-

Posts

427 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DB789

-

Grecian is looking super, such an unusual but great looking boat. I think very likely my next build after completing Alert. Maybe Ranger beforehand in the highly unlikely event I complete Alert before the Grecian kit is launched. Grecian looks an easier step up than diving straight into Speedy/Flirt. Thanks for another excellent prototype build log James. I’m missing not having one of yours on Alert!

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

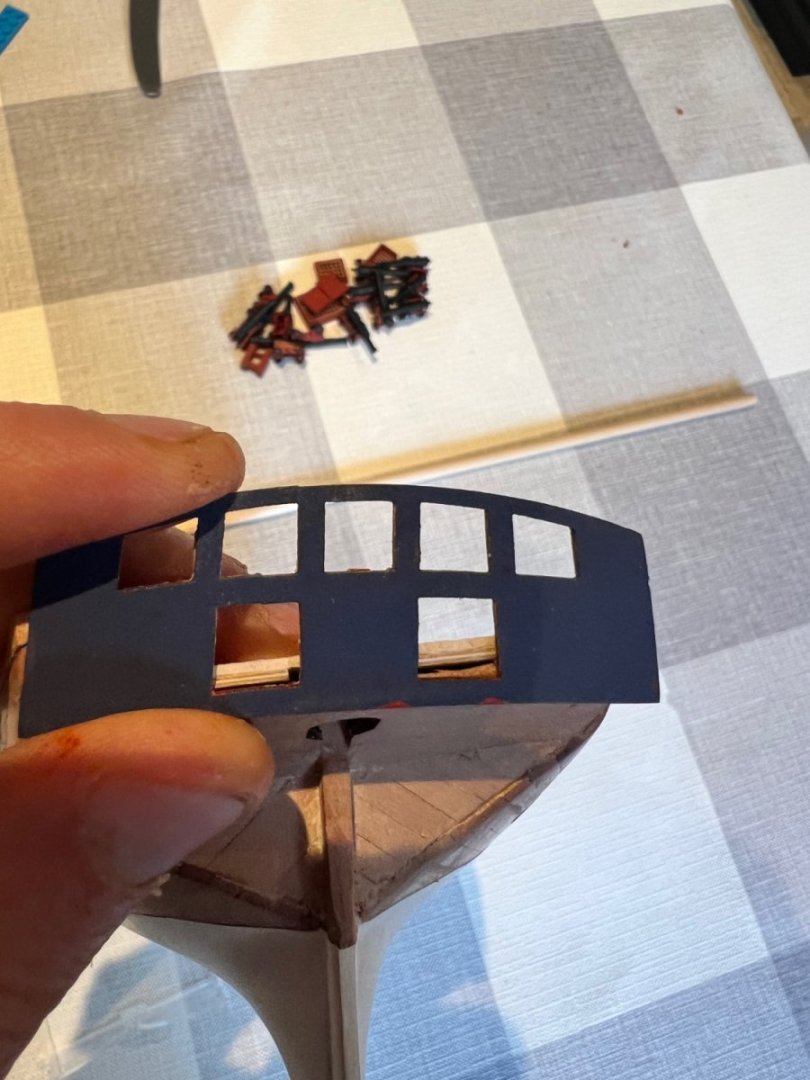

The problem at the stern that Thukydides has highlighted is that the bulkheads aft are too low where it joins the stern board and the rough tree rail is then too low. There’s also the problem on my build that the deck area is too high at the stern for the gunports pushing the stern board even higher. I would like the stern ports, are they gunports? To be at least level with the deck, so I’ll need to add a plank lower than the stern board and raise it a bit higher. These are the wedges I’ve added to compensate. Probably could have added more! Also painted the blue area between the gunports. It’s one plank wide except for the new wedges which I’ve needed to estimate.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

