-

Posts

169 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BrianK

-

Great idea Richard. Just transfer the marks. Might as well go all the way onto the chipboard side. I have a little square somewhere..... Brian

- 37 replies

-

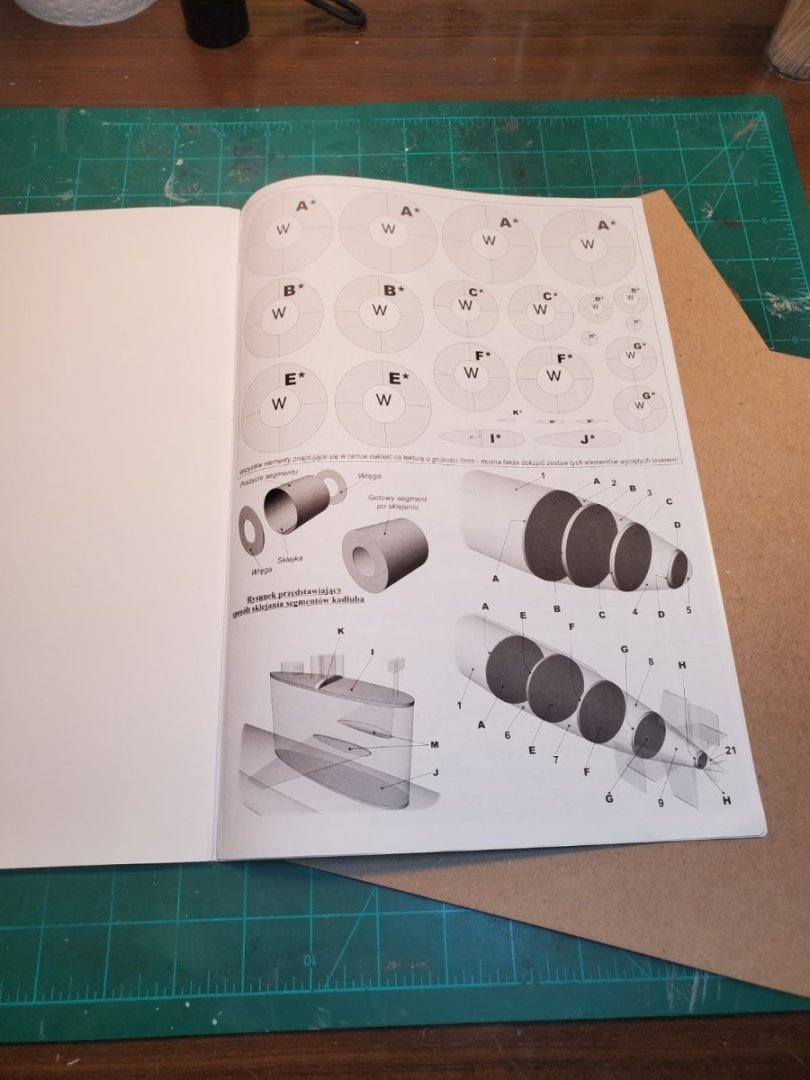

Bulkheads are done. The 1mm thick chipboard backing was not too terrible to cut with the angle craft scissors. I used a knife for the little bulkheads. A chisel knife cutting little tangents as I worked around the curves of the small pieces seemed to produce ok results. I used some 220 grit sand paper and an emery board to smooth the bulkheads. They will not be visible so I only worried about the edges and deburring the flats where two bulkheads will meet. I was originally planning to glue the chipboard sides of the bulkheads to each other when bringing hull sections together. However, the four cardinal registration marks on the card model side might be useful. I am not sure I trust the craft adhesive though. It should be permanent the way I applied it. The card model cut outs seem well attached to the chipboard. Any thoughts?

- 37 replies

-

"Give me a lever long enough and a fulcrum to place it on and I'll move the world."........ or a 1/200 scale paper model 😃

