-

Posts

3,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dan Vadas

-

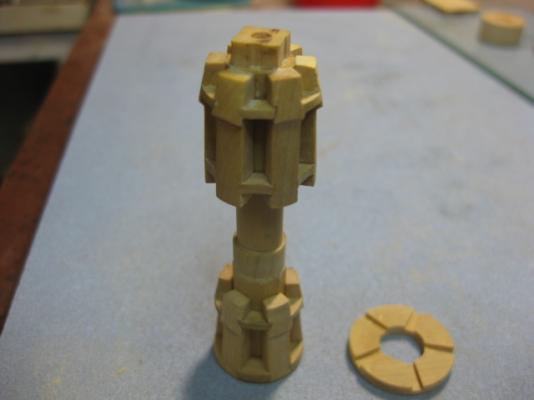

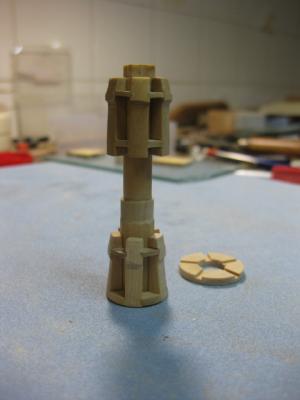

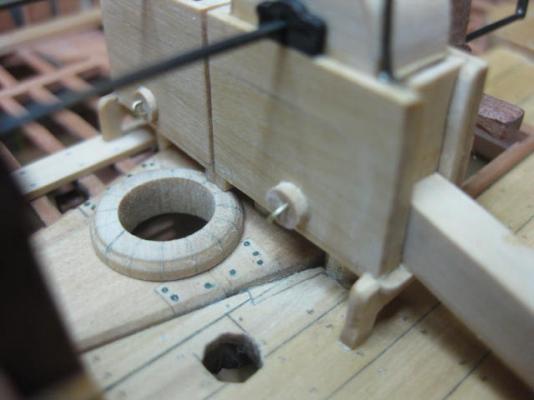

Thanks very muchly Randy, Adrian, Russell, Mark, Sherry, Michael and Pat . Geez Russell, does that mean I need to post something NEW every day? :D I'll do my best not to disappoint Pat, the only things I did differently with the Drumhead Ring was up the RPM to near Max and slow down the Feed to near Zero with the Cutoff Tool - that worked a lot better, as you can see below. The ring has only just been glued in and still needs finishing, but it came out IN ONE PIECE : Note - the top face of the ring is straight off the Cutoff Tool. The bottom face has been machined to fit the groove. Danny

-

HMS Royal Arthur. Danny

-

Sorry Crackers - different ship (a few years earlier). EDIT - just saw "st george" s post - give the man a cigar and let him have the next go . Danny

-

Thank you Anja - I've only played this game once .... about 5 years ago . Here's mine - might be a bit tricky, the pic isn't very good quality (cameras were fairly new back then ) : Danny

-

HMS Frigate Unicorn. Danny

-

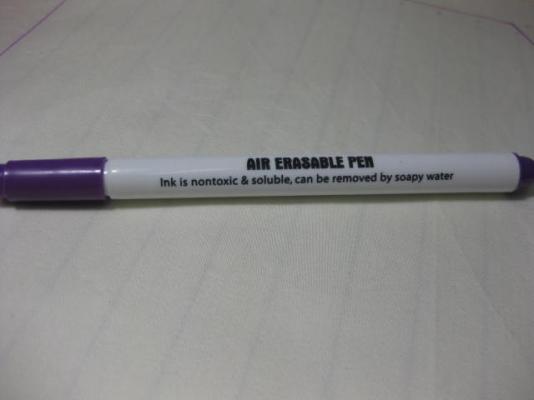

Hi Philo, A product that is easier to use than starch is this one : It does all that Frankie mentions above about using starch, but is a simple "paint-on" application. It washes out in water when you've finished cutting, sewing etc. It's also available from most Sewing Stores. My preferred material for sails is Egyptian Cotton, with the smallest weave you can get (1,500 TPI - threads per inch - is good, 2000 TPI is even better but a lot more expensive). One Pillowcase is enough to do all the sails for a 1:48 Cutty Sark with some left over . Here's a pic of my 1:36 scale Norfolk Sloop's Gaff sail. Note the fine weave - the stitches are 0.75mm long : The purple pen markings you can see are a "Disappearing Ink" pen also available from sewing stores. Much better than using a pencil for marking out the sails - pencil marks are very hard to remove (but as Frankie mentions work OK for Bands etc on smaller scale models) : Danny

