-

Posts

518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by oakheart

-

Thanks @druxey I have just started reading the thread that Craig @iMustBeCrazy gave a link too above. Was there any conclusion yet? I can't see any details on the drawings I have, also the kit that @Thunder built did not give any details either. Was it just a given. The shipwright just did what was always done. I will be quite happy to make something suitable for this cutter model if I can find the shape and size. It's all a voyage of discovery for me at this stage in my model ship building. Tim

-

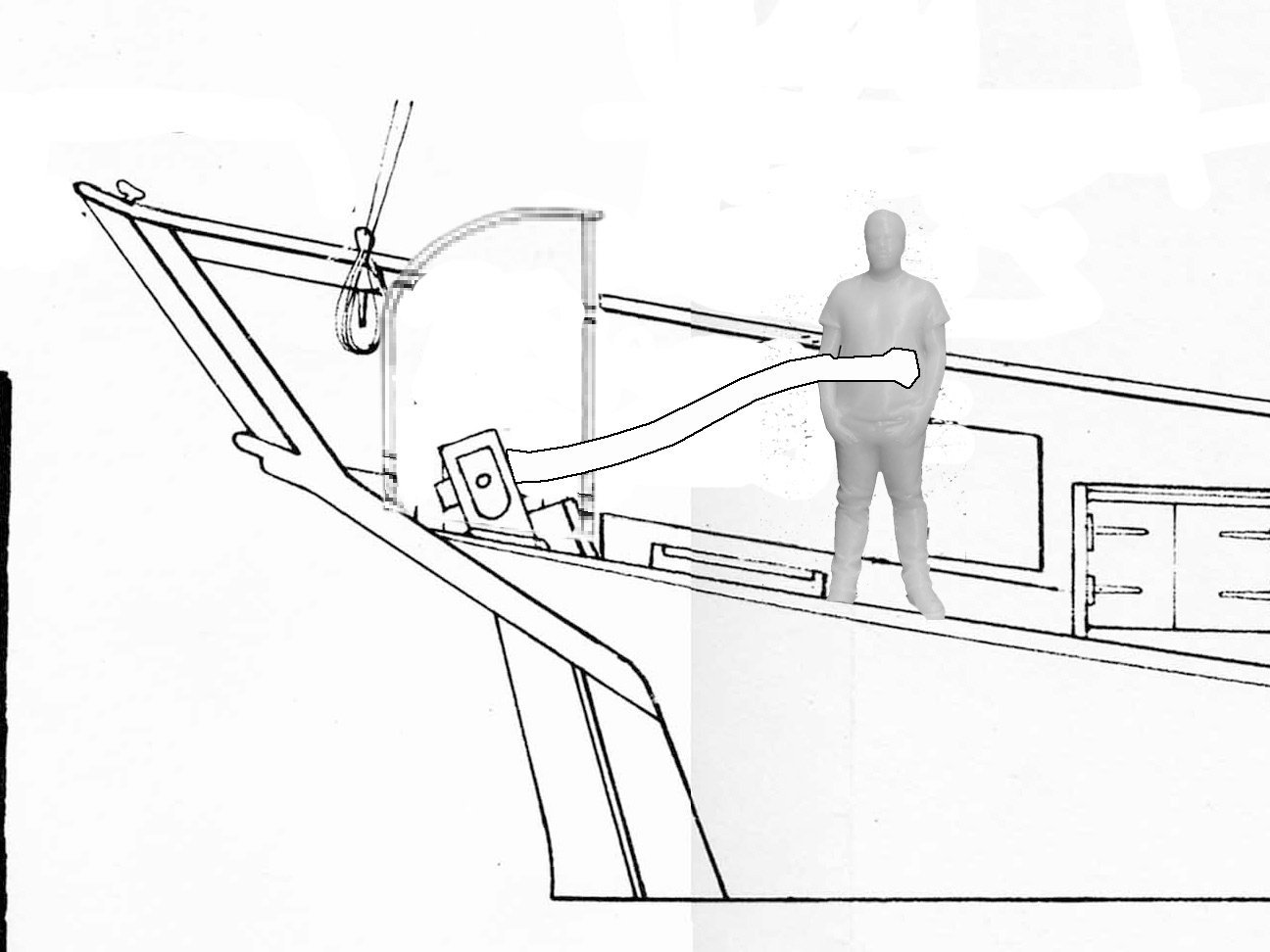

