-

Posts

498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by fifthace

-

That all looks fine to me. And hey, you managed to get your port patterns down without bubbles at the bow like I did lol If it's any comfort...I hate planking. I find it the most dull repetitive slowest part of a build and seems to go on and on...especially as you sit back and think "yeh finished" ... then realise you have it all to do again lol

-

Hi Ian. Just to echo what David said, and to expand...depending on how anal you are, I wouldn't worry too much about the 1st planking. As long as you have a good smooth surface it doesn't really matter what it looks like...and to a certain extent, in the Vic's case the same applies to the 2nd planking. Everything below the waterline wont be seen once the coppering is done, so again as long as you get a nice smooth surface, you only really need to worry about the 2nd planking above the waterline. Keep going

- 191 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

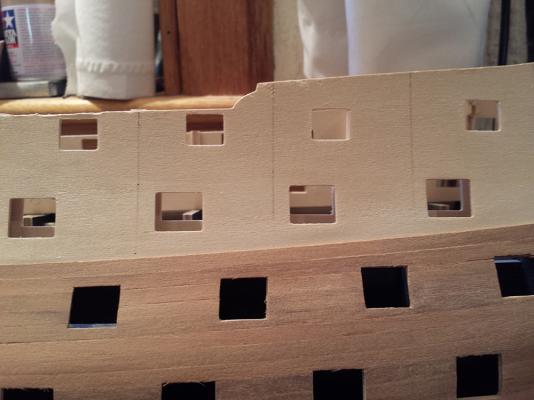

Fitting the inner bulwarks. Already fitted these once but removed them as they slipped during clamping and shifted horizontally. In hindsight probably just as well as they were a little too easy to remove, so clearly I was too conservative with glue. Refitted and allowing to dry. I'd have liked to plank planked the inner bulwarks off ship, but the nature of the lidless gun port lining made that impossible. Oh, anyone else having built this, did you happen to notice the 1x16mm wood for the lidless linings was very brittle/weak ?

-

Planking on this deck is complete. There were a few moments I wasn't sure how it was going to turn out, and being self critical it didn't turn out quite as well as I was hoping. Although I showed these pictures to my partner and the first thing she said was "it looks old" That makes it all worth while, as that was the look I was after, so I'll take it

-

Very quick update, not much to report. Decking progressing nicely. I think after this being the 5th deck I've planked using this method for simulating the caulking I am happy with it. It has the desired effect without being too obvious or too perfect. It's not perfect as above...but then neither are the real things. I'm still looking into a method of drilling the treenail holes in batches so they are mostly uniform. Something I may look into for the q/waist and poop deck(s)

