-

Posts

1,298 -

Joined

-

Last visited

-

cotrecerf reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

cotrecerf reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Mark Pearse reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Mark Pearse reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Jack12477 reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Jack12477 reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Bedford reacted to a post in a topic:

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

Bedford reacted to a post in a topic:

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

-

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Bedford reacted to a post in a topic:

Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

Bedford reacted to a post in a topic:

Libertad 1925 by Valeriy V - Scale 1:100 - Spanish Type F Light Cruiser

-

Mark Pearse reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Mark Pearse reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Jack12477 reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Jack12477 reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Bedford reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Bedford reacted to a post in a topic:

Pomeranian Rahschlup 1846 by wefalck – 1/160 scale – single-masted Baltic trading vessel

Bedford reacted to a post in a topic:

Pomeranian Rahschlup 1846 by wefalck – 1/160 scale – single-masted Baltic trading vessel

-

MAGIC's Craig reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

MAGIC's Craig reacted to a post in a topic:

Herzogin Cecilie 1902 by Jim Lad - Four Masted Barque

-

Keith Black reacted to a post in a topic:

Tally Ho by vaddoc - scale 1:12 (maybe) - as rebuilt by Leo

Keith Black reacted to a post in a topic:

Tally Ho by vaddoc - scale 1:12 (maybe) - as rebuilt by Leo

-

Keith Black reacted to a post in a topic:

Hercules by vaddoc - 1:64 - Steam Tugboat

Keith Black reacted to a post in a topic:

Hercules by vaddoc - 1:64 - Steam Tugboat

-

Keith Black reacted to a post in a topic:

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

Keith Black reacted to a post in a topic:

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

-

KeithAug reacted to a post in a topic:

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

KeithAug reacted to a post in a topic:

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

-

Having crewed the 123 year old steam tug Waratah and having been below in the aft accommodation (nowhere near as grand as Cangardas) I can assure you that even in that old girl you could not hear the shaft spinning. I would imagine the only thing that might create a disturbance is the propeller when she goes astern or if it catches air, I imagine it would be very well balanced.

-

Bedford reacted to a post in a topic:

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

Bedford reacted to a post in a topic:

Cangarda 1901 by KeithAug - Scale 1:24 - Steam Yacht

-

John, my ex wife used to do family daycare so there were always kids in the house and one in particular saw my model of the schooner for Port Jackson and straight away commented how cool it was and "can we play with it"? Thankfully it was up high and protected by glass. That particular little demon would have turned her into kindling in minutes.

-

I'm with Wefalk, just the other day thinking we haven't seen Michael for a while and suffering pilot cutter withdrawal. Welcome back Michael

- 2,215 replies

-

Yes, now that I've seen it I can't unsee it. I guess I was too focused on the details to see the whole properly.

- 33 replies

-

- gaff sloop

- restoration

-

(and 1 more)

Tagged with:

-

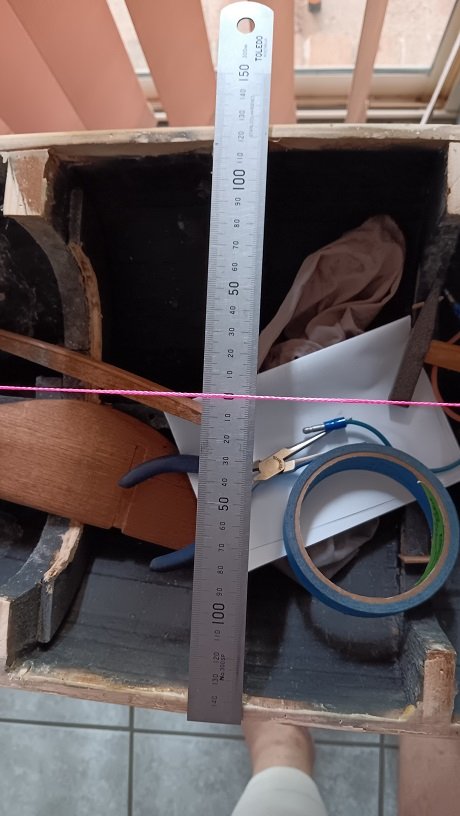

I just took some more measurements, mid ships, and she's actually out by 20mm! No idea by looking at it without the string line but it's painfully obvious with it.

- 33 replies

-

- gaff sloop

- restoration

-

(and 1 more)

Tagged with:

-

Well there's news on this one and it's all bad. I've been laid up with a new knee so thinking a lot about this build and today I was well enough to set it up on a table and run a string line down the centre. This was important because if I'm going to put the effort into this then it's going to get a proper deck with the planks following the curve of the hull and joggled into a king plank and if she's not symmetrical that becomes very problematic. I can shave planks here and there to fake it for minor discrepancies but although she looks pretty good to the eye the string line tells a very different story. The hull isn't straight and there is as much as 9mm difference from one side to the other, it's also got a bit of a twist in it. What does all that mean? She'll be scrapped as I'm not interested in the nightmare that would be in trying to make a silk purse out of this particular sows ear. If I decide I really want such a model in the future I have a set of plans for "Altair" and it will be a lot easier to build something straight from scratch than to fix this.

- 33 replies

-

- gaff sloop

- restoration

-

(and 1 more)

Tagged with:

-

Mate, my son works for such a contractor and hates it, always trying to convince him and the guys that the right way is generally quicker and gives a much better outcome. On the subject of model boat interiors, I met one of Jim Lads compatriots ( a model maker at the Australian National Maritime Museum ) who had been to England and visited the NMM there just as they were using an endoscope to look inside the old admiralty models. These models, as many know, were used instead of drawings to show the admiralty what every deck would look like so they are fully detailed and had not been seen by anyone since the admiralty signed off deck by deck as they were closed up with the weather deck.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.