-

Posts

655 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rlb

-

What kind, brand and where do you buy your end mills?

rlb replied to rlb's topic in Modeling tools and Workshop Equipment

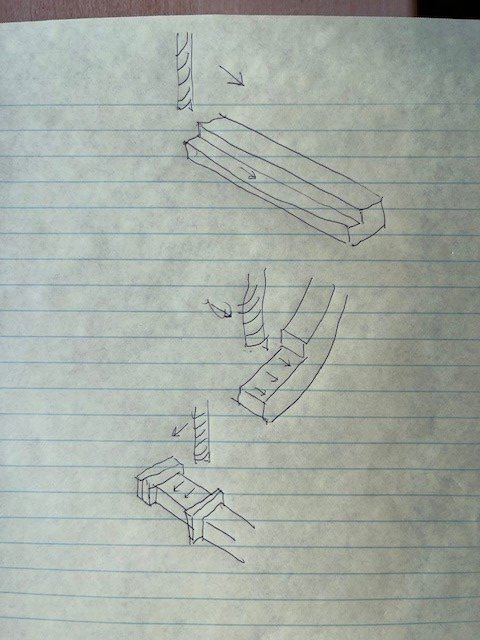

Paul, thank you for referring me to "No Idea"'s build log. That is exactly the type of milling that I need to do. I just want to make sure I buy the right type and quality of end mill bit. Here is a sketch of some of the cuts. Yes, Jaeger, all can be done with a chisel (and I have made them all more than a few times!), but with so many to be done, learning to do these with a milling machine will save me much time. Ron -

What kind, brand and where do you buy your end mills?

rlb replied to rlb's topic in Modeling tools and Workshop Equipment

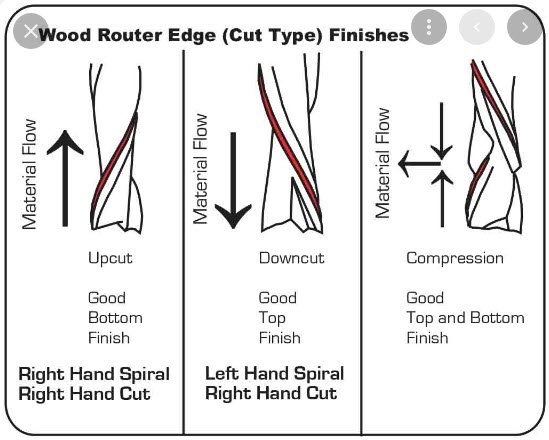

I'm talking 1/4" or 1/8" shank size, 1/16" to 1/4" cutting size. See below. This image refers to "router" bits, but I have seen the terminology when talking about end mills as well (not even sure what, if any, difference there is between the two). Ron -

Forgive me if this has been discussed--I did a quick search but didn't find what I was looking for. I'm new to milling (other than some crude experiments with a Proxxon rotary tool in a drill press type holder), and I'm trying to get my information in order before spending any more on bits/mills It seems that a 2-flute end mill is good for wood, upcut or downcut I'm not sure, but thinking downcut may be better. I'm not sure how much this matters. Some don't say whether they are up or down cut. I'm looking for good quality, smooth finish, minimal tear-out. What do you recommend, and who do you get them from? Any other useful info that I should know about end mills? Thanks, Ron

-

Thanks, CiscoH, Håkan, davec and JJ, and all who are looking in and liking. Yes, I like the "workaday" stowed look better than perfectly coiled lines. The inspiration came from seeing how the working carronade on the Niagara replica ship had been tied down. There is a photo of it earlier in this log (post #116), but here it is again-- My take on it is a little different (simpler to accomplish), but retains the idea of wrapping the tackle falls back and forth across the top of the carronade. The 6-pounder long guns have been installed-- Now it's time to put the ship away again-- And continue work on Oneida's spars-- All for now, Ron

-

I spent the last week lashing down the carronades-- At the bow are the tackles for the two 6-pounder cannon, and also their breeching lines. The two carriages are nearing completion here, black monofilament fishing line was used for the truck "pins"-- After they were finished, fitting the breeching lines was next. One end was lashed to it's eyebolt and temporarily fixed into the bulwark. The line was checked for length, allowing for a loop around the cascabel, and the fastening to the other eyelet-- The cascabel loop was temporarily tied, as well as the first lashing of the eyebolt, and the length was checked again-- As the first breeching line was finished, the second could be made up more quickly using the first as a guide, without needing to check it in place on the ship-- I've reached my stopping point for the day. Ron

-

How to "unstick" this chuck from the mill spindle?

rlb replied to rlb's topic in Modeling tools and Workshop Equipment

Got it!! After a few more vigorous taps (still with a very small hammer) it came loose-- Thanks everyone for your help--this case is now closed. Ron -

