-

Posts

215 -

Joined

-

Last visited

Reputation Activity

-

FreekS reacted to Greg Davis in Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

FreekS reacted to Greg Davis in Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

Craig -

I really appreciate you taking the time to (re)check the blade to shaft ratio and I'm glad we came to a similar conclusion!

I had been taking note of the prop/hull clearance both in pictures and in the previously mentioned video. It looks like there wasn't a good deal of space! I also had kept an eye on the approximate location where the blade tip intersects the diagonal brace from the engine pylon to the nacelles. The prop / hull clearance was the main reason that I though the first propeller mock-up didn't look convincing enough.

Today I put together propeller mock-up No 3 (starting to use the SD numbering system, but don't want to make it to No 18 here!). This one is built to the 2:1 ratio and is scaled to match a propeller with a 2.25 meter diameter.

This one looks pretty good to me currently. The blade shape still needs some refinement as it blends into the shaft - the transition seems a little abrupt right now.

I think that some metal is coming out next.

Also, I've made a decision to have the front of the engine as similar to how it sits in his workshop in this photo:

The mechanics associated with the water pump up front is the same as in this photo:

But not as it had been in the No17 nor when the engine was being installed on the No18:

In the later (final?) set-up, it appears that the water pump is run off a belt drive from a larger pulley mounted to the propeller shaft. This arrangement wasn't present when the engine was being installed.

-

FreekS reacted to AntonyUK in Tally Ho by AntonyUK

FreekS reacted to AntonyUK in Tally Ho by AntonyUK

Good morning.

Just a little insight into how the drawings are created.

I use Fusion360 Hobby Home version.

The plans were imported and scaled to the correct length at the waterline. Then there positions were adjusted to match together so that when you rotate the drawings it looks and reacts as it should in 3D.

All the Components then have Drawing plane's on all X Y and Z planes added(Just a habit encase I need them latter on)

Each part has its own drawing so that I can use Origin Shaper add-in to export the SVG files in the next stage.

The parts are drawn one at a time in the correct order so I can see them to check on the fairings and assembly alignment.

A few screenshots.

The Keel is made using a bread and butter construction. This gives me a true shape and is easy to fare when it comes to the sanding. Used dowels to get the alignment spot on. The layers are 4.2mm in thickness. and the bottom one is 6mm thick.

Sternpost is made up using 4 parts and and I used 16mm thick timber. All the parts were marked with a laser and also marked the rabbet line at the same time. parts were cut with correct grain direction.

Final fitting with file and chisel to get the fit.

The stem was done using the same method as the Sternpost. Using 14mm thick timber and the mast step was 21mm timber.

The assembly matched together.

Assembly with Frame drawings. Showing the lines very nicely.

The frame drawing were put onto a sketch which is the size of my laser. this made it easy to manipulate the parts ready for Shaper to do its magic.

The inverted building Base.

That's it for now.

Regards AntonyUK.

-

FreekS reacted to highlanderburial in USS St. Louis (CL-20) by highlanderburial - FINISHED - 1/200 scale - 3d Print and 1/150 Restoration

FreekS reacted to highlanderburial in USS St. Louis (CL-20) by highlanderburial - FINISHED - 1/200 scale - 3d Print and 1/150 Restoration

There be anchors here. Of all the unique features on this vessel the fact it carries both stocked and stockless anchors each on their own chain is very cool to model. I also started on the ultra fine stack rigging.