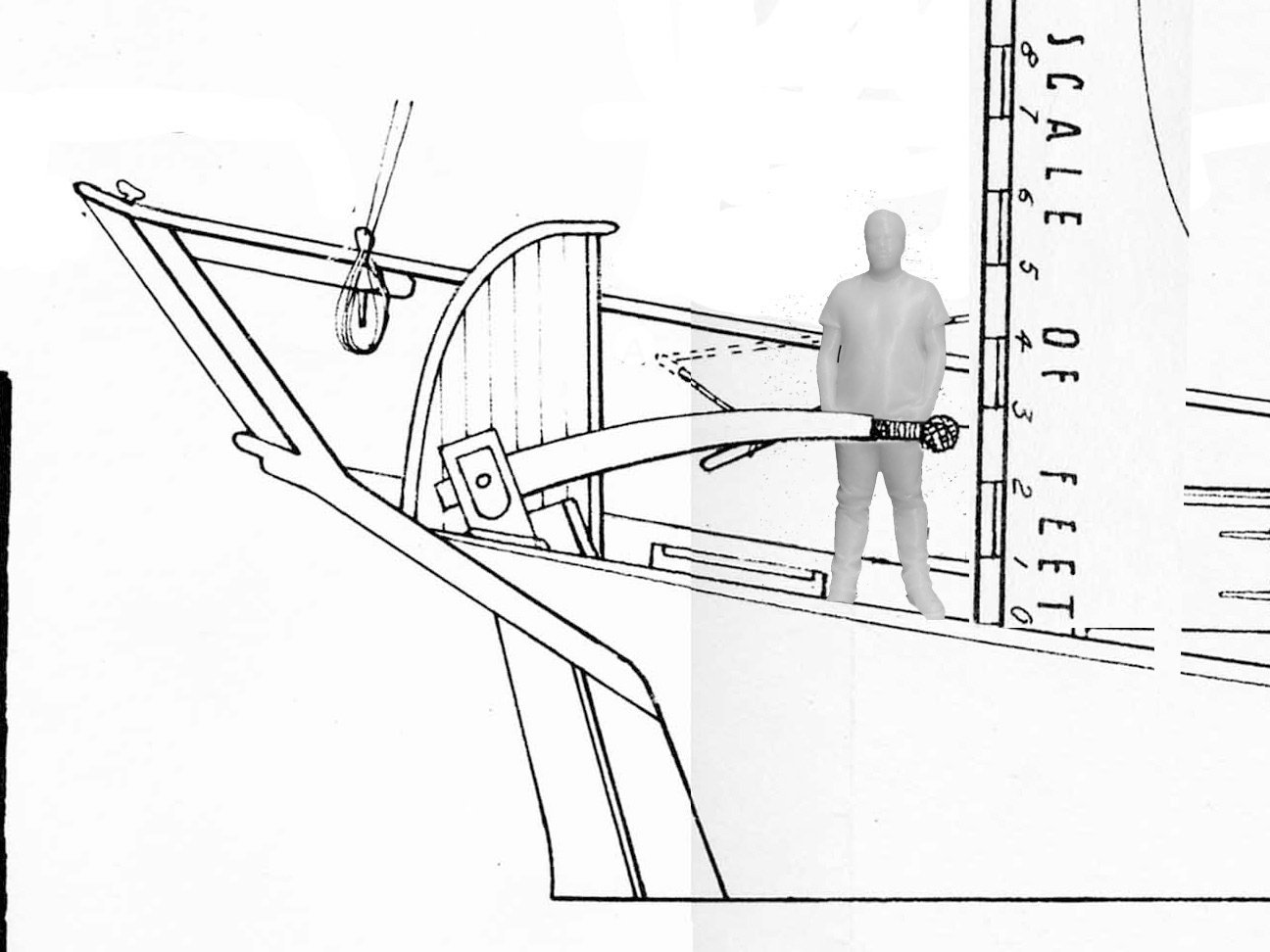

Working up to the tiller. My feeling about the original drawing is that it does not look right? I have a scale and figure ( @ 1:48 about 5' 9" tall ) which I have placed in bills drawing I have this photo of BM45 Pilgrim built in 1895 ( much later I know ) but about the same size as speedy. here is my rough cut based on Bills original drawing does it need to be longer / higher to look right ? Tim and yet another rabbit hole, Alice here I come.............. may be of interest to others, here is Pilgrim BM45 in 2008 before her £1 million rebuild

