-

Posts

1,557 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mike Y

-

So happy to see an update from you! Interesting contrast between the beefy beams and slim deck planks. Do you know what was behind that practice? Availability of wood? It probably triples the number of seams that need to be caulked, maintained, can leak, etc... Happy New Year, let the new one be trouble-free and full of build progress!

-

Recommended First Machine

Mike Y replied to vvvjames's topic in Modeling tools and Workshop Equipment

One more vote for the disk sander (model TG 125/E). It is so valuable that it is the only tool that I keep permanently on the table. Regardless if you build from a kit or scratch or in between. And Ian has a good point, that miniature Veritas block plane is another go-to tool involved in most of the operations -

A very cheap and simple, but effective MF70 upgrade is to install an axial bearing for the Z-axis. It would be much smoother operation afterwards, especially if you need to crank a lot when using it like a drill press The bearings it needs are standard dimension, I bought the 6x12x4.5 size. Installation does not require any modifications, just disassemble the z-axis and add them between the rod and the wheel. Google "MF70 axial bearing upgrade" to find step-by-step guide. Installing them for other axises is also possible, but a bit more involved and less necessary, the table is smooth enough if lubed and tuned correctly.

-

Tool to Take Measurement Inside of a Hull

Mike Y replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

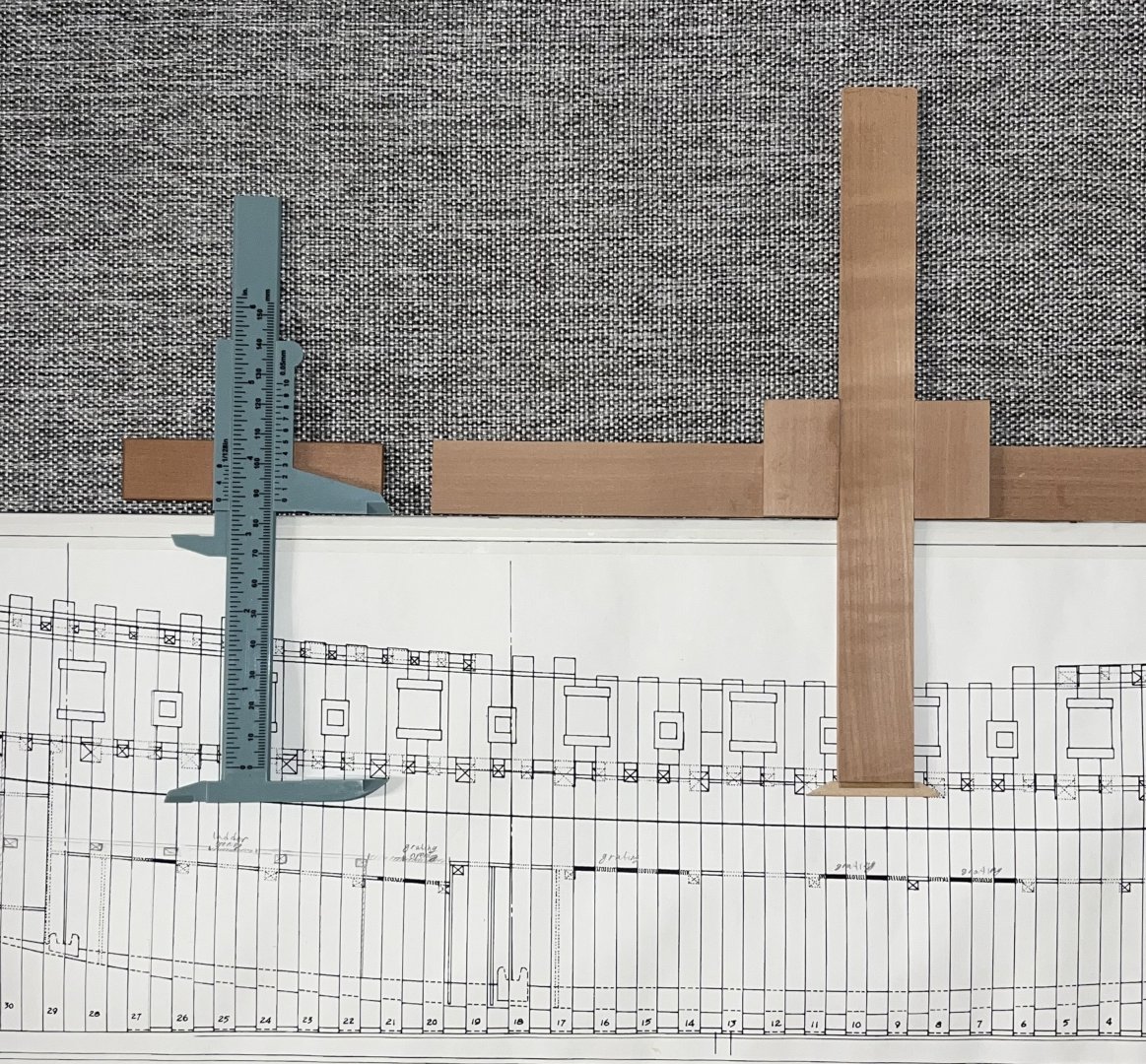

I assume you mean the vertical measurements? Then it is easier to think of it as a tool to transfer dimensions from the side plan to the hull, rather than a measurement tool. You would need some kind of a sliding gantry with a fixed height (Hahn method makes that easy since you do not need a gantry, the jig is playing its role. But you will see all sorts of aluminum profile or wooden constructions in other logs!) From that gantry you can clamp a vertical strip with pointy tip. Then I glued the side plan to some backing material, cut with an offset to match the gantry / base jig thickness. Then you can transfer dimensions from plan to model without any calculations - but by putting that cross-slide directly on the plan, locking in position and then transferring to the model: My first version was a friction fit one, just two perpendicular sticks, can't really make it any simpler: The second version was slightly fancier, but I built it because I had a loong pause and forgot that I have the simple contraption They are functionally identical. -

Fund raising

Mike Y replied to Russ2025's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Had the same problem, paypal was rejecting my card that works fine in dozens of other shops and services. Or maybe my bank already considers paypal a method of choice of scammers and fraudsters... The only method that worked was a bank transfer to paypal account and then a direct transfer to NRG (not using the donation link). Maybe that would work for you? It might imply extra fees and FX conversions, but better than nothing. Contact https://modelshipworld.com/profile/19284-ferretmary1/ to get an email for the direct transfer without the donation box. -

How serious do you get about dust protection

Mike Y replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

To illustrate the points from my previous post - recorded a video that shows the extent of the efficiency of this small purifier. Even large and visible particles are picked up easily, so hopefully tiny invisible ones follow even better You can also judge the noise - you can't really hear it, especially behind the dremel Sorry, no more updates on this, I promise! -

