-

Posts

172 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by The Gimps Chimp

-

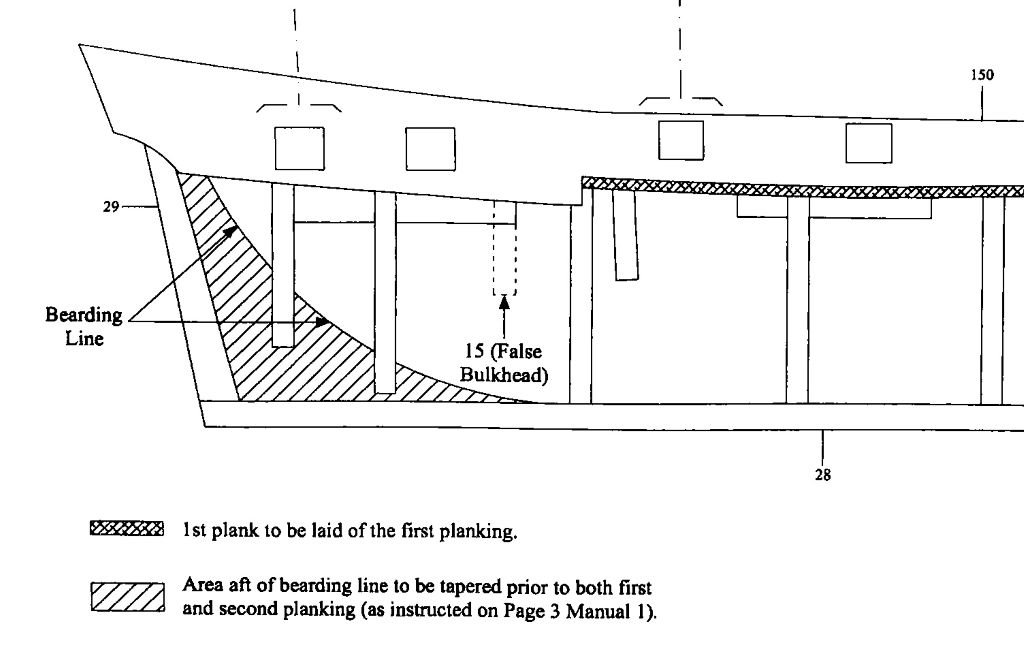

Two steps forward, one step back.... Progress has been a little slow but I'm still moving in the right direction, just. I've bent and fitted the gunport patterns to the bulkheads as per the instructions, no issues there. The only point of note is that the instructions make a point of stressing that the gunport patterns should only be trimmed at the stern end. I found that I needed to take some material from the bow end otherwise the notch in the gunport patterns which should sit on bulkhead 7 wouldn't sit at the correct location. Even after taking some material off the bow end the notch was still sitting towards the stern (see photo below): The first planking has now started and will probably take me a couple of weeks to complete at the rate I work One word of warning is that the bowsprit step (part 72) which is fitted into bulkhead 1 is very susceptible to damage. I snapped it off when fitting the gunport patterns whilst fitting a clamp. The clamp was supposed to be sat on bulkhead 1 and the bow. Unfortunately the clamp rose up the bulkhead and moved to the bowsprit step. As I tensioned the clamp the bowsprit step obviously couldn't take the force and snapped. However, it was quite easy to fix and repaired well. Unfortunately the same thing happed again when I was fitting the first plank. I couldn't believe how stupid I had been. So now I'm not going to repair it the second time until all the planking and sanding is finished. Geoff

