-

Posts

88 -

Joined

-

Last visited

About Nearshore

- Birthday 11/25/1963

Profile Information

-

Gender

Male

-

Location

Key West, Florida

Recent Profile Visitors

-

Nirvana reacted to a post in a topic:

HMS Flirt by TJM - Vanguard Models - 1:64

Nirvana reacted to a post in a topic:

HMS Flirt by TJM - Vanguard Models - 1:64

-

Bill Morrison reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

Bill Morrison reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

Bill Morrison reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

Bill Morrison reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

Bill Morrison reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

Bill Morrison reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

Bill Morrison reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

Bill Morrison reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

yvesvidal reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

yvesvidal reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

yvesvidal reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

yvesvidal reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

ccoyle reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

ccoyle reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

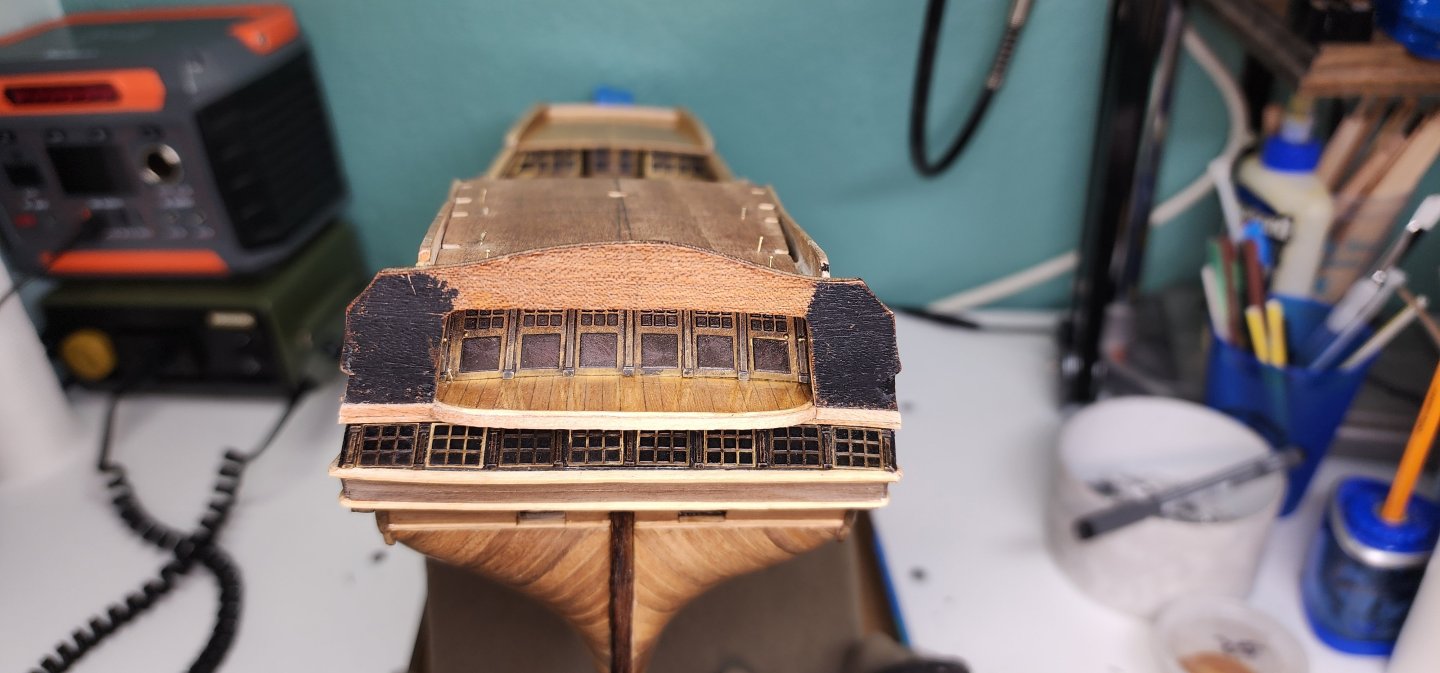

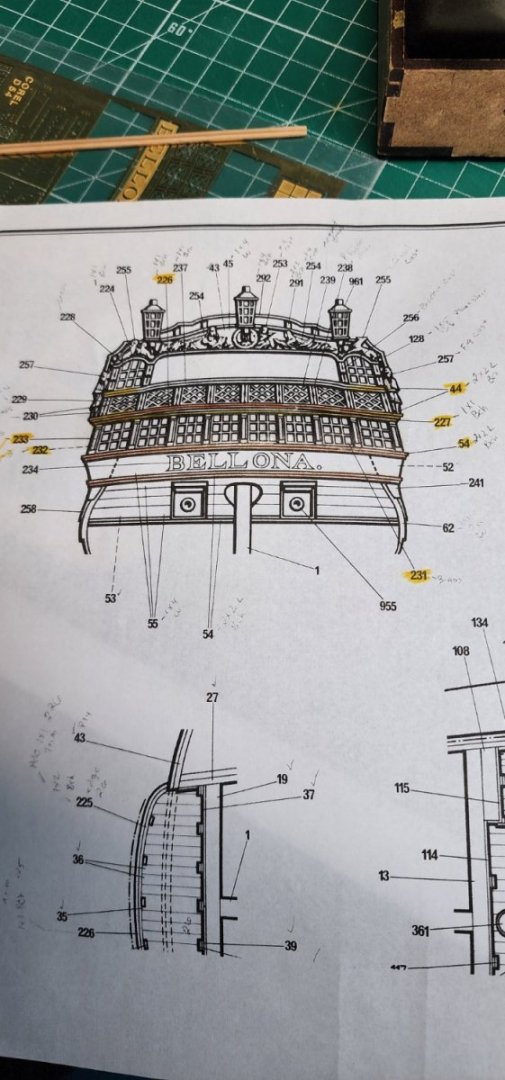

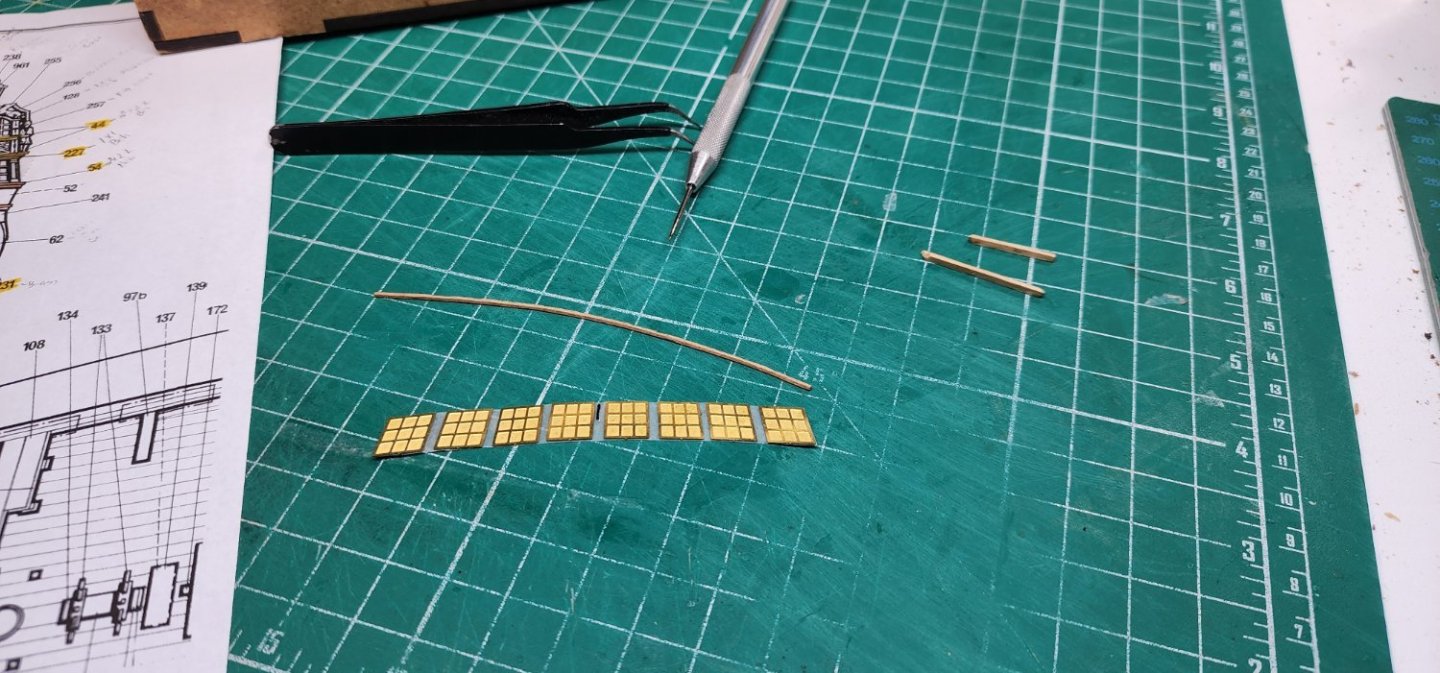

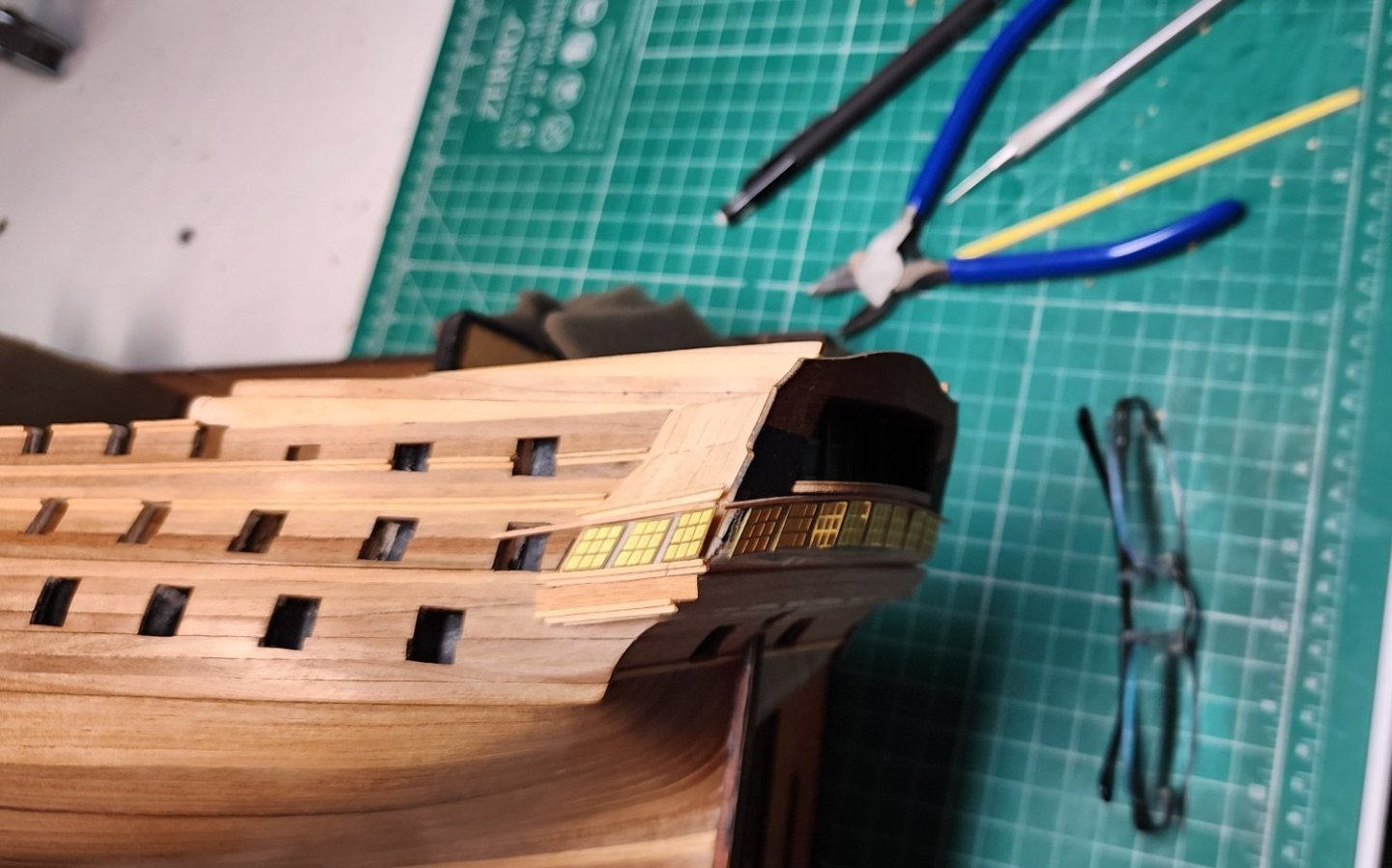

Hello all, Well, it’s been a month or so since my last update on the Bellona. I have managed to make a little bit of progress on the stern galleries. I installed the lower windows on the port and starboard sides and the top moldings above the windows. I installed the transom windows starting at the outer corners and working my way to the center, alternating between port and starboard so that both sides met in the middle at the same time. I began to install the transom planking starting with the 1x1 molding board and “L” molding. I did not use the “L” molding that came with the kit and decided to use the 1x2 beach wood and add the 1x1 molding to it to make the “L” so that the color would be consistent. The plans called for installing the molding in this manner for the transom decking and applying the “L” molding supplied with the kit for the