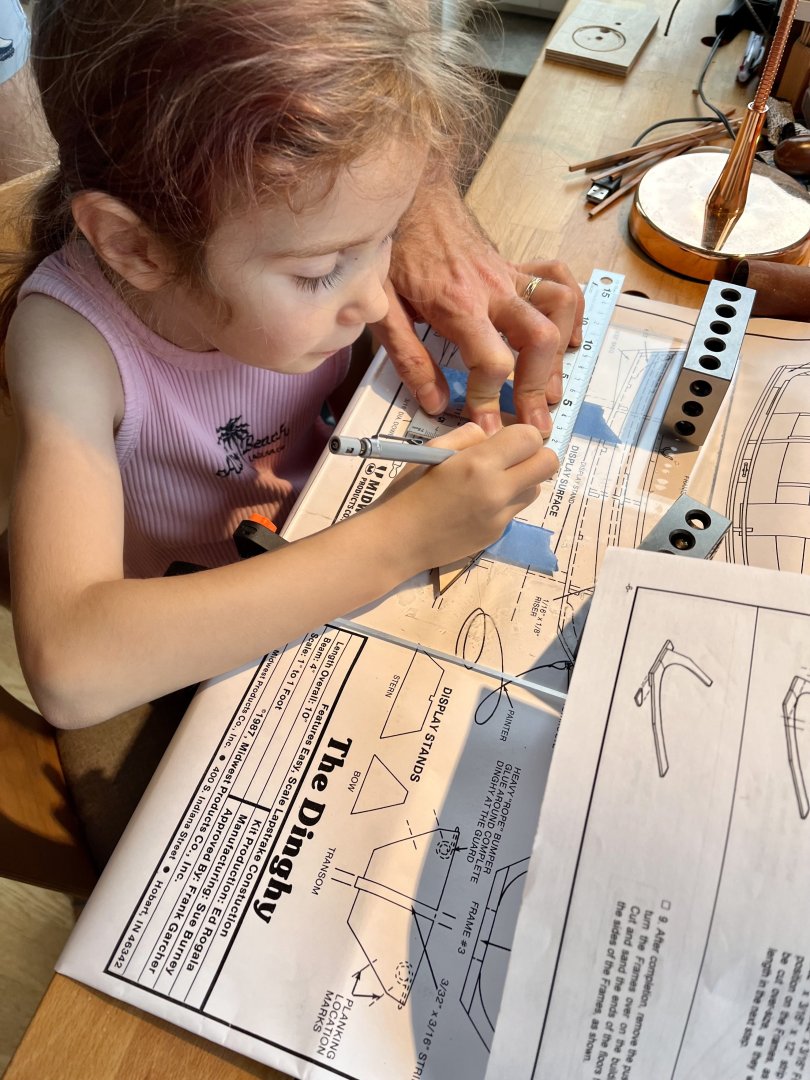

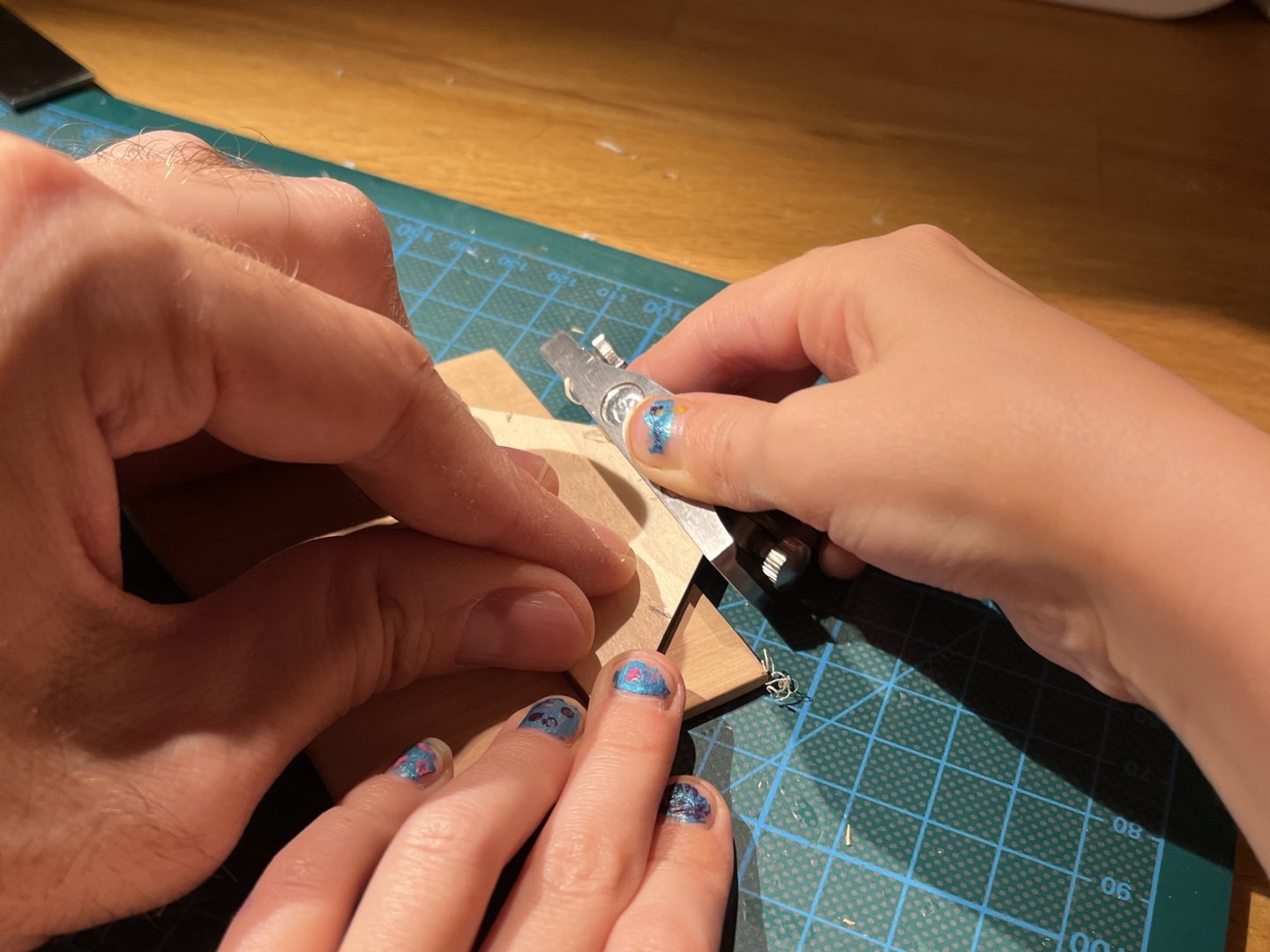

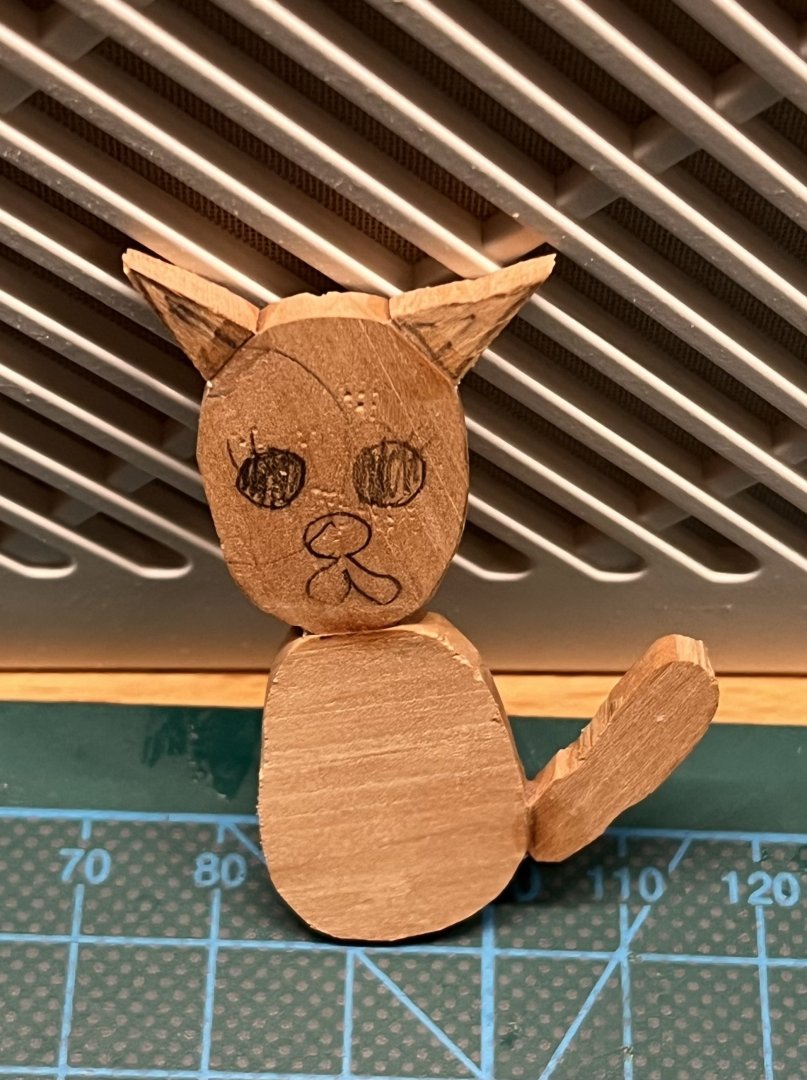

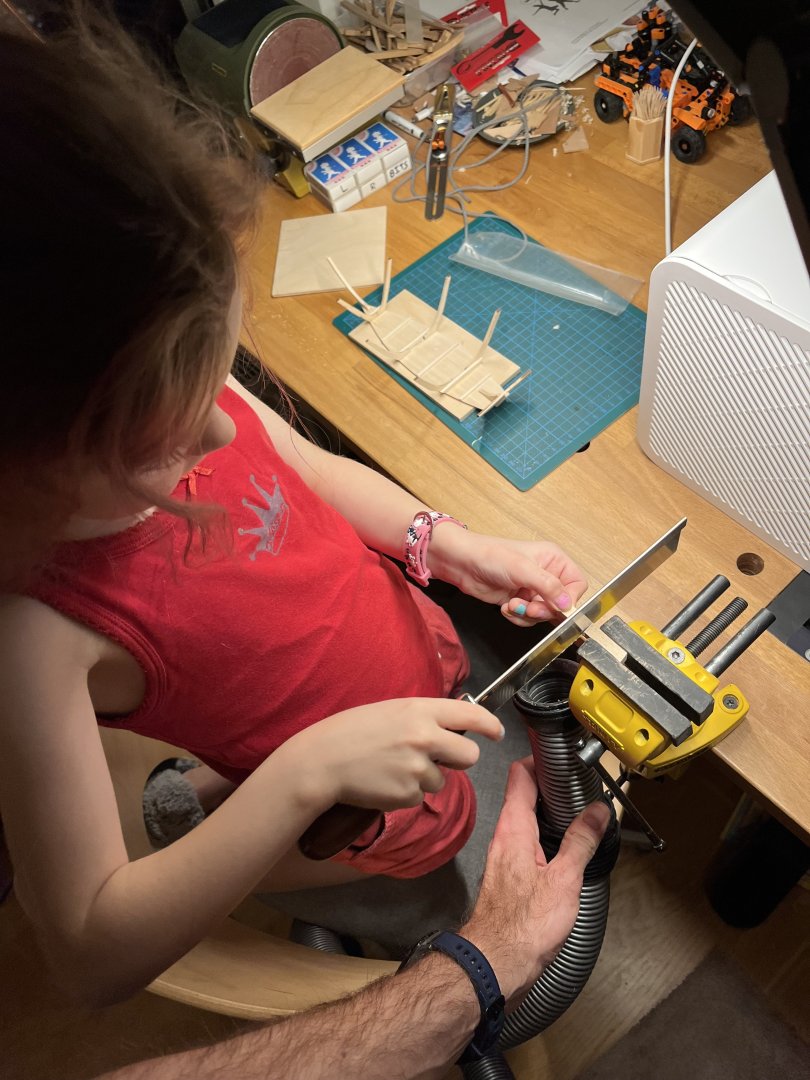

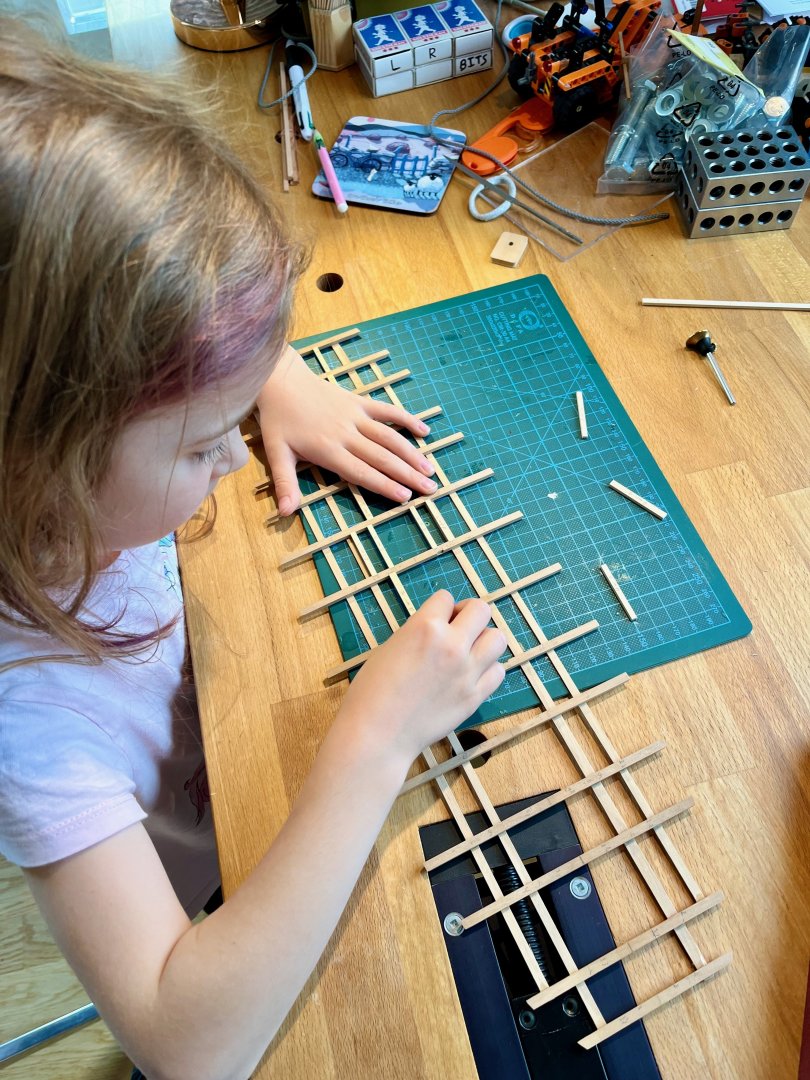

I started with both of my daughters around the age of 6 (see the Polotsk build in my signature, the youngest does not have a build log yet). It may sound young, but at that age they usually have basic precision required. Of course the motivation is different, they saw me modelling and wanted to try that too, to a large extent as a together-time, as opposed to going into the hobby purely for the sake of hobby. They were never interested in getting the final result, but wanted to try the process. Sanding wood, shaping wood - all of that was a learning curve and a joy. It is very different with plastic and not sure fiddling with plastic glue and tiny parts is enjoyable. Do not expect that the model would be completed, it's too much of a stretch. And by the age of 10-12 they have got a lot of other hobbies, so might be too late Expect that they would never finish the model, and by that age - would stop caring about finishing, but would hopefully cherish the memories you had together. Modelling for them is just an excuse to try all these new skills and spend time with their dad, while feeling a joy of building something more complex than a Lego. Surprisingly the type of a ship does not really matter, as long as it is a fairly straightforward kit where you just cut pieces, glue them together, etc. But it is really beneficial to have a kit with pre-splined planks that would fit together nicely. Skill-wise expect to teach them the very basics, that we, adults, do not even think about. Keeping the knife straight (yes, they can already use it carefuly), moving file straight, how to hold a piece of sandpaper between your fingers, how to draw a pencil line on wood, etc etc. And prepare some scrap to practice, of course. Some tools are off-limits though - no table saw, very careful with disc sander. Dremel is fine, but watch out for hair and sleeves. Band saw can be introduced a bit later. Introduce dust and eye protection for certain operations from day one, for them it is very natural and not weird if they see you do it as well. Prepare for practicing every new skill on scrap pieces, for kids to sidetrack to "side projects" like building random stuff out of cutoffs and similar foolery. It might be frustrating, but again - the journey is the goal, not the destination. Of course it is all very anecdotal and your experiences may vary, just sharing mine. Do not wait until they are pre-teens, do not start with plastic, just dive right into the wood if that is what they want. There is nothing extremely difficult in cutting and gluing wood pieces for elementary school kids. Just need supervision and patience. Some teaser pics, she has just turned 6.

