Supplies of the Ship Modeler's Handbook are running out. Get your copy NOW before they are gone! Click on photo to order.

×

-

Posts

213 -

Joined

-

Last visited

Reputation Activity

-

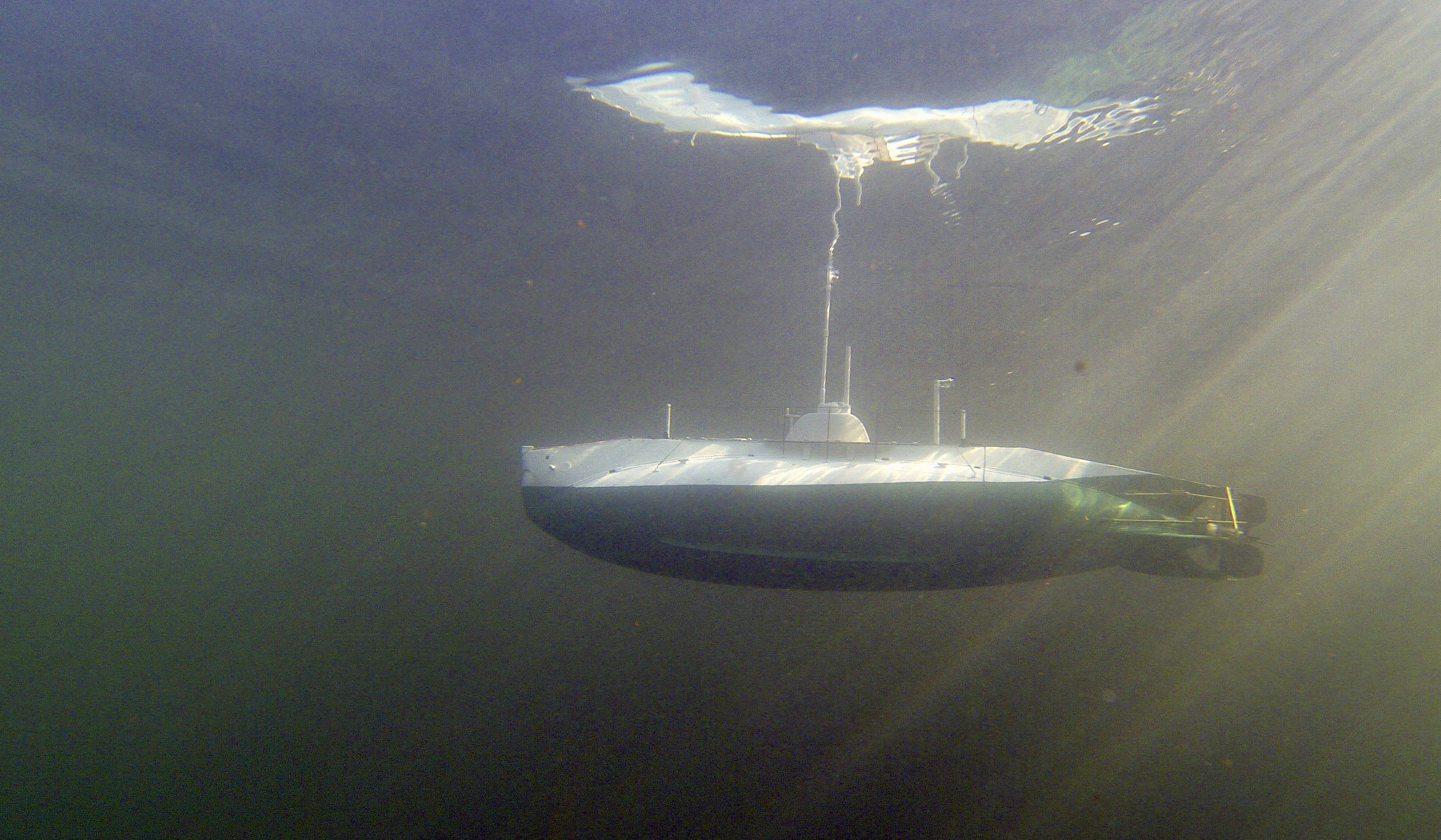

FreekS got a reaction from KeithAug in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from KeithAug in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from KeithAug in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from KeithAug in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Thanks Ron! I will watch that! I’ve been mounting and remounting the propshafts dozens of times to correct the alignement ! I’ll be mounting the gears on the shafts today I hope!