-

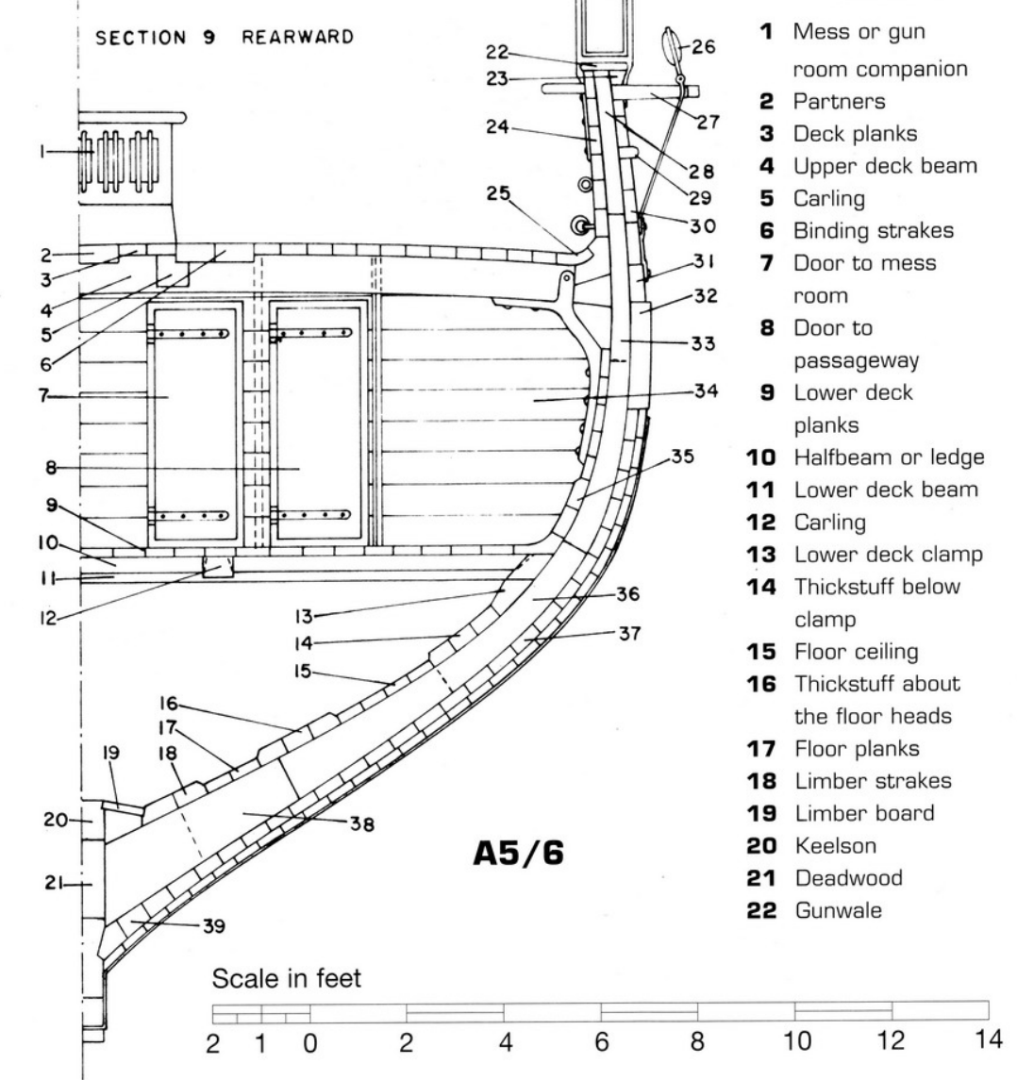

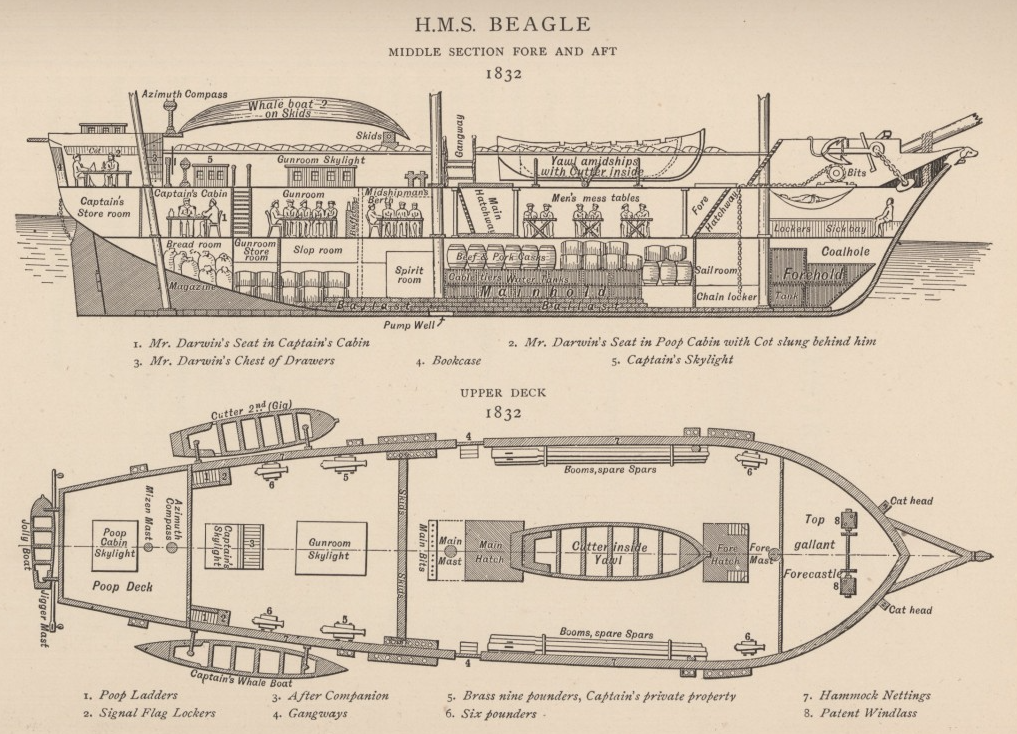

Hi 'Maid of the Mist' Your build is looking great and of high quality! The 'small deck huts' are actually skylights for the rooms below. Here is a diagram showing the Beagle: Keep up the excellent work. Geoff