-

How serious do you get about dust protection

Mike Y replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

If you put it close to the object (close enough to not be in a way of your tools and files) - with the right light angle you can visibly see how fairly large dust particles are immediately sucked by the stable airflow into the filter, away from you. I assume that the much more dangerous fine particles (the ones not visible with the naked eye) are following the flow even better It's not like the vaccuum hose sucking from one spot, but it creates a continuous movement of air towards the filter from a much wider area. So yes, it is not very powerful at all, but by putting it next to the sanded object you end up with fairly good efficiency. When experimenting you will see that the distance is crucial. Move it away - and you no longer capture particles at the source, but start filtering the "air in the room", needing large fans with much larger surface area and airflow. And it is also very quiet, so you will run it for hours, and not turn off immediately (any tool is better than the tool turned off ). You would not sneak away to sand things quietly, avoiding a loud dust collector to not wake someone up. It would be quite useless for general woodworking or sanding large surfaces - since you would no longer be able to place it close enough. But perfect for our needs I think (sanding a small part by hand or in a vise, with a part located close to the filter). Remember that it is just a replacement for a vaccuum hose, not a magic tool that solves all dust issues. This is what it replaced for me - a fiddly hose that I always need to somehow place as close to the vise as possible, it falls off, bumps around, and is less efficient on such distance, since it creates a very local suction zone, rather than a steady airflow away from me. Ofc the vaccuum is still used with power tools (table saw, disc sander, mill, etc) - anything where the dust source is fixed in place with a way to get the hose very close to the source. I still wear a respirator mask when sanding - when working close to a part with an optivisor on you can inhale dust straight from the source. None of the dust protective measures are 100% effective on their own, it is all about multi-step reduction and reducing percentages. The mask would also not be working well if you are sitting for hours in a cloud of fine dust, the vast majority of the dust must be removed away from you before it can spread around. This compact purifier is taking that role, while the mask is preventing you from breathing it in too easily. Masks are also sensitive to the proper fit, not really compatible with beards, etc. -

