-

Posts

387 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SiriusVoyager

-

I model because it allows me to create something both artistic and technical. I have never been good at anything artistic nor at creating things with my own hands. I enjoy the personal challenge, as it allows me to work on and improve on something that I find very difficult. I choose ships because of their majestic appearance and the history and exploration that they represent. It also gives me a mental escape from stresses and responsibilities of the "real world."

-

Welcome to MSW! I have been doing this a little over a year now, and I have found that The Ship Model Builder's Assistant by Charles G Davis and Historic Ship Models by Wolfram Zu Mondfeld seem to be the best books go spend the most using and have the most detailed, but general, information. They both have a textbook type feel to them.

-

Absolute beginner here - new to ship modeling

SiriusVoyager replied to AlanR's topic in New member Introductions

Welcome to MSW! -

Welcome to MSW! Nice job on your first build

-

Thanks! Yes, that is part of the fun though it may not seem like it in the moment. Each one is a learning experience. Thanks for following along!

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Thanks Chuck. I look forward to seeing your build.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Nice looking little boat there! Not sure how I missed your log on this one, but I am glad to have found it.

-

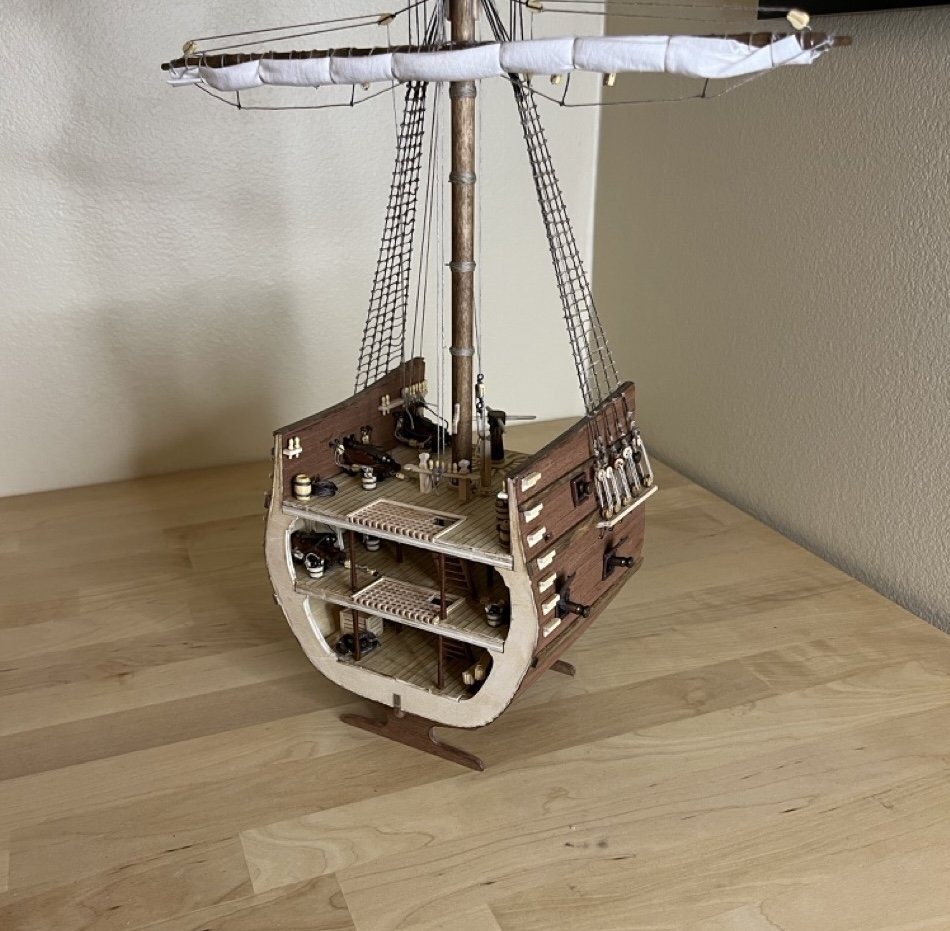

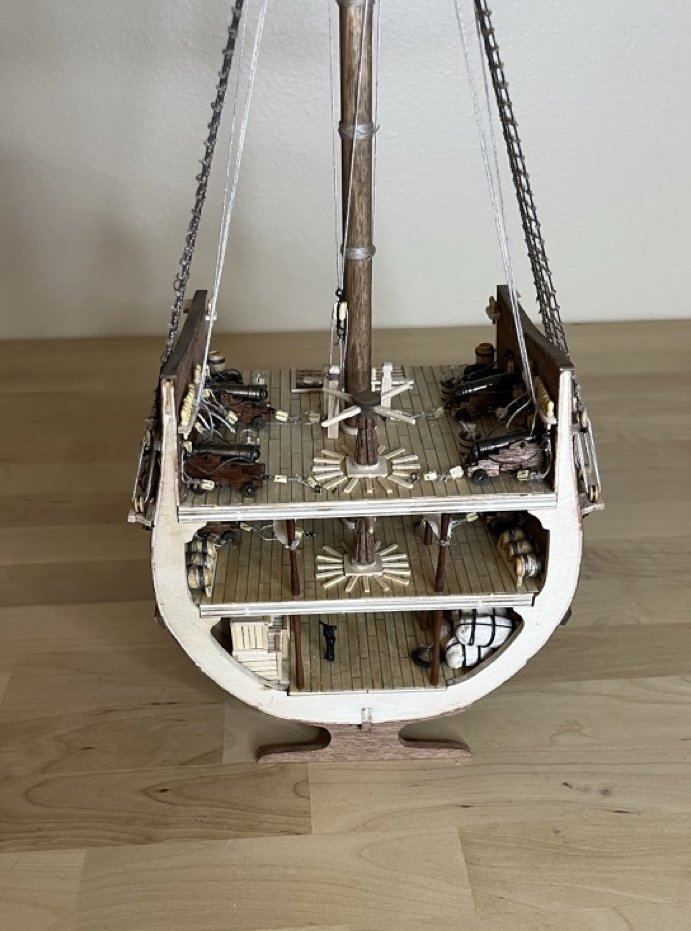

Here are the last few photos before she heads to the shelf next to her friends. Thanks to everyone who has followed along and for the likes, comments and words of encouragement!

