-

Posts

908 -

Joined

-

Last visited

About giampieroricci

- Birthday 01/30/1965

Profile Information

-

Gender

Male

-

Location

Martina Franca, Italy

Recent Profile Visitors

-

scrubbyj427 reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

scrubbyj427 reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

scrubbyj427 reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

scrubbyj427 reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

Desertanimal reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

Desertanimal reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

Cpt.Barbossa reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

Cpt.Barbossa reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

druxey reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

druxey reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

davec reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

davec reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

Rudolf reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

Rudolf reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

Rudolf reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

Rudolf reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

Rudolf reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

Rudolf reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

Rudolf reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

Rudolf reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

giampieroricci reacted to a post in a topic:

Nate's PANDORA in 3D

giampieroricci reacted to a post in a topic:

Nate's PANDORA in 3D

-

giampieroricci reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

giampieroricci reacted to a post in a topic:

Speedwell 1752 by giampieroricci - Scale 1:96 - from Antscherl & Herbert monograph

-

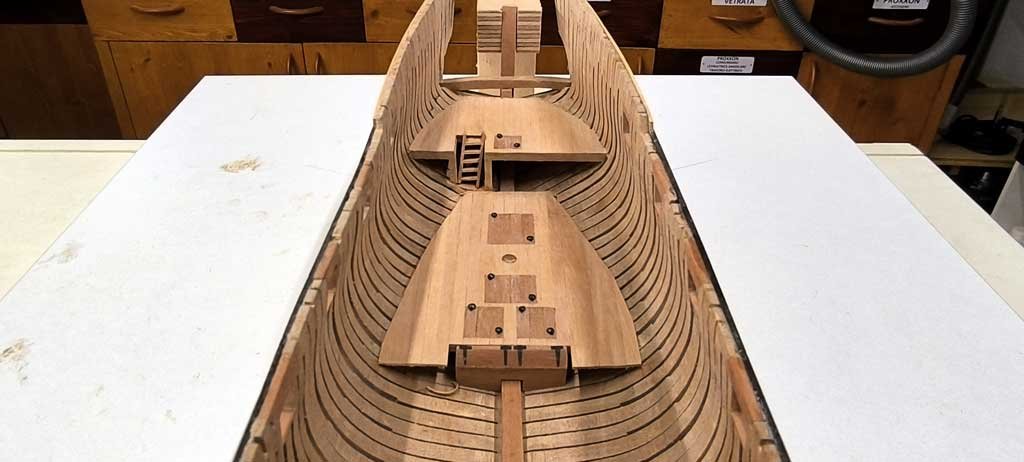

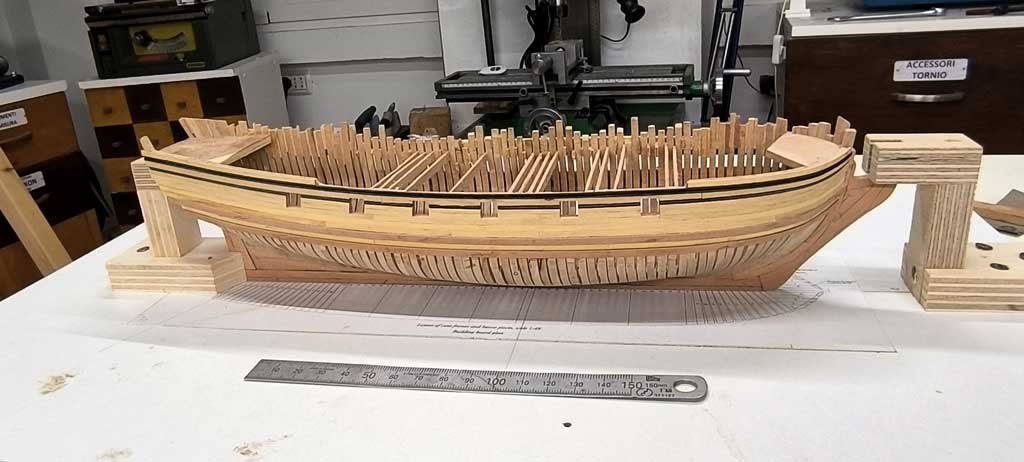

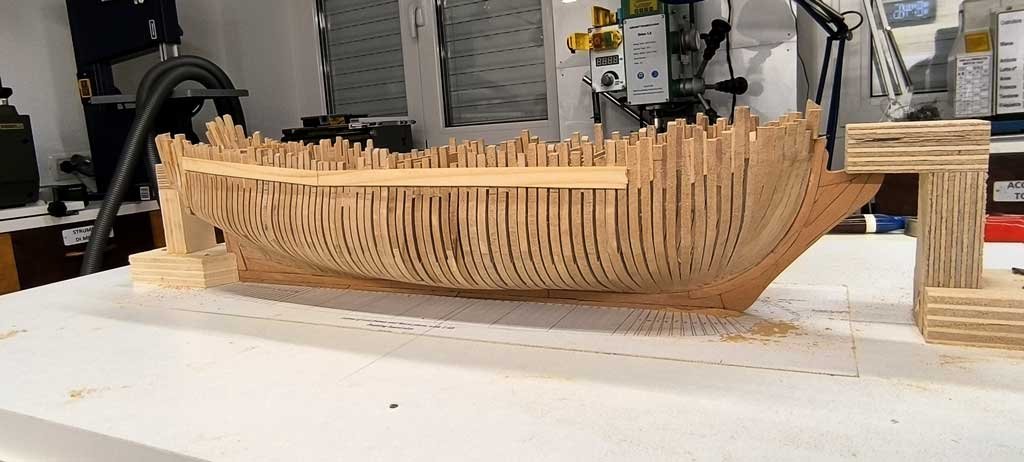

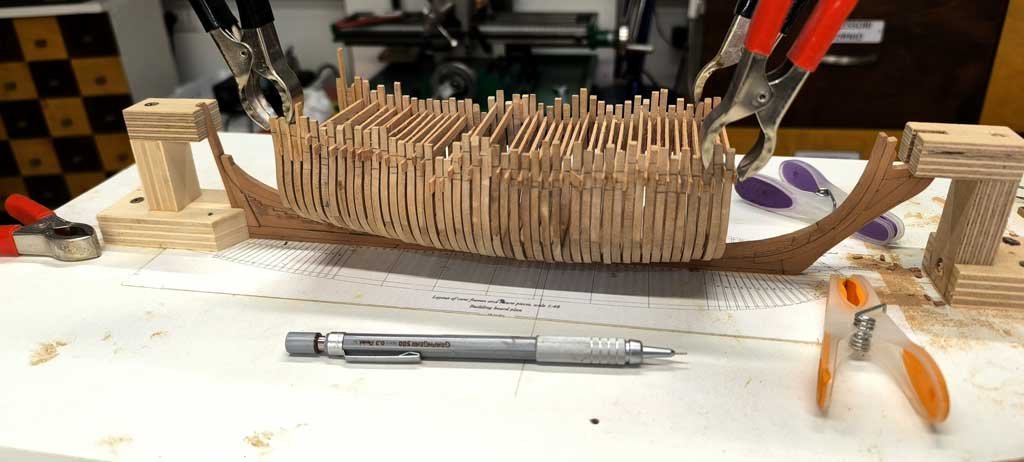

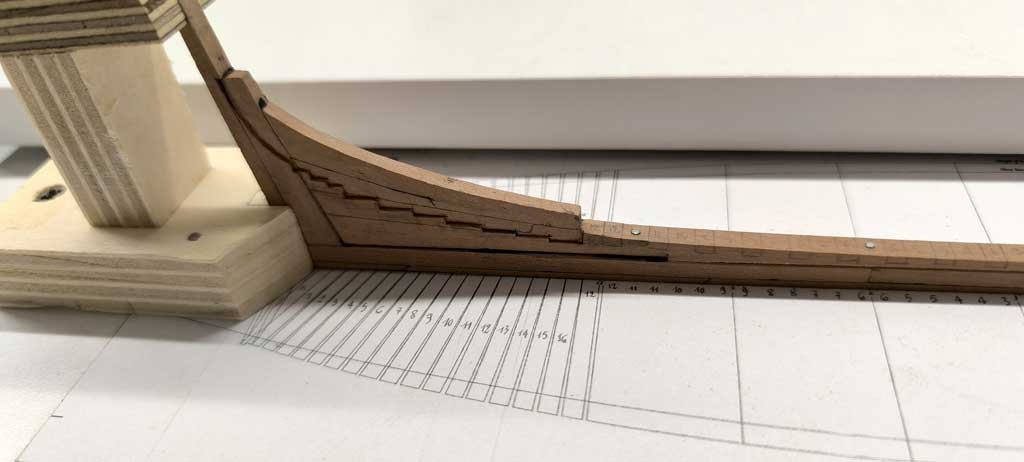

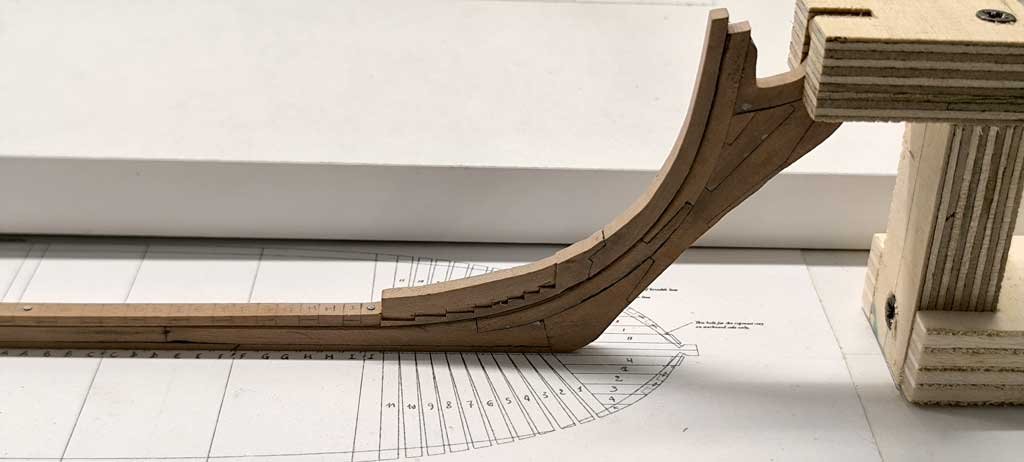

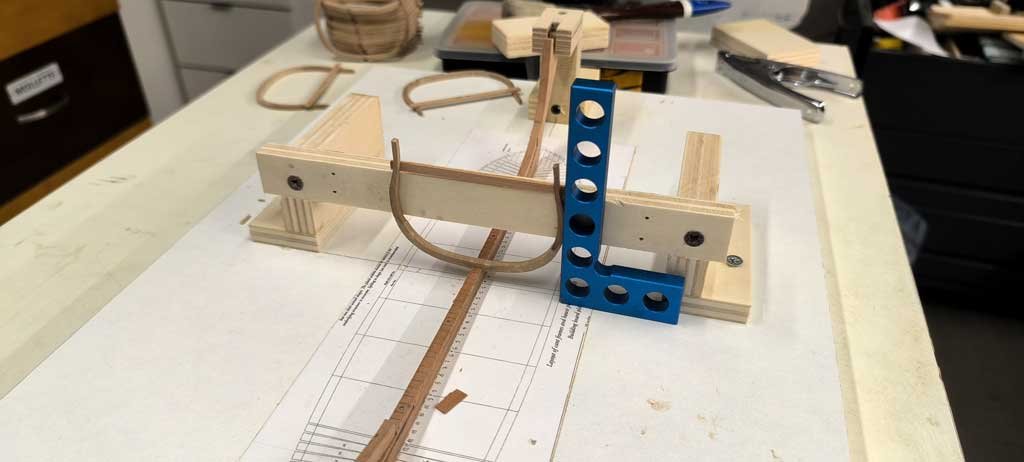

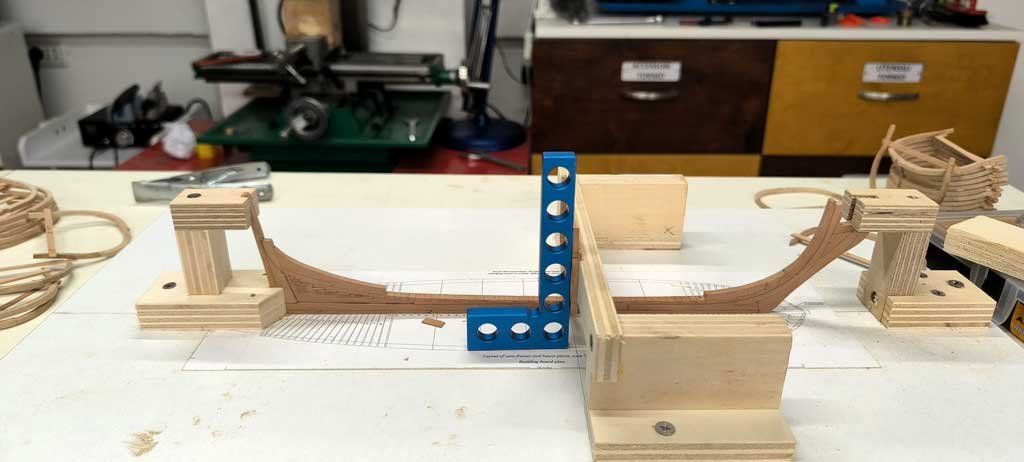

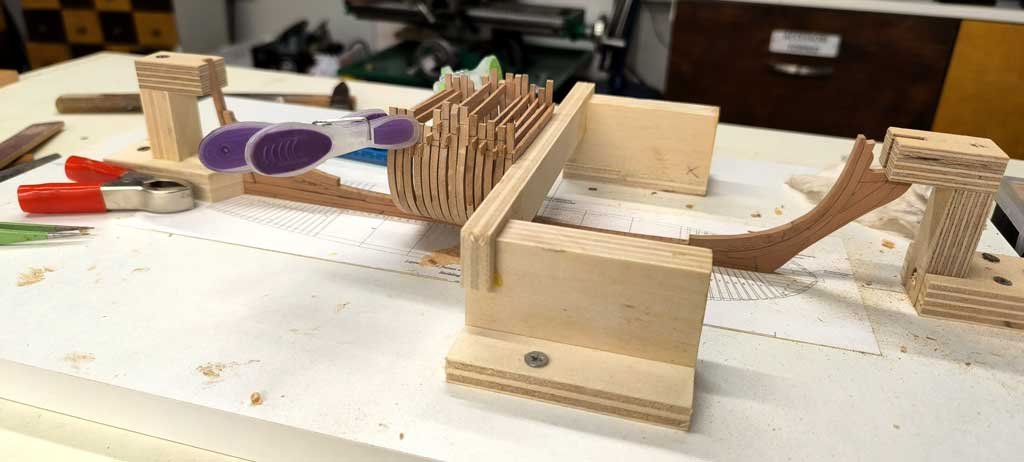

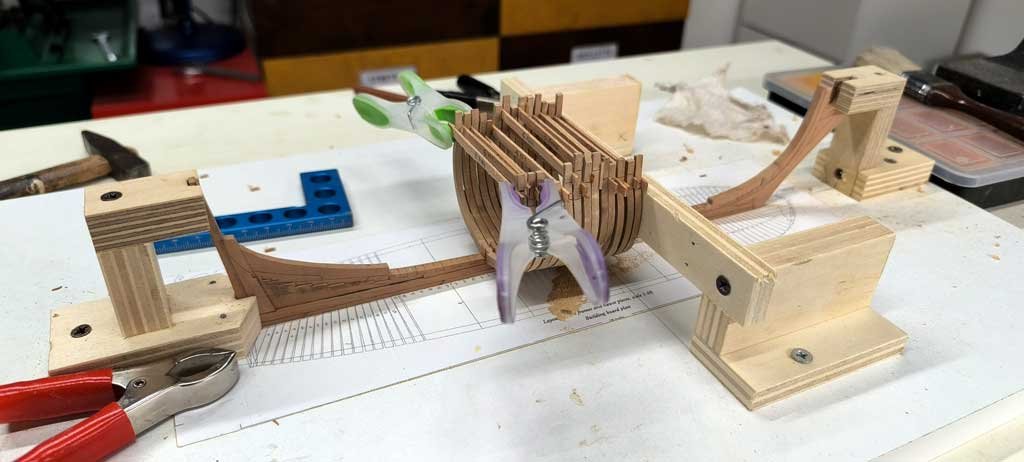

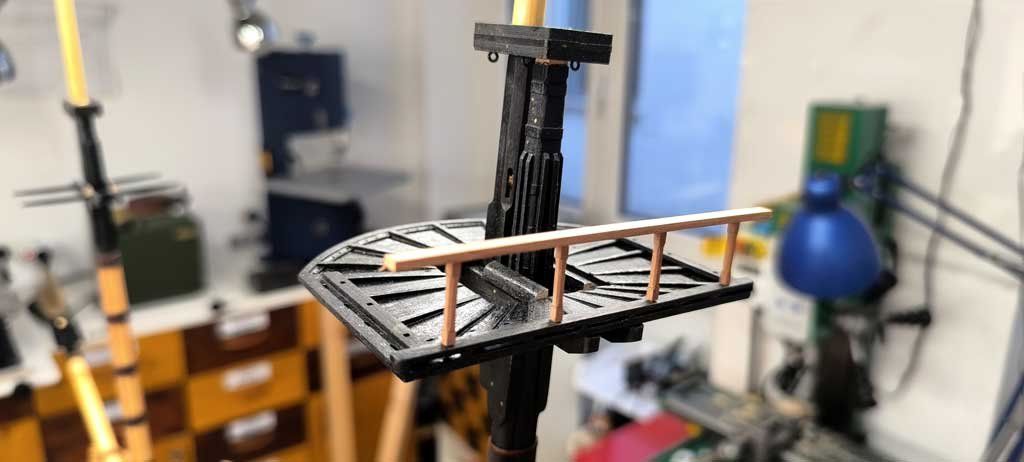

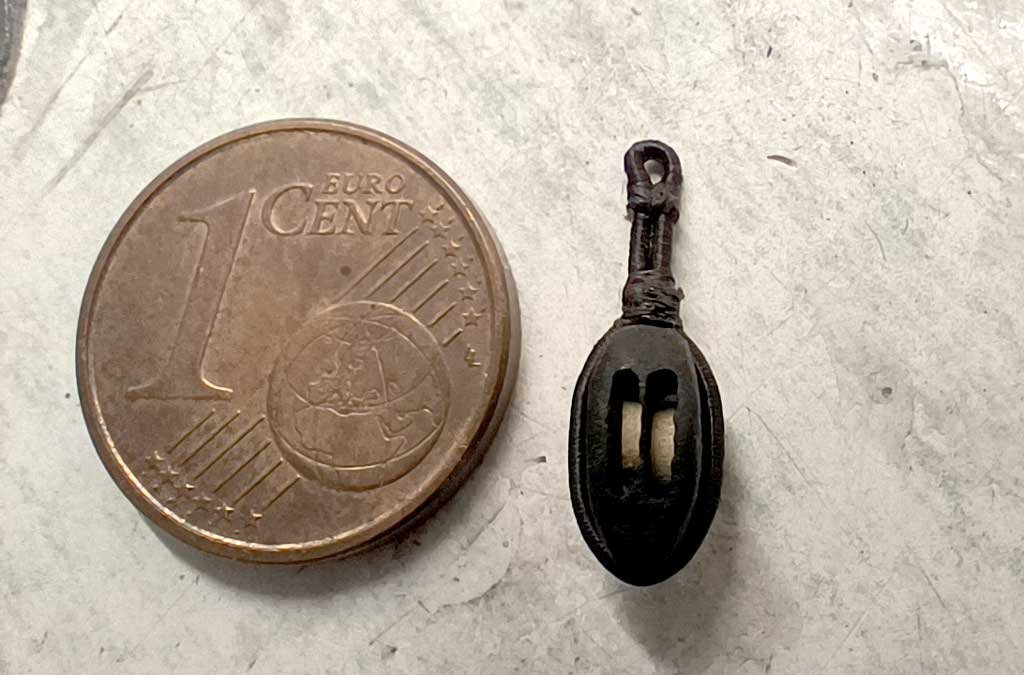

I have temporarily paused work on the Pegasus, which I will finish shortly, and in the meantime I have begun a new challenge, or rather, a double challenge: the basic idea is to build the same model twice, namely the Speedwell from the splendid monograph by David Antscherl and Greg Herbert, first in 1:96 scale complete with all its equipment and then the same model in 1:48 scale, leaving only the hull to appreciate its splendid curves. I hope I succeed! Translated with DeepL.com (free version)

