-

Posts

3,084 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jaager

-

Guessing that you are asking about AliExpress Under Home Improvement is tool try 12V DC motors and drill chucks also have water stones They have low cost flex shafts with 1/4" sockets and chucks that mount there. I needed for 1" / 2" / 3" bowl sander tools (hook & loop media mount) ( PeachTree)- but I bit the bullet and bought a Kirjes flex shaft from Lee Valley to finish inside frame bevels instead of the low cost Chinese tools. The cost is generally very low at Ali - and mostly they are reliable - shipping is surface post and not too long. There were a couple of mistakes- and instead of a refund - I got some sort of something for a cell phone - a device that I am mostly a Luddite about.

-

Small DC motors with chucks = AliExpress a commune of sorts in China Marlin P Jones motors, wires , and a DC 2A power supply that is 3/4.5/6/7.5/9/12 V with banana plug and gator clamp wires - no need for batteries and speed control from power supply @ $17 it would not take many batteries for it to be cost effective

-

The General version has been on Micro Mark for a while. There is a Jacobs chuck that fits it, so wire gauge bits can be used with it.

-

Roger B. Taney rigging and sail plans

Jaager replied to captpjn's topic in Masting, rigging and sails

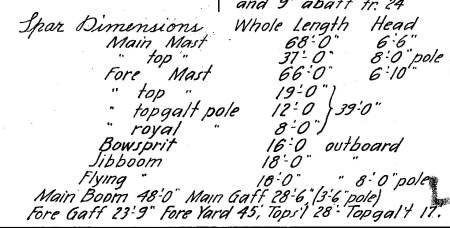

Roger B Taney Revenue Cutter Launched 12/26/1833 Isaac Webb design LBP 74.5" Beam 20" 8.5" Depth 7.5' Howard I Chapelle drafted a hull plan and it is available from The Smithsonian They also have spar plan for the near contemporary Revenue cutter Jefferson and one for the Revenue cutter Washington. Since Jefferson may have been a sister, this plan may be close enough. Chapelle provided the following data on his plan of the Taney Help for the details may be available in one or all of the following books: LEVER,L DARCY EDWARD W SWEETMAN CO NEW YORK 1963 MASTING - RIGGING ART OF RIGGING, THE 1848 BIDDLECOMB,G EDWARD A SWEETMAN NEW YORK 1969 MASTING AND RIGGING KEDGE ANCHOR, THE 1876 BRADY,WILLIAM N MACDONALD AND JANE'S LONDON 1974 MASTING AND RIGGING SEAMANSHIP 1862 NARES,GEORGE S GRESHAM BOOKS SURRY 1979 SEAMANSHIP 19TH MASTING RIGGING SAIL Rigging Period Ship Models Petersson, Lannarth Seaforth 2011 I have not looked at the books to see which are really helpful for a small vessel like this. -

How serious do you get about dust protection

Jaager replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

From the pictures, there seems to be a very important component missing: The plus added to your vac system by having a passive cyclone dust separator inline is difficult to over state. Very little reaches the body of the vac. I too have an Oneida Dust Deputy. I got one on sale, but it is worth list. An RCV switch - garage door type unit to turn on power to the vac - is very handy. -

The dust from a bandsaw is a somewhat minor aspect. There is a vac port. With a cyclone trap, the vac filter does not clog nearly as often. For me, it is the blades. A table saw has finer teeth, and higher velocity, so the dust is a lot worse. A thickness sander IS dust. A real advantage with a bandsaw is that if you have access to rural areas, and a chainsaw, wood can be harvested on the hoof. Species can be obtained that are not available commercially.

-

Why not use an aqueous aniline wood dye? Wood Craft has pre mixed concentrates that can be mixed to produce a continuum of possible shades. Test it on your available wood stock to find the best compatibility and result. With a deep penetrating dye, the grain is not hidden. Given your location, have you checked out: http://worldofhardwoods.com/Location.php

-

What brand of #11 blades do you use

Jaager replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

Following suggestions from here, I am now experimenting with violin-makers knives for the jobs that these disposable blades do. Not enough experience with this yet. -

What brand of #11 blades do you use

Jaager replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

MicroMark #11 pk of 100 frequent strop using scrap leather and FlexCut Gold cmpd -

I have it in my memory that years ago, a journal article said that there are probably way more SOS kits (and Victory as well I'm guessing) sitting unfinished and likely unstarted on closet shelves than are ever finished. Your feeling of being overwhelmed is a totally valid response. A first rate man-o-war was a major undertaking for a country. A model of one is a virtuoso undertaking. To make matters worse, the small scale (1:90 ) gets close to miniature scale, which because of the physical limits of modeling materials - wood mostly - skilled tricks are needed for various components. There is just a lot more of everything - a serious amount of repetitive work. Looking at pictures, it is difficult to realize, but a 74 is a really major undertaking and a 1st rate is essentially twice as large. A brig is a good first choice. But still a substantial undertaking. You do seem to have a knack for finding "not now being manufactured" kits. Perhaps Ebay is a solution to the kit in the closet. Or maybe it is like the exercise springs present that my ex-inlaws used to pass as a joke each Xmas - the same kits over and over. Wo bist du? You do not list a location. Economical sourcing of wood is location dependent. choosing species that are optimal for scaling down is tricky.

