-

Posts

172 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by The Gimps Chimp

-

Hi Tom, I'm sure that cradle will serve you well for this and future builds. I would love to take credit for the design of the cradle but have to admit I got the idea from the late Hubert Sicard and his website "Wooden Ship Modelling for Dummies". Chimp

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

Here are some notes and thoughts about my build and the OcCre Beagle kit. After I had finished my previous kit HMS Ballahoo (Caldercraft), which was my first ship build, I started looking around at what to build next. To some extent I was overwhelmed by the choice available on the market. It therefore needed to be narrowed down to something which was within my capabilities. Despite feeling very confident after completing Ballahoo I was conscious that I didn't want to make too big a leap forward and over-stretch myself. Therefore, I restricted myself to looking within a certain price range, which was still toward the lower end (max £150/$185). I considered many kits but eventually settled on the Beagle for a number of reasons. First of all HMS Beagle was a very historically significant ship and this would be a good way of finding out more about her. OcCre appeared to offer good value for money as a supplier and there were also good resources to help the build, OcCre's 130 videos of the entire build plus the AOTS book. After ordering and receiving the kit I checked the parts and discovered the flags were missing. I contacted OcCre about this and they immediately dispatched the missing parts without any issue. This would indicate that their after-sales service is very good. Unfortunately, after I received the missing parts I found the original parts within the kit placed under other parts. The build has taken me nearly 3 years to complete so I'm not a fast builder, but as someone rightly commented "It's not a race". Generally, the quality of the kit is good/reasonable. Along the way I have had some issues with the kit, luckily nothing major. The main issue was the instructions on how to mount the fore channels, which supports the dead eyes for the fore mast. The instructions show the channels mounted the wrong way around (3 dead eyes followed by 2 as opposed to 2 followed by 3). Luckily this has been picked up in other build logs so I was alerted to it before I also made the mistake. It would be good if OcCre would amend their instructions or maybe just add an addendum note in the kit. The kit material quality and quantity were generally fine. Timber for first and second planking, I had enough to build two models. Other timber and some brass wire I would have run short of if I hadn't been very careful. My biggest gripe was the supplied thread for the rigging. In my opinion I would say it was hopeless and I refused to use it. The thread was 'hairy' and in my opinion would ruin the model. In a way this was a blessing for me as I then acquired a ropewalk and made my own rope using Gutermann thread, which was far superior. This will now carry forward onto future models. I've not been aware of others complaining about the supplied thread so it might be that I had a particularly bad batch or maybe OcCre have improved their supply. (or maybe I'm just too fussy). The instructions for the kit were frustrating at times as there are multiple A3 sheets covering different areas, part identification, hull assembly, mast assembly, and rigging. I don't have much space where I build my models and I always had problems finding the right page on the right set of instructions and ended up have to flick between different sheets time and time again. Then I would jump over to the video instructions on YouTube and check with the AOTS for the Beagle. There did seem to be much cross referencing between different parts of the instructions. By the time I had finished the build I knew where the different information was and it became a lot easier. I know it sounds like a minor point and a failing on my part but when you're struggling with a particular part of the build the last thing you want is to be sent on a wild goose chase to find a piece of information. I would say the scaling of some parts and accuracy of others (e.g. belaying pins, mast metalwork) may not be as accurately modelled as they could be but I guess this is a compromise for many reasons. In hindsight I don't think I should have chosen the Beagle as my second build mainly because there is a lot of rigging, being a three masted ship and this was something which could have been too overwhelming. Luckily my attitude of "As I had paid for it then I was going to build it" saw me through. I'm sure this amount of rigging wouldn't be a problem for others. Generally, I was happy with the kit and how the build progressed. Yes, the kit quality could have been better but it's very good value for money. I've used the build as a learning process to try and improve my skills and in some way, not having perfect parts has made me think about how things could be improved. The supplied thread/rope and my adventure into making my own rope is a good case in point. My final comment is about this build log. At first I was very apprehensive about writing a build log, thinking that my skills weren't good enough to showcase and it would be embarrassing to demonstrate my lack of skill. Clearly I had no need to worry as nobody is judgmental here and everyone is immensely supportive and encouraging, which is a great motivator. It's also good to get other peoples opinions which broadens your outlook and future approach to issues and can often trigger further research into subjects. I would fully encourage anyone starting out in this hobby to start a build log, you will find it so rewarding. I will definitely be writing a build log for my next build. And finally, to anyone who has bothered to read this far, many thanks for your help and support during the build and I hope to see you on the next one . Best regards Chimp