-

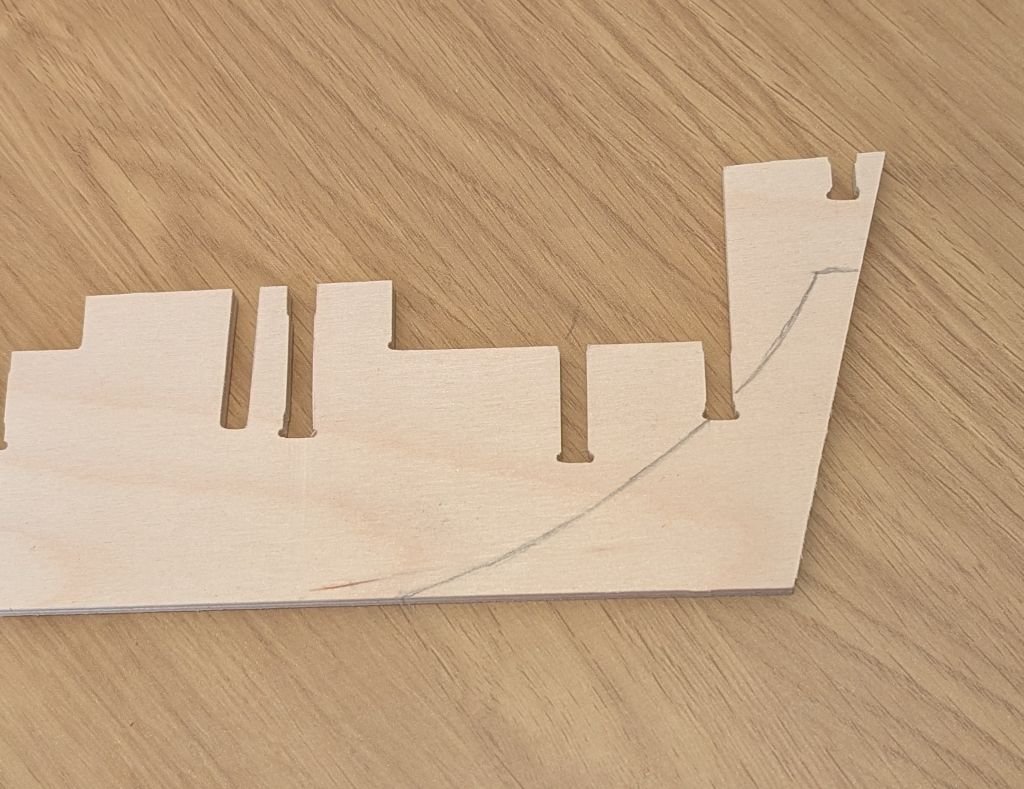

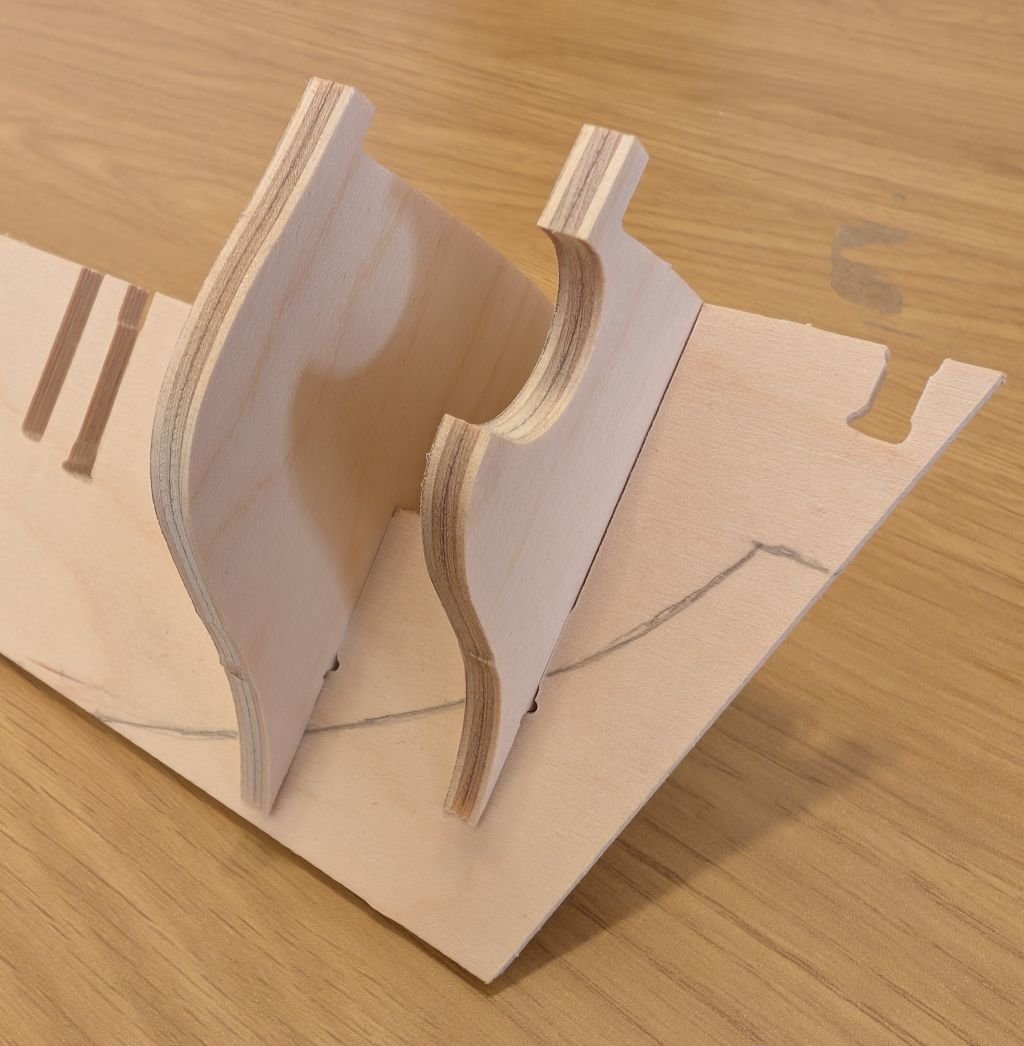

Just a quick update as to where I've got to. As it turns out, not very far The bulkheads are fitted to the main keel. I've decided not to fit the walnut stem and false keel yet until all the fairing is completed as I think it would be too easy to damage these parts when sanding the bulkheads. Below is a photo of my attempt at fairing to my repositioned bearding line Bulkhead 1 coarsely sanded to start the fairing process. I've had trouble understanding how the final bulkhead 10 can be sanded during fairing as there isn't any material below the stern's transom. So what I've done is to add some scrap wood which can be tapered down to provide a little more material for the planks to attach to. It might turn out that this isn't required but I would rather add it now just in case it is required. Hope to post another entry soon. Regards Geoff