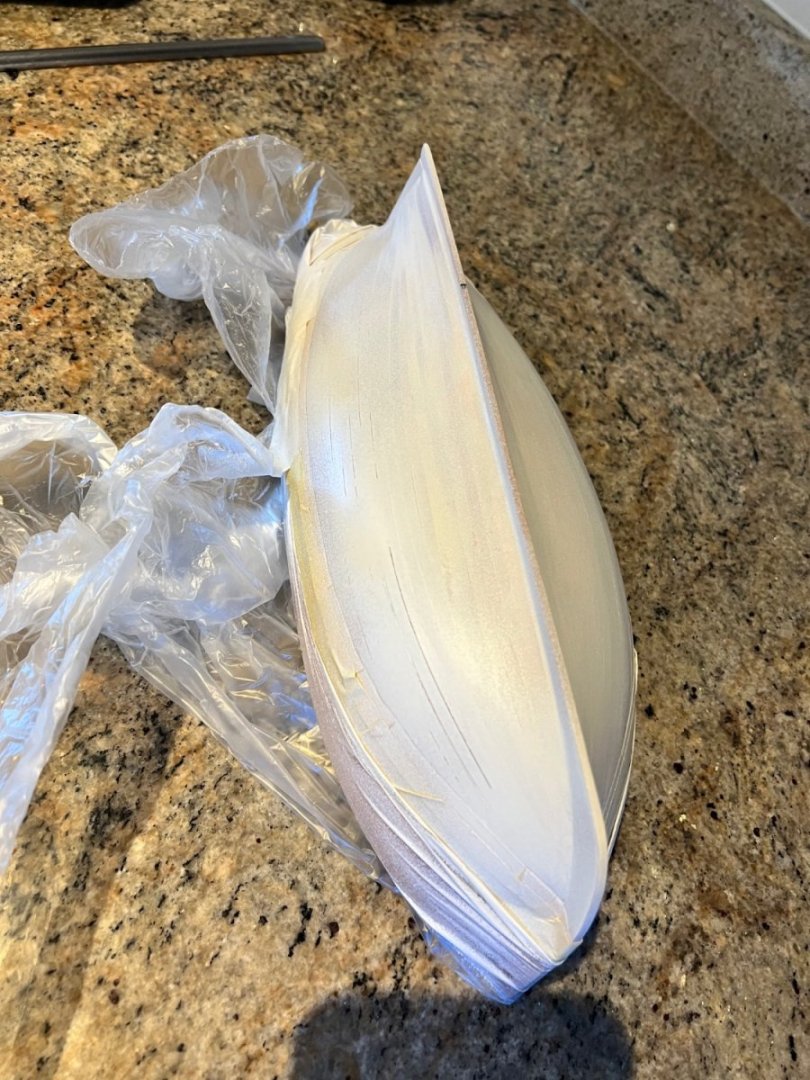

Hull painted white. Not perfect but as good as I’m going to get it! At the stern I’ve added small wedges to the stern bulwarks to make them a bit higher as per Thukydides’s build log. I’ll come back to this in a moment. Then added the rest of the inner bulwarks, painted red. Seems a pity to cut gun ports into the smooth, flowing lines of Alert’s hull. But needs must. I’ve been dreading this job, but following the other build logs on here I’ve used Glenn UK’s method of taping the ports before cutting them which worked well. The job was much easier than expected. MSW is a fantastic resource! Taped and ready to go. Port side complete. Starboard side underway. Once cut out vertically with a razor saw I used a scalpel for the horizontal cut and filed the edges clean. Gunports complete. Starting to look more like a warship.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I managed a little time ship building recently. Main deck clamped and glued. Inner bulwarks started. Shaped to fit, then painted red and glued. Also painted the step below the tiller platform. annoyingly some of the paint has bled under the tape and instead of waiting for it to dry and scraping off I’ve made the schoolboy error of trying to remove it whilst still wet and it’s spread across the tiller platform. Fingers crossed it will sand out. Concurrently I’ve marked the waterline and added masking tape. I’ve used the Tamiya tape with polythene attached to protect the rest of the hull. First spray of white paint shows up a lot of imperfections. Several layers of white paint, filler and sanding later, still not done. More painting and sanding to do. I’m not after a perfect finish and it’s getting closer.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Gus, I’ve built both Nisha and Saucy Jack, both are lovely kits to build. Nisha is slightly easier due to a less curved hull shape and a little easier to rig as the belaying pins at the foot of Jack’s mast are fiddly - not a great deal in it though. Enjoy!