-

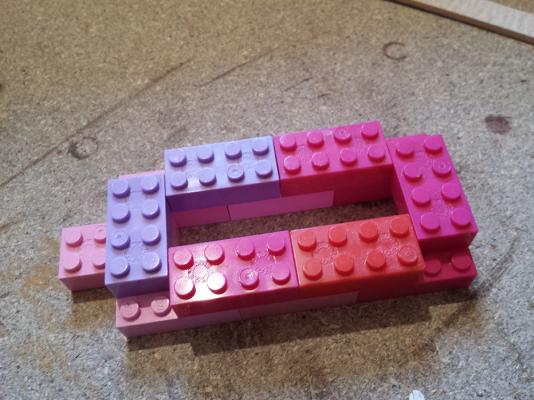

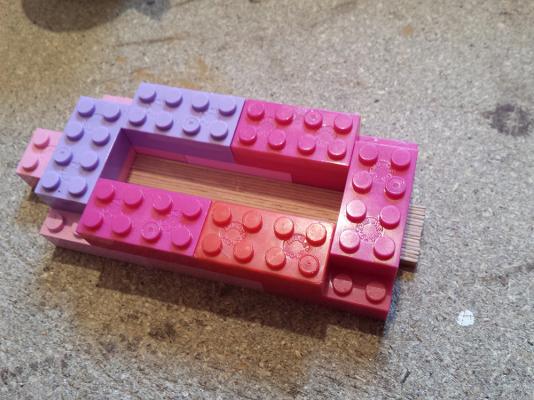

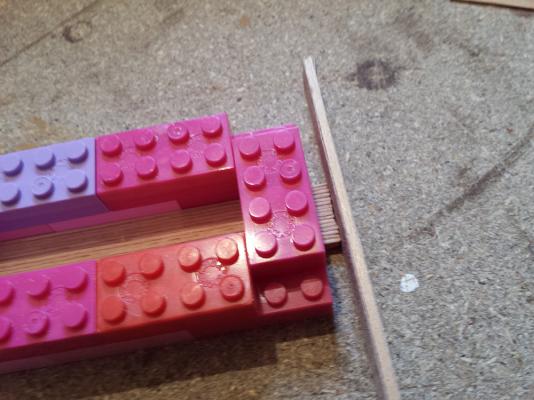

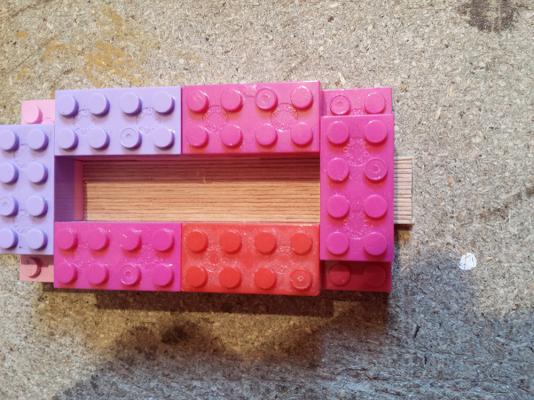

I decided to rethink my jig for preparing the deck planks. I wanted something that would allow me to get the correct length uniformly as well as smooth all the edges of the deck planks in bulk, or batches. I came up with a small block with a walnut frame open on one end. The frame is 1mm lower than the width of the planks. I placed copper tiles on the block beneath the open end. The length of the slot for the planks included the copper tiles is exactly 85mm: This means I can place groups of roughly-cut-to-length planks edgeways into the slot, sand the edges of them all uniformly, as well as sand the ends so that they are all the same length. Then remove, flip, insert reversed and repeat. The copper tiles prevent the length being inadvertently shortened over time due to sanding. I can fit 22 planks in this each time, which fit snugly and require slight pressure to slide them all in. This helps to ensure they stay in place during sanding. I was able to over the space of about 2 or 3 hours quickly and accurately prepare about 300 planks. And the result on ship:

-

Thanks Jerry. I'm glad it's not just me then. Currently I am marking the position of the decking on the false deck and pre-cutting the planks. I've roughly worked out I will need around 360-ish. I made myself a wee jog to aid me keeping all the planks the same length, in the absence of a more precise cutting tool. Made of lego. (Has so many uses that stuff does).

-

Thanks Kevin. I see Rich had to do the same as well. It's always more comforting knowing other people had the same issue. That upper gun deck though! Really have to give it some bend to get it in place I've not been able to properly dry fit it as I don't think I'd get it back out again if I did. Bang goes me planking it off ship