-

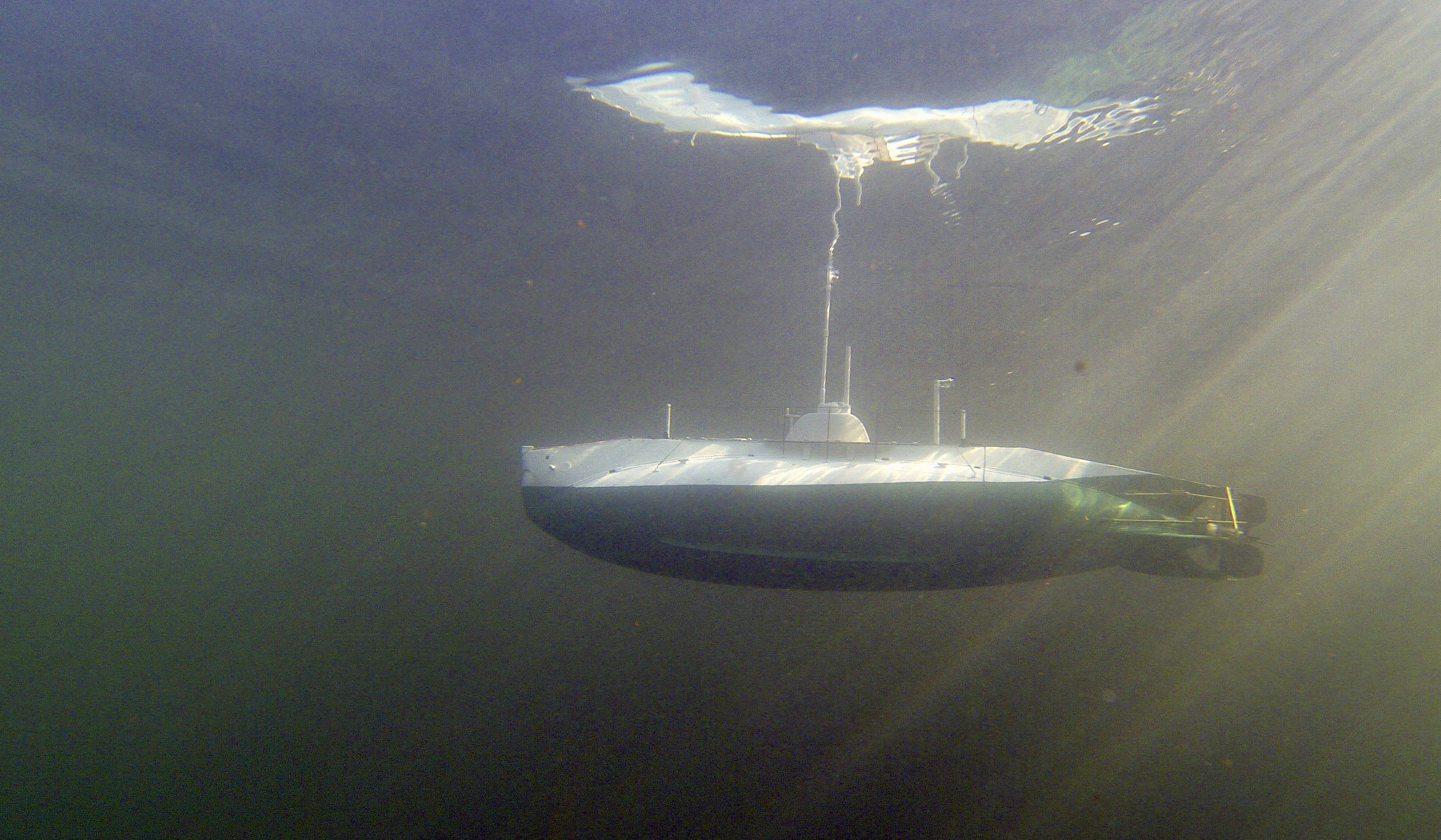

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Decals mounted and covered with a few layers of varnish…..

-

FreekS got a reaction from mcb in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from mcb in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Decals mounted and covered with a few layers of varnish…..

-

FreekS got a reaction from Javelin in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Javelin in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Decals mounted and covered with a few layers of varnish…..

-

FreekS reacted to Javelin in Chaconia by Javelin - 1/100 - RADIO - LPG Tanker

FreekS reacted to Javelin in Chaconia by Javelin - 1/100 - RADIO - LPG Tanker

Waited to respond until I had something to show.

Sorry for trying to put years of operations and many courses and manuals in a single post... I guess that was a bit much.

In any case, as mentioned before, the first liquid line was the hardest as I had to line it out, get a good length etc. Once this one was done (and for those paying attention, in the last picture it had already its end flanges and orange painted extremities in place), I could continue with the others.

I was very reluctant to glue it in place, due to so many things that need to line up at one time, that I didn't glue it in place for a long time. Although I wanted to continue aft with the vapor line next to my finished liquid line, I decided not to do that.