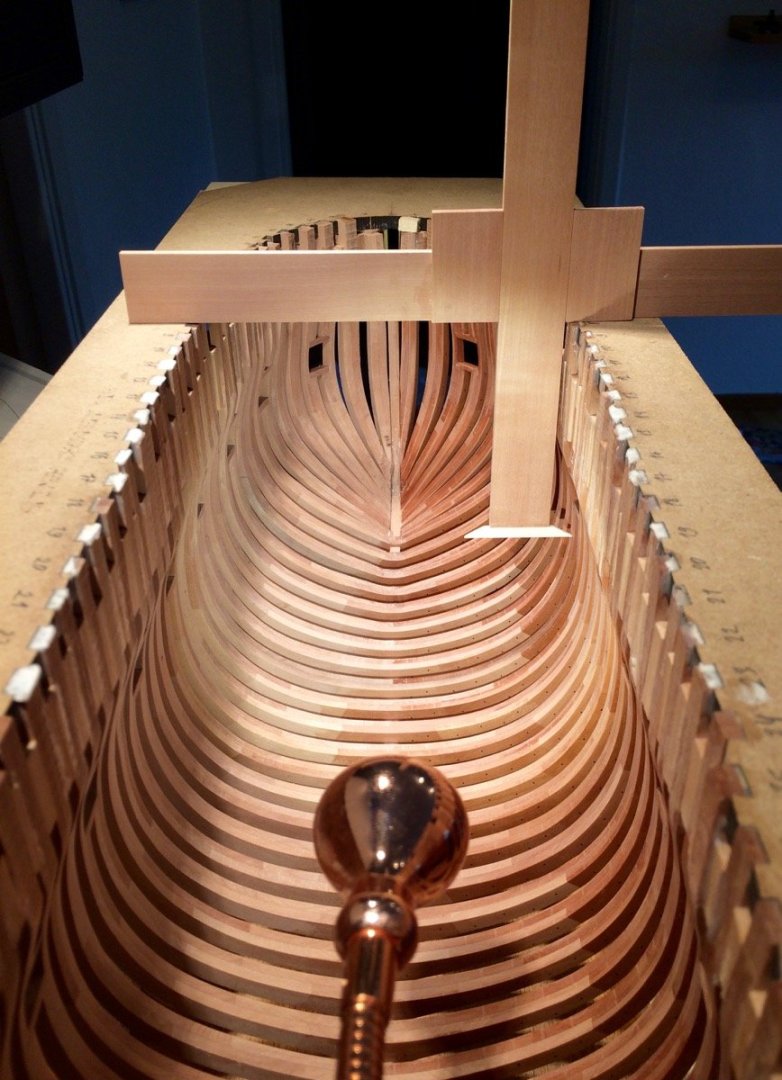

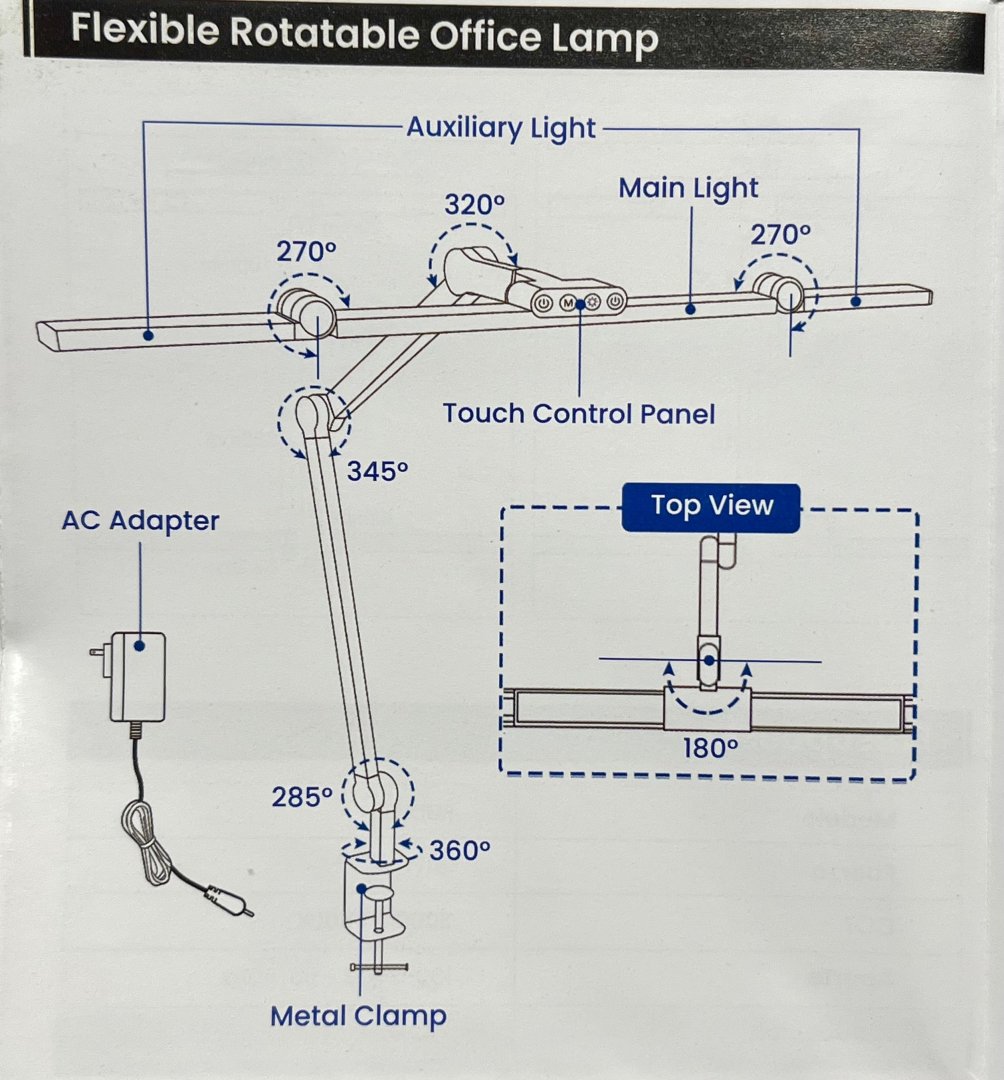

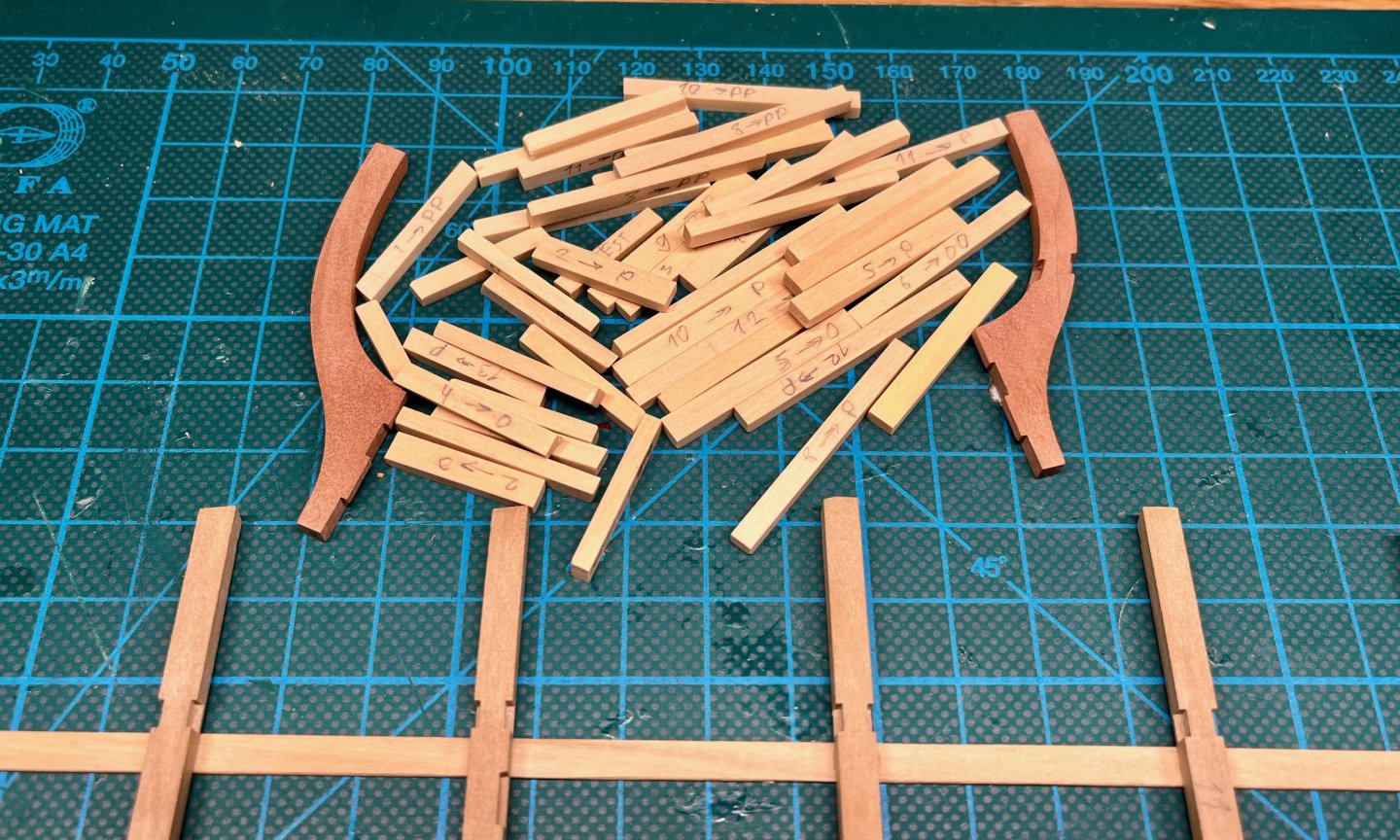

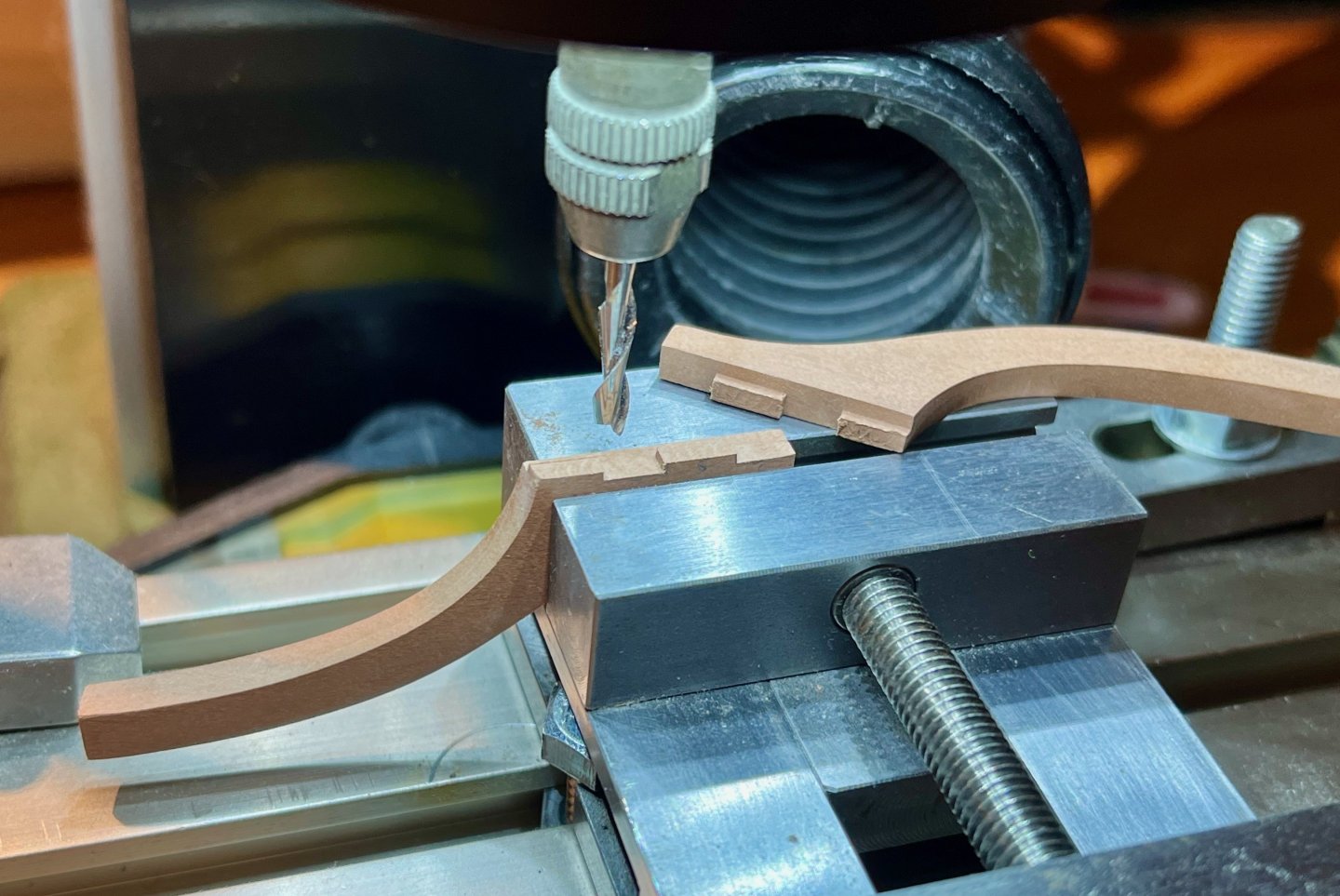

Beam arms Beautiful piece of the deck structure, was waiting for this moment for a while! Tried to use my fancy Vallorbe files, but the easiest way to shape these was a coarse sanding stick followed by a quick pass with finer grit. Then scraping to flatten the edge - and you get a fine finish with very little effort. Just need to be mindful of grain direction to not scrape against the grain Joints are milled, of course. That kind of precision work is where a mill really shines! Speaking of milling - I added a crudely made light into my Proxxon MF70. It is based on strange 3d model that I found online, trimmed off all the strange bits and glued in a cheap USB-powered LED strip, cut into short pieces and soldered with dodgy cuts of solid wire. It works, excellent value for money! Can definitely recommend to spend time on making your own, one of these "I should have done that sooner" moments. There is nothing off the shelf that you can buy for MF70, only some dim LED ring on ebay for way too much money. In other LED updates - got a lamp similar to the one recommended by Chuck (amazon/aliexpress, 50 USD, likely same manufacturer, but smaller size). It is awesome! Angled "ears" allow you to illuminate the piece from multiple angles, which is very handy when carving notches. The light quality (colours, flickering) is very good in my unscientific tests, and makes for a good photo light. The adjustable arm is solid (joints not too tight, not too loose, very elegant), and it is not an eyesore. A lot of adjustability and tilting angles. More than enough brightness, and the adjustable colour temperature is handy. The only downside is that the touch controls are facing forward, so I touch them by accident way too often The arms are slightly curved to follow the deck shape. I over-curved them at first, but luckily had enough margin to smoothen them with some battens. The resulting curve is very gentle: And here they finally glued in. Actually the first part of the deck that is now permanently glued in place! I am avoiding the final glueup as much as possible, feels much better when everything is dry fit Now I have a pile of carlings ready for installation And here they are all in place! Notches on the exposed side are left empty to avoid obstructing the view. I might put some carlings into them later. They needed more care than the non-empty notches, since you want all notch surfaces to look smooth and pretty, no chance to cover them with a carling later on. So I was cutting a smaller notch and then make a few final cuts once it is done, cutting off any tear-out. That concludes the carling phase, next in line are the lodging/hanging knees and ledges!

