for storing maps and navigation tools?

- AJohnson and Keith Black

-

2

2

-

4 hours ago, Gregory said:

FWIW, The stack on that binnacle does not seem to be documented anywhere, nor does it appear on any contemporary models that I am aware of.

What we have seen are vent holes in the side of the cabinet..

A bit of discussion here.

I is showed on several drawing in the The Armed TRansport Bount by John McKay. I see he is an architectural draughtsman and he has several referances.

I must admit I'm not deep into the sourcees on ship, yet ( but may come over time)

So I trust this guy.

So I trust this guy.

My kit is far off the real Bount, so I guess by following John McKyay as far as possible would be good. Can't follow everything since my kit Bounty is not in correct scale.

- AJohnson and Keith Black

-

2

2

-

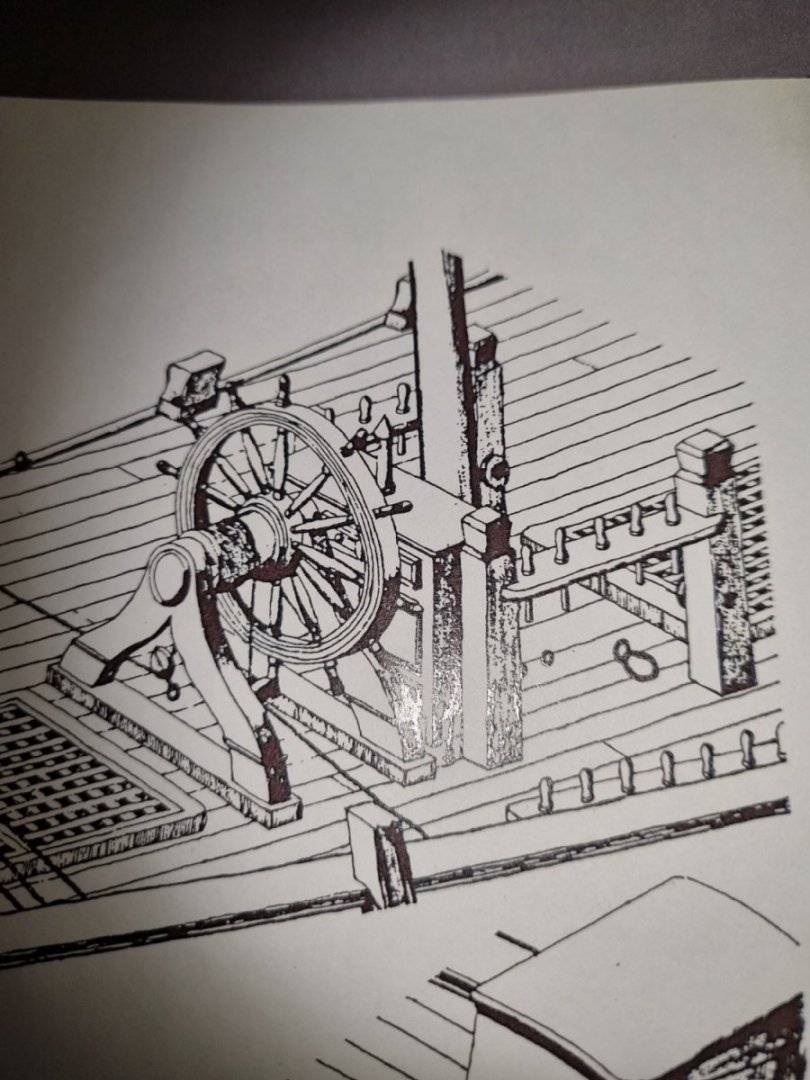

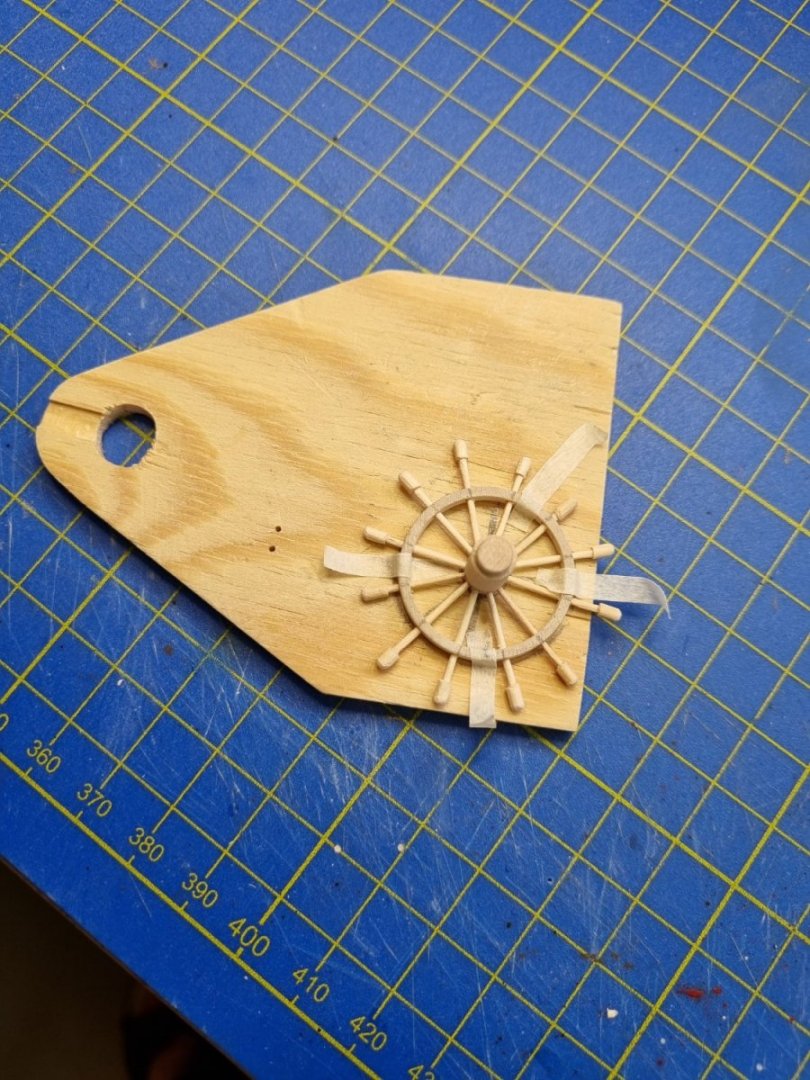

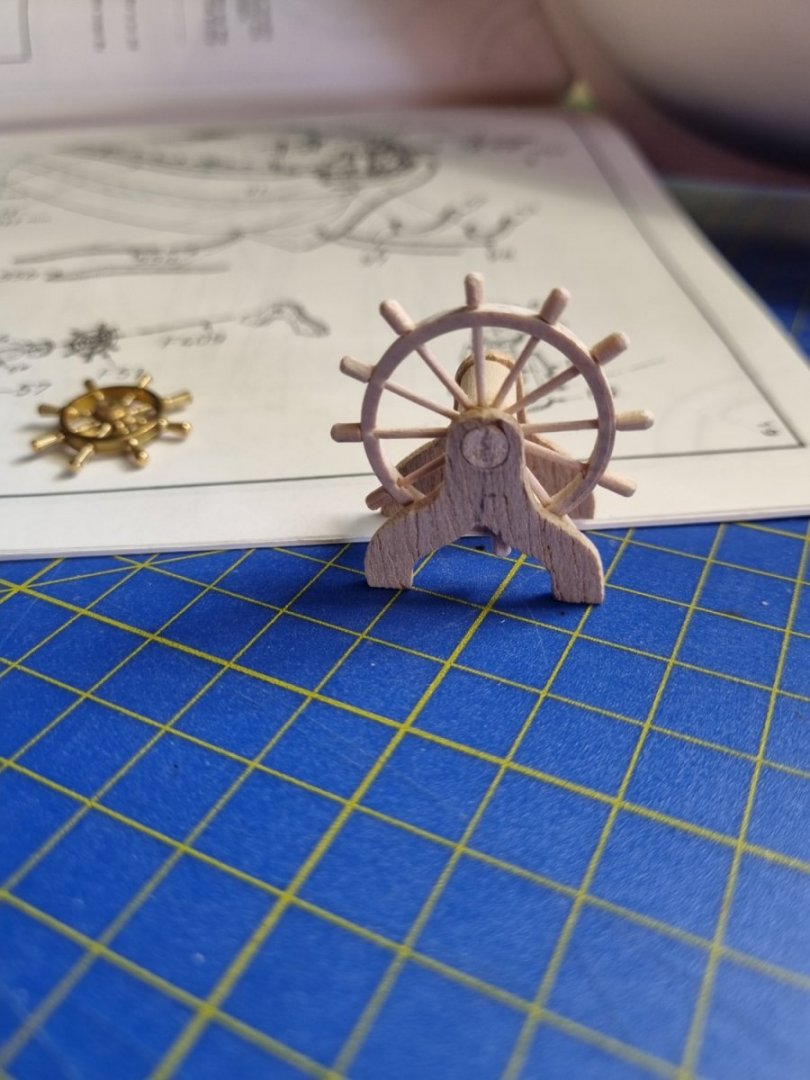

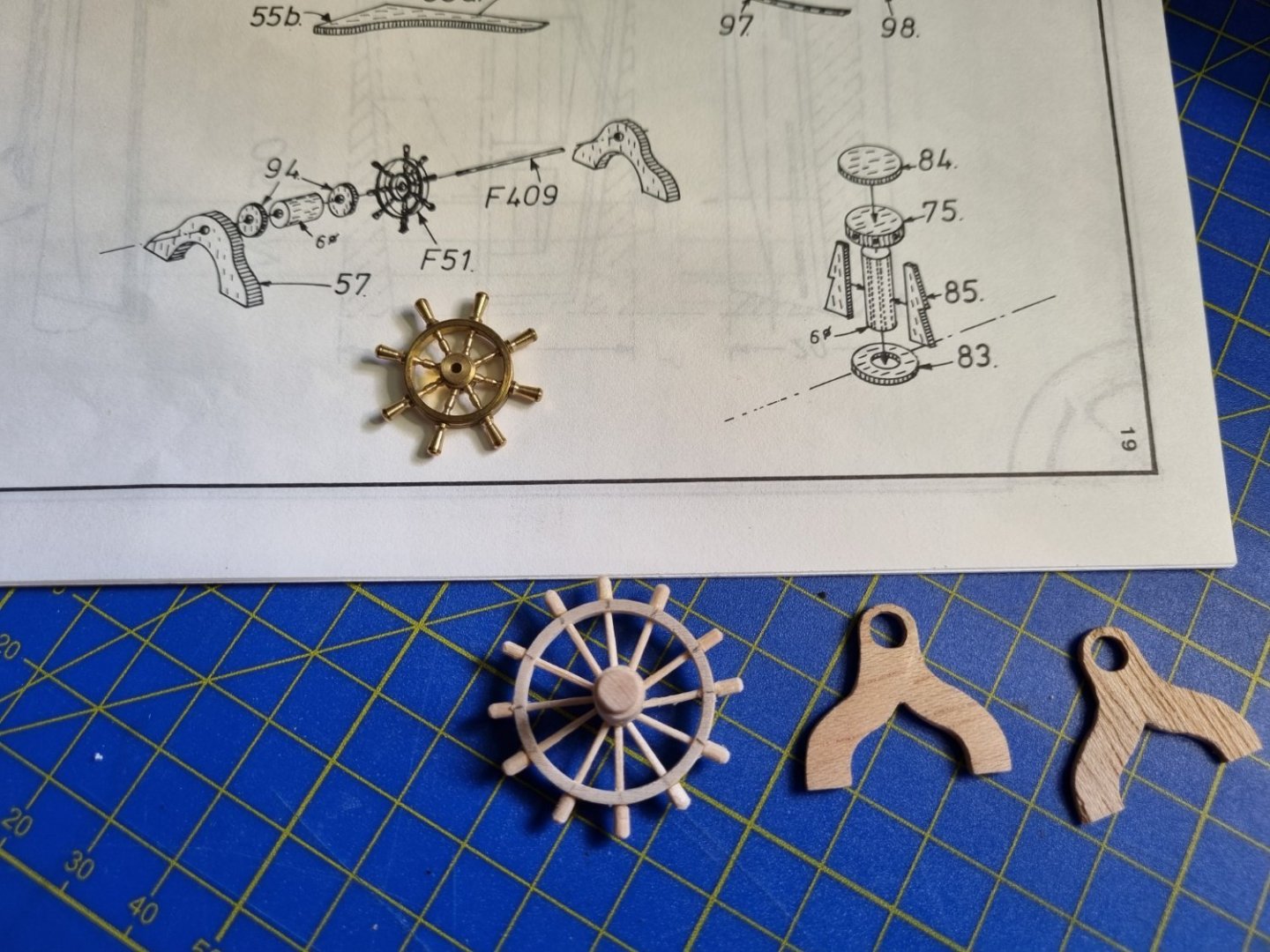

Here is a try-out on placing out steering wheel, shelf and rope securing station (don't know what is called, need to look it up).

