-

Posts

528 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FifeModels

-

With some more progress made on the hull up to the point where top and bottom have met at both the bow and stern, I decided to work on the stern itself. I fitted the stern post and trimmed back the keel and after a few other modifications to shape/size everything fitted nicely. I planked the stern itself aside from two small area's at the very top where the upper planking hasn't been done yet. I planked the curved transom, or part of it, so I could get the hawse and tiller holes cut to shape.

-

Just re-read your question. The rubbing strakes should follow the top edge of the bulwarks, the same curve, except at the stern the main strake you will notice decreases it's gap and instead hugs the bend of the hull. Do your second planking first. For a start if you plank the rubbing strakes first they won't be raised above the surface of the hull quite as much as they should be, and second you will find when sanding down the hull after the second planking you may catch the rubbing strakes and damage the edges.

-

Mike, as requested. I've marked some key points on the photo. The two lighter blue lines the distance between the top and bottom of that line is 19mm. The darker blue line the distance is 18mm. 18mm along the length, I've taken the measurements from the strake that runs beneath the capping rail at the bow. (Yellow if using the admiralty colours). Keep in mind the difference in scales though mate. (I've not reduced the size of the photo so you can click on it for a closer view.)

-

Mike the position of my marker plank was dictated by many things, some of which unique from ship to ship. Firstly, at amidships I usually start at the same level as the utmost mid-deck, then it depends on how that deck slopes from amidships to stern and amidships to bow. Most of the time, not always, but most of the time keeping in-line with the mid-decks slope from bow to amidships to stern will result in the plank being straight if you look at the ship from the side. Sometimes depending on the type of hull however laying the plank like this will result in a slight curve upwards towards the bow/stern, and indeed on this one it does slope upward slightly at the bow and even more slightly at the stern, as you can see from the bow photo...however it looks straighter if you look from the side. What I tend to find and someone can correct me if I am wrong is that this plank can be laid with no tapering either end, allowing it to find it's own way for the most part. All that probably isn't very much help at all sorry.

-

Good afternoon. I've been working on a few different areas at the same time today. I've planked the transom and whilst waiting for that to dry I fitted the 4 piece keel in place. Back to the transom after trimming back and sanding smooth I marked the position of the rudder chain hawse and drilled them out, I also marked and cut the gap for the rudder itself. It's strange AL provided dimensions and position for the chain holes but gave no information on the size of the rudder gap, so I had to approximate it as best I could from the photos provided and the box art photographs. And finally, I added my two marker planks for the 2nd planking. This roughly follows the slope of the main deck as opposed to the curvature of the hull.

-

Sort of. And thanks. I did taper planks and bevel the edges to get a pretty smooth fit with the minimum of lateral twist...although not as much as should be done for the reason you pointed out, the thickness of the wood allows some margin so sand out the clinker and it's a base layer and won't be visible. If it was a single plank hull then yes the planks would have to be shaped as yes you would still be able to sand them down but they would be visible and wouldn't look as good.

-

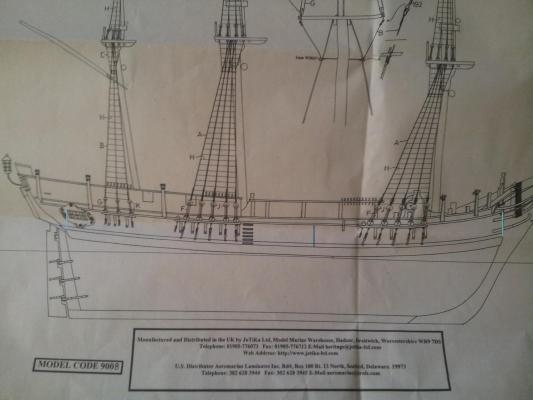

Sheets A, B, C, D, G and J all show the position of the strake at the bow, albeit a small section due to showing the cutaway side. Unfortunately those plans aren't at 1:1 scale but should be enough for you to approximate it pretty closely.

-

Look through your plan sheets. They should be at 1:1 scale so you can take the measurements from those to position the strakes.

-

No-ones fault. Just the nature of ply. The larger, or longer a single piece is, the more likely it is to warp. It's an unfortunate scenario that is generally unavoidable. Of course there are corrective measures but these can take days sometimes weeks. That's why I much prefer multi-part keels, less likely to occur as the parts are shorter, although it still happens. Don't worry too much, I don't think I have built and planked a keel/frame set yet where at least one frame was out of line, and to be honest once you get to the other end of the build unless it is a massive kink, only you will notice it. If it is any comfort, my Santa Maria had a warped keel right at the stern between the last frame and the end, worse still it was twisted on two axis! I was lucky as it was minor and I was able to pull it straight by way of the false deck. Doing a great job so far

- 265 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

Mike if you did decide in the future I am sure you must have a Home Bargains somewhere near you? If you don't and want to buy a job lot sometime, let me know and you can send me the money and I can go get it for you and post it up Also, I have found with it once you have opened a new tube, through the black lid away! It's as useful as a chocolate kettle! Instead, a map pin fits snugly in the in the nozel and makes an airtight seal, so the metal of the pin won't stick to the plastic of the nozel as there is no air to complete the chemical reaction. Even if you don't use it for planking this time, it has a range of other uses just within ship modelling.

-

Runny CA makes a mess...but you can buy it in differing thickness' from CMB...or use a gel...if you wanted to go down that route anyway.

-

Grand job Mike, be proud of that hull! Sod the second planking, just stain it walnut and varnish it job done! LOL no just kidding, although you'd probably be able to get away with it. Me personally I use Cyano for the second planking, mainly because they sell Locktite Superglue Gel near me for a £1 a tube, instead of £5 a time! The gell is much better as the thin veneer doesn't soak it up and it does give you a few second manouvering. If you're unsure though I'd stick with PVA, as once stuck...you can get it off but it can be a bit fiddly and damaging.

-

Thanks Capt.F I agree with you most of these kits allow very little or no margin for error...they expect everyone to be able to build as perfect as their modellers do. Although have to say...in their Santa Maria kit that I am building now, the studio model that was used to provide the photo's for the colour guide...well who ever was building it did a p**s poor job on the first planking! Makes me feel much better

-

Hiya Capt.F. Looking great so far. I'm glad I am not the only one who takes advantage of the thickness of planks allowing for sanding and not worry about the slight clinker effect It's comforting. Can I ask...how short was the supply of planking? I am going to be getting this kit later this year and want to know what I am letting myself in for...and whether I should think about ordering replacement wood at the same time as the kit itself?

-

They definately aren't the same kit, I can answer that with 100% certainty. There are quite visible differences. AL has two launches for example, Oc only has one. Oc has a more square sail right above the launches, (sorry I don't know the term), where as AL's sails are triangular. AL's version: http://www.artesanialatina.net/articulo.aspx?ref=22810&des=bounty-99-con-velas-cosidas OcCre's version: http://www.occre.com/model-ship/frigate-bounty.html Both from their own webpages. Danny thanks for the answer about the oddities with scale/dimensions, I was wondering why the numbers seemed back to front, but that makes sense now.

-

Hi again. After finishing the work above decks, it's time to start the planking. I won't go into too much detail nor post many updates until the first planking is finished as it's pretty repetative stuff. I started with a full length strake right below the pre-fab bulwarks, sloping upward slightly at the bow. Following that I filled in the gaps at the bow above that strake, then added another one below the first one. Then switched to the keel and fitted the garboard. The small triangular gap at the stern below the garboard I won't add these first planks, as when I add the veneer they would be much wider than the stern post/rudder, and sanding then thinner and tapering them would result in a in-out-in bump and would look just...wrong!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.