-

Posts

907 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by drtrap

-

Thank you jason. I've finished with the breeching rope rigging of all the 16 carronades and the 2 cannons. It's time to test the 2mm aftermarkt blocks using 0,1 mm natural rope to create the tackling for the whole of the weaponry.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi guys, any quick tutorial on how to create hooks from eyelets? Thanks

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Sometimes I think to use blackened elevation screws Jason, as a natural sign of corrosion/wear etc....

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

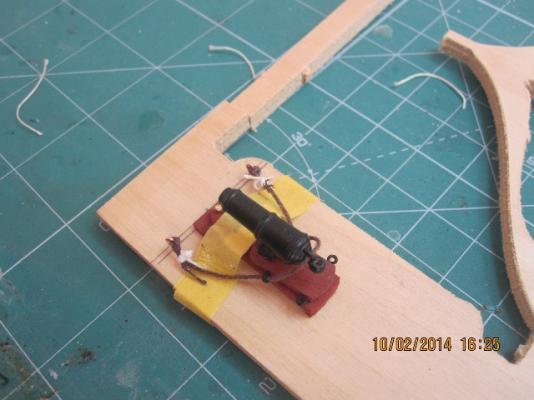

Chequing up the relative heights and aft space of the deck to accomodate the most aft pair of carronades. My plan is to totally thread and accomplish the rigging of the posterior/aft pair of carronades to be able later on to fix the ladders at the right place/distance...

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

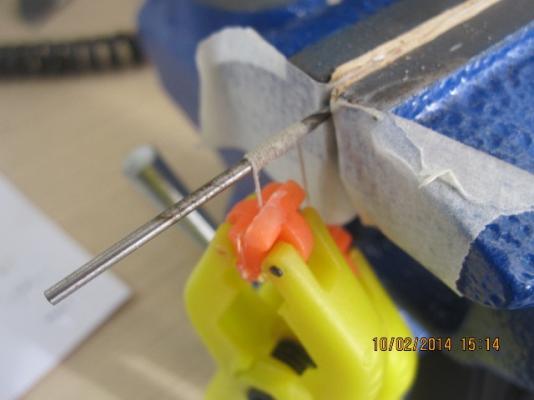

Zip seizings in progress... I'm turning the line around a drill of 1,5 mm diameter according to the correct theoritical ratio... I've purcased the line from the local stores. The ideal would be to use a line of 0,25mm but I prefer much better this type for the mo

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi mates. I would like to ask you, what’s the best stage of the construction to upgrade the base of the model in your opinion. I’ve created in advance two holes (3mm in diameter/9mm depth) under the ship to support her with the relative 3mm rods. Do you believe that the mentioned diameter and depth of the wholes/rods will be secure for the stability of the ship in to the future? Thanks.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks Jason, I'm thinking to use the same aftermarket 1mm Amati line. It is the testing natural line in my last photo... I suppose that you've placed only a single half-hitch at the eyes, am I right? Thanks.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Next step, trying to improve my other skill: seizing of the breeching rope. Except the tecnique I'm showing in the photo (green testing rope), I'm trying to find any step by step tutorial to seize the rope using multiple (I think) "half-hitch" knots... Any idea on this? Thanks. The naturac color rope is Amati, 1mm in diameter. I wonder how could Jason pass it through the eyelet, even with the edge hardened with cyano....

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

These are the relative heights using the 24's and 32's carronades respectively... http://modelshipworld.com/index.php?/topic/634-hms-snake-by-stergios/page-9

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi Norman those pics are without the placement of the rear elevation screw and just for practice.. In every case I'll test the relative heights.... Thanks

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Trying to set a correct device for the rigging of the guns. This is a second hand "jig" for 24's carronades (I'll use the 32's) just to feel more familiar with the rigging of the breeching rope. The whole procedure especially for the seizing and using PVA to secure the knots is so time consuming... Thinking of use cyano to proceed faster. In the other hand an alternative option to avoid the knots: pro-made seizing (using 0,25 line and PVA. Cyano glue makes too dificult to withdraw the setting from the drill...).

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Still waiting for the "out of stock" replacement parts... In the meantime I'm looking for any tutorial or guide to help me with the rigging of the breeching rope and the tackle for the guns. Have u used any special method? Thank you

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

...I've problem with two elevation screws as they can't penetrate the respective hole of the barrel.... I've applied for replacement at cornwallmodelboats....

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Fixing the wire-hole for the breeching rope.. The second photo illustrates a minor complication regarding the thread of the passing screw...

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi mates, a question in brief...: how can I measure the width of a rope/line of the market, I mean how can I make clear its width/diameter? Thanks

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks again Jason! Another one question: how have you fixed the deck blocks (walnut part No 1 ) on the deck of the model, using PVA or any kind of glue or drilling the deck for every kit to pass the 1,5 mm rod through each deck block and fixing them in place? Sorry to ask you so many questions but to my knowledge you;re the first and the only one who purchased those after market kits. Cheers. Stergios

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Thank you Jason, I think you told me to use cyano glue to fix them on the barrels, is thsi correct?

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I'm about to create the hole for the rope on the cannons using the 0,8 mm wire. May I ask you Jason, how have you bend and cut/shape those wire hole-curvatures for all the barrels? Thanks!!

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I can't wait for another 15-20 days to have back the [in question] replacing walnut parts. I had to wait 25 days to receive all the seven kits in two posting periods... I'll try to fix the problem by my own to a couple of the kits. The other five left, are fine.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I'll try to talk to them Jim, even I'm not so hopeful....

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Started to unpack the fittings of the kits of the aftermarket 32's carronades... The quality of the 2 mm walnut is so poor, that I can;t stand it, and I paid a lot of money for all of them !!

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.