-

Posts

47 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paryzek

-

These "modern" ships are not in my area of interest, but I'm happy to rate something that is really good. Beautiful model.

-

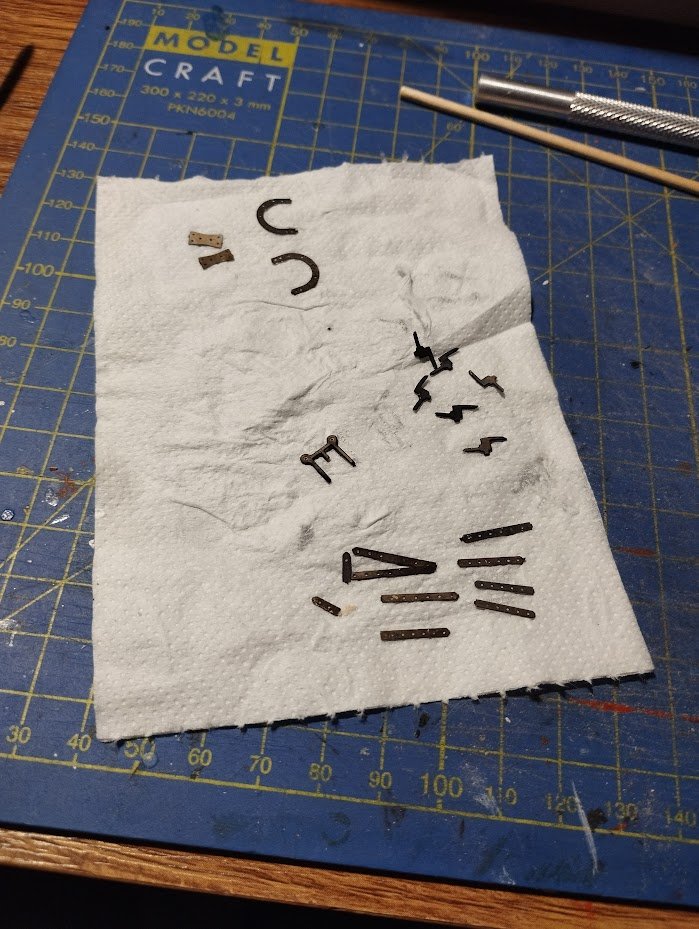

Another small step. I finished the horseshoe plates and stern fifshplates on both sides and the rudder complete hinges. The wood under the walles got its first coat of wax. I also folded the rest of the bow under the grating and installed it on. The second layer of siding doesn't look bad, so I decided not to use white paint. I like wood. Today I also installed gun port parts on the closed gun ports on the bow and stern and am working on the hull side stairs. I will take pictures later.

-

I think if I were to remove everything from under the side gallery windows. I can first glue the wooden moldings properly, and then install the new brass ornaments between them. The problem is that they cannot be removed without serious damage. I can make the ornamental moldings myself, I have pear wood, but I can't deal with those etchings. And if I pull them down, I will destroy them.

-

I'm reporting the next step. Unfortunately, I did something wrong. Very wrong. I installed the decorative moldings on the side galleries incorrectly and the whole thing didn't fit properly. It can't be removed without serious damage. I'll try to order new brass etchings from Mr. Watton (if possible) and redo the whole thing. I can make wooden moldings myself, but unfortunately not brass etchings. Where were the main mistakes? 1, I didn't read the instructions, my fault 2. I don't know how to work with CA glue very well, I'm more of a carpenter. 3. I was in a hurry and didn't think, another fault of mine If it's not possible to buy a plate with etchings, I'll have to leave it like that

-

Hello, I'm back after a while. Health problems caused a delay. (sore back, herniated disc) I added the second layer of planks. It's not quite 100%, but I like it quite a bit. I decided not to use white paint on the bottom part and leave only wood. After adding the brass parts, there will be wax. Now I'm figuring out how to install the rudder Small hole.

-

I report further progress. The first layer of lining is ready. I used wood putty on the small bumps, sanded it smooth. I will apply some thin wood glue and I can continue. Linden is a fairly soft wood. I had to grind carefully. It would probably be better to use a stronger profile. At least 1.5mm. But the second layer will strengthen the whole thing.