- 206 replies

-

- Vanguard Models

- Brixham trawler

-

(and 2 more)

Tagged with:

-

Bulkhead ears and stern timbers removed. The etched main deck is fitted and not glued yet. The tiller deck not fitted yet. More sanding of the hull still to do. Second set of six cannons built together with most of the hatches. Inner bulwarks planking next - then time to cut the dreaded gunports! I doubt I’ll have any time in the shipyard over the next fortnight. School holidays so busy with the kids!

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks for the warning Thukydides. You’re right, I have thinned the stern post slightly. I’ll make sure not to do so any further.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

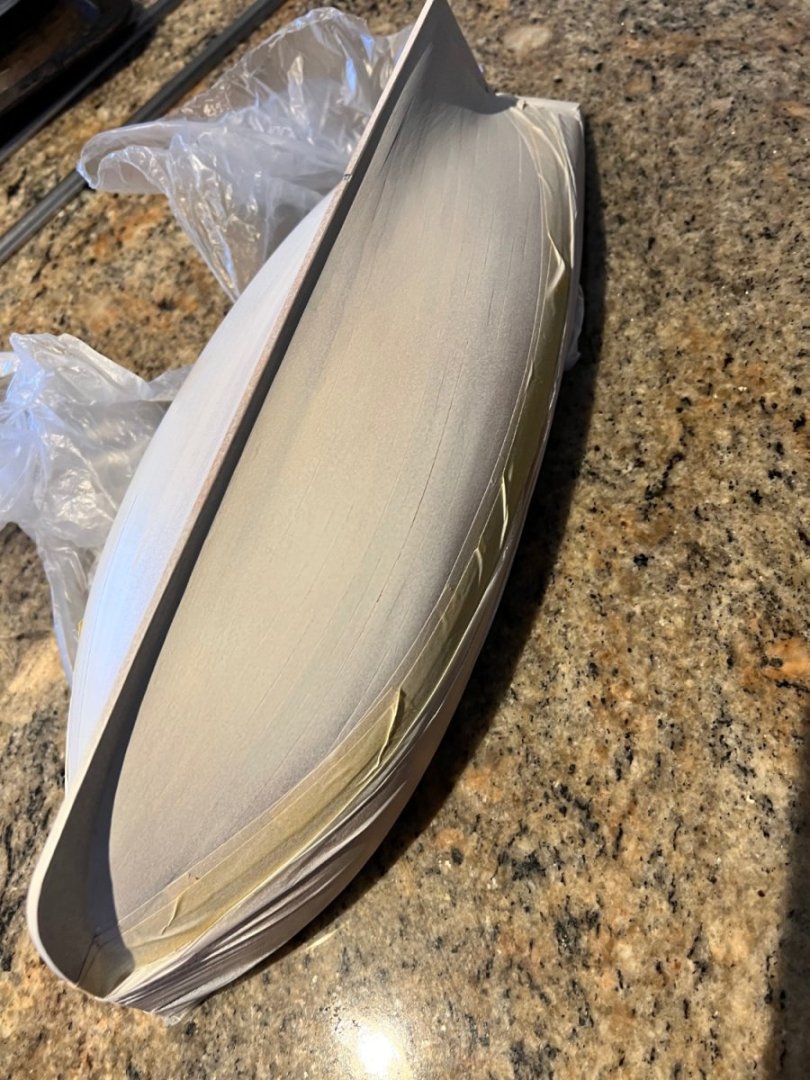

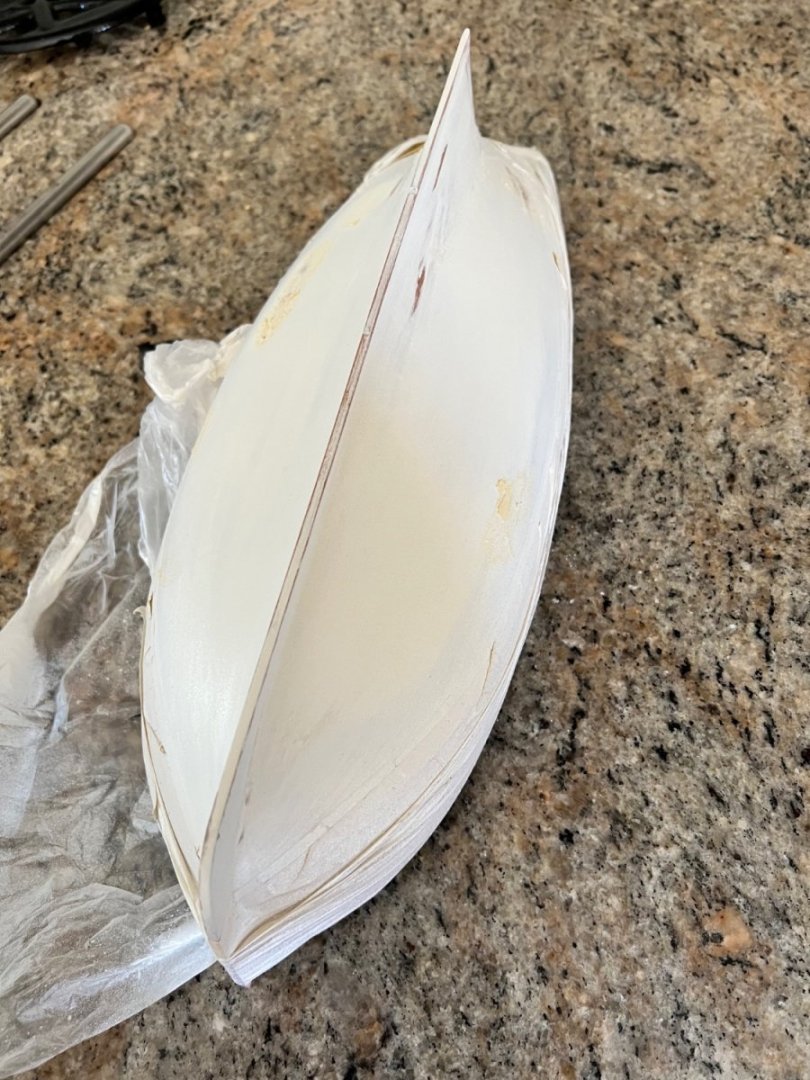

Thanks Bowline. Pale Moon, great to have you aboard, Alert’s hull is a lovely shape. I strongly recommend this kit, although if you’re a complete beginner to modelling with no skills, like I was very recently, I suggest a Vanguard fishing boat would be a touch easier. The second planking is now complete, it’s reasonably tidy above the waterline, less so below where thankfully it will be covered in paint. Failures all mine, not the kit’s! The next two photos show the port side filled below the waterline and sanded whilst the starboard side has had preliminary sanding but no filling yet. I’ve tried different patterns of planking below the waterline. I struggled to get a garboard plank to fit and plank up from it (port side) so lots of filler required. On the starboard side I added the garboard plank at the end and it worked better for me. Once painted they’ll look largely the same. I think the problem was towards the stern where I had thinned the first planking to the rudder post to create a rabbet, I hadn’t thinned the first planking further forward to accommodate this and the planking bulges a tiny bit. Lots more filling, painting and sanding to do here. Also worth noting that the planking strips vary in colour. I had plenty of darker pear planks to plank the visible upper planking, but wouldn’t have had enough paler pear planks so glad I checked before starting planking. You can see the light and dark planks mixed in below the waterline in the photo below. She is starting to look very nice though. Two of the stern timbers have broken off. But the planking is now sanded in line with these and my next job will be to remove these and the bulkhead ears.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