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

It's incredible what a bit of sanding can do! If only you could have that magic wand in other areas, not just woodworking Very nicely done, waiting in suspense for the post-finish photos

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

How serious do you get about dust protection

Mike Y replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

Discovered a very neat solution for sanding dust that is not coming from a particular tool (e.g. manual sanding). I work in a living room, so putting any workshop dust filter on a ceiling is not an option. But IKEA has a purifier UPPÅTVIND of just the right size - you can put it right on the table, capturing dust very close to the source. Impressively quiet (55db) even on the max speed (with a flow rate of 55 CFM), has a decent filter (EPA 12 class) and is very cheap (35 USD in Sweden, 50 in US. Filters are 5 and 15 USD respectively). Making a DYI version would cost many times more, and there is nothing in the market in that form factor. Proxxon ASA is mysterious, haven't seen one in the wild, and it is 4 times more expensive. Now I always have it on when modelling, just in case. It is that quiet, that you do not even think about it - just turn it on max for hours, you might even forget to turn it off afterwards -

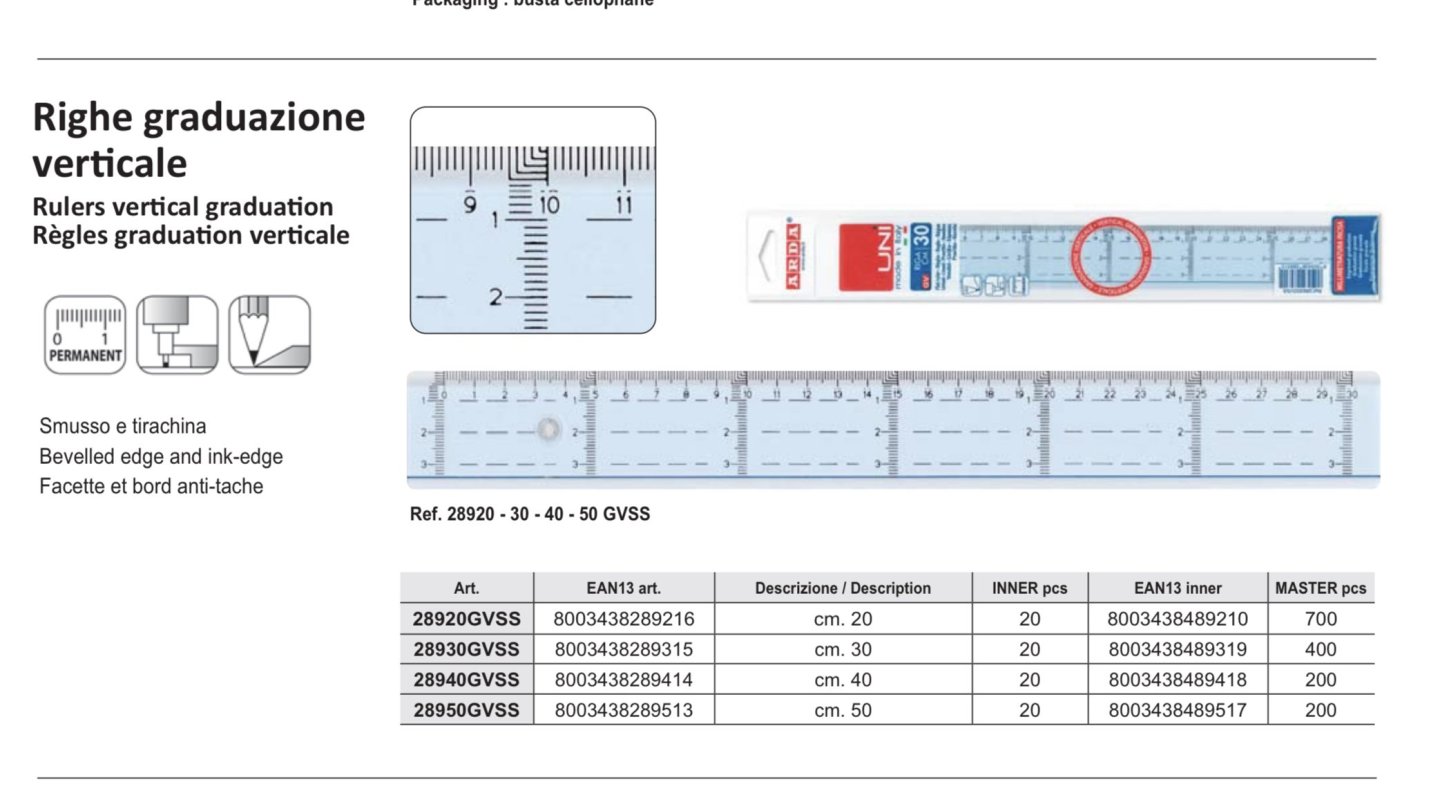

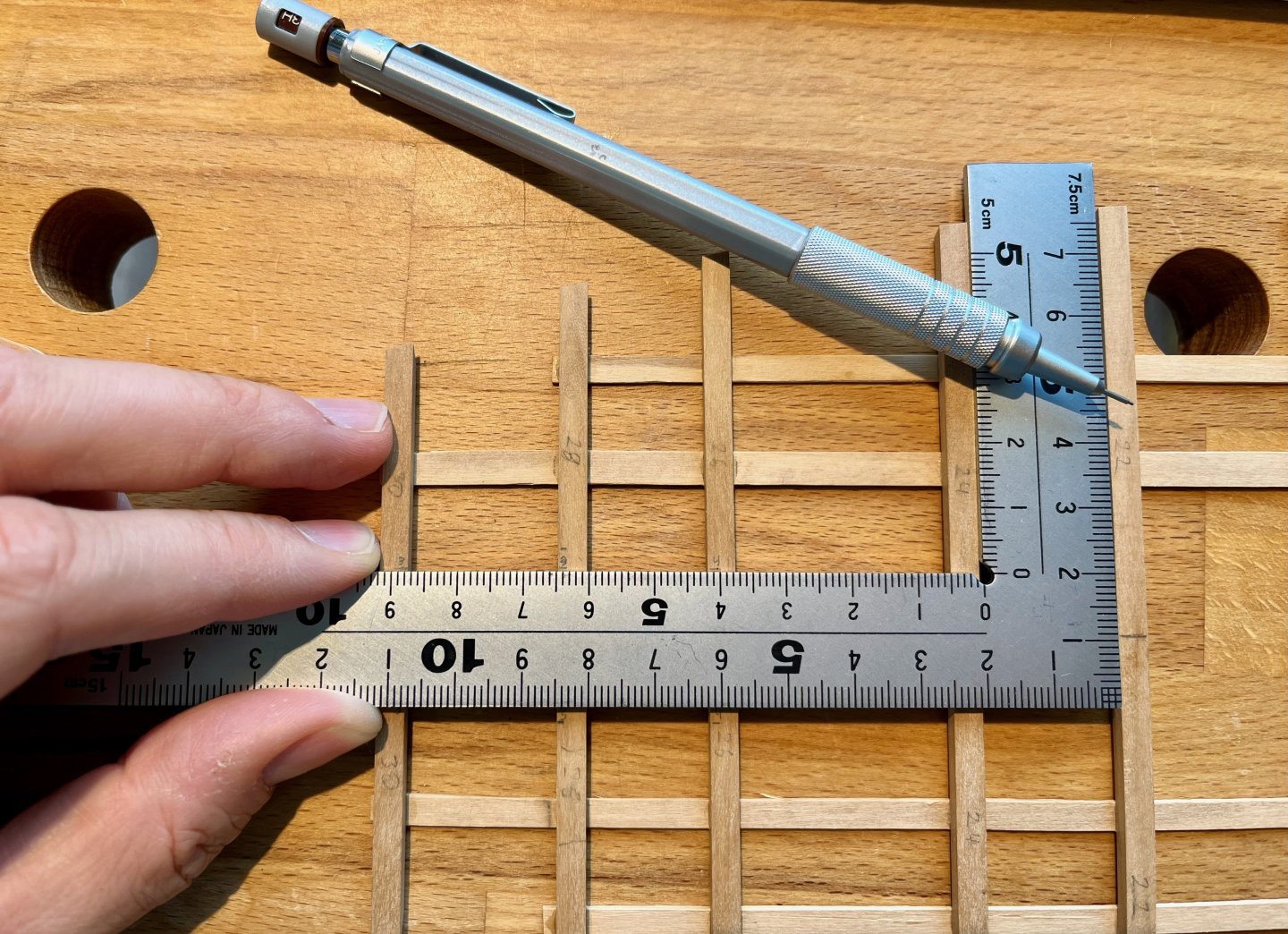

I got it in a local craft shop and had no idea it is somehow rare. Can’t find it on Amazon, but it is an Arda brand. It is an Italian company, so doubt they make an imperial version. Here is their catalogue, see page 32. I mostly use the 30cm version, but it depends on the scale you are working in. https://www.arda.it/cataloghi/2025/ARDA - DISEGNO 2025.pdf But I found alternatives! Search for the ”graph ruler plastic” and you will find some others with the same idea - graduated in both X and Y axis. Maybe Druxey can shed some light on the intended usage of such rulers in the graphic / drafting world 😊