-

Hi Cathead, It was good to have you along for the whole journey . Many thanks for your interest, 'likes', kind words and encouragement along the way. Hope to have you along on my next one . Chimp

-

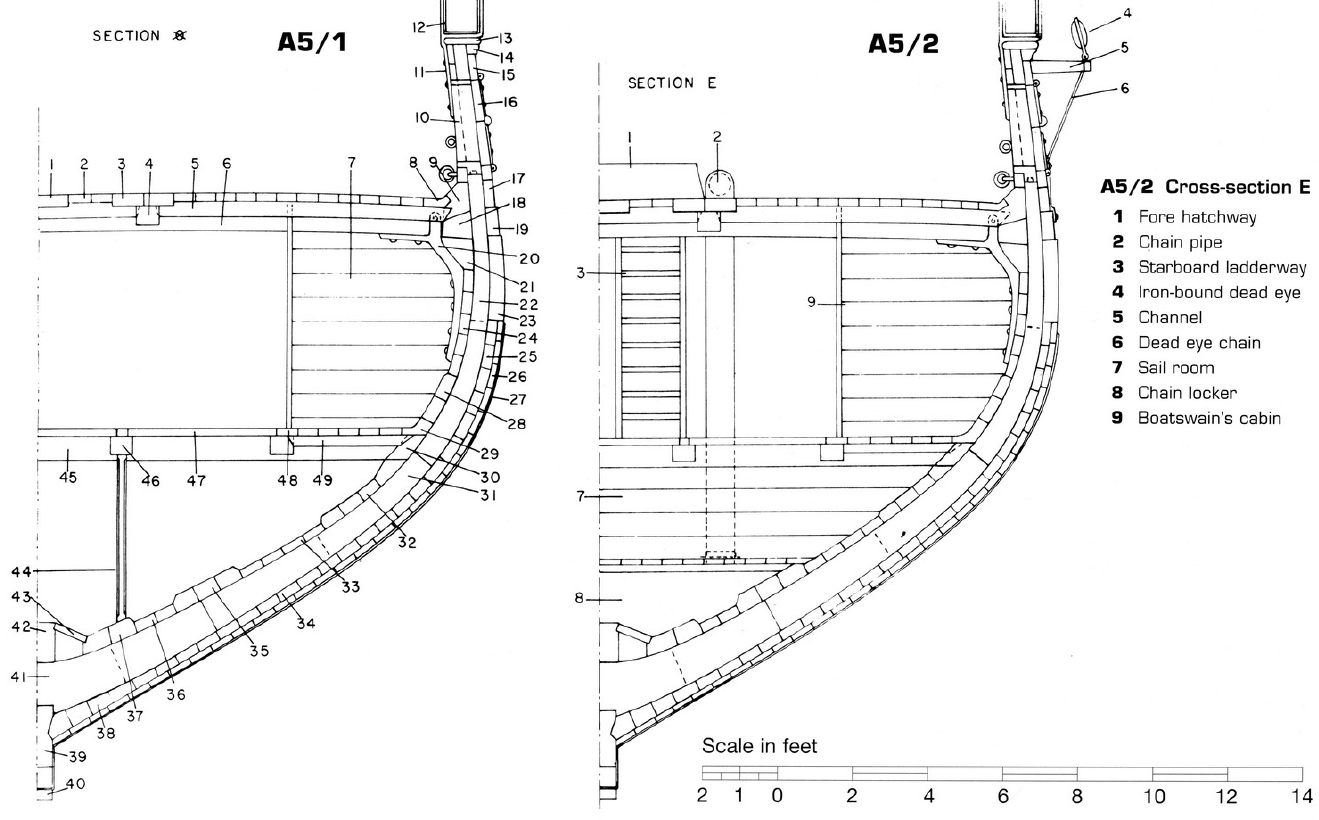

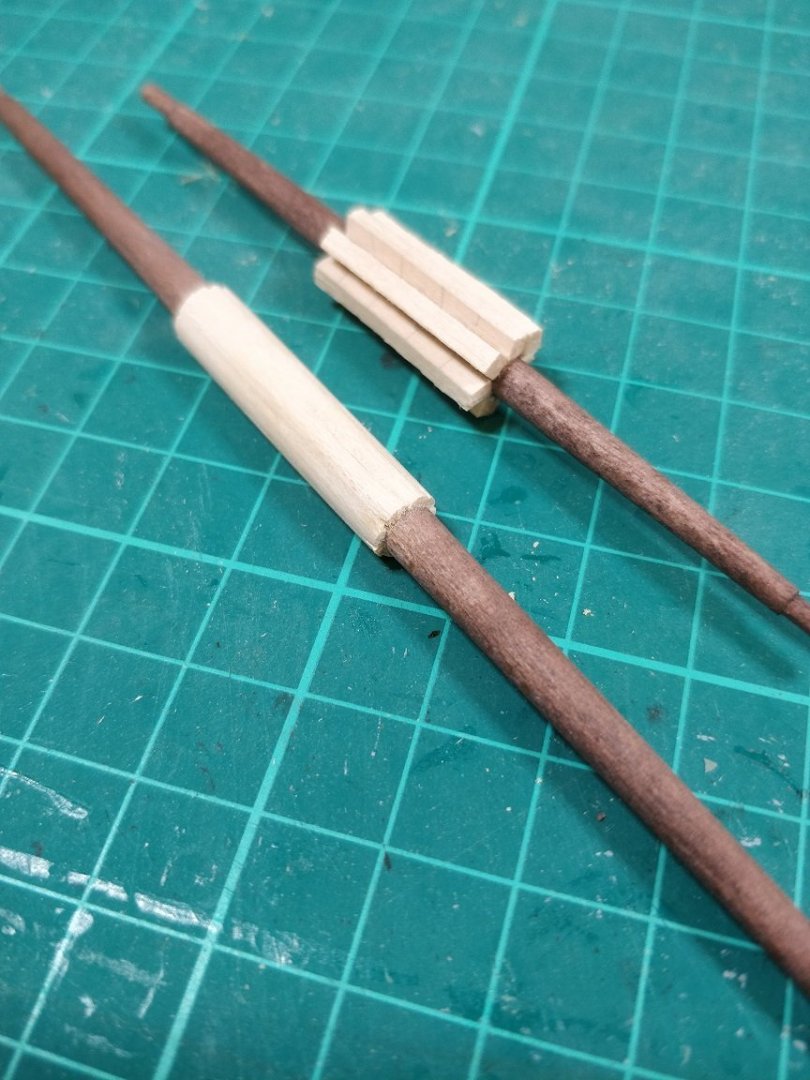

Hi SHJ, Many thanks for your comments. There are many things with which I'm not 100% at ease with on the model and think I could have done better, had I put in more effort. However, this has been a learning curve for me and I've gained an enormous amount of knowledge and experience (and pleasure) from the build. Given the quality of the kit, and my inexperience at this hobby, I understand why it's not up to the standard of many ships on this forum, but I'm fine with that. If nothing else it gives me something to aspire to. You're correct when you say you think the thickened sling section on the mast is too 'fat'. The OcCre instructions indicate using 1mm x 3mm lime wood for this. However, during my build I was running short of that for some reason and used 5mm x 2.3mm from what was surplus from the first planking. This was then cut in half, so 2.5mm x 2.3mm. This then made it way too 'fat' and I shaved it down to what I thought looked about right (to the instructions). Looking into it following your comment I realise maybe I should have taken it down further to maybe 0.5mm. The studding sail booms are made from supplied 3mm lime wood dowel. The rings are made from supplied 1mm diameter brass rod. Again, looking further into it you're correct in what you say and these might be oversize. I guess OcCre want to limit the variety of supplied material to keep the cost of their kits down. Regarding the placement of the studding sail booms it appears I didn't follow the instructions. They should be placed 45deg forward of the yard (although not very clear in the instructions). According to the instructions the stirrups for the foot ropes should descend 5.5mm from the yard. On my model I made them 8.5mm, not because I thought that was better but it just happened that way. Again looking further into it, it would appear to me from pictures I've found that 8.5mm x 65 (scale) = 0.552m (21.75 inches) maybe a little short?. I would be interested in what others think. With regards to the deadeyes, unfortunately on this kit the supplied deadeyes were plastic, so not that easy to colour. I believe OcCre now supply wooden deadeyes for this model. Looking into the points you've raised has encouraged me to do further research, albeit to late for this model, but will be useful for my next build . Once again thanks for your comments. Chimp