First planking now complete. I reverted back to the travel iron and jig bending tool for the port side so no scorching of the wood this side. Starboard side is filled and sanded a couple of times. Port side pre-sanding and still clinkered in appearance. Both sides now filled and sanded. Very smooth but maybe one more fill and sand as there’s a couple of low points. Stern post fitted and diagonal planking on the aft bulkhead. Top 4mm plank was soaked in hot water for 30 mins and then clamped in place without glue and left to dry overnight. Then glued and filled and sanded once dry. Stopping the front plank short of the stem post was one of those things that I was dreading, but was quite easy with this technique and clamps. Stern planking complete and stern counter fitted. As per other builds I’ve curved this a little to match the side trim that will be added later. The counter was also soaked in hot water and clamped in place whilst it dried to help it adopt the curved shape. Pretty much ready for the second planking I think. Starting to look like Alert!

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Hi Jim, Thanks so much for the advice. Believe it or not I have watched this before and use a plank bending jig based on Chuck’s. I don’t do the lining off for tapering - I lack the patience - and taper as per the method in the instructions. Where I’ve strayed further from Chuck’s method this time is first bending on this jig with a travel iron and then using the soldering iron type bending tool to bend the plank around the hull - watching Chuck’s tutorial again I see that I should be able to achieve the shape of plank I need using just the first jig and travel iron. I’ll try that for the port side and it should avoid the scorching too. Chuck makes the bending look so easy, but I find judging where to bend and how much tricky. The pins will come out fine with a scalpel and it’s only the first planking, I don’t mind what it looks like if together with filler and sanding it provides a good base for the second planking. On Alert I have doubled up the fifth bulkhead with additional MDF to enable me to split the first planking into bow and stern sections. On some of Chris’s fishing boats he builds up the middle bulkhead for this purpose, so I’ve copied that method here. Thanks again for the advice, it’s still a big learning curve! Best wishes Dan

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

A little progress on Alert. Thanks for the advice on further fairing, I think it’s paid off. First I couldn’t resist making some cannons as I haven’t done so in a previous build (not being a standard fitting on a fishing boat). The first six are complete and temporarily aboard Erycina to keep them safe from the children and to stop my son “borrowing” them to play pirates. I’ve also been building some of the hatches and gratings for the deck, but I’ve got a query in to Chris about these, so I’ll update more when he’s had a chance to get back to me. The first planking is complete on the starboard side. It’s not beautiful and there’s some clinker. The main difference I found here over the fishing boats is that the lime strips are 1.5mm thick instead of 1mm which makes them harder to bend and more likely to snap when doing so. I needed to damp the planks and bought a plank bender of the soldering iron type with a bulbous end on it to do so. This worked well but gets very hot and in places has scorched the planks (they’re the dark patches). Fine for the first planking, wouldn’t look good on the second planking above the waterline. Need to find a different solution for that. Because the planking is harder to bend (even testing to see where the heat and damp applied bends should be) I found myself manhandling the hull more with the inevitable consequence that I broke off the forward starboard bulkhead ear and also two of the stern timber frames. The outer timber frame and the bulkhead ear glued back on OK using liberal applications of titebond. They’re all sacrificial so won’t matter longer term and seem to be in the right places at the correct angles. I even bought a keel clamp to hold her better. The benefit of the 1.5mm strips is that the overlap is greater between planks and it should be more forgiving to sand. I’m pretty confident this will sand down to form a nice base for the second planking. She looks better in real life than the photos! Port side next.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Andrew, your build of Nisha is amazing. I’m very envious of your skill in adding all the details and those sails are so realistic. My Nisha looks bare and unfinished in comparison! Been fascinating to follow you building her, thank you.

- 206 replies

-

- Vanguard Models

- Brixham trawler

-

(and 2 more)

Tagged with:

-

Hi Glenn, your Nisha looks superb. Really nice to see one of these fishing boats without sails. Shows off her very clean lines. Look forward to seeing you build Indefatigable.