Although everything is far from perfect, I had a feeling that the longitudinal distance between the manifold flanges would be very important for the overall view of the model. I therefore went ahead with the aft liquid line. Once that was done, I could go towards the center and make sure those distances were at least symmetrical.

Again everything was laying dry fitted for a very long time, until I was sure that I had at least the space to cram in the other lines.

I then glued the two liquid (orange tipped) lines in place and continued inward with the vapor lines etc.

Here you see how I lined up all manifold flanges to be at a straight line transversally. Because I had the two liquid lines fixed, I could use a straight piece of styrene touching the flanges. I then marked the edge of the "new" pipes and cut them off at that mark.

Once I had the flanges on on one side, I then used that piece of styrene against all flanges (with the white pipes still dry fitted) and used the same trick to mark out the other side. Then I cut that side and glued the flange. Up till that moment I had the "flanges", small rings, that I needed for valves, loose on the pipes. Once the flanges were in place, I could measure and glue the first flange for the first valve and so on.

And a bit of extra. As you can see on the liquid manifold ends, there are two valves. 1 is manual, with a wheel (inboard), the other is hydraulic (outboard), with a big actuator. The manual valve is called a double shut valve and is installed because a single valve can leak, chances of having two valves leaking at the same time are much smaller. Since the liquid lines can go quite high in pressure, this is a requirement for liquid lines only. On the vapour line you can see there is no more manual valve behind the hydraulic actuator.

The high pressure line also has a double valve (more work for me again).

I've been thinking of making the manifold flanges bolted, in a similar way as the strainer lids. But eventually I decided against it. It would probably be out of scale, take a long time to make and I had already used blank discs as end flanges on other parts of the vessel, so it would be out of the normal to have them with bolts here.

And last but not least I tested with a paper template, the walkway that's supposed to come on top. To my greater surprise (I had to make some things slightly out of scale and expected the accumulated error to be quite large), it fitted quite well.

I will make a cardboard adapted version of this catwalk before I make the final one in the same way as I made the driptray gratings.

-

FreekS reacted to Javelin in Chaconia by Javelin - 1/100 - RADIO - LPG Tanker

FreekS reacted to Javelin in Chaconia by Javelin - 1/100 - RADIO - LPG Tanker

Well here we go then. Hope this clarifies a few things. Always a big difference between a regular diagram and the actual construction. A lot of complexity is added simply by having those 2 fully separated systems (marked on the lines by a single line or a double one).

The diagram is a single tank depiction with only a single pump. To make things worse, the tanks are split longitudinally in 2 halves for stability reasons. 1 pump is located in each half. The top and condensate system however, are connected, to keep the pressures equal (so you can't mix put two products in 1 tank).

For loading there is a (small) valve located between the pumps so you can equalize the liquid levels. The different lines on the drawing are colored in the same color as the lines on the ship, so that should be clear. I believe I marked everything from the drawing on the picture.

This drawing would only explain loading or discharging, but there are additional lines that are used for "special operations", eg. dry docking, changing cargo etc.

Normal life cycle would be something like this:

- Dock: Ambient air

- drying the tank (dry air) (ambient temperature, vessel underway to loading port)

- Inerting the tank (removal of oxygen to avoid flammable mixtures when loading flammable gasses) (ambient temperature, vessel underway to loading port)

- Filling the tank with cargo gas (depends on which gas you will load, done to remove the inert gas from the system, since that doesn't work in the reliquefaction plant later on and it would still retain some moisture in the system, which you want to avoid) (ambient temperature, arrived in either special port to receive small amount of cargo, or in loading port itself)

- Cooling down of cargo tank (going from ambient to loading temperature using condensate line top spray)

- Loading of cargo

When going to dry dock:

- discharging last cargo as much as you can (cold temperature)

- sending warm gas to the bottom to remove last liquid cargo

- warm-up of cargo tank to warm up the insulation and tank walls

- inerting of cargo tank

- aeration of cargo tank

- once gas free, vessel can enter dry dock

In the above sequences a lot of different non-fixed connections are made between the pipes and I'll avoid pointing all those out in detail. When changing cargo it's practically the reverse. First you prepare the vessel like going to dry dock and then you prepare it for the next cargo, much like after dry dock. With propane and butane you can often cheat a bit, but you can't do that when going from propane to ammonia etc.