- 37 replies

-

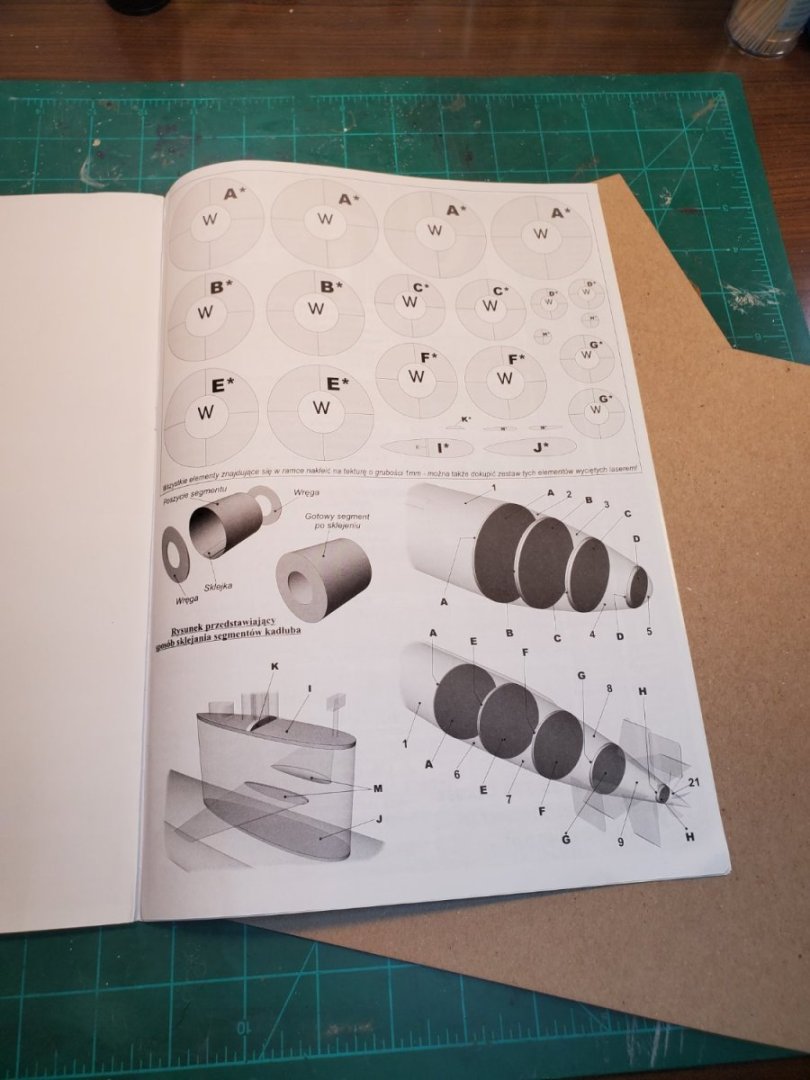

For a first step, I cut out the page of bulkheads and divided them into sections. I cut rough-matching pieces of 1mm chipboard using right angle craft scissors. The scissors are big but sharp and accurate. More importantly my hand does not hurt when cutting the chipboard. 😃 In my paint booth I sprayed Elmer's craft adhesive on the chipboard sections and then laid the bulkhead page sections on them. The smell evaporates pretty quick. The adhesive spray reminds me of using hairspray as a scenery adhesive. I punched out the holes in the bulkheads with some leather punches I had. After cutting the bulkheads out I smooth the edge on some 220 grit sandpaper. Hope to finish them up in a day or two.

- 37 replies

-

Thanks Yves and Chris, and everyone else for the early thumbs.... Chris I found right angle heavy duty craft scissors to try out. The bulkheads are not too challenging so I am hoping it will not be to frustrating..... For the record Chris you are one of the reasons I am enjoying card models so much. Your builds are pretty spectacular.