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

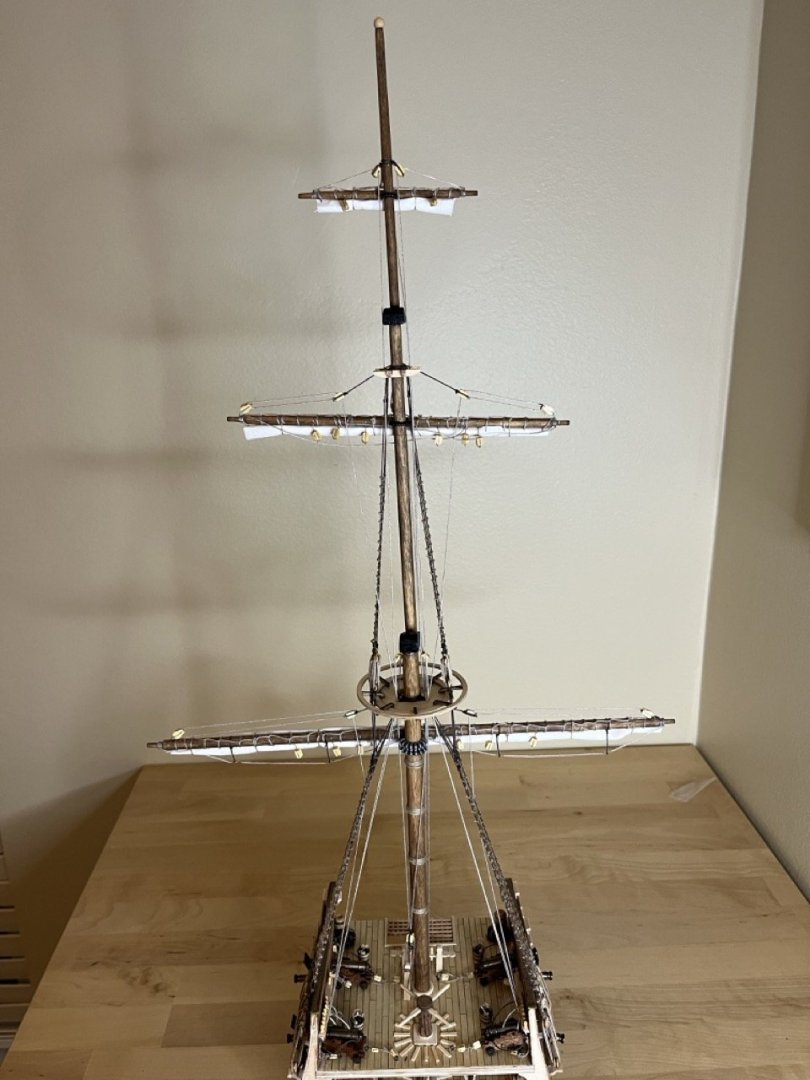

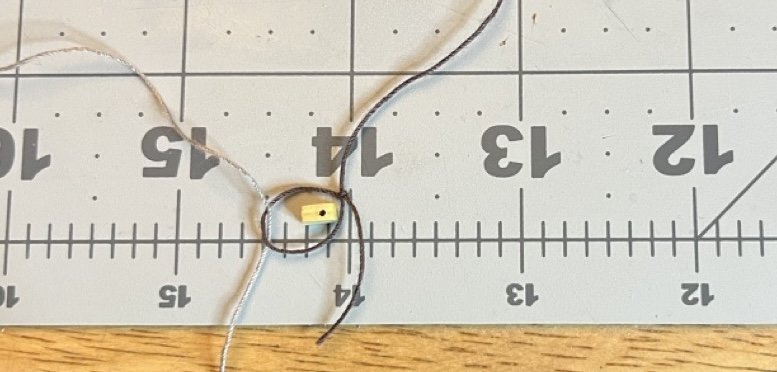

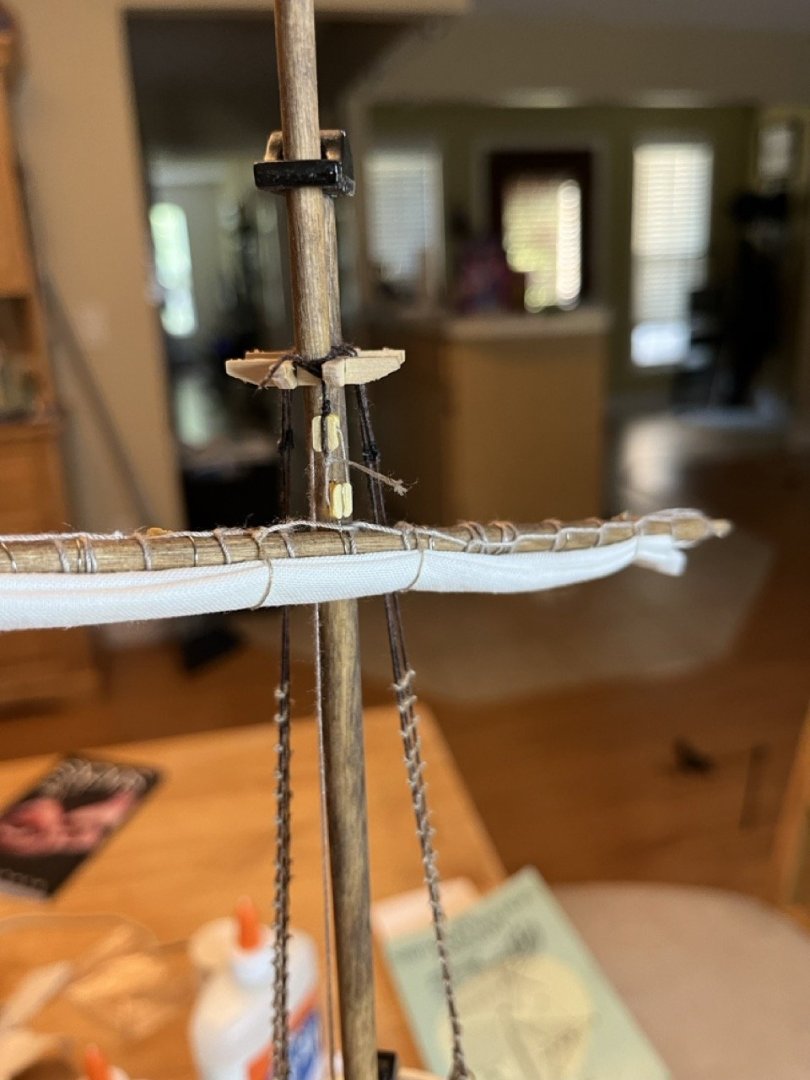

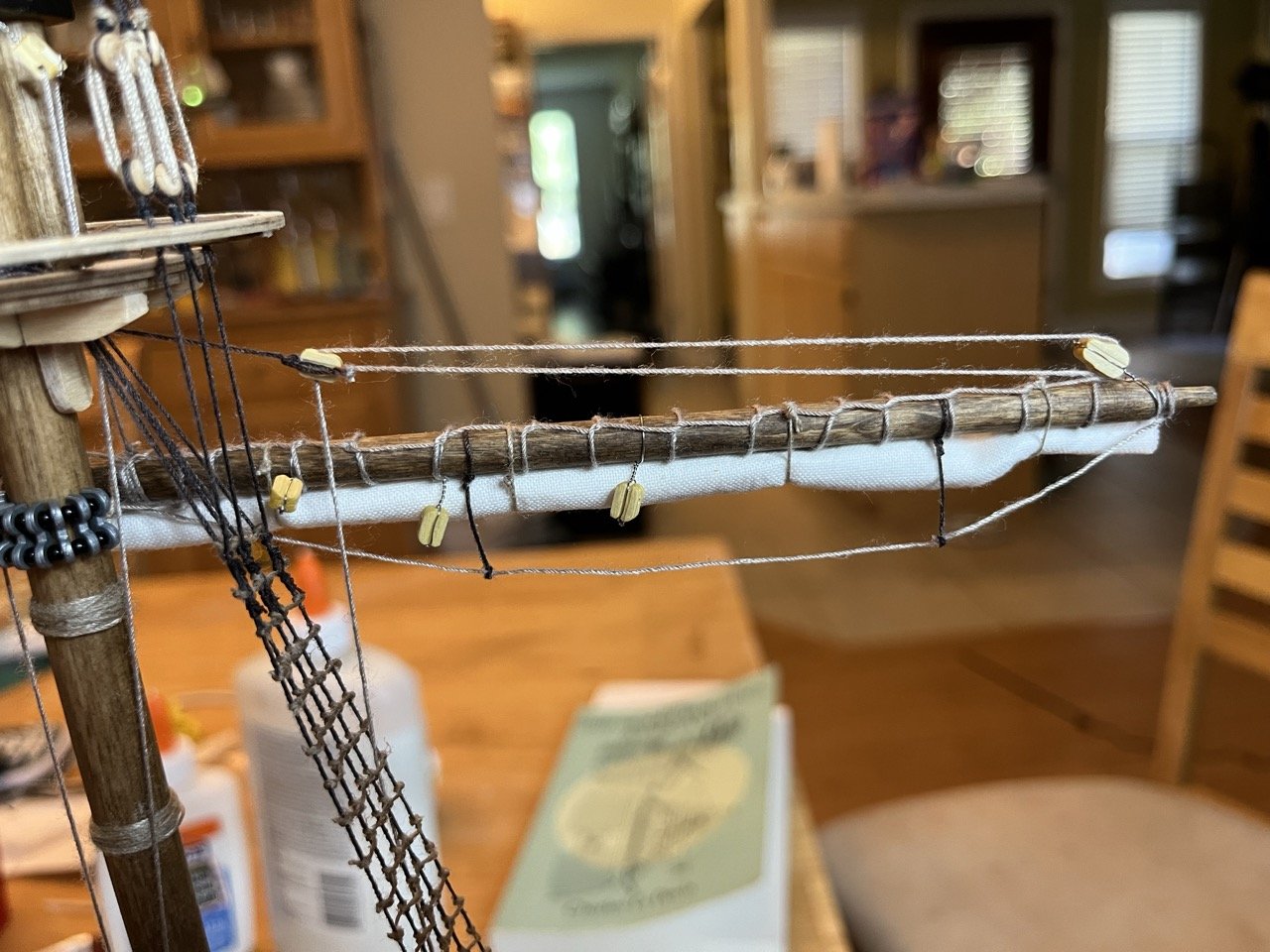

The top mast and the top gallant mast were very similar in how they are made and attached. I found a better way to fold the sails, but I still can't get them to look good on the ends. I think better material would make it easier to get the edges looking better. The top mast being held by the halyard. Here are a couple of photos on how I tied my blocks. I made a loop to tighten around the block with the line pulled through it. I tightened the darker line then tied the lighter line in place. There were also small pin rails for the flag lines. These were much easier to make off model, then attach to the bulwark after. At this point I ran into a problem while rigging the rest of the yards. I ran out of thread (good reason to make my own rope from here on out). I also looked at the remaining rigging and the couple of resources I have, and the rigging didn't make any sense to me. It seemed like they were just running lines around the model to make it look "cool." I could be mistaken and the rigging could be perfectly legitimate, but I was unable to make sense of it. I also had a problem with the flag. It was a large sticker and it folded over onto itself essentially ruining it. I am not a fan of stickers anyway. After a day and a half of contemplating I decided to call it compete as is. I learned a lot, including that I still need to work on slowing down and taking my time. Also trust my gut regardless of the instructions. Every time I didn't do what I wanted to do, I regretted it later. Things like staining the frames and adding the furniture on the lower decks prior to building up. I can say that I am content with this model and I think it would look ok to the uninitiated eye. Eventually I will build a model that I am really proud of, but in the mean time, keep practicing. Final pictures to follow next post.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

I had this same problem with the transom knee alignment. It seemed to workout ok with my model, but I think you will be glad that you moved it. Great start with your Dory.