-

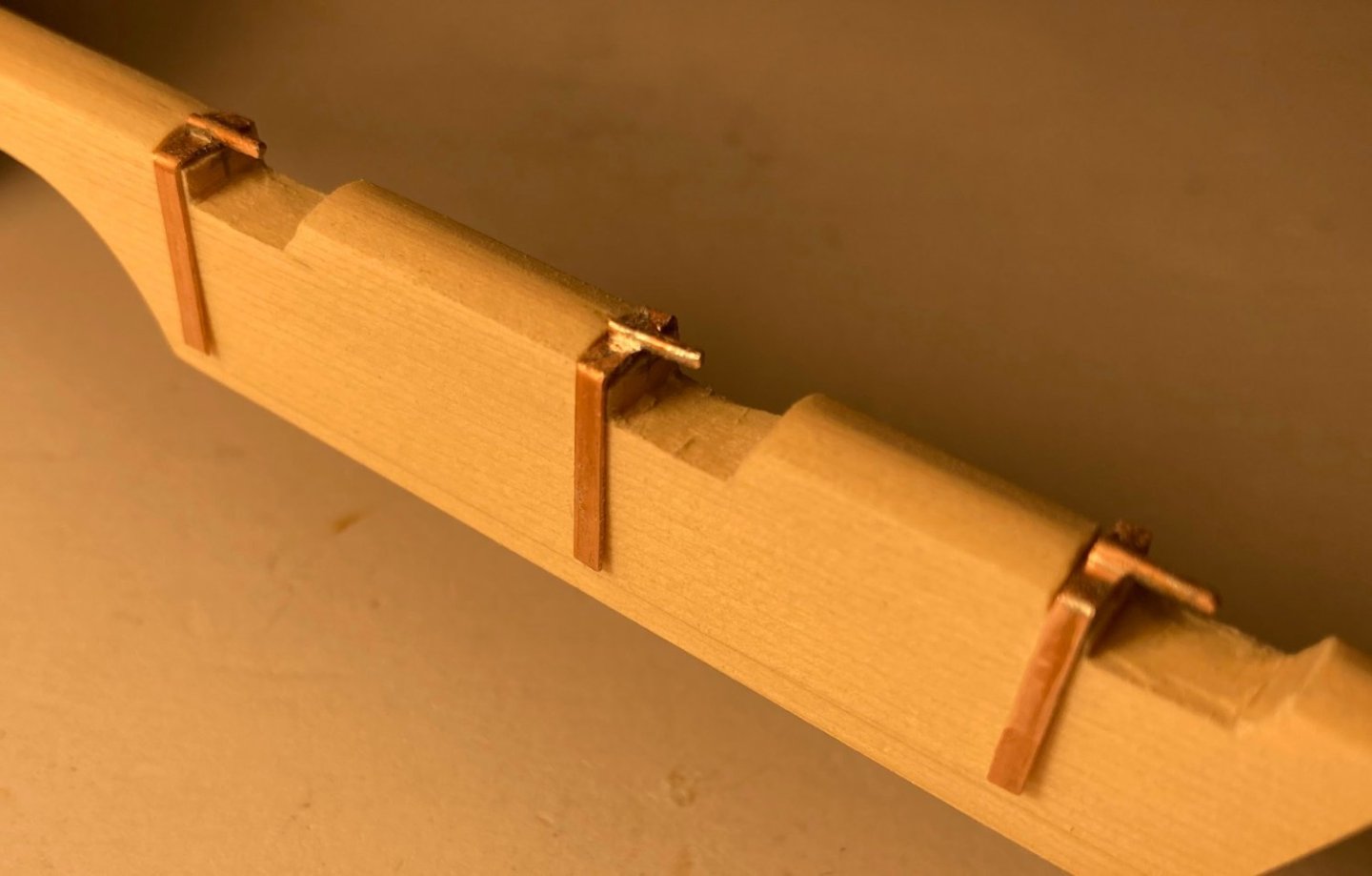

Always ready to rush ahead. I tapered the rudder top to bottom and fitted the top two pintles. Then blacked them, I think they turned out pretty well. I am very pleased closeup you can see there is a bit of bleed round the straps but it almost adds to the reality of the model? they do look the part Tim

-

Hi Ian I have used Pritt stick to glue printed paper plans to ply wood, just needs a wet rag wiped over the paper to remove. With my 1:48 scale, 85ft Harbour tug I used 3mm ply for bulkheads, 3mm ( 1/8") balsa planks 6mm wide, then used brown parcel paper and Ronseal matt varnish instead of fibre glass with Halfords grey primer over the top of that. It ran all last summer without a leak 🙂 I wish I had taken photos of the build now. I used cereal packet card for the superstructure which was also painted with Halfords grey primer. I am amazed at how well it has performed at the clubs pond all last summer, as long as it does not sink I hope to keep going for years. I love its knock about quality. The other things I am build tend to become precious, you worry about damaging them. Tim