remaining trim. The kit molding is I believe boxwood and the color contrast just was not pleasing to me seeing that I am not going to be painting the model but keeping the natural color of the wood. Once I completed that molding, I installed the remaining transom planks and trimmed them to the proper shape. Once I completed that task, I discovered that I had a problem with the next level, primarily the corner where the transom transitions on the port and starboard above the lower windows. I put a blue circle on the attached picture for clarity. The plans don’t really give any detail on this area, and I assumed that a plank sheer would be covering this area, so it wasn’t too much of a concern. Well, I was wrong. I had to remove the molding and carve out an area on the transom so that the molding would mate in the corners. After this was completed, I continued installing the remaining PE parts on the starboard side up to the last of the windows at the 3rd level. The windows are only dry fitted at this point as I still have to apply the backing to the pilasters before finial installation. It is at this point that I will finally be able to finish the planking up to the poop deck. It doesn’t seem that a lot of progress is being made, but the time it takes to get to this point takes far more time than scrolling through the pictures. Lol It is true, that a picture is worth a 1000 words. Well, that’s all I have so far and as always, your comments and guidance are always welcome. Cheers Nearshore

-

Nearshore reacted to a post in a topic:

HMS Bellona by yvesvidal - CAF Model - 1:48

Nearshore reacted to a post in a topic:

HMS Bellona by yvesvidal - CAF Model - 1:48

-

Nearshore reacted to a post in a topic:

HMS Sphinx 1775 by Erdict - Vanguard Models - 1:64 scale

Nearshore reacted to a post in a topic:

HMS Sphinx 1775 by Erdict - Vanguard Models - 1:64 scale

-

Nearshore reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Nearshore reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Nearshore started following HMS Flirt by TJM - Vanguard Models - 1:64 , NRG Rigging Project by tlevine , Period Scale Model Masting and Rigging Tables and 4 others

-

Old Collingwood reacted to a post in a topic:

HMS Bellona by hamilton - Corel - 1:100 - 1780 refit

Old Collingwood reacted to a post in a topic:

HMS Bellona by hamilton - Corel - 1:100 - 1780 refit

-

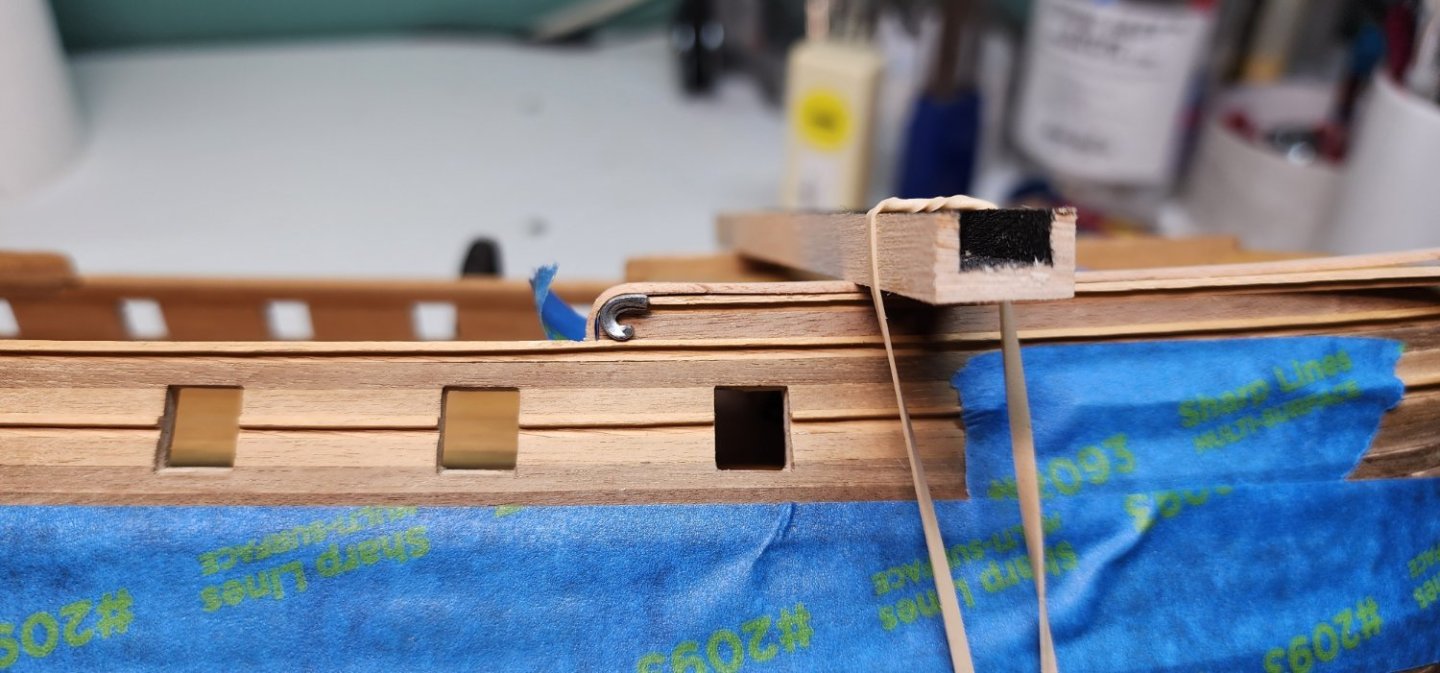

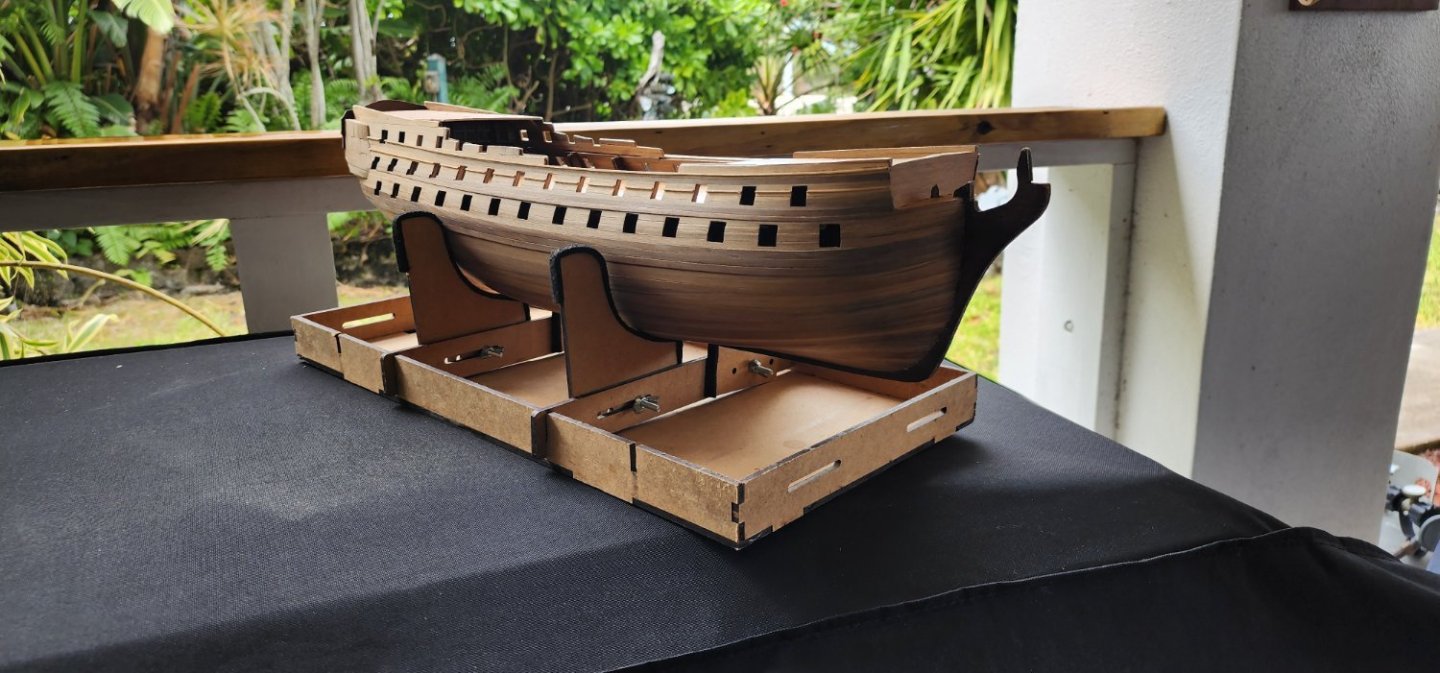

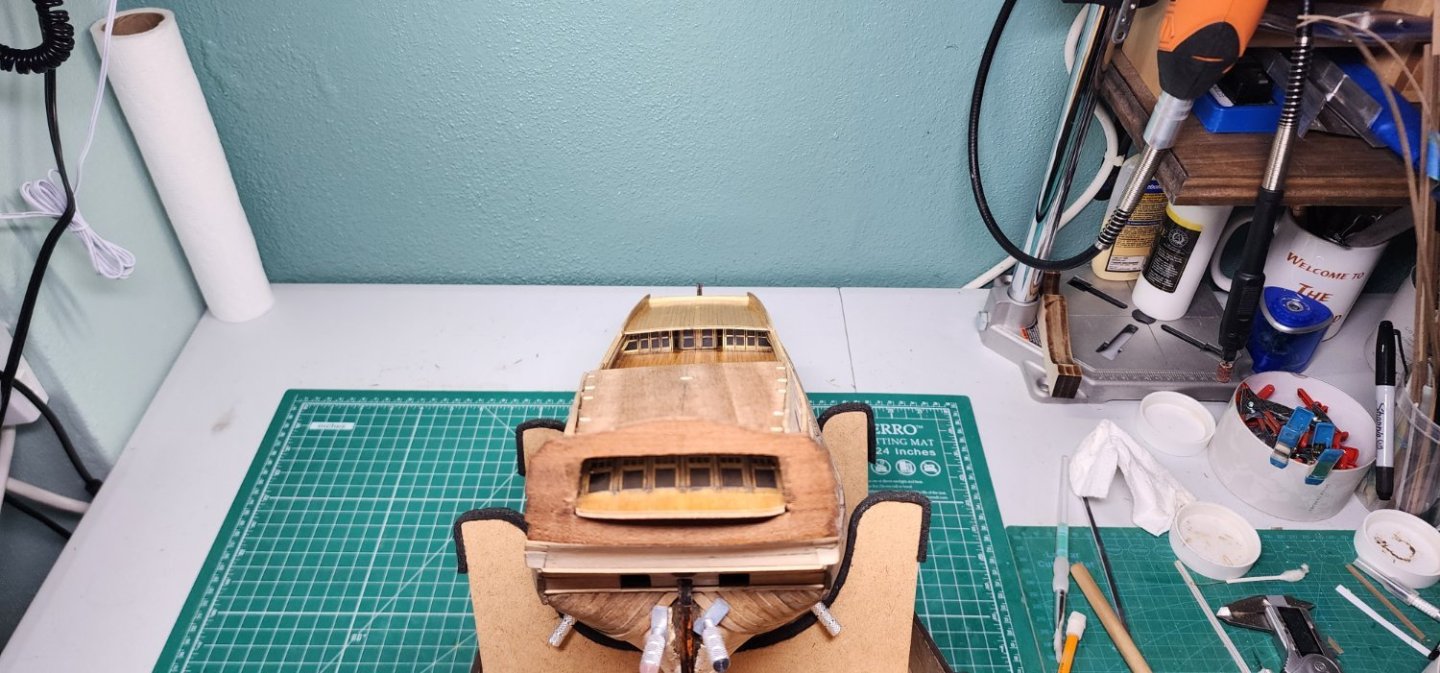

Hello All, It’s been a month or so since I updated my build log on Bellona. I have completed both port and starboard planking to equal levels of assembly just below the top portion of the galleries. As stated in my last post, I think that I may have an issue with the way the angle of the planking is running on top of the galleries. Both port and starboard are equal in the way the angles lay, so if it is a problem, at least I was consistent. 😊 I installed the chain plates, for lack of a better term, on both the port and starboard and install the additional plank just above the wale on the port side. I began to start laying out the photo etched brass pieces that are to make up the galleries on the stern and port side. The parts look very similar, especially the pilasters, and they all have the same part numbers. So, once I remove them from the brass sheet, it is very easy to mix them up and lose track of their positions. As a temporary means of attaching them to the ship, I used two-sided tape and tracing paper. I put the tracing paper on the plans and secured it in place so it would not shift on the plan drawing. I then applied the two-sided tape to the tracing paper and stuck the brass parts lining them up carefully according to the drawing. Once that was completed, I cut off the excess tracing paper and applied the two-sided tape to the areas I was dry fitting. This worked out well and I didn’t have to worry about the individual pieces shifting or falling off from the areas I was working on. During the dry fitting of the first row of windows on the port side, I found that the wooden piece below the window was not thick enough to fit the two wood trims properly. I had to add a small shim to extend it down to be able to fit both wooden trim pieces. The kit came with bass wood for pieces 