Hope it's a bit more clear, let me know if you want more details.

-

FreekS reacted to Greg Davis in Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

FreekS reacted to Greg Davis in Santos Dumont No. 18 Hydroplane 1907 by Greg Davis - FINISHED - Scale 1:16

Here is what 9 fins look like as compared with 6. I think this will do!

Still a bit of solder clean-up on the top two sets of joints. I have some smaller dimensioned brass square tube on order for the top and bottom caps. I had used 1/8" on the 6 fin attempt. It looks like I might be able to get 2mm square tubing which would give a nicer fit.

Currently there are small brass strips soldered on the backside to hold the fins, but your glue and spacer idea would most likely yield a nice result - one that might get the fins even closer together than my slotted jig can achieve!

Sorry about posting so often tonight, but this subassembly has just been getting to me and I the venting is helping!

-

FreekS reacted to Riotvan88 in Zwarte Zee by Riotvan88 - 1/75 - RADIO - 1st scratch build

FreekS reacted to Riotvan88 in Zwarte Zee by Riotvan88 - 1/75 - RADIO - 1st scratch build

Small progress, had to make the anchor details for the fore deck before being able to glue down the forcastle deck and finish painting the hull

-

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Decals mounted and covered with a few layers of varnish…..

-

FreekS got a reaction from Ian_Grant in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Ian_Grant in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Decals mounted and covered with a few layers of varnish…..

-

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

The cranes have been completed, the main cables are 0,3mm stainless steel which hopefully stays nicely straight over time. In the background the same cranes as I built them from wood twelve years ago on my K-XVIII model (after sailing 78times these still look good!).

Also the wooden deck has been constructed from 1x1 mm wood bought at a rare model shop. A bit thick at this scale, but I don’t think I can sand it down nicely enough, so I’ll leave as is.

For the moment covered by two layers of clearcoat, will add some more once the decals are mounted.

-

FreekS got a reaction from Valeriy V in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Valeriy V in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Decals mounted and covered with a few layers of varnish…..

-

FreekS got a reaction from ccoyle in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from ccoyle in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Decals mounted and covered with a few layers of varnish…..

-

FreekS reacted to MAGIC's Craig in TWILIGHT 2007-2009 by MAGIC's Craig - Scale 1:16 - RADIO - Pacific Northwest cruising powerboat

FreekS reacted to MAGIC's Craig in TWILIGHT 2007-2009 by MAGIC's Craig - Scale 1:16 - RADIO - Pacific Northwest cruising powerboat

To wind up this month's posting, I continued to build out the interior of the pilothouse while Vicky leant her talented and steady hands to some detail varnishing. A brass bezel was made for the engine instruments

Vicky also detailed the varnishing of various topsides bits of mahogany.

And as you can see in this photo to the left, controls and instruments are being placed.

A cove between the house and the level of the deck is curing. Hopefully, unlike the first attempt, this cove will only glue to the house and not the deck.

So step up and take a look.

That will do for now. Thank you for following along.

Craig

-

FreekS reacted to MAGIC's Craig in TWILIGHT 2007-2009 by MAGIC's Craig - Scale 1:16 - RADIO - Pacific Northwest cruising powerboat

FreekS reacted to MAGIC's Craig in TWILIGHT 2007-2009 by MAGIC's Craig - Scale 1:16 - RADIO - Pacific Northwest cruising powerboat

April 2, 2025 update:

Prior to permanently closing over the raised portion of the house above the forepeak, I made provision for the speaker which is used to fool you into thinking this wee craft has a Gardner diesel in it. A hole was drilled from below for the body of the speaker and a guard bent up to protect the projecting lower portion of the speaker whenever the PH module is removed from the deck.

The cabin top was then planked over with basswood, faired and sealed with 'glass/epoxy. The next task on my list was to begin the construction of the window framing for the pilot house. Upper and lower plates (head and sill?) were laid out and shaped to lay above the curved vertical face of the pilot house.

