-

Posts

720 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Geoff Matson

-

I also have the kit, it will be awhile before i get to it though. It will be great to follow yours and Jeffs progress. So make some sawdust guys so it will be easier for me.

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

I am aware of that spar. Thanks for the update though. I am actually getting pretty good shaping these things by hand. The first ones are the hardest, then the second seems easier and so on. Right now I am spending more time planning than building.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Jay The boats are a fun build. You can put as much or little details that you want into them. I have even seen som covered with tarps. Each on is a model in itself.I am still futzing with yards. Almost have one done.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Bowsprit and martingale are looking good. Nice dervision from the rigging.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

New Tool Syndrome

Geoff Matson replied to capnharv2's topic in Modeling tools and Workshop Equipment

Harvey I know just how you feel. Sometimes the old proven ways seem the best. Right now I am working on the yards. I have no lathe so...... All the shaping is done by hand. I used all kinds of sanding stick, files, my dial caliper,etc. Nice slow pace and a few hours later I have my yard. All I had to do is remove everything from the dowl that didn't look like a yard I think some day I might get a lathe, but I will have to win the lottery first. -

X-Y Attachment for Dremel

Geoff Matson replied to Martin W's topic in Modeling tools and Workshop Equipment

She is a great help Martin. I must admit I do borrow the optivisor from her from time to time time to time. -

Jay the dogs name is Hiedi. She was a rescue St Benard and we have had her two years now. I must confess I do borrow the optivisor from her once in a while. I could not do the close up work without it. As we get older I wish I had smaller hands and bigger eyes . Your rigging is coming along nicely. The one thing I noticed about gluing and rigging. You have to be careful of the glue. Once applied it tends to tighten up the lines a little. Even the diluted white glue. This can be a plus to tighen up slack lines a little, but not good if it makes the lines too taught. It has the same effect on port to starboard lines.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

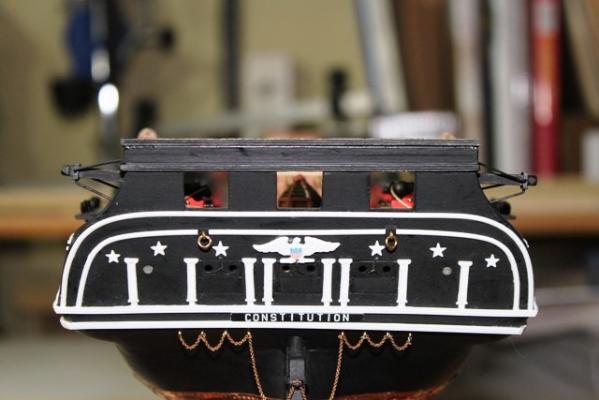

Thanks for your interest The lettering on the name plate is just dry tranfer lettering from woodland senics. Very east to use. As for the chains on the rudder. I think you are right about it being a fail safe to keep the ruddr from breaking away. Not sure as why there are three loops. That is what is on the plans. If I were to do it over I would blacken the chain and not have it brass.

-

Steve To simulate wood grain on plastic I have seen modelers use sandpaper to roughen up the wood, paint it brown or the color you and and then use a light black wash to simulate the wood grain. That is why I used maghony on the stern whale boat. I really liked the grain of the wood. You can see how much interrior you hide by filling the boats will the extra stuff.

-

I also thought of painting the boats green as they are now. But....I really like the white so that is the way I went. I just think a green boat would be hard to spot on the water. As for the plastic on a wooden model. I thought long and hard about about that one. I like to experiment and try things for future builds. The plastic worked well at the scale of the Conny. Thats why used boxwood for the interrior on the large boat, cherry on the two side boats, and mahogany on the stern boat. I have also used plastic for some iron bands and bands in general and painted them black. All worked well. I have also soldered a lot of fittings and once you paint them black you cannot really tell the diference. Some modelers use card stcok in the same manner. On the bowsprit I did use metal for the all the fittings. Except for the the bands for the jibboom . I made those band from plastic and apinted them black. I guess it is personal preference. I really like working with 1/48 scale and would probably used all wood and, brass, and wire at those scales. Thanks for the comments as they are always welcome and taken seriously. It still amazes me how many ways there are sre to do the same thing in modleing

-

Looks like we are at the two ends of the state. I am right on the Ill. Wis. Border. Thanks for the comments. I wish the Conny was of a larger scale so you could show more details. But if it was You have have to keep it in a garage! I am now working on the yards, A lot shaping and sanding to get them right.

-

Gee Jay I go away for a couple of days and come back to find my St Benard rigging you boat. Just kidding, looks light you are making major progress. Still have some experimenting to do on the rigging lines but I still have time. I have just started working on the yards. Lots of shaping to do on those ole dowels.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

X-Y Attachment for Dremel

Geoff Matson replied to Martin W's topic in Modeling tools and Workshop Equipment

Check out www.vanda-layindustries.com I have there tree nailer and hold it and like them very much. But i agree you need a firm base to get anything accurate -

Thanks for posting your build log. This one is one to do list. Your presentations are always a joy and never too long. I hope to be at the meeting Sat if I don't have horses to haul and listen to your next talk.

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Thanks for the pictures Jay. That is kind of what I had in mind. There always seems to be some alligators getting out of the pond on this build.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

One thing I noticed is it is going to be a project to thread the chains thru the stem up and around the bowsprit. Not too much room. I was thinking of trying to run a thread thru and then attach the chain. Oh well I have awhile before I need to that. I will just wait and see what you do

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Looks like it won't be long for the bowsprit to find a home. Nice job on the scroll work.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Dan I enjoy following your build and always learn something. The tip on the eyebolts for the cannons was a great one.

-

Well, I finished the fore and aft bumpkins. I used basswood for the bumpkins Square plastic for the iron band and wire for the rods. Just took everything off the plans. The one Thing I noticed is that once the bowsprit is installed it is going to be a tight fit to install the chains around the bowsprit

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.