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

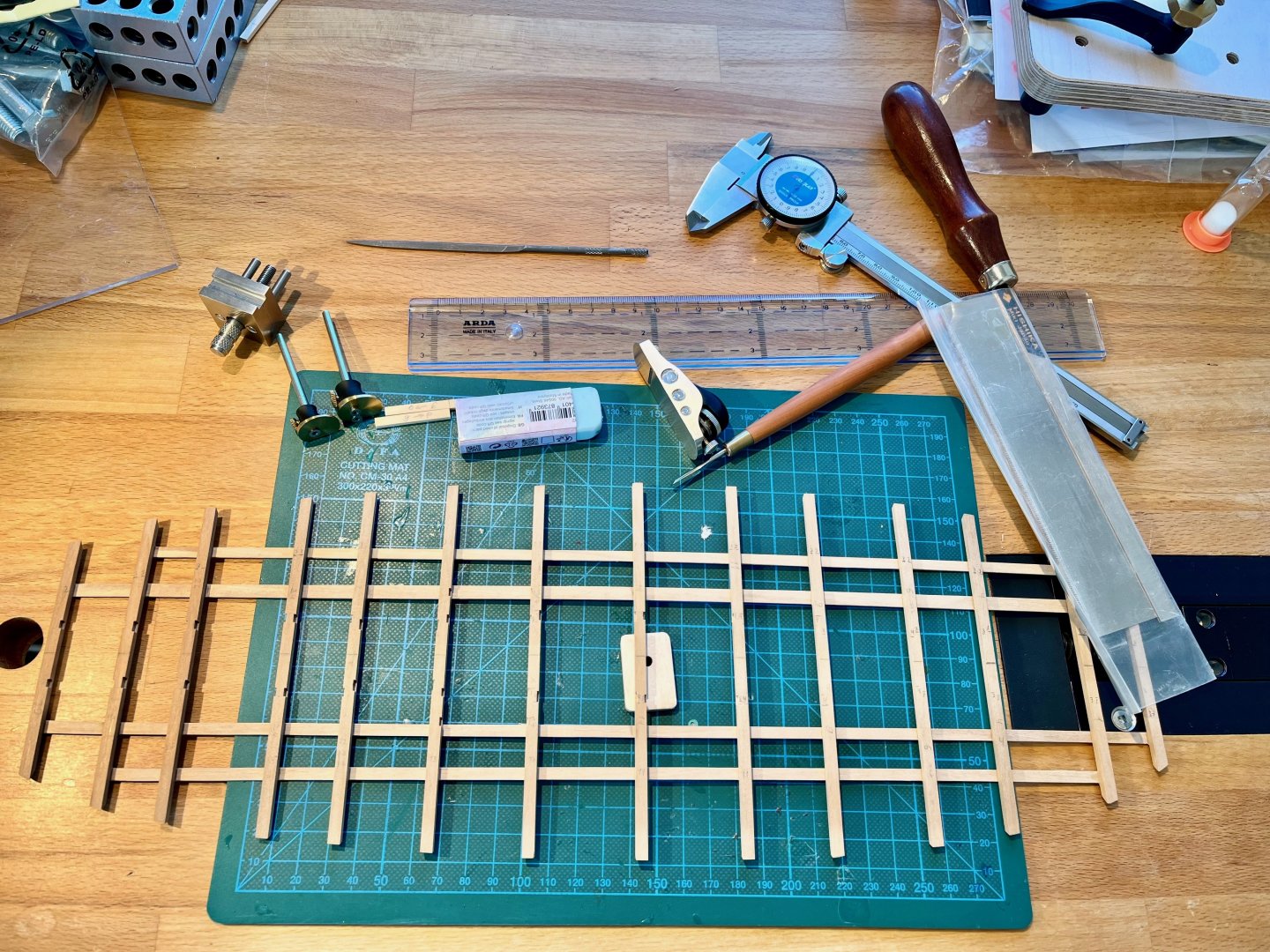

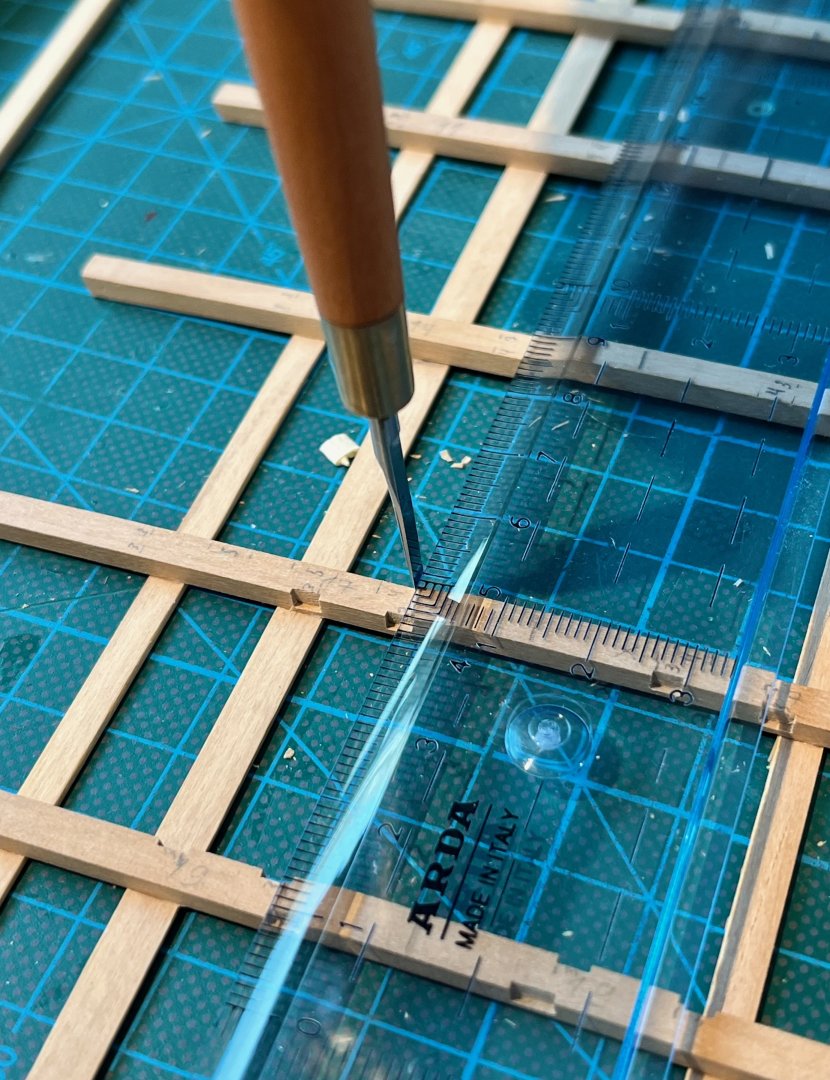

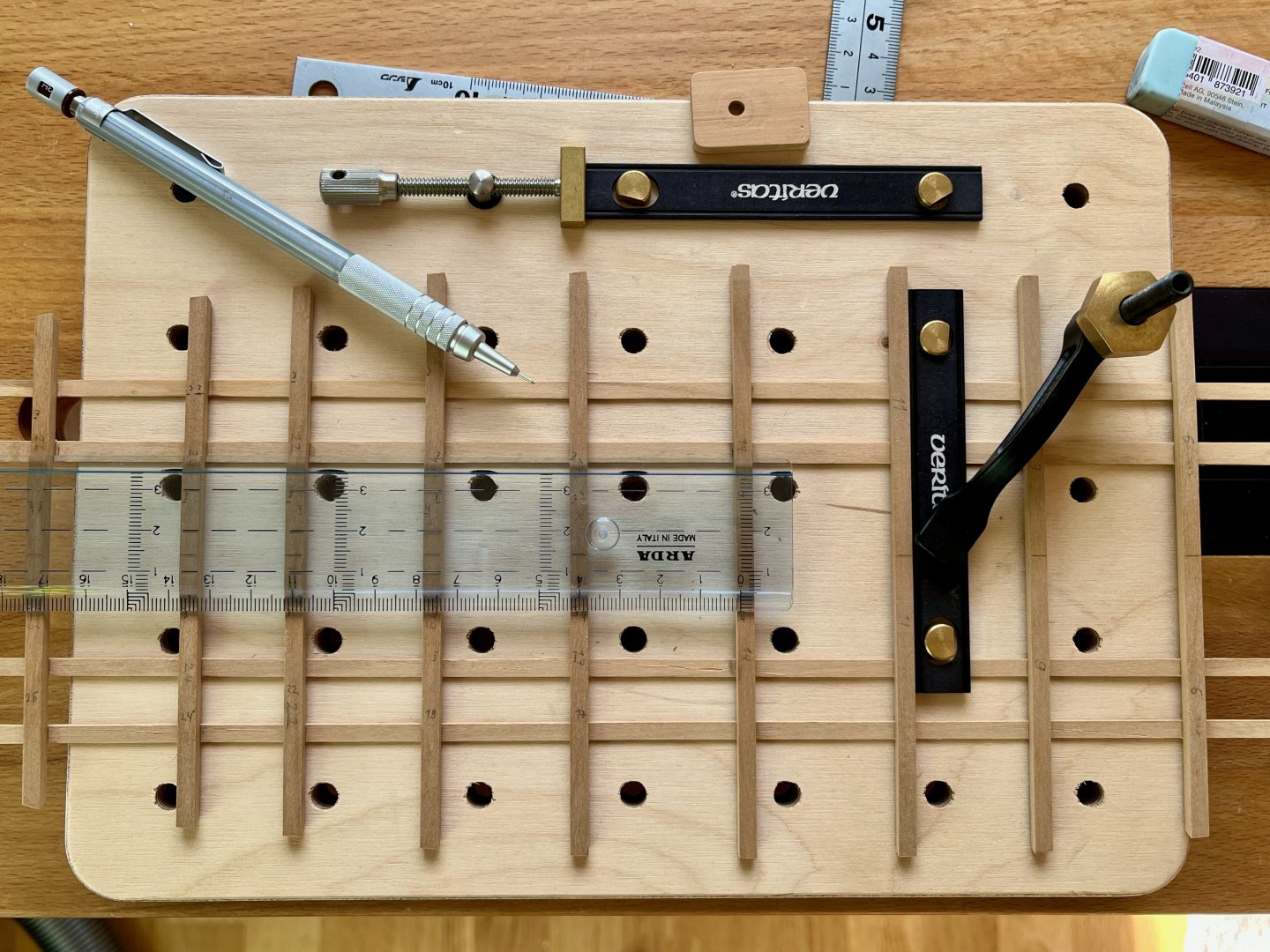

Framing the deck - continued Assembling the deck as one piece off the model is really comfortable, I am blessed to have a hull shape without an extreme tumblehome First I tried to mark up the layout using the a square. Unfortunately not all beams are perfectly perpendicular, not to a visible degree, but enough to make that method unusable. After some experiments I settled on this setup: The deck is clamped in place and an unusual ruler is used to mark up relative to the centerline. That ruler has graduations in two axises, with notches following the 1, 2 and 3cm from the edge. That makes it ideal for the task - "these two notches should be 18mm from the centerline", while the ruler makes sure your centerline is not skewed. Invaluable! I got it in an arts & craft shop, not sure if there is a special name for that kind of a ruler. Suddenly you need quite a lot of precision. Even a 0.3mm pencil feels too thick, and you need to account for the line thickness. In the end I only used pencil marks as a rough guide. The final markup is done with a chisel with its back resting against the ruler: Make sure to only mark one side of the notch, "the reference side". The other side can be fine tuned to fit, avoiding an accidental skewing by adjusting the notch width from both ends. While cutting the carlings I used a new toy - a tiny vice is square and strong enough for such holding, feels very convenient for working on tiny pieces! Can recommend: The whole process is very therapeutic and is exactly what I needed. The "thinking" part is over, now it's just making tiny wooden things and cutting notches, over and over. I can sneak in a 30min session here and there, cut a few notches every day and keep progressing! Here are all the tools that I need for a single session, keeping them close to reduce the setup time Mini marking gauges are set up in advance, one for the depth and one for the height. My youngest enjoyed this wooden puzzle, asking me to dry fit the deck over and over again And yes, she is starting her own first build (MS Midwest Dinghy) as we speak! The build log might follow. Intermediary result so far, like the contrast of the fresh wood! Only dry fit and no sanding. Woke up in the middle of the night - how would I remove the deck if hanging knees are installed? They are notched in deck clamps, so I can't lift it or turn it sideways. And installing them later is not possible since they sit between a beam and a lodging knee. In the end I will be saved by omitting the hanging knees on the open side of the hull (left on this photo). But if I would have built a symmetrical hull with both knees on both sides - then I need to somehow perfectly fit everything off the model, assemble it and then sand the deck on the model, without scratching the hull? The magic of sanding would barely be available then… That sounds very complicated. A lot of build logs just omit that problem, going directly to a fantastic finished result! Now I am very curious 🤓 Will go silent for a couple of months, the task is repetitive and I just need to finish the rest of the carlings, ledges and knees.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Fantastic and long awaited news! Really hope it would work out, getting in line for a couple of machines Pardon for the provocative question - but do we know who is taking over and what kind of quality standards to expect? Is it licensed to some external company that would produce the machines following the existing design, or is it someone "inhouse" taking over the manufacturing with Donna overseeing the quality?

