-

Posts

409 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alross2

-

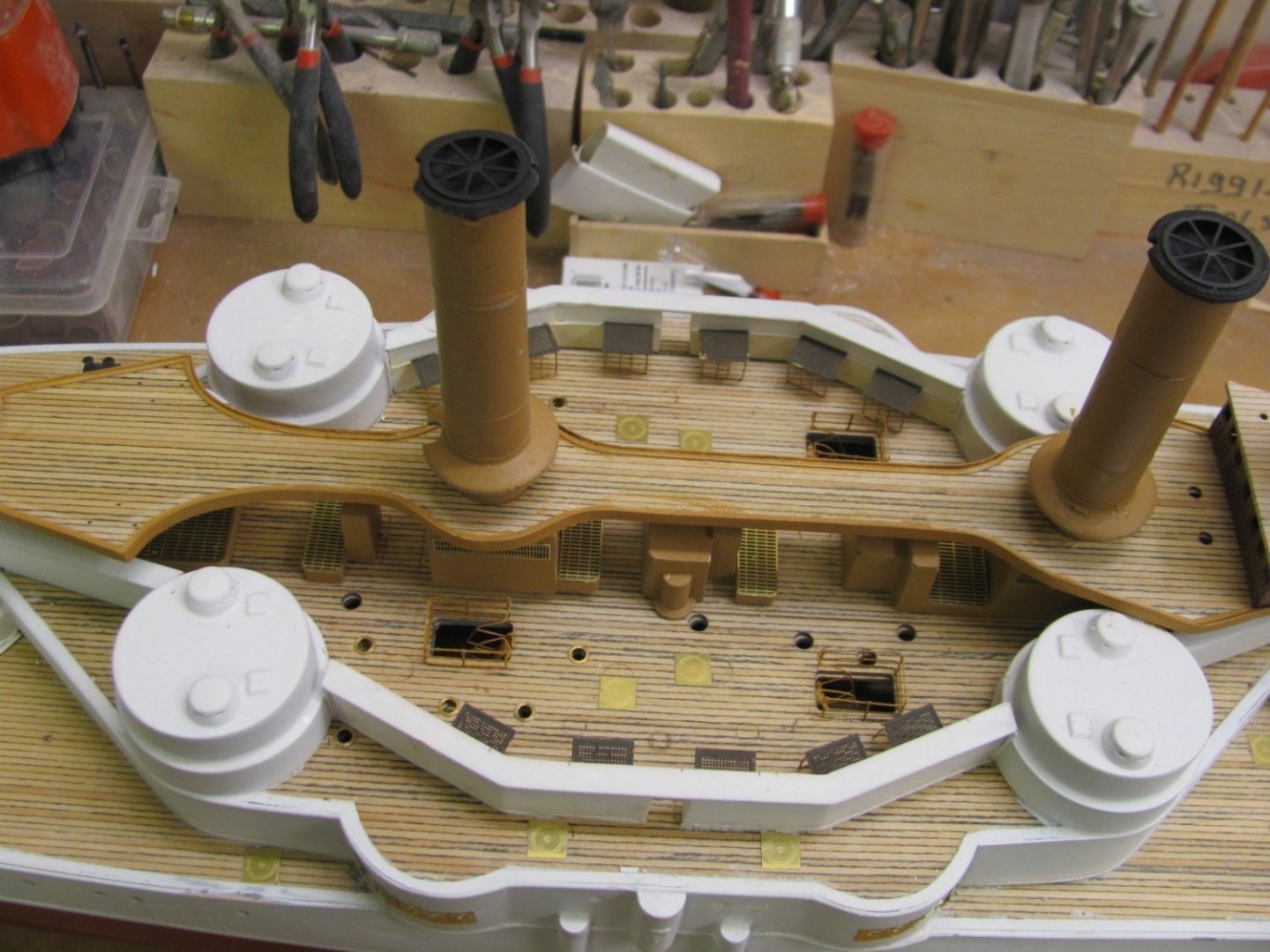

Test fitting the photoetched railings to the hurricane deck. There are four pieces per side and they are designed to fit in specific locations. This will require some careful bending and fitting to get them right. The end stanchions are a bit longer than the rest, so locating holes have to be drilled in the deck. An inclined ladder fits in the opening.