- 48 replies

-

- Nisha

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thank Jim, will follow your advice. Plenty more fairing…

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I’ve made some progress. The longitudinal frames and stern timbers were added together with bulkhead 10. I realised I did need to add this after all to get a smooth faired hull. As other logs have forewarned, the outer two stern timbers (parts 19) don’t quite line up with their slots, but forewarned I gently bent them into the slots. Then added the main deck, rudder platforms and the small bulkheads to the rudder platform. I’ve started fairing the bulkheads, but quite a bit more work here required, especially towards the stern. Outermost stern timbers (part 20) needed to be shaped to fit flush against bulkhead 10 and be at an angle to the main stern timbers. Despite being careful I still managed to break off one of the outer stern timbers. But it’s glued on fine for now and is cut off latter. As with the other Vanguard boats, this hull construction is very well thought out and creates a strong, solid hull base for planking whilst ensuring the bulkheads are lined up and the keel straight.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you all for the advice. That makes sense, I couldn’t see if I was missing a trick here as all the version 2 build logs were using the PE and I couldn’t see why they weren’t using the wooden ones. Now I understand!

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

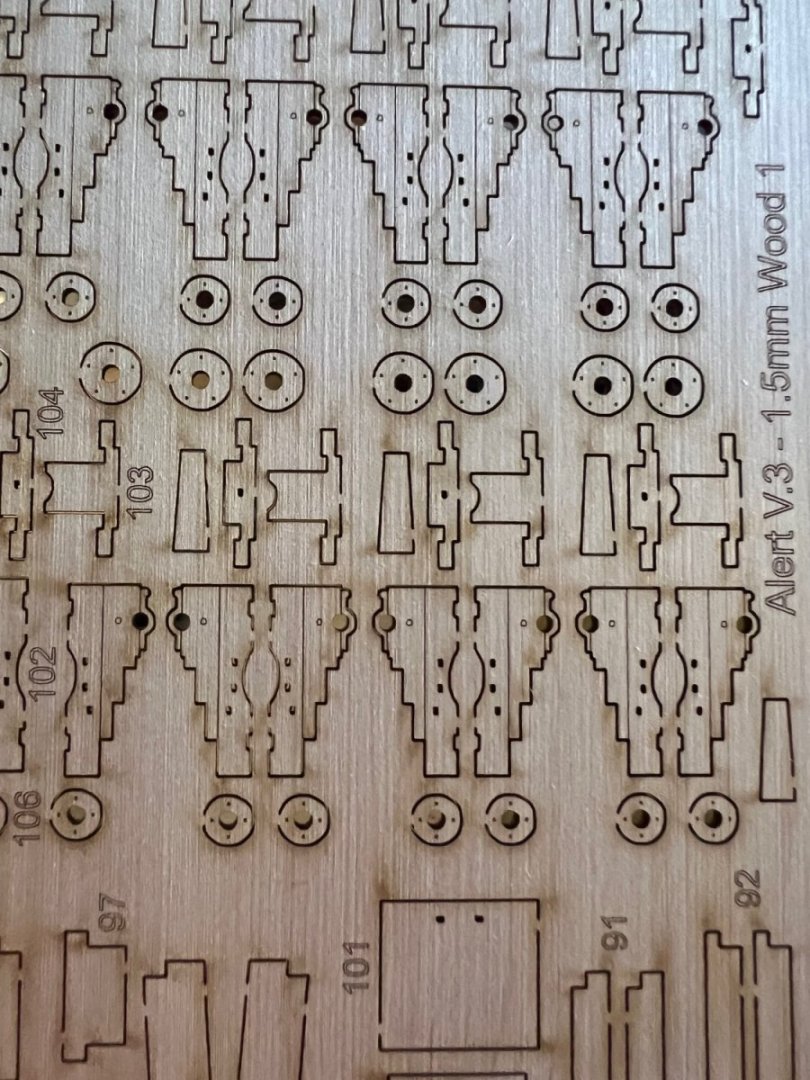

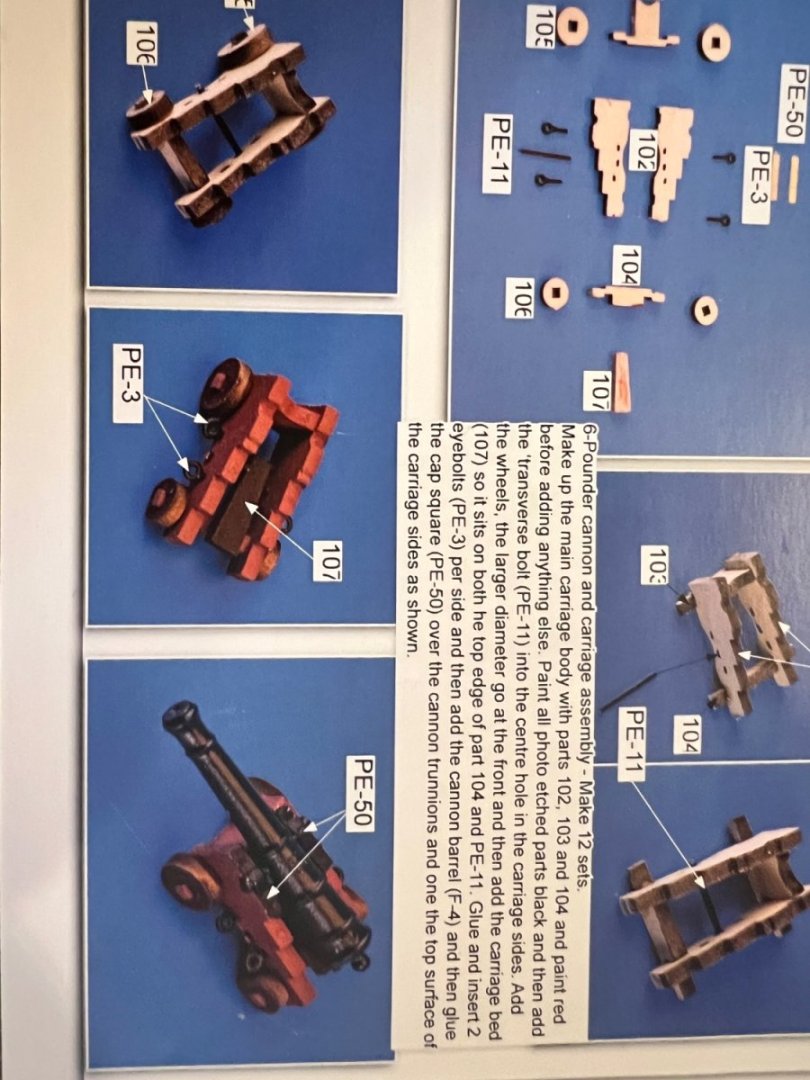

Whilst the hull dries I thought I’d make a start on the cannons, having never made one before. I’ve a query for anyone who has built the second edition of Alert. The instructions show a piece of PE (PE-50) across the top of the carriage over the barrel’s trunnions. The kit has a wooden hole in the side of each carriage (photo below). Should I use the wooden holes for the trunnions or cut this off and use PE-50? Not sure if this is a difference between the two editions of Alert? To me it makes most sense to use the wooden holes, but this will change the sequence of building the cannon as the barrel will need to be added before the carriage is fully assembled, not afterwards. Any advice much appreciated. Many thanks

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks Jim and Bowline. Please do, I’m sure I’ll make lots of mistakes to learn from.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

