-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by LoydB

-

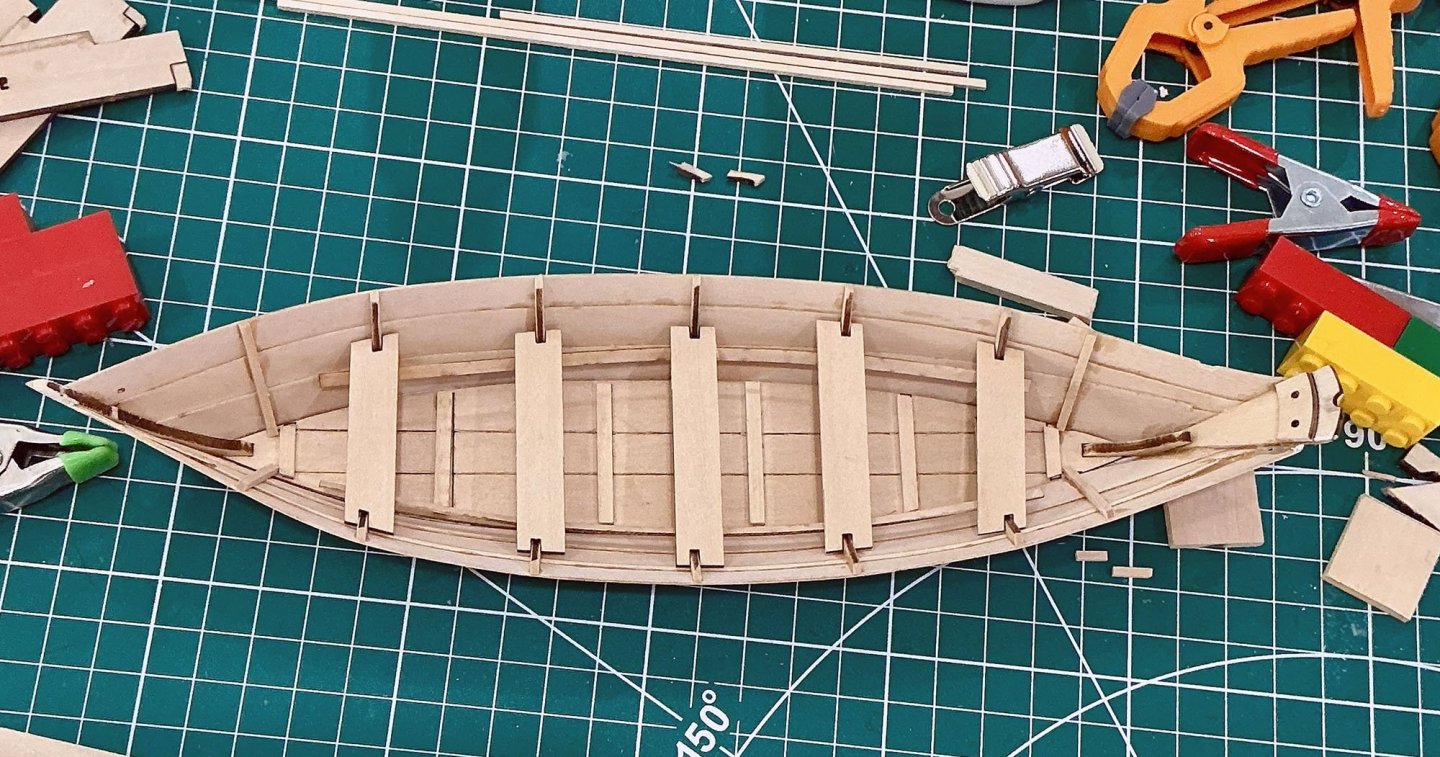

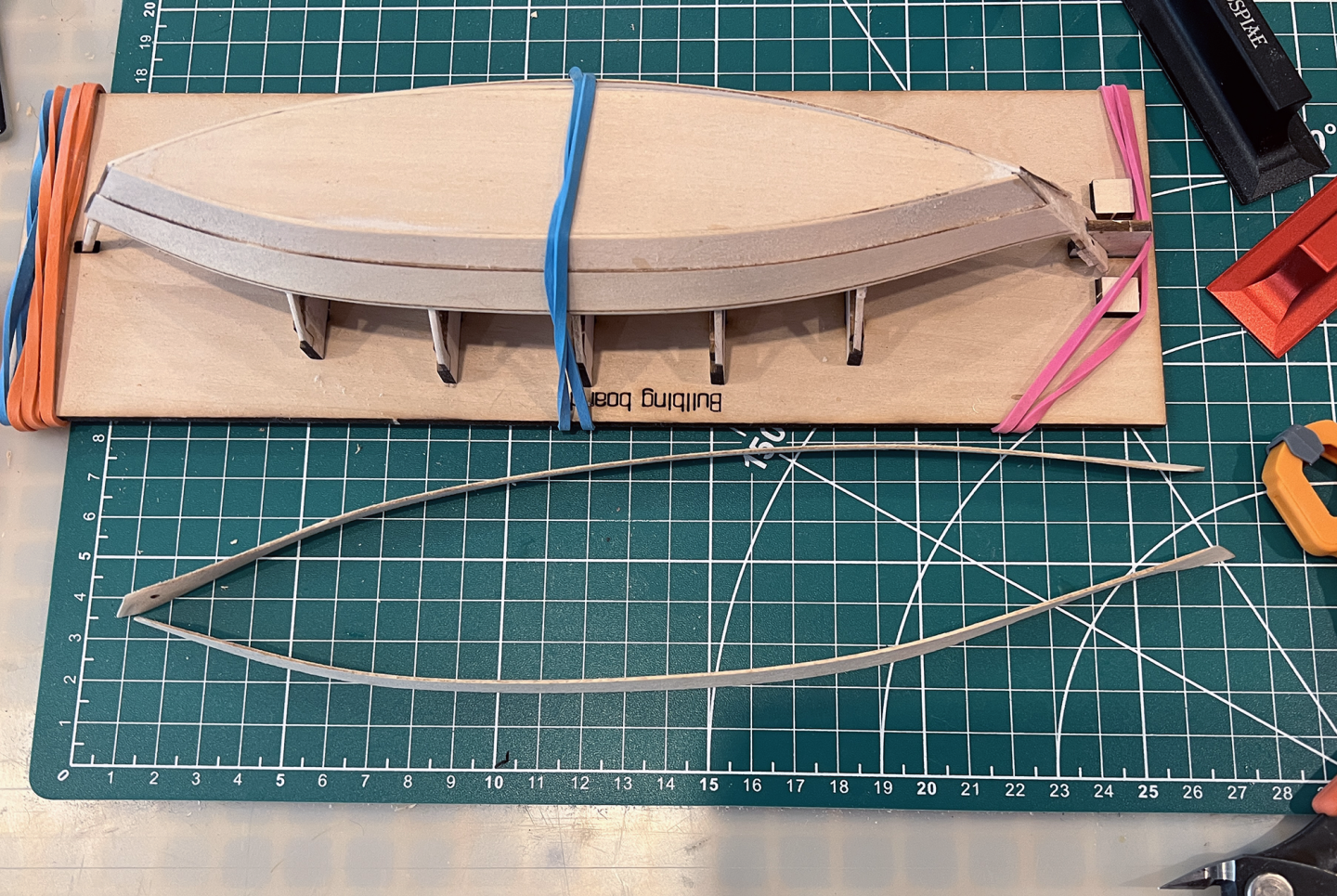

I used basswood strips. I gotta say, having a labeled view off all of these lasered sheets would have added 2 pages to the instructions PDF and would have been immensely helpful.

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

Ahah. There's no actual picture, it's just on the plan sheet. I missed that completely, thanks y'all.

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

I don't see any outboard bands in either the instructions or in the various pix I've seen online, but I'm also a noob, so maybe I'm not looking for what I think I am. I'll email Expo when I'm back at the house later, thanks.