-

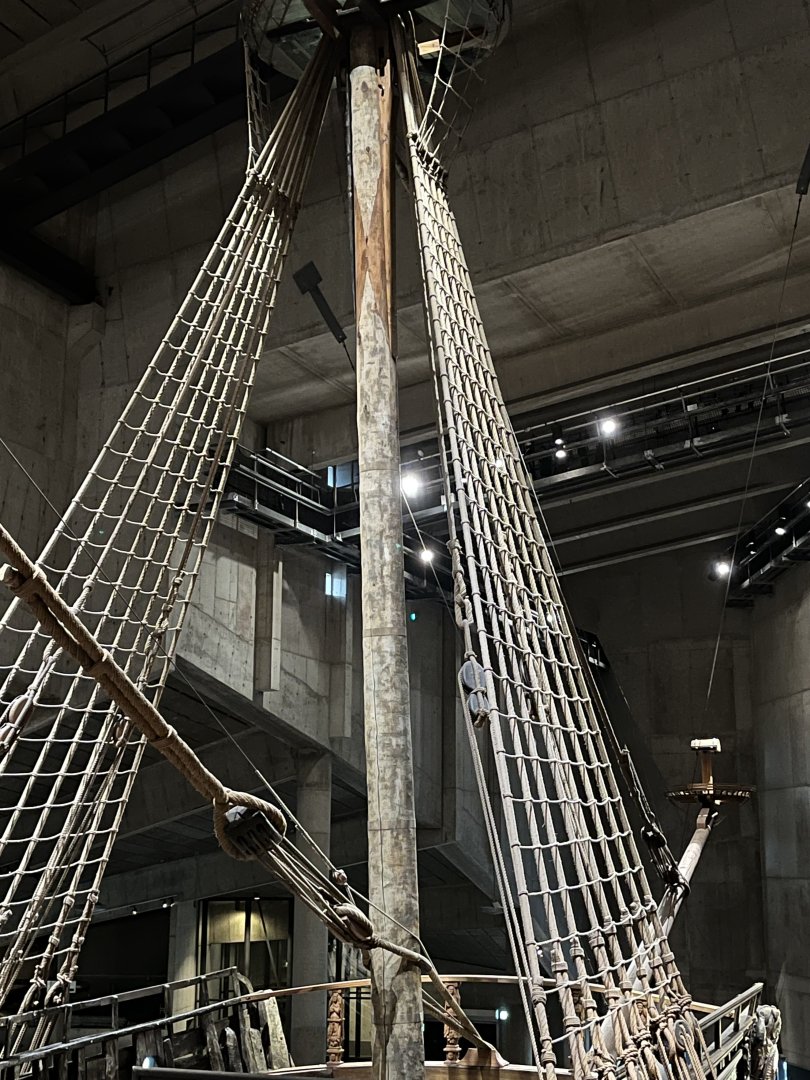

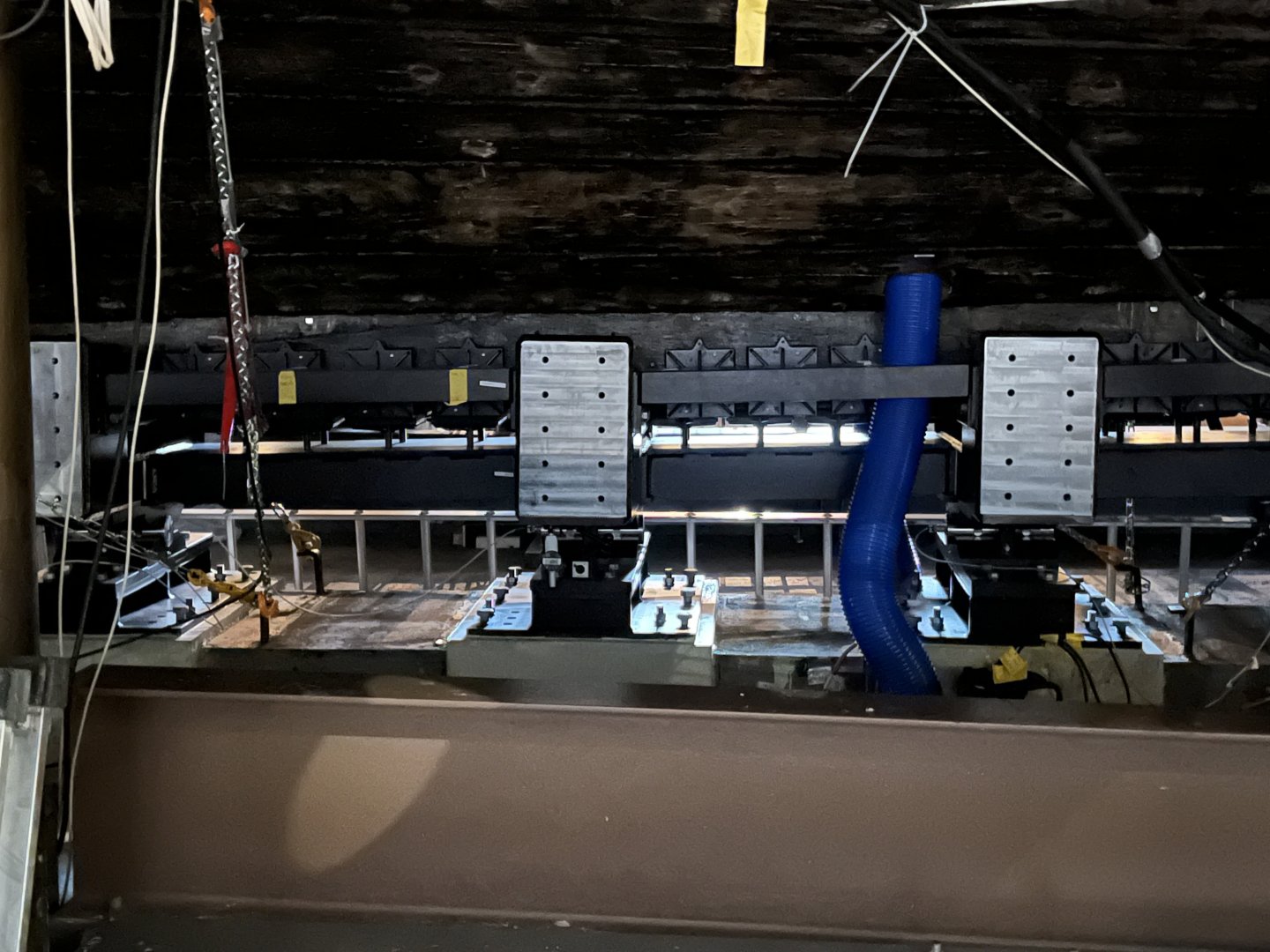

Forgot one more documentary that might be of interest, with some fresh videos from onboard: https://www.svtplay.se/video/jBvRER5/vasa-1628/avsnitt-2 Beware - it will probably be deleted 13th January 2026, make sure to download / screenshot before that Your post inspired me to visit her again. Can report that the installation of the new support system is visibly progressing! You can see the new cradles, with a lot of fine adjustment built in, side by side with the old fixed ones (with wood blocking): The keel supports are fully replaced and look fancy as well: By the way, are you planning to build her "as launched" or "as salvaged"? Note how the original wood differs from the replacement one in colour, creating very nice contrast: By the way, despite thousands of photos online - let me know if you need some very specific angle. I work fairly close to the museum and have an unlimited entry, so can easily come by during lunch and take any pictures you desire. Unfortunately not from the inside

-

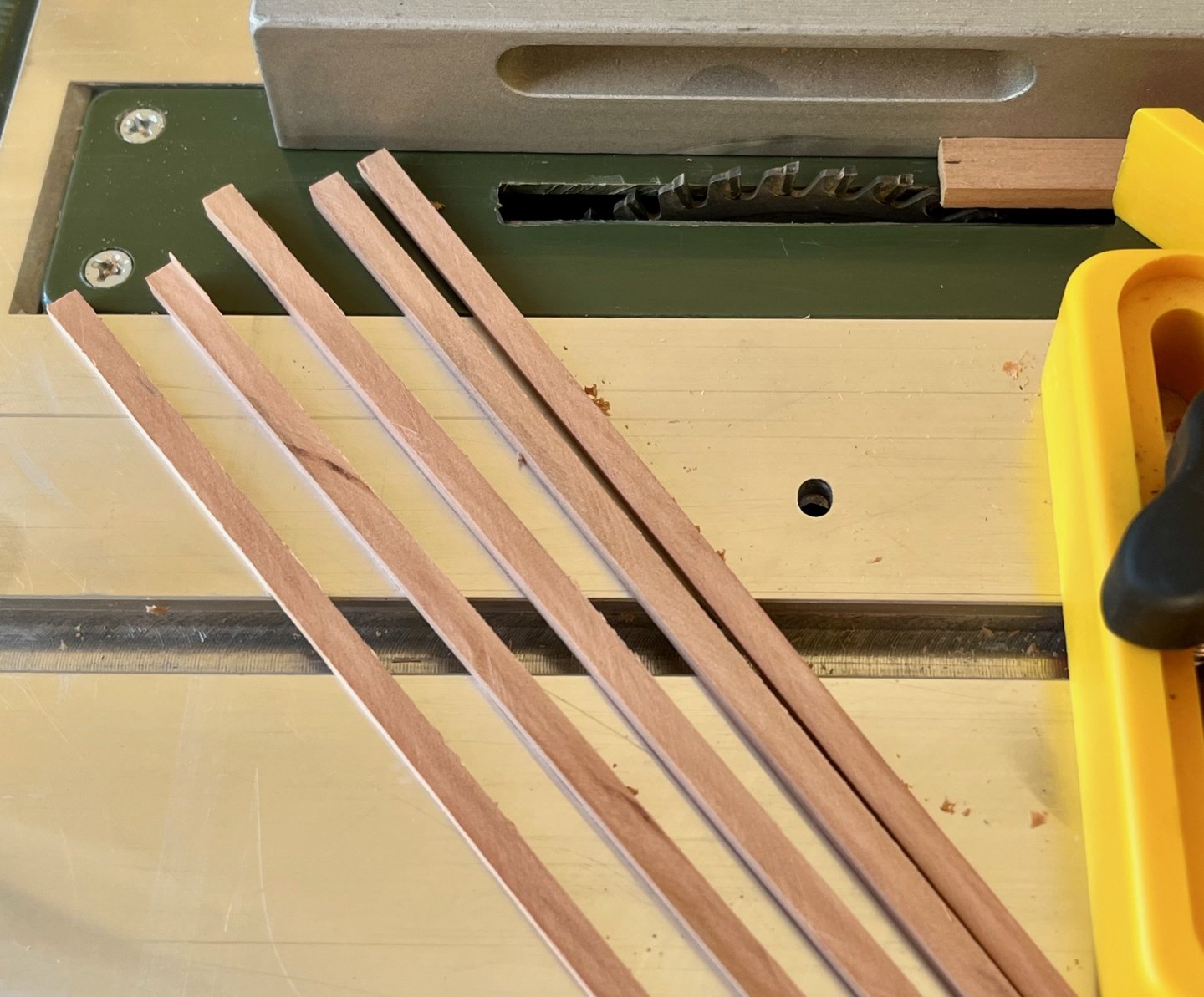

Thanks Mark! I am not planning to show the binding strakes due to aesthetics reasons. Most likely the lower deck would have no planking at all, or maybe a waterway only. But appreciate the point, you are right! I used to plane thin strips between the blade and the fence, but doing it on the other side is much more convenient. The piece is not jammed between the blade and the fence, reducing unnecessary damage with deep saw marks. When cutting "thin side outside the blade" - you can easily push it away with your finger (behind the blade), ensuring that the strip would not touch the back of the blade, regardless of any internal stresses and deformations. A riving knife would probably be a good idea, but this saw does not have one