- 28 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

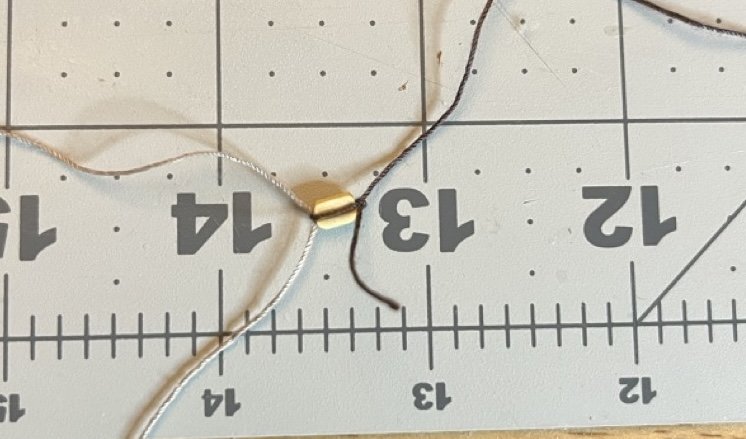

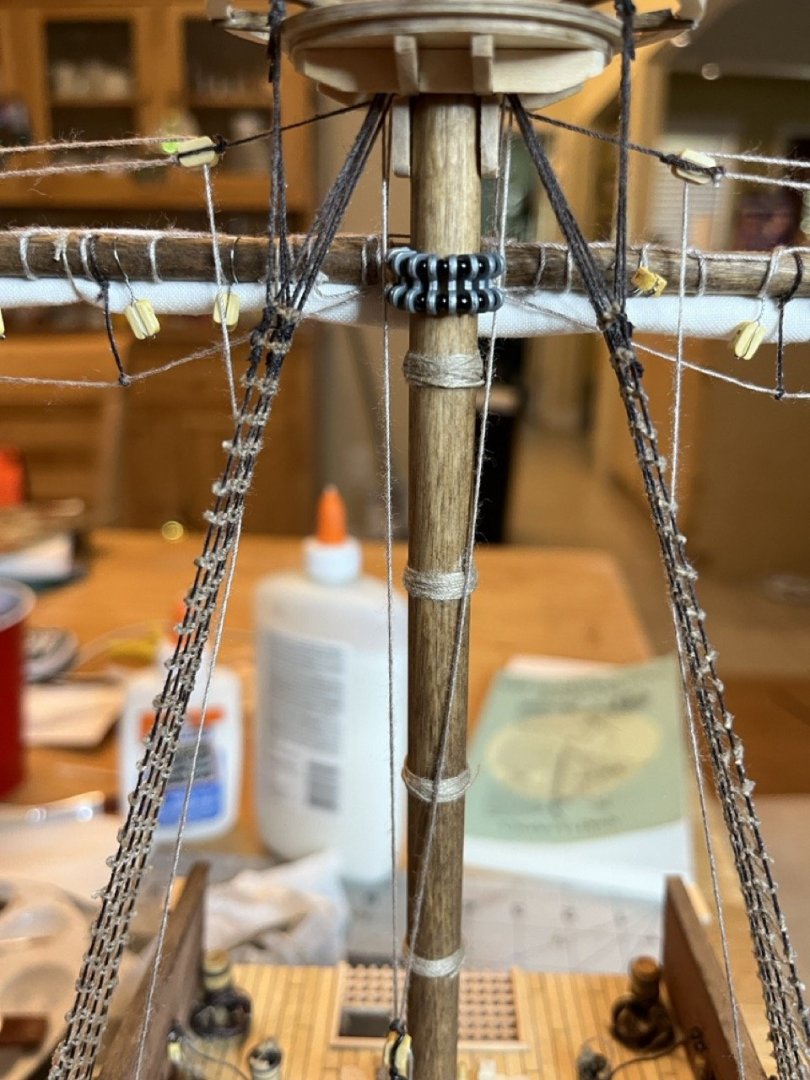

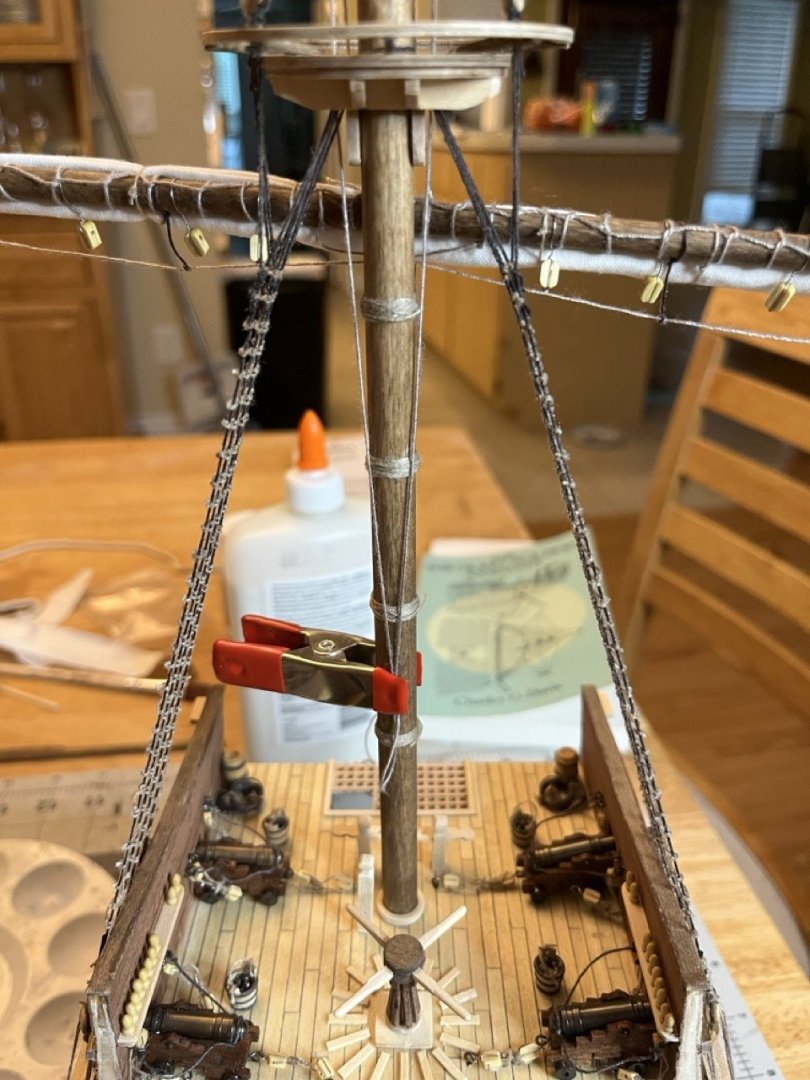

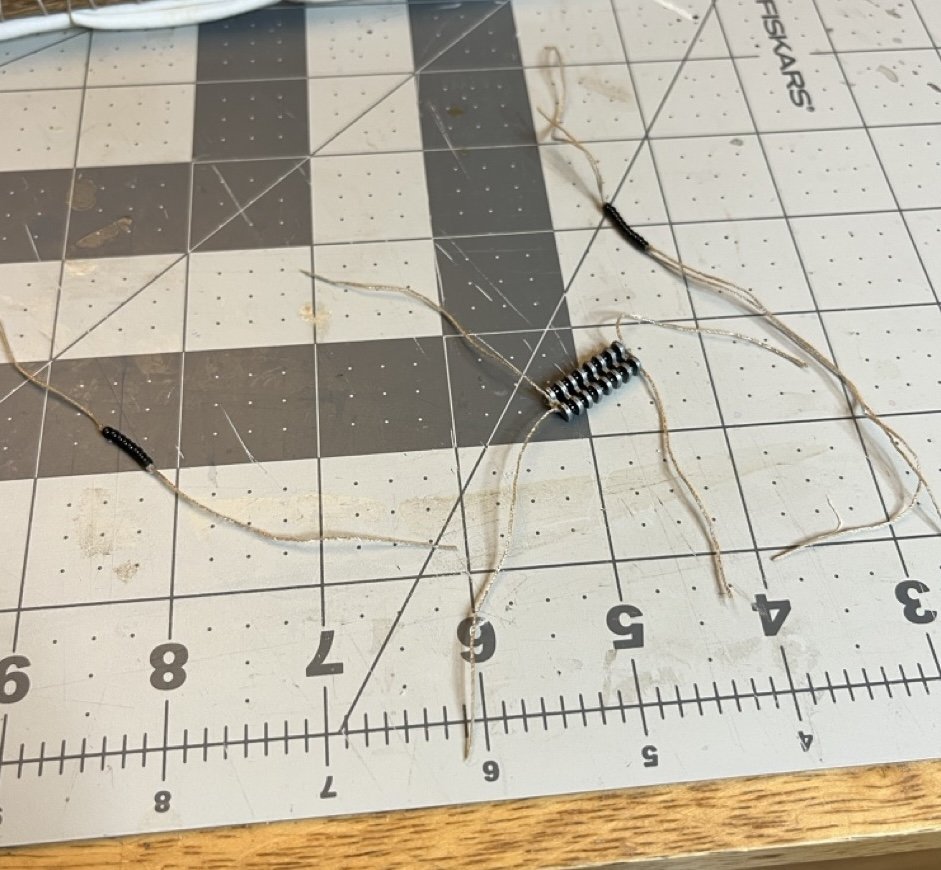

It is finally time to raise the main mast. The halyard blocks are held up by wire, which I am pretty sure is not historically accurate. I am not even sure if a halyard on the main mast is historically accurate. I have seen conflicting information on that. I was concerned that the blocks would slide down the mast, but they actually seem to be holding up ok. Trying to hold the mast up while adjusting the length of the halyard was a bit tricky, but clips helped. The cross jack lifts are next. There is little guidance from the instructions on how tie off the blocks or how to attach them to the mast. I ended up tying them to the trees. The lighter colored line coming off of the end of the block is tied to the darker line that is tied around the block. The instructions make it look like the two lines might be joined somehow on each end of the block, but it is hard to tell in the low resolution photo. I couldn't position the camera to see the lines tied to the tree. Lines tied down to the belaying pins. I think I should have used more string to have large amounts of coiled line. The mast couldn't realistically be lowered with that little line. The parrel beads were tricky since there wasn't an easy way to hold them tight to the mast. I essentially had to barely clip them onto the side and tie off each end loosely, then tighten each side up. I am pretty sure that they aren't rigged realistically and the instructions give no guidance on how to rig them, so I simply tied them to the mast. The cat is not impressed.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Greetings from a clueless Patrick O'Brian fan

SiriusVoyager replied to Galkar's topic in New member Introductions

Welcome to MSW! The amount to learn can be overwhelming. I find that the best bet is to learn as you go. I found that trying to learn too much too quickly just meant that I was taking in a lot of info that was meaningless to me at the time, and thus not retained. -

Welcome to MSW! I started modeling as an adult and still have questionable results but don't let any that stand in your way. Just enjoy what you are doing!

-

This is by far the most simple way. If you save the photos to files rather than the camera roll, the iphone can quickly convert them to jpg. It takes a few steps though and may be more trouble than you want to deal with. As a side note, apple uses HEIC files because they take up less space, so by saving photos as jpg you will fill up your memory more quickly.