I do have a challange and that is securing the shelf before placeing the rope securing station , in accordence to book.

Does anybody know anything about the securing rope?

The only "rope" i have is a whit "rope" that following the kit or black sewing machine thread.

I need to get myself a rope machine.

- Keith Black, AJohnson and Gregory

-

3

3

-

3 hours ago, allanyed said:

Hi Trond,

Kudos for making the wheel from wood!!! It really looks great.

Is there a reason you used 12 spokes instead of the 10 (or 8 on smaller ships) normally found on RN ships. Lavery, Arming and Fitting pages 22 and 23 goes into detail on wheel construction.

Allan

I'm useing Armed Transport Bounty as referanse since the kit drawing is very bad. In the book the drawings show 12 spokes. It was a very challenging job, but satisfied when I completed it.

Sometime I feel I'm doing more scratch building than kit building and I couldn't have done it without the book.

- Keith Black, Gregory and DaveBaxt

-

3

3

-

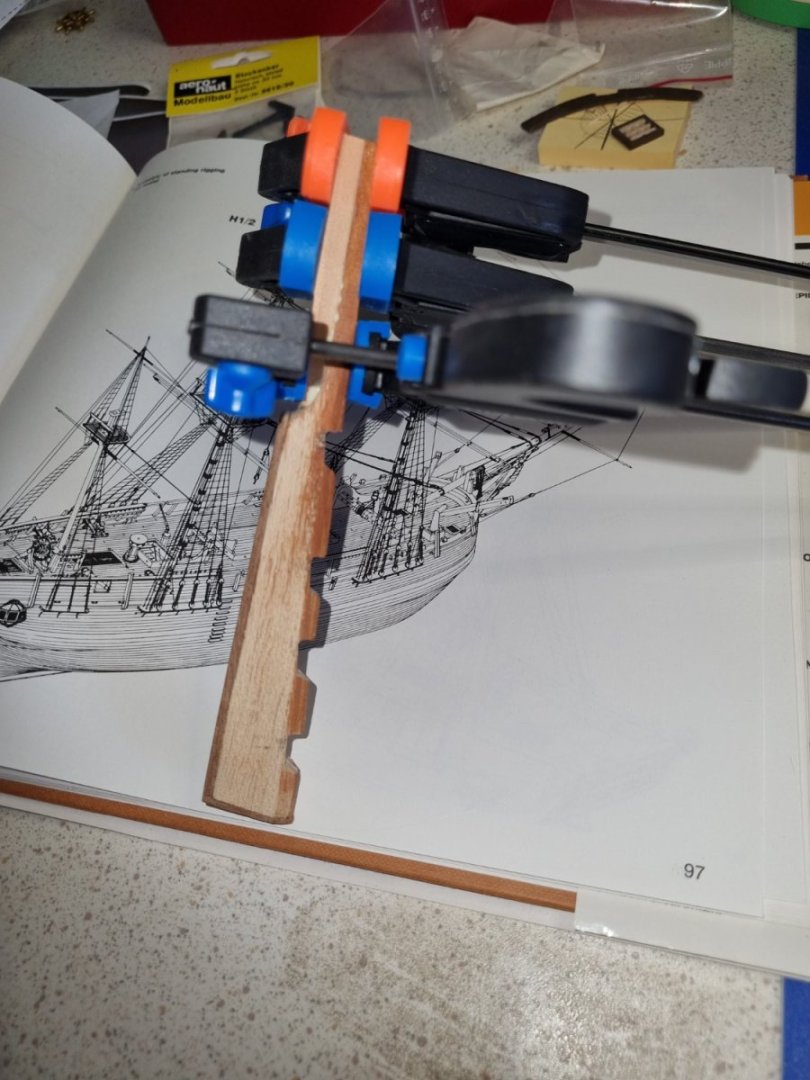

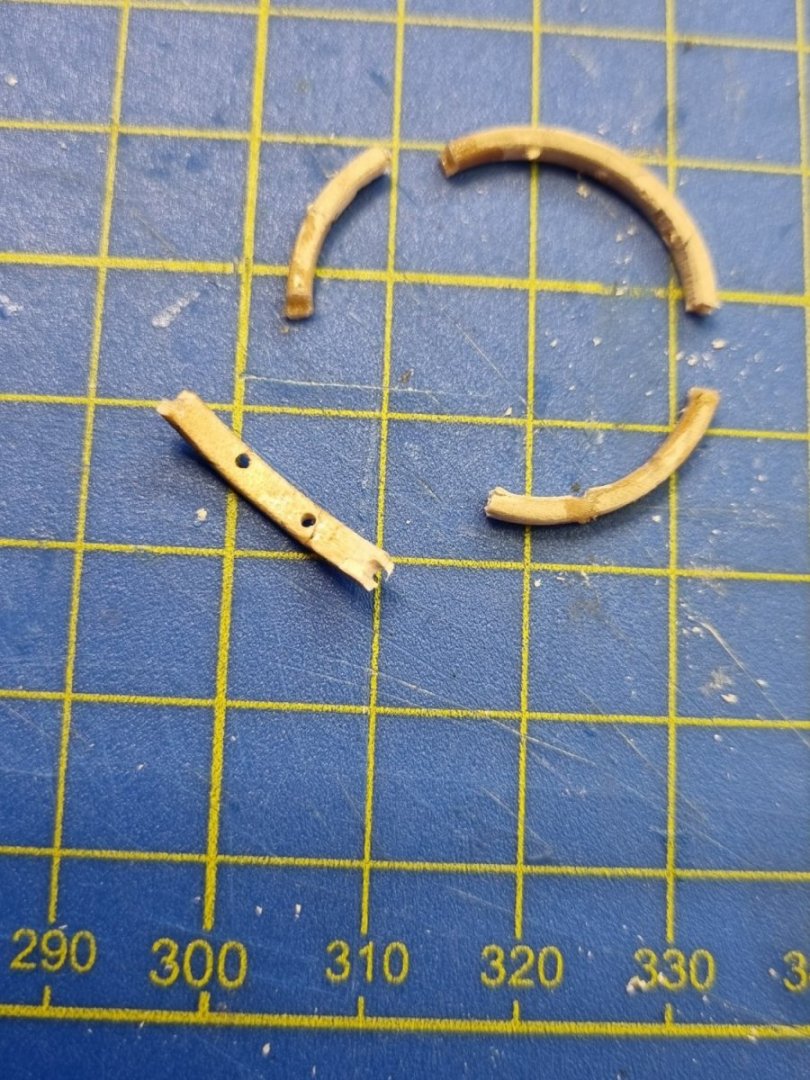

I had a lot of problems making the helm and had to get different woods, something that is hard.

Did a lot of trial and error.

A lot of frustration when almost everthing is ready then, the last part of making breaks all.

Well, after may tries I got it right, and that makes all the failure forgettable.

I used wooden toothpick as base for making the helm pins.