-

Thanks for the tip Harvey. Actually, if you hold the drawplate nice and flat on the sandpaper the holes should all be enlarged by the same amount - that's not really a problem. You'd have to allow for this on the Byrnes drawplate which has the hole sizes marked next to them and simply shift to the next size smaller hole (or two) which would now be the correct size. It would take quite a bit of sanding to get anywhere though - that Byrnes plate is VERY hard steel . Danny

-

Bamboo. Actually, it's not a wood - it's a grass. The perfectly straight grain and it's toughness make it relatively easy to pull through a drawplate. It also accepts a stain to a certain degree - I give the piece to be drawn a wipe with Walnut stain before inserting the treenails - it gives them a more realistic appearance. Danny

-

Thanks Ben and John. The problem there John is that I have to finish it flush with the top of the trundlehead, and the best way of doing that is sanding it down. Stained wood might come out a bit uneven if the stain doesn't penetrate far enough. Soaking the piece in stain for half an hour might work though, as the end grain is at the top and would take stain more readily. Anyway, I'd rather not find out that it DOESN'T work - removing a poorly stained ring would be a real pain . Danny

-

Thanks Brian and Adeline. None that are as black. It was more to do with my cutting technique I think - I probably didn't have the lathe speed fast enough and the feed too fast. No real problem though (apart from finding the pieces ) - here's the finished result after sanding the ring flush : Danny

-

The Drawplate definitely doesn't qualify for this list - although some of the inferior quality ones probably do. I've used my Byrnes Drawplate to make over 25,000 bamboo treenails for my last two ships and it's still working perfectly. That's about 80 METRES of bamboo . That's more to the point Frankie - you've tried to use it for a purpose it wasn't intended to do. Most timbers won't "draw" very well without snapping off in the smaller sizes. Also, the drawplate only makes parallel cuts - yards are tapered, so it's useless for attempting to shape them. Bob - how do you sharpen a Drawplate without enlarging the holes ? Danny

-

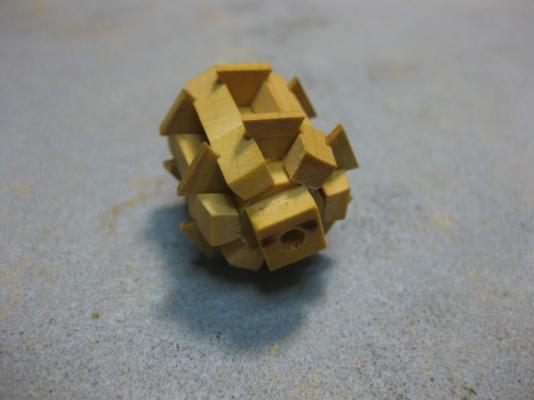

Thanks for dropping in again Christian, John, David, Sjors and David . Yeah, it reminded me of a Rubic's Cube or Chinese Puzzle when I took the pics . 37 so far David - there are quite a few more to come . Here's the next stage of the Trundlehead and Drumhead. I've glued the two pieces of trundlehead together and turned out the recess for an "iron" strengthening ring. This will be made from Ebony. There are actually two of these for each head - one in the lower section and one in the upper of both. I'm only doing the upper ones, as the lower ones can't be seen. I've also milled out the ten slots for the Upper Capstan Bars into the Drumhead : I turned the ebony ("iron") ring about three times thicker than needed - it still snapped into 5 pieces on the final cut . It took a while to find the pieces around the lathe, and a bit longer to sort out which one went where, but they eventually fitted into place with very little sign of breakage. I'll sand them flush on the lathe after the glue dries. I'm hoping for a better result for the very visible Drumhead rings : Danny