-

Thanks very much for the 'Likes' and kind comments everyone. They are very much appreciated . I feel that now I've finished the Beagle I should sum up my experience of building the kit, which may be useful to others thinking of building this kit. I'll gather my thoughts and post something in the coming days. It's taken nearly two years for me to build so I guess I might have a lot to say! Chimp

-

SHE'S FINISHED!!! Finally, after many, many months of work (on and off) she's finished. Here are some photos of the finished article (apologies for the number of photos). And finally one of her alongside my first ship HMS Ballahoo. Now I need to clear my workspace before embarking on my next ship, HMS Granado. A kit which I've owned for some time now but haven't wanted to start until the Beagle was finished. Well, that time is now! Many thanks to all that have followed this log, left comments, given advice, pointed out errors etc, etc... Hope it's been of use. Hope to see you on the next one (hopefully coming soon). Chimp

-

In the last few weeks I've made great progress with the rigging. All three masts now have their yards rigged and are fixed in place. I must admit tying off the lower section of the foremast was very difficult as access was near impossible now all the deck fittings are fitted. The belaying pins under the forecastle by the winch were particularly difficult to get to and I ended up tying them off to the top of the pin and not looping underneath but it was the only way I could get them to attach. Apologies for the quality of the photo but it's on max zoom. Other parts of the rigging went well and were more pleasing to accomplish. Tying off to the belaying pins on the side of the deck was so much easier! At one point I came back to the model to continue work and discovered the rigging at the top of the mizzen mast was all slack. Which after all this effort was somewhat disheartening, to say the least. I thought I would have to strip it off and refit it all. I couldn't understand what had happened. It was then under closer inspection that I discovered that the joint of the fore topmast and topgallant mast had failed at the topmast trees and cap. It might have been better to pin these joints rather than relying on a glued joint. This was fixed by clamping the topgallant mast just above the cap and driving a wedge between the two to force them apart and back into position whilst some new CA glue was applied. When dried the clamp was removed and fortunately it worked. Now I just need to fit the davits, boats and anchors and I'm done! I'm not going to be fitting the sails to this model. It shouldn't be too long now before it's finished Chimp

-

Hello from the Thames Valley, UK

The Gimps Chimp replied to Pitan's topic in New member Introductions

Hi Robert, welcome to MSW. I've just had a quick look at the 'Captain John Smith's Shallop'. It looks like the perfect first kit. I agree with Graham, start a build log and you'll be able to seek advice and opinions whenever you need it. Good luck! Chimp (Bristol) -

Hi Rob, Good to see you back working on the Beagle. I too have extended periods away from the hobby as life sometimes gets in the way My thoughts on the bulkhead filler would be to fit the fillers in the forward two bulkhead spaces at the bow and the rear most space at the stern. I don't think the others will help you much. Having said that, if you have them cut it won't hurt to fit them now. I struggled a little when I did my first planking and wish I had fitted fillers. The first result wasn't pretty but with wood filler and sanding it came out okay. After the second planking was fitted you would never know what mess lay beneath it. Looking forward to seeing your progress! Chimp

