-

Posts

3,084 -

Joined

-

Last visited

Reputation Activity

-

Jaager got a reaction from Matrim in Plum wood

Jaager got a reaction from Matrim in Plum wood

Any fruit wood is usually an excellent choice. The best time to harvest is usually when the tree is dormant.

It will probably be harder that Cherry, close the Apple - which is King.

For hull planking, you will have to see the actual planks re: the color and uniformity. But for anything else, fittings, furniture, catheads, beams, etc. it will be excellent.

The harvesting technique has been covered in this form several times.

The short list is:

seal the ends - old paint will serve do it ASAP

debark - insect larvae that bore live there. Drawknives were designed for this but freehand bandsaw is less actual work, but can cost more wood

Get it into billets soonest if you can. A free standing bandsaw is the more efficient tool to do this.

Sticker - good ventilation and air circulation - in a covered location or an atic Access to a kiln gets the seasoned wood more quickly. Air drying = 1 year per inch in thickness.

-

Jaager got a reaction from Greg M in Plum wood

Jaager got a reaction from Greg M in Plum wood

Any fruit wood is usually an excellent choice. The best time to harvest is usually when the tree is dormant.

It will probably be harder that Cherry, close the Apple - which is King.

For hull planking, you will have to see the actual planks re: the color and uniformity. But for anything else, fittings, furniture, catheads, beams, etc. it will be excellent.

The harvesting technique has been covered in this form several times.

The short list is:

seal the ends - old paint will serve do it ASAP

debark - insect larvae that bore live there. Drawknives were designed for this but freehand bandsaw is less actual work, but can cost more wood

Get it into billets soonest if you can. A free standing bandsaw is the more efficient tool to do this.

Sticker - good ventilation and air circulation - in a covered location or an atic Access to a kiln gets the seasoned wood more quickly. Air drying = 1 year per inch in thickness.

-

Jaager got a reaction from mtaylor in Hull Planking

Jaager got a reaction from mtaylor in Hull Planking

An 1826 contract for two US navy corvettes specifies that deck planks be Heart Pine 40 feet long. Those primeval Pines were still tall and straight. My thinking is this would be the outside limit for any component. The hull planking was a lot less heroic in length. A good ball park length would be 20 to 25 feet long.

-

Jaager got a reaction from Canute in Ebony For Ship Planking

Jaager got a reaction from Canute in Ebony For Ship Planking

I suspect That Ebony is the subject of more misleading substitution than is Boxwood. In any case, there is not the profit or social status with ship models as there is with guitars as far as the decoration.

My bias suggests that using one of the Ebony group on a kit upgrade is like doing a high class upgrade in a trailer park. The quality is evident, but the environment makes the effort a misplaced one.

For a substitute, Holly is appropriate, but the Wood Database lists other species that accept dyes.

This is a situation where slang shorthand can lead to misunderstandings.

A stain - the noun - is a form of semi transparent paint - surface only. It is pore filling and this makes the product a problem with PVA bonding. Actual black paint may as well be used.

To stain - the verb - includes the use of the semi transparent paint and also the effect of a dye.

Wood dyes are available from wood working vendors - there are two types - alcohol and water. The alcohol does not raise the grain, It also does not penetrate as deeply as water based dyes.

For black, I would think that two treatments should work, with a sanding step after the first treatment to repair the raised grain. The dye can be used on the loose plank and it will PVA bond as well as if it were not treated.

I have it in mind to try a technique used by a traditional Carolina furniture makes (PBS). He dissolved a steel wool pad in a quart of vinegar (5% acetic acid) . He then wet pieces of Maple with a solution of tannic acid and

sanded /scraped the raised grain and then coated it with the iron acetate solution. The effect was a dense black.

-

Jaager got a reaction from mtaylor in Ebony For Ship Planking

Jaager got a reaction from mtaylor in Ebony For Ship Planking

I suspect That Ebony is the subject of more misleading substitution than is Boxwood. In any case, there is not the profit or social status with ship models as there is with guitars as far as the decoration.