- 37 replies

-

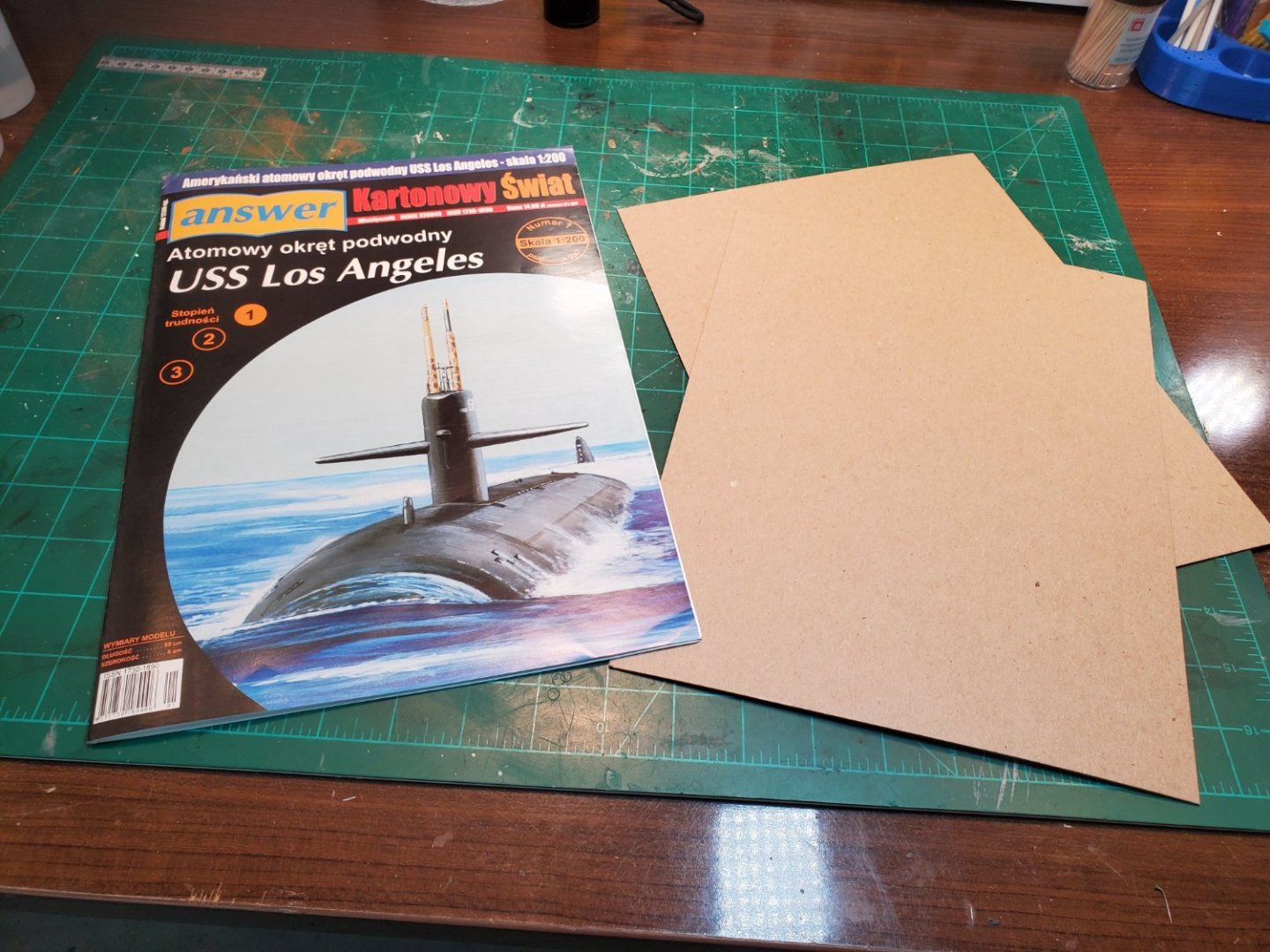

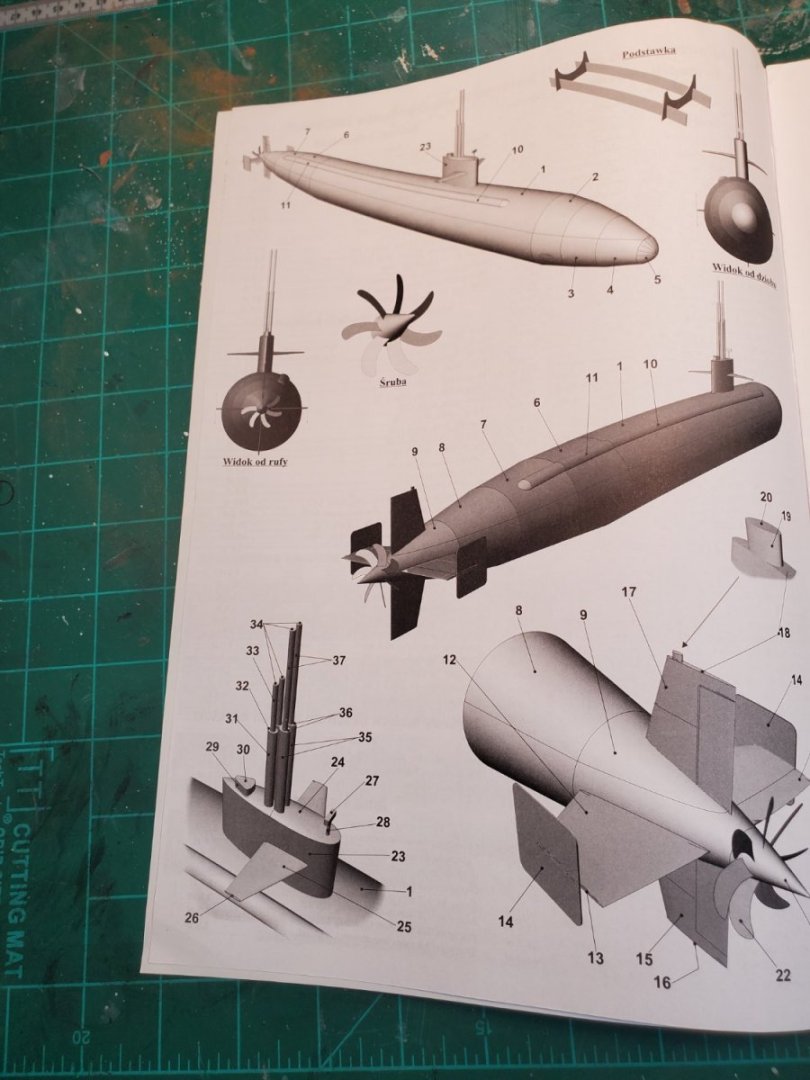

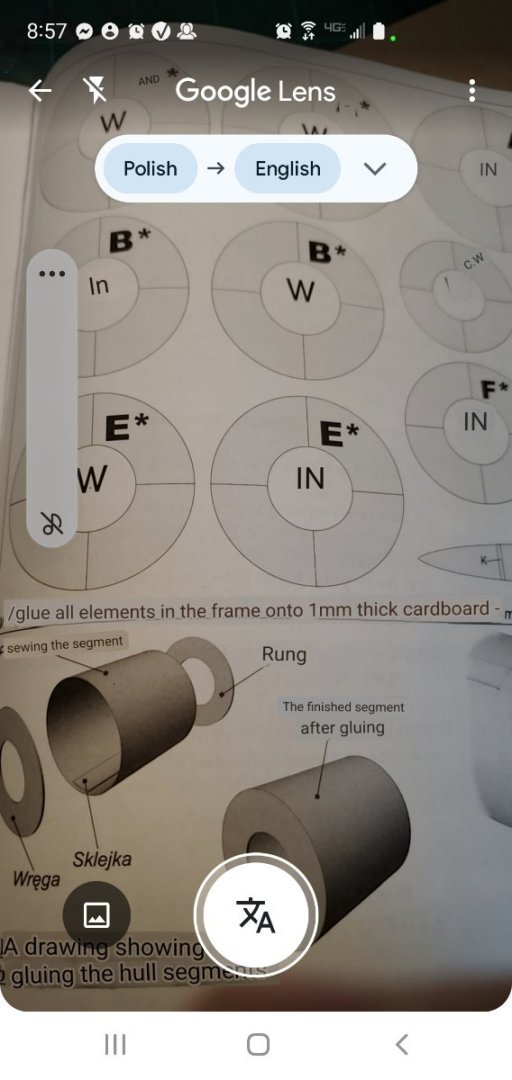

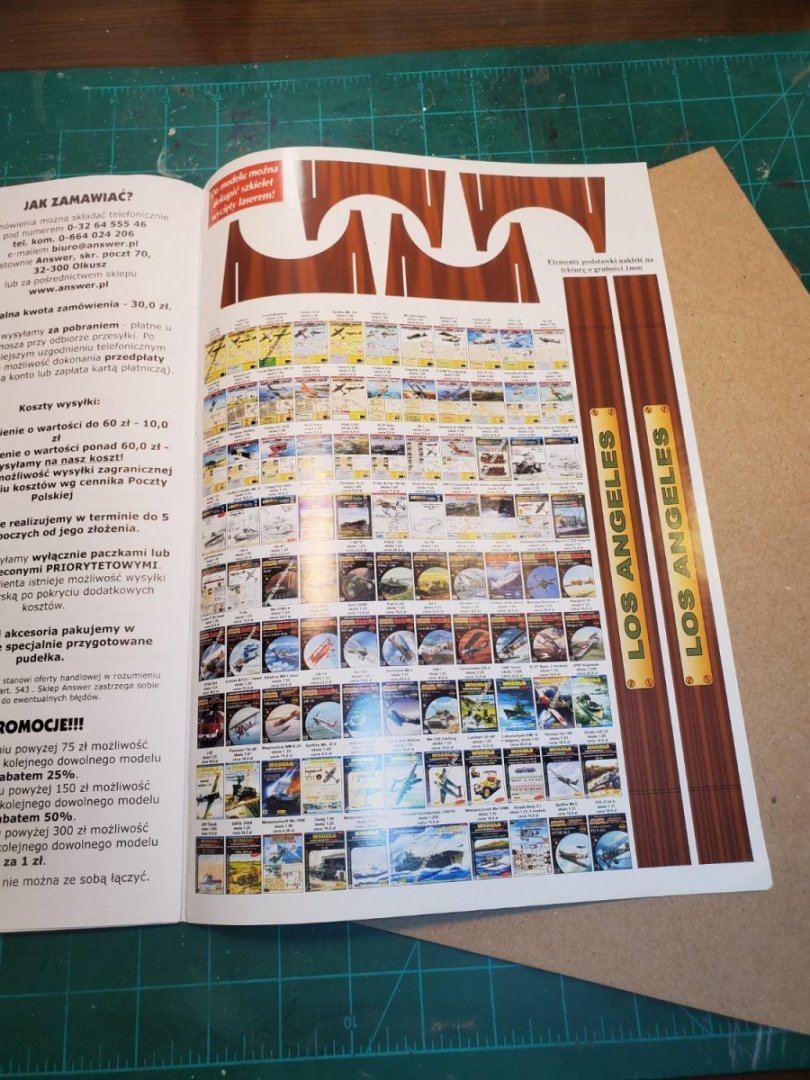

First build log. I teach electrical engineering and a colleague who teaches mechanical engineering is a retired sub driver. Captain Paul Dinius skippered the USS Helena, SSN 725, during one of his tours. I thought I would make him a model of the type of submarine he was on. I looked for a reasonable sized card model. This is a model of the USS Los Angeles which was the first of the 688 class. The Helena was a Flight II version and had 12 vertical Tomahawk missile tubes. I may look at adding details for those if I can figure out an easy change. Here is the front cover with a couple sheets of 1mm thick (40 point) chipboard that will be used for section bulkheads. The text inside is all in Polish. Thank goodness for Google translate: Hover my Android's camera over the Polish instructions and Viola! English translation appear in real-time! I think I can figure out 'rung' should be 'ring'. 😃 Here we go!

- 37 replies

-

Chris, I am struck by how the little white circles with red numbers seem now to be very much in the minority compared to your earlier photos (like in that broadside photo in mid-February). It must feel good to see it look more and more complete. I am excited just watching it grow and take shape from here! 😃 Brian