The upright window jambs were fashion from some teak and made with tenons top and bottom. Corresponding mortices were cut into the plates.

This somewhat wobbly construct was then braced up and glued together.

When set atop it's future location, I realized an oversight on my part: the window framework tilted aft a bit rather than presenting a vertical face to the elements. For most of it, the tilt was not a problem but the after jambs had to ultimately be cut free of their tenons and re-aligned to vertical to deal with the doors. A yellow cedar header was laminated up and glued to the head plate, beveled to follow the curve of the overhead plywood from the main cabin.

The door framing was gotten out of some of that lovely Cuban mahogany and they were glued into place, reinforcing the re-positioned after window jambs port and starboard. As mentioned earlier, the whole pilothouse module is removable by lifting it out vertically.

And the next photo gives an idea of basic area of the interior of the pilothouse. The final picture before I break this post up into two sections to keep it manageable shows the forward curved faces of the PH with a laminated moulding curving around the forward portion. Then we will visit the interior of the house.

More to follow...

-

FreekS got a reaction from Valeriy V in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Valeriy V in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

The cranes have been completed, the main cables are 0,3mm stainless steel which hopefully stays nicely straight over time. In the background the same cranes as I built them from wood twelve years ago on my K-XVIII model (after sailing 78times these still look good!).

Also the wooden deck has been constructed from 1x1 mm wood bought at a rare model shop. A bit thick at this scale, but I don’t think I can sand it down nicely enough, so I’ll leave as is.

For the moment covered by two layers of clearcoat, will add some more once the decals are mounted.

-

FreekS reacted to AntonyUK in Tally Ho by AntonyUK

FreekS reacted to AntonyUK in Tally Ho by AntonyUK

The boat Tally Ho.

I got interested in this cutter from a YouTube series by Leo.

https://www.youtube.com/@SampsonBoatCo/videos

Followed the build all the way through. Leo is a Boat builder and sailor. (His words)

Started on this boat in August 2024 by ordering a set of plans from the Albert Strange Trust https://albertstrange.org/

I decided that the model should be :- 1000mm at the waterline and 1173 from Stem to Sternpost and a 287 Beam.

I used Fusion360 (Home hobby version) to bring the 2D plans into 3D which took me till December.

My son purchased a Laser cutter for me as a Christmas present. 22 watts and a cutting bed area of 410X400.

Then it took me 2 months to learn how to use it and to set it up in my shed with a Ventilation extraction system.

The software I used was Shaper Origin Addon in Fusion. to export the .svg file to Inkscape. And then into LaserGRBL for the cutting interface to the Laser cutter.

The Stem Sternpost Deadwoods are 16.6 timber. They were marked by laser engraving a line onto the timbers and band sawing the parts out. They were finished to size using a Proxton mini mill to square and split the laser line.

The Bow and stern sections were assembled and checked and glued.

The Keel was made up by using a bread and butter construction method. The layers were cut on the laser using 4.2mm pine from my local DIY store. I had 4 dowel pin holes along the length of the keel to ensure the straight and true alignment.

Dry assembled and checked for length shape and alignment. All good so on with the gluing.

The frames were laser cut using 6mm laser ply. This was my first real cutting with the laser.

The Bow Stern and keel were glued and pined together. Wow this is going to be a BIG model.

I also designed a Jig to build the boat on fusion to help with the alignment.

Building this boat inverted as it best for me. The keel and Stem and Stern post were added to the Jig then the frames were placed in place on the jig. Everything looked spot on so i glued them together.

Small bits if off cuts were added between the frames to maintain the correct frame spacing.

Now we are up to date with the build as it is now.

Next week.

Going to fill between the frames with 40mm insulation foam boards. This will provide me with something to fare the frames and to lay fibreglass onto.

Not done any fibre glassing before so ANY advice would be helpful.

Regards AntonyUK.

-

FreekS got a reaction from amateur in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from amateur in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

The cranes have been completed, the main cables are 0,3mm stainless steel which hopefully stays nicely straight over time. In the background the same cranes as I built them from wood twelve years ago on my K-XVIII model (after sailing 78times these still look good!).

Also the wooden deck has been constructed from 1x1 mm wood bought at a rare model shop. A bit thick at this scale, but I don’t think I can sand it down nicely enough, so I’ll leave as is.