-

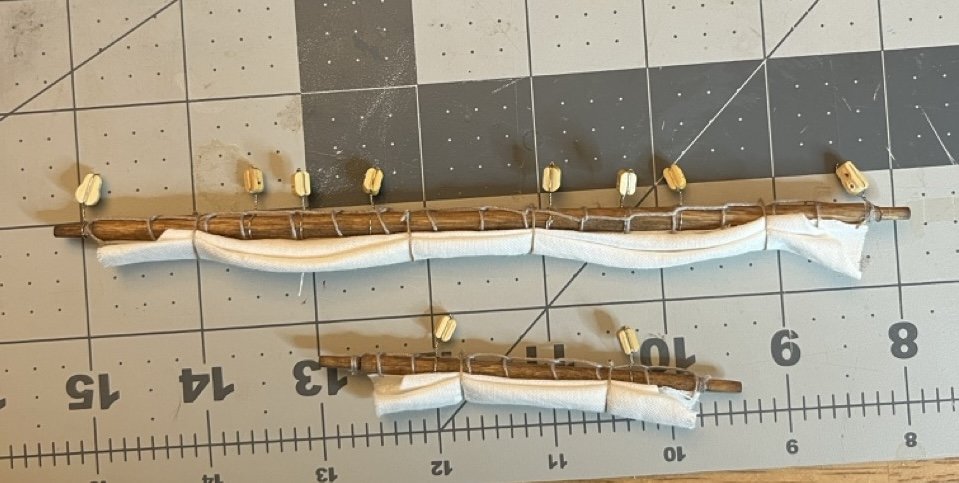

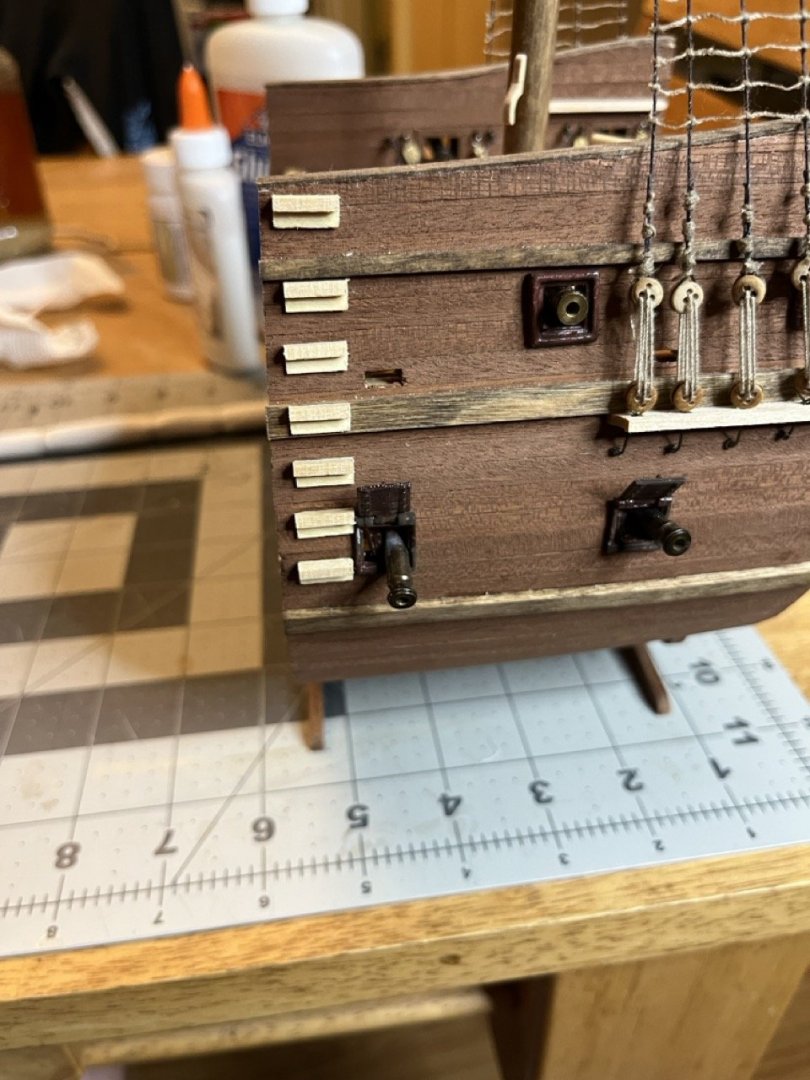

The top step on the port hull ladder wasn't lined up right which is now fixed. A little IPA and careful use of a hobby knife separated it fairly easily. The soft wood didn't stand up well, so another step was cut. Blocks placed on the yard. Fortunately it wasn't a problem having the sail furled to the yard. For the footrope, the instructions call to use metal wire for the strop to hold the shape. I understand why since the lightweight string may not hang properly, but I didn't want to use wire, so I used the dark brown thread. Care must be taken to ensure they are the same length. As far as holding the shape, I used some clamps to provide tension and use PVA to stiffen the strops. Once that dries the ends will be tied to the yard arms. The next step will be to hoist the yard up to the mast so I figured now would be a good time to put the belaying pins in. When I first made the rails, I suspected that the holes for the pins would be much too small. They were. I wish I would have checked this sooner so I could widen the holes without the shrouds being in the way. I'm not sure why the instructions don't have you install the pins when making the rails. While working on the fife rail, the soft wood basically disintegrated. It took two attempts to make a new fife rail. The stem of the belaying pins has a slight taper to it which resulted in them not sliding all the way into the rail. I filed them down to fit as well. I didn't want to make the holes in the rails too large and split the wood. Starboard belaying pins installed.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

