-

Posts

21 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Winthrop,MA

-

Interests

Guitar, Fishing, RC Flight, Computers, Photography

Recent Profile Visitors

-

GrandpaPhil reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

GrandpaPhil reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

Nirvana reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

Nirvana reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

fatih79 reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

fatih79 reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

fatih79 reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

fatih79 reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

fatih79 reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

fatih79 reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

fatih79 reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

fatih79 reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

augie reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

augie reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

Pygothian reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

Pygothian reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

ModelExpoOnline reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

ModelExpoOnline reacted to a post in a topic:

US Brig Syren by Gahm - Model Shipways

-

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

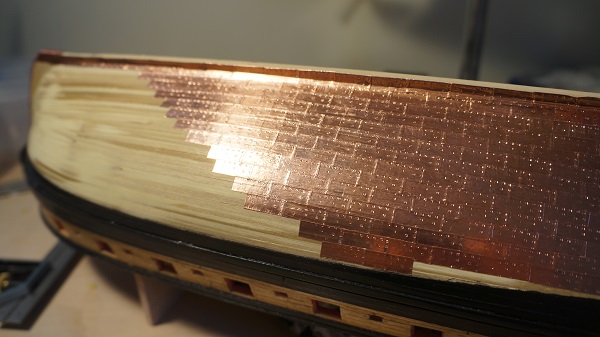

Part 8. Copper Plates/Rudder Copper plating went fairly well. I know there is a copper plating schematic included in the practicum that shows a more complex plating pattern, I'm not sure how many builders follow that, I know I didn't. The hardest part of coppering is actually keeping the copper plates clean!! I used a fairly rudimentary method of stamping and cutting the plates. I found an old rc reciever and cut some of the connection pins down to match the pattern suggested. To do the port side I cut them down again. I then stamped 4 at a time until I got tired of stamping and then cut them to size using an exacto. The most time consuming part, however, was removing the backing from the plates before attaching. Once the plates were attached I burnished them with a piece of balsa. Drilling the hole in the transom for the rudder was scary, but went fine, as did the painting, staining and plating of the rudder itself. I cut down some nails and glued them to the pintles, covered with copper plating and glued them to the rudder. I made a bit of a mess glueing the gidgeons onto the hull. There's quite a bit of CA on the surrounding copper. I'm probably going to attemp a cleanup with some laquer thinner. If anyone has another suggestion for cleanup I'd welcome it. I was able to use white vinegar to remove my initial fingerprints from the copper.

-

Part 7. The Deck. Doing the deck was one of the less stressful part of the build so far. While I have seen some Syren logs where the shipwright tapered the deck planks towards the rear, I chose not to go that route for simplification's sake. I also did joggle the planks into the margin strip, which wasn't too difficult, although my end result could have been a tad tidier. Once the deck was complete I treenailed it in the same manner as I did outer bulwarks planks and stained in the same manner as well. I used a slighly smaller bit to drill the treenail holes and as I result my treenaling looks less defined on the deck. (the treenailing actually looks more pronounced in photos than in person)

-

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

markfrommelt reacted to a post in a topic:

US Brig Syren by markfrommelt - Model Shipways

-

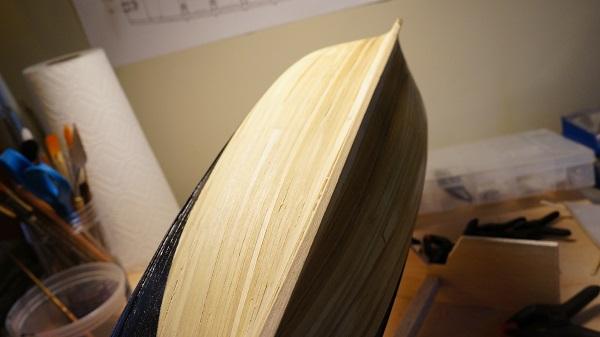

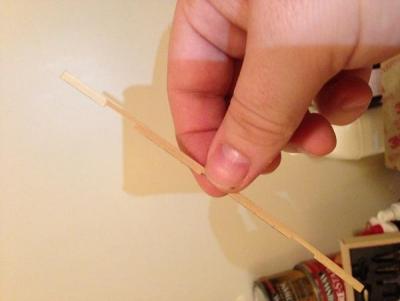

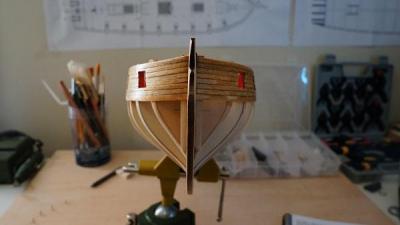

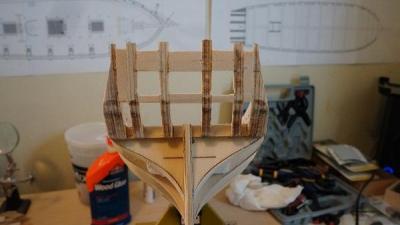

Parts 5b and 6 . Planking the Hull. Finishing the Stern and Inboard Planking. Ok, so I got my hull planked..it was not pretty. But I went into it knowing that I would be covering it with copper, so I my goal was getting a smooth hull. With the help of lot of filler I think I accomplished that goal. The first thing I did was add the second layer of wales. This should have been straight forward however the 5/32 X 1/32" strips required per the practicum were not included with the kit. After contacting Model Expo I was informed that these were not to be provied with the kit. (I'm not sure why this is, but I'll add this to my list of extra parts needed at the beginning of my log.) After a quick trip to Northeast Scale Lumber this was remedied. Once I had the parts the second layer of wales and sheer strake were easily completed. Things go interesting once the plaking began. I took the approprate measurement and did the required calculations to figure out how much I needed my planks to taper at the bow. The number were right in line with what they were supposed to be so I had at it. A couple of things I took from this... If tapering planks by hand with a sanding block, taper a few planks at once. It keeps the planks from rolling on thier sides while sanding and it saves time. After some practice I was able to taper planks using my micro belt sander. Measure carefully and take your time. I got careless with my measurments and I payed the price towards the end when I ran out of room for planks at the bow. I found it was much easier to use CA glue for planking. I also used fixer on the CA for the stern where the extreme bends make things more difficult to keep in place while glue is setting. It took a few single plank inserts to get this done. Once the hull was planked I applied copious amounts of filler and sanded the bejesus out of the hull until smooth. Whew!!! I think the shape came out pretty nice over all even though you couldn't stain the hull. I once I transfered the waterline to the hull I gave it a few coats of Golden's Carbon Black. Because I'm using acrylic paint I am also using a water based finish coat of Minwax Polycrylic. I like the look overall, but be warned the clear satin may be a bit too glossy for some. I did finally get my lasercut transom from Model Expo, which allowed me to finish the stern. No real issues here to report. Fairly straight forward. Be sure to sand the stern down to at least 3/32 as per the practicum. I was a little over and it became an issue when installing the cap rail. After the stern was complete I began planking the inboard bulwarks. Again this is just like planking the outer bulwarks, no real suprises. Once the inner planking was complete I gave the inboard a couple coats of red, some Polycrylic to finish and got to work on the cap rail. I visited my friends at Northeast Scale Lumber again to grab a 1/16" thick sheet of basswood for this. I was able to get the outer curve of the bulwarks by tracing the as per the practicum and to get the inner curve I used a french curve. After carefully cutting out on side I used it as a template for the other...making sure of course the hull was symmetrical enough to do so. This was only necessary for the first 3rd of the rail. The remainder was completed with a 3/16 strip. Although I'm not sure I wouldn't use a 1/4 inch strip if I had to do it again, since you need to add a 1/16 x 1/16 strip to the outer edge later anyway. Next Up is the Deck Planking.

-

Really like these cross section builds, yours looks great!

