-

Posts

3,156 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glenn-UK

-

Thank you. I am happy with the finished model.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

I started the build of the Cutter Alert 3 months ago. It has been a great boat to build and I am reasonably happy with the end result. My model building skills continue to improve with each project, and of course the quality of design, materials and build instructions provided by @chris watton makes it so much easier to build a beautiful model. My next build will be the Sphinx, so fingers crossed @James H will be able to complete the prototype (which looks amazing) as quickly as possible. I have been debating buying a camera so I can take better photos as the phone is OK but is not great. I am not sure what camera to buy as they is a wide price range and I have no idea what I need. One that has caught my eye is the Canon ESO 4000D DSLR. I have taken a few pictures of my completed build.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Looking good. I have completed my current build and I'm eagerly waiting to start The Sphinx, when the kit is released.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Allan The deadeye came with the kit and knowing how much research Chris Watton does I would assume it is accurate.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Very quick update. The rigging is now complete. I have also added the rigging for the Jib Sail but I just need to add the toggle to complete. All that is left to do is to add the swivel guns and cannons and then to secure the two anchors. I will do a more detail post with some better photos once the model is complete, but here is a quick photo.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

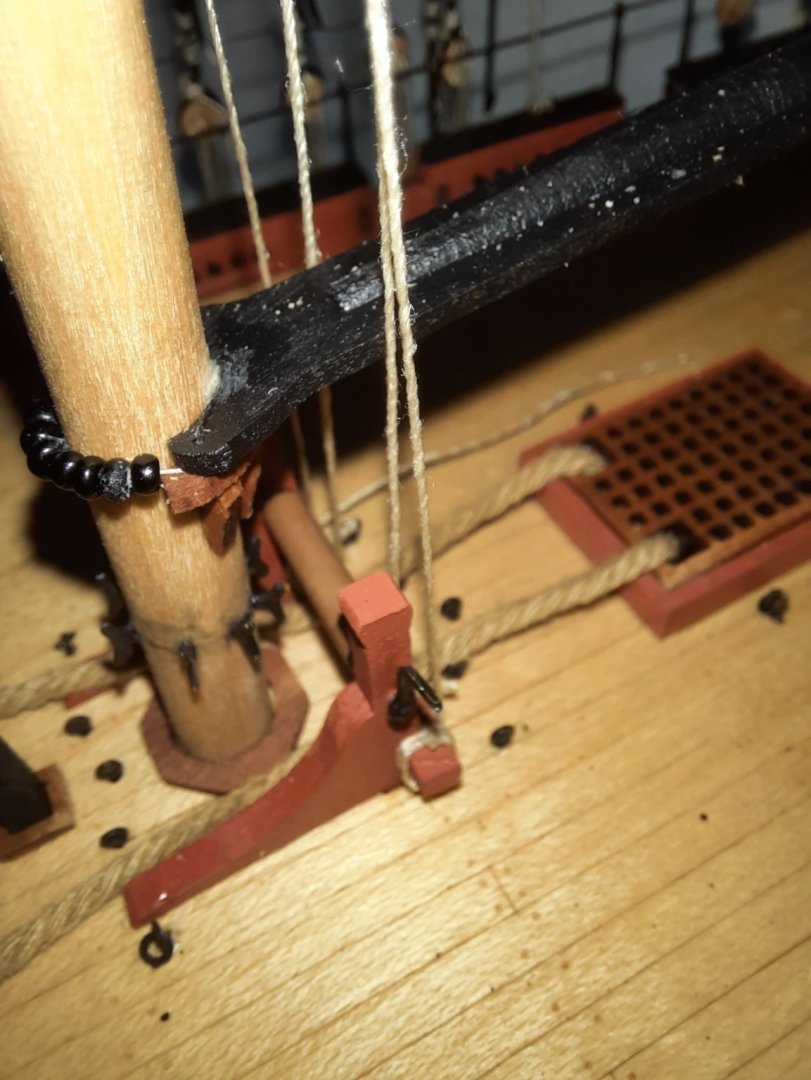

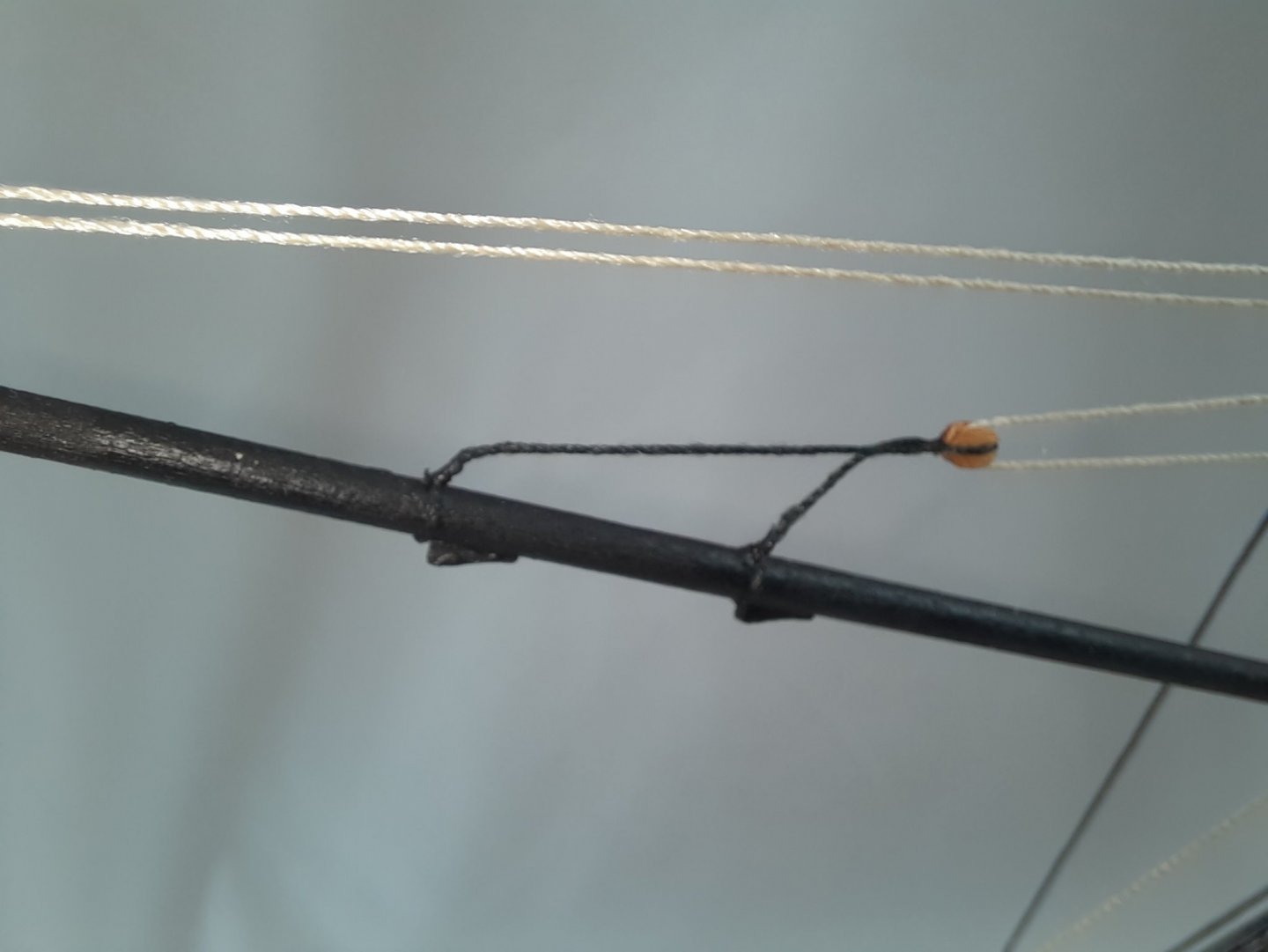

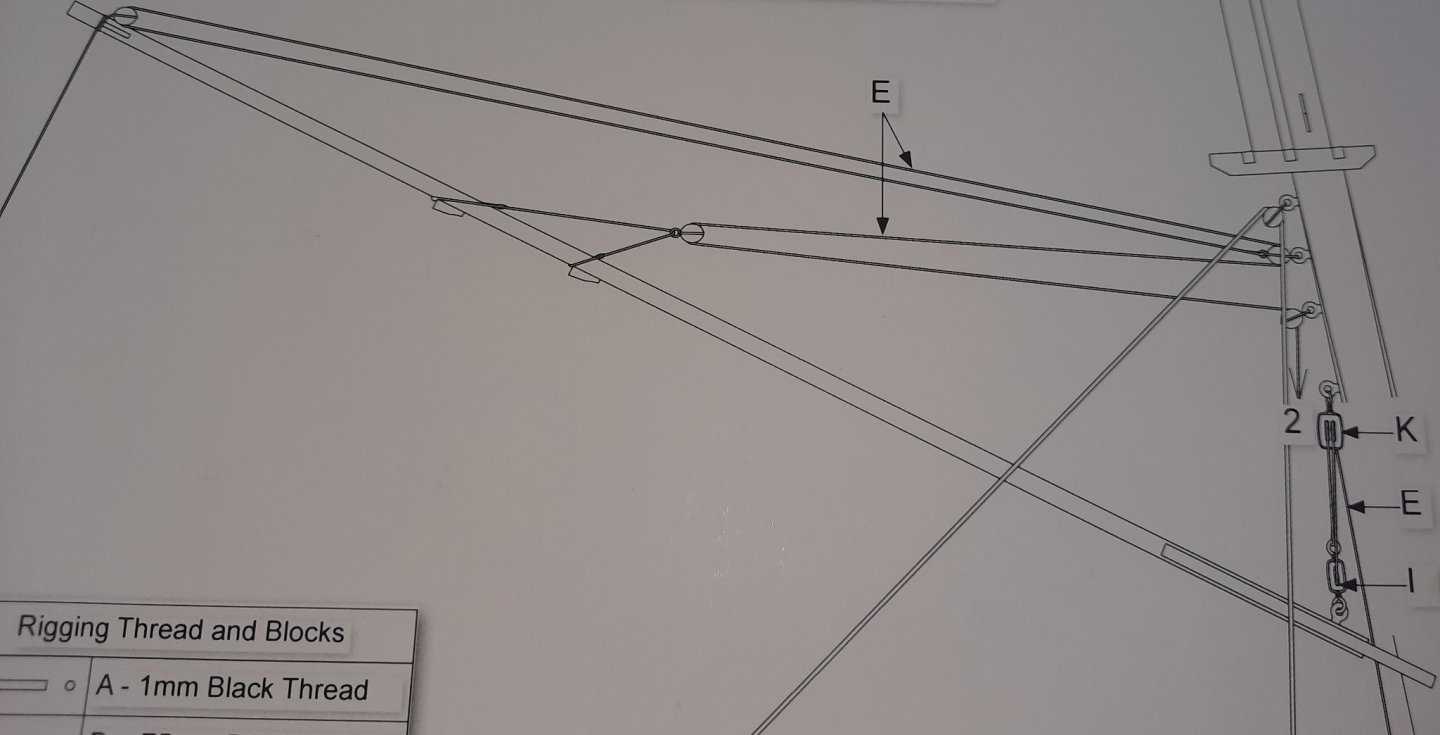

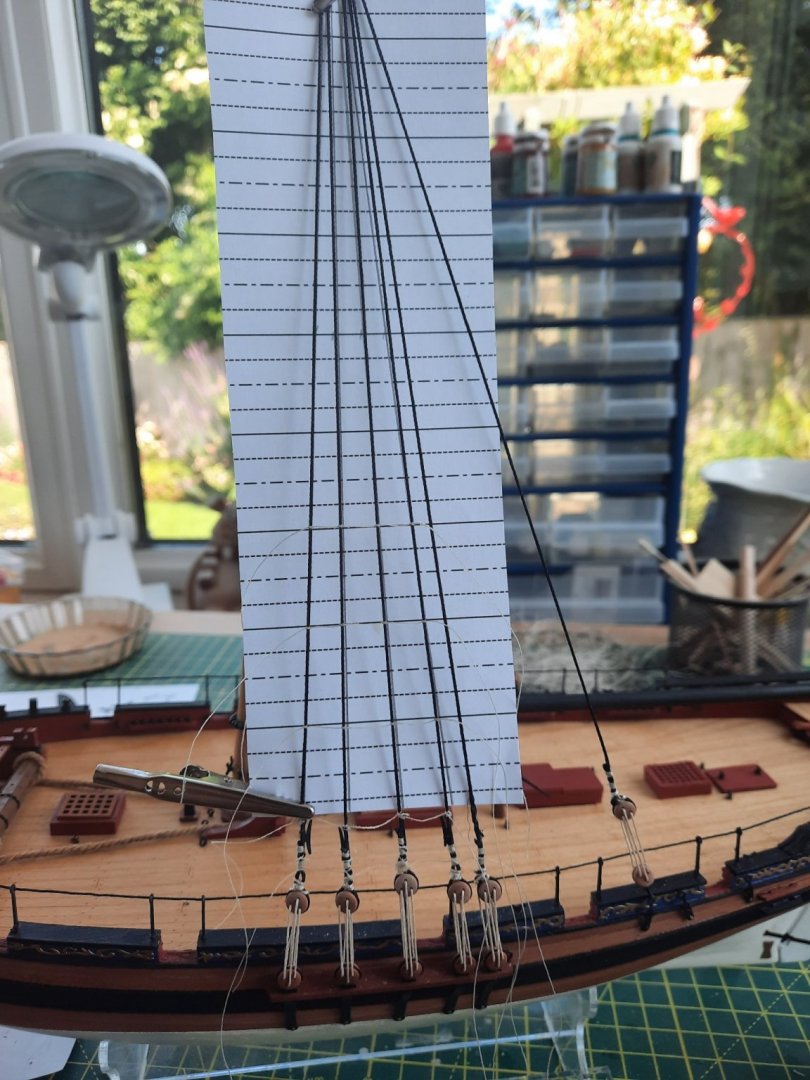