-

Hi Cathead, It's been about 2 years since I finished the Beagle and I've now finally got around to starting next project, HMS Granado. Link is in my signature if you're interested. Would love to see you there :)) Regards Geoff

-

Hi Tom, So you saw it through to the end, well done! What a great build and what a fantastic build log. I'm sure future builders of this kit will find your build log invaluable, very comprehensive. Where you've chosen to do the additional research and deviate away from the kit instructions, I'm sure will have given you extra knowledge and experience, which will be useful for your next build. It also provides food for thought to other builders of the kit. You say you may not produce a build log for your next build. What I would say is, doing a log is not only useful for future builders seeing alterative approaches but it's also an easy way of asking for advice or hearing differing opinions. Whatever you decide to build I'm sure you'll do it well. Best of luck with it :)) Chimp

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

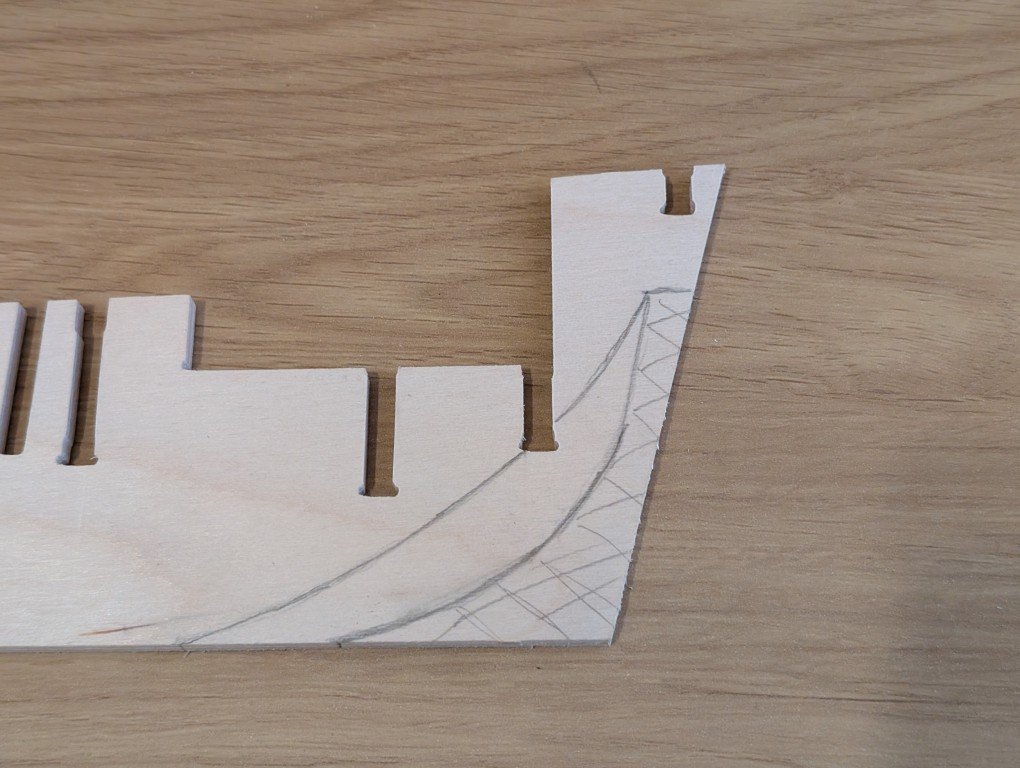

Hi guys, After two years, almost to the day, I'm back with another build log! I've finally got around to starting my Granado, which I purchased about three years ago. I won't write a brief history of the ship or a description of the kit as HardeHarHar and Vane have already provided that information in their build logs and have been more comprehensive than I would. What I will say about the kit I received was that it must have been a Friday afternoon special as it had two false keels, three sets of midsection bulkheads but was missing the fore and aft bulkheads. However, after a comprehensive check of the kit contents and an email to JoTiKa-Ltd (manufacturer) and Cornwall Model Boats (supplier) the missing parts were very quickly supplied. The positive point here is that I now have some spare parts if I were to make a mistake. Following on from my last build, which was the Beagle by OcCre, I feel I'm a little more experienced and I'm keen to make this kit to a higher standard. Don't get me wrong, I was very happy with how the Beagle turned out and I'm very proud of it but I would like to improve. I'm particularly keen to improve on my planking, so my intention is to follow the excellent document "Simple hull planking techniques for beginners" so let's see how I get on with that. I've cut out the false keel and bulkheads and transferred the bearding line onto the hull as described in the instructions: Now before I have even glued my first part, I have in issue which I need to resolve and would welcome some comments. My issue is that following a dry fit of the bulkheads I see that the bearding line is well above the lowest section of the bulkheads. I can't see this makes any sense at all, surly this is an error in the instructions. The bearding line must be below the lowest part of the bulkheads. Hopefully someone can confirm my thoughts are correct before I make my first mistake. I suppose if I do wrong I have a spare. Chimp

-