-

Understood George. That makes sense that the amount of tension is a limiting mechanical factor with drill-n-glue. There is very minimal tension with the sheets and stays I put on the Academy 1/350 Cutty Sark and none at all with the plastic shrouds....... BrianK

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

George , to anchor stays (and some sheets) I just used the drill-and-glue method on my little plastic Academy 1/350 Cutty Sark. I would never presume to suggest my amateur techniques should be used on your incredible first-rate build, but it was easy...... 😃 Brian

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

George, the masts look incredible. I am looking at a Sherline lathe and everytime I see another great post like yours I inch closer to the 'put in cart' button. 😃 I bet the Ukrainians will get plenty of offers to help remove that hammer and sickle when this mess is over.... Brian

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Keith, based on that ebay price for the name plate, can we extrapolate the value of the whole ship in today's dollars? 😃 BrianK

-

Keith, you have our thoughts and prayers and respects. The hobby and the Tennessee are patient. They will be there if you decide to call upon them to help you through this. With all my regard, BrianK

-

Looks wonderful George! I like your narrow chainplate trick. I will borrow that one! BrianK

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Another great tip Keith! Thanks. I think I may try to integrate laced deadeyes onto a ratliner so the deadeyes, shrouds AND ratlines are done off model. Anyone have experience with that? The length would be critical since the slack would be at the top......maybe the last couple ratlines go on at the model. BrianK

-

Beautiful Chris. The level of detail just screams patience to me on your part too! What were those naval architects thinking putting all those exposed pipes there like that anyway? 😃 BrianK

-

Chris, the pipes look great! A question about using CA on them.... I get that you roll them first but with CA how do you get the edge flat along the seam without using your fingers and risking you becoming part of the piping? Is it all in the rolling? Like it needs to be in perfect shape with perfect seam before the glue gets near it? Sorry for all the questions. My inner engineer and inner novice card builder are clashing. 😃 BrianK

-

chirs, how did you do the funnel ladder rungs? I don't think I could cut all those square holes with an xacto, without making a costly mistake...... BrianK

-

Looks gret George! Neat trick for hiding wire strop twists. I will file that tidbit away (along with the many others you have supplied !) BrianK

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.