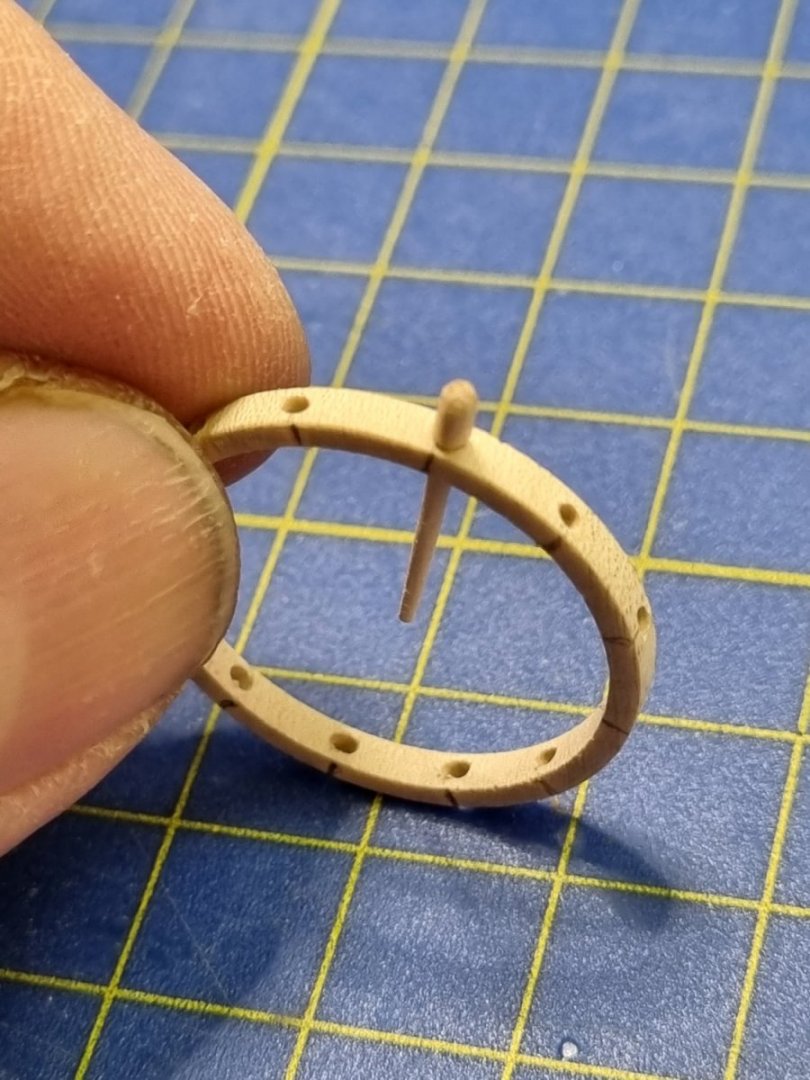

Made a jig for installing the pins.

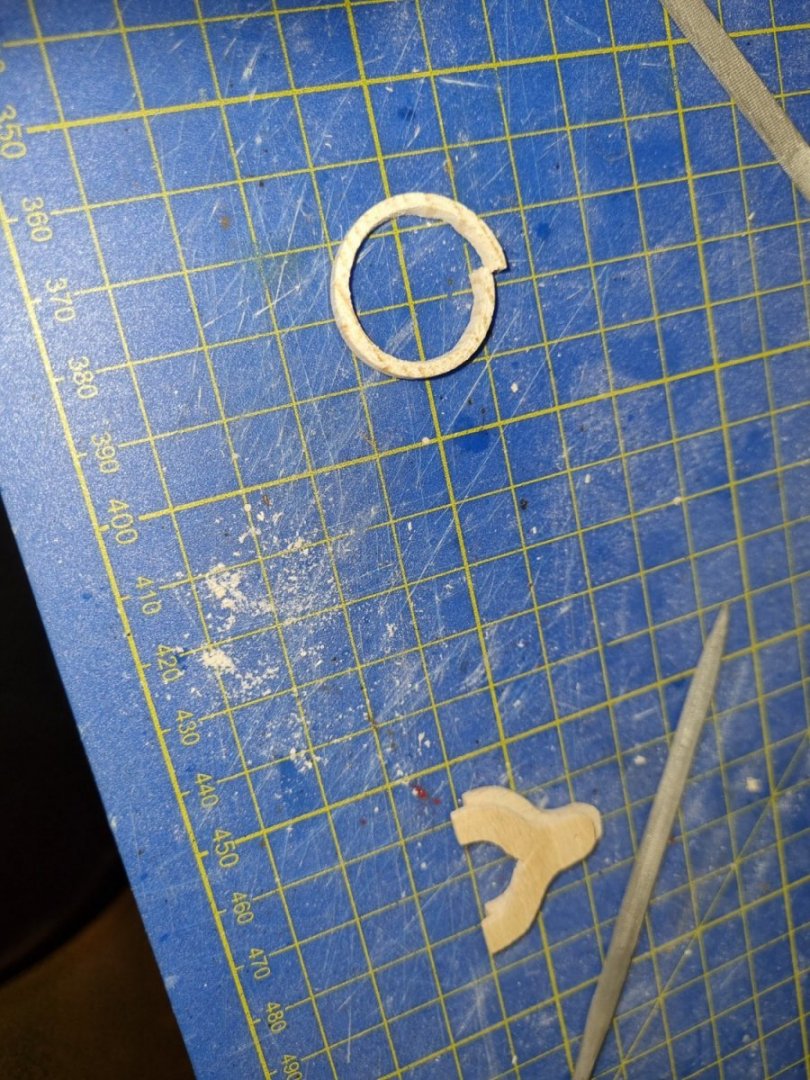

Picture showing trying out the jiig and see if I drilled the holes correct, inner stem and outer ring, ok.

So the final product before paint.

And compare to the kit helm....

HMS Bounty by Trond - Billing Boats - 1:50

in - Kit build logs for subjects built from 1751 - 1800

Posted

Finaly got my deadeys, but now have a new challange and that is sodering.

My deadeys are 6, 4 and 3mm

I've looke d at Youtune and done a lot of tries, but it is a not easy

d at Youtune and done a lot of tries, but it is a not easy

I've made a tool for holding the largest

Have finishe one of many