Hi, Just stumbled across your build log. Looks like you're having fun and making some excellent progress. I made this kit a couple of years ago and looking at your build log has taken me back to some of the same issues I had experienced. As you have already identified, the instructions in the kit are of variable quality and sometimes contradict the video instructions. What I would say is, yes it can be very frustrating when you have incomplete or conflicting instruction but it does give you the opportunity to look into the issue a little further to find a solution. Then hopefully you will have gained some extra experience and knowledge. I found I was constantly referring to the excellent reference book "Anatomy of the ship - HMS Beagle" by Karl Heinz Marquardt. Not sure how available this is these days but I'm sure a copy can be found in one format or another. I will be following your build with interest. Remember, it's not a race :)) Chimp

-

Hi Tom, Your ship is looking great, you're doing a fantastic job! Regarding the fuzzy thread which Occre supply with their kits, I think it's appalling and I refused to use it when building my Beagle. I was so disappointed with the supplied thread, I raised a question on the forum to which I had quite a few suggestions on how to resolve the issue: Unfortunately, I didn't find any of the suggestions really solved the problem to a quality to which I was happy with. As I explain in the link above, my solution was to 3D print a cheap ropewalk. This really solved the problem and provided me with the ability to make as much really high quality rope as I wanted at minimal cost. It's also a lot of fun to make the rope and I find it very therapeutic. So much so that I'm now looking into making a computer controlled ropewalk just for the fun of it. I know the thought of making a ropewalk will instantly put many people off but it really isn't that difficult at all, and the benefits are huge. Why spend hundreds of hours working on a model, making it as beautiful as you have, only to detract from the model by using the kit supplied thread? It's a no-brainer in my mind. Hope you find a good solution to the issue which suits you. Keep up the good work! Chimp

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

Congratulations on such a beautiful build!! I too have been a little shocked on the cost of display cases and are considering to build my own. I've just started following your next build. Looking forward to following your progress. Chimp

- 90 replies

-

Looks like you could do with more filler. Be careful you don't sand too much and break through the wood. Chimp

- 47 replies

-

I would say that's looking good! When it comes to sanding just be careful and don't be too aggressive. Chimp

- 47 replies

-

I think the one I would try and follow is this one: http://modelshipworldforum.com/resources/Framing_and_Planking/plankingprojectbeginners.pdf To be honest, if you mess up the first planking it's not too much of an issue, as long as you can fill and sand to a smooth finish. However, it would make sense to try and master the skill if you can. The second planking in this kit is very thin and forgiving so as long as you can cut it to shape, it will fit and look okay. Again it would be better to try and master the skill but I think with this kit you can't go far wrong. Chimp.