Here are some more pictures of the Cutter Alert. I have moved on to fitting the yard braces. This is not too difficult, it is simply a matter of reeving the thread through the blocks from point to point, ensuring the lines are not tangled with existing lines as they are taken to the different belaying points. I think there is about 2 or 3 days of work left to complete the build, but as my time is limited at the moment I think will probably be completed sometime next week. Work in progress on my untidy workbench. The vista is very nice. Spreadsail yard brace rigged but not belayed Spreadsail yard brace rigged and belayed Spreadsail yard brace block Completed spreadsail yard brace Current state of rigging

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

I am now on the home straight with the rigging and there is only a few more days left. That said my time in the shipyard will be a bit limited for the next few days. I am eagerly waiting for the release of The Sphinx and fingers crossed that @James H is making good progress with the masts and yards and that @chris watton is making good progress to allow for the pre ordering of the kit in the very near future. Today I added the 4 x yards and their lifts to the main and top mast. Before the yards were fitted I ensured the various threads could be reeved through the various yard and mast blocks, and where necessary I ran a micro drill bit to enlarge the block holes. Once I was happy with how the threads could be reeved I applied some ca gel to the pins on the yards and secured them to the main and top mast using parrel beads for three of the yards. I then added the yard lift rigging. I have included a selection of photos showing different aspects of the yard lift rigging. The current build status Spreadsail Yard Lift Squaresail Yard Lift Squaresail Yard Lift Belaying Spreadsail Yard Lift and Topsail Yard Lift Belaying Yards