240 and 241. I decided that I would use walnut instead of the material that was supplied with the kit as these two pieces will be visible from all points of view. I installed the remaining stern planking and trim. The trim took me some time to miter as it was a compound miter and I wanted it to look somewhat presentable. I painted the transom black as well as the side galleries to help blend in the blackened brass pieces once installed. I blackened the brass that makes up the first row of windows and completed installation of the planking and trim up to where the brass will be installed. I will be shifting my efforts to the starboard side so that both port and starboard are at equal stages of assembly before I glue the first row of brass windows. Well, that’s all I have for now, and as always, your comments and guidance are always welcome. Enjoy the pics. Cheers Nearshore

-

hamilton reacted to a post in a topic:

HMS Bellona by hamilton - Corel - 1:100 - 1780 refit

hamilton reacted to a post in a topic:

HMS Bellona by hamilton - Corel - 1:100 - 1780 refit

-

Nearshore reacted to a post in a topic:

HMS Bellona by hamilton - Corel - 1:100 - 1780 refit

Nearshore reacted to a post in a topic:

HMS Bellona by hamilton - Corel - 1:100 - 1780 refit

-

Nearshore reacted to a post in a topic:

USS Constitution by mtbediz - 1:76

Nearshore reacted to a post in a topic:

USS Constitution by mtbediz - 1:76

-

Nearshore reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Nearshore reacted to a post in a topic:

HMS Indefatigable 1794 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Nearshore reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

Nearshore reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

-

Nearshore reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

Nearshore reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Nearshore reacted to a post in a topic:

HMS RESOLUTION 1667 by KarenM

Nearshore reacted to a post in a topic:

HMS RESOLUTION 1667 by KarenM

-

Nearshore reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

Nearshore reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

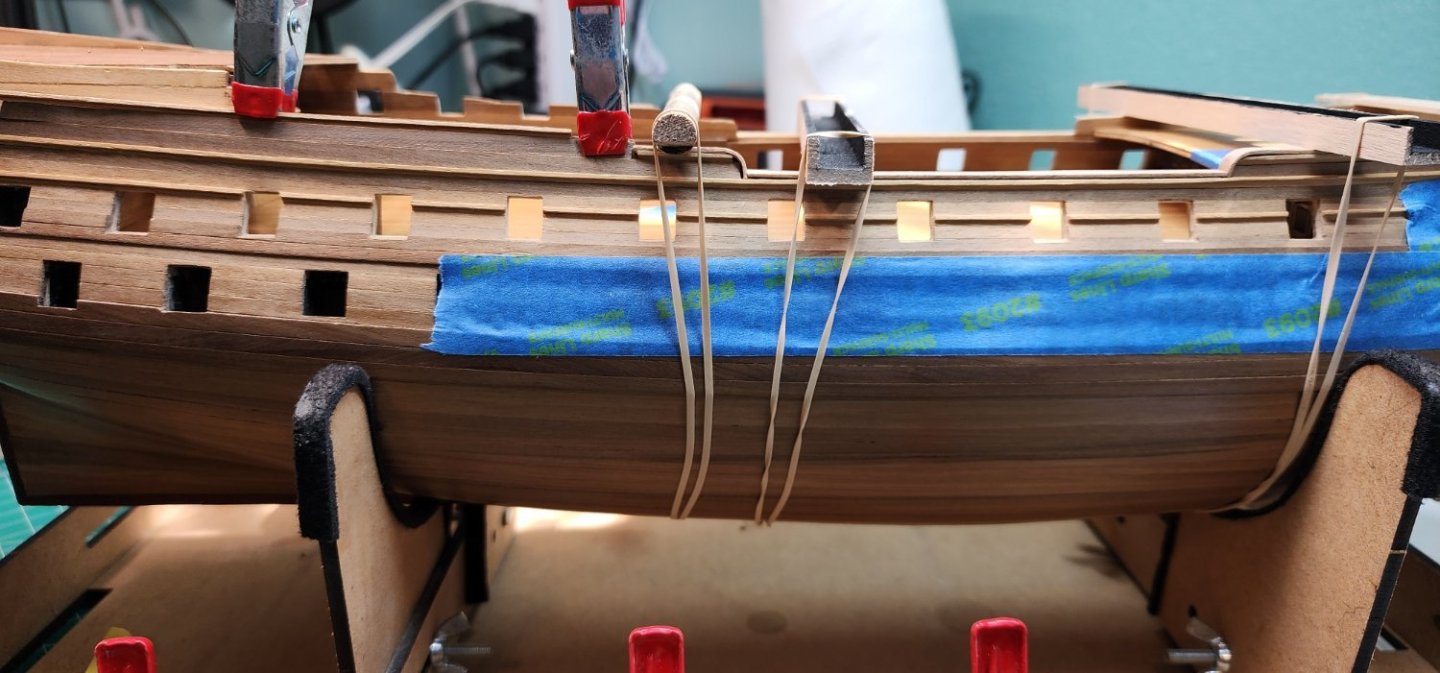

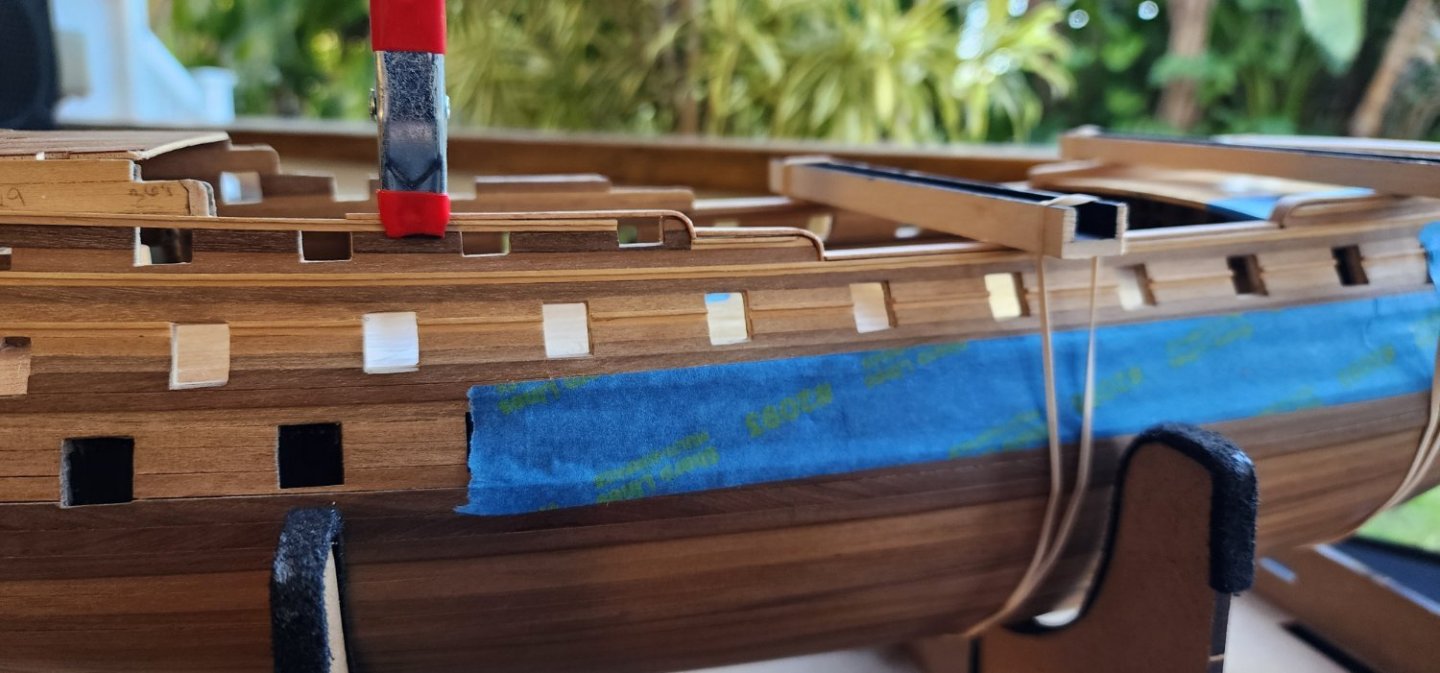

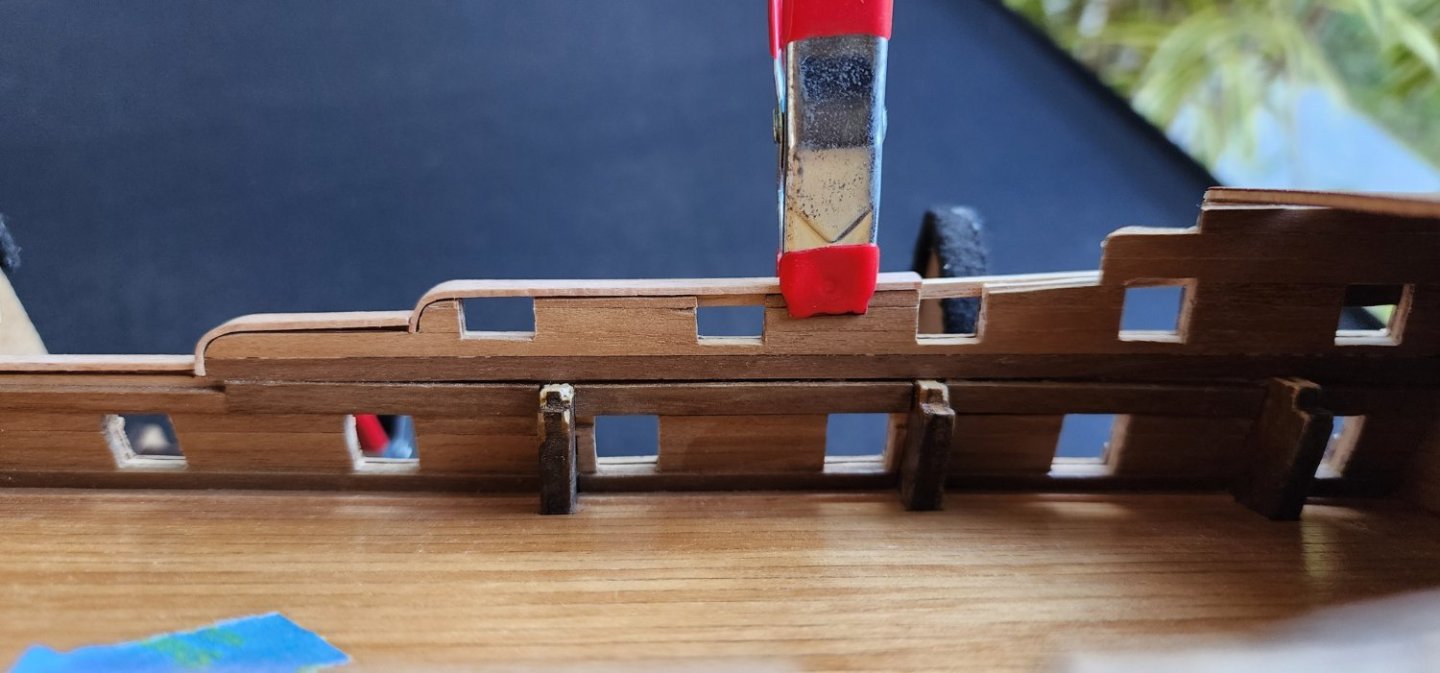

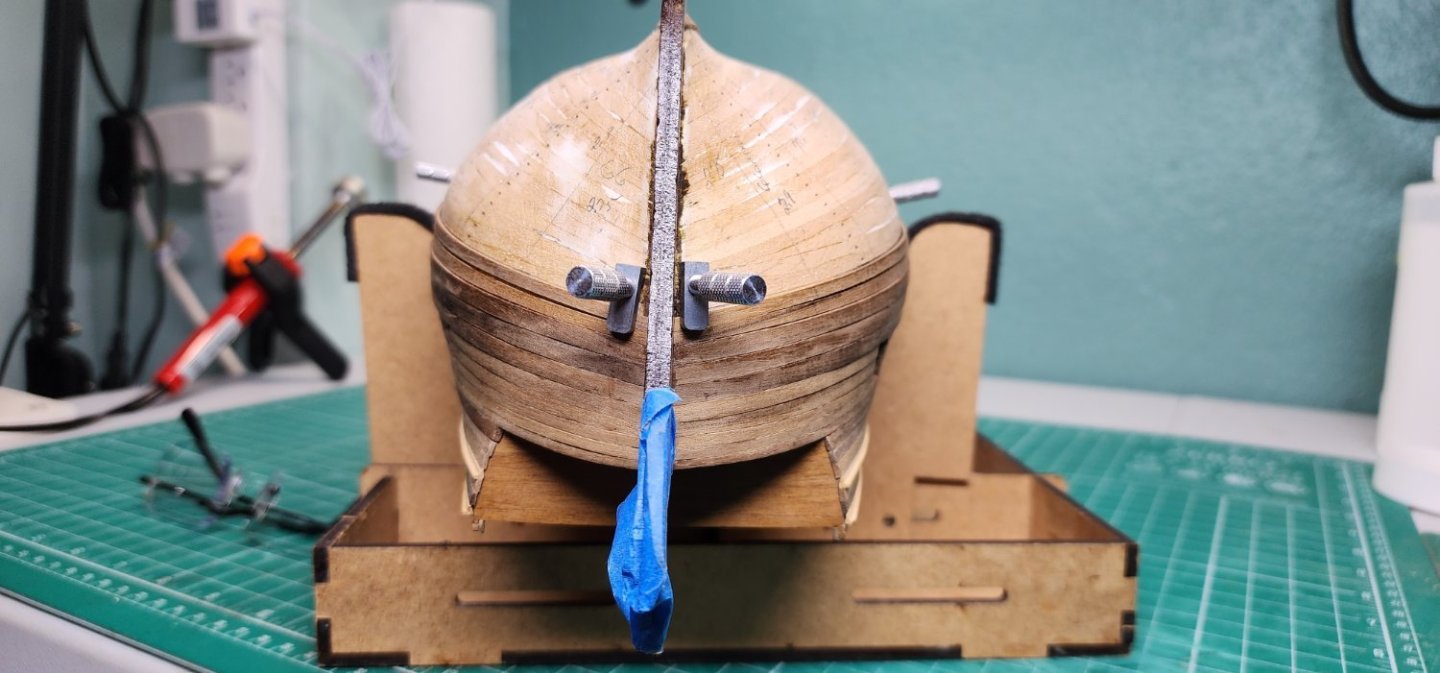

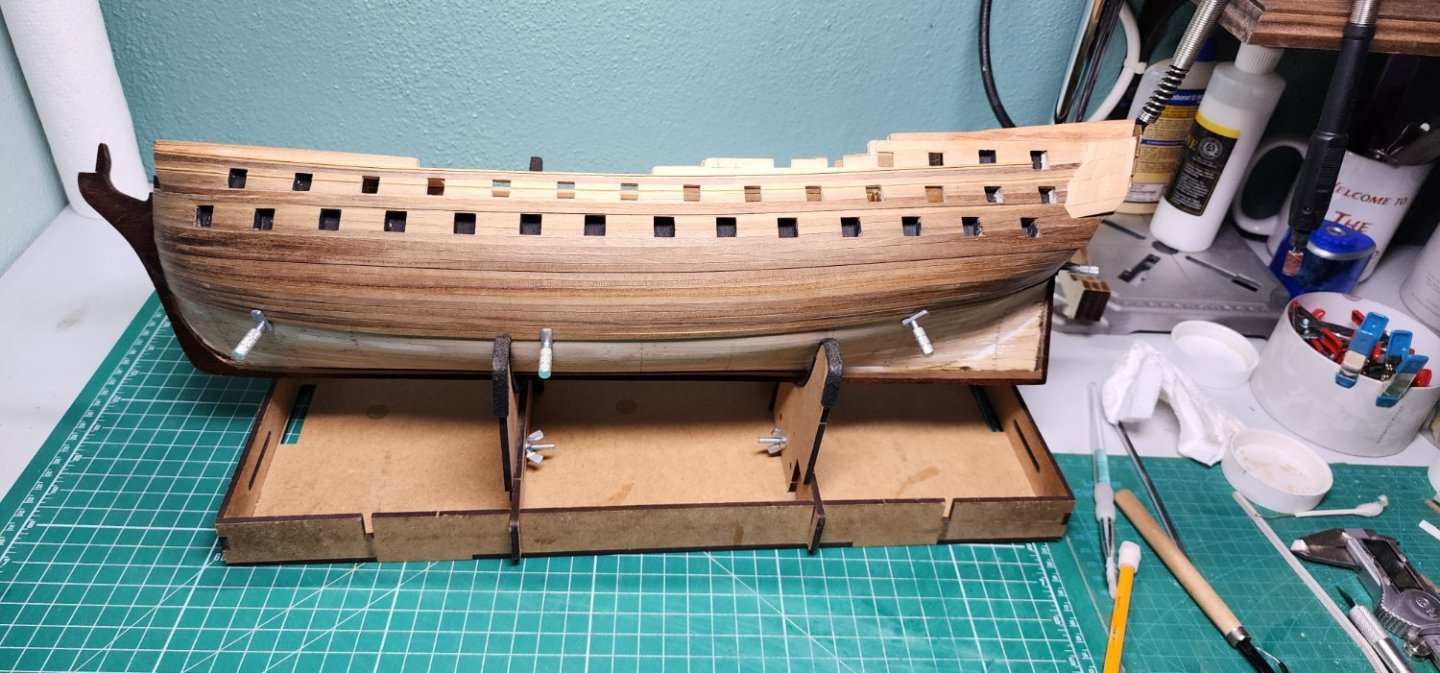

Hello All, Small update on the Bellona. I finished off the hull from the wale planks to the keel with three coats of WOP, sanding between coats with a 400-grit paper. I managed to tidy up the false keel from the dents and dings she received during the planking task. I have begun installing the remaining planks and trim up to the sheer planks. I managed to shape and dry fit the shear planks and dry fitted the dicast metal ornaments to find the radius of the bulwark and shear planks. I used a series of dowls and my small iron to shape the curve of the plank. I started with a 6mm dowl and reduced to a 4mm dowl to achieve the final shape. Installing the remaining planking, I discovered that the bulwarks were too low and needed to be raised. I installed about 2mm of planking material to bring it up to the proper elevation and angle. I also cut out the remaining cannon port that I was saving till this point so I wouldn’t break the small stub off. I would have thought at this point that the remaining planks would be a breeze, but I am quite wrong about that. There is still quite a bit of tapering that needs to be done for a proper fit. I am at a point where I am going to hold off on installing the remaining planks above the gallery. I am pretty sure I have a problem with the way the angle of the galleries are set. I am going to begin working on installing the bits and pieces that make up the stern galleries to try and figure out how far off I am. Not installing the remaining planks above the gallery may give me an opportunity to fix and hide my mistake. Well, that’s I all got for now, and as always, your comments and guidance are always welcome. Cheers Nearshore

