-

Posts

1,605 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by vaddoc

-

I just registered what the second picture shows following Row's comment and I caught my self smiling, this is style in modelling!

-

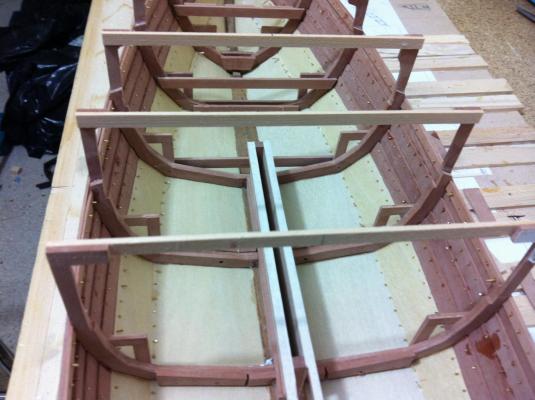

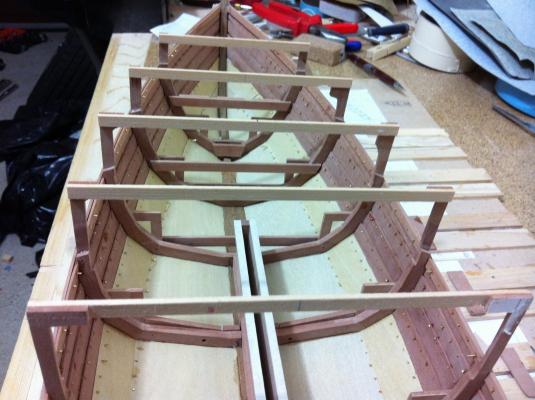

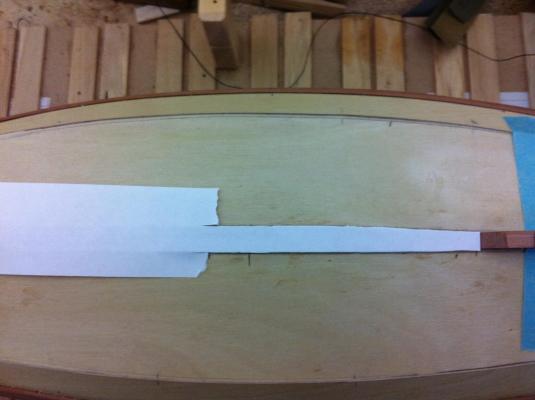

Thank you all, I really appreciate your support. I must admit though I am not at all confident that the boat will end up looking as good as it deserves. With a baby now in the house work progresses slowly. The sheer plank rivets are now left and of course all rivets forward of station 0 at the bow. This plank was left unpainted by the american team and I am tempted to do the same. There will also be a rub rail added which will hide the uppermost rivet line. In the next picture also note the shaping of the stem which at the level of the sheer plank is left square. I needed a brake so I concentrated on the false stem. It was first shaped with the needle files and then glued to the hull. Hopefully there is some similarity with the previous picture. With this done its back to riveting. I am concerned that the CA glue will stain the wood and although this is not a problem for the lower planks, if the sheer plank is left unpainted it will need a lot of sanding which with all the rivets will be ddifficult. I am also concerned that there will be a lot of stains on the inside of the hull but there is no better alternative to superglue. So here it goes. First I covered the plank and then marked the width of the rub rail to make sure all upper rivets will be hidden And drill and glue and drill and glue and drill and glue... Drilling 200 holes in a row is very satisfying And another brake was necessary, so I finished cutting the centerboard slot And finally all rivets done! There are a few left at the bow but the cant frames need to go in first. The sheer planks are sanded with 180 grit but the glue stains are still somewhat visible. And finally, the long awaited moment has come. The boat needs to be taken off the jig, turned around for the cant frames to be installed and then positioned back to the jig for the rest of the rivets to go in and then fairing, priming and painting. Picking up the boat I was surprised, the hull is very light but extremely rigid. Next the cant frames went in which took a bit of head scratching but I am happy with the result. Lots left to be done but making progress at last!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

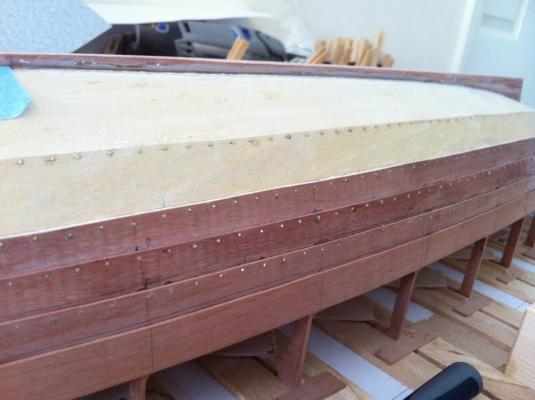

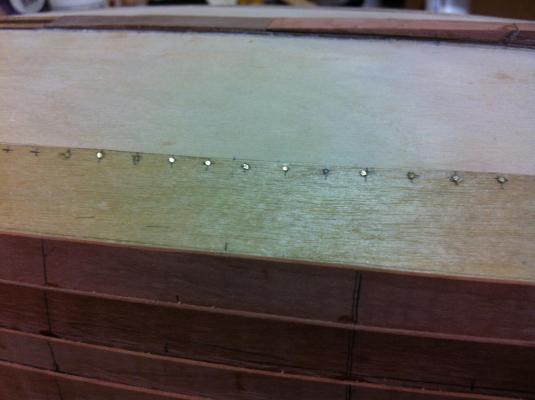

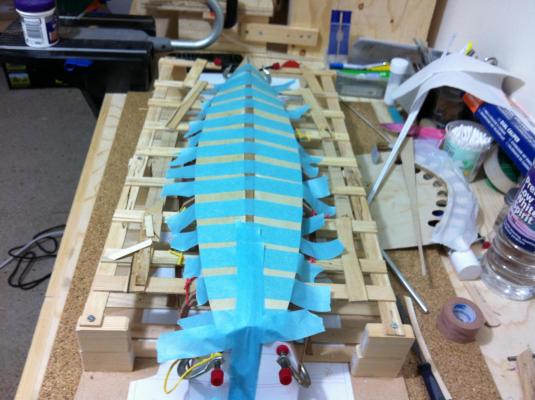

Nothing really exciting to show, life is a monotonous mask-drill-glue-file. But I think that the the first 500 rivets deserve a post! I only took a photo of one side, no strength left to photograph the two rivet lines on the other side. 700+ more left...