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

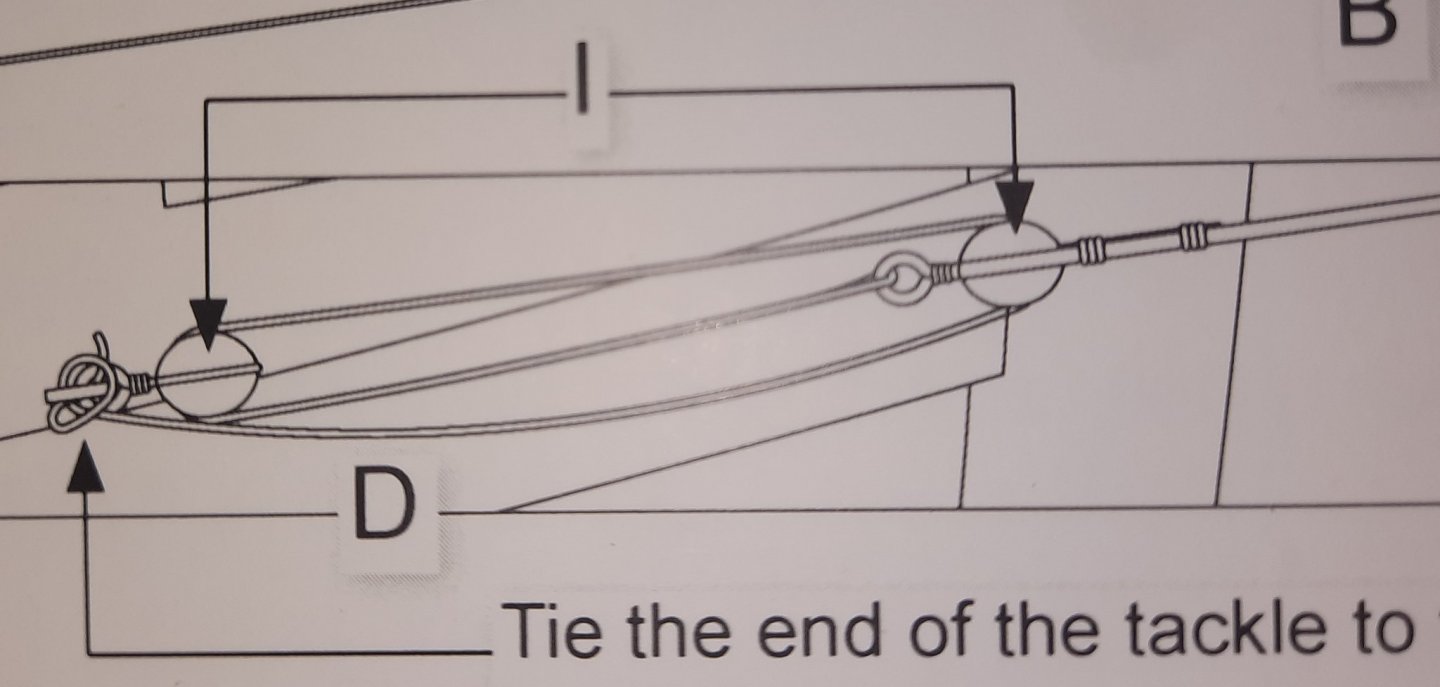

The driver and main booms have now been rigged. When completing this task I made a note for any future builds to check and enlarge as necessary the holes in the various blocks before they are fitted to masts and yards so that the threads can pass through them. Initially I had great difficultly trying to get the stiffened ends of the 0.5mm and 0.25mm natural thread to feed through the 3mm single and 4mm double blocks. It was not an easy task to enlarge the various block hole in situ, but thankfully I was able to do so without damaging anything. DRIVER BOOM The driver boom was held in position using the quad hands so the parrel beads could be added to secure this boom to the main mast. I then moved on to adding the driver boom lift. I cut a length of 0.25mm natural thread and once I had enlarge the block holes it was a simple task to rig. The end was taken down to the belay point on the main mast bitt The final rigging of the driver boom was a bit more complex, but in reality it was simply a case of running the thread from point to point. From its starting point from a loop on a block on the main mast it is fed through the end block and then returns and is fed through the mast block. The thread then goes back and is fed through the mid point block on the driver boom and then returns back to another block on the main mast where the thread is taken to the belaying point. This photo shows the mast blocks This photo shows the driver boom before the final belaying to the main mast bitt. MAIN BOOM This was a much more straightforward task. The main boom lift was a simple rigging task, as shown below Next the two lines from the end of the main boom were added, one was threaded through the block and one was added with a loop. The line from the end block was then taken to the end of the driver boom, where it was fastened with a loop and the other thread was taken to the top block on the main mast. A block was then added to the end of the thread. The line is then belayed as shown below. The thread is fed through another block which is hooked to an eyebolt on the channel back up and the returns, after being passed through the splitting block, to be belayed on the cleat located on top of the capping. The completed driver and main boom rigging

