-

Posts

1,152 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Some Idea

-

Byrnes table saw - belt tensioning

Some Idea replied to Mr Pleasant's topic in Modeling tools and Workshop Equipment

Hi I've also had this issue and changing the belt made no difference either. I contacted Jim who advised me to place a couple of washers behind the tensioning spring. It's a little fiddly to do but it works great and is a permanent repair. It just pushes the motor back that little further which is what is required. Mark -

Mike I'm so glad that you are going to reprint these books. As soon as they are available I will be ordering a set from you and if you can let me know when they are available I would appreciate it. I'm not so good with ebooks but I think what you are doing is a great idea - I'll wait for the reprint. As I understand it with the original series it was possible to buy an encapsulated frame plan view. If so will this be available too.

-

L'Amarante by marsalv - 1:36 - POF

Some Idea replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

Hi marsalv I'm just catching up and how I missed this I do not know. Its another fantastic build and I'll be following along - Mark -

Hi Marc I'm just catching up on your amazing build. I have used Birchwood and I also had issues with it rubbing off when it was handled. I did exactly as you using acetone to clean the parts before dipping them in the solution. I then (after) read the instructions and they advise cleaning the part in alcohol (IPA) and then washing this away with water before dipping. After doing it this way the results were excellent. Keep the updates coming as this is such a fantastic build.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

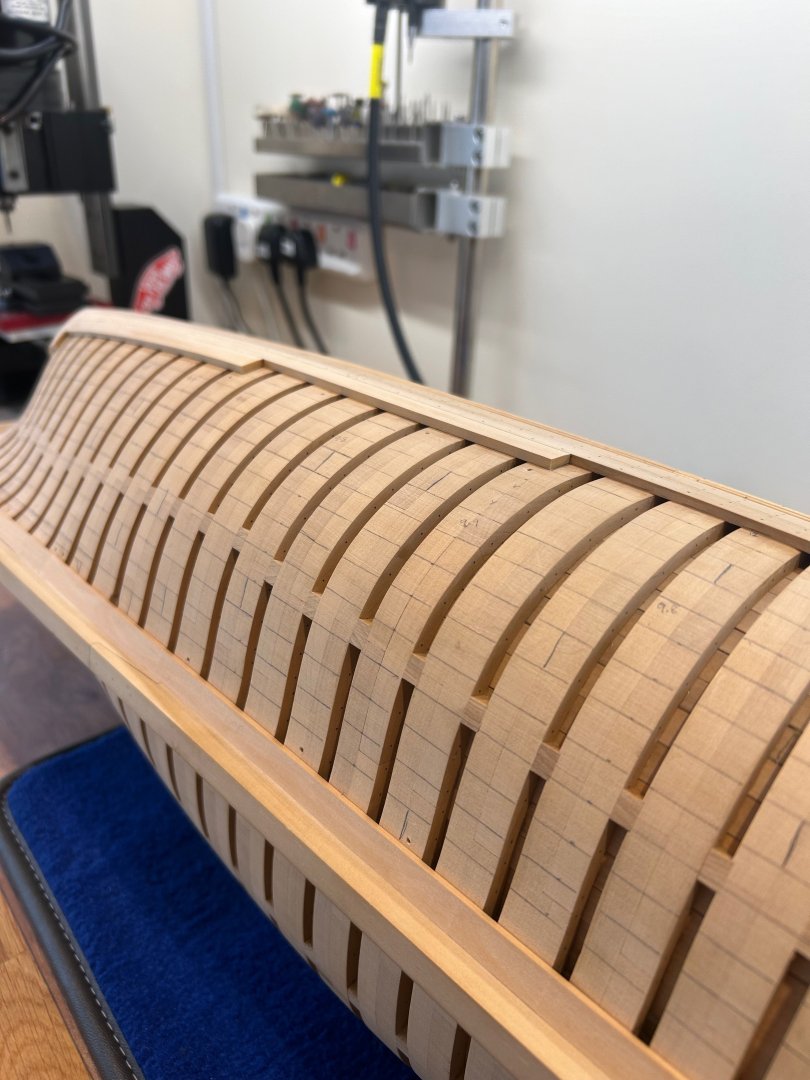

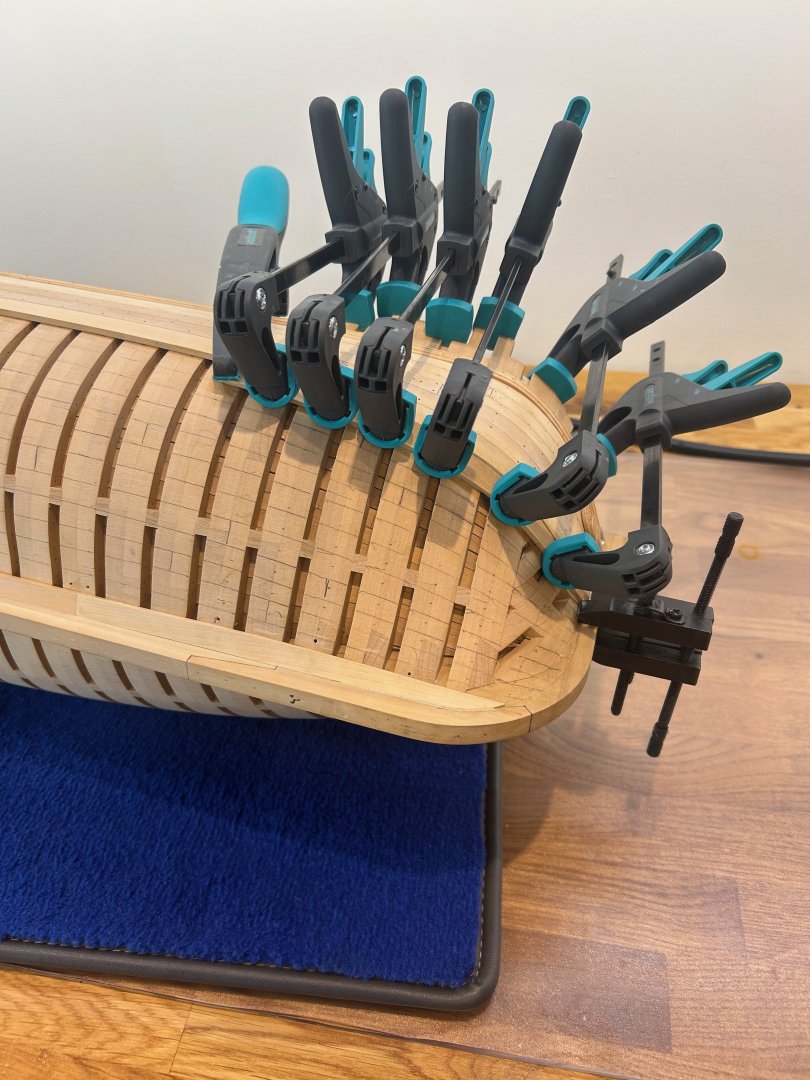

Hi All I've not checked in for a while as I cannot get any work done on my ship at the moment. My workshop has been turned into a storage room due to a contractor letting us down to fit a complete bathroom - The bathroom is in my workshop - such is life. It looks like it's going to be this way until October so I will have to be patient. I did start the planking and it was going on very nicely following my marking out. I did find it quite hard though as the planks are 3.2mm thick so require a lot of clamps. Here's a good indicator - the coin is a pound coin. The bow and stern required spiling as otherwise the planks just don't fit and will not sit flat on the frames. Now here is where I hit a really big problem. If you look at the above photo's you can see that I used a black toolmakers clamp. It was brand new and did the job great. Unfortunately what with the moisture and heat in the planks the black oil coating ran straight onto the ends of 4 planks. It didn't do this for the first 3 planks and then Boom! I tried every kind of solvent to try and remove the blackness - it was so bad at the tips that I tried to cut away part of the tips and replace them with small scraps. I even tried diluted bleach but the results were very bad - see below (I had already removed one plank). Basically at this point I was bodging it up! So I realised that I was trying to cut corners and I could not leave it looking like that. I removed the stained planks and that's where I'm at now. It's going to need a really good clean up but thats OK. I also have to damaged planks to use a templates too. I'll recut the rabbit and clean up the stem at the same time. As soon as I get my workshop back I'll be at it again and hopefully never make the same mistake again. If you've followed my build this sort of thing is pretty much on par for me Thanks Mark

-

HMS VICTORY 1765 by albert - 1/48

Some Idea replied to albert's topic in - Build logs for subjects built 1751 - 1800

Albert that is beautiful 👍 -

Byrnes Saw for sale in the UK

Some Idea replied to Some Idea's topic in Modeling tools and Workshop Equipment

Shipping costs about £350 to the UK as it has to come by airfreight. It also included angled table which is quite expensive. Add onto that the 20% VAT we have to pay on arrival plus handling fees. -

David that would be great and have a nice holiday in Shetland too

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

David congratulations on your finished build it looks fantastic and I have enjoyed watching your progress. Good luck with Speedy.

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

Byrnes Saw for sale in the UK

Some Idea replied to Some Idea's topic in Modeling tools and Workshop Equipment

Also selling a thickness sander https://www.ebay.co.uk/itm/186417418533?itmmeta=01HWG33Z91A44S3HKQM7B6RGG4&hash=item2b67581125:g:ASgAAOSwNRtmLKTK -

Nothing to do with me but I saw this on eBay so I hope it helps someone https://www.ebay.co.uk/itm/186416714352?_trkparms=amclksrc%3DITM%26aid%3D777008%26algo%3DPERSONAL.TOPIC%26ao%3D1%26asc%3D20240131095853%26meid%3D8def67556d804af1b662f9d2c097a3da%26pid%3D101949%26rk%3D1%26rkt%3D1%26itm%3D186416714352%26pmt%3D0%26noa%3D1%26pg%3D4375194%26algv%3DRecentlyViewedItemsV2Mobile&_trksid=p4375194.c101949.m162918&_trkparms=parentrq%3A202fce9818f0a8cd77bf80b9ffff20f6|pageci%3A5f064672-04ab-11ef-8221-ee1deb3fac2d|iid%3A1|vlpname%3Avlp_homepage

-

So sorry to hear this Kevin and I would have done exactly the same thing as you.

- 443 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Tobias in hindsight I should have used your method as it's far more accurate than the way I made these parts. When it came for me to apply the planking to the dogs legs I had to thin them out to get the correct hull shape. This pretty much showed my errors in the way that I made them. I can see by the way that you have made yours you will not have the same experience as me. I shall be using your method on my next build and thanks for sharing how you did these difficult parts. Cheers Mark 😃

-

I have to say that your work is fantastic - Great joints and it's so symmetrical too. I found that making the fashion pieces correctly to fit the wing transom and filler pieces was particularly difficult and you have smashed it - top job!

- 99 replies

-

- ancre

- La Mahonesa

-

(and 1 more)

Tagged with:

-

Hi Nic and welcome - thanks for showing your grandfathers build that really is a lovely ship. If you would like to get into ship building get in touch with @chris watton as he supplies the most beautiful kits. He's based not far from you in Gloucester

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.