For the moment covered by two layers of clearcoat, will add some more once the decals are mounted.

-

FreekS reacted to Valeriy V in Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

FreekS reacted to Valeriy V in Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

General view of the cruisers hull with side keels.

-

FreekS reacted to Valeriy V in Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

FreekS reacted to Valeriy V in Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

Screw steering device, but without screws.

-

FreekS reacted to Valeriy V in Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

FreekS reacted to Valeriy V in Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

The propeller shaft brackets are assembled.

-

FreekS reacted to Dr PR in USS Cape (MSI-2) by Dr PR - 1:48 - Inshore Minesweeper

FreekS reacted to Dr PR in USS Cape (MSI-2) by Dr PR - 1:48 - Inshore Minesweeper

It has been a while since I updated this log. I have been working to finish the rigging on my topsail schooner build, and that has been very time consuming. I had to order more rope for that job, and also ordered a helm (ship's steering wheel) for the Cape's pilot house.

I considered carving one from scratch, but noticed that Syren had two "mini kits" for ship's wheels, 15/16 inch (26.34 mm) and 1 ¼ inch (31.75 mm) diameter.

The kit wheels are ten spoke wheels, and the Cape's wheel had eight spokes. I originally estimated from the pilot house photo that the wheel was about 4 ½ feet diameter. So the 1 ¼ inch wheel would be closet. But I have since found a blueprint that says the wheel was 48 inches diameter – 1 inch at 1:48 scale. So this wheel is a bit oversized. But only the top will be visible in the model's pilot house, so this is good enough!

If I had the proper tools I might try making a wheel, but the Syren kit is a lot simpler, and can be finished faster. So I decided to order the Syren kit and see how it works out.

Here is a build log for the Syren 1 ¼ inch Ship's Wheel kit.

The kit comes in a small plastic bag with seven small pieces of laser cut Castello Boxwood and a kit label. You must visit the Syren web site to get the instruction sheet PDF file.

The instructions caution to not use CA (cyanoacrylate) glue for assembly. It sets too fast, and you need to be able to align parts before the glue hardens. Syren recommends water soluble yellow glue. I used Sig-Bond aliphatic resin.

The instructions say to sand all sheets lightly to remove laser char. These are solid wood sheets, not plywood, and they have grain. If you bend the thin sheets along the grain they will break. Handle with care!

The two largest sheets must be carefully aligned and glued together to create a jig for the wheel assembly. The ten round holes in the bottom sheet should line up in the center of ten arc holes in the top sheet. I used the shank of a 3/32 inch (0.094 inch, 2.4 mm) drill bit to align the center holes.

Next you should remove the "rim segments" – the short arc pieces – and carefully sand or file the curved edges to remove char. The short end sides should not have the char removed so they will fit tightly in the assembly jig holes.

The instructions suggest using 320 grit sandpaper and sanding lightly to remove char. I used a small "D" cross section file and used very light pressure.

I used tweezers to hold all of the small pieces firmly while removing the char. Some of these parts are only 0.025 inch (0.6 mm) thick and fragile. By filing only where the tweezers hold them I avoided bending the parts. Even so, I did break off a bit of one of the "C" shaped pieces, but it glued back together nicely with Duco Cement.

It didn't take long to remove the char from all the parts. Extra pieces are included for the rim segments and spokes in case you lose or break one.

The next step was to place the rim segments into the positions in the jig. Here you see seven of these pieces in the holes in the jig, and three more waiting to be placed. They are not glued!

I found it necessary to file the curved sides a bit to remove all of the char before the pieces would fit into the jig. The rim segments are thicker than the jig piece and stand proud.

Next the ring "C" pieces were glued to the rim segments. You must use glue sparingly, placing a small drop on the rim segments to ensure that you don't glue anything to the jig. Clean up any glue that squeezes out.

Here two ring pieces have been glued in place and the third is waiting. Position these carefully over the rim pieces so a bit of the rim segments shows on both sides.

I used Sig-Bond aliphatic resin to glue the parts together. It is slow setting and that allowed me to center the ring pieces on the rim segments. I allowed the glue to set several hours before working with these pieces.