-

Once the holes for the main deck stanchions are drilled, the holes in the side of the hull for the awning stanchions are drilled. The blue tape ensures that they are all at the same level below the deck. Their locations are marked on the template. Both types of stanchion have a mechanical stop on their bottoms to ensure they are at the same height.

-

Strangely, I absolutely loved his Richard Bolitho novels but couldn't even get through one of his MTB ones! Since I focus on this type of vessel, you'd think it would be the opposite. Maybe I should try to read one of the MTB novels again.

-

What would have been PT52 was also a 77' ELCO. It was built for the RN as MTB310 and was lost at Tobruk in 1942. The 80' ELCOs depicted by the kit ran from 103-196.

-

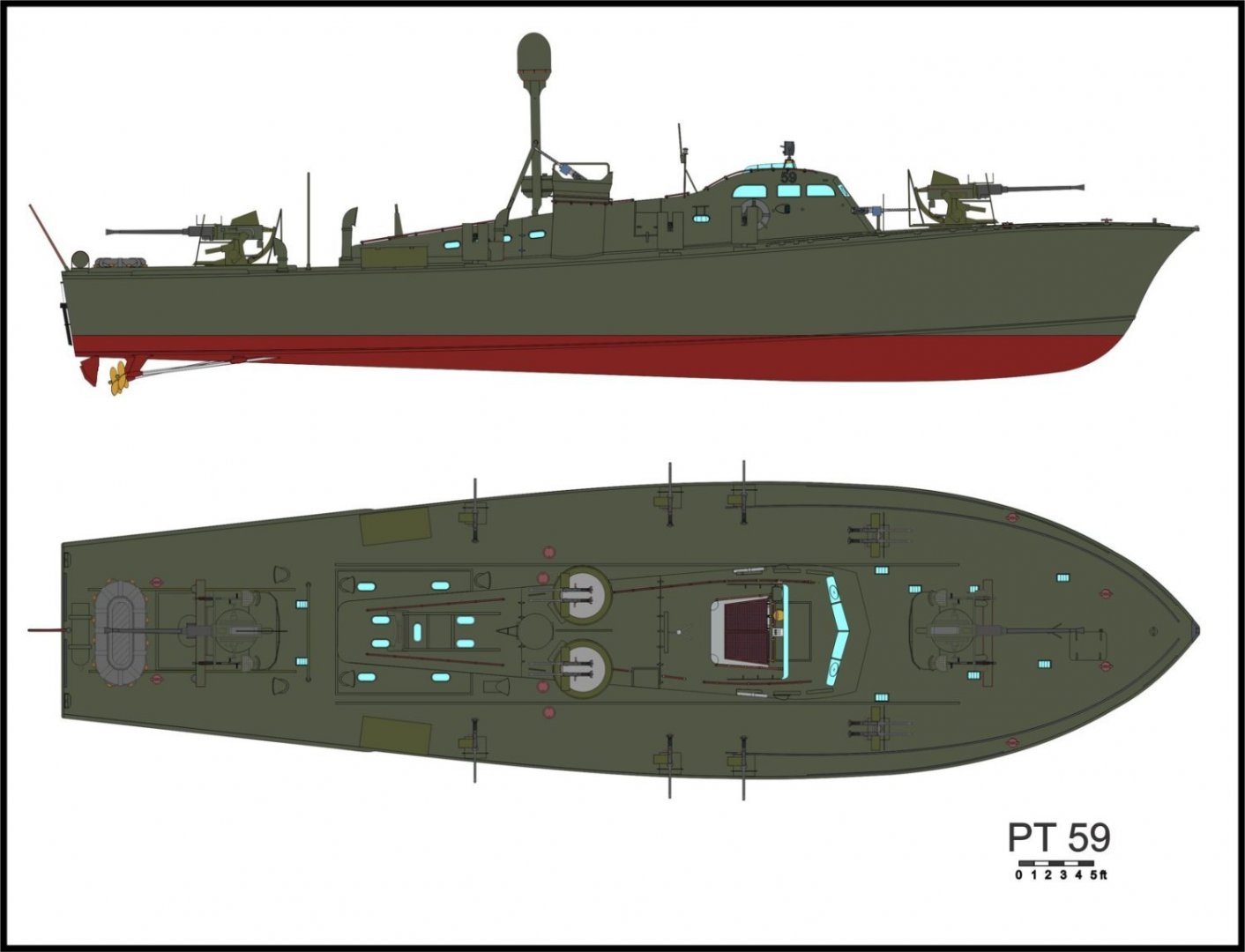

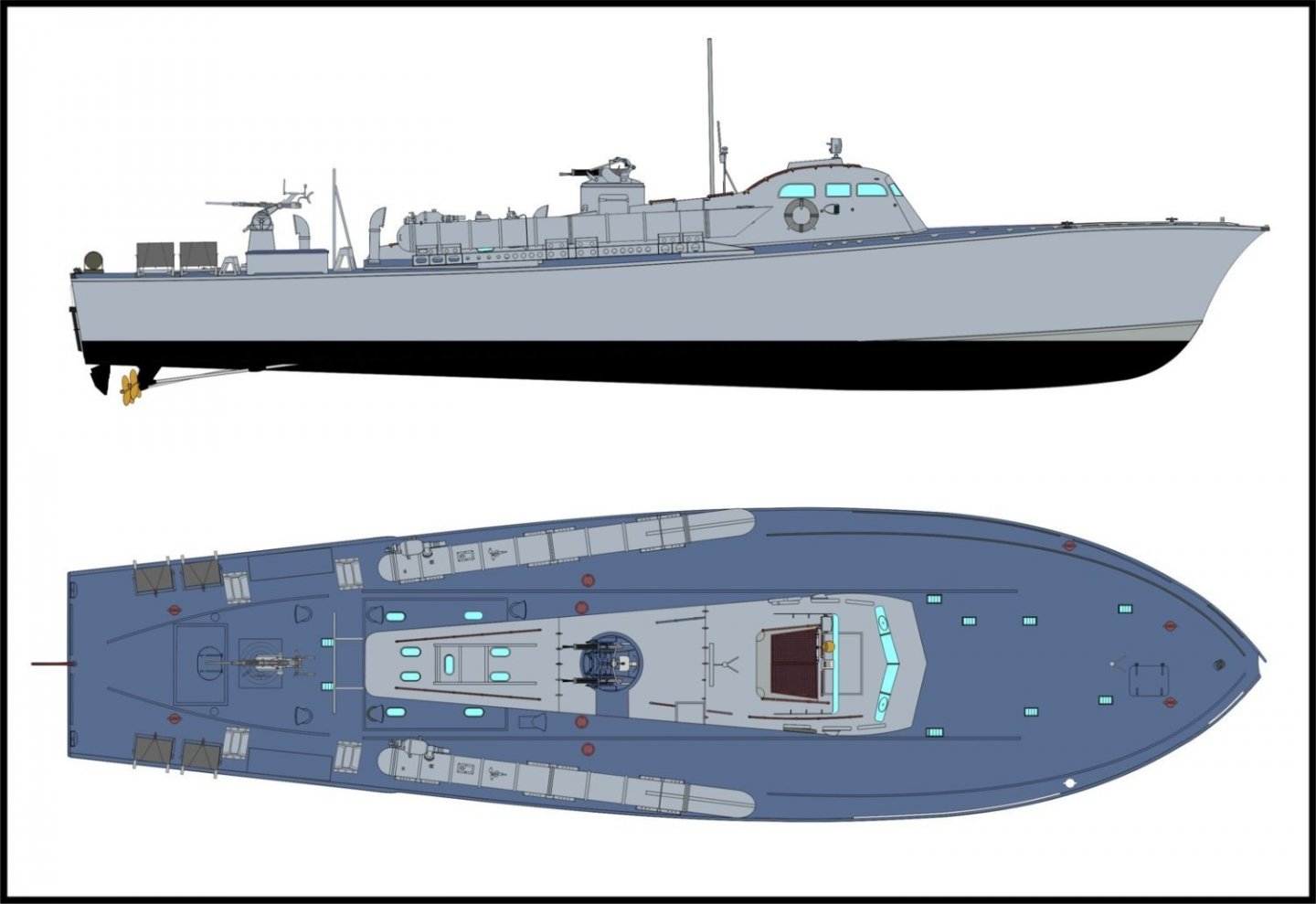

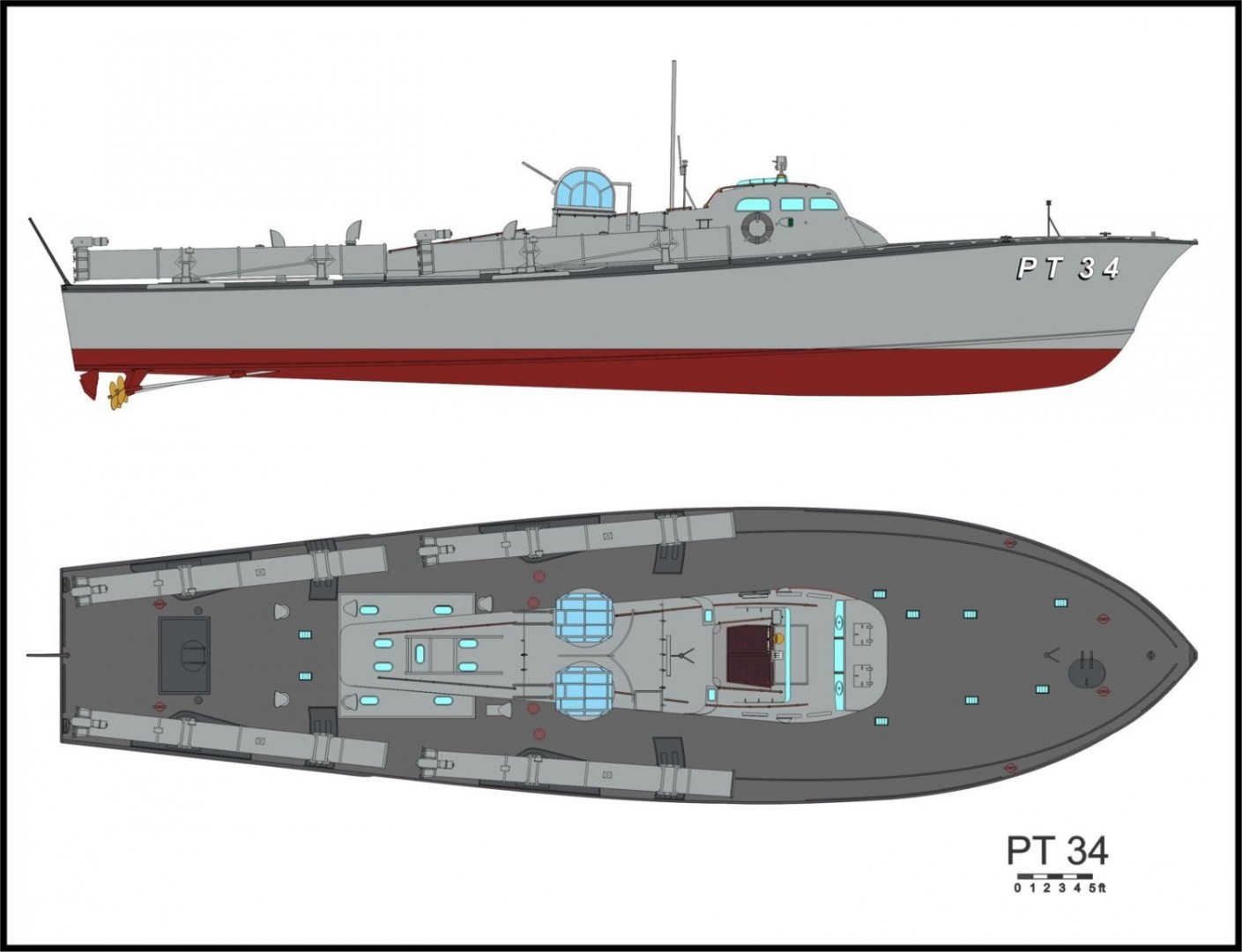

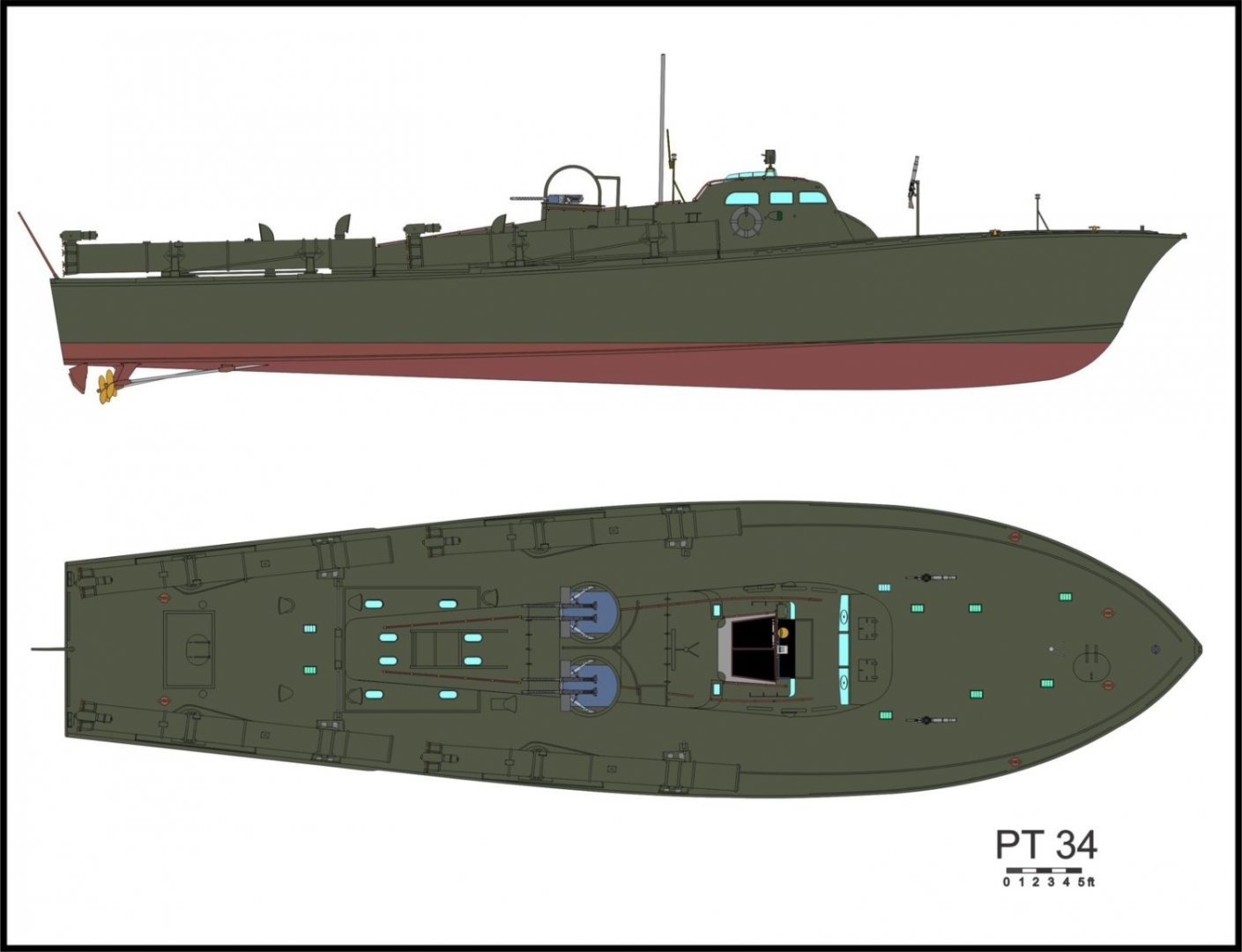

The RON3 boat were 77' ELCOs; this is an 80' ELCO. In the movie, they used two 80s and four Huckins boats, none of which looked like a 77'. Here are two renderings of what they would have looked like. The gray image is as they left the factory in Bayonne. Once the war began, they removed the domed covers on the turrets and painted the boats green. My Dad was the quartermaster on PT34 at the time. She was lost on 9APR42 and he was captured a few days later, spending the rest of the war as a Japanese POW.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.