-

Posts

3,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dan Vadas

-

Dutch ironclad Hr. Ms. Hertog Hendrik, renamed Vliereede and finally Ariadne.http://warshipsresearch.blogspot.com.au/2011/09/dutch-ironclad-hr-ms-hertog-hendrik.html Danny

-

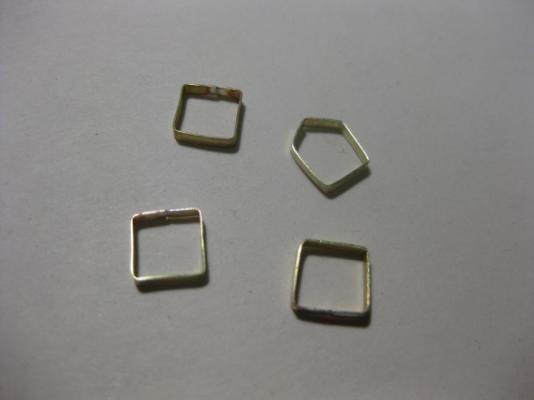

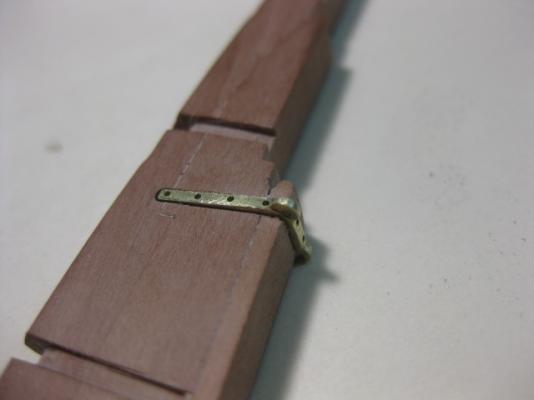

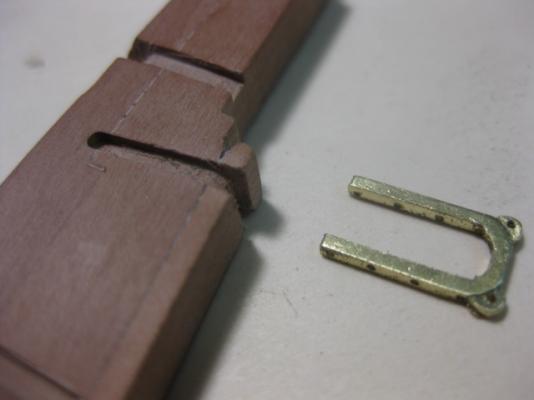

Gudgeons First I marked out the position and length of each gudgeon on the hull - I used a square to mark out the forward end of each from the sheer plan and then used cardboard strips to work out the actual length of each one from the centre of the sternpost: I fabricated the Gudgeons from 1.6mm square brass. I milled it to 1mm on one face, drilled the holes for the bolts and tapered each one to 0.5mm at the forward end. Then I filed a groove and silver soldered a small section of 1mm ID brass tubing into the centre for the eye. Next I cut and bent each piece to shape, holding the rudder in place to align them properly. The aft end of the sternpost needed notching out to bring each forward part of the gudgeon's eye almost flush with the aft end of the post - there should be just a bare minimum of gap between it and the forward edge of the rudder. As the gudgeons are fitted to the surface of the planking and not to the frames I fitted four slivers of Castello into the positions of the gudgeons on the unplanked side to bring them to the correct height. I'm hoping this will look OK when everything is glued in place : Danny

-

Thanks go out to Randy, Robbyn, Grant, Wayne, Adrieke, Mark and Brian - I appreciate your interest and comments . Good to see you come out of the closet Wayne . Can't get much closer than that Adrieke . Make a family day of it and take them to the vineyards afterwards (lots of things for kids to do at Hunter Valley Gardens) and allow 1.5 hours for the trip each way. BTW - my best time from the start of the F3 to Abermain was 38 minutes in an A9X Torana back in my younger (and sillier) days - don't even THINK of trying to do it that quick .... I was doing 250kph in some parts of the freeway . Danny

-

Correct Wayne. This is the Bourbon Mistral (and she's not actually sinking ) - your turn. Danny

