-

Posts

2,698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by HIPEXEC

-

I finished eleven rows of planks. Six to port and five to starboard. This material is hard as steel. It doesn't want to bend, twist or sand/file easliy? It will bend up or down while laying flat, though.So far I've managed to keep these planks the full length of the hull (27 inches). Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I don't know which is slower...a tortise, a glacier or my planking speed. Like I said at the beginning of this project..."How do you eat an elephant" "Start chewing on the toe." Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thank Brian, I'm going to try some of your magic. My bending tool is okay, but I think shaping the plank right on the hull might be better. We'll see. Thanks, Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I just bought one of these Model Expo Plank Benders and after reading this blog decided to only use the tool with wet strips of towel material under and over my rather thick strips. The result is a steam effect that doesn't char the wood and gives me decent bends in a few minutes. Frankly, I thought it would bend my planks like spagetti, but I guess they don't make magic bending tools. Rich USS Constitution hipexec

-

Sanding Block

HIPEXEC replied to Hexomega's topic in Building, Framing, Planking and plating a ships hull and deck

I just take small strips of scrap wood about 3/4" Wx 3" L x 1/8" to 1/4" thick and glue different grades of sandpaper to them. They are like a sandpaper files and work nicely for me. Rich USS Constitution hipexec -

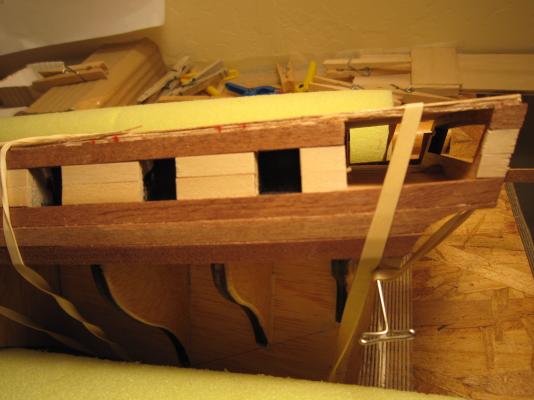

I finally finished roughing all the false gun ports! They were my second biggest worry, but they came out fairly square and all lined up. . My first worry is how will I build the upper gun ports? I'll cross that bridge after 50 or 60 more hull planks below the false gun ports. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I faced the same dilema with my USS Constituion. The plans called for me to plank the hull then cut the gun ports. I didn't like that since I'm not that good at measuring and cutting and the hull planks are heavy duty and hard to cut.. So, I made frames in the hull for all 30 gunports then I cut the hull planks in my miter box and get nice square cuts. It worked! I'm happy with the false gunports. For me it was easier to measure and make frames. They didn't have to be perfect. The ports wound up be fairly accurately placed. I made a strip of light balsa wood and drew the ports on it from the plans. The I used that to locate each port one at a time. I also made a exact square the size of the port to use as a check before I glued anything in place. Sounds more complicated than it was. I'm sure I didn't save anytime, but I wound up with nice ports. Hope this helps a little Rich hipexec USS Constitution

-

I just tried my new plank bender. It's not magic and it takes the same amount of time to get a bend as my iron did, but the curve is nice and smooth. I'll see what it looks like in the AM when it will be dry. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I planked and varnished my below decks even though I'm not sure anyone will ever see them when they look down the grates. I asked that same question when my plans called for me to plank these hidden decks. I think it was Augie or Sjors who said, "You'll know they're planked even though you can't see them." Well, mine are done. It didn't take that long. Rich USS Constitution hipexec

-

The electric plank bender came after I ordered it from ModelExpo on E-Bay. It's a Model Shipways Electric Plank Bender with a curved pattern block. Model Expo is a great place to buy hobby supplies. I'll let you all know how the bender works after I soak a few planks and try it. I built an aluminum clad holder to set the hot bender on while working. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

False gun ports finished starboard side and almost finished port side. I'm waiting for my new electric plank bender before proceeding with the rest of the planks. Using the steam iron just is not precise enough. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

It's Rich not Rach? Typed too fast. Bought some new tools to make building a little easier. A new all-angle cutter (heavy duty), new snips, and some maleable aluminum strips (made out of roof flashing) to get the exact shape of my next plank. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

That cutter just might do it, Harvey. Here's some pics of the roughed out gun ports on the starboard side. When I finish planking, this will all be filed and sanded smooth with straight edges. Rach

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Actually the challenge all this presents is the fun of it. Before I closed up the gun ports, I painted the back walls flat black. I didn't want anyone to be able to see all my construction markings in case they peeked into the small gun ports. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

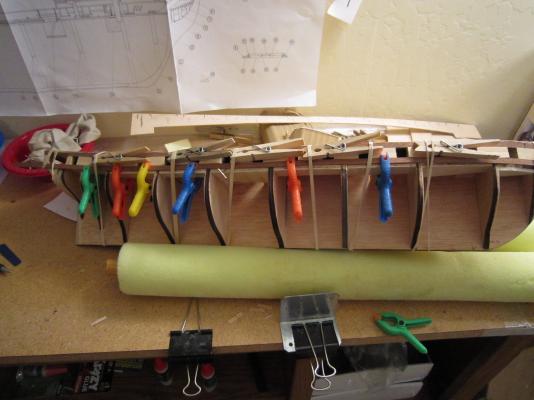

This pic shows the machinations I go through to glue on a plank. This is a pic of the fourth plank starboad side. I rough finished the starboard side false gun ports. They came out pretty good. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Broke my plank cutter on the 2mm x 6mm Sapelly plank provided in the kit. This stuff is like iron. Doesn't want to bend or cut. I broke down and ordered a electric plank bender. The iron I was using made creases in the planks. I'll have to buy a new plank cutter...more heavy duty than the last one.I'm working on the false gun ports starboard side. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Augie, Harvey and Wes, Thanks for the help. After I glue this first plank, I am using much smaller lengths to do the next courses. I'm going to have to get some planking screws. My glue is very good. It sets fast and holds tight. Exactly what is edge glueing? Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Plank number one is defeating me. The kit calls for planking once with 2mm X 6 mm dark Sapelly wood. It's very stiff and subject to cracking and splitting. I soaked the first peices and put them in a jig after using an iron to bend them. They came out near net shape. The plans call for me to pin them temporalrily until the glue sets. Either the pin bends and the pin splits the wood. I'm now soaking new pieces. I will attempt to use guide pins (removable) and rubber bands to hold each plank until the glue sets. Wish me luck. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Still plank bending and hull prep. I made sanding strips to shape the hull. They work very well. Better than a file and safer that a Dremel. I'm bending planks horizontally as well as vertically to shape them as close as I can to make them fit without forcing the plank. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks for that advice, Wes. I didn't do that with my first build. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I built this tube soaking tube because the only place to soak 30 inch planks was a bathtub. I got the concept from our website. I'm also building up the stern and bow filler blocks to make the planks fit better than just jumping from frame to frame. Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I only hope I can do half as good a job. Rich hipexec

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.