-

Doing a single fold, the cut edge is on view. I am thinking that painting a thin strip of a clear material that dries stiff over the line to be cut ( on the backside ) will stop fraying and give a clean looking edge. Shellac, varnish, lacquer come to mind. of the three, I think lacquer may be the better choice - except that the solvent is so fierce for close up work, inside.

-

Holding bulkheads while drying

Jaager replied to Don Quixote's topic in Modeling tools and Workshop Equipment

Search: fair a frame in the tools and equipment forum and read before you consider this tool. -

Things that look strange to my eye: No windlass Cathead looks too small No cradle the boom jaws on the main No lower boom on the fore if it was a schooner If it was brig rigged on the fore, width of the lowest yard does not look wide enough for a mainsail more like a spreader for the fore topsail The bowsprit being square outboard - I am surprised how unattractive that looks tome. The jibboom looks under size The lack of ratlines There is a significant drag, I would have mounted it with the waterline horizontal. My money is on this being a decorative model, rather than an historical presentation. Being heretical here: because this is not a visitor from the early 1800's - I would go wild with the repairs, and pick a close vessel from about 1812 and upgrade it to match.

-

I tried a scroll saw, first the Unimat attachment version and then a MicroLux Mini. I do not like the lifting the work effect due to the up-down cutting action. I got a generic 9" bench top band saw that Micro Mark sold for a while. I adapted a Carter Stabilizer guide to it and with a 1/8" blade, it does an excellent job of scroll cutting. The cutting action helps hold the work on the table, rather than vibrating it. The blade has a set, so I do not cut right up to the line, but I would finish with a disk or drum sander in any case. No way to use it for closed inside cuts, not something I have needed to do, but I have a hand fret saw if I ever do need to do it. I work at 1:60 scale, which is 4 times your scale on a 3D basis, so you might like the thinner blades with a scroll saw, but a sander will have a easier time of it at your scale too.

-

From my perspective neither. Dremel made a 4" table saw. It no longer seems to be in their inventory. I have had one for a long time. It works. The design and engineering are average at best. If you are going to half *** this endeavor. It might be worth using if you find it cheap enough. I have a 4" Jarmac. It is a bit better, but not much. I have no experience with any Proxxon products. If you are serious about this and plan to be at it for the long haul: the Byrnes table saw is the way to go. For 3" and 4" inch blades, I doubt a better designed or built unit can or will ever be offered for sale. It is a serious machine. They are the product of a home business. Life being what it is, the machine will not always be available. I imagine a time in the future, when the resale value of one of these units would exceed it present cost.

-

Wafalck, I am sure that you are correct, and no offense was intended. I was being pedantic and technical because, rather than being at a conversational level, I was thinking that some may try to source materials on line, based on this discussion and some commercial sites tend to be rigid in their descriptions of what they are selling. A lot of times, you have to be a member of their club to know what are the actual sizes of their items. Linen tended to be a nightmare in that regard. Now, you are lucky to find anything to be frustrated with. I think one site I found was only interested in selling shipping container volumes, from India, I think. The site was so obtuse, I couldn't be sure.

-

Of your local wood species, only Cherry and Maple would interest me. Black Walnut is a beautiful wood, but it is open pore. If the part is totally hidden, Oak, Hickory, Walnut, and Pecan are hard enough and tight enough. I got some rough 2" stock from a local guy who sourced an estate sale. I got a lot of Maple, but I also bought a bit of what I thought was Cherry. It is actually Elm, I think, not sure of the species. Great color, grain contrast is more than I like and it is moderately open pore.

-

With proper attention to priming and fine sanding, I am pretty sure that you can get a base for your finish coats that can look as though you are painting over glass if you wish to go that far. Before you do that though, given that you are asking the question, you should do the boring, nerdy, and teachers pet thing of practicing on scrap wood first - a lot. Even to the point of getting some additional Basswood planking size material and gluing it planking style on a flat piece of scrap plywood. If your practiced priming and painting result on that is acceptable, then use that on the hull. I would not use exotic or expensive wood species, that are best used natural or dyed, as a base for a painted finish. If you were in the Pacific Northwest and could get the Cedar from a local mill, it might be cost effective. Since you are in Arkansas, the commercial species from your region that have the tight grain and closed pore traits that you need and come as veneer include Black Cherry and Hard Maple. It is a crime to cover up Cherry, so that leaves Maple. While Maple is certainly suitable in a natural state, it is light colored. But it is also on the low end of cost. I looked and you seem to be in a desert as far as walking into a local WoodCraft and pulling a pack of veneer off the shelf. Your kits are POB, planked with Basswood, and with the wide spacing of the molds, you can get a smooth hollow free hull with a single layer? You might could consider covering the Basswood layer with a second layer of the thinnest Hard Maple veneer to be had. The planks can be spilled using a steel straight edge and a #11 blade or knife with a similar shape. With the Maple, you can go much lighter on the priming and have a finish that looks like there is scale wood underneath. You could also experiment with using a black dye or India ink on the Maple and clear finishing that. If you copper the bottom, given that copper sheeting is already thicker than scale, over the primary Basswood planking, you might could do an intermediate layer of bond paper, under the copper, to shim it out to match up to the Maple veneer.