-

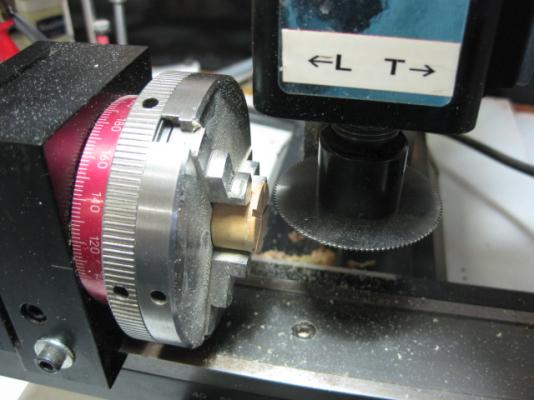

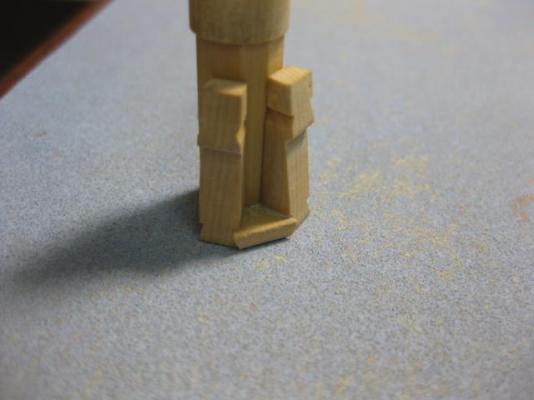

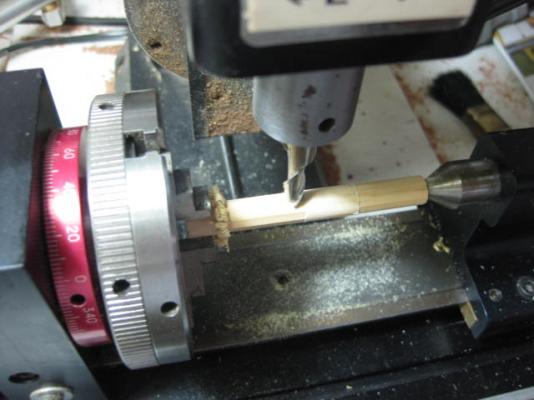

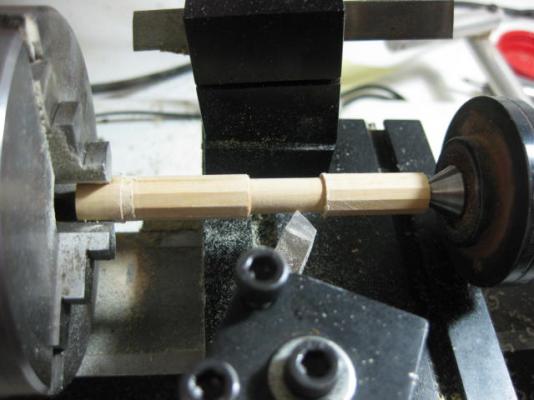

Thanks John and Mark . Next comes the Trundle Head - this is made from four pieces of timber. Two are edge-glued to make the 1'9" wide piece needed. I made sure the grain was running in different directions to make it stand out as two actual pieces later. The other two were treated in similar fashion. NOTE: I didn't really need to do this for the trundlehead, but I thought it would be a good practice for the Upper Capstan's Drumhead which is a lot more visible - turns out it was, I made a setup error that would have stood out later on. Then I turned up a "dummy shaft" which could be chucked in the 3-jaw chuck. I spot-glued the head to it for the machining work. The square cuts for the Capstan Bars were milled in next, using the dividing head again. Not possessing a mill cutter of the required diameter (0.73mm) I used a 0.38" slitting saw which needed setting up twice for each cut : Then I chucked both parts of the Capstan Barrel complete with Whelps and Chocks back into the lathe and trimmed down all the chocks. I also used a Boring Bar to take out the inside diameter of the trundle head where it fits to the barrel. I should have done this earlier while it was still in the lathe, but no biggie - it was still glued to the dummy shaft. I separated the head from the dummy shaft with Isopropyl : The lower chocks in each section have a Concave outer edge. I filed these in with a half-round needle file : Danny