My bias suggests that using one of the Ebony group on a kit upgrade is like doing a high class upgrade in a trailer park. The quality is evident, but the environment makes the effort a misplaced one.

For a substitute, Holly is appropriate, but the Wood Database lists other species that accept dyes.

This is a situation where slang shorthand can lead to misunderstandings.

A stain - the noun - is a form of semi transparent paint - surface only. It is pore filling and this makes the product a problem with PVA bonding. Actual black paint may as well be used.

To stain - the verb - includes the use of the semi transparent paint and also the effect of a dye.

Wood dyes are available from wood working vendors - there are two types - alcohol and water. The alcohol does not raise the grain, It also does not penetrate as deeply as water based dyes.

For black, I would think that two treatments should work, with a sanding step after the first treatment to repair the raised grain. The dye can be used on the loose plank and it will PVA bond as well as if it were not treated.

I have it in mind to try a technique used by a traditional Carolina furniture makes (PBS). He dissolved a steel wool pad in a quart of vinegar (5% acetic acid) . He then wet pieces of Maple with a solution of tannic acid and

sanded /scraped the raised grain and then coated it with the iron acetate solution. The effect was a dense black.

-

Jaager got a reaction from Bob Cleek in Ebony For Ship Planking

Jaager got a reaction from Bob Cleek in Ebony For Ship Planking

I suspect That Ebony is the subject of more misleading substitution than is Boxwood. In any case, there is not the profit or social status with ship models as there is with guitars as far as the decoration.

My bias suggests that using one of the Ebony group on a kit upgrade is like doing a high class upgrade in a trailer park. The quality is evident, but the environment makes the effort a misplaced one.

For a substitute, Holly is appropriate, but the Wood Database lists other species that accept dyes.

This is a situation where slang shorthand can lead to misunderstandings.

A stain - the noun - is a form of semi transparent paint - surface only. It is pore filling and this makes the product a problem with PVA bonding. Actual black paint may as well be used.

To stain - the verb - includes the use of the semi transparent paint and also the effect of a dye.

Wood dyes are available from wood working vendors - there are two types - alcohol and water. The alcohol does not raise the grain, It also does not penetrate as deeply as water based dyes.

For black, I would think that two treatments should work, with a sanding step after the first treatment to repair the raised grain. The dye can be used on the loose plank and it will PVA bond as well as if it were not treated.

I have it in mind to try a technique used by a traditional Carolina furniture makes (PBS). He dissolved a steel wool pad in a quart of vinegar (5% acetic acid) . He then wet pieces of Maple with a solution of tannic acid and

sanded /scraped the raised grain and then coated it with the iron acetate solution. The effect was a dense black.

-

Jaager got a reaction from Binho in Strange Hooks on Roman Ships

Jaager got a reaction from Binho in Strange Hooks on Roman Ships

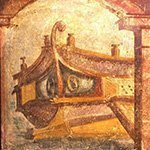

It is always associated with a spar and an attached yard and sail jutting out over the bow.

Do a mock up and determine what sort of staying lines and retaining structure is needed to make this sail functional.

Determine if it would require an active human presence at the fore end to handle the sail.

This could clear up the function and just how large and strong it would have to be. It is near impossible to forget how it all evolved over the next 1500 years but the bare minimum is likely to be close.

-

Jaager got a reaction from Canute in A Clear Finish Coating Strategy

Jaager got a reaction from Canute in A Clear Finish Coating Strategy

Sanding sealer is for use on open pore species, such as Oak, Hickory, Ash, Walnut. The pore and grain structure places them in the category of woods that scale in an undesirable way and are not appropriate for our uses. The desired species do not need their pores filled and there is no need for a sanding sealer type product.

The material itself tends to leave a layer that is too thick for scale uses.

-

Jaager got a reaction from Bob Cleek in A Clear Finish Coating Strategy

Jaager got a reaction from Bob Cleek in A Clear Finish Coating Strategy

Sanding sealer is for use on open pore species, such as Oak, Hickory, Ash, Walnut. The pore and grain structure places them in the category of woods that scale in an undesirable way and are not appropriate for our uses. The desired species do not need their pores filled and there is no need for a sanding sealer type product.

