-

Posts

720 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Geoff Matson

-

Steve Glad I could help you out. The only bad thing about all the stuff that goes in the boat is that it really hides the interrior of the boat. You might want to thin out the boat details. If I had to do t over I would not put so much detail in the boats. As for the keels I put the one on the big boat so it would fit in the chocks over the hatch covers. And the other three will be hanging over the sides so I put them on also. I am building the Conny following Bob Hunts practicum and taking alot of information off the plans. Good luck with the boats!

-

It looks like your plan is working for you so just keep going the way you are going. It looks great!

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Jay That rigging surely makes you think and plan ahead.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

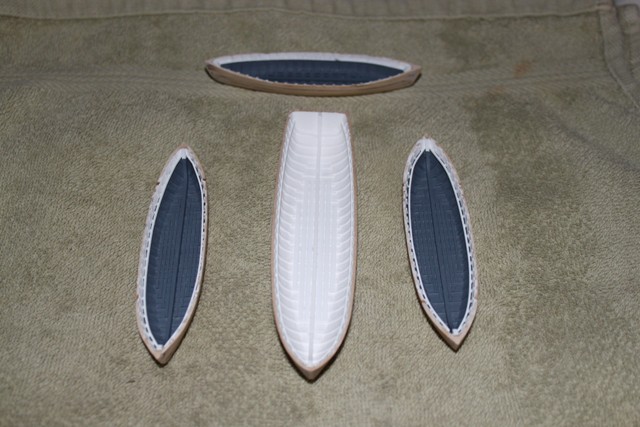

Steve Thought this might help Here is the Evergreen plastic that I used for the boats I used evergreen styrene plastic for the interiors and it was: Part no 112 .015 x .040 strips for the whaleboat footlings, Part no. 122 .020 x .040 strips for the pinnace & whaleboat ribs, pinnace floorboards, pinnace & whaleboat gudgeon and pintle, Part no. 124 .020 x .080 strips for the pinnace footing, pinnace caps, pinnace, oarlocks, Part no.131 .030 x .030 for the pinnace thwarts, waleboat rising. Part no. 9010 .010 sheet for the pinnace portable pannel Again, just check the plans and see what you need.

-

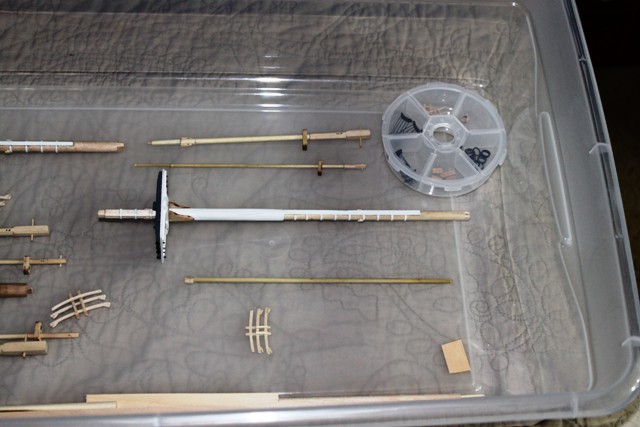

Sure Hope this helps out Here are couple of pictures: The stryrene bends easily and is ca glued in the boat. Here is the interior a little further along Here is all the boats with the interior and painted The last picture shows what I made for the interrior. Just play around with the styrene and see what happens.

-

We are all going to have to build one very large case for Conny.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Looks like you are getting the rigging under control. Nice work on the pendant lines.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

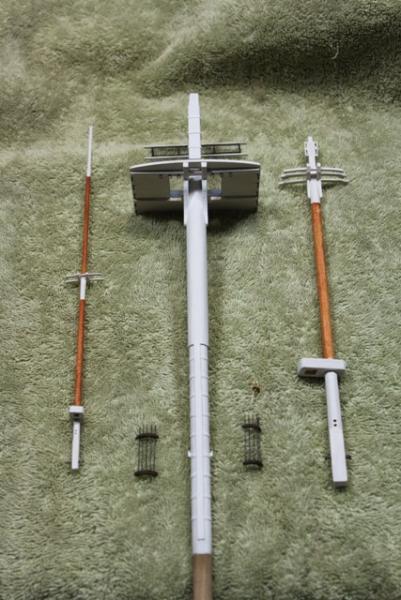

Jay I got the rings and mizzen mast all ready to go. There are a lot of items like like. You relly have to be sure before you glue something on the masts. Thanks again