How to "unstick" this chuck from the mill spindle?

rlb replied to rlb's topic in Modeling tools and Workshop Equipment

Thanks for the video, Dziadeczek. He looks like he is tapping harder and with a bigger hammer than I did, so I will probably try this again. The mill sat unused for many years, which might make the chuck harder to dislodge. I did try with a wooden wedge, but the wedge broke apart. Ron -

How to "unstick" this chuck from the mill spindle?

rlb replied to rlb's topic in Modeling tools and Workshop Equipment

Thanks everyone for your advice. Sherline does sell a "knockout bar" as described by Roger Pellet, so perhaps they expect light tapping (with a soft hammer) would not be harmful? I do take mnl's caution seriously though, and I have also looked into the Jacobs chuck wedge sets. With shipping and tax one of those would be around $30, not the end of the world, but it would be easy enough to make a similar "U" shaped hardwood wedge that I think I will try first. -

How to "unstick" this chuck from the mill spindle?

rlb replied to rlb's topic in Modeling tools and Workshop Equipment

Thanks Pat and Alan. I was able to find a draw bar in the box of accessories, and thread it into the top of the chuck through the spindle assembly. I gave it a few taps with a small hammer but it didn't budge. I'm nervous of hitting it too hard. But am I on the right track? Ron -

Hello all, Today I had the opportunity to buy a used Sherline lathe and mill, so I did. I have no prior experience with them so I am reading the online manual from the Sherline website, and trying to familiarize myself with the basic nomenclature and basic operation of these machines. From what I have learned so far, they are somewhat older machines, (probably pre 1999) but still model 4000 for the lathe, and 5000 for the mill. I have one roadblock immediately. The jacobs chuck is stuck in the mill spindle-- Am I right that this should be just a friction fit? What is the best way to loosen/remove this? I ask this knowing that some may be thinking "if he can't do this, these machines are wasted on him". Any advice is appreciated. Ron

-

Thanks, JJ. Now that I have finished stropping the blocks, the ship comes out on to the table for rigging the carronades, and two 6-pounder cannon-- . Tackle lines have been cut, dyed a little darker, and are in process of tying to an eyelet in one of each pair of blocks-- I had assembled one of the 6-pounder cannon carriages a while ago, now I need to assemble the other one, as well as finish the first with cap-squares, breeching rings and other eyelets. I have two extra axles pieces here!-- All for now, Ron

-

HMS Euryalus 1803 by rlb - 1:48 scale

rlb replied to rlb's topic in - Build logs for subjects built 1801 - 1850

Hello 2024! Time to work some more on Euryalus! In preparation for assembling the stern framing and aft cant frames, the deadwood assembly piece needs a great deal of shaping, which I had started before my long hiatus, and I now continue-- Perhaps I am 75% done. The goal is to get close to the correct concavity in the area between the bearding line and the keel and sternpost, so that a minimum of additional fairing need be done when the frames are on-- . All for now, Ron- 122 replies

-

- Euryalus

- Plank-on-frame

-

(and 4 more)

Tagged with:

-

Thanks Håkan. Only a few photos today, but I'm happy to report that I worked up the motivation to finish the carronade tackle blocks. This shows the 13 sets that were done, and last four sets (16 blocks) I still needed to do-- The total here is 17 sets, because one is on the already rigged carronade that has been on the ship for years. And here they are done-- That was probably the least pleasant task I have had to do on the build so far (literally taking me years of off and on work), and I'm glad they are finished! And here is one of the topgallant masts roughed out, next to a topmast, and the other topgallant blank-- Next is rigging the carronades, and continuing work on the masts. All for now, Ron

-

Thanks Håkan. I can only guess that when they were assembling that page of the book, the true scale illustration just looked too small on the page, so they enlarged it and didn't change the caption. Who knows?! Hopefully I will remember to always double check the illustrations. I finished the trestletrees, and test fit the pieces, checking to make sure they would also fit on the topmast-- Then I made a rudimentary jig to hold the trestle pieces, for gluing the crosstrees. I rarely make these kind of jigs, because I am too impatient and lazy, but it was a good idea to do this, and it only took a few minutes-- I ended up making deeper notches in the trestletrees, and none in the crosstrees, though you can see I had marked some, and even started to cut a couple notches in one of the crosstrees, before deciding it would be wiser to just notch the trestletrees even though not historically accurate. I test fit the crosstrees many time, adjusting the notches in the trestle trees for depth, and to make sure the crosstrees were parallel to each other, and perpendicular to the trestletrees. I then glued the crosstrees in-- The photo makes that first set of notches look very bad. It's not so noticeable in person, but I'll fill the gaps and all will be stained black when done-- There is more work to do now on the topmast: filing a tenon on the end, for the cap, and angling the top of the octagonal haunch so the trestletrees sit parallel to the water line-- Now it's on to the topgallant masts. Ron