-

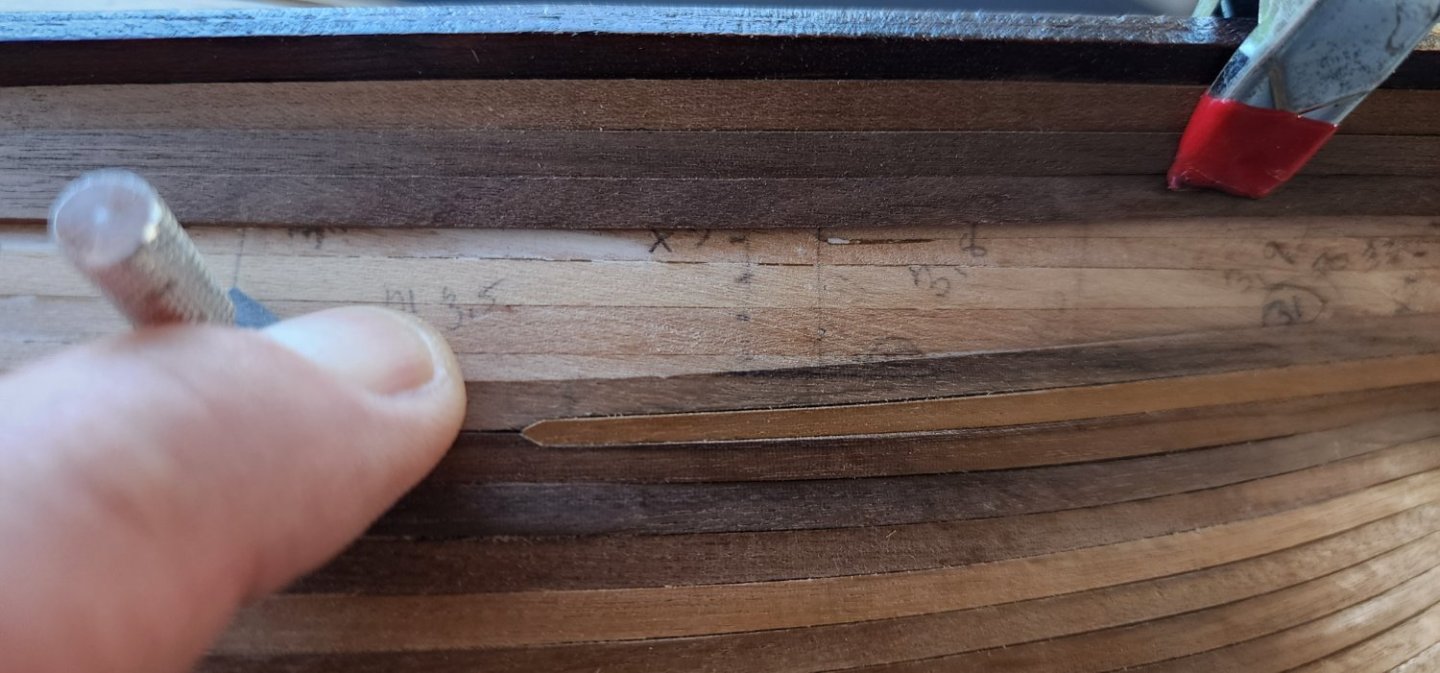

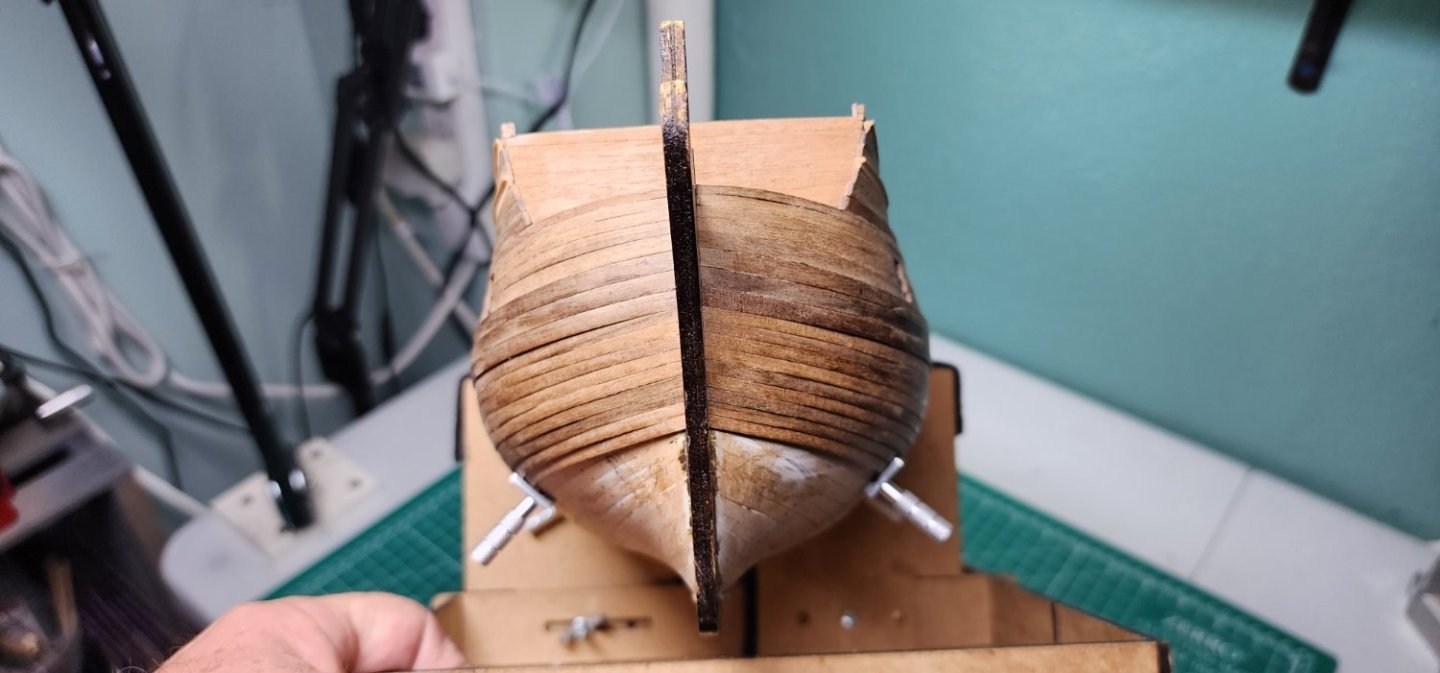

Hello All, Well, I have an update on the Bellona. I was able to get some shipyard time in over the holidays in between working on a life size project, remodeling the master bath, and entertaining with friends and family. I also added a new top to my workstation desk extending it another 10 inches. This has made a big difference and gives me quite a bit more surface area to work on. I feel I have reached another milestone completing the planking from the wale strakes to the garboard strakes. This was a very challenging task, and it did take quite a bit of time to complete. I did not update this log during this task because, well its planking and quite boring. I am including pics though of the progress from where I last left off to current. I had a few challenges, as the plans call for installing 3 stealers in the planking detail. When I lined off the hull, I could not figure out how to plan for installing these 3 stealers. I would have had to taper some of the planking at the stern to less than 2mm which would have been more than half the stock plank width. It took 24 planks from the wale to the garboard on both port and starboard at the bow and 25 at the stern including the stealer. The way I lined off the hull, only one stealer would be required at the stern. I did not want to force the issue as the planking was lining up very nicely with the way I lined off the hull and I am not very experienced in planking. The last time I planked a hull was 37 years ago. Well, I still have a way to go, cleaning up the false keel from all the nicks and scratches from the planking battle (should have seen the other guy) to finishing up the planking above the wale. I applied a coat of WOP on what I have completed so far and still have a bit of sanding and touchup. Enjoy the pics and as always, your comments and guidance are always welcome. Cheers Nearshore

-

Hi Hamilton, I don't think you have a big problem here. I am assuming that you are referring to the planking that terminates on bulhead 16 and that you did not continue the planking around the stern. If you fair down the planking to give it a smooth transition the second layer lanking will butt up against the planks on the transome and shouldn't cause you a problem. I attached a pic as referance although I did plank around bulkhead 16. If memory serves me, i think the instructions suggest doing it the way you are doing it. You may have a bit of fairing to do, but i think your in good shape here. Your build is looking great! Keep up the good work. Cheers Nearshore