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

Patrick Such elegant work and such a nice model! The sails add so much! Looking forward to your next posts Regards Vaddoc

-

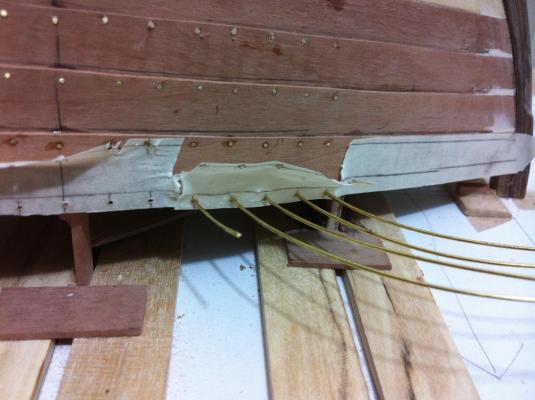

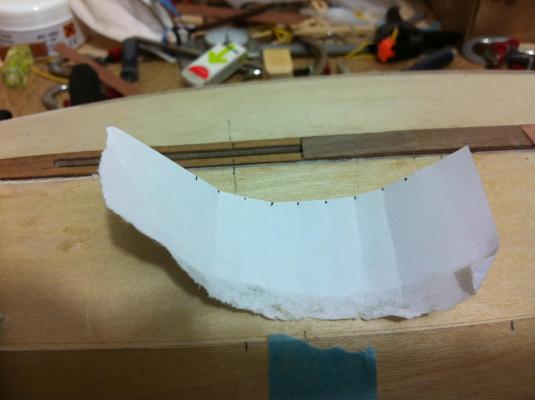

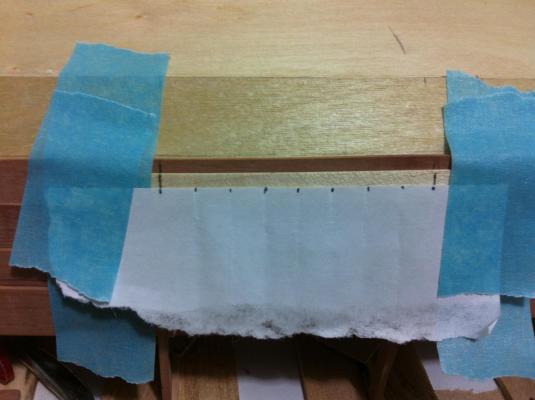

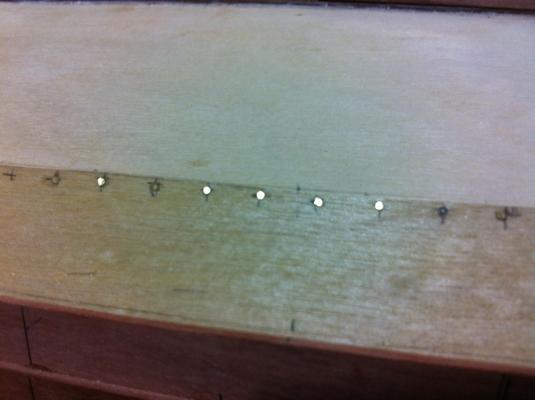

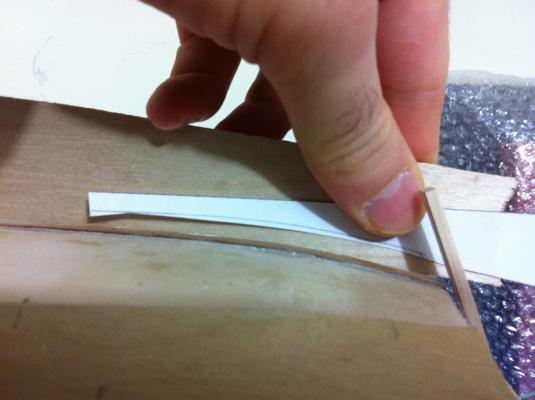

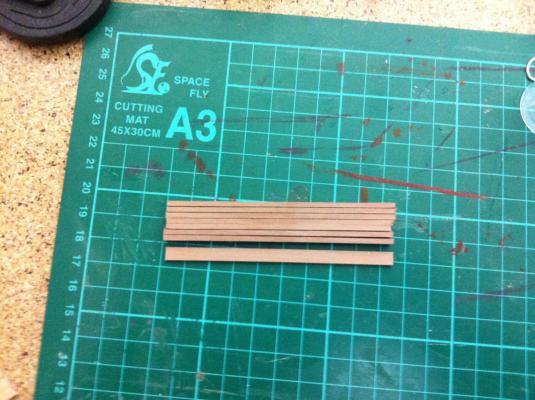

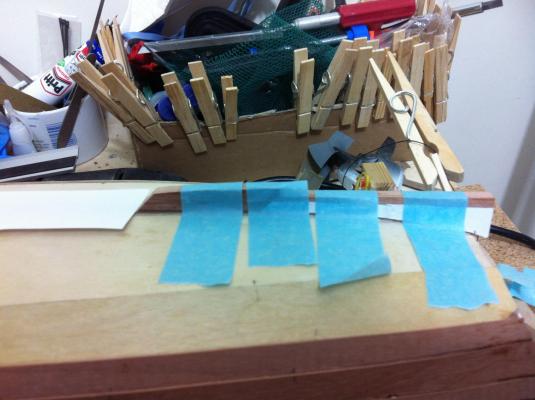

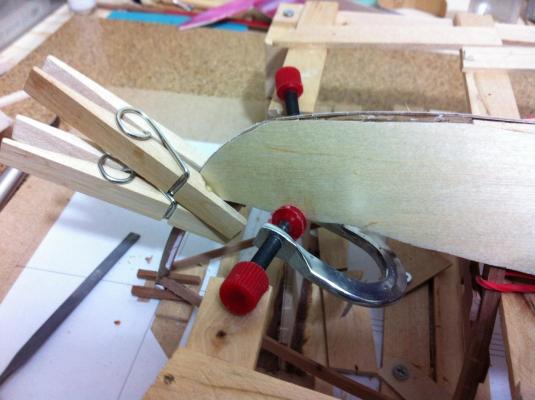

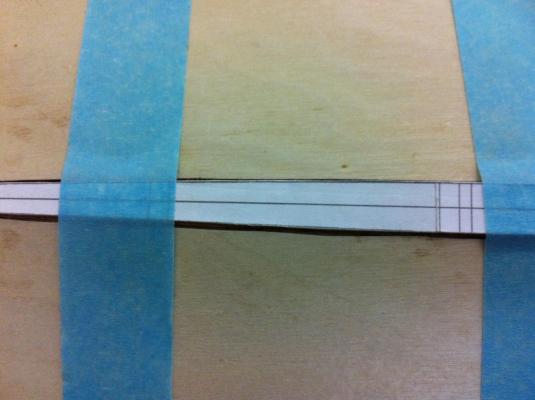

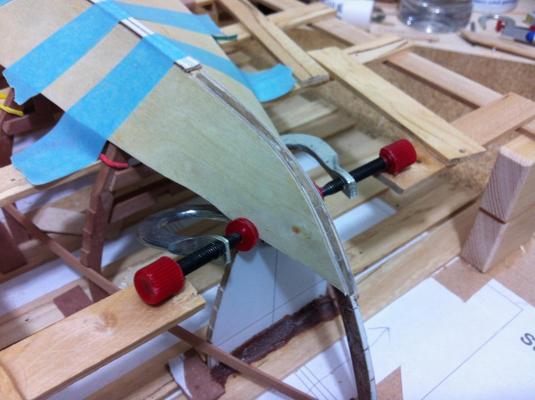

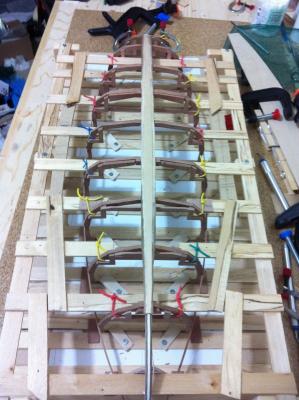

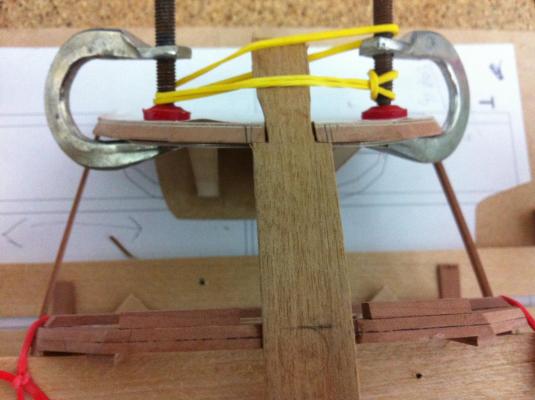

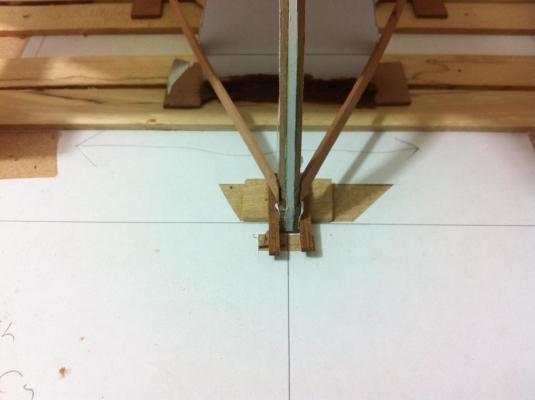

The work continues and new problems and challenges pop up all the time! The fairing putty I got from the model shop is really good, much nicer to work with than the one from the DIY shop. I faired the bow and also trimmed the planks at the the stern and faired the transom. I have already decided to rivet the boat and I think I should tackle this now. Besides, it would be a nice change from all the laminating and woodwork. I realised however that I did not mark the position of the frames during planking. I tried a simple solution This did not work due to the curvature of the hull so a more complex tool had to be improvised which worked fine. The positions of all frames is now marked. I next need to make a pattern so that all rivets all equally spaced. A short maple strip and a folded piece of paper was an easy solution. It was easy now to mark the position of the rivets. The thickness of the plywood is only 0.8 mm so the overlap is too small for the rivets to go through both panels so this line of rivets is not going to be