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

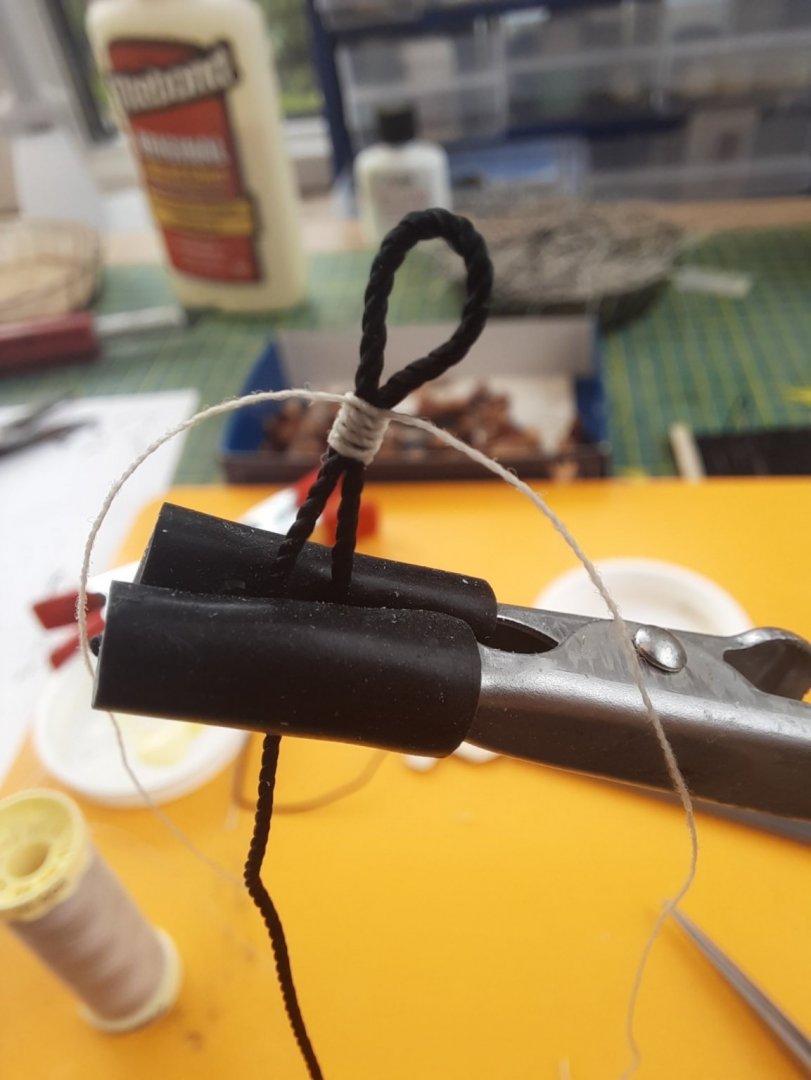

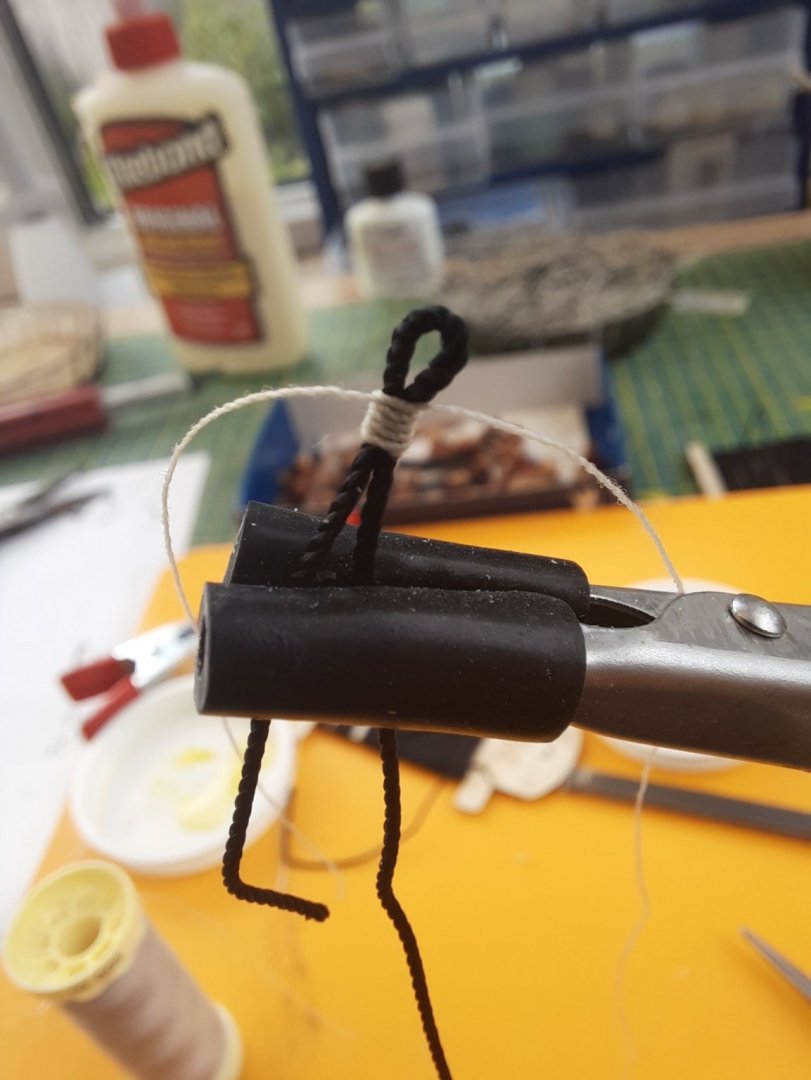

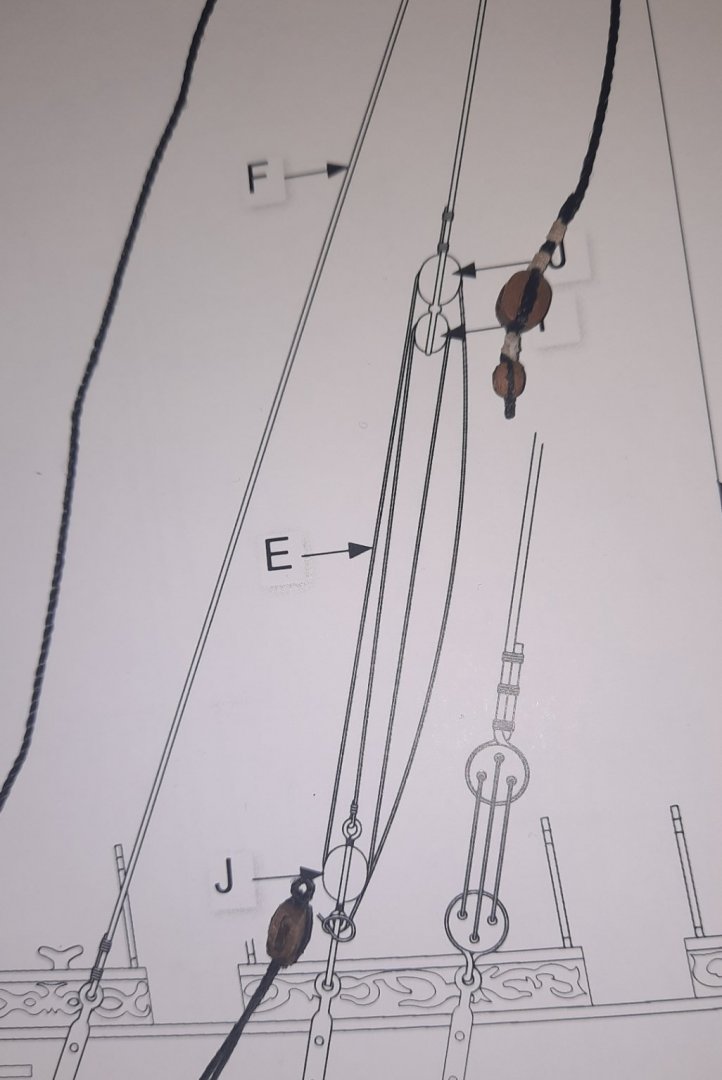

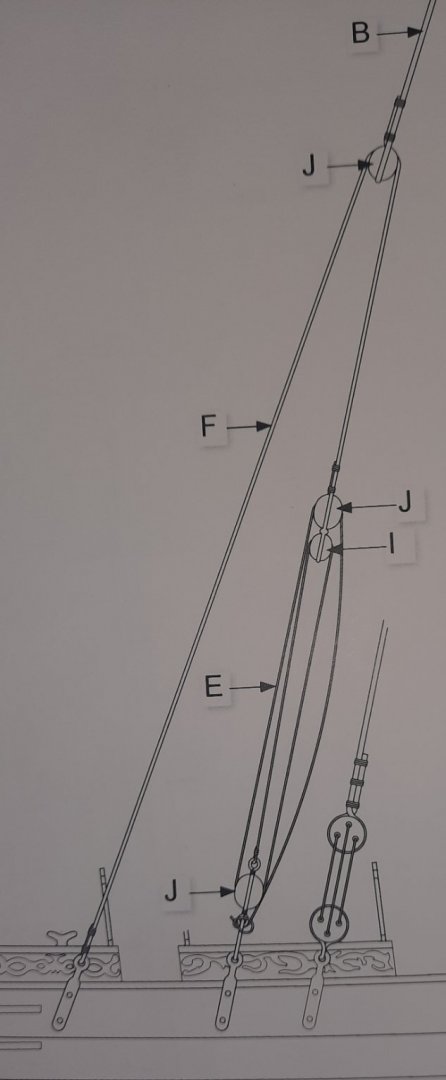

An easy rigging task today, which was adding the two back stays and single fore stay for the topmast. I started by cutting a single length of black thread for the two back stays and secured this thread (at it approx. mid point) to the topmast. I used a simple clove hitch knot which was then coated with a diluted pva solution to keep the knot tight and in place. Each end of the thread was then fed through their respective eyebolts and seized. This is a photo of one of the eyebolts, not my best work at seizing This photo shows the completed back stays. The topmast fore stay line has been added but not fully rigged at this stage. Moving on to the topmast forestay the thread has to pass through the centre hole on the triple block fitted to the end of the bowsprit. This turned out to be the most difficult aspect in terms of trying to get the thread to slide through the hole. I resorted to using a 0.9mm micro drill to enlarge the hole which did the trick. The end of the topmast fore stay is then attached to the starboard side of the hull with a using a double thimble arrangement. The next photo shows this before I have completed running the thread through the two thimbles. Finally a picture of the completed stays. My next job will be to rig the main and driver booms. Having already studied the rigging plans I have decided that the driver boom needs to be rigged before the main boom. There are three main aspects to the driver boom rigging. The first to add the parrel beads so the driver boom can be attached to the main mast. Next the position of the driver boom on the mainmast will be set by adding the lift rigging. This is shown on the right hand side of the next photo and is a standard single and double block arrangement. Finally the rake of the driver boom is set by a thread that passes through 4 different blocks, 2 blocks on the main masts, 1 block at the mid point of the driver boom and 1 block at the end of the driver boom.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