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

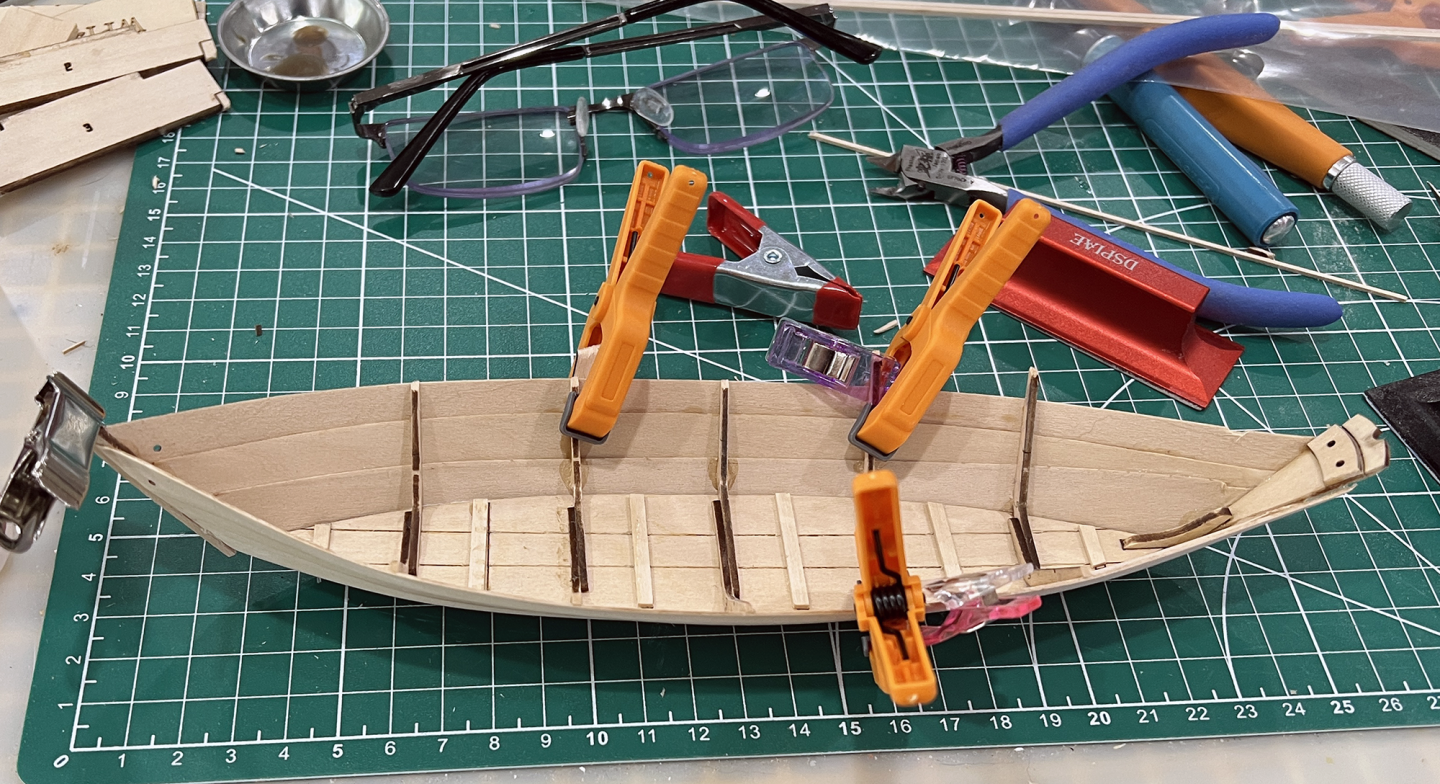

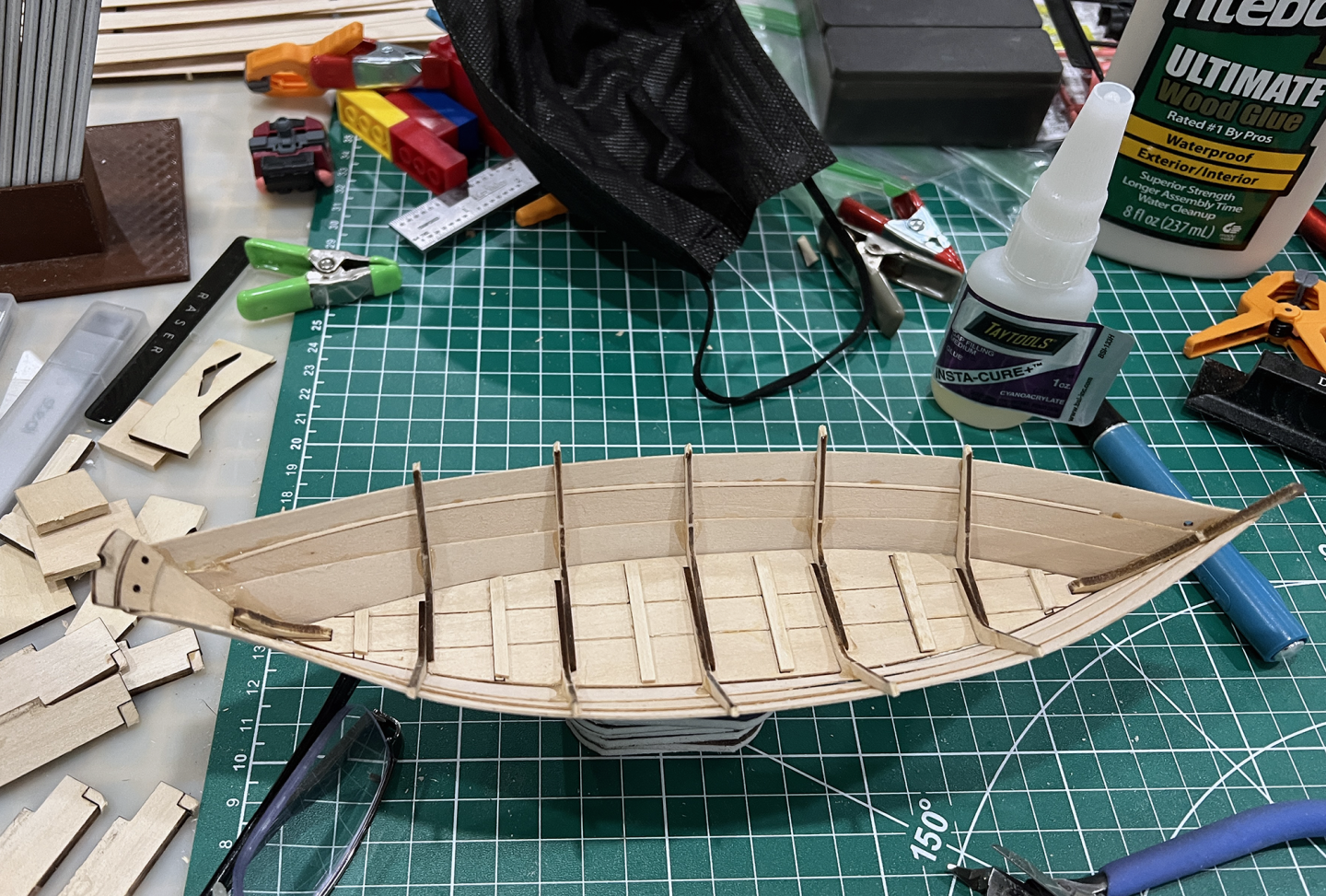

The seat risers have already been installed. In the instructions, the gunwales are made from 1/16" square stock. I have no idea what else it could be for.

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