too functional but it needs to be done to stay as close to the original design as possible. Interestingly, the american team added stringers at the lower chines, the next photo shows these as they reach the transom. Either way I think the floor boards will hide this lower river line. I drilled the holes with the Dremel and a 0.7 mm good quality drill. I used brass wire for the rivets and CA glue and used masking tape to prevent the glue staining the wood. There was a learning curve to go through but it worked ok. A few of the rivets have a lot of material to be trimmed on the inside of the hull. I used the grinding wheel on the Dremel to trim the rivets flush with the planks but it did not work out, the wire gets very hot, the glue melts and the rivet just slides in. Trimming with the needle file was much more efficient. There will be 6 rivet lines per side with approximately 100 rivets each, so around 1200 rivets! That's a lot! I will not rivet past Station 0 as I will complete this job after the cant frames are installed. I also redid the false stem and added the final plank to the keel. I took the precaution of blocking the centerboard slot to make sure the epoxy does not drip. Next job to glue in and trim the false stem, do some more fairing and of course more rivets!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

Thank you for the encouragement Patrick, it really motivates me to push forward! You are right about the keel, it is really hard work, it took 2 days of hard work to reach this stage and even sanding these small pieces was physically tiring as the laminates are really hard. Yes, both me and the Butterfly Explorer are looking forward to break free of the support and sail into the horizon! Not too long now I think.