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

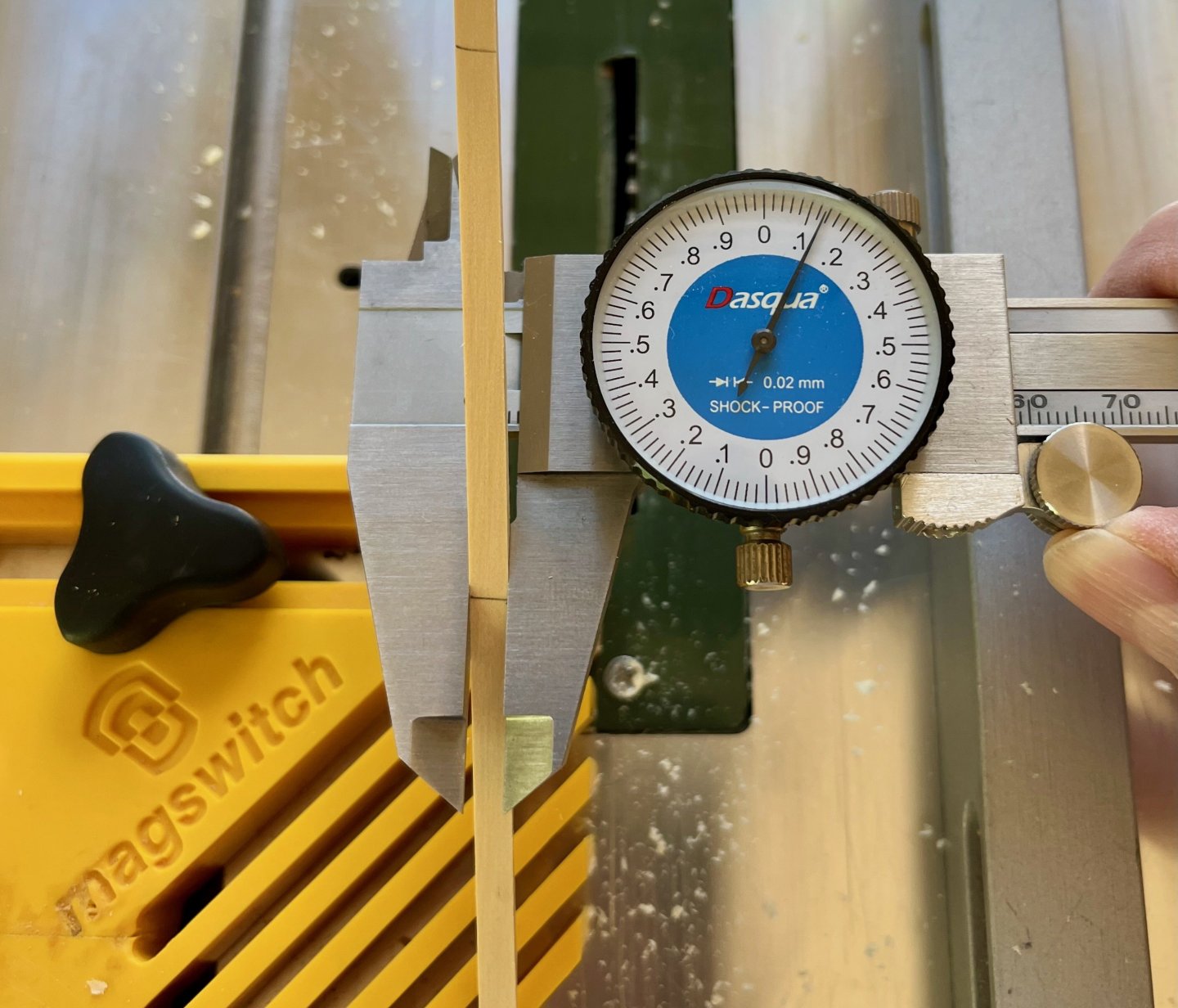

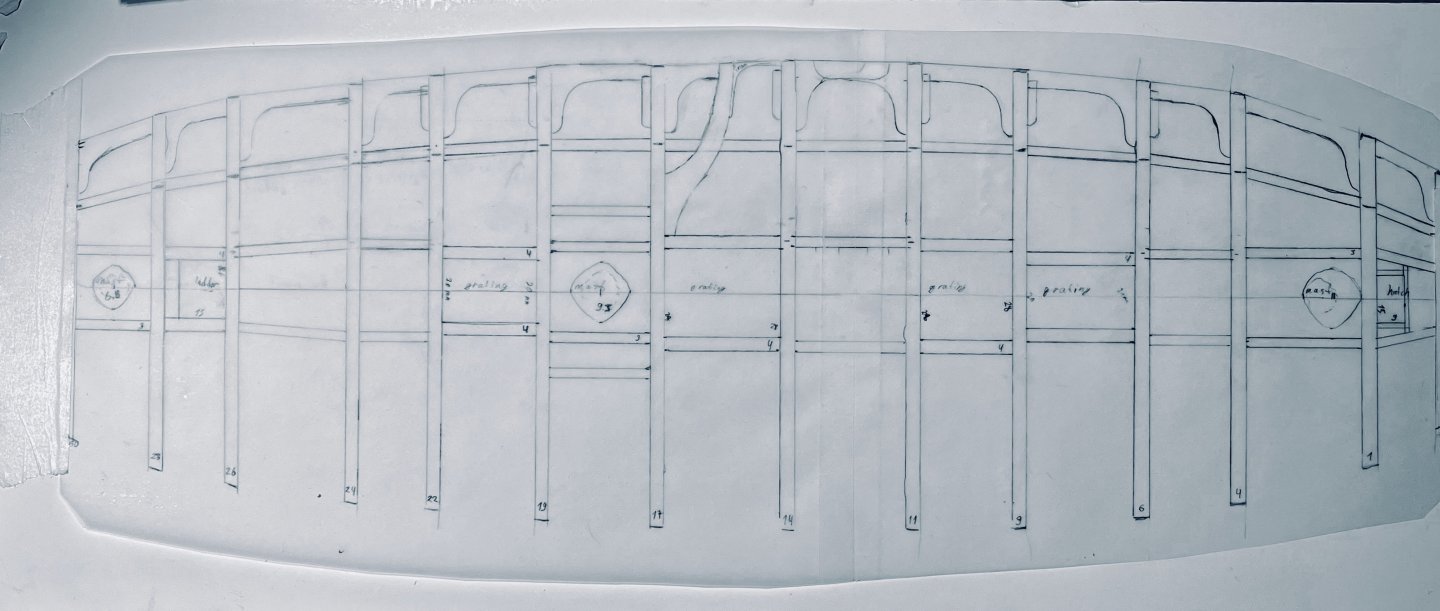

Thank you all, your support means a lot! ☺️ Deck framing preparations Here is the "final" deck layout that I settled on. Knee shape is quite approximate and would be refined on the model, but the carlings are all in their final spots. Ledges are omitted for clarity, but they would be placed on the top and middle part of the deck, leaving the bottom one fully bare. Depending on the visuals I might add the bottom row of carlings later on. If anyone can spot any mistake - please let me know before it is too late! Always a difficult decision point for me - what colour scheme to use for the next phase of the build? I want some contrast, but not too much. After hours of scrolling through amazing build logs here on MSW as well as photos of classical models - settled on the following palette: Carlings: boxwood, same as the beams. Lighter boxwood would represent the "heavy" timbers of the deck. Lodging knees: light pear, non-steamed. Hanging knees, beam arms: Swiss pear, steamed (darker variety) Ledges: have not decided yet, will try cherry. Something dark, but not black. Hope cherry is not too grainy for these tiny pieces. Here are the wood sheets planed to thickness and sanded. I will likely keep it unfinished, and use finish only for the top decks that might be touched. Next is milling the stock for carlings. It took too much effort for pillars, so trying to refine my technology. Ideally I just need a proper thickness sander, but I don't have one (or a space/time for the DYI variety), so was curious if my Proxxon FET table saw can do if I treat it with some love and care? Any tool shines better if you actually spend time tuning it.. At least the fence angle needs to be adjusted to avoid pushing wood into the blade (or away from it), it does make a difference! First was trying a slitting blade with 1mm kerf and no set. It leaves a fairly smooth finish, but tends to burn the wood and is harder to control. Switched over to the regular carbide tipped blade which has an effective kerf of almost 2mm. Sounds wasteful, but it is easier to control, so fewer planks would end up in the scrap bin. No burning, but the blade marks are slightly more visible. Close-up of test pear strips cut with both types of the blade, the surfaces are quite different: I do not have a proper "thin strip jig" that acts as a bump stop on the other side of the blade, but this saw also has a micro-adjuster that I have never tried before. Fiddly to use, but once you get the hang of it - it actually allows to move the fence quite precisely. If I need 4.0mm piece - I move the wheel to 6.0mm and with a blade kerf of almost 2mm I do get consistent 4.1mm thickness (with, say, +/- 0.05 tolerance). Not too bad for a saw that is not really designed for that kind of precision! They are 0.2mm oversized, leaving just 0.1 on each side to remove saw marks and any imperfections Boxwood carling blanks straight out of that saw, with no touch-up / sanding / scraping: Then some very careful planing in my thicknessing jig, taking care to not take too much material. I was worried that strips would fall on a side and I will end up with parallelograms instead of squares, but with the narrow face of 2.5mm and a crisp edge it was not an issue, they were standing upright. Now I have a bunch of blanks ready. They are straight, smooth and satisfyingly square in all directions and with dimensions down to +/-0.02mm! I did not expect to enjoy it that much

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.3250ab8b5ce52dfb25832000ec8c5faf.jpg)

.thumb.jpeg.d934cde94343ca28dd025f3edf1b2dc0.jpeg)