-

FreekS got a reaction from Mirabell61 in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Mirabell61 in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Further with the rear of the boat.

the rudders and diveplanes are made by soldering a 0,5mm brass plate on the shaft, then covering it with wood before sanding. Here the diveplanes were added - these are controlled through a brass rod coming vertically down from within the boat. Should be near invisible

The prop shaft is a little too low here - it is driven from the above describes brass gearbox and fixing this meant reprinting the rear bulkhead of the WTC with a small 5 degrees offset from the horizontal.

Both propshafts are reasonably aligned and holes made in the hull. The brass fins in below picture will be soldered to a structure in which the shaft runs and to the hull. This is a quite tricky part - I have little or no room for a proper motor-shaft coupling - so alignment must be very good to avoid vibrations.

-

FreekS reacted to KeithAug in Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

FreekS reacted to KeithAug in Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

Thank you John / Gary.

It is time to start what I anticipate to be a long planking job.

I am starting at the bulwark. I plan to plank the hull with mahogany planks of .062" thickness by nominally .220" wide. The plank widths will obviously vary to conform with the hull shape as progress is made. The bulwark will be made from a nominally 1" wide by .032" thick birch ply which will be clad with .032" mahogany planks as per the attached sketch.

The bitch ply cannot follow the line of the bulwark exactly without shaping so it is being put on to sit slightly above the line of the capping rail. It will be cut back to the capping rail shape later in the build.

I started by glueing bits of scrap wood to the frames. These position / support the plywood during gluing. Each one cut back to conform with the shape the plywood strip wants to take.

At this stage I also did the final sanding of the hull.

Then followed the slow process of fitting the plywood strakes. They were glued in position with a ample layer of PVA wood glue.

The strakes were held in place with plenty of notice board pins and elastic bands while the glue dried.

The plywood sheet wasn't long enough to extend the full length of the hull and the stern needed separate strips.

I didn't get one to the frames right and this was revealed "too late" by the application of the bulwark strakes. I will need to correct this before I plank the bulwarks. Stupidly having noticed the mistake I the repeated it on the other side. There is no fool like an old fool.

Applying the bulwark strake to the stern was quite challenging due to the extreme curvature.

Before attaching the ply to the stern I slotted it with a series of horizontal cuts.

With a bit of fiddling this enabled it to wrap around the stern.

A bit of sanding produced an acceptable shape for subsequent planking.

That all for now folks!

-

FreekS reacted to KeithAug in Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

FreekS reacted to KeithAug in Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

Thank you Andy and John.

I spent a few hours today completing the rudder (excluding finishes).

The shaft is 0.16" diameter while the plate is .04" thick. I therefore needed to machine slots in the the cladding 0.08" radius by 0.06" deep. See blue arrows on next photo. I also cut the plate along the line of the shaft removing a .016" wide strip.

The brass pieces were then assembled on the cladding and glued in place using CA glue.

The other side of the gladding was then glued in place forming a brass sandwich.

The rudder is fitted with anodes. All the anodes on Cangarda are of the same flat plate type. I drilled the holes for later anode attachment.

To get the taper sanding of the cladding symmetrical I employed a flat sheet of aluminium oxide paper and a bulldog clip.

The bulldog clip is holding the front of the rudder clear of the sandpaper and at a constant angle while the taper is sanded. The bulldog clip spring is hard enough to resist the abrasion of the oxide paper. The taper on the front edge of the rudder was formed in a similar manner.