-

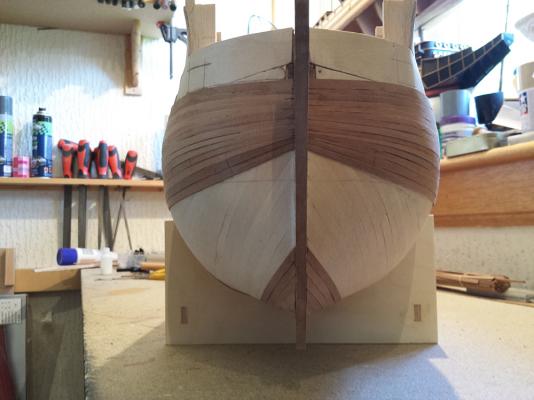

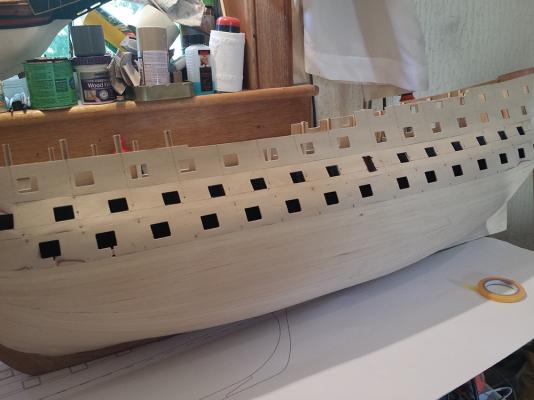

Good evening folks First part of the second planking is finished, sanded, gunports trimmed etc etc, but I've encountered an...issue. First, pics of the planking progress: I've fitted the deck camber beams, that was ok: When dry fitting the deck and the inner bulwark patterns, they fit perfectly on the horizontal, but are several mm too high. I've gone back through my steps and the outer patterns were fitted correctly...ok maybe not perfectly but they were in the right place. So unless I've missed something, or the inner templates have been cut incorrectly, or am completely missing the point...there is a problem. Both sides are the same: Any ideas?

-

Good day folks. I've finally finished the lower planking. Glad it's done with as it was starting to grate on me. For some reason it didn't go as well as the first planking, especially the second half of it. Thankfully none of this will be seen once the coppering has been done. The hull looks glossy as it's wet. I brushed over 50/50 watered down PVA to help seal any planks that worked loose, which were a few. Reason being it makes sanding smooth impossible if you have sections of plank that have popped up, as they just spring beneath sanding. All the PVA that has settled on the surface will get sanded off, but the planks will be sealed underneath. I took a small break from the planking to start tackling another problem. A bug bear of mine with kits. Those pre-fab parts that fit under the q-galls never, well, fit! Not for me at least. They are either always too big or too small. In this case, too small. And to be honest the detailing wasn't that great on them anyway. So I added some balsa blocks and sanded to shape and size. I will finish shaping and add the details later on in the build.

-

Thanks Kevin. A lathe will have to wait for now...I simply have no where to put it. Dont know how yet I am going to complete this Vic...she is longer than my current workbench I've been looking at Gil's methods. The 1 on page 3 is interesting...not sure if I read it wrong, (and haven't read/checked the plans yet), but it seems the taper he made on the lower foremast is only on the side, so are they actually not round then?

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

Jerry not at the moment. I have a 4 by 6 corner of our bedroom at the moment. Early into next year though I am having a large section at the top of my garden decked and a purpose built workshop built on it so I can start to invest in a few larger power tools. My method for tapering is I simply fit the mast into a low powered drill and use sandpaper and taper that way...but it leads to rather warm hands

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

I keep looking at your last photo and the way the masts are reminds me so much of how she looked back in 2011 in Portsmouth... Can I ask, how you tapered the masts? I am asking because I have no lathe or other tools to be able to taper easily. All I have is a david plane that I rarely use as when I do I end up taking far too much off

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

awww Kevin don't worry I will slow right down once I hit the gun port lining and then again the ratlines. Two of my hates about this hobby, sooooooo repetitive In all seriousness I doubt I will complete this in one go. I have several projects on the go at once and I swap among them to keep everything fresh. Currently I have the Soveriegn to finish (as soon as I get the remaining issues), a smaller Vic thats actually behind this one now, and Hermioné. I think you're safe. I must drop in on your log though haven't had a look for a few days.