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

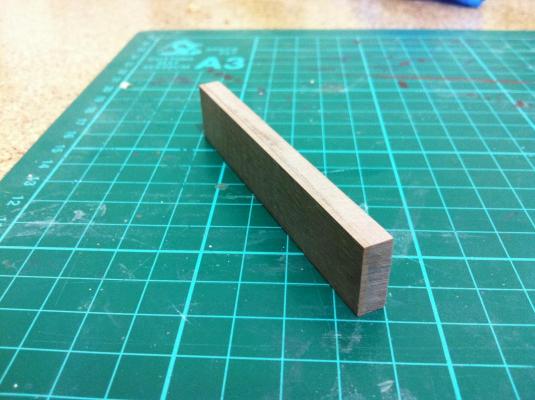

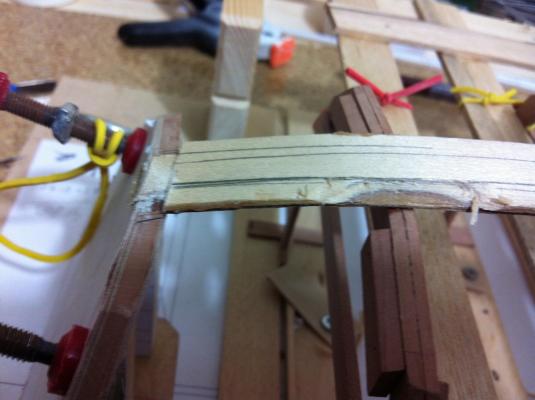

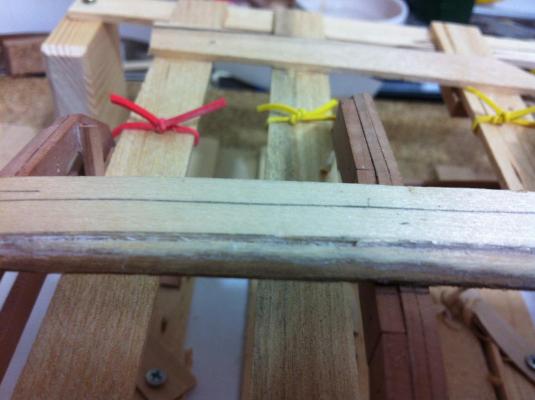

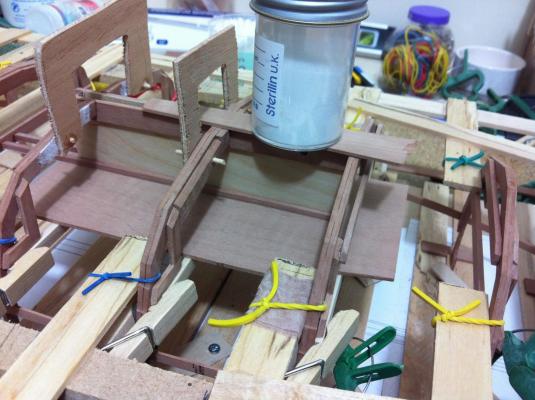

I somehow managed to find a bit of time to work on the boat. I am waiting for some timber to re-do the false stem and also some filling putty to fair the hull. It is time to concentrate on the keel. The strip shows the shape of the keel and of the deadwood I decided to cut the centerboard slot, there will be more wood added but best to do it in two steps as pear wood is hard. The job was done with the Dremel using a drill bit to remove the wood like a milling machine and finishing off with the hand files. I was surprised as it was a relatively easy job Checking again the shape of the keel. This is tricky due to the curve of the keel but also due to the fact that its width changes along its length. The best way of approaching this is to put it together in segments, which is how the full size boat would be built. A lot of laminating and sanding had to be done but it seems to come along fine. I made a pattern of the keel near the Transom Then I laminated some pear strips to make the deadwood The deadwood was not wide enough so I added some more wood and also laminated another piece. This is a nice solid piece of wood! The Dremel moto saw only just managed to cut it. Fits reasonably well The space is starting to fill up I added the second piece, nothing is glued yet I made a paper pattern of the shape of the keel to prepare the third piece All three seem to fit OKish Lots of sanding later it definitely looks better but long way to go More wood needs to be added. There will also be another long plank added on top which need to be shaped All segments so far, getting closer to the end It only needs some more sanding so that the long plank fits flush but I think it is almost done. I will need to laminate and install the false stem before gluing everything together, and some serious fairing will need to be done first

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

Hi Patrick You are building an amazing model, the amount of detail is astonishing! The reel has a marking that looks like 28 g so maybe 0.32 mm?

-

Congratulations to my Admiral for bringing to the world a beautiful little girl! One Butterfly will need to wait for the other I guess!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

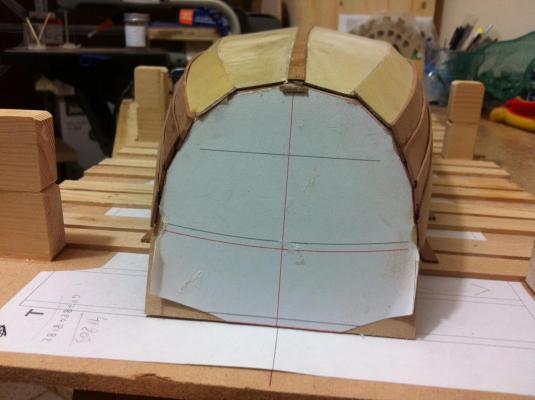

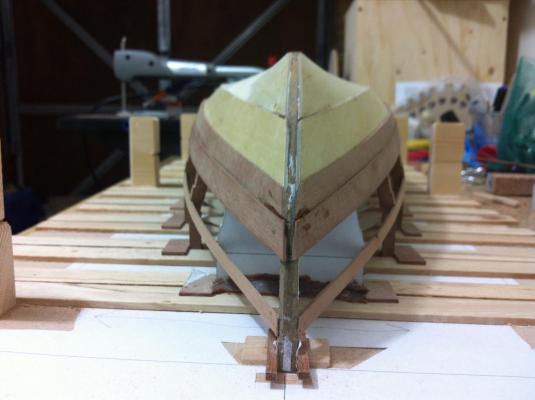

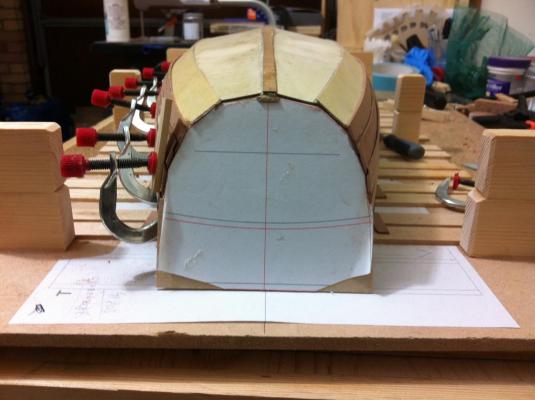

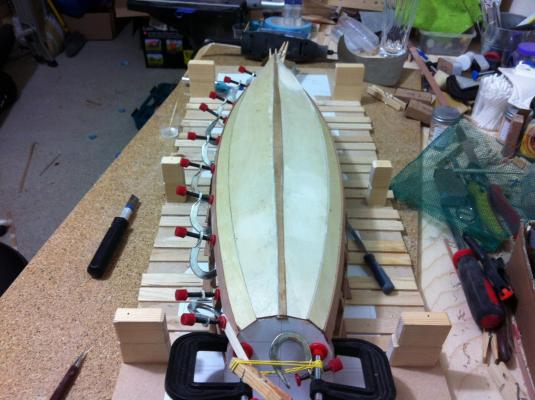

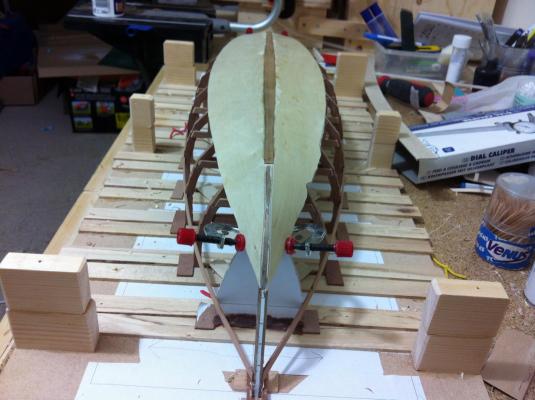

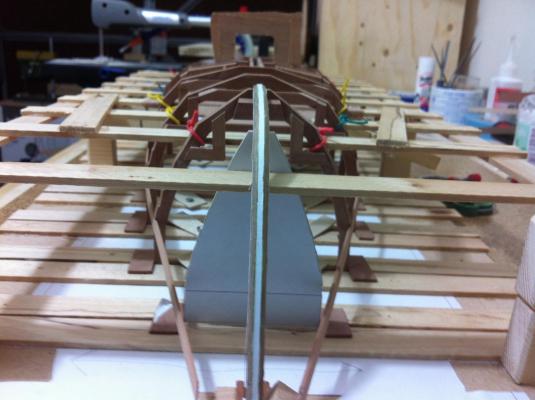

Planking is finished! Still couple of things left, to trim the end of the planks at the bow, add the false stem, the keel and the rivets, do a massive amount of fairing and possibly paint. The transom looks ok, I think the important thing is the pair of planks at each chine to line up. Again a lot of fairing is needed.