- 47 replies

-

Build is looking good. Looking forward to following your progress Chimp

- 47 replies

-

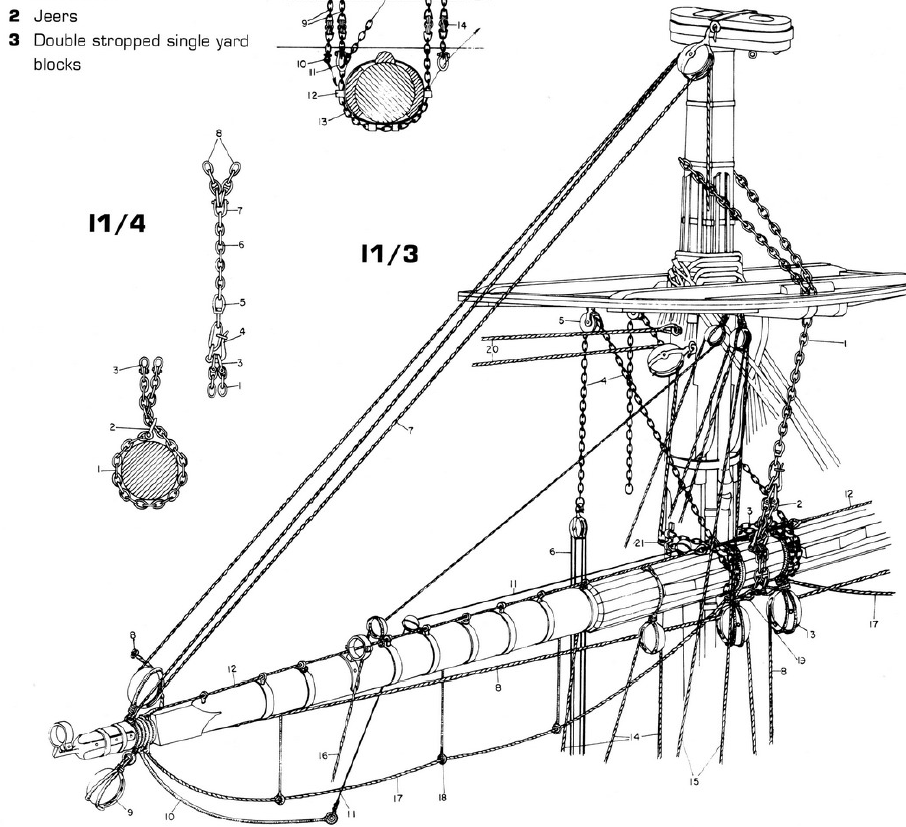

Hi Stauf, This is a difficult one to answer as everyone will have a different opinion. All models will differ from the actual ship they portray to some degree. Looking at the model from a distance I would say it's a reasonable representation of the real ship. The closer you get and the more detail you study it becomes clear there are inaccuracies. Some of these will be down to cost and some will be down to practicalities of modelling. One of the first items you come across in the build are the brass etched doors, which look okay but some people choose to make them more accurately from wood. The deck parts again are generally okay but maybe don't have the precision of detail. As already mentioned, the rigging of the cannons is massively oversimplified. Again these issues can be rectified during the build if you wish. I think the most inaccurate area are the masts and rigging which have again been over simplified. To be honest I can see why that is. Looking at the AOTS the rigging is very complex and I for one wouldn't have been able to finish the build if it was accurately modelled. In the AOTS there are many chains used whereas in the kit rope is used for everything. Here is a good example from my build: I'm not sure giving the accuracy of the model a percentage is meaningful but if pushed I would give it 90% to 95%. You also need to think about the marketing aspects of the supplier. I would say these kits are not at the high end of quality and are intended mainly for people to make and have an impressive model to display. If you want high accuracy you can spend the time and improve the 'Out of the box' product, or maybe even scratch build. I for one, used the kit as a learning experience and was happy that many aspects had been simplified, otherwise I would never have finished it. Having completed my build I was motivated to improve the quality of my workmanship on my next build. Had it been unfinished I wouldn't have considered tackling another ship. Chimp