-

It's been a couple of weeks since my last update. Progress is still being made, albeit slow but steady. The remaining three small boats have now been finished and are ready to fit. Some of the minor details may differ from the manufacturers plans but I don't think it's significant and I'm happy with the way they look Rudder chains fitted The remaining deck fittings have all been fitted: The bowsprit has been fully rigged and the ship's mascot fitted. I decided to paint it like a real beagle as I feel the ships crew would have done that. Obviously I'm open to comments to the contrary And one additional big step is that the yards have now all been fitted. This is a significant step and is very visual, so it now looks close to being finished. My next step is to concentrate on finishing the rigging. Access into the deck for tying off the rigging is now very compromised and I'm starting to question if I'm up to it. I've just purchased some long tweezers so I'm happy to give it a go and see how I get on. What's the worst that can happen? No, maybe I shouldn't have thoughts like that... Looking forward to posting the next update. Chimp

-

Hi Patrick, Your build is coming along well and is looking great. Regarding kit materials I've found them to be variable. The timber for the first and second planking I had enough to build two kits. As you say, the brass wire is limited. The 0.7mm brass eyelet (part B ) was in short supply so I got some brass wire from Amazon for a couple of pounds and made my own. There are a couple of instances where you have to open up the eyelet to join it to chain and I found the one's supplied with my kit weren't malleable enough and would snap. The one's I made from wire were fine. Regards, Chimp

-

Here I am, "back in the saddle" (again). It's been several months since my last post. This has been due to me taking a break from the build due to other work and the fact that I had got a little frustrated with the rigging instructions. However, I'm back now and intend to see it through to the end as I have another ship ready to start which I've promised myself I won't start it until this one is finished. I say finished but I've already decided I won't be fitting the sails as I don't like the quality of the supplied sails and feel when fitted they hide much of the detail of the rest of the ship. I had considered trying my hand at making sails from tissue paper but think this might be a task for a smaller ship in the future. My previous task on this model had been to fit the masts and complete much of the standing rigging. Strangely I really enjoyed tying the ratlines and think they really add much to the look of the model. My next task was to complete the yards. I had previously made the yards for the foremast but that was over a year ago so I had to try and remember the process. Once I got started it all felt rather familiar. With the yards for the main mast now completed, my next task will be to fight with the instructions again and get them and the foremast yards fitted to the two masts. Now I'm back in the swing of working on the model I'm determined to see it through this time Chimp

-

Hi Patrick, Your build is looking fantastic, keep it up! Regarding the number of holes, I think you're absolutely right. Looking at the AotS for the Beagle it only shows two ropes, one each side. The forward one is the fore topmast stay and the rear one is the fore topmast preventer stay. Looking the Occre's own assembly video it shows only two holes and not the four shown in the instructions. Unfortunately this doesn't surprise me as I've found their instructions to be riddled with errors and inconsistencies. However, some might say this is a good thing as it forces us to research things further..... No, it's just frustrating. I was just trying to find something positive to end on Regards Chimp

-

Hi Penfold, They're also looking good to me, you've done a good job there I know there's talk about the position of tholes and seats which are all valid and interesting but as long as it looks okay and you're happy with the result that's all that counts. On my model I've done quite a few things which may not be 100% accurate but they look okay to me. When members point out inaccuracies I try to learn from them and take it forward into my next build. Keep learning and keep up the excellent work! Chimp