My plan is to get on to the planking next. I expect it to be a long job so if you want to skip it I suggest you rejoin in about 2 months.

-

FreekS reacted to KeithAug in Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

FreekS reacted to KeithAug in Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

Thank you Richard and Pat.

Gary - She says it is her greatest pleasure to be my forever financial burden. She also says my efforts are earning points which will influence her when choosing the quality of retirement home she will be putting me into when I can no longer look after myself.

And so on to the rudder.

I started with a brass sheet .040" thick.

I drilled a number of holes at the centre of the various edge curves. I also turned up some filing buttons - blue arrows.

I cut away the waste brass and using the buttons I filed the edge curves.

The rudder is profiled / streamlined although the front and rear edges are blunt.

The outer rudder shaft was made from brass tube with bearing ferrules at the upper and lower ends. The ferrules are drilled .040" diameter to take the fixed inner bearing shaft.

The small upper section shaft was made in a similar way. Below all 3 parts are assembled.

I will form the outer shape of the rudder by attaching mahogany to each side and then sanding to shape. Below the mahogany "cladding" has been cut and glued prior to attaching to the rudder shaft.

That's all for now.

-

FreekS reacted to KeithAug in Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

FreekS reacted to KeithAug in Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

Well the family are all gone and it's back to some workshop therapy. I continued cutting out the inside of the frames and test fitting them on the base board. I am at that interesting stage where she is starting th look like she will become a ship at some point.

Many hours later.

I also started to sort out the bow.

-

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Thanks Ron! I will watch that! I’ve been mounting and remounting the propshafts dozens of times to correct the alignement ! I’ll be mounting the gears on the shafts today I hope!

-

FreekS got a reaction from yvesvidal in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from yvesvidal in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Further with the rear of the boat.

the rudders and diveplanes are made by soldering a 0,5mm brass plate on the shaft, then covering it with wood before sanding. Here the diveplanes were added - these are controlled through a brass rod coming vertically down from within the boat. Should be near invisible

The prop shaft is a little too low here - it is driven from the above describes brass gearbox and fixing this meant reprinting the rear bulkhead of the WTC with a small 5 degrees offset from the horizontal.

Both propshafts are reasonably aligned and holes made in the hull. The brass fins in below picture will be soldered to a structure in which the shaft runs and to the hull. This is a quite tricky part - I have little or no room for a proper motor-shaft coupling - so alignment must be very good to avoid vibrations.

-

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Further with the rear of the boat.

the rudders and diveplanes are made by soldering a 0,5mm brass plate on the shaft, then covering it with wood before sanding. Here the diveplanes were added - these are controlled through a brass rod coming vertically down from within the boat. Should be near invisible

The prop shaft is a little too low here - it is driven from the above describes brass gearbox and fixing this meant reprinting the rear bulkhead of the WTC with a small 5 degrees offset from the horizontal.

Both propshafts are reasonably aligned and holes made in the hull. The brass fins in below picture will be soldered to a structure in which the shaft runs and to the hull. This is a quite tricky part - I have little or no room for a proper motor-shaft coupling - so alignment must be very good to avoid vibrations.

-

FreekS got a reaction from KeithAug in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from KeithAug in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Further with the rear of the boat.

the rudders and diveplanes are made by soldering a 0,5mm brass plate on the shaft, then covering it with wood before sanding. Here the diveplanes were added - these are controlled through a brass rod coming vertically down from within the boat. Should be near invisible

The prop shaft is a little too low here - it is driven from the above describes brass gearbox and fixing this meant reprinting the rear bulkhead of the WTC with a small 5 degrees offset from the horizontal.

Both propshafts are reasonably aligned and holes made in the hull. The brass fins in below picture will be soldered to a structure in which the shaft runs and to the hull. This is a quite tricky part - I have little or no room for a proper motor-shaft coupling - so alignment must be very good to avoid vibrations.