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

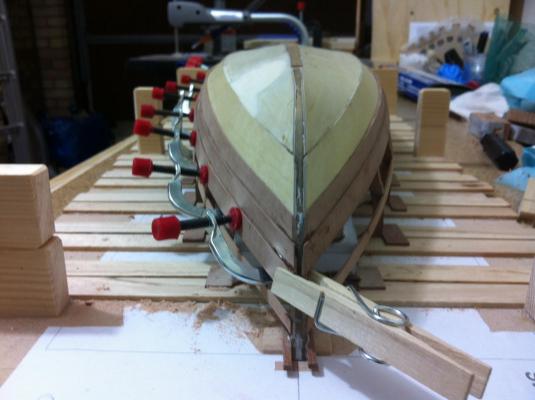

Thanks Patrick and Bob, I now have huge respect for the traditional ship builders of old that were lofting on floors and putting these boats together with hand tools! Tad was right, planking goes faster now or maybe I go further in my learning curve. Two more planks to go! Just a few more pics There are I think significant similarities to the photos of the american team at the same stages, if we overlook the abysmal difference in the quality of the work. I hope the bow will come out like this!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

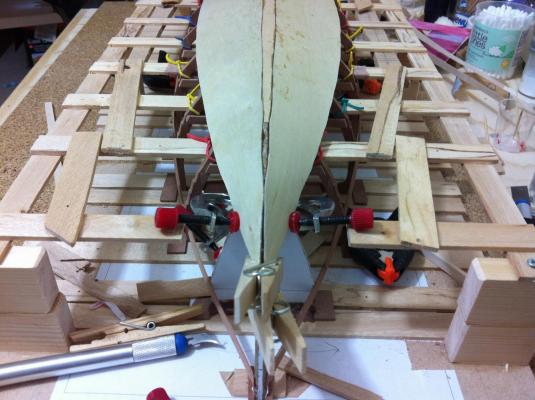

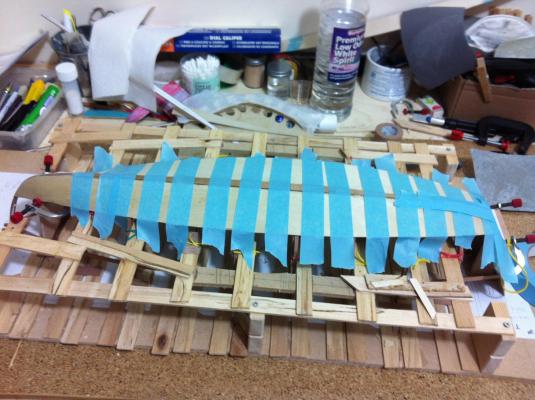

Thanks Michael, I am following your Skipjack amazing project, thankfully no engine in this boat! I decided to take a break from the stressful planking and laminate the false stem. I used again walnut which bents, glues and sands beautifully. It came out fine but maybe just not wide enough. It probably is just half a millimetre too narrow on each side but I d rather do it again than sand the planks, this is a decision for later. Even with all the planks fitted it will still be possible to laminate the stem. The next job to be completed was to fit the next plank up, which was a mountain to climb and took 3 days! The plank would not sit properly and finally I realised it was 2 cm shorter than its pair! I had to do it again but still in order to sit properly the previous plank had to be bevelled and some of the notches slightly adjusted. Generous bevelling was needed at the stern and bow. Finally I managed to get it into place and I am happy with the fit. I have no idea how the next planks will fit, hopefully they wont be far off. The original plans call for riveting but it is very difficult to fit the planks just with rivets so I used a minute amount of epoxy to glue the plank to the frames. I experimented with 0.7 mm brass wire I had and it looks ideal to be used for rivets, using CA glue and the dremel with the grinding stones to grind the wire flush. I couldn't resist a glimpse of the hull! I need to get many spare drills and a collet for the dremel as there will be hundreds of holes to drill. I think I should finish planking and then do the rivets. Also I still have not decided what to use for fairing the hull, the options could be PVA glue with woodflour or some filling compound from the model shops. The putty from the DIY shops is really difficult to work with.

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

I don't really know what to say, I never expected such honours! Great to have you along in this journey Tad! The pressure is really on now!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

Thanks for the good words Patrick, actually I have not contacted him but you are right, he probably would like to know!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

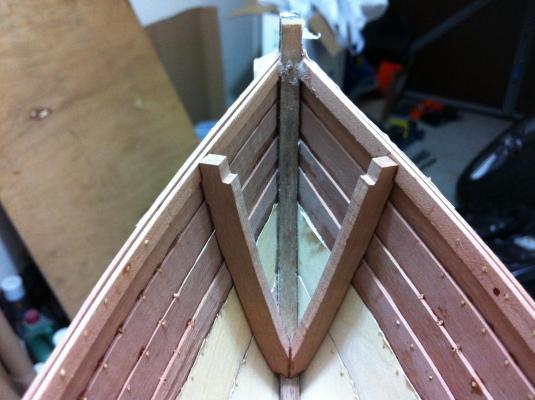

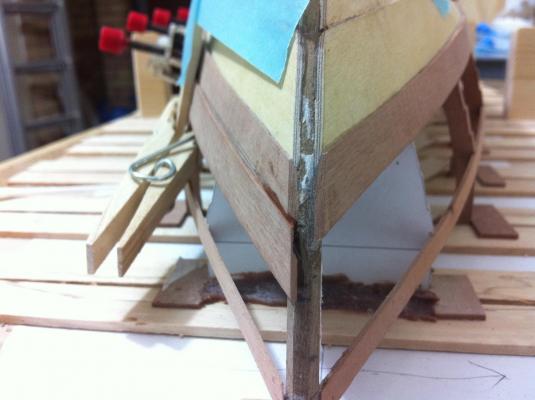

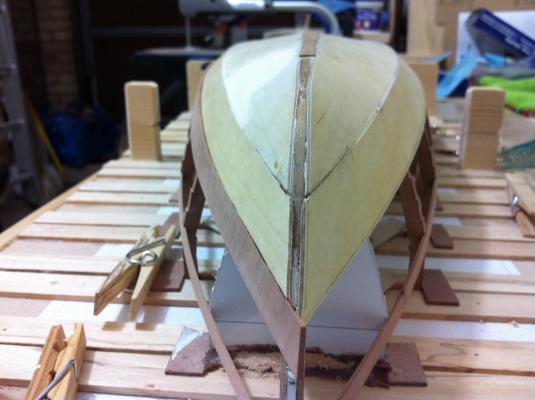

The boat is coming along slowly due to other commitments and also due to the complexity of the built. I finished trimming the sides of the bottom panels forward of frame 1, where the lapstrake should gradually fade reaching the stem. Then the lower chine panel was fitted, one side at the time. The transom proves particularly challenging to address. The fairing compound seen near the bow is to fill a large dimple which I think is the result of cutting the panels quite larger than needed to have plenty to trim, this probably did not allow the plywood to bend smoothly. The lower chine panels also need trimming. The lower edge should not be touched in any of the boards and planks as it defines the shape of the boat. Next the lower of the 4 planks was fitted. The next photos show the bevel at the bow. Both sides done, again the transom area was difficult to tackle. One thing's for sure, I will need to fair the hull until my fingers bleed. The boat is now starting to show its size, It is really a large model but also the beam looks much larger than it does in the plans. I think that I should laminate the false stem before adding the rest of the planks.