-

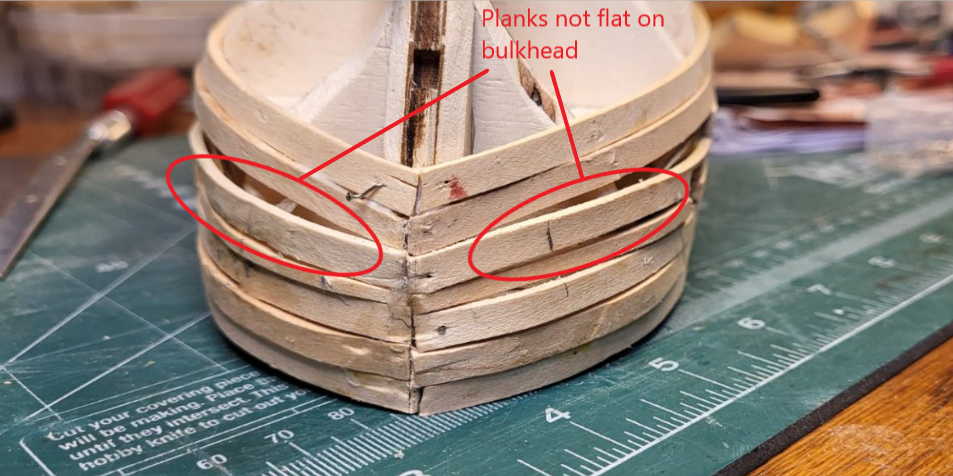

Hi Capella, I see your concern here. I also had issues with my first planking if you look at my build log. To me, it looks like some of those planks don't appear to be sitting flat on the first bulkhead. As you get the planks closer to the bow not only do they bend in towards the bow (vertical plane) but they also start to roll over in the horizontal plane. A couple of the planks appear to remain vertical. You could just use plenty of filler and sand it all to shape and that does generally work well for the first planking. My concern would be that there may be some points where the inside of one plank sticks out further than the outside of an adjacent plank. This could result in you sanding through an entire plank when trying to get the high-points down. If you decide to go with the fill and sand method I would glue in thin slithers of wood between the planks where you have gaps to ensure there is plenty of wood there to provide strength to the structure. Alternatively if you cut out the offending planks and reset them flat on the bulkheads that may solve your problem. Don't worry about running short of the planks as I had enough to make two models. Hope I've managed to explain my thoughts here. It was clear in my mind what I was trying to say but maybe it didn't come out that well. (feel free to ask me to explain further) Chimp

-

Hi Capella, When I did my first planking on the Beagle it looked absolutely appalling. However, by the time I had filled and sanded the hull it didn't look too bad and I was quite happy with it. My advice would be to allow the planks to follow a natural path without applying too much force to make it fit. Looking at the last photo of your post I would say the top plank looks to be in the correct position. (maybe I've misunderstood your question) Chimp

-

Hi Capella, I didn't use the nails provided in the kit but preferred to use the clamp technique using small bulldog clips on the bulkhead and/or removeable noticeboard pins. Not sure if the supplied nails should be left in or removed. If they're left in then sanding down the planks once finished is very difficult. If they are to be removed then they shouldn't be pushed fully home otherwise it will be very difficult to pull them out once finished. Chimp

-

Hi Rob, Wow, that's a long list! Not wanting to make the list any longer but have you considered the rope? I see that you now get wooden blocks, deadeyes and belaying pins so hopefully the quality of the kit parts are being improved. If so, then maybe the quality of the supplied rope has improved. The rope I was supplied was poor so I decided to make my own which I very much enjoyed doing. Now I don't worry about being frugal with the rope I use You look to have made a fantastic start! I'm following your build log with interest. Chimp

-

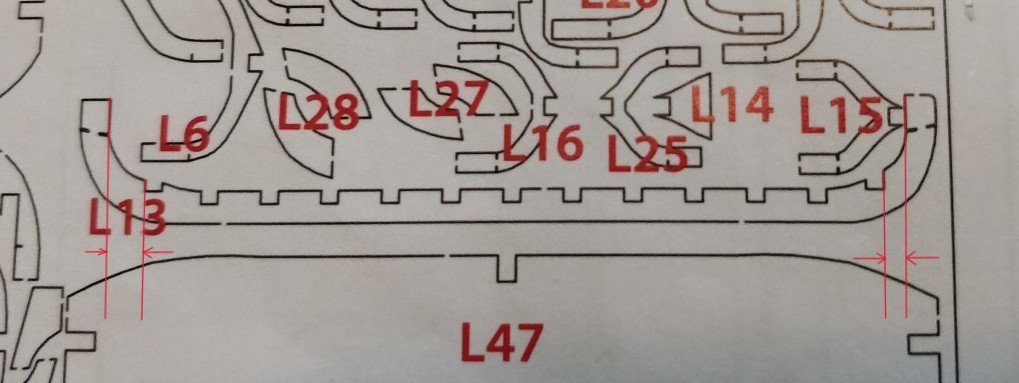

Hi Capella, I've just measured the wood I had in the kit for the deck planking, it measured 0.5 x 5 x 600. In the parts list it mentions Sycamore, Lime wood and Sapele having a 0.5 x 5 cross-section. Now I can't remember three types, only two types - one dark and one light. Having said that it was quite some time ago now so may have been three Over the time of building this kit I have developed a love/hate relationship with the instructions (more hate than love dare I say). The build logs on this site are a fantastic source of information to supplement the instructions and are a good way to rationalise the instructions. Chimp

