Pirate adam

NRG Member-

Posts

199 -

Joined

-

Last visited

About Pirate adam

Recent Profile Visitors

-

BradNSW reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

BradNSW reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

gjdale reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

gjdale reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

jpalmer1970 reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

jpalmer1970 reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

bdgiantman2 reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

bdgiantman2 reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

westwood reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

westwood reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

cotrecerf reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

cotrecerf reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

Thukydides reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

Thukydides reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

Keith Black reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

Keith Black reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

Chuck reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

Chuck reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

catopower reacted to a post in a topic:

Admitting some kits are now beyond me.

catopower reacted to a post in a topic:

Admitting some kits are now beyond me.

-

Admitting some kits are now beyond me.

Pirate adam replied to bigcreekdad's topic in Wood ship model kits

I would second cathead’s point. There are tons of possibilities to what can be done with hull models or even half hulls. They are generally the only practical solution for most people when it comes to larger vessels, as the size of the display is dramatically reduced. This is especially true when you move to larger scales. There are lots of cool examples on this site as well as the various museum web pages and virtual tours. If I was to do a kit that way I would probably just build per the directions until you get to the installation of the masts and cut off the lower mast as an un-rigged stub.   Adam -

Pirate adam reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

Pirate adam reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

Pirate adam reacted to a post in a topic:

L'Invention 1799 by Greg Davis - Scale 1:48

Pirate adam reacted to a post in a topic:

L'Invention 1799 by Greg Davis - Scale 1:48

-

Pirate adam reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

Pirate adam reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

Pirate adam reacted to a post in a topic:

Amanda F Lewis 1884 by SardonicMeow - Scale 1:48 - Chesapeake Bay pungy

Pirate adam reacted to a post in a topic:

Amanda F Lewis 1884 by SardonicMeow - Scale 1:48 - Chesapeake Bay pungy

-

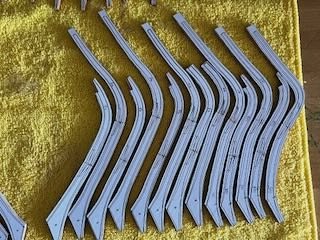

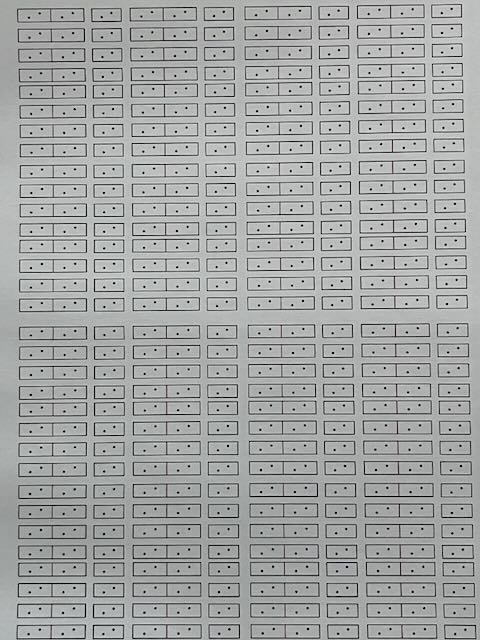

I finished gluing up the aft cant frames. My plan is to simulate the frame bolts with copper wire and blacken any exposed bolts on the model with liver of sulfur after fairing. I used wire labeled 0.019" diameter to simulate scale bolts 7/8" diameter. There are 2 types of joints on the cant frames. One type uses chocks and the other a simple scarph joint. I wanted to save some time laying out the bolt patterns on the frames, so I printed up some guides on label paper. I found that to work great. I drilled the holes using a micro drilling accessory on the Sherline lathe. I broke my last drill bit, so no more holes until I find some more. Adam

-

Yet Another Pandora 3D build

Pirate adam replied to herask's topic in CAD and 3D Modelling/Drafting Plans with Software

This is so much fun to watch. It really makes you feel like you are at the actual shipyard. Amazing work. Adam- 118 replies

-

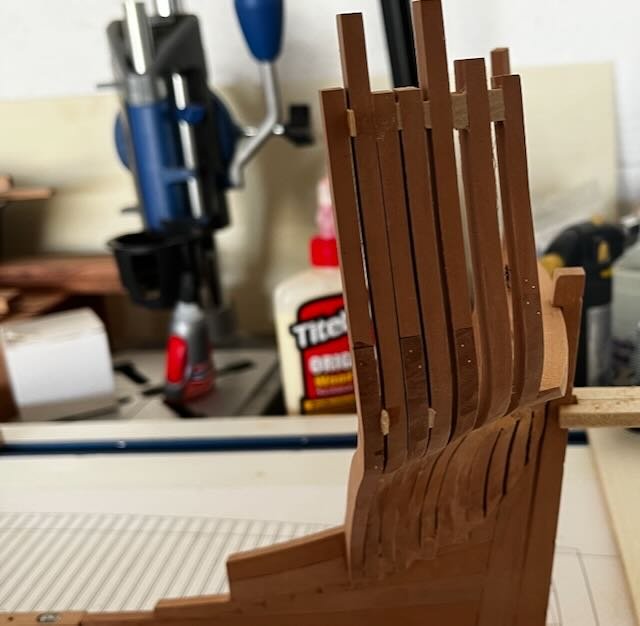

Cutting of frames for the chocks. I cut these using the Sherline mill. I simplified the chocks a bit by not beveling them. I only cut to the depth of what would be the shallower side so as to not expose the nose of the chock when the frames are faired. The chocks are a bit funny looking now due to the excess wood outside the actual frame lines. One side of the chock will be a bit off after fairing, but I don't think they will be especially visible when the frames are glued up anyway. I used regular scarph joints for the top timbers. I will pin them later with copper wire to simulate bolts. Here are two sample frames. With a bit of alcohol just to highlight the joints. I'm pretty happy with the look so far. There are 117 frames to do in total counting the hawse timbers, but the nice thing is they are a great project to work on just a bit a day after work. Adam

-

Pirate adam reacted to a post in a topic:

USS Constitution by mtbediz - 1:76

Pirate adam reacted to a post in a topic:

USS Constitution by mtbediz - 1:76

-

Pirate adam reacted to a post in a topic:

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

Pirate adam reacted to a post in a topic:

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

-

Pirate adam reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

Pirate adam reacted to a post in a topic:

HMS Crocodile 1781 by Pirate adam - 1/48 scale - POF

-

With the transom shenanigans out of the way I am finally ready to start making frames. Here I have marked out the blanks for the aft cant frames. The black lines are the actual lines for the frames. I added the green lines to make sure I have plenty of wood for fairing the cant frames as well as to make sure the frames are sufficiently tall. Experience tells me that I just can't help myself when it comes to leaving enough wood otherwise. Familiar sight for anyone who has built POF. Adam

-

I made a slightly larger building board to provide a bit more room to install the frames at the ends of the model. Long story short, when I setup the new build board I found some issues with the alignment of the transoms and aft fashion piece. I have known for a while that something wasn't right with the alignment, and happy to figure it out before doing a ton more work. I envisioned this would be a problem that would follow me through the whole build, so got out the isopropyl and re-built the transoms and aft fashion pieces. I also used the opportunity to add a 4th filling frame which looks much better to my eyes. Adam

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpeg.002827fc6cb97213a0818b06bdfc6b4c.jpeg)