The material itself tends to leave a layer that is too thick for scale uses.

-

Jaager got a reaction from Devildog36 in Anyone familiar with this place for wood and supplies

Jaager got a reaction from Devildog36 in Anyone familiar with this place for wood and supplies

Devildog,

You may have more resources than you realize. The Washington Ship Model Society is based in northern Virginia. Between it and the local woodworkers guild and the local schools, you may have access to the use of the necessary machinery to produce your own stock.

Not far from you - in Elkwood, VA is C.P.Johnson Lumber - with excellent prices on Hard Maple, Black Cherry, Yellow Poplar, Yellow Birch their inventory is out of the two exotics that I would consider = Yellow Heart (Pau Amarillo) and Granadillo (Macacauba). The other domestics have unuseful grain characteristics.

-

Jaager got a reaction from Old Collingwood in A Clear Finish Coating Strategy

Jaager got a reaction from Old Collingwood in A Clear Finish Coating Strategy

Sanding sealer is for use on open pore species, such as Oak, Hickory, Ash, Walnut. The pore and grain structure places them in the category of woods that scale in an undesirable way and are not appropriate for our uses. The desired species do not need their pores filled and there is no need for a sanding sealer type product.

The material itself tends to leave a layer that is too thick for scale uses.

-

Jaager got a reaction from mtaylor in Anyone familiar with this place for wood and supplies

Jaager got a reaction from mtaylor in Anyone familiar with this place for wood and supplies

Devildog,

You may have more resources than you realize. The Washington Ship Model Society is based in northern Virginia. Between it and the local woodworkers guild and the local schools, you may have access to the use of the necessary machinery to produce your own stock.

Not far from you - in Elkwood, VA is C.P.Johnson Lumber - with excellent prices on Hard Maple, Black Cherry, Yellow Poplar, Yellow Birch their inventory is out of the two exotics that I would consider = Yellow Heart (Pau Amarillo) and Granadillo (Macacauba). The other domestics have unuseful grain characteristics.

-

Jaager got a reaction from Bob Cleek in ‘Universal’ Primer

Jaager got a reaction from Bob Cleek in ‘Universal’ Primer

Shellac is as close to being a 'universal' primer as can be had. It is available as flakes and already in solution.

The flakes are for when a clear finish is the goal and no darkening of the wood is desired. The solvent is alcohol. Super Blonde is close to being water clear,

but the solubility in alcohol is about 1/2 that of Garnet. If a paint is going over it, it is easier to just purchase is premixed and dilute it.

The first coat should a half strength concentration .

The hows and whys of using shellac have been discussed more than once in this forum. Bob Cleek has done the best job of explaining,

It is a very old and times tested material so it has old measures - pounds cut - which is pounds of flakes per gallon of alcohol. I think garnet is 10 lbs cut for saturation which rounds out to being a 10% solution. Battery operated small scales are not expensive, so it is easy to weigh out 10 gm and qs to 100 ml with shellac thinner or 5 gm of super blonde and qs it to 100 ml with shellac thinner.

-

Jaager reacted to Bob Cleek in Question about painting and staining

Jaager reacted to Bob Cleek in Question about painting and staining

What Canute said. Stain penetrates the wood, so if shellac seals the wood, stain can't penetrate it. One of the problems to note about staining is that the stain has to be compatible with whatever coating you apply over it, as well.

I don't want to start a big controversy here, but I can't resist offering my two cents' worth. I'm not a fan of staining on models. There are some times when it might be indicated, on spars, perhaps, or possibly laid decks, but the simple fact is that the real purpose of stain is to make one wood look like another and, like most faux finishes, it may come close, but never hits the mark completely. Stain enhances the figuring of some woods, which is good for furniture, but since there aren't any woods that have grain features that are to the scale of most any model, enhancing the grain of wood on a model is the last thing a modeler should want to do. Some like to portray their models "au natural," without any paint. This style best exhibits the exact construction features of the prototype and the skill of the modeler, with each faying surface highlighted in black and every fastening in its proper place. In that case, the best approach is to use a fine finish wood species that serves the purpose and looks well clearly sealed or lightly oiled or waxed. If it's the beauty of bare wood you want, there's so little wood in a model that there's no reason not to buy the good stuff and show it off. Staining basswood is like trying to polish a turd.