-

Hi Allan, You're absolutely right in what you say. However, when I did mine I wasn't aware of this and just followed the instructions. I don't believe there is any camber included on the bulkheads in the kit and are made flat. Of course you could modify the bulkheads to include a camber. Looking at the AotS for the Beagle, there doesn't appear to be much of a camber, and I would say much less than 9 inches. As with all these things in scale modelling, how far do you go? I must admit there has been so much about this kit which I've found frustrating but have learnt to accept it for what it is and use it as a learning process to try and hone my skills. As with any kit, it's a starting point. We are free to change any aspect of the kit we so choose to. I suppose the ultimate is to scratch build, but my skills are a long way from considering that unfortunately. As I said above, how far do you go? Chimp

-

Hi Capella, I think the sequence you are suggesting makes sense. From memory I recall my sequence being very similar: 1) Dry-fit bulkheads 2) Dry-fit UN-PLANKED deck 3) Glue bulkheads to keel 4) Plank deck 5) Glue PLANKED deck to bulkheads To be honest It amounts to the same thing. What I think is important is that you plank the deck before gluing it to the bulkheads. It will be so much easier to plank the deck on a flat surface rather than trying to plank it after it's glued to the keel. Chimp

-

Hi Capella, Many thanks for the words of encouragement. I'm currently a bit bogged down with other things and have lost my way a little with the build. I found the rigging of the masts became a little onerous with conflicting and confusing instructions. My intention is to restart the build very soon (New year and all that...). I'm hoping to get it finished soon as I have another kit waiting to go and I don't want to have two kits on the go at the same time. I'll be watching your build log with much interest Chimp

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.3f2314e7162579ae08a2a6ae2eef9a3d.jpg)

.thumb.jpg.7a0d1d855115a367dd35415bee9b66fc.jpg)

.thumb.jpg.94aaadcf5d523a160ed8b682d3a218be.jpg)

.thumb.jpg.5e9c4c8eef028420626957fa42ae52ce.jpg)

.thumb.jpg.8d3739e330296621f1e83c85354f3a9c.jpg)

.thumb.jpg.e9a7a4cc51d49b76f67501b03a60a3d3.jpg)

.thumb.jpg.8fc7029ee7e7bc5f1bad182f33f1ff54.jpg)

.thumb.jpg.3520ae6c262db6bce17d3b0c53eaed78.jpg)

.thumb.jpg.bf082d593c55a20a9663435111fb9968.jpg)

.thumb.jpg.e427182a7839a51d8a73eed377ec7ec2.jpg)

.thumb.jpg.758868e2efb73d2ef960025902db7517.jpg)

.jpg.ca2f3caf9c5c45f3a9fd89ceda7d0ca4.jpg)

.jpg.2f0e9403a9ab56fb656bb93e2e3b3a39.jpg)

.jpg.c1fa2ed13dbd627b3c03a10980a3734b.jpg)

.jpg.acbc07f8c904ce29b1d1603d1e8085d9.jpg)

.jpg.7ba1929ca586809d575f9e5bfcca4bda.jpg)

.jpg.7c7a068cf8be7a79c886d4faa49f816d.jpg)

.thumb.jpg.06c6cfea7144771a20dd0ff6e0d476ad.jpg)

.thumb.jpg.5c9530f43183b58166870dc7eaafae98.jpg)

.thumb.jpg.80e745b9fe926c67801d978f16212f5f.jpg)

.thumb.jpg.d917bb3e2c13c14a06db88b332316571.jpg)

.thumb.jpg.cd12b1b10fd49ead5f721a65fe8d93cf.jpg)

.thumb.jpg.d54aeb2216a350e4f3b09e586ee85574.jpg)

.thumb.jpg.969f1b618e69b253f6382fbc32031106.jpg)