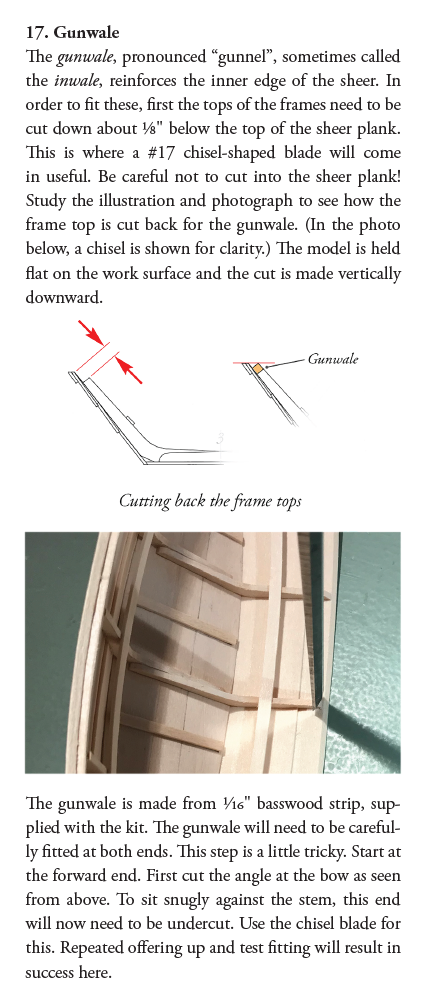

Finally back on this after the holiday season, hope everyone is doing well in 2026. I cleaned up the seats and added the seat risers, I'm closing in on it. Question though, what are the pieces circled in red? I'm starting to get 'Why are there leftover bolts?" after reassembling something vibes.