-

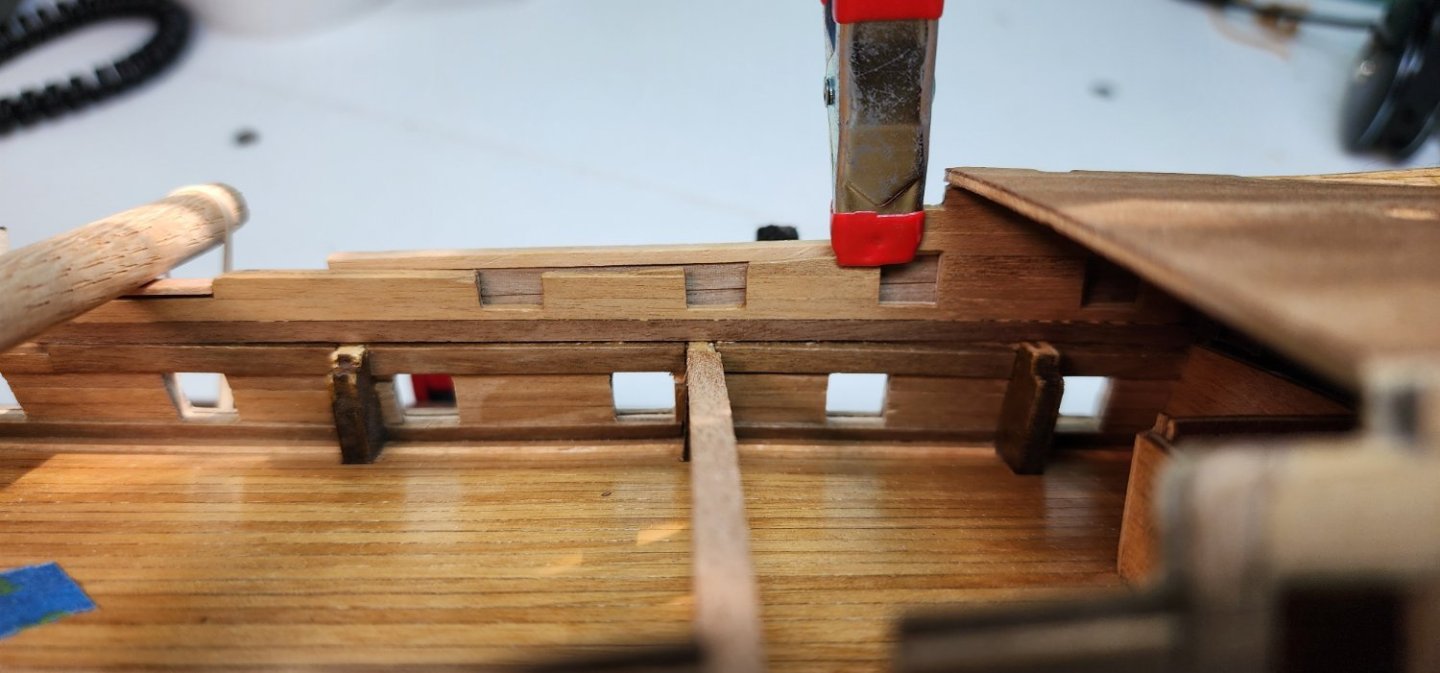

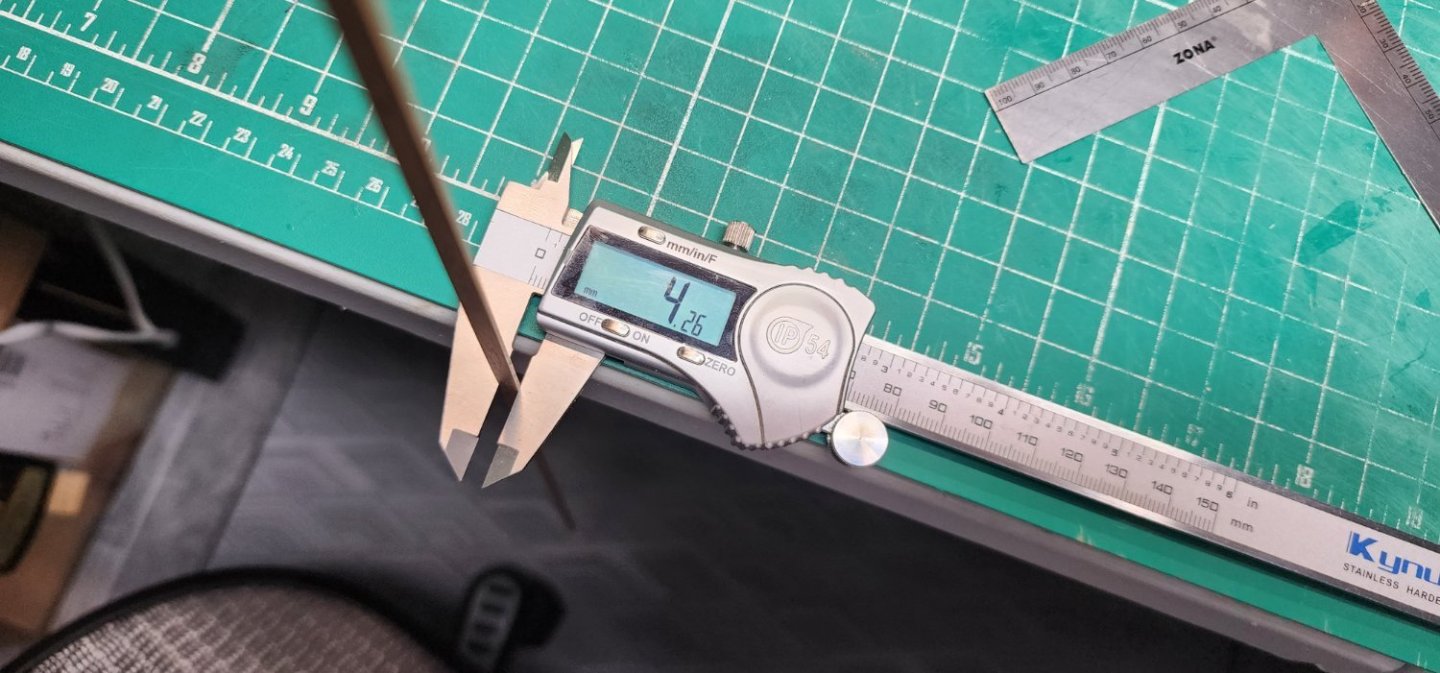

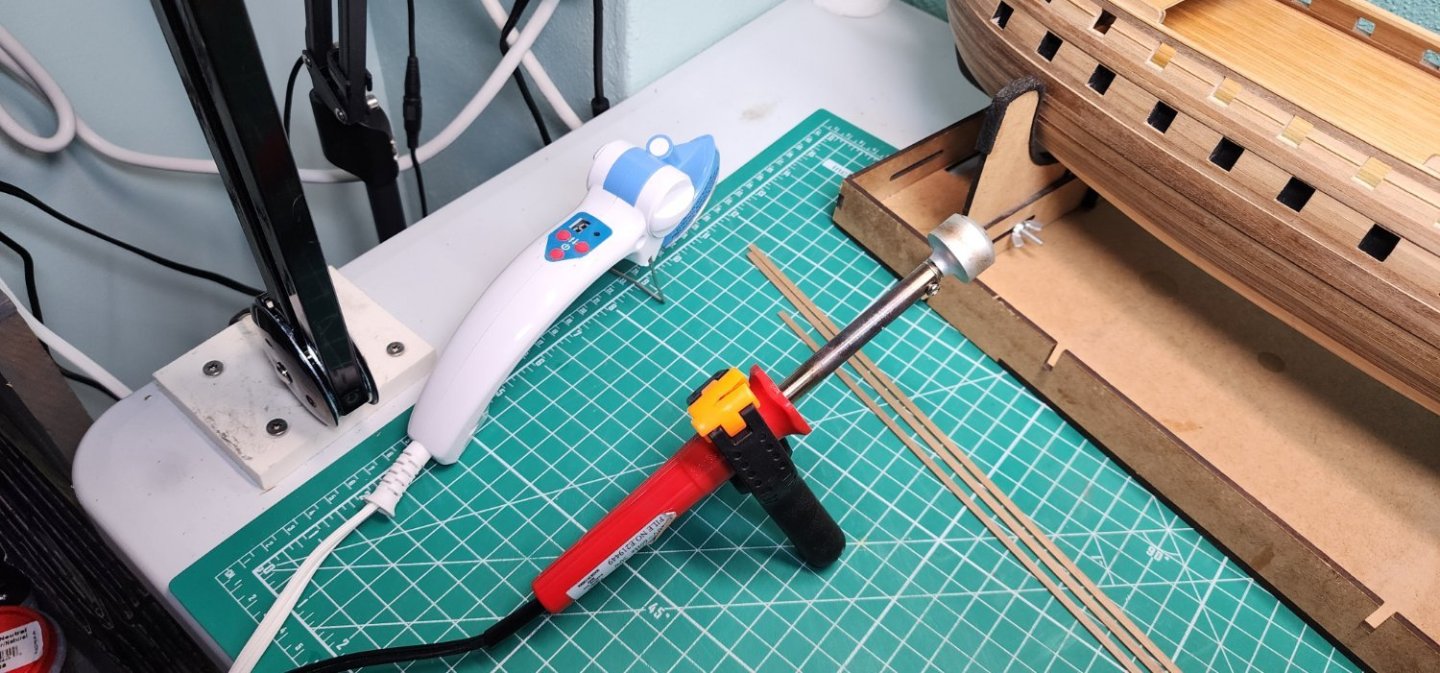

Hello All, I have a small update on the Bellona. The second layer of planking is taking some time to accomplish. The width of the planking that came with the kit, on average, is 4.25mm in width and what I need is 4mm to match the proper number of planks that are needed. As you can imagine, .25mm can add up fast and throw off the number of planks that have been calculated. The measurement from the garboard strake to the wale at the longest measurement on the hull is 96mm. Dividing that by 4mm gives me the even number or planks at 24. This matches the number of planks that are shown on the plans excluding the 3 steelers at the stern. Not trimming the planks to this width would definitely cause me problems the closer I get to the garboard. After adjusting the width of the planks, I started by tapering the bow planks first and then shaped them with the plank bender. I found a pretty cool tool while wandering around the craft store. It’s a petite press by Oritz. It is basically a miniature iron. It works very well shaping the planks while they are on the hull. It’s not very useful in making the sharp bends at the stern, but once the shape is close using the plank bender, it’s very useful as a press to help maintain the plank shape against the hull. I worked each plank from stem to stern and then back to the stem fitting the stern plank to the stern trim piece, and then adjusted the stem plank by trimming it down so that there was no buckling. I always dry fit 2 planks and then glue one plank and shape another plank so I always have 2 planks that are dry fitted. This gives me a bit of a look ahead and I can adjust accordingly if there are any errors. This technic has been working well and I am pleased at how the strakes have laid up at the stern. I still have a way to go, so it’s still bottoms up for now. As I have stated earlier in my log, the kit directions do not provide a clear sequence of assembly. It has taken me a while to come up with my strategy on this build. My strategy is to complete the second layer planking, and then move on to the galleries and then the forecastle and bow before I move on to the interior. I will complete the main deck first and work my way up to the poop deck, that being the last deck that gets installed. I temporarily have pinned the poop deck in place to help protect the fixtures that I have already installed. This is a very complicated model to assemble and has certainly challenged me and is a real fun project. Well, that is it for now, and as always, your comments and guidance are always welcome. Cheers Nearshore

-

Horseshoe Plates

Nearshore replied to tmj's topic in Building, Framing, Planking and plating a ships hull and deck

I'm pretty sure the shape has something to do with they didn't have welders back then. It would have been easier to bend a peice of flat stock then to forge separate peices together. Just my opinion on the reasoning behind the shape. Nearshore -

What an amazing build. You skills are very impressive!! You have given me some ideas to use on my build. Nearshore

- 487 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Nearshore started following Blue Ensign

-

Hi Hamilton, Glad to see you are back working on the Bellona. Looks good so far and you will probably catch up to me soon. LOL As far as the first planking and whether to carve the rabbet and bearding lines, that’s what I did on mine. I then had to carve them out again to accept the second layer of planks. If I can be of any assistance, please don’t hesitate to contact me. I will be watching you progress and look forward to having a partner building the same ship. Cheers Nearshore

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.