Next the wheel hub was made by gluing a "star piece" to a circular disc. I used the 3/32 inch drill bit as a mandrel to ensure that the pieces were centered correctly.

After the glue set I scraped the char from the star piece. I probably should have done this before gluing the pieces together. Any glue that squeezed out was removed.

After the glue had set the wheel rim was removed from the jig. To do this I pushed through the holes from the back of the jig, one at a time gently until the ring was free. The wheel spokes will fit into the gaps between the rim pieces.

The "C" pieces are very thin and will break if you put too much force in any one position. Work slowly and work the piece free a bit at a time.

After it is free from the jig you can sand both sides of the ring to make them smooth.

The wheel spokes have square cross sections when removed from the sprue. The instructions say to remove the char from the square parts that fit into the ring and the hub, but leave the char on the parts that need to be rounded. This makes it easier to see the places that need to be rounded, and those that should remain square.

I used a motor tool to spin the spokes and the D cross section file to turn the parts between the ring and hub. The handles on the ends of the spokes were also fashioned with the file.

The instructions say to turn all fourteen of the spokes provided with the kit before trying to place any on the ring and hub. You will get better at it as you go, and afterward you can select the ten best spokes to use in your ship's wheel.

You can see where the file slipped on the bottom spoke and rounded the edges of the square segment close to the handle. Another spoke has a handle that is too large.

Next the spokes must be trimmed to length. The jig has a pattern that can be used to trim off the extra material.

The ends that fit into the notches in the star piece of the hub need to be filed to a "\_/" blunt point shape to fit

All of the pieces need to be the right length so the square cross section pieces fit between the ring and the hub. This was the most difficult part of the build.

I used the drill bit to center the hub on the jig. The holes in the jig were used to align the ring centered on the hub. Double sided tape held the ring in place while each spoke was trimmed to the same length.

The spoke on the right is trimmed so the square section at the ring aligns on the inside with the edge of the ring. The piece on the left is a bit too long, so the inner part of the square section is too far out from the hub. I filed some off of the hub end until it was the correct length.

With all the spokes the correct length it was time to glue them to the hub and the ring. Again, it was necessary to be careful that the ring, hub and spokes were not glued to the jig.

For this job I used Duco Cement. It makes a good bond between wood pieces and takes a bit longer than CA to set so the pieces can be repositioned as necessary. After the glue set the surface was sanded smooth.

Next the remaining "C" pieces were glued to the ring. I used Sig-Bond glue for this.

The "C" pieces must be positioned carefully to be centered on the rim pieces.

After the glue set the wheel was carefully lifted from the double sided tape. Then both sides were sanded with 150 grit paper to reduce the thickness of the "C pieces to about 0.012 inch (0.3 mm). Then they were finished with 220 grit sandpaper.

The resulting wheel looks pretty good! I put a layer of shellac on it, and may follow up with more to darken it a bit.

There are a few places when some of the char is still visible, and this probably should be filed off.

If I had a lathe I might have turned some knurls or rings on the spokes like on the Cape's wheel. But I wasn't going to attempt this using a motor tool and a file!

The original wheel had some brass parts around the hub. I am not going to try this at 1:48 scale.

Now I just need a pilot house to put it in!

-

FreekS reacted to gak1965 in RRS Discovery 1901 by gak1965 - 1:72 - First Scratch Build

FreekS reacted to gak1965 in RRS Discovery 1901 by gak1965 - 1:72 - First Scratch Build

Okay, another brief update. The outer hull is painted. It needs a bit of touch up, but otherwise is in pretty good shape.

I've subsequently started the deck. Annoyingly, the main deck needs to be 24.5 inches long, and I can primarily find 24 inch long lumber. So, the question is whether to do a proper, stepped set of planks or to find some alternative. Ultimately I remembered that the last couple of inches of the main deck are covered by a monkey poop and won't really be visible (as seen here):

So, bottom line is that I'm just going to join them all at the stern. It's not as neat as staggered joints, but it will be hidden, so, no matter. The forecastle is closed on the Discovery, so the deck only needs to extend a bit forward of the third bulkhead.

As always, thanks for looking in and the likes!

Regards,

George