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

I think we have the name there Patrick, "Butterfly Explorer" !!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

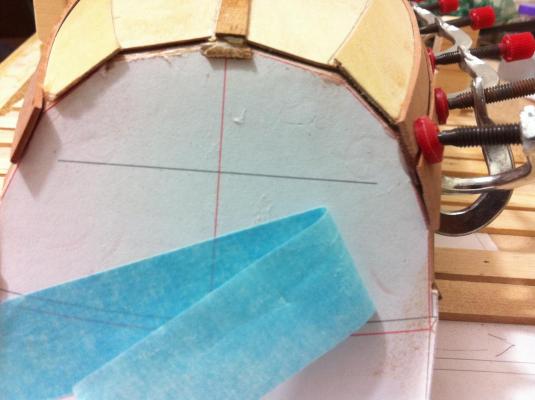

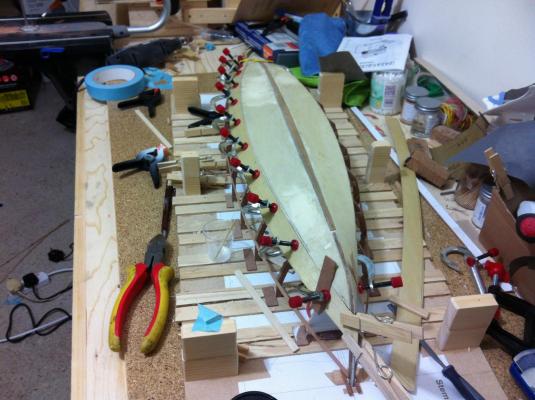

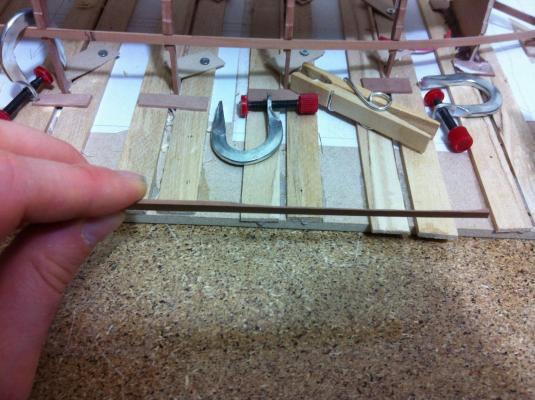

The work progresses at a very slow pace now. At every step new challenges appear. Also, I try to plan as far down the built as possible to avoid finding my self in an impossible situation. I use a lot of epoxy at this stage which is a dangerous glue as it is impossible to undo in case of a mistake. Measure 10 times and cut one! I did some work on the centerboard, the edges came out very nice. It is time to think now about painting, as the centerboard will need to be installed before the floor boards. I will be following closely the american team so the top of the CB will be red, there will be a red strip on the sides of the boat and the planking will be white (or something like that). I used Acrylic paint in the past and found it very difficult to use due to visible brush strokes and extremely poor coverage. I found enamels much better. In any case, I got some acrylic paint from a DIY store, Valejo acrylic, artist acrylic paint and Humbrol enamel and tested it on plywood previously sealed using high quality brushes. Enamel wins hands down, no brush marks, a single coat equals to 4 coats of acrylic, no nasty odour, at least not in my garage. Strangely, I did not find significant difference between the different acrylics. The bottom panels are now solidly glued to the frames and transom so it was possible to finally glue to the stem which was much simpler than I expected. I have cut the panels much larger, to be trimmed afterwards. The apron laminate is still incomplete, there is 1 mm to be added. The structure is so strong that instead of two layers of 0.5 mm I will just add a 1mm walnut strip. The next photos show the test fitting There is about 1 mm gap as fitting snugly the bottom panels to the apron was beyond my skills. This will be filled however later on. The panels will also need fairing and this will be done before adding the remaining planking. Next I sanded the panels to the stem surface, preparing for the lamination of the false stem And I added the final layer to the apron I suspect the structure now is very rigid. The jig is in the way so I cut it in half and removed one side to have more space to trim the bottom panel. There was absolutely no play in the hull. The next panel (lower chine) will overlap the bottom panel so I can use it as guide to trim appropriately. This is done very carefully as removing to much wood will lead to a hole in the hull and much excitement. I realised though that the other half of the jig was still in the way, so I removed it. The hull is rock solid. Could not resist some photos though! The apron is now fully laminated and I have a suspicion that the gap is actually filled by the excess epoxy that squeezed out but I ll check this later. I have also trimmed one panel but only up to frame 1 as trimming up to the stem will be a more complex issue. The last three photos show the outer clamp and the test fitting of planks No 2 and 4. I must say, they fit like a glove and rest effortlessly on the notches at every frame! A rather pressing problem is what to use for fairing the panels. I tried some filling putty from a DIY store but it is not fit for purpose, it dries very quickly and is very hard to sand. Any suggestions?

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

Thank you both, hard work indeed! I did some more work today on the apron. I first bevelled the junctions to the frames and then connected the dots. The different colour layers of the laminate help figure out how much wood to take. One side done The bottom panel finally looks like it has the correct shape. I did the other side and I am happy with the result. It is not a close fit as there is up to a mm gap here and there but I think it should be fine with some filler. There are a few problems though 1. The overlap of the planking should gradually fade as it approaches the bow so some bevelling is needed 2. A lot of bevelling is needed and probably wood removed where it meets the next panel towards the sheer 3. I used 1 mm plywood but still it is very unwilling to take the sharp bent at the bow. Maybe 0.8 mm would be preferable 4. I am not sure how to keep the plywood panel in position until the epoxy cures Certainly though, there is progress!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

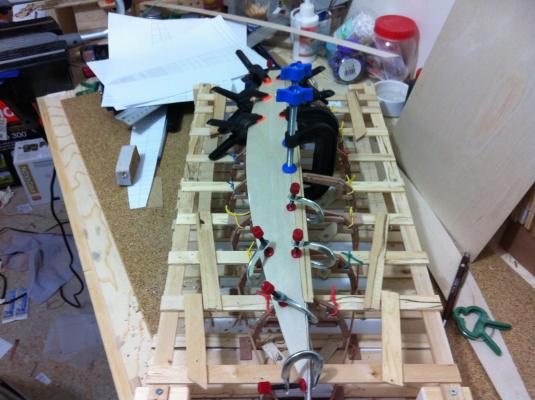

Actually, I just realised that the jig needs to be cut to be removed as the apron is now in place. Also the hull looks really solid, so I just glued some more wood to strengthen the jig prior to cutting as it may ned to be used again. The epoxy has partially cured so I removed the plastic bag for a couple more pics