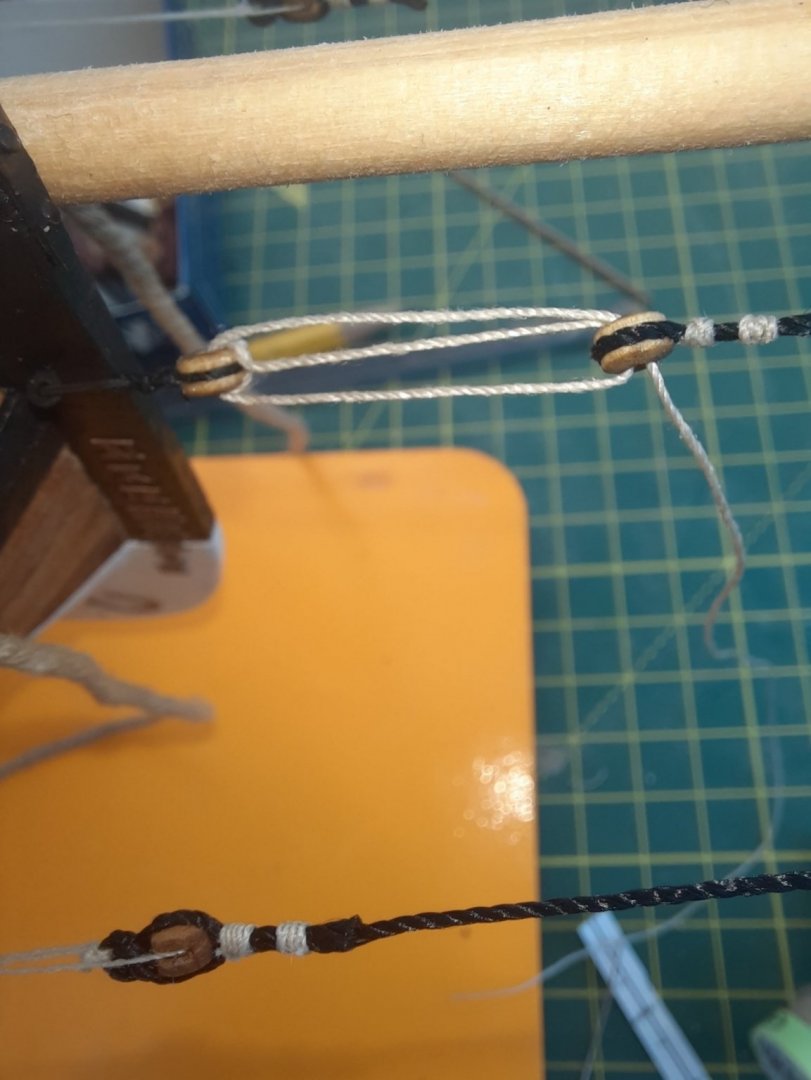

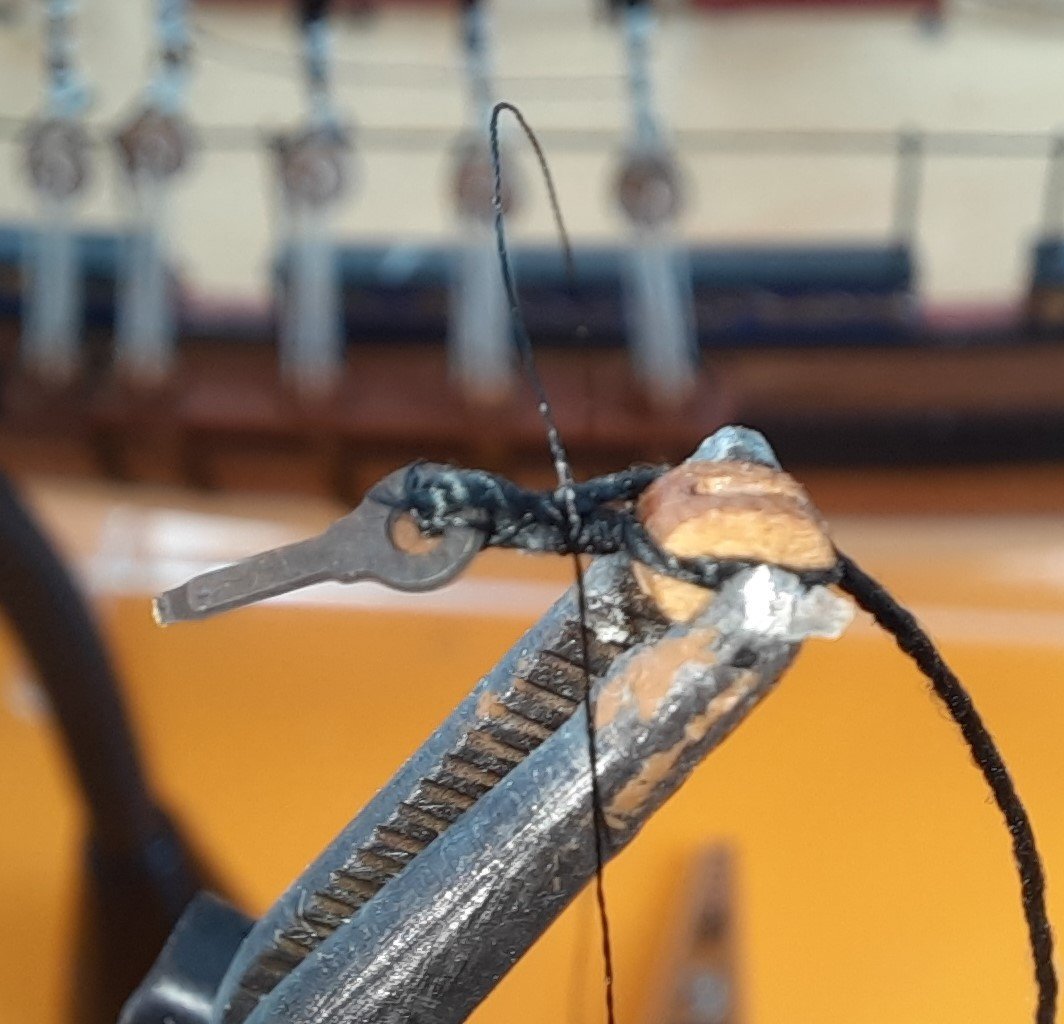

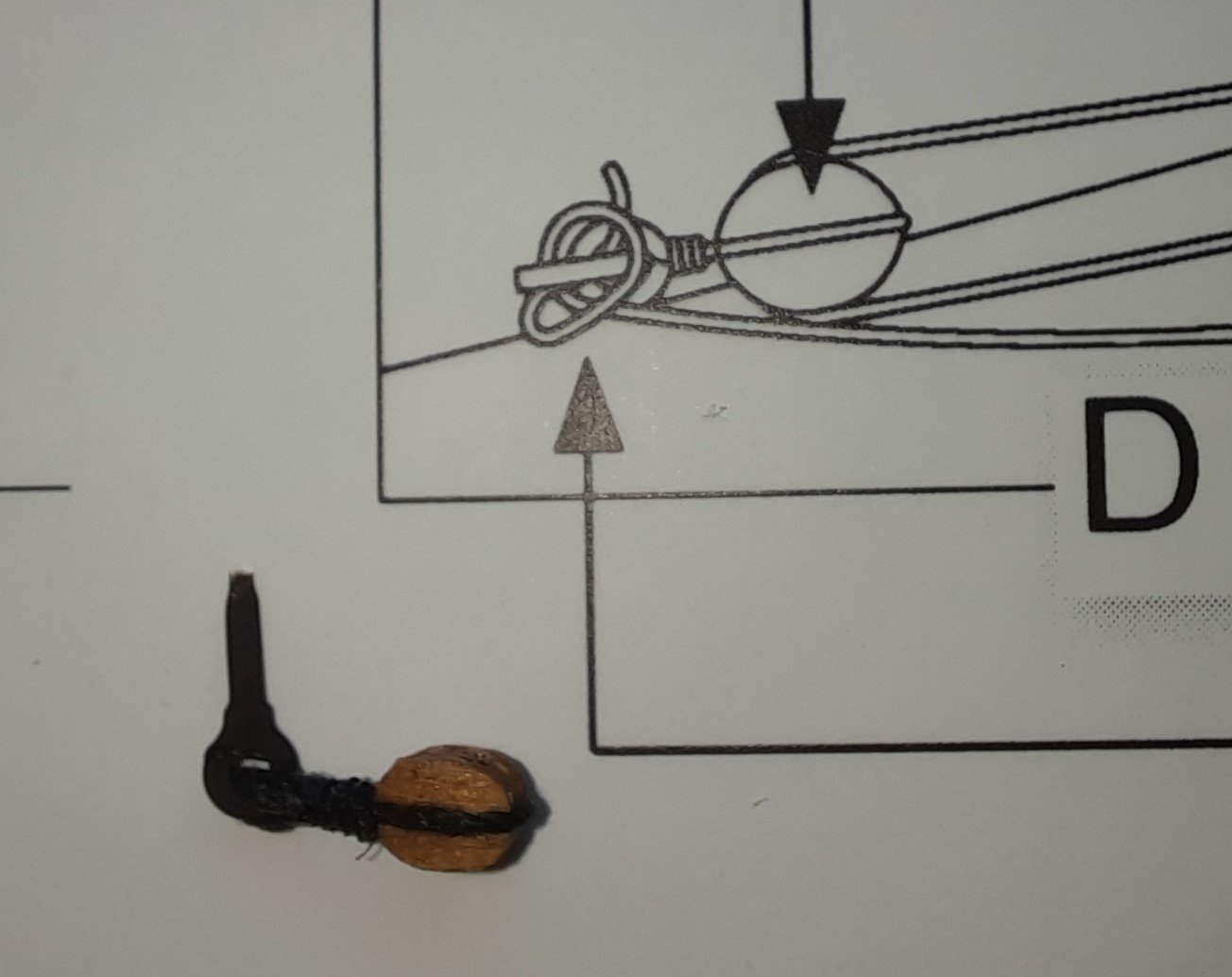

Today I thought I would detail the complete process I used for the start of the bowsprit rigging. I always study the rigging plan to ensure I fully understand what is required and to then contemplate how best to implement. This is picture of the blocking arranging required for the task in hand on the bowsprit. There are two 3mm blocks required. The right hand one requires a loop end and the left hand one requires an eyebolt. I always find it better to fit the eyebolt to the block before fitting the eyebolt in place. Using a length of 0.75mm black thread I formed the loop around a metal pin and used a standard reef knot to secure. Next 1 added a diluted pva wash on the loop to help ensure it retains its shape. With the loop formed the thread was then seized to a single 3mm block. Two seizing loops were shown on the plan sheet. I opted to use 0.1mm gutterman natural thread for the seizing. I use the alternate top and bottom half hitch knots method for the seizing. The photo below was taken after completion of the first seizing and I have just started to add the second seizing. I found it better to leave the metal pin in situ at this stage. The next picture shows the completed block. The use of the quad hands for these types of tasks is without question a great time saver. Many thanks to @DelF for sharing this tool on his Speedy build log and for some of the rigging method outlined in this post which I have copied. With the 2nd 3mm block held in the quad hands a short length of 0.25mm black thread was positioned around the block, as shown in the next photo. Using the alternative half hitch knot method, with fly tying thread the block is soon seized Next I cut off one of the two lengths which leaves the block with a single thread tail, as shown below. Again coping something I had seen DELF do the thread tail is passed through the eyebolt and then clamped to the side of the block, as shown below. Using black fly tying thread the eyebolt is seized to the block, and the picture below shows the start of this process. Using the alternate half hitch knot method the job is soon completed, and a quick check shows it looks something like the plan. A touch of ca gel was then applied to the eyebolt before it was fixed in place on the hull. The other block thread end has now fastened to the end of the bowsprit. With both blocks in place the last task is to add the 0.1mm natural thread rigging. This is shown in the next photo. The free end of the thread just requires belaying to the eyebolt, as was shown in the first photo in this post. I will do this once I have repeated the process for the post side.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