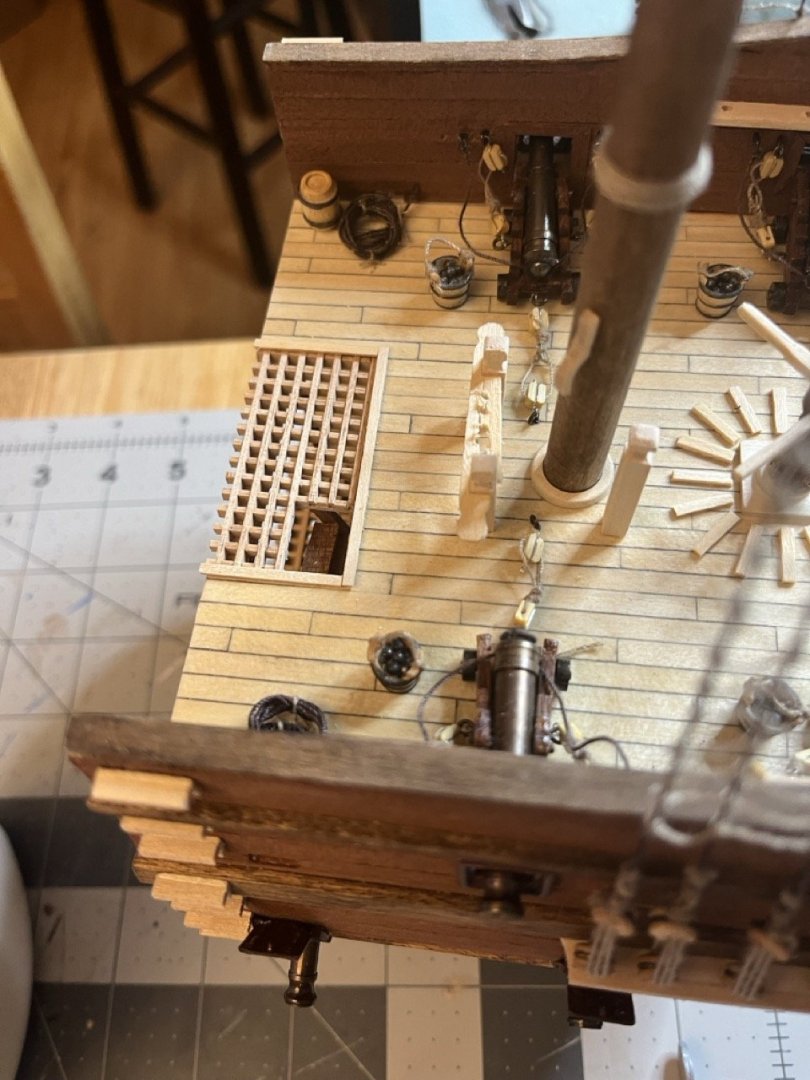

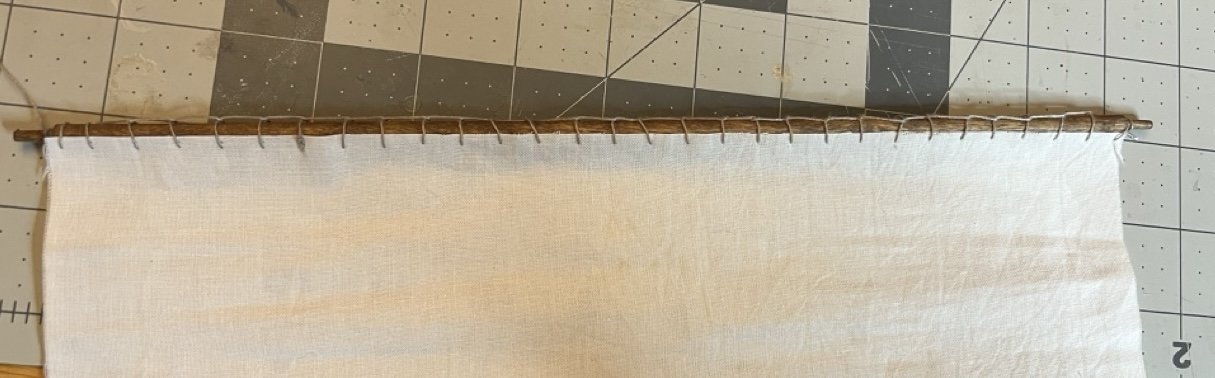

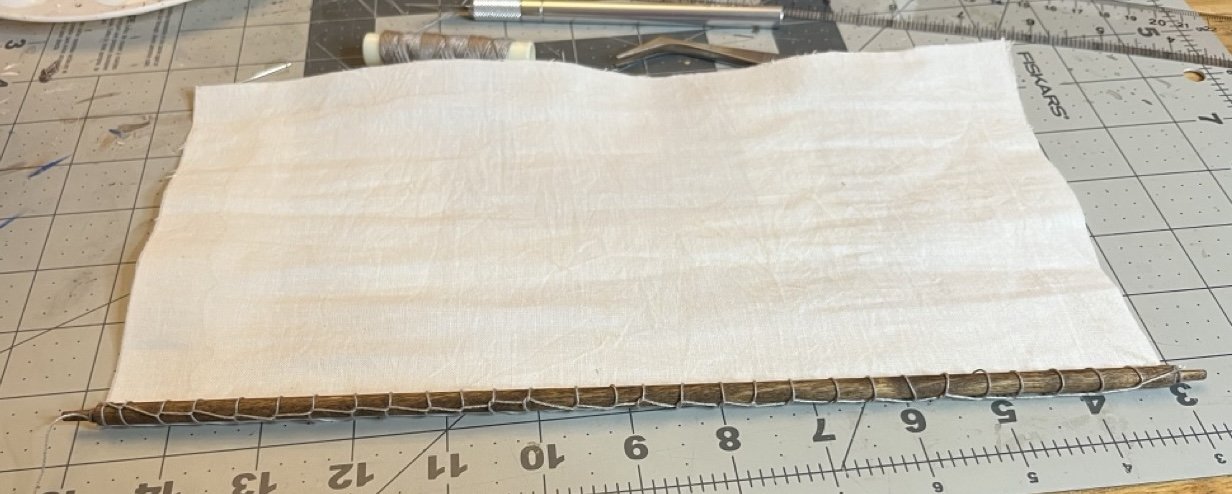

Ladders on each side of the hull installed. The instructions called for the inboard pieces to be made from a 4 mm x 2 mm strip. I could not find a full one in the box, only scraps. According to the parts list there should be one included with the kit. It looks like there is an earlier step that calls for the same part number. Either there is an error in the parts list and instructions or I messed something up. I had a 4 mm x 1 mm strip so I used that instead, a relatively minor change. P Parrel beads for the three yards. I started working on first yard. The kit doesn't include sails, but I wanted to add furled sails. After studying the instructions and doing some research I had second thoughts since rigging such as the clew lines were also not included. Ultimately I decided to add some furled sails anyway. I started out cutting some fabric, gluing the edges to prevent fraying and marking where the bends will go. It seemed like the sail should be bent on to the mast prior to the rigging. This was way too much fabric so I trimmed it down to keep the furled sails from being too bulky. I had a heck of a time trying to furl the sails in a way that looked sort of natural. Here is the end result. Hopefully it wasn't a mistake furling the sail prior to attaching the rest of the gear.

- 86 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Very nice looking Dory!

- 28 replies

-

- Lowell Grand Banks Dory

- Shipwright Series

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.