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Jay Thanks for the information before installing the masts. I will really plan ahead before I do that. Lots of relationships to look at.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

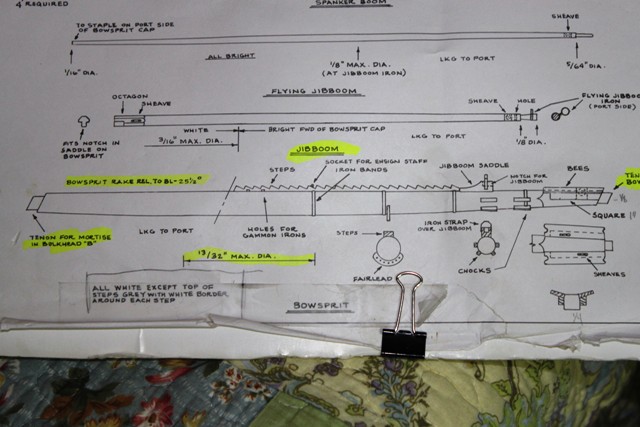

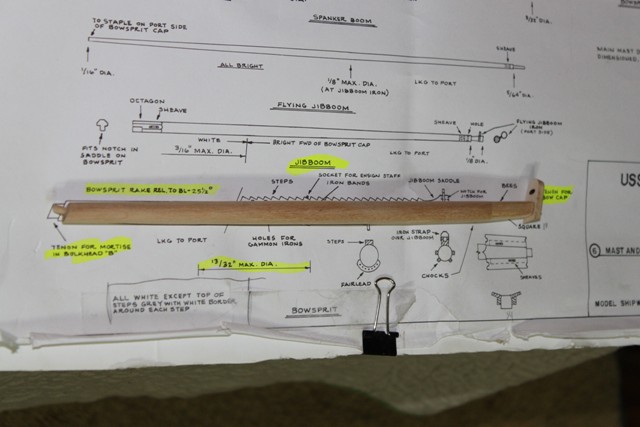

Jay I finally got the bowsprit all figured out. Thanks to you and the other guys for their help. I am getting close to the rigging process and am thinking of how to approch it. I am not going to the rig the sails as you are so I should only have half the problems I am seriously thinking of installing the masts, then do the ratlines, the the topmasts, and ratlines, etc. That way I won't have all the lines hanging in my way. I am also thinking of prerigging all the masts as you are doing, but only dry fitting the attachment points in place. Mark them and then when it comes to rigging, all I have to do is install them. That way I will have a baggy full of line reay to go. It will be a big thought process, but I will see what I can come up with. I will be following your progress and that may help me in my decisions. Thanks

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Looking good Dan. THe first one is always the hardest.

- 64 replies

-

Ok! I finally figured out the bowsprit. Only in ship modeling would you take a wood dowel and keep the top level the entire length. Then on the aft end make a slight taper on it. Then form a tennon on a angle cut while keeping the bottom level in the middle. Then on the bow end make a slight taper the goes from round to square and form a tennon on the end for the bow cap at an angle! But I did it and here it is: Glad this part is done.

-

In addition to the conservators wax I found three kins of bees wax off the internet The basic yellow color, black, and a white or neutral color. I also found a thread treatment from an American company www.herrshners.com It is similar to the conservators wax. I still learn to the conservators wax

-

Looks great Jay. The sheave block adds a little character to things.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Using Blacken-IT

Geoff Matson replied to fnkershner's topic in Painting, finishing and weathering products and techniques

Floyd Thanks for the interesting post. It looks like the answer to all your questions is bascially Yes. As with most chemicals you need to experiment with all of them and brass being used to fins your best results. I have used the basic blacken it and my results have been mixed. It seems to be chaulky and rub off. I have had good results with Burchwood Casey. It is a basic gun blackening agent picked up at most gun supply stores. The Brownells Oxpho Blue gives a more blue hue to the brass. I like this product when I make small scale pikes, boat hooks etc from brass. It is also sold at a gun store. I think the most important thing is make sure the brass is well cleaned as you mention in your points.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.