-

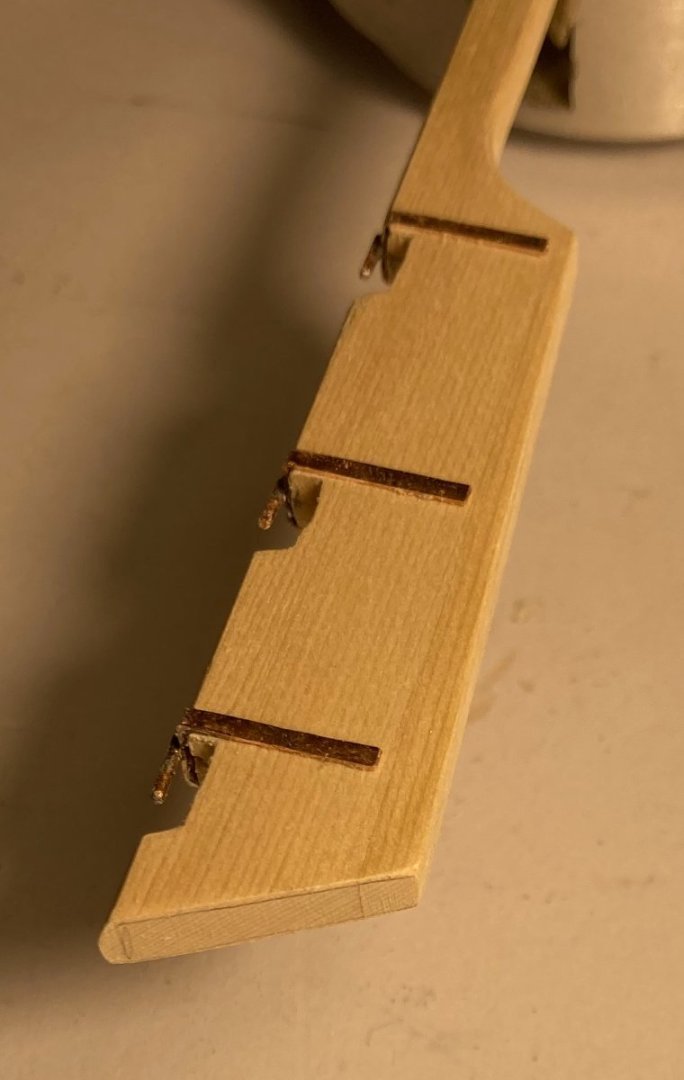

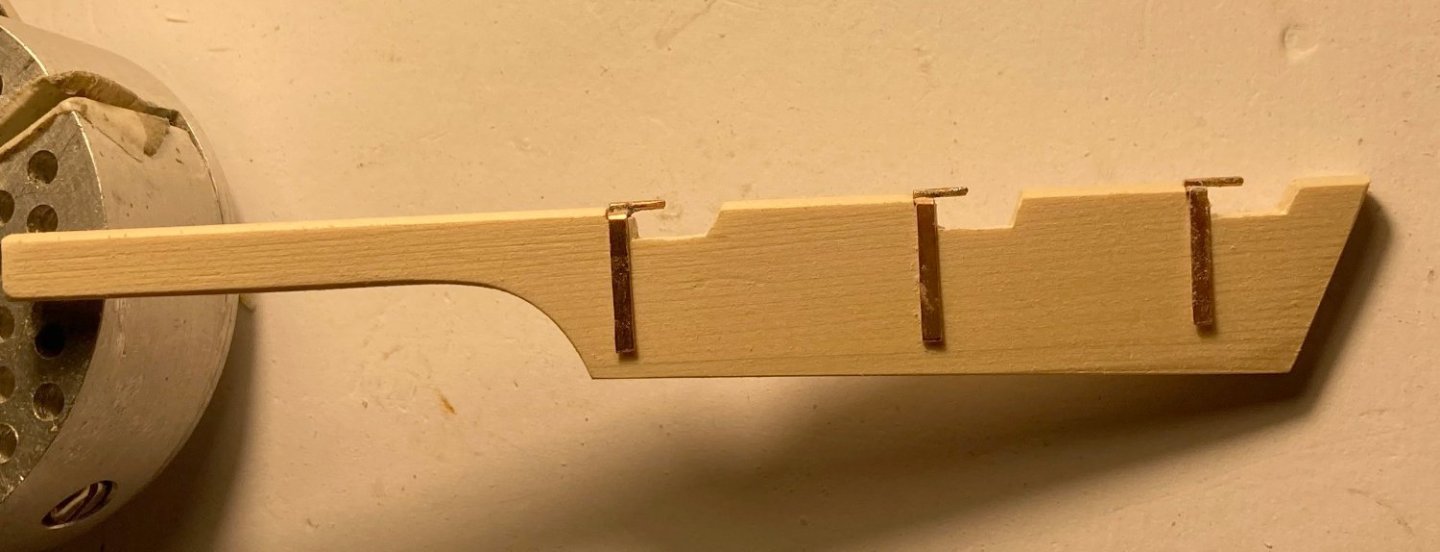

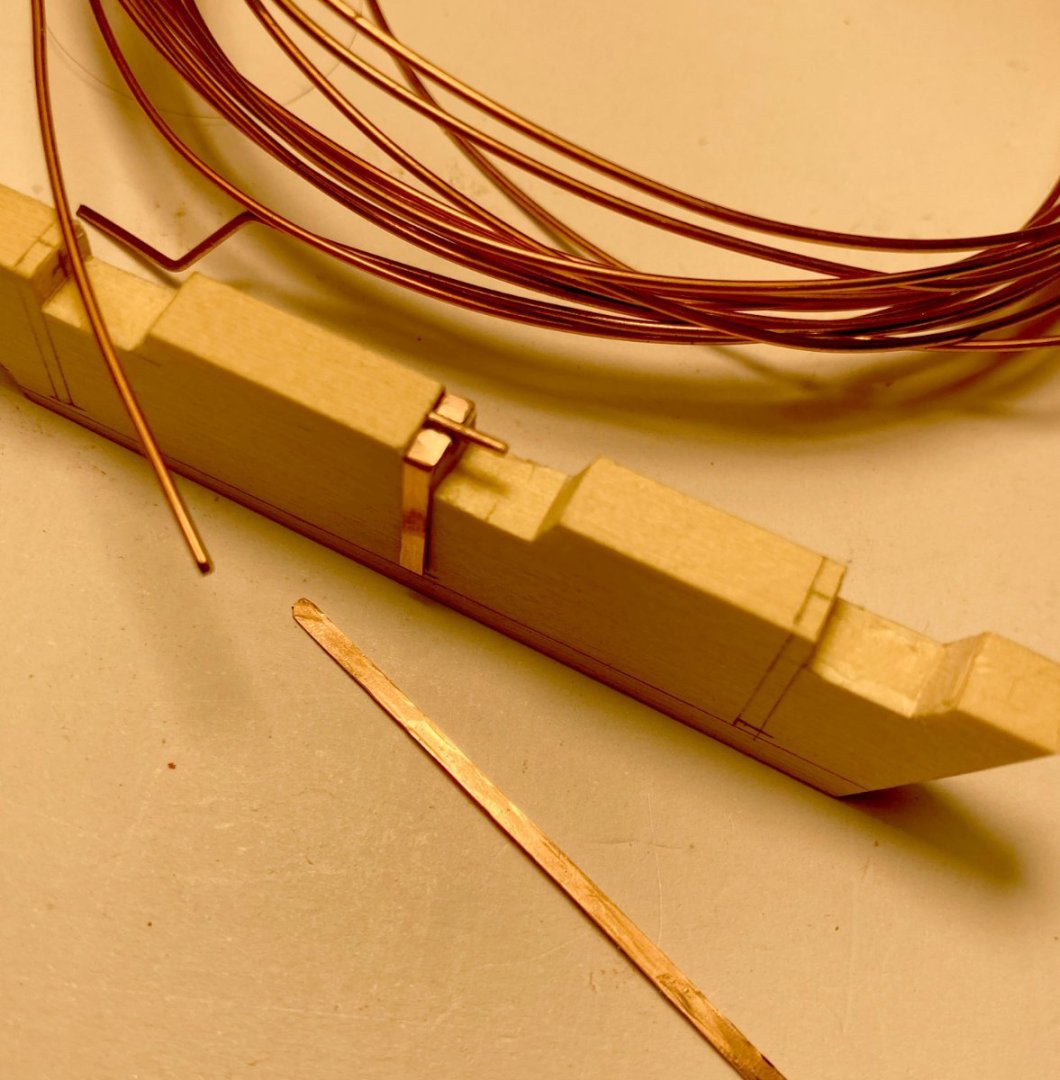

Here is my first attempt at making a pintle. I had some 0.8mm dia. copper wire which looks about the right size for the pin, amazingly when hammered flat it is also a good match for the straps. When I have completed it I will black it with Liver of Sulphur as advised by Allen @allanyed The parts are 'soft' soldered together with some good old lead based solder I have from years ago. When I have decided on the final shape of the rudder I will remake it to suit the profile. I am assuming the centre of the hinge should fall in the gap between the rudder and the sternpost? This is fun. Tim

-

Wow : Thanks for all the research, the first one looks like it could be an angled leading edge. The drawing / painting looks more like a bevel than rounded. I does look like a flat plank. As this is no longer a model of any real cutter, I may use artistic licence here. Personally I quite like the angled look, so I may just go with that. Tim

-

Hi Gregory Thanks for that, it will certainly be enough for me to make mine. Oh dear I seem to have done it again, I was going to line the gun ports, now suddenly I making the rudder. Focus, focus, focus now I am here I will complete the rudder, pintles and gudgeons. Thanks for all the help, advice and likes Tim

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.