-

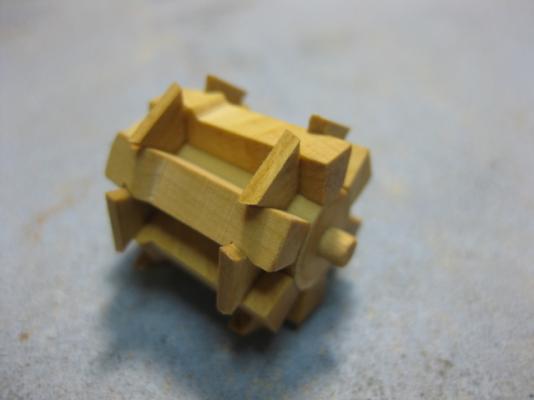

Thank you John and Grant - you ain't seen nuthin' yet . Next trick was making the Chocks. The five lower Lower Capstan ones are 3 3/4" thick, the six lower Upper Capstan ones are 3 1/8" and both sets of upper chocks are 2" thick - keeping them separate was a trick . The chocks taper inwards and are also bevelled for the scarphs. The upper capstan ones have a slightly different angle to the lower ones. I started by sanding one edge on the Byrnes disc sander using both the angle gauge and tilt table. Then I cut them all to width on the Byrnes saw using the angle gauge for the other edge, and freehand sanded the bevel into each one : Then I glued the Whelps and Chocks to the Barrels : I left all the chocks oversize on the outer edges at this stage. They will be turned down to size in the next stage : Danny

-

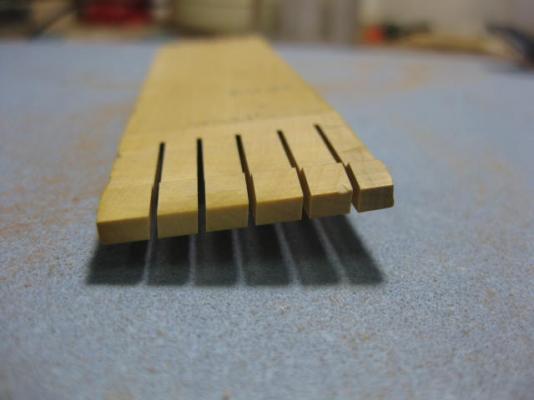

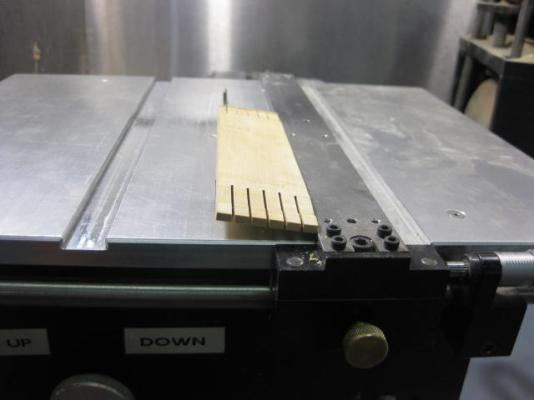

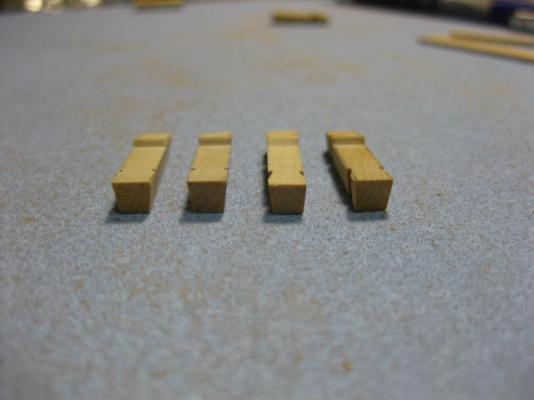

Thank you very much for the kind comments Eric and Frank . Continuing on with the Capstan, the next job was to finish shaping the Whelps. Looking from above they form a wedge shape, with the outer edge 2" thicker than the inner. To cut these angles I made a wedge-shaped block of scrap timber which I lightly PVA'd to the underside of the piece that I'd Milled the faces to. I cut one edge on all 11 pieces, then I used Isopropyl to remove the wedge, let the alcohol evaporate thoroughly, and glued it back to the opposite side to cut the other angle : After cutting them all to length I set the saw blade to protrude just 0.25mm above the bed. I carefully marked the positions of two of the Chock Scarphs in one each of the Upper and Lower Whelps (there is a slight difference in them), set the fence to the first cut and did all of them. Then I reset the fence for the other 3 measurements and cut all the remaining ones : The two on the left in the pic above have only been cut on the saw. The two on the right have had the Mortices cut into them. I used a #11 Xacto to cut the angles - they were quite easy to do, owing to the saw cuts. Another pic showing the wedge-shapes of the whelps : Danny