-

giampieroricci reacted to a post in a topic:

L'Artésien 1764 by Cpt.Barbossa - 1:48 - 64-gun ship from plans by Jacques Fichant

giampieroricci reacted to a post in a topic:

L'Artésien 1764 by Cpt.Barbossa - 1:48 - 64-gun ship from plans by Jacques Fichant

-

giampieroricci reacted to a post in a topic:

HMS ANSON 1781 by albert - 1/48 - 64 guns

giampieroricci reacted to a post in a topic:

HMS ANSON 1781 by albert - 1/48 - 64 guns

-

giampieroricci reacted to a post in a topic:

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

giampieroricci reacted to a post in a topic:

HMS Thorn by Kevin Kenny - 1:48 scale - Swan-class - David Antscherl practium

-

It's fantastic to watch the video and hear Kevin's voice speaking Italian! The wonders of AI.!!

- 1,132 replies

-

giampieroricci reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

giampieroricci reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

giampieroricci reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

giampieroricci reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

giampieroricci reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

giampieroricci reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

giampieroricci reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

giampieroricci reacted to a post in a topic:

La Renommee 1744 by ChrisLBren - 1/48 - 2025

-

giampieroricci reacted to a post in a topic:

HMS Cumberland 1774 by Jack H - 1:36 &1:48 - POF - kit development for True Image Models

giampieroricci reacted to a post in a topic:

HMS Cumberland 1774 by Jack H - 1:36 &1:48 - POF - kit development for True Image Models

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.