-

Posts

1,152 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Some Idea

-

The Foredom drill press is a very well made tool and its accuracy is fantastic. I bought one hoping it would justify the price and they certainly do. I also recommend the Starrett pin vices they are very good indeed and are well worth the money. They will last you a lifetime and then some. The comments about the drill bits are spot on - I buy cheap HSS jobber bits from RS in the UK and they last ages. They are also slightly flexible which helps when drilling in an awkward place say inside the hull with a 0.3mm bit.

-

Lovely work I used to worry about all of the little scratches and marks but I have found that as the ship progresses they disappear into the detail. When I cut my rabbets I did them too shallow - when I build me next ship I will have an actual plank ready to help me cut to the right depth. Keep the updates coming!

-

Hi All Is Ancre responding to any messages on their website - I've sent them 2 messages via their website over the past few months and never received a reply. Has anyone else had this problem or just me? I want to order a new monograph but I would like some extra plates for the axial parts and frames for accuracy. Its seems as though they are not receiving the messages sent. Let me know as I have also checked my junk mail just in case Thanks Mark

-

L'Amarante by marsalv - 1:36 - POF

Some Idea replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

The way you solve both clamping and machining operations is inspirational - stunning -

Your attention to detail is simply mind blowing - wow

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Beautiful work - your joinery is spot on.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The capacitor in our saws is a start and run. It doesn’t only help the initial kick it also runs the motor whilst using it

-

Planking Method Name

Some Idea replied to Thukydides's topic in Building, Framing, Planking and plating a ships hull and deck

That looks like a hooked scarf joint to me -

I have found the switches to be a slightly weak point but are easily changed. The capacitors are start and go and are also easily changed too. If you do replace the switch you can go a bit top gun! I love my new switch on my sander - it adds nothing to the machine but makes me smile.

-

L'Amarante by marsalv - 1:36 - POF

Some Idea replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

That really is beautiful work - I found planking the ceiling particularly difficult and your result is amazing -

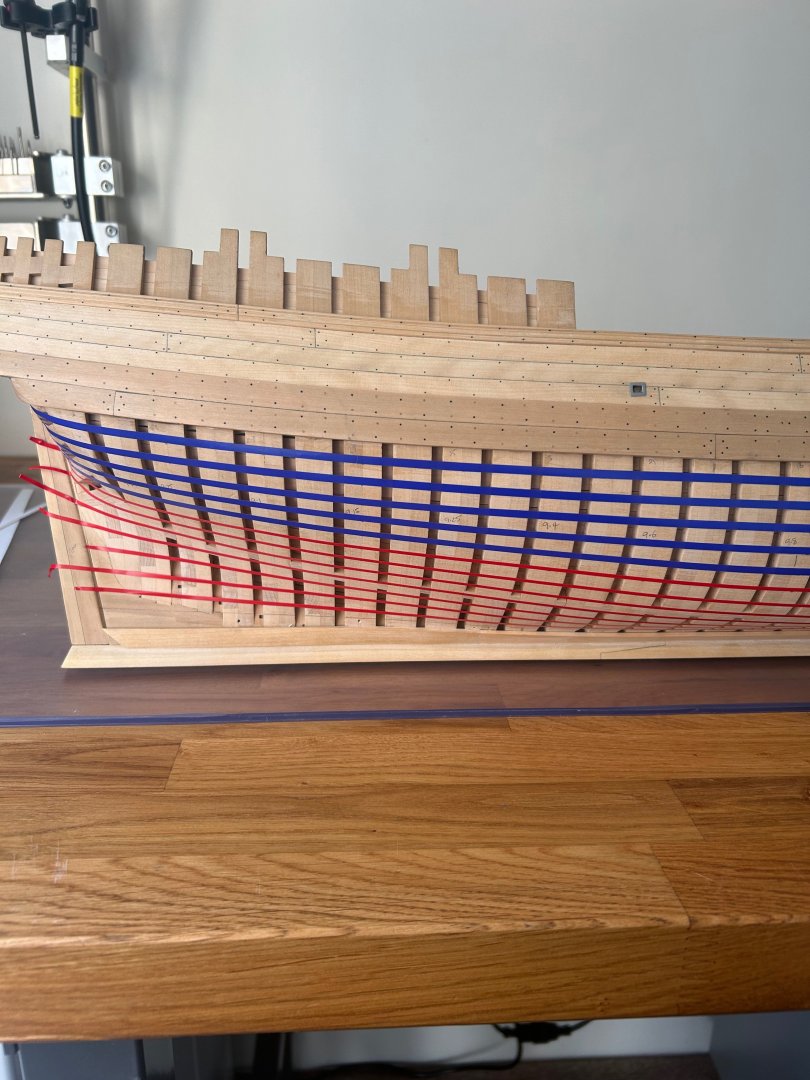

If it helps this is my Le Rochefort build - I too am very much learning on the job but I have received much help on this forum to get me to this point. Also Gerard Delacroix is a member of this forum and always answers my questions regarding this lovely ship when I get stuck. Drop him a message I'm sure he will be more than happy to help.

-

Help with tapering

Some Idea replied to N1ckel's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Nick - Sorry I should have read this thread earlier. This is how I carry out the planking process which has always served me well. Firstly I firmly believe that if you can mark out and draw every single plank then you can make them too. I literally spend days marking out to get a good look with the correct spacings too. I use automotive tape so that I can see and adjust the runs of each strake and I like to do this after I have placed the garboard strake. Just for clarification a strake is simply a length of planks all joined up which run from stem to stern. Doing this work up front first makes seeing the individual planks easy when it comes to actually making them. There are very very few parallel planks on a ship and it's also very time consuming but so satisfying when you get it right. I also only bevel one edge of a plank which for me is always the top side of the plank. I leave the bottom of a plank square. That way the next strake meets a square edged plank and I cut the bevel to suit. I have put loads of words down so here's a picture that explains what I mean. If you don't plan it from the start you will be chasing each and every plank which is a nightmare. -

Stunning work Ben your attention to detail is fantastic

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.8ba7c8a47bafd4dc679c2898cfbb64ae.jpeg)