-

Thanks John, it's a lot of fun . Michael, we have a Topic devoted to this very subject : How I fix Boo-Boos and Oopsies by Dan Vadas - Share your own "Fixes" here Danny

-

Capstans The start of the Capstans. There are two of them - the Lower Capstan on the Upper Deck, and the Upper Capstan on the Quarterdeck above it. They are joined together between decks to work as one. I'm using English Box for all the components - some of them are quite small and require a very good timber. The Lower Capstan Barrel has 10 flats milled into it to take 5 Whelps, and the Upper Capstan has 12 flats and 6 whelps. I decided to turn and mill both together for ease of setting up. They will be separated between decks for installation purposes. I used the Dividing Attachment on my Sherline mill to cut the flats : Then I turned down the centre portion : I've also started making the Whelps. The ones for the Upper and Lower Capstans are of different sizes, there is also a corresponding difference in angles. I'm also using the Mill to cut the angles, with the aid of the Tilting Table : Danny

-

Don't you just love it when you THINK you've got something wrong .... and it turns out you are right after all ? :D My apparent problem with the Aft Hatch being too short turns out to be just a discrepancy between TFFM and the NMM plan - Vulture has an Aft Hatch EXACTLY the same length as I've built it. Somewhere along the line (and it was a while ago) I'd actually used the NMM plans to set it out. Yeeeehah . Danny

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

Dan Vadas replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

YES PLEASE - all your Tutorials on how you make those (words fail me - brilliant, superb, etc etc) Carving moldings were lost in the Crash. We'd love to see your method again - along with all the other great tips you had on before. By the way - your English is very good ... a lot better than my Czech (I don't know one word of Czech ). Danny- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

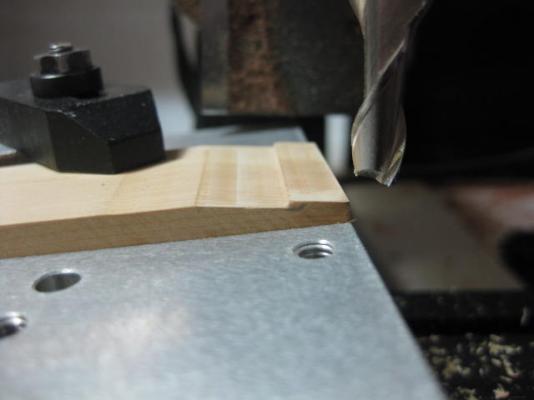

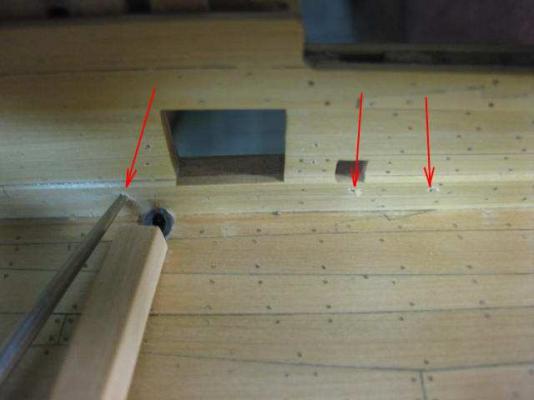

All under control John - there's not much aft of here until I get to the Lower Capstan (my next job, and one I've been looking forward to . Janos - your methods may well work, but they sound like too much hard work for this situation (and I'm with John - I'd probably set MY ship on fire as well ). Thanks for the tips, and I'll use them if I have to - these ones drilled FAIRLY easily, although a couple are done on a bit of an angle ... easily corrected when I fit the eyebolts. Christian (et al Swan Builders) - here are the eyebolts holes I mentioned earlier. TFFM mention them a few steps further down the track (9.33 and 9.34 - would have been a lot better earlier on before the Pumps ) : The ones adjacent to the Main Mast Partners will be "sort of" the same on all the other Swans - Vulture's partners are on an angle rather than parallel to the centre line. I've done a bit of my own "shipwrighting" here - the eyebolts would have to be drilled into the Partner Carlings, which is what I've done. I've also placed each one on a Ledge. Danny