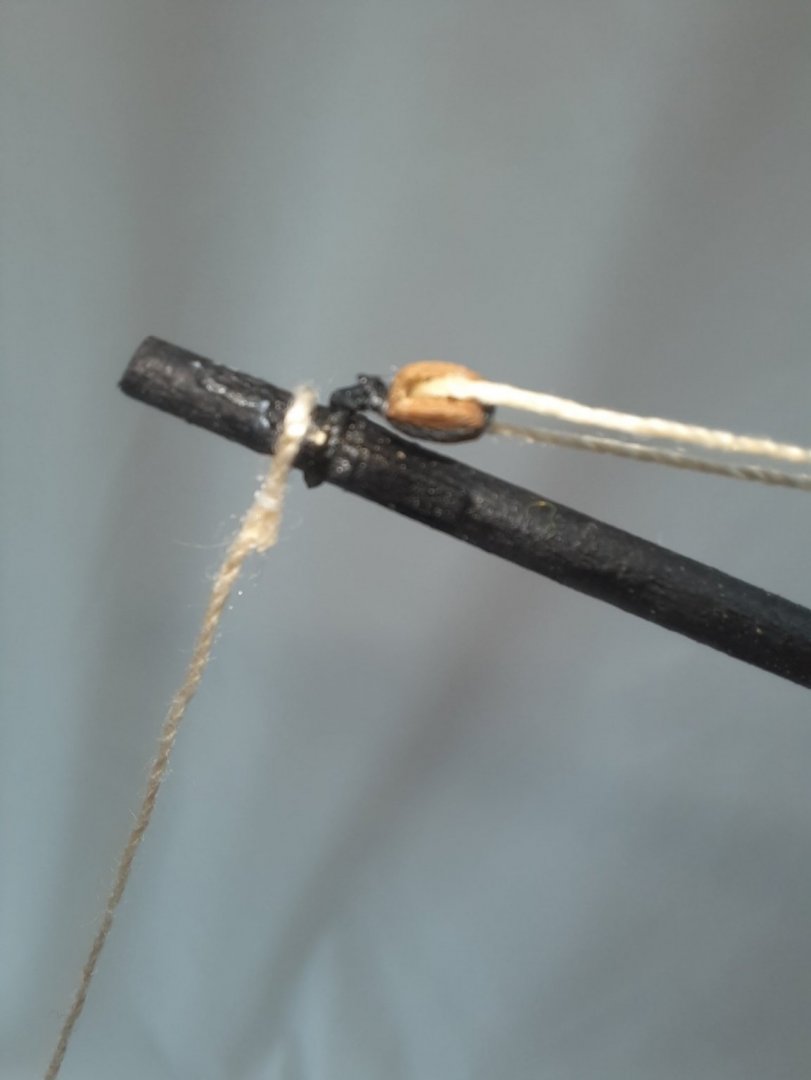

Lower Forestay Part 2 Following on from my previous post earlier today I have now added the second lower forestay. This is a picture of the one of the thimble seized to the thread before it is secured to the stempost U eyebolt. I made a loop in the 0.25mm natural thread and then started to rig it between the two thimbles. A close up of the completed thimble rigging. I tied the loose end to the stempost ‘U’ shaped eyebolt. A picture of the completed forestays I have now added the bowsprit which is ready to be rigged, which will be my next task.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

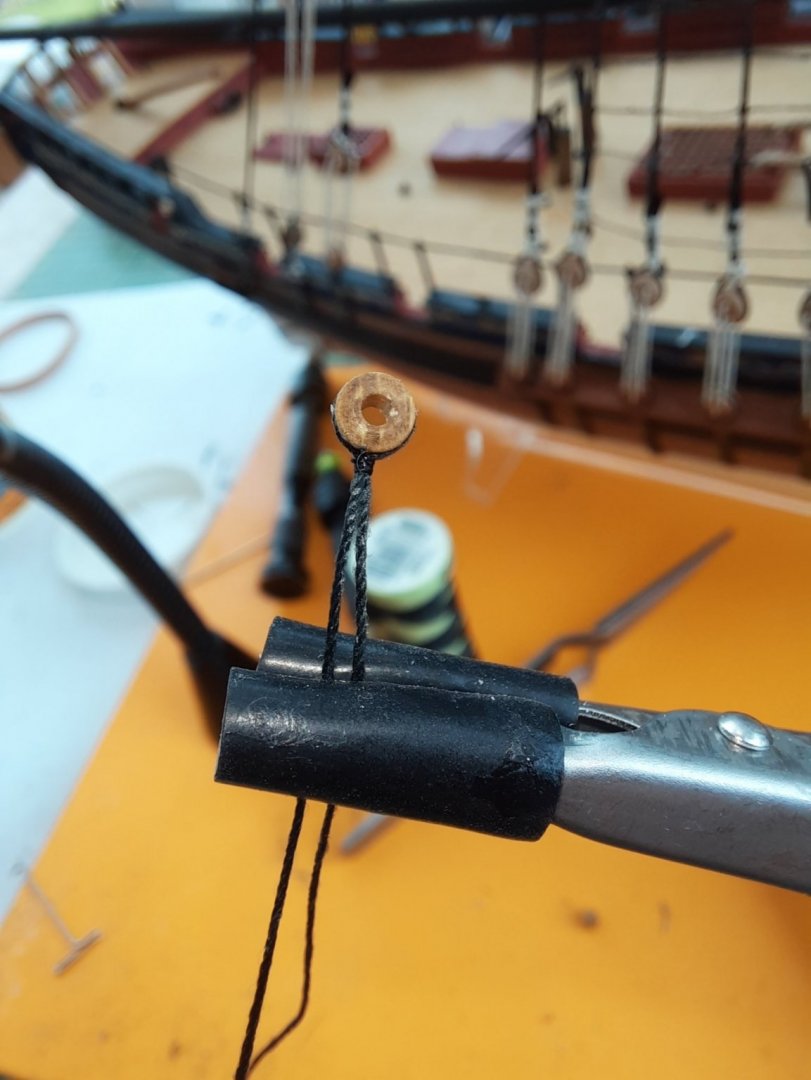

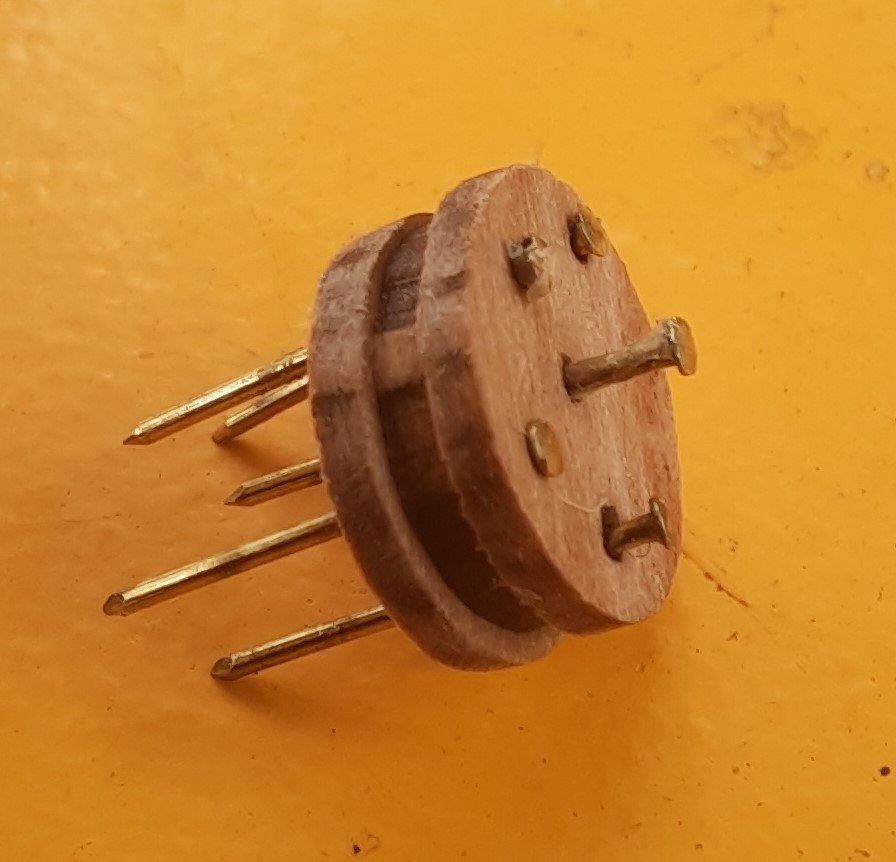

Lower Forestay There are two forestays, the lower one is 1mm black thread and terminates at the bow via a deadeye. The other one is 0.75mm black thread and is terminated at the bow using two thimbles. The first task is to make the deadeye from three pieces. To ensure the parts line up I used some pins to align the parts. The parts were glued and clamped which resulted in a completed deadeye The next task is to make the loops in the forestays. For this task I used my quad hands. Using a series of alternate half hitch knots I started to seize the loop. I was not to worried about the size of the loop as I can pull the free end to close the loop up I have now pulled the loose end to get the required loop size. This is the completed loop The two fore stays are placed around the main mast. The lower stay will require a mouse to set the position of the loop. This picture gives an idea of how the stays will look I have now added a mouse. I simply used some 0.25mm black thread and some half hitch knots Next task is to add the deadeye, this is the picture of the deadeye fitted to the stay line The next picture is the completed lower forestay / deadeye. The final task is to add the lanyard, as shown below. The end had been fed through the eyebolt and is ready to be tied off once the lanyard has been adjusted.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