- 21 replies

-

- constitution

- mamoli

-

(and 1 more)

Tagged with:

-

markfrommelt reacted to a post in a topic:

Syren by joef - Model Shipways - US Brig

markfrommelt reacted to a post in a topic:

Syren by joef - Model Shipways - US Brig

-

This looks great. Thank you for going through the effort of reposting, your log is really a great resource for those of us who are also building a Syren.

- 127 replies

-

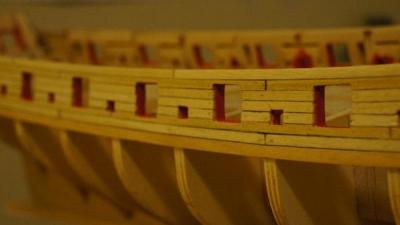

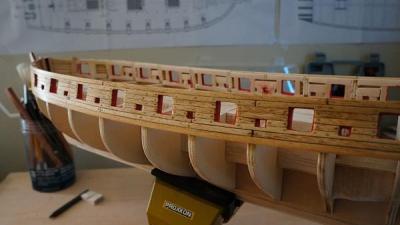

Part 5a. Planking Above the Wales Started by preforming the upper whale using a jig. I decided to do both sides at the same time so I pre-formed both the starboard and port wale before proceeding. Using the reference line created by the batten earlier I made sure to glue each wale to the bulkheads so that they followed a smooth curve from stem to stern. Planks 2 and 6 were the toughest. It was here that I had to notch out the clearance for the ports, while maintaining an additional 1/32 " of clearance. Plank 2 was the one that would pretty much set the tone for this aspect of the planking. I took my time and treated each plank as a separate project (as suggested). My results were mixed. While I did get better as time went on the end result was a little un-even. Not every port is precise as I would have liked and the clearance "lip" of 1/32 is closer to 1/16 in many places. But overall, given my understanding of how the build proceeds it should be fine. Around the 6th plank I ran into another more serious issue. While I was planking both sides at the same time I failed to notice that at the bow the top of the third plank was sitting much higher on the starboard side than on the port side. I almost looked like I had an addtional row of planking done on starboard. To remedy this I had to remove the 3-5 plank on the starboard side and sand down the lower edge of plank 3. (This can be seen in the pics.) after doing this things come out pretty evenly (but not perfect). The reason for this became clear later after plank 7...I seemed to have a more pronounced downward swoop in planks from the stem to bulkhead 3 on the starboard side compared to port. Additionally after completing the 7th plank I noticed that I still have bulkheads clearing the planking fore and aft. Not sure how to preceed here. Should I add another row of planking to make up for the clearance, or do I just sand the bulkheads down level with plank 7????? After the planks were complete I tree nailed and stained using the same process and mix as in part 2 of my log. Be carefull if using the wood fill method of tree nailing as I did. Use only a small amount of fill directly in the hole. If you use to much you will have a heck of a time sanding it out completely. Also may have used a slightly larger bit than needed ...but overall I'm satisfied with the look. Looks like I'm in a holding pattern for a bit as my lasercut sheet containing the transom was not included in the kit...waiting for the part!

-

Part 4. Stern framing. This was pretty easy thought step 4. At step five I ran into a little bit of an issue. While trying to establish the correct sill height. If I followed the template to mark my sill tops, but based on my cannon mockup they would have been too high for the cannons to clear. I wasn't sure if I was positioning the template correctly or where the discrepancy came from. In the end I decided to trust the cannon mockup more and move my sills down to accomidate. You can see in the top picture the difference between the middle sill and the two outer gunport sills. Lintels and fillers (including the filler between the B and C posts) were glued into place next. Take you time with Step 7. Using a planking strip to mark the outer stern shape proved a little tricky, but all in all it worked out fine. I roughed out the outer edge with a rotary tool and then completed by hand. I used some balsa scrap to make the stern filler block. Sanding them to shape was something you'll just have to feel your way through. I'm still not sure I sanded the fillers that lay horizontally enough. I figure that will become clear later on. We start planking next!!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.