-

In the fiber industry, I think yarn has a specific meaning - the first stage in twisting up natural fibers. At least in the case of linen, the progression is: plant fiber -> yarn -> line/thread -> rope -> = twist up to linen fibers are pretty much larger than cotton thread, but in larger scales, make impressive looking scale rope. Cotton fibers are so fine that I think that it pretty much starts as thread as far as availability. There was a time when most of us would have been up close and personal in the process of turning wool fibers/hair into yarn. Silk thread comes in fine diameters. Cotton thread comes fairly fine. Although my focus is largely on hull fabrication I give thought to scale effect on paint choice and rigging. I think the eye sees rigging as being larger than it is, so I am considering ignoring the compulsion to match scale rope diameter to its full size counter point. I am thinking that a hair finer in diameter would look better. In the case of busy work like serving line size, I am thinking that more than a hair finer than scale would actually look more authentic. It has to be neigh on to impossible to get the gaps as tight as full size.

-

Thanks for the heads up, I also got 2 and the net with shipping was about $20 each. The quality was much better than would be expected at this price. They really are pencil boxes. I did not get them for this purpose, but they are too shallow for palm chisels.

-

Cliff, Good start. You have more bravery than I have. Being compulsive, I would have taken the sanding planer with me. I am never sure how much thicker my stock must be to get a 220 finish on both sides and have all of the blade scars removed. I try to keep it as close to final as possible to get max yield. The additional passes thru the thickness sander is tedious, time consuming and poor wood economy. In your place, I would find out the blade length for their bandsaw and if I could use my own on their machine. If I could I would purchase 3 or 4 1/2" Wood Slicer blades from Highland. A 5/8" or 3/4" blade is not better at resawing than a 1/2" blade. The steel is top quality. the blade is thin and it only has a minimum set, so the kerf is as low as can be had. These blades last longer, but they are expensive and you only want to use them for resawing. The trick for efficient tracking when resawing, is not having a wider blade. The trick is in the blade position. The cutting edge of the teeth should ride on the crown of the top wheel. And, a wider blade will not stop it wandering when the cutting edge gets dull I know for a fact that even a hard steel blade will snap if you push it when dull. The blade only needs have just enough tension. A tighter blade does not resist wander, it just more likely to break. I would also make friends with a couple of local tree service companies and pay them for any Pear, Hawthorn, Plum, and especially Apple butts and large limbs. 18-24" is plenty long. Cherry is great, and Sweet Cherry is similar in hardness and grain to Black Cherry, but the color is tan. Unless they work old fence rows, a tree service is only likely to cut eatable cherry trees. Fortunately, Black Cherry is readily available from commercial sources. And half the work is done over self harvest, billeting, and drying. You are a good haul from the mountains and the deals to be had on rough cut Hard Maple and Black Cherry, But it may be worth a trip, especially if you do not have a retail yard like Yukon Lumber near by who also sell rough stock.. The mill planers take off significant wood, so a smooth planed 3/4" board at a retail yard is 1- 1 1/4" thick at a country saw mill. And yes, it is a PITA to get smooth face on the top and bottom edges of slabs resawn from rough boards, But frame timbers do not need this anyway and you have up to a 1/2" more width - depending on how much checking there is.

- 19 replies

-

- milling wood

- echo cross section

-

(and 1 more)

Tagged with:

-

For convenience and ease of use, I have been enjoying the Dremel 8050, but it requires additional collets and its price on European Amazon is absurd

-

Wood that seems to be too brittle or splinters is probably because an unsuitable species was chosen by the kit company to begin with. Living in a World of short lived manufactured items and plastics that either oxidize or continue to polymerize to brittleness over a short time span, it is easy to forget that when harvested, some wood was already several hundred years old on the hoof. The rapid growing species are often too soft, or coarse, or contrasty, or easily split to be appropriate. An exception seems to be various ornamental Pear. But their size and branch habits do not lend them to commercial interest. They are essentially DIY. The goal of seasoning is to get wood into a hydrated equilibrium with its ambient atmosphere. It can't get any dryer than that. If the kit has been stored in a humid environment, it could have been invaded by fungus and ruined, but the box would have all but disintegrated too. Some members here have been on builds a lot longer than the 12 years your kit has been around.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.