- 90 replies

-

Hi JFMJr, Not sure I fully understand your question when you say the brass wire is a poor fit. I presume you are referring to the 1.5mm brass pin (H5) which acts as a hinge pin for the rudder to rotate. When I fitted mine I crimped the metal band a little so the wire was a close fit. I also added a drop of CA to ensure it remained in place and didn't drop out. I'm struggling to see why/how it could be a poor fit. I guess you could make these pins from wood but I think that would be much harder and I can't see why or how they would be a better fit. If you are referring to fixing the metal band to the rudder then this is done using the metal pins (A). Chimp

- 31 replies

-

Good to see you decided to start a build log. Looking at what you've done so far you shouldn't have too many problems with completing this build. I'm sure you'll get plenty of advice and support from everyone here. Regarding the nails, I don't think you'll need them from here. Looking forward to the rest of the build Chimp

- 31 replies

-

Hi Sparkov, looking forward to seeing your progress Chimp

- 14 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

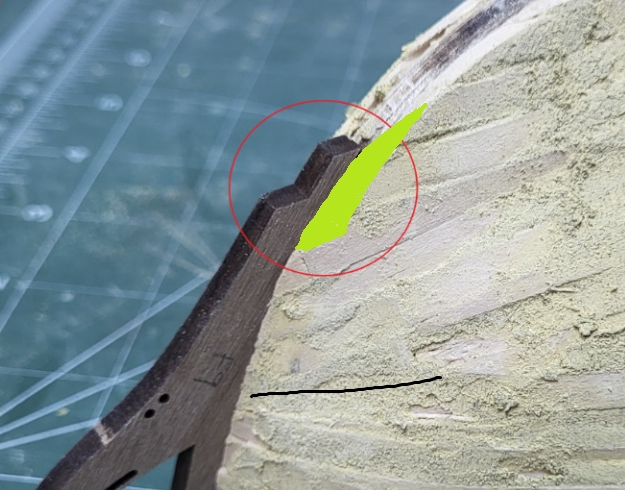

Hi Capella, Looking back at my build it looks like the keel was recessed at the bow but was then level (or even slightly proud) along the bottom. See photos: To be honest, I don't think it really matters as long as the keel is firmly attached to the false keel and the second planking is fitted up to it. The important issue is that the hull is smooth along it's length. So where I said about extending the first planking or using filler where it steps (where you circled), this needs to be smooth. You could build up the shorter planks with wood or filler, just a single piece of scrap wood is required: Or you could smooth down the longer planks to match the shorter ones. It doesn't really matter which way you choose Remember, the first planking is just a base for the second planking. It doesn't need to look nice but it's shape and profile is important. Chimp

-

Hi Capella, It's great to see you back working on the Beagle. Your photos in your last post look very similar to my build. At this point I was worried that it didn't look very good and was concerned as to how well the second planking would sit and how it would look. As it turned out I had nothing to worry about, once it's filled and sanded it's all good. Just be careful when sanding you don't go too far and sand through to the inside . Patrick B has some useful advice above and I too had the intention of doing the second planking 'properly' However, I ended up not following any advice and just did my own thing and it ended up looking okay. This is a link to that stage in my build log: Have a look at posts #55 and #61 My intension is that on my next build (HMS Granado) I'll do the second planking 'properly' and follow the technique detailed in this document: plankingprojectbeginners.pdf Looking forward to seeing your build progress Chimp

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.aa3aedd1a8c7f2b1b84719cd13aeebf6.jpg)

.jpg.f1d771e4356e757c14a84547c9b0462a.jpg)

.jpg.54e2cf32ea98ff1b30400adc4ff3a93f.jpg)

.jpg.3e0f9984c39fdde186ab06a585cefc91.jpg)

.jpg.99c35ef86f7996056508bd1867c834b1.jpg)

.jpg.82780aed569673087813b5f4b294b7cd.jpg)

.jpg.d9d1cdfeb3999075ea20b628e6a285dd.jpg)

.jpg.1bac5e2676b89eade7e4611643348114.jpg)

.jpg.6200c4ddb3a16a2e9e2809d290e17932.jpg)

.jpg.d4286562043a5acf6a806906bbc288d7.jpg)