-

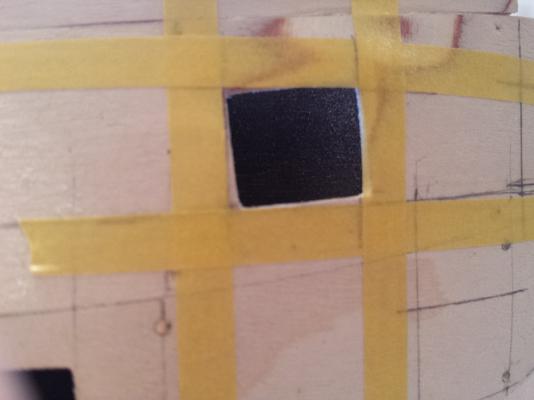

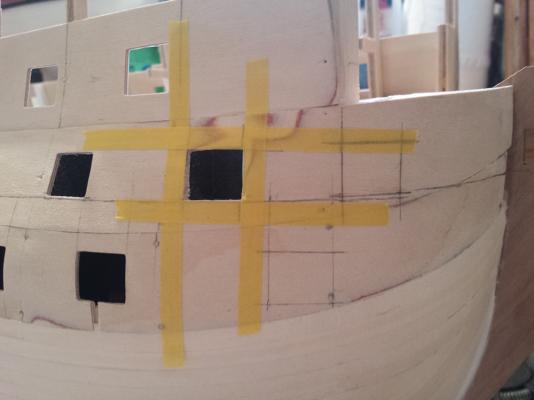

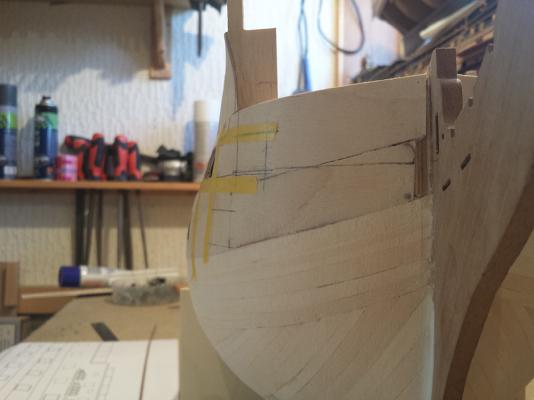

I've marked the forward ports now, well half of them anyway. I've paused to show you this. Before I could mark them, as I would be locating them based on the position of the foremost pre cut port, I needed to correct that port. It got warped due to that bubbling I had when fixing the template patterns. I was expecting to have to correct it. It wasn't too much out of line, the top left corner was correct, but the entire port was slanting upwards from that point. Using the plans I marked it's correct position in pencil and then with masking tape, and cut the excess away. This will leave an odd shape on one side, however I will correct this with the 2nd planking. Then I was able to mark the other two ports into position. I should also be able to correct my wales, as I was marking from slightly too high...doesn't explain why they appear to slope down...am sure it's had an affect though

-

I've been marking the starting point for the 2nd planking...in this case, the upper edge of the middle wale. Thankfully it seems to confirm that I did get everything in the right place, as it follows a lovely up-down-up curve...well, except at the front. Going by the plan, the section from the 2nd gunport (1st in the photo as the actual 1st isn't part of the template...confused?) when veiwed from the side seems ok, but when veiwed from the bow, looks like it's going down towards the stem. It could be an optical illusion due to the edge of the beakhead sloping upwards...what do you guys think ? (final photo)

-

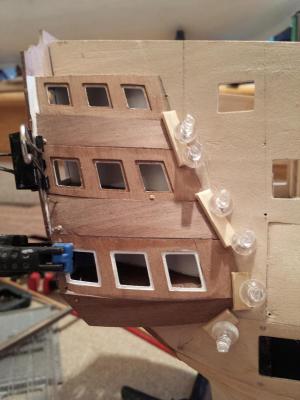

I decided to fit the q-gal fascia's now after all. The second planking would allow me to hide any imperfections in where they meet the side of the hull. Although, unlike Kevin's build, I found this section quite cumbersome to do. I had several attempts at dry fitting in place before I got a fit I was happy with. Despite the instructions saying to glaze the inner side before fitting, I decided against it. It would create a noticeable gap between glass and the PE frames. So I will cut to shape the glazing and fit to the back of the PE frames and then fit them in place on the fascia's. Once I was happy with the fit, I glued and pinned in place. Once dry, applied filler and sanded smooth. Currently I am repeating with the other side.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.