And I'll mention in passing that "wipe on poly" is a rip off. It's just polyurethane varnish that's been thinned, canned, and marketed to consumers who don't know the difference. Thinner is relatively cheap. Buying thinned varnish and paint for the same price as the thick stuff is a waste of money. Thin your coatings yourself and save a bundle.

-

Jaager got a reaction from mtaylor in Strange Hooks on Roman Ships

Jaager got a reaction from mtaylor in Strange Hooks on Roman Ships

It is always associated with a spar and an attached yard and sail jutting out over the bow.

Do a mock up and determine what sort of staying lines and retaining structure is needed to make this sail functional.

Determine if it would require an active human presence at the fore end to handle the sail.

This could clear up the function and just how large and strong it would have to be. It is near impossible to forget how it all evolved over the next 1500 years but the bare minimum is likely to be close.

-

Jaager got a reaction from davyboy in Wooden Ship railings -help

Jaager got a reaction from davyboy in Wooden Ship railings -help

The core of your problem is due to the species of wood that was supplied,

If your objective is to assemble the craft using the supplied materials, fight on.

If your objective is to develop skills and progress to more complex subjects, use this as an opportunity to slip in a bit of scratch building experience. Replace the supplied wood with a species that will hold up to what is being asked of it.

-

Jaager got a reaction from obsidean12 in Wooden Ship railings -help

Jaager got a reaction from obsidean12 in Wooden Ship railings -help

The core of your problem is due to the species of wood that was supplied,

If your objective is to assemble the craft using the supplied materials, fight on.

If your objective is to develop skills and progress to more complex subjects, use this as an opportunity to slip in a bit of scratch building experience. Replace the supplied wood with a species that will hold up to what is being asked of it.

-

Jaager got a reaction from mtaylor in Wooden Ship railings -help

Jaager got a reaction from mtaylor in Wooden Ship railings -help

The core of your problem is due to the species of wood that was supplied,

If your objective is to assemble the craft using the supplied materials, fight on.

If your objective is to develop skills and progress to more complex subjects, use this as an opportunity to slip in a bit of scratch building experience. Replace the supplied wood with a species that will hold up to what is being asked of it.

-

Jaager got a reaction from Moab in A small cog c. 1410 by Brinkman - FINISHED - scale 1:20

Jaager got a reaction from Moab in A small cog c. 1410 by Brinkman - FINISHED - scale 1:20

Silverman,

That planking technique is unique or seems to be. The illustration clarifies the what and how. This craft may well be a "missing link" in the transition from shell first to frame first.

I wonder if that particular planking joinery may have left something to be desired as far as stability and reliability? The result of that experiment being the reason it was where it could be found far in its future instead of joining the fate of its fellows?

I can see how for everyday full size projects, Fir vs Oak is a choice to consider. In the scale model world, I recommend forgetting that Oak even exists.

Oak is hard, but it is also pug ugly at most any model scale. It may be useful for totally hidden structures. But a negative factor for even this is that in some species of Oak, the fibers, being coarse, do not hold together at shape edges and the way out of scale pores could be at the edges and leave dips. They are awful enough on the surface.

One of my preferred species of wood is a Maple that is fractionally harder than White Oak. It is no problem as long as tools are sharp, motors are powerful, and for bulling away a bulk of it - 60 or 80 grit sandpaper. I find that the resistance to being able to easily overdo its removal to be a plus.

All the more power to you, but the fuzzy nature of a true Fir would have me wanting to act out in frustration. I find this is much more fun when the species of wood being used works with me, and rewards me in how it looks when replicating something its miniature in scale.

-

Jaager got a reaction from Moab in A small cog c. 1410 by Brinkman - FINISHED - scale 1:20

Jaager got a reaction from Moab in A small cog c. 1410 by Brinkman - FINISHED - scale 1:20

Chuck,

I completely agree about the three carvel strakes and then clinker possibility.