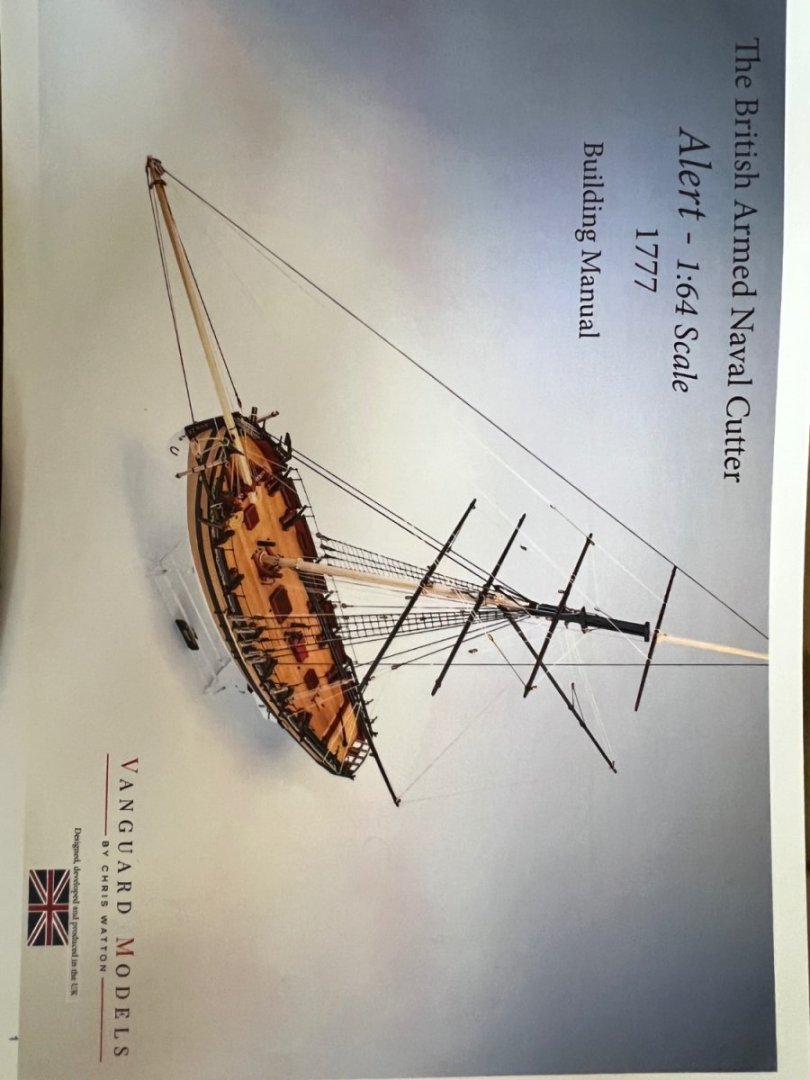

This will be my sixth build and all from Vanguard. That makes me sound experienced - I'm not - all the other five have been from Vanguard's excellent range of fishing boats. This will be my first warship, first at least partially square-rigged ship, first cannons, etc. There's some excellent logs already on MSW on Vanguard's Alert, so I won't bore you with a box contents post and instead will dive straight in. First impressions are that this is another excellent kit. This is the second edition kit with some improvements. I like the huge manual with the plans bound in. Will save me lots of time later trying to find the correct plan. The keel needs to be shaped where it meets the rudder post to leave room for planking. I’ve followed the procedure in lots of other logs and used a 1.5mm strip of masking tape to ensure the sanding is to the correct depth. Bulkheads and lower deck fitted and glued with diluted PVA. I haven’t glued the longitudinal beams yet. They’re dry fitted to keep the bulkheads square. I haven’t added the aft bulkhead 10 yet as without the rudder post only half the slot is there. I may do some fairing of the forward part of the hull before adding bulkhead 10 and the stern frames to lessen the chances of breaking one.

- 70 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 46 replies

-

- vanguard models

- Erycina

-

(and 3 more)

Tagged with:

-

Thank you all for your very kind comments and encouragement. Alert it is next!

- 46 replies

-

- vanguard models

- Erycina

-

(and 3 more)

Tagged with:

-

Thanks, I really enjoyed the Lady Eleanor, I thought that she was the easiest build of the Vanguard fishers. Good luck with your build!

- 46 replies

-

- vanguard models

- Erycina

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.