I have now added the back stays. This should have been an easier task than I decided to make it. In the first instance I think it would have made life easier if I had not pre fitted the backstay iron plates. After much huffing and puffing I ended up removing both the middle backstay iron plates. Secondly, despite my best efforts, I developed an inane ability to wrap the back stay lines around the other back stay lines without noticing so I lost count of the number of times I had to redo bits to untangle the lines. As shown on my previous post the two back stay lines were already secured to the main mast using 0.75mm black thread with a single 5mm block seized to the end. Each 5mm block needs to be rigged to the back two backstay iron plates using 2 x 5mm block and 1 x 3mm block per stay, as shown in the first photo. Following the plan sheet I seized the various blocks to the required threads. As always I used my tried and trusted top and bottom half hitch method. The threaded eyelets were formed around a 0.8mm metal rod using a standard reef knot. The eyelet was coated with a diluted pva solution to help ensure it retains its shape. I found it much better to secure the 5mm block to the middle backstay iron plate prior to fitting to it to the hull, A single 5mm and single 3mm block were seized together to form a block pair. To do this I started with seizing the 5mm block, leaving the thread so the 3mm block could be seized. I finished the assembly off by whipping some thread between the two blocks. I started the rigging process by threading the 0.25mm natural thread through the block arrangements. I then attached the backstay iron plate back to the hull. Next the 0.5mm black thread was fed through the top 5mm block and secured to the rear backstay iron plate. This is shown in the next photo where I am about to add the seizing to secure the thread to the rear backstay iron plate. Once the rear backstay iron plate was complete I adjusted the 0.25mm natural thread rigging and once I was happy I held it in place with a pair of reverse action tweezers for a quick photo. The final loose thread was then tied off around the middle backstay iron plate and the Cutter Alert was sent back for another photo. What cant be seen in this photo is the upper stay line is wrapped around the other back stay line. The easiest solution was to remove the deadeye lanyards to untangle. I then repeated the process for the other stay and the completed back stay rigging is shown below I plan to add the two forestays next before moving on to the bowsprit.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

I think I just about reached the start of the home straight as the other 7 runners crossed the finish line

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

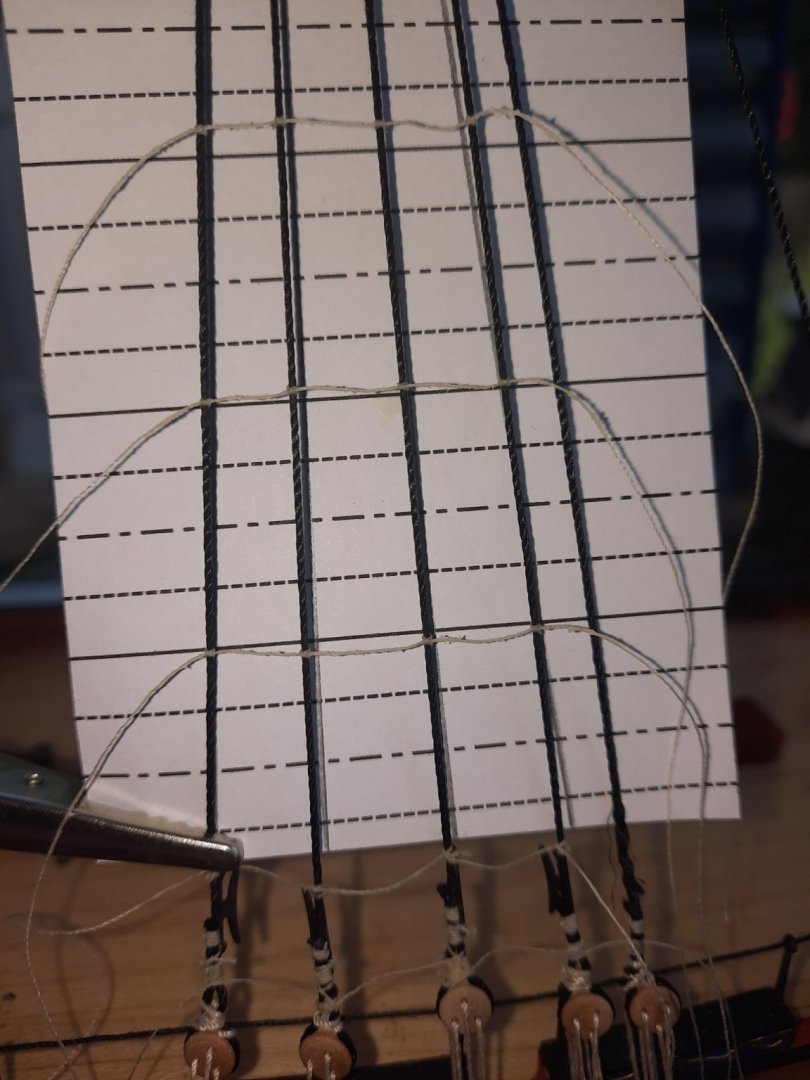

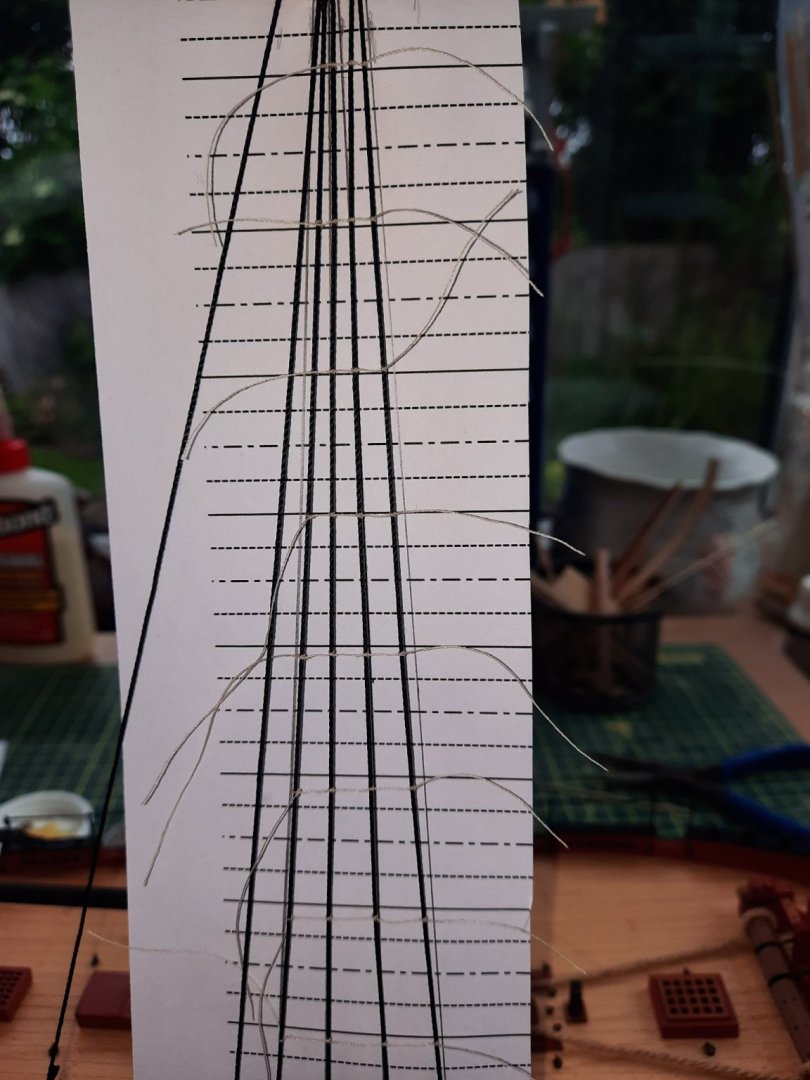

No time spent yesterday in the shipyard due to my track and field racing. I have included a picture taken yesterday of one of my races (400M). What is most noticeable is all the other runners appear to be around 17 to 18 years old and they were all very fast and very lean. I weighed in at a stately 63 years and was quite slow and not very lean🤣. I have been busy today and I completed the port side ratlines. It took me aorund 4 minutes to add each ratline, a couple of hours of effort in total. In this picture the template has been positioned and the first three ratlines added. This is a close up of the first 3 ratlines. These ratlines are correctly positioned, they look wrong due to the parallax error. The ratlines are completed, some ends still require to be trimmed. This is the indian ink I use to dye the ratlines The ratlines have been trimmed and dyed black. As can be noted in the picture I have also started to add the missing back stays. Each of the two 5mm single blocks that are dangling from these stays will be rigged through some more blocks before being secured to their respective backstay iron plates

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Hello Mike I am not a great picture taker, but I am glad you are finding my log helpful.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