It is this interpretation that I am having a question about. The same plank going from carvel to clinker along its length? I can only see it as being one or the other. If I am right, it saves a lot of work.

There are a couple of clinker projects that are active now. When I looked up a question on the strake lap transition at the bow and stern rabbets, in a modern text, (John Leather) I also checked how the fittings were done. Were there spikes that just went thru the plank overlap and were clinched on the lower strake's inside face? It looks like the spikes were only at the frames and went thru the two planks and also the frame and was clinched on the inside face of the frame. Were there any spikes that went thru one plank and then thru the frame? No. It appears that it was only at the overlap.

My problem with the garboard description was because I have never seen any reference to a garboard having fittings at the rabbet at the keel and thru the plank into the keel. My question is, why mention the absence of something that was not done in most any situation anyway?

Thinking about why this would be the situation:

That seam is the most troublesome of all of them. It is at the place where two different planes meet, with different dimensional flexing, I would guess that spikes could impair garboard reactive movement. The stress could generate a split along the row of spike holes and turn the garboard from one board into two boards producing a fatal leak. This happening when the sea was particularly lively. I recall an illustration a ship suspended between two oncoming waves. One was holding up the bow and one was holding up the stern, with the middle hanging in the air. I believe it was about hogging and what could cause it.

-

Jaager got a reaction from Moab in A small cog c. 1410 by Brinkman - FINISHED - scale 1:20

Jaager got a reaction from Moab in A small cog c. 1410 by Brinkman - FINISHED - scale 1:20

The description in the thesis is clear as mud to me. It does not read as though it was written by someone who understands hull construction.

You could correspond with him and further define just what he means by:

"lay flush"

"were not fastened to one another" - as opposed to?

"stakes overlapped" a picture of what exactly he means

"the central......garboard....not connected to it." apart from Med very ancient blind mortise and tenon plank to plank - the attachment is plank to internal structure - the between is for waterproofing material

"the bottom and bilge strakes..." is he describing carvel planking where the planks would grind in a beach? There was a time of transition from clinker to carvel - but I imagined it was between strakes and not within one. The hull having a carvel planked bottom and lapstrake sides up to the rail.

About the plug. The trick is to fix each plank to its final curve before it is attached. Pre-bent as it were. This way, they stay were you fixed them.

Plank bending 101

The lignin that holds wood fibers together is not soluble in water.

Heat loosens its bond and allows for bending while hot and staying in its new position when back to room temp.

Steam transfers heat better than dry air . Wetting wood before bending is to provide steam. The time of immersion need not be long.

Different species of wood have very different reactions to being bent. Some are pliable and some would rather break.

Lignin is soluble in ammonia. But it is the anhydrous ammonia that was used for commercial refrigeration and is liable to explode. The active part of cleaning ammonia solution as far as bending is the water that it is in. The ammonia there just ruins the surface of the wood and makes it an ugly color.

There are many ways to provide the heat. The trick is to choose a way the does not cook you in the process. Does not char the wood. Does not dent the wood while bending it.

Your homemade draw plate =

to cut/shave the wood, hard steel = good.

stoning and honing a crisp cutting edge at the hole and holding it hard steel = good

drilling the hole to begin with hard steel = not so easy

For draw plate trunnels - bamboo is pretty much it getting something to draw from wood is too much work and too much is wasted.

For short - just for show trunnels you can find examples here of steel medical needles -- tip ground to be like a lab cork borer - drill press - stock is a block of wood and boring it on an end grain face.

If you drill thru the block, the trunnel is longer, but stays in the bore. I do not know if boring the next open will push the earlier one up the bore of the needle or just stop the process. If it moves on up, I guess the quill center could fill with trunnels. If it does not move, pulling the needle , and ramming the trunnel out for each one would get tedious real fast.

The other way is to bore part way and when as many as can be got are bored, the distant end is cut off at the intersection at the depth of cut.