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

Cutters, Choppers, Guillotines, Slicers

LoydB replied to MintGum's topic in Modeling tools and Workshop Equipment

I have the DSPIAE one (and many of their other tools) and really like it. It's heavy and well-machined. -

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

Half Hull Planking Kit

LoydB replied to DGraley's topic in Building, Framing, Planking and plating a ships hull and deck

This is my next kit, where are you seeing problems? Thanks. -

That came out really nice, great work!

- 90 replies

-

- Friendship Sloop

- bluejacket shipcrafters

-

(and 1 more)

Tagged with:

-

Starcraft Adjutant AI by yvesvidal - 1/6 - RESIN/PLASTIC

LoydB replied to yvesvidal's topic in Non-ship/categorised builds

Following, very cool project. I need to install a new extruder & hot end on my PLA printer, this is motivating. -

Good 'Hobby Quality' Metal Lathes

LoydB replied to tmj's topic in Modeling tools and Workshop Equipment

I love my Sherline. -

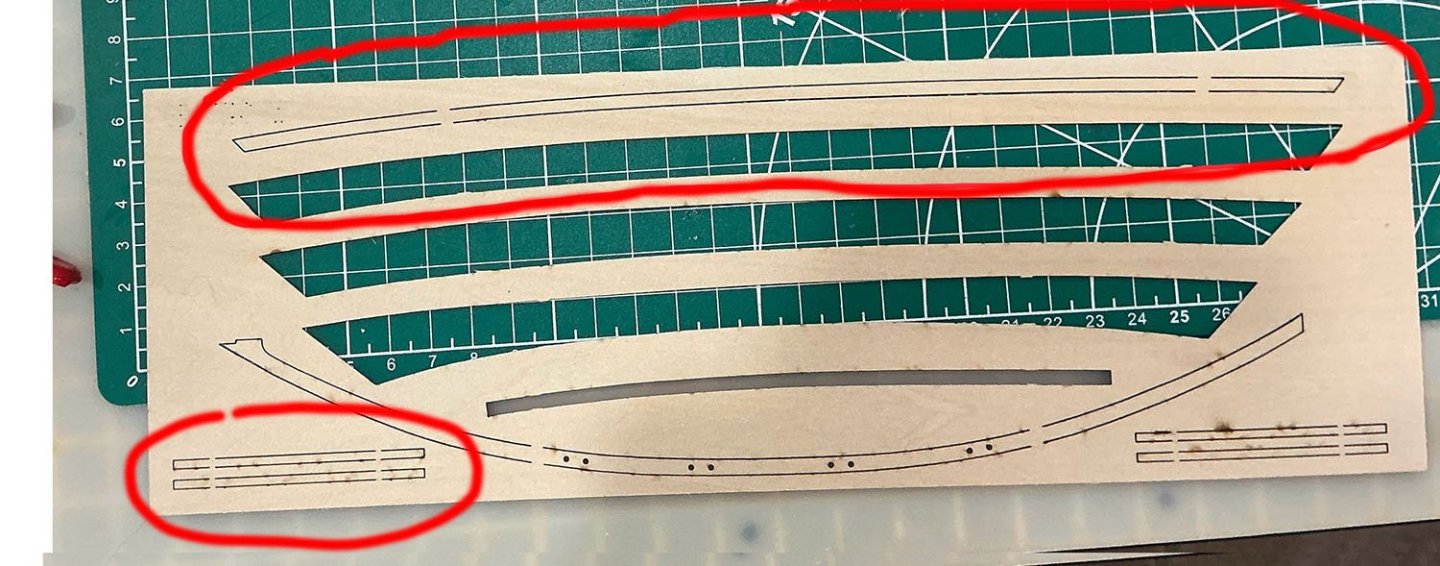

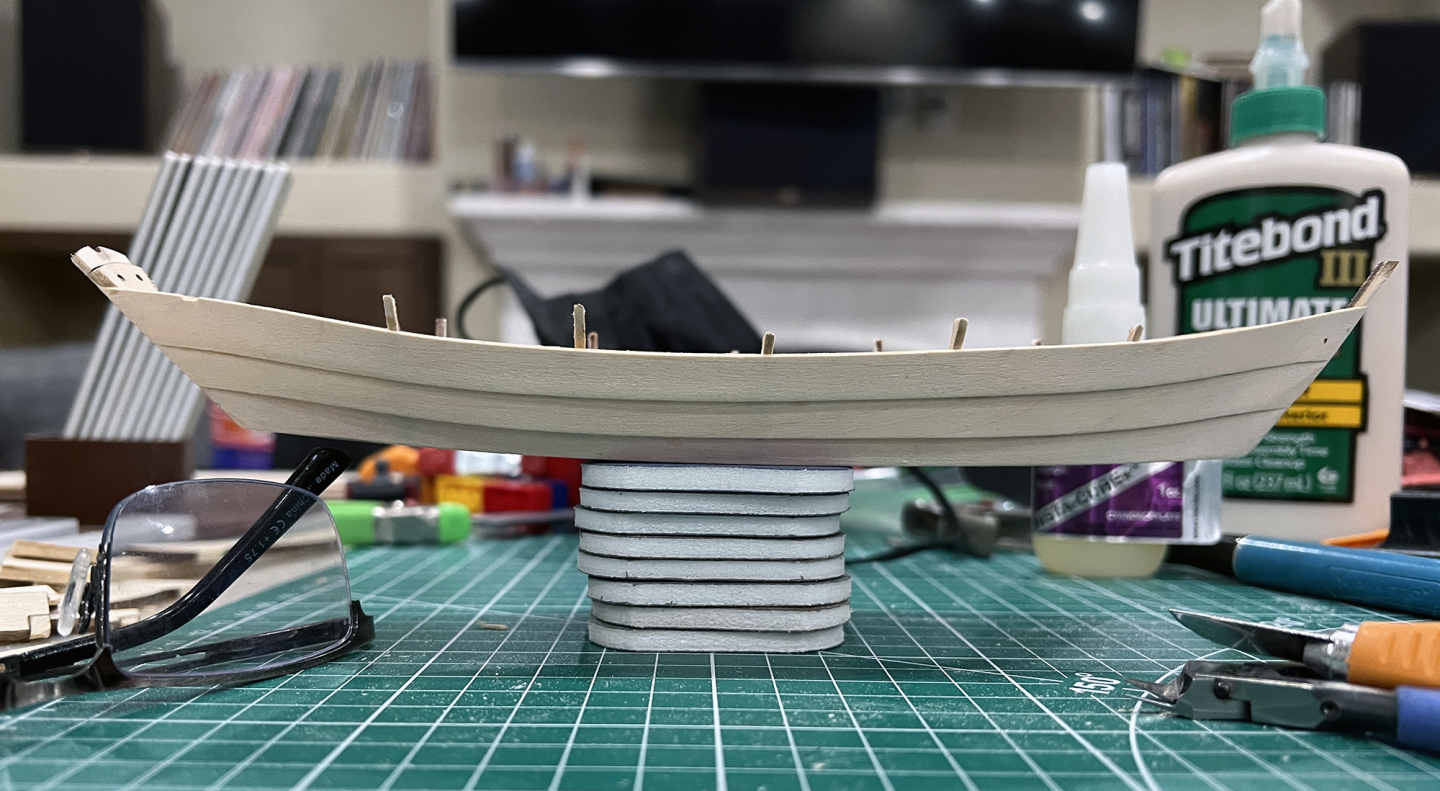

After getting it off the stand, realized there were a few places that the plank didn't completely touch the frame, so touched those up. Plus added the bow strip. I'm just guessing on which thickness of wood to use, as the instructions don't mention it and I don't see a plan view that specifies.

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

This is the main reason I'm not doing the Pram that is the next step of the Shipwright set, that crazy thin wood. I'm doing the NRG Half Hull instead, I think that it will be a better use of my time as far as preparing me for the Sherbourne.

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

Ok, finished off the sheers last night and released from the frame. The exterior has been sanded through the entire micromesh set. ANYONE READING THIS LOG IN THE FUTURE PRIOR TO BUILDING: The planking is incredibly thin/delicate, and using clamps on it is a crapshoot at the bow and stern. It's mostly not visible from the exterior, but the interior view shows plainly where breakage occurred. What I eventually did was use superglue to tack down the plank on the bow, just using finger pressure to hold until it sets. Then wood glue for the rest, except the last one on the stern, which was back to superglue.

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

HMS Beagle by Tecko - OcCre - 1:60

LoydB replied to Tecko's topic in - Kit build logs for subjects built from 1801 - 1850

That base really brings home how freaking huge that is. Following. -

- 45 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.