-

Sorry Anja - try again. Danny

-

-

Hi Sjors, Now all you need is a lathe, a scroll saw and (most important) a disc sander and you will have the complete workshop . Have a good trip. Danny

-

Depending on which bit of Sydney you live in it's only a bit over an hour's drive Adrieke . Danny

-

The final pieces of the rudder itself - I've inserted 52 blackened brass "bolts" into the pintles and also the 19 bolts that go through the main piece and blade to hold them together : Danny

-

Thanks for looking in again John, Druxey, Adeline, Ben, Allan and Pat. Right on the waterline Ben. The way it's been drawn in TFFM leads me to believe it's rebated, though it isn't mentioned in the text. Hi all, There are three Bands around the upper section of the rudder to strengthen it. These were hammered on hot on the real ship and not bolted, although I don't know how they would have done that with the lower one - the rudder is thinner in section at that point than it is at the top. I silver soldered the two top ones and just epoxied the lower one. All the pintles, bands and spectacle plate have been epoxied in place - they will also be "bolted". The epoxy makes a bit of a mess, especially when you make a slip with the toothpick. It's easily cut off after 15 minutes drying time - a lot better than trying to wipe it off when wet ... that makes an even bigger mess . The hole for the Tiller has also been cut in - this hole tapers from 9" square to 7" square at the aft end - quite a trick to get right. I made the taper on the tiller as well to ensure it will fit later on. Danny

-

World Discoverer wrecked in the Solomon Islands. Link Danny

-

Hi Sjors, Not me - it was mentioned in TFFM. I hope I got it right . Hi Mark, Oh, that bit. I thought you meant the pintle pin. No, it didn't even get warm when I ground it so I didn't bother. It cuts wood just fine, don't know how it would go in metal though. Danny

-

Spectacle Plate The Spectacle Plate holds the two chains to the rudder. These prevented the total loss of the rudder if it became accidentally unshipped, and could also be used as emergency steering if there was damage to the ships wheel etc. I made this in similar fashion to the Pintles from one piece. Note the thinning of the eyes : I actually had to make two of these - I measured the wrong part of the rudder the first time and finished up 3mm too short . It took me about 2 hours to mill, drill and file each one. I also made another lower Pintle - if you look back at one of the previous pics where I dry-fitted the blackened pintles you'll notice that the lowest one is a little short. That's now fixed. Danny

-

Thank you Mark, Brian, John, Druxey, Grant, Randy, Russell, Robbyn, Ben, Geoff and Sherry . No, should I have ? Yes Brian, at least on the Swan Class ships. It created a little less drag in a straight line. Bundy and Coke - maybe you're right . Whoah Back Robbyn - I already have three other ships I need to finish for someone else . Nah - sounds too much like hard work. Appreciate the offer though Geoff . Danny

-

Bingo - you've got it. I thought you may have used the clue in the original post as to the ship's name. The Australian National Maritime Museum is in Sydney, and they have an exhibit of all the "HMAS Sydneys" that existed (see here). Over to you David. Danny

-

Keep guessing . Danny

-

Nope.

-

Yes David - now it's only a matter of deducting WHICH one . Danny

-

Sorry David, not HMAS Newcastle. Danny

-

Thanks Adrieke - I read something about her a while ago and it jogged my memory . Here's a pic of a model in the Australian National Maritime Museum : Danny

-

The largest iron hulled sailing ship still afloat - Wavertree. Danny

-

Hi Sjors, Oh dear, I hope it wasn't something I said . Don't worry Sjors, a couple of weeks of vacation will soon have you wanting to keep building Mirage I'm sure . Trust me - it will look great, and you'll be wondering why you were worrying about making such any easy "fix" in the first place . It's nowhere near as big a job as when I pulled up the entire quarterdeck on "Supply" because the kit plans were wrong, or when Grant pulled off the whole stern of his Victory because he wasn't happy with his first efforts. You'll finish up a much better modeller after you have done it and you realize that ANYTHING can be fixed - and it's not anywhere near as hard as you thought it would be . Danny

-

Correct David - your turn. Danny

-

-

FS246, renamed to "Lieutenant Raymond Zussman" and later renamed again to "Penguin II". Danny

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.