-

Very good. I don't deal with the first layer too much. I will glue, fill the gaps, use putty and sand paper to a smooth hull. The first layer is not visible.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Dutch Whaler by aliluke - Sergal

Paryzek replied to aliluke's topic in - Kit build logs for subjects built from 1501 - 1750

It looks very good for a first model. -

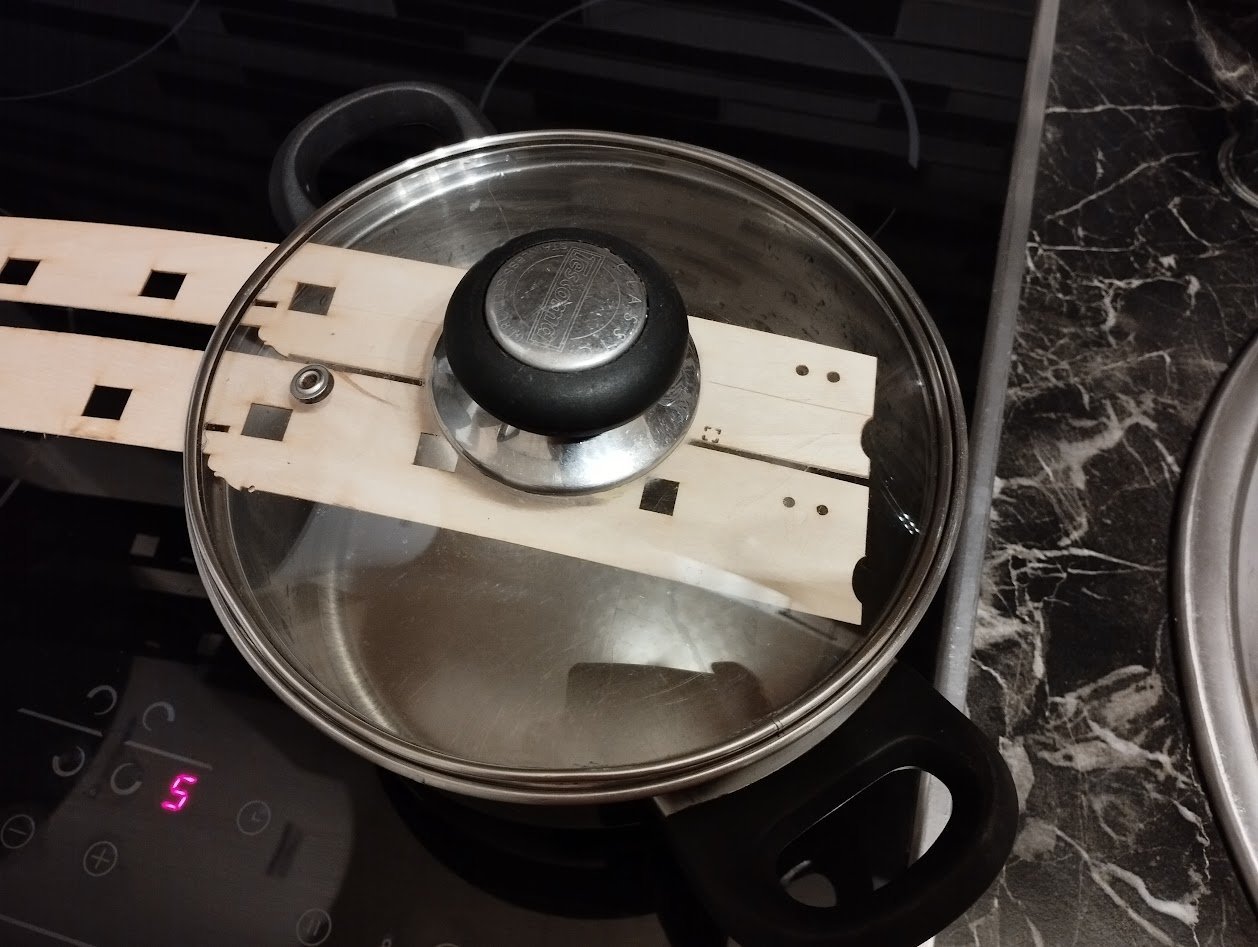

I'm starting to plank the hull, it will go slower now. I was thinking about using my own material instead of the linden from the kit. 2x4mm spruce beams. But it was really a problem to bend them in the back so that they fit properly. Very stiff material for such an arch. So I'll trust Chris that the linden is fine. What the hell is the translator doing? I entered the text in English, and he returned it to me in Czech. (automatic translation in google chrome)

-

I prefer to grind by hand, so you can monitor the line better. Machine sanding saves a lot of work, but can make more mistakes.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I'm glad it's going well. I'm watching from the front row.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.