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

On a different note, I do not think there are any copyright issues from the photos I uploaded. I think I should add the sites for reference Tad's site http://www.tadroberts.ca/ The american group's site http://www.boatproject.org/#628 If there are any issues I would be grateful if the moderators would remove material appropriately

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

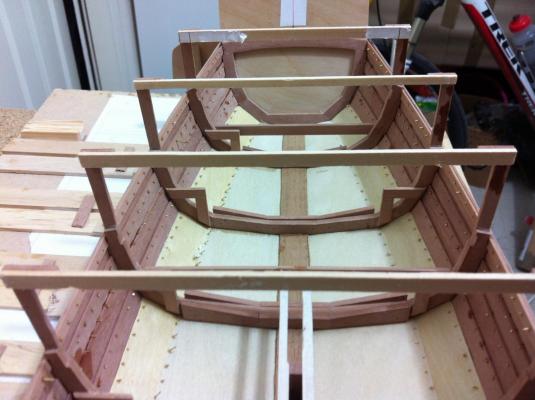

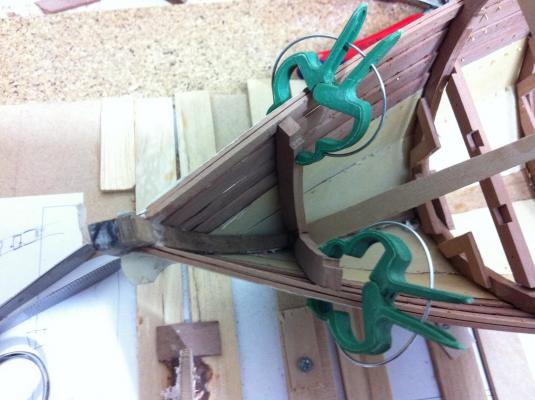

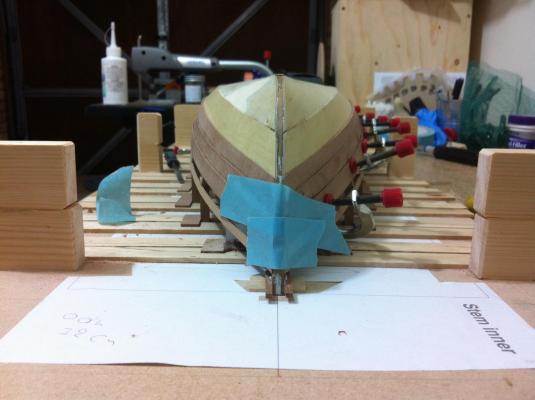

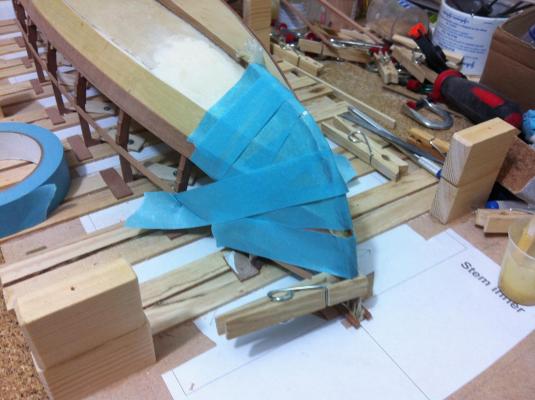

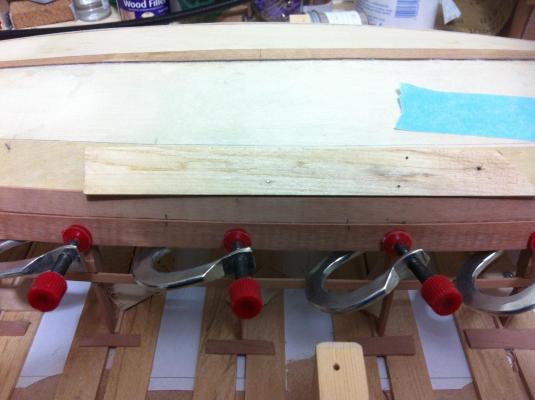

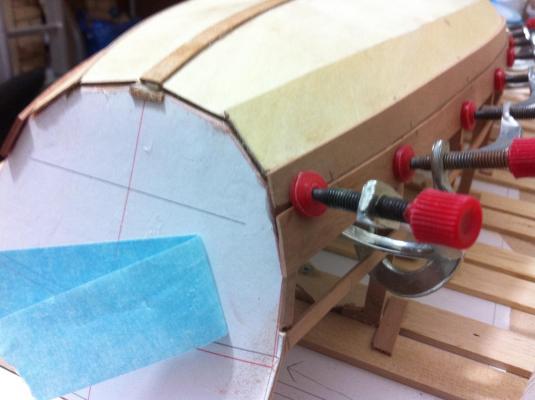

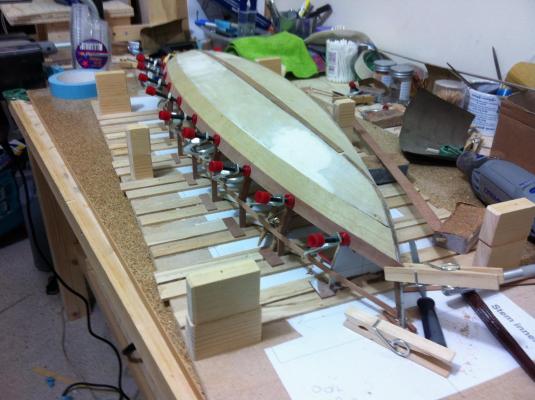

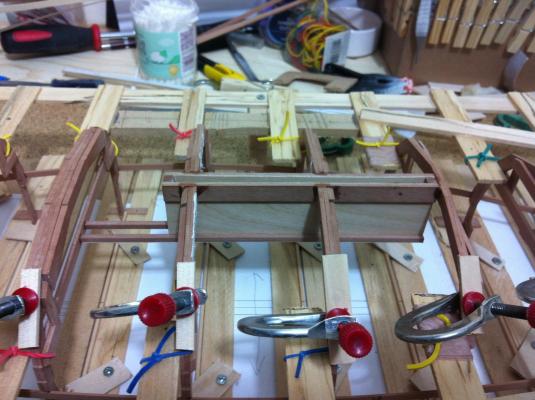

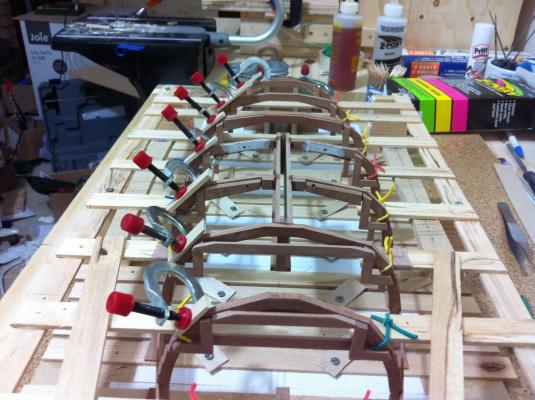

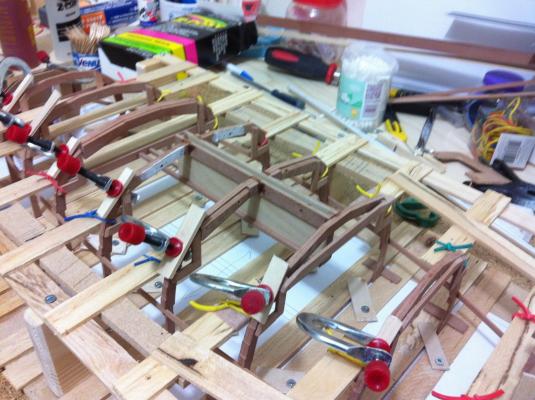

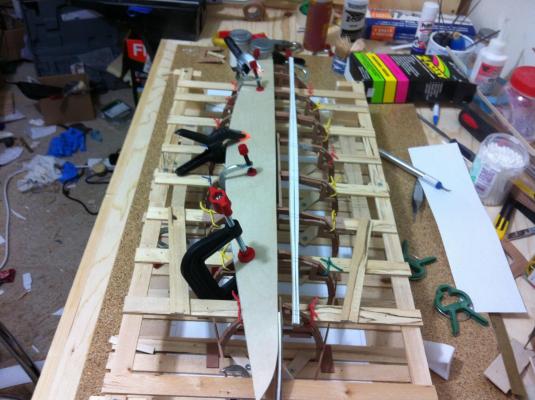

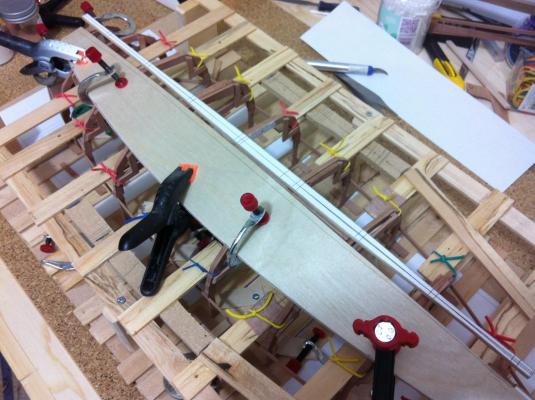

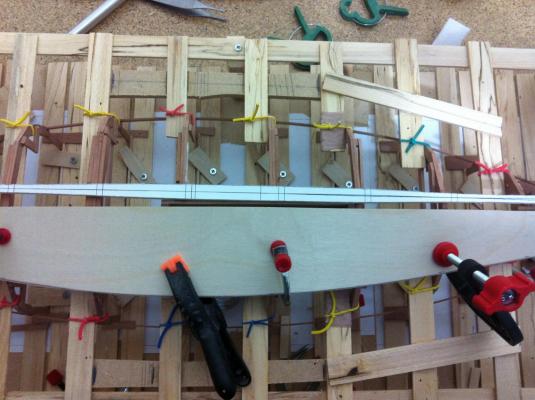

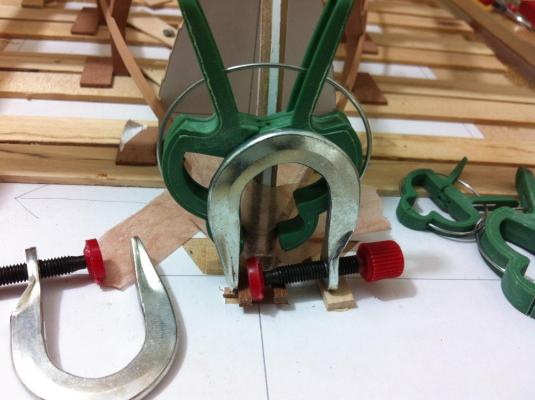

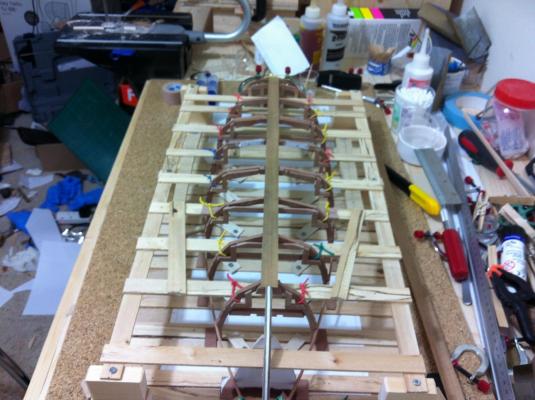

Progress has been very slow recently as I am really struggling with the keel, the bevel it should have and the shape of the bottom panel. I finished the CB case and installed it. I first used epoxy to glue the case to the frames. I tried packing the case but it distorted the frames. I was very careful with the epoxy as it is a very messy glue. I also added the outer clamps and glued the stem to frame No 1 I then reinforced the CB case with epoxy filets. It looks a bit messy but all these will be covered by the floor boards. In my CAD plans I designed the bottom panels but did not take into account that the rabbet line is not