-

Yes, Håkan, more practice!! I had cut out the trestle trees, and glued the crosstrees down to a piece of paper, to "hold' them while I filed the tapered undersides. But a nagging feeling that they were too big wouldn't go away. After holding the topmast close to them, I was pretty sure of it. I looked at some photos of other models and then got out Lee's "Masting and Rigging", and calculated the length of the crosstrees according to that source. Sure enough, it appeared that I had made them about 50% too long. While I love Petrejus' book, this is the second time I've gotten burned using his illustrations without checking the scale accuracy. Although the caption for the crosstree illustration read "full size" (meaning full scale size), it was actually quite a bit larger. Here are the new crosstrees, roughly shaped, compared to the previous ones-- I glued them down and tapered the undersides-- I cut out new trestle trees, and here they are along with the crosstrees, and a wrong sized trestle tree and crosstree-- The crosstrees need some more work, generally narrowing the depth and breadth a bit, and cutting notches for the trestle trees. The trestle trees need deeper notches, and some further shaping, then I'll try assembling them and see how they look on the topmasts. Ron

-

Thanks bigcreekdad and Håkan. I have used that technique often, anytime I need a number of identical parts that have some kind of non-square shape, such as cleats, or even the anchor stock planking of the wales. They are glued together with a bare minimum dab of white (PVA) glue, as the iso alcohol does take time to do soften the glue. In fact, hot water works better for that. A few posts back, JJ (scrubbyj427) suggested that denatured alcohol works much faster than iso, and I will be trying that soon, since I need to redo the crosstrees! Ron

-

Happy New Year! Thanks CiscoH and jereramy, and those liking and looking in. To replace my toothpick topmast fids, I filed a pair from brass-- Next these were blackened, along with some eyebolts, ringbolts, and four hooks that I need to finish the carronade tackle blocks-- Next task is the topmast crosstrees, following the illustration in Petrejus' book "Irene"-- I glued six blanks together so I could do the rough shaping for all of them at once-- When I was satisfied that the rough shape was close, the block was given an isopropyl alcohol soak to separate the pieces-- I notice some irregularities, mostly the right side end is a little "bulbous", and they look just a bit chunky to me, but there is still a lot of work to do on these: drilling holes in the ends, notching for the trestle pieces, tapering the underside, and refining the overall thickness and curves-- All for now, Ron

-

Thanks Hamilton and all who hit the like button. Two blanks for the mast caps-- A few tries later, I got two good ones. The problems were various--inaccurate spacing of the holes, holes being filed out too big, or out of round-- Here are the masts and topmasts temporarily on the ship-- And disassembled again. I have temporary fids made from a toothpick, I'll make a couple from brass. To the right are two blanks for the topgallant masts-- All for now. Ron

-

Thanks JJ and Dowmer. The wood is Swiss Pear. Filing the tricky tapered octagon at the top of the topmasts- All that's left at this point is making the hole for a sheave near the base-- And, pretty much done on the two topmasts-- Next will be the mast caps, and then I'll be able to set the masts, tops, and topmasts up (temporarily) on the model! Ron

-

Jean-Paul, Congratulations! Beautiful work and great job on "personalizing" your wonderful model. Ron

- 57 replies

-

- marisstella

- batelina

-

(and 1 more)

Tagged with:

-

Here we are with 2023 almost done, and I have finally felt like working on Oneida again. Continuing with the main topmast (which is identical to the fore topmast), I roughly marked the various transition locations, and began roughing out the shape with a file-- With the top reduced to the correct dimensions (minus some chamfering which will come at the end) I began filing the taper into the main part of the topmast-- Once the taper along the topmast was correct, I then filed the corners, turning this section into an octagon-- At this point I filed the eight edges of the octagon on the center section of the topmast, masked off the upper and lower areas for protection, and began sanding that central part round-- Hopefully more updates soon! Ron

-

Thanks, JJ. After a couple of tests with different numbers of threads, I was able to make a cable of the right size for Oneida's larger anchors-- The anchors won't be attached until near the end, but I wanted to get the cable on board before getting heavy into the rigging, and access to the deck becomes more difficult. Ron

-

JJ, the mast work is all Swiss Pear. Parts of it will be stained black. Most of the model is Swiss Pear. The Carronade carriages are Castello Boxwood. The decking is Maple. The few carvings and and the head rails are Castello. I have been applying a Tung Oil finish, which seems to take some of the pink out of the Pear. All the wood looks almost the same color in the photos. In person the difference is more discernable, but it is not pronounced. Over the years the Castello and Maple have oxidized, and with the Tung Oil finish, they're not far off from the Pear.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.