-

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Further with the rear of the boat.

the rudders and diveplanes are made by soldering a 0,5mm brass plate on the shaft, then covering it with wood before sanding. Here the diveplanes were added - these are controlled through a brass rod coming vertically down from within the boat. Should be near invisible

The prop shaft is a little too low here - it is driven from the above describes brass gearbox and fixing this meant reprinting the rear bulkhead of the WTC with a small 5 degrees offset from the horizontal.

Both propshafts are reasonably aligned and holes made in the hull. The brass fins in below picture will be soldered to a structure in which the shaft runs and to the hull. This is a quite tricky part - I have little or no room for a proper motor-shaft coupling - so alignment must be very good to avoid vibrations.

-

FreekS got a reaction from Ian_Grant in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Ian_Grant in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from _SalD_ in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from _SalD_ in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from Wreck1919 in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Wreck1919 in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from PvG Aussie in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from PvG Aussie in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from yvesvidal in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from yvesvidal in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

Good Day All,

I carved the mid-ships pack, the top surface of which is at an angle as shown.

Then I made and glued on the hands.....he is happy to have his hands! The right hand is hollowed out to accept the paddle.

I cut the rudder out of aluminum with a tin snips, and then sanded the sharp edges smooth. I cut a slot for the rudder using a thin-width blade in the hull for the rudder and then installed the rudder with super glue.

And now for the final piece....the paddle!

Next I wrote out the words on the bottom of the canoe and then etched them into the wood with an awl. Sanding the wood and the cast metal worked grey metal dust into the wood grain.

Now time to get some paint! I will do some painting before final assembly of the parts.....in fact I wish I would not have glued in the aft pack already.

-

FreekS got a reaction from Rik Thistle in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Rik Thistle in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from bridgman in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from bridgman in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!

-

FreekS got a reaction from Jack12477 in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Jack12477 in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Ok, further with self-taught engineering. Many if not all concepts below are well known in the model sub world, I did not invent them! I want to have a final design of the water-tight compartment (WTC) and its connections to propellers and rudders because only then can I plan and make the required holes in the wooden hull and finish the hull.

The WTC will consist of three connected PVC pipes connected with 3D printed parts

- aft: 44mm ID with the motor, motor controller, and two servos for the rudders and diveplanes,

- middle: a 69mm ID pipe with the dive tank (a 60mm PVC tube), the receiver, the pump, a self-made valve as well as the ballast tank controller.

- bow: another 44 mm ID pipe with servo for front dive planes and the batteries.

These components will be housed in a techrack which is pulled out of the WTC. I’ve been designing these in Fusion360 and printing them on my 3D printer. The techrack will be mounted on four M3 rods to give it strength.

here on the left the aft WTC , connected to a printed bajonet (located on the “cut” in the boat in background), and then to the right the beginnings of the techrack and dive tank

The dive tank (here left) has a water-in and air-out brass connection. The resistance between these is measured by the dive tank controller to determine if the tank is full. The pump is a 500ml/min gear pump, and since gear pumps are not closed, I’ve re-purposed a mini-servo to pinch the air-out tube closed so no water leaks in when pump is idle. A 40 MHz 8 channel receiver will be mounted here as well.

the rear WTC with motor axle sticking out (through a seal) and two o-ring holders for the pushrods to the planes and rudder. The motor drives a gearbox “in the wet” which drives two shafts and 30mm Raboesch props. The white printed part will be glued to the PVC pipe, but the motor can be unscrewed from the outside so that the rear techrack can be removed for maintenance. The screws must be sealed.

here the tank again with its controller forward. Many electrical and signal wires will pass over the tank (which will be inside the 69mm ID WTC).

finally, I did manage to do a little woodwork, the main rudder consists of two 0,3 mm brass sheets soldered to the 3mm shaft, and then covered with two layers of 1 mm boxwood on both sides. then sanded in shape. Also the future mount of the diveplanes is visible.

sorry for the technical stuff - subs are a technical game, but I will get to the nice part of making the conning tower later!