-

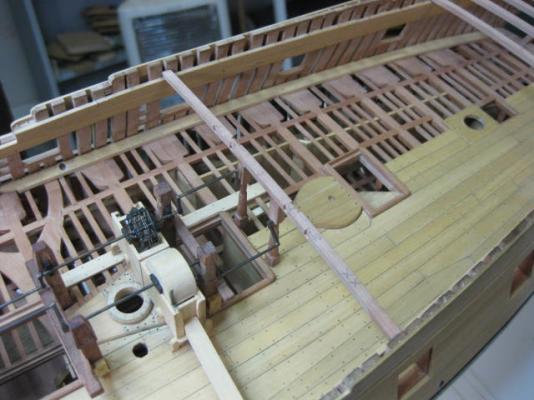

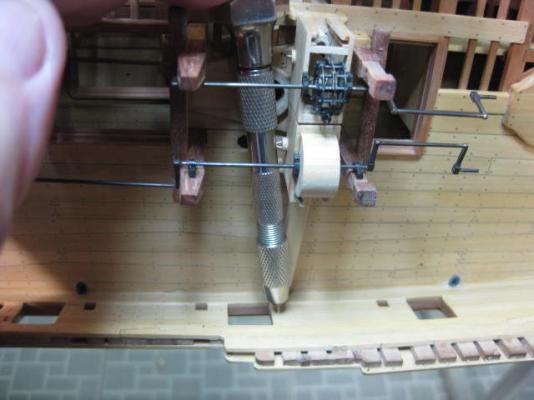

Thanks for looking in Christian. BTW - there are four eyebolts immediately either side of the Main Mast and three on each side adjacent to it that should also be drilled and fitted before any work begins on the Pump Cranks. I'll drill these now and show you the updates later. Hi all, The final part of the Chain Pump setup - I've glued in the Pillars at the aft ends of the cranks. I was bumping and bending the aft ends of the cranks quite a bit, so I figured it was time to stabilize the whole structure. This meant fitting the 3rd Quarterdeck Beam as well : My Aft Hatch is a little out of alignment - it's actually 2mm too short. I knew this a while ago - the problem is much further down. The Lower Well was slightly too far forward (2mm to be precise) and things further upwards had to be shifted to accommodate this. I'm not about to rip up two decks to fix an otherwise minor error properly . Danny

-

Thanks to Ben, Geoff, Adrieke, David, John and Shaz . They already have : Proxxon Right-Angle Drill . Unfortunately, I don't own one - yet. In round figures - NONE . The last time I can remember breaking a drill bit was when I tried to go just a bit too far up a piece of round bar in my lathe - that was about 6 months ago . Concretor (32 years), Industrial Painter, Forklift Driver and Truck Driver (last 13 years). Model building is my escape from all that . Shaz, I'm coming from the exact same place as you - I knew nothing about REAL ships either until I joined MSW. I started out with just making Kits as per instructions (some a bit better than others), found MSW and all the guys who REALLY know ships, bought a few books recommended by them and went on from there to Kit-bashing and now Scratchbuilding. It's been a great learning experience, and I'm STILL learning every day - and will be until the day comes when I can no longer do this hobby for whatever reason (death of old age probably ). Danny

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

Dan Vadas replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Hi Doris, I'd always thought your models were excellent until I clicked on one of the pics above of the carvings in the bow - the High Resolution pic looks ..... INCREDIBLE . That's WAY beyond excellent. Danny- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Thanks Janos and Joe . To those other Swan builders (and anyone else for that matter) who intend fitting Guns to their ship I STRONGLY advise that you drill the holes for the Breeching Rope and Port Tackle Eyebolts BEFORE you add too much Upper Deck "furniture". This can get a bit awkward if you don't : Danny

-

Yeah John, I'm pretty happy with the amount of work I did this weekend - especially with how detailed all this is . Hi all, The last couple of things for the Pumps - two Bungs, complete with handles, and the Latch that secures the Cistern Hood : Danny

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.