-

Jaager got a reaction from Moab in A small cog c. 1410 by Brinkman - FINISHED - scale 1:20

Jaager got a reaction from Moab in A small cog c. 1410 by Brinkman - FINISHED - scale 1:20

Silverman,

Three thoughts:

Your choice of wood: Fir (the English seem to interchange Fir as a name for what is Pine here, but regardless, similar characteristics for this use.)

Using a softwood species for frames, planks, beams, chocks, ... you are making this a more difficult, frustrating, less elegant process than it could be.

Guys a lot closer to you than to me, seem to have ready access to all the Pear they need. You would probably really like how it looks and works a lot more than Fir.

If you want a lighter color, there is Maple - in your case - Common Name(s): Sycamore maple, European sycamore Scientific Name: Acer pseudoplatanus

The planking - The usual nature of lapstrake/clinker planking is flush - in a gradual transition - only at the ends. Are you certain that the middle is flush?

Frame first - Have you considered making a plug/inside the planking mould? Planking over that? Adding the frames to the inside of the hull?

I will be subjected to stoning, but if a Byrnes draw plate costs more than is in your comfort zone ( I own one, so it is not about quality) drill gauges can do the job.

Here, wire gauge drills, there are two necessary #80 to #61 and # 60 to ~1/4" not sure - but only the #50's really matter.

Bamboo skewers can make strong trunnels. The species of Bamboo used can make a big difference in how easy it goes.

hard strong holds together needs a lot of force

hard brittle fights you all the way low vield

soft holds together peels off with less work - do not hammer -push

soft splits easily crushes not worth the effort

This may require visiting different vendors - if you have a local independent Chinese grocery store - there may be several types available as well as Bamboo chopsticks

Gripping the bloody things - to pull them thru - without crushing - a constant challenge.

-

Jaager got a reaction from mtaylor in Converting a Backyard Shed into a Model Workshop

Jaager got a reaction from mtaylor in Converting a Backyard Shed into a Model Workshop

Hank,

Starfoam is how coworkers who were from eastern KY pronounced Styrofoam. (The patient water glasses at our VAMC were actually beaded starfoam cups.)

A door with hinges at the top - to seal the storage cubby. When I imagined this solution, I envisioned the opening as being pentagonal - and thought that two half doors would do the job - but it looks like you finished it to be rectangular, so one will do.

A loop of bungee cord for a handle - a gaff hook to pull it open and place the loop in the hook that keeps it open.

American Science & Surplus has a tube of 29 plain donut magnets for $6.00. They are strong enough to keep a seal if paired and 4 or 5 sites are used.

The only downside is the spam catalogs - but the paper is the right stuff for starting a fireplace log.

-

Jaager got a reaction from mtaylor in Converting a Backyard Shed into a Model Workshop

Jaager got a reaction from mtaylor in Converting a Backyard Shed into a Model Workshop

Hank,

I would give serious thought to using a sheet of 2" Starfoam (E.KY) insulation. It probably only comes as 4x8.

One sheet may get you a double layer.

Hinge it along the top edge. A long pole can keep it open or a distal hook in the ceiling and a loop with the sheet.

It may require 1/4" ply to hold the hinges. It is porous enough for PVA to hold it all together. LiquidNails also works. Weather stripping along the border and strong magnets at few points to hold it all closed tight.

-

Jaager got a reaction from Hank in Converting a Backyard Shed into a Model Workshop

Jaager got a reaction from Hank in Converting a Backyard Shed into a Model Workshop

Hank,

Starfoam is how coworkers who were from eastern KY pronounced Styrofoam. (The patient water glasses at our VAMC were actually beaded starfoam cups.)

A door with hinges at the top - to seal the storage cubby. When I imagined this solution, I envisioned the opening as being pentagonal - and thought that two half doors would do the job - but it looks like you finished it to be rectangular, so one will do.

A loop of bungee cord for a handle - a gaff hook to pull it open and place the loop in the hook that keeps it open.

American Science & Surplus has a tube of 29 plain donut magnets for $6.00. They are strong enough to keep a seal if paired and 4 or 5 sites are used.

The only downside is the spam catalogs - but the paper is the right stuff for starting a fireplace log.