I have finally completed the ratlines on the starboard side. I had to do it in fits and starts as my mother was being moved into nursing care so I had quite a bit to sort out in that regard. I have a track and field event tomorrow where I will be racing 400M, 800M 1500m and 5000M so will have little or no time to start on the port side ratlines. I am currently ranked no 1 in Yorkshire in my age group (60-65) and 14th in the UK. These rankings will drop dramatical as the lockdown eases and the proper track and field runners start competing again. Pictures of the completed ratlines The display case I ordered for my Duchess Of Kingston build arrived yesterday. The Duchess does look nice in the case, however the case does not look right on the planned location which is a shame so putting the Duchess in a glass case has been side-lined for the time being and she is now uncased and back on top of the book case in our dining room.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

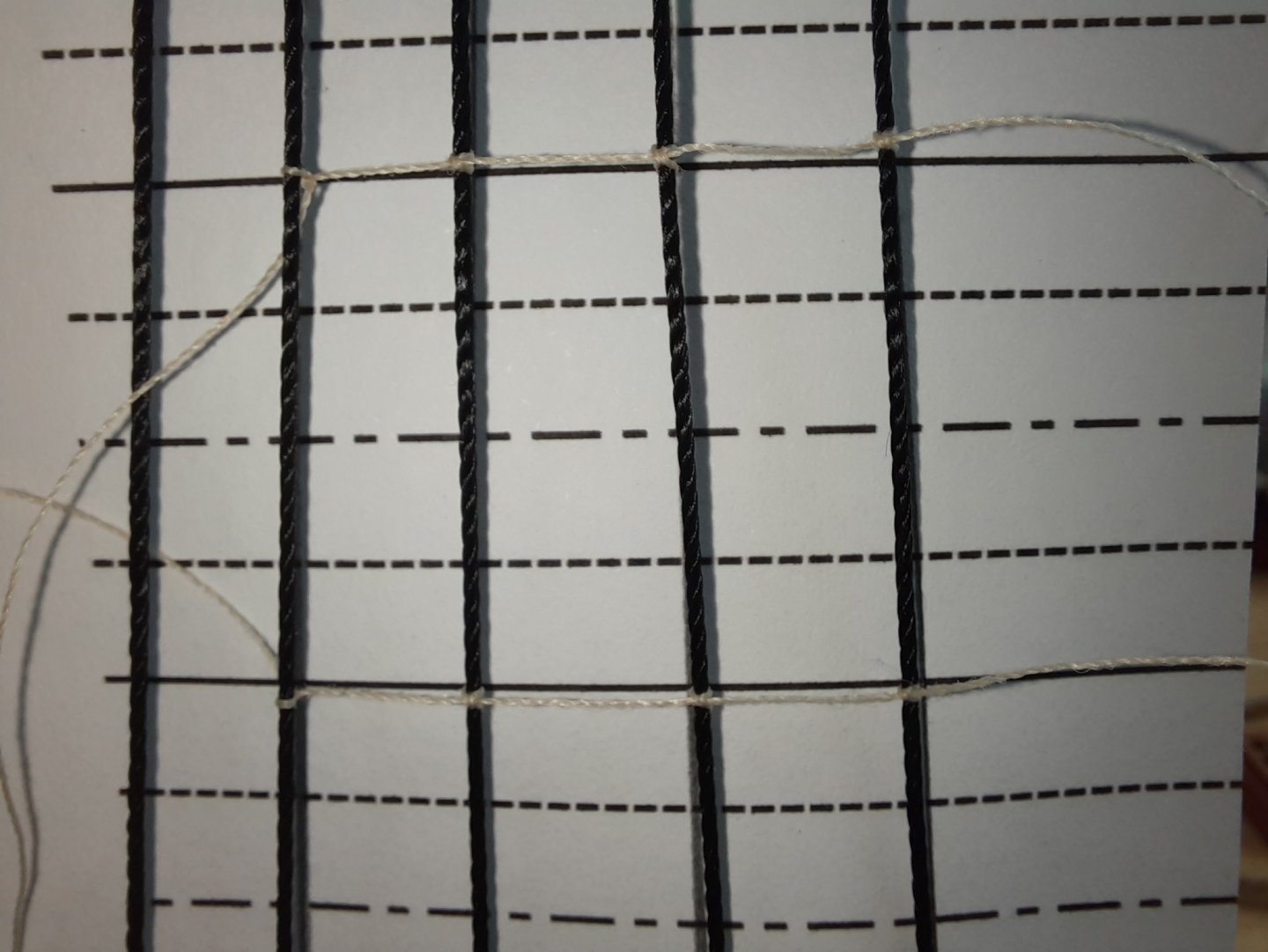

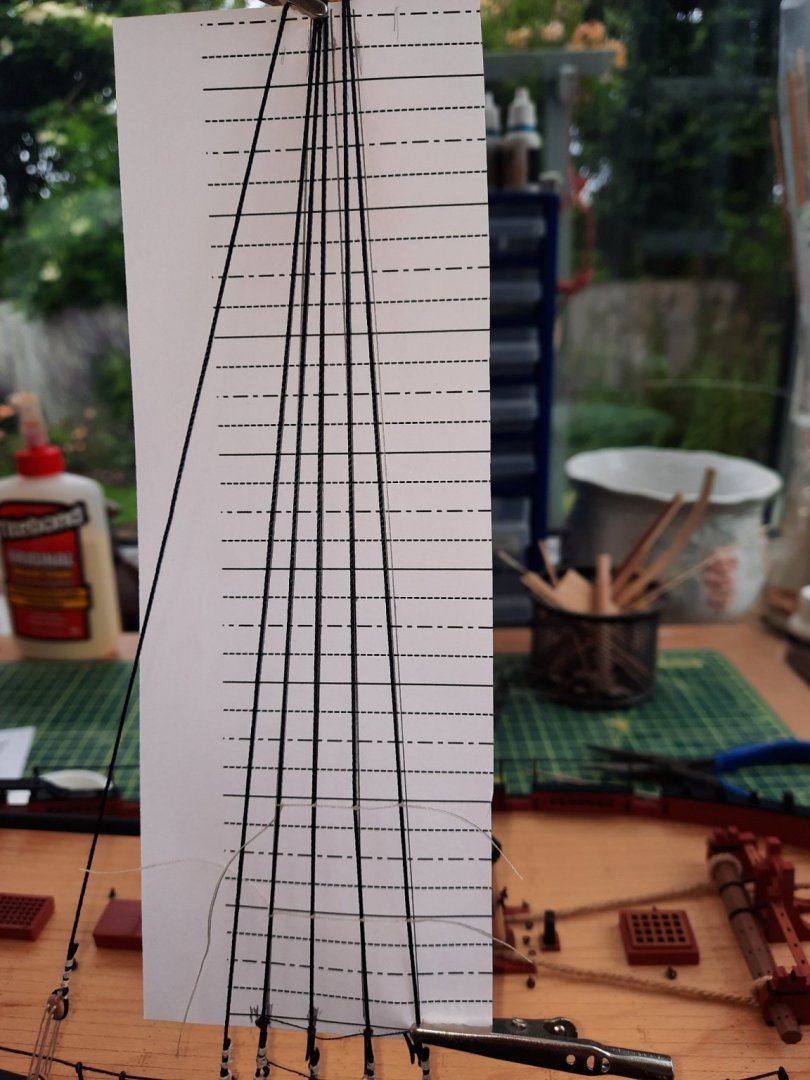

Moving forward I have now added the shroud lines to the channels. Before moving on to the ratlines I decided to add the Main Boom as well. A couple of pictures of the completed shrouds and main boom This is a close up of the parrel beads securing the main boom to the main mast. With regard to the ratlines I decided I would add the bottom two ratline first as these need to be positioned around the seizing and shroud cleats. I used 0.1mm natural thread. I opted to use the Gutermann colour 722-1 thread rather than the kit supplied thread as this type of thread was supplied with the DOK kit and I really liked it. The natural thread is dyed black. The completed ratlines are not brilliant but I can live with how they look. As I have said before I actually like the task of adding the ratlines. The process I use is to fit every 5th ratline first, then I add the middle ratlines between each 5th before adding the remaining two ratlines. I can only work left to right as I seem to get a brain freeze when trying to tie a clove hitch knot when working right to left. This is the start of the ratlines. This picture shows the template in position. The solid lines represent every 5th ratline line position. The dot-dash lines represent the middle section between every 5th ratline and the dotted lines represent the final ratlines to be added. I have now added every 5th ratline. They are all correctly positioned even though the camera angle makes it look otherwise. These completed ratlines have had a diluted pva solution applied, wihich will help to stiffen the ratlines and will also (hopefully) prevent the knots working loose when the excess thread ends are trimmed. I will dye all the ratline black on completion.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Hello Jacek Many thanks for your comment, I am not the best rigger but with each build I am improving. Glenn

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Hello Tim Many thanks, you comment is much appreciated. Glenn

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.