straight but widens at the centerboard. Also, the panels need a lot of bevelling where they meet the next panel towards the sheer. Overall I still have not pinned down the right shape. I have lined how much I think needs to be removed I attached the outer clamps to the stem Next I started laminating the stem. The plans call for 16 mm wide strips and I could only get this dimension in walnut 1 mm thick. The overall thickness of the stem is 3 mm and I think that the resulting 2 layers of epoxy might not be enough to provide rigidity. I managed to find 0.5 mm maple sheet to cut strips for the laminate which will double the epoxy layers. I will first laminate the first 2 mm, bevel these and then add the last 1 mm which will be shaped as the keel. I am hoping the bottom panels will then fit flush sitting nicely on the bevels. The american group did something similar It will not work of course as it is far too optimistic a plan but I will give it my best shot. Besides, this is what I would do building the full scale boat. The first strip 1mm thick is epoxied into place. The transition from the last frame to the Transom does not look too faired but it is too late now. Preparing to laminate the rest of the layers You can never have enough clamps The hull should now be very rigid. I will probably add another strip to connect all frames (beyond the sheer line) to strengthen the structure even further and remove the cross beams of the jig. The stem will probably need some form of re-enforcement as well. Things are getting very complex and difficult now. And with all the epoxied parts there is no